Abstract

This study explores the impact of instant controlled pressure drop (DIC) technology on the cardamom FA profile in terms of composition and changes depending on DIC conditions, treatment time, and temperature. Cardamom (Elettaria cardamomum) is a spice native to Asia, which is very appreciated for its sensory characteristics, delicate aroma, and unique taste. Cardamom contains Fatty acids (FAs) that can benefit human health. For this reason, technologies such as DIC have been applied to increase FA yields and quality. The results show that the DIC process affects the FA profile of cardamom. The analysis of FAs via GC-MS revealed the presence of 8 fatty acids. Regarding the elements that influence the composition of these primary constituents, it is presumed that a combination of temperature (T) and treatment time (t) shapes their composition. This holds for seven cardamom FAs: palmitic acid, stearic acid, oleic acid, elaidic acid, α-Linoleic acid, α-Linolenic acid, and arachidic acid, where a combination of T and t contributes to their composition; in contrast, for myristic acid only the temperature exerts a significant influence. Optimizing the combination of temperature and treatment time can enhance both the yield and quality of fatty acids, suggesting that controlled DIC processing may improve cardamom’s nutritional and sensory attributes.

Similar content being viewed by others

Introduction

Green cardamom is an aromatic spice indigenous to Asia. Due to its aromatic properties and culinary utility, cardamom is highly regarded, rendering it a valued constituent in gastronomy and traditional medicinal practices1,2. Cardamom cultivation is practiced in several countries, such as India, Guatemala, Mexico, and Tanzania. Guatemala is recognized as the primary producer, with India closely trailing after3,4.

Cardamom has been utilized since ancient times across different cultures and countries, such as India5. Assyrian doctors and chemists employed medicinal plants, including cardamom, for their therapeutic properties5,6. In ancient Rome and Greece, where spices symbolized wealth and prestige, cardamom held historical importance6. Even today, cardamom still finds applications in the cosmetic industry and is used as an ingredient in the culinary and pharmaceutical industries. Alongside essential oils (EOs), fatty acids (FAs) are obtained from cardamom seeds. The importance of FAs resides in their beneficial properties for human health7.

Fatty acids (FAs) are a diverse group of molecules characterized by long hydrocarbon chains with a terminal carboxyl group (-COOH). They are typically classified into three categories: saturated, monounsaturated, and polyunsaturated fatty acids (PUFAs), depending on the number and position of double bonds in their structure. FAs serve essential roles in biological systems’ structural and functional aspects. Structurally, they are critical components of cell membranes, particularly as part of phospholipids, contributing to membrane fluidity, stability, and function8.

In addition to their structural importance, FAs are integral to energy metabolism; they also play a crucial role in signaling pathways, influencing gene expression, hormonal responses, and the production of bioactive substances such as eicosanoids and prostaglandins, which regulate inflammation and other physiological processes9. For instance, PUFAs like α-linoleic acid and α-linolenic acid are very important for cardiovascular and neurological health, and they exhibit anti-inflammatory properties, reducing the risk of chronic diseases such as type 2 diabetes and cardiovascular disease 8,9.

Fats and oils represent important human nutrition constituents, predominantly by energy-rich carbon compounds that supply calories and essential fatty acids. Their significance extends across various fields, encompassing the medical, pharmaceutical, nutritional, and cosmetic sectors10. Given consumers’ heightened awareness regarding the ratio of saturated to unsaturated fatty acids in their diets, there has been a recent focus on the lipid composition of fruits and vegetables. In recent years, consumers have demonstrated a particular interest in essential fatty acids, emphasizing the potential health benefits of polyunsaturated fatty acids. These fatty acids are believed to naturally contribute to the prevention of cardiovascular diseases and the mitigation of other health issues, owing to their capacity to reduce both total and high-density lipoprotein cholesterol levels, thus influencing the food industry now focusing on healthier fats that are of nutraceutical importance7,11.

The initial purpose of developing the Instant Controlled Pressure Drop technique (DIC) was to enhance the texture of bioproducts during drying operations. However, its application quickly expanded to various industries, including pharmaceuticals, food processing, and cosmetics, particularly in processes such as food decontamination and extraction of phytochemicals12. DIC is a thermomechanical method that involves subjecting the sample to high-pressure of saturated steam (ranging from 0.1 to 1.0 MPa) for a brief duration of time, typically a few seconds, followed by an immediate pressure drop near to vacuum conditions (around 30 mbar)13. The instant drop in pressure towards a vacuum induces the auto-vaporization of water, causes the matrix to swell, and potentially weakens the cell walls. This facilitates the enhancement of solvent diffusion within the solid material and improves mass transfer, thereby significantly accelerating the extraction kinetics of DIC-treated substances13,14. Given these characteristics, it is possible that by combining both technologies, DIC and accelerated solvent extraction (ASE), the cardamom FAs extraction could be enhanced, thus potentially improving their biological activities. Figure 1 shows a general diagram of DIC equipment and a typical DIC treatment cycle.

(A) General diagram of DIC equipment. (B) General diagram of a DIC cycle, where: (a) is the establishment of an initial vacuum in the processing vessel; (b) is the injection of saturated dry steam at the selected temperature; (c) is the maintenance of treatment temperature during the time chosen; (d) is the instant controlled pressure drop towards a vacuum; and (e) is the release to atmospheric pressure.

Accelerated solvent extraction (ASE) represents a relatively recent automated methodology employing low-boiling solvents or solvent blends at elevated temperatures of up to 200 °C and pressures reaching 3000 psi to extract specific compounds. This approach enhances the solubility of target compounds and accelerates solvent diffusion rates and mass transfer while simultaneously reducing solvent viscosity and surface tension15,16. ASE offers numerous advantages over conventional solid/liquid extraction techniques. Unlike traditional methods, which necessitate substantial quantities of hazardous organic solvents and entail labor-intensive procedures with prolonged extraction durations, ASE operates with reduced solvent volumes in a shorter timeframe. Furthermore, it is automated and maintains samples in an environment shielded from oxygen and light, mitigating potential degradation concerns17,18. Figure 2 shows the ASE equipment and a schematic representation of the ASE process.

To the best of our knowledge, no previous studies have investigated the use of DIC technology as a pretreatment for cardamom seeds prior to fat extraction or its influence on fatty acid composition. Therefore, this comparative study evaluates the effects of using the ASE method alone versus combining DIC pretreatment with ASE on the resulting fatty acid profile.

Results and discussion

Fatty acid analysis by gas chromatography–mass spectrometry (GC-MS)

To investigate the impact of DIC treatment on the chemical composition of fatty acids in cardamom seeds, gas chromatography-mass spectrometry (GC-MS) was employed as an exploratory method to identify the predominant FA families present in each treatment. The analysis confirmed the presence of eight major fatty acids in cardamom seed extracts across all samples (including the control and various DIC treatments). The components, as well as their classifications, are found across the samples and are shown in Table 1. While most identified FAs were consistently present across all samples, some exceptions were observed. Notably, stearic acid, α-linolenic acid, and arachidic acid were absent in specific treatments, suggesting potential alterations in FA composition due to DIC treatment.

Table 2 provides a comprehensive summary of the fatty acid composition, expressed as a percentage of total fatty acids, across 13 different cardamom extract samples subjected to various DIC treatments, along with a control. The analysis reveals the presence and concentration of eight key fatty acids, including myristic acid, palmitic acid, stearic acid, oleic acid, elaidic acid, α-linoleic acid, α-linolenic acid, and arachidic acid. Notably, variations in the fatty acid profiles are observed between treatments, with significant fluctuations in the concentrations of major components such as oleic acid and palmitic acid. Some fatty acids, like arachidic acid, appear only in certain treatments, further suggesting the influence of DIC on fatty acid composition.

Results are given as the average of triplicate determinations ± SD. Content is expressed in percentage.

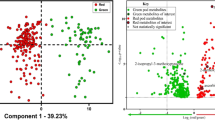

Fatty acid analysis has gained significance due to the growing understanding of the nutritional and health benefits of lipids. Based on the composition percentages presented in Fig. 3, the comparison between saturated and unsaturated fatty acids shows that unsaturated fatty acids, particularly monounsaturated fatty acids (MUFA) like oleic acid, prevail in the samples, contributing roughly to 60.82% of the total fatty acid content. This high MUFA content is consistent with the results observed in other studies, such as the one conducted by Parry et al. Parry, Hao19, where the team characterized various cold-pressed seed oils, including cardamom, where oleic acid was a major component accounting for around 49.2% of FA content. The second most prevalent FAs are saturated long-chain fatty acids with a concentration of 25.88%, a lesser value that contrasts with the work conducted by Ramadan, Khider20, where they analyzed the composition of cold-pressed oil from cardamom seeds, obtaining around 31.51% of these compounds. Lastly, the polyunsaturated fatty acids (PUFAs), including α-linoleic acid, account for 13.30%, which is a higher content in comparison with studies conducted using traditional solvent extraction such as the research by Arpitha, Srinivasan21, where they reached a total of 8.16% of PUFAs with acetone as the extraction solvent; and even more so in water extract, where they did not detect these compounds. These specific compounds, PUFAs, are of special interest due to their health benefits, particularly in reducing inflammation and supporting cardiovascular health21,22. These differences could arise from extraction methods or varietal differences. In general, DIC pretreatment did not induce the extraction of “new” fatty acid, but rather, it affected the relative amounts of those usually present.

The analysis of cardamom extracts subjected to different DIC treatments revealed significant variations in the fatty acid profiles across samples, as shown in Table 1; Fig. 4. The predominant fatty acids identified include oleic acid (42.75%) and palmitic acid (21.20%), whereas the lowest percentage present across all samples were arachidic acid (0.31%) and stearic acid (1.51%). On the other hand, there were polyunsaturated fatty acids (PUFAs) present, such as α-Linoleic acid (10.67%) and α-Linolenic acid (2.9%). These results align with findings from the study on cold-pressed cardamom oil by Ramadan, Khider20, which similarly reported oleic acid as the dominant fatty acid in cold-pressed cardamom oil, comprising approximately 43.7% of the total fatty acids, with notable amounts of palmitic and linoleic acids as well. These results are in also agreement with Ashokumar et al. who report that the composition of oil of cold-pressed cardamom seeds mainly consisted of oleic acid (49.2%), palmitic acid (26.4%) and linoleic acid (15.2%)3. This suggests that DIC treatment does not significantly alter the proportions of the major fatty acids, but slight variations could be due to the processing conditions.

Interestingly, some saturated fatty acids, such as stearic acid and arachidic acid, are present in lower amounts, with arachidic acid being detected in specific DIC treatments but not in all samples. This could indicate that DIC treatments have a selective impact on the retention or extraction of these less abundant fatty acids. The overall presence of saturated long-chain fatty acids (25.91%) suggests a balance between saturated and unsaturated fatty acids, which may enhance the functional properties of cardamom extracts in various applications20.

In comparison to the study by Zhang, Seck22, which evaluated the effect of low-energy X-rays on the fatty acid composition of cardamom, the DIC-treated samples showed no drastic reduction in PUFAs, while Zhang’s study reported a 20% decrease in PUFA content post-irradiation. This suggests that DIC treatment may be less detrimental to the integrity of sensitive polyunsaturated fatty acids compared to irradiation, making it a more suitable method for preserving the nutritional quality of cardamom.

In order to investigate DIC operating parameters, experimental data were analyzed using a central composite design. This analysis resulted in a polynomial model that quantifies the impact of process variables and their interactions on the measured outcome. The Figures (5–12) show the impact of steam processing temperature “T” and thermal processing time “t” on the yield of each fatty acid. The Pareto charts in (A) illustrate the significance of these factors, while the surface response equations in (B) provide a mathematical representation of the relationship between T (temperature), t (time), and FA content. This analysis highlights the role of these processing parameters in modulating the fatty acid composition, with significant variations observed across different fatty acids. Regarding the factors that impact the composition of each major component, it is worth noting that only one of the eight components were influenced by the studied factors.

The response surface model for palmitic acid indicated a significant negative linear effect of temperature and a positive effect of time (Fig. 5A). In practical terms, palmitic acid concentration decreased as DIC steam temperature increased, whereas extending the treatment time at lower temperatures could slightly increase palmitic acid levels. The highest palmitic content was observed in milder temperatures and higher processing times, such as DIC 9 (T = 122 °C, t = 41s), whereas the lowest content, was found in DIC 3 (T = 140 °C, t = 45s). This result aligns with previous studies on Camelina sativa and rapeseed seeds, conducted by Allaf, Fine23 and Besombes, Bouallegue24, where increasing temperature in DIC treatments was shown to cause a reduction in saturated fatty acids, such as palmitic acid. In the case of rapeseed oil, higher temperatures and longer processing times have similarly resulted in decreased levels of palmitic acid23. These behavior can be due to that high temperature likely accelerates thermal oxidation of the FAs, hence lowering its proportion. Given these tendencies, Eq. 1 suggests that lower temperatures coupled with longer processing times increase palmitic acid levels.

In the case of stearic acid (Fig. 6A and B), the Pareto chart demonstrates a moderate sensitivity to processing time. Still, the surface response model shows that higher temperatures reduce stearic acid concentration, but overall the concentration hovered between 1 and 3%, with the highest content reached in DIC 4 (T = 140 °C and t = 30s) with 3.34% and the lowest being DIC 3 (T = 140 °C and t = 45s) with no detectable presence as it was the case also for the control. This stability can be attributed to stearic acid’s saturated structure lacking double bonds, so it is resistant to oxidative or thermal breakdown under the moderate conditions such as the ones tested in this study. Previous research concurs that saturated fatty acids remain largely unchanged by thermal processing unless conditions are extreme25. Equation 2 Stearic acid’s response to DIC treatment is relatively stable across the tested temperature and time ranges, showing a slight decrease at the highest temperature points. This observation is consistent with research on olive leaves, conducted by Mkaouar, Charfi26 where stearic acid concentrations were minimally affected by DIC treatment under varying temperatures26. The minimal impact on stearic acid content could be attributed to the inherent stability of this saturated fatty acid under thermal processing conditions27. The Pareto analysis (Fig. 6A) showed no significance for stearic acid in the analyzed parameters, reinforcing that neither T nor t had a notable effect. This means DIC can be applied without concern of losing stearic acid content, a benefit, since stearic acid has a neutral or even beneficial effect on human cholesterol levels compared to other saturated fats28.

On the other hand, elaidic acid exhibits a complex response to temperature and time (Fig. 7). Equation (3) shows that moderate temperatures and longer processing times optimize the obtention of elaidic acid. In this case the highest content was found in DIC 8 (T = 122 °C and t = 19) with 27.32%, while the untreated sample showed a 8.54% content. Here The increment in this compound of moderate temperature vs. lower temperatures can could indicate that a portion of oleic acid is isomerized to elaidic under heat increasing conditions. This aligns with reports that trans-fatty acids are more stable under controlled thermal conditions22.

The polyunsaturated fatty acids, α-linoleic acid (Fig. 8) and α-linolenic acid (Fig. 9) demonstrate sensitivity to both temperature and time, with a negative quadratic relationship for temperature for α-linolenic acid. This can also be observed since the better permorming treatment was DIC 8 (T = 122 °C and t = 19s) for both compounds, with 19.04% and 5.08% respectively, while for the control the content was 5.96% for α-linoleic acid and for α-linolenic acid there was no detection. The equations for α-linoleic (4) and α-linolenic acids (5) show that shorter times preserve these fatty acids, which is consistent with the known instability of PUFAs under heat20. Studies on the extraction of rapeseed and soybean oils support this finding, indicating that PUFAs are sensitive to thermal degradation during high-temperature treatments29. A similar reduction in PUFA content was observed in the extraction of bioactive compounds from olive leaves, where higher DIC temperatures decreased sensitive fatty acids26. These trends underscore the need to use mild conditions if retention of essential PUFAs is a priority. These trends can be explained by PUFAs undergoing oxidation or other degradation pathways at sustained elevated temperatures, leading to disappearance or conversion into secondary compounds30,31.

The effect of temperature and time on arachidic acid (Fig. 10) is closer by having a linear impact. The surface response model (Eq. 6) suggests that higher temperatures (< 120 °C) reduce arachidic acid content, a finding that correlates with previous studies on the degradation of long-chain saturated fatty acids under heat20. Regarding time, arachidic acid showed a linear decrease in extended processing times. Previous research in processing date seeds and rapeseed has shown that DIC treatment at lower temperatures and shorter times preserves long-chain saturated fatty acids like arachidic acid24. Given its very low starting level, small absolute changes could make it undetectable. It’s possible that arachidic acid might have limited extractability unless cell structures are sufficiently disrupted. Some mid-range DIC conditions might not fully release it, whereas more extreme conditions might degrade a portion of it. From a nutritional standpoint, this FA are minor and their fluctuations are not likely significant for oil quality.

Regarding myristic acid, the surface response graph (Fig. 11) shows that higher processing temperatures significantly decrease its concentration. This can also be observed in the Pareto chart, where temperature (T), both the linear and quadratic aspects, directly influence this behavior. This trend is consistent with previous findings in Camelina sativa and soybean (treated with DIC) oil extraction, where myristic acid levels declined when DIC treatments were conducted at higher temperatures24,27.

Finally, oleic acid (Fig. 12) remains relatively stable across temperature ranges, indicating its resilience to thermal processing. In this case, the highest performer was DIC 3 (T = 140 °C and t = 45s) with 78.76%, whereas the control content was 66.75%. The model had no significant linear or quadratic effects of T or t on oleic content. Even at the highest temperature/time, the oleic acid percentage did not significantly drop. This suggests that oleic acid, having just one double bond, withstands the short thermal exposure of DIC relatively well. It may also imply that any loss of oleic (e.g., slight isomerization to trans form) is counterbalanced by concentration due to loss of other FAs. This is consistent with oleic acid’s high stability reported in other oil extraction processes20,22. These findings align with findings from rapeseed and camelina sativa oils, where DIC treatments maintained oleic acid levels23,24. This stability can be attributed to the resistance of oleic acid to oxidative degradation, making it less vulnerable to changes in processing conditions compared to polyunsaturated fatty acids (PUFAs). Overall, oleic acid’s stability under DIC is a positive outcome, it means the primary component of cardamom oil is preserved. Our findings are in coherene with the literature on moderate thermal processes, in which oleic acid generally is not significantly degraded at low temperatures for short timeperiods25. In our study, oleic acid’s slight variations lacked a clear trend with DIC conditions, and thus, no firm conclusions about factor effects were drawn.

Our results also indicate that the DIC pretreatment can improve oil extraction performance. Although this study focused on composition, the accompanying increase in oil yield was observed anecdotally (DIC-treated samples yielded slightly more extractable oil than untreated). This is in line with literature on different DIC-treated oilseeds, where substantial improvements in yield have been recorded. Research on different seed oils, such as safflower seeds, revealed an increase (ranging from 10 to 70%) in extracted oil after DIC treatment32,33.

In addition to the extraction and compositional optimization achieved via DIC, the health-promoting potential of the resultant cardamom oil arises from its fatty-acid profile, oleic acid, a predominant MUFA in cardamom oil, has been linked to reductions in blood pressure and cardiovascular disesease risk in dietary studies34, while linoleic acid intake is associated with decreased LDL cholesterol and lower coronary heart disease incidence35. It is also worth noting that replacing saturated fats with unsaturated fats, such as PUFAs, enhances insulin sensitivity and blood-glucose regulation36. Moreover, PUFAs have been shown to attenuate systemic inflammation and support cognitive function preservation during aging37,38.

Materials and methods

Raw material

The cardamom seeds used in this study were sourced from Finca Argovia in Tapachula, Chiapas, Mexico, which seeds had an average length of 4 mm. The solvents employed in the research were of HPLC grade and were purchased from Sigma-Aldrich (Sigma-Aldrich, St. Louis, MO, USA).

Methods

Experimental design and statistical analysis

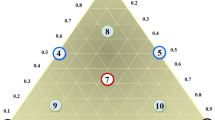

Response surface methodology was applied using a central composite design, completing thirteen experiments, which included four center points (refer to Table 3). The primary focus of this study was the FAs profile. The variables examined were the saturated steam temperature, measured in degrees Celsius, and the thermal processing duration, measured in seconds.

The statistical analysis was performed using Statistica Software (TIBCO Software Inc., 2020. Data Science Workbench, version 14. http://tibco.com). For the experimental design of the DIC treatment, the analysis included the use of Pareto charts and surface response methodology. The Pareto chart was utilized to assess the influence of variables on the responses, with the vertical line indicating statistically significant effects at a 95% confidence level.

DIC treatment

The DIC treatment of cardamom seeds followed a four-step process. A schematic of the DIC cycle is shown in Fig. 1. First, 100 g of seeds (with a humidity of 10% )were placed into the DIC reactor, and after the first vacuum stage was applied (30 mbar) (Fig. 1a). Next, as illustrated in Fig. 1 (b, c), saturated steam was introduced into the reactor, raising the temperature to the desired level (0.17 to 0.7 MPa), and this temperature was maintained for a short time (15 to 45 s). Then, the samples underwent an instant controlled pressure drop (∆P/∆t > 0.5 MPa.s−1) toward a vacuum (30 mbar) (Fig. 1d), causing auto-vaporization and matrix swelling. Finally, the pressure was released to return to atmospheric pressure (Fig. 1e), and the cardamom seeds were collected (with a humidity of 14% after treatment). The DIC equipment used in this study was the LAB DIC 0.1 model (ABCAR-DIC Process, La Rochelle, France). After the DIC treatment, the seeds were stored at -80 °C for later analysis.

Accelerated solvent extraction

ASE extraction was accomplished with a Dionex ASE 350 Accelerated Solvent Extractor (Dionex, Sunnyvale, CA). The pressure was held at 1500 psi with a constant temperature of 110 °C. Each sample (1.0 g) was ground with 2 g of diatomaceous earth and placed in an 11 ml extraction cell loaded with a cellulose filter. Each sample was extracted three times with 15 mL of hexane: isopropanol (3:2) with a static time of 2 min. Then, the solvents were evaporated in a vapor bath, and any residue left was eliminated by placing the tube in an oven at 100 °C for 5 min. The obtained fat was kept in Eppendorf tubes and stored covered from light at -20 °C until analysis by gas chromatography.

GC-MS analysis

Fifty milligrams of oil were dissolved in 900 µL of high-performance liquid chromatography (HPLC)-grade chloroform. Esterification was carried out by adding 100 µL of 5 N sodium methoxide and stirring for 5 min. Fatty acid analysis was performed using a gas chromatograph coupled to a mass detector equipped with a split/splitless injector and a selective mass detector operating in electron impact mode at 70 eV. The FAs were separated using a capillary column (HP-88, Agilent, 100 m × 0.250 mm × 0.20 μm) with the following temperature program: initial temperature, 50 °C; increase to 85 °C at 2.5 °C min− 1; increase to 170 °C at 10 °C min− 1; constant 170 °C for 20 min; final increase to 250 °C at 10 °C min− 1; and a constant 250 °C for 25 min. Using a 2:1 split, 1 µL methylated sample was injected, with the injector temperature at 250 °C. Helium was used as the carrier gas at a 4 mL min− 1 flow rate. The area under each FA peak, relative to the total area of all FA peaks, was used to quantify the FAs identified. The results obtained are reported as a percentage of FA.

Conclusions

In summary, the trends observed in this study are consistent with findings from other DIC applications in oil extractions. Myristic acid and palmitic acid showed significant reductions at higher temperatures, while oleic acid remained relatively stable. The behavior of polyunsaturated fatty acids, particularly α-linoleic and α-linolenic acids, confirmed their high susceptibility to thermal degradation, requiring lower processing temperatures to preserve their concentrations. Arachidic acid and elaidic acid showed varying sensitivities depending on the processing conditions, but their retention was generally reduced at higher temperatures.

These findings underscore the importance of optimizing DIC parameters to preserve specific fatty acids, especially those prone to degradation under high-temperature conditions. Overall, DIC technology proves effective in modulating fatty acid profiles, allowing for targeted preservation of compounds of interest while minimizing losses in more heat-sensitive fatty acids. In our study, despite some reduction in PUFAs at extreme settings, moderate DIC conditions preserved the quality of cardamom oil’s fatty acid profile. In fact, DIC’s ability to inactivate enzymes and kill bacteria could help stabilize the oil against rancidity, potentially extending shelf life.

In conclusion, the DIC treatment shows promise as an effective method for processing cardamom seeds, with its ability to modulate the fatty acid composition based on processing conditions. These findings are consistent with existing literature on DIC applications in oil extraction, particularly in preserving oil quality while optimizing extraction yields. In the context of cardamom and similar spices, DIC pretreatment could be applied to improve the recovery of valuable oils for nutraceutical or flavor applications, or to create extracts enriched in certain fatty acids. Future work may explore combining DIC with other novel downstream extraction operations (in a comparative manner) to fully grasp the effect of the DIC technology. By leveraging DIC’s rapid and gentle processing, it is possible to innovate more efficient extraction processes that meet the dual demands of high yield and high quality, an increasingly important objective in the natural products and food industry.

Data availability

Additional data is available upon request to the corresponding author.

References

Ikeda, R. M. et al. The monoterpene hydrocarbon composition of some essential oils. J. Food Sci. 27 (5), 455–458. https://doi.org/10.1111/j.1365-2621.1962.tb00126.x (1962).

Nigam, M. C. et al. Essential oils and their constituents XXVIII. Examination of oil of cardamom by gas chromatography. J. Pharm. Sci. 54 (5), 799–801. https://doi.org/10.1002/jps.2600540533 (1965).

Ashokkumar, K. et al. Botany, traditional uses, phytochemistry and biological activities of cardamom [Elettaria cardamomum (L.) Maton] - A critical review. J. Ethnopharmacol. 246, 112244. https://doi.org/10.1016/j.jep.2019.112244 (2020).

Sengottuvelu, S. Cardamom (Elettaria cardamomum linn. Maton) seeds in health. In Nuts and Seeds in Health and Disease Prevention (Preedy, V.R., Watson, R.R., Patel, V.B. Eds.) 285–291. (Academic, 2011).

Zachariah, T. J. Chemistry of Cardamom, in Cardamom: The Genus Elettaria (2002).

Masoumi-Ardakani, Y. et al. Chemical composition, anticonvulsant activity, and toxicity of essential oil and methanolic extract of elettaria cardamomum. Planta Med. 82 (17), 1482–1486. https://doi.org/10.1055/s-0042-106971 (2016).

Daga, P. et al. Lipidome analysis and metabolite profiling of fixed oils from selected spices. LWT 160, 113308. https://doi.org/10.1016/j.lwt.2022.113308 (2022).

De Carvalho, C. C. C. R. & Caramujo, M. J. The various roles of fatty acids. Molecules 23 (10), 2583 (2018).

Calder, P. C. Functional roles of fatty acids and their effects on human health. J. Parenter. Enter. Nutr. 39 (1S), 18S-32S. https://doi.org/10.1177/0148607115595980 (2015).

Venkateshwari, V. et al. Leaf lipidome and transcriptome profiling of portulaca oleracea: characterization of lysophosphatidylcholine acyltransferase. Planta 248 (2), 347–367. https://doi.org/10.1007/s00425-018-2908-8 (2018).

Fadavi, A., Barzegar, M. & Hossein Azizi, M. Determination of fatty acids and total lipid content in oilseed of 25 pomegranates varieties grown in Iran. J. Food Compos. Anal. 19 (6), 676–680. https://doi.org/10.1016/j.jfca.2004.09.002 (2006).

Allaf, T. et al. DIC texturing for solvent extraction. In Instant Controlled Pressure Drop (D.I.C.) in Food Processing (T. Allaf and K. Allaf, Eds.) 127–149. (Springer, 2016).

Téllez-Pérez, C. et al. Instant controlled pressure-drop DIC as a strategic technology for different types of natural functional foods. In Functional Foods (Lagouri, V. Ed.) . 25 (InTechOpen, 2019).

Mounir, S. et al. Instant Controlled Pressure Drop Technology: From a New Fundamental Approach of Instantaneous Transitory Thermodynamics to Large Industrial Applications on High Performance–High Controlled Quality Unit Operations. Vol. 17(3). 261–267 (2014). https://doi.org/10.1016/j.crci.2013.10.019

Luthria, D. et al. Accelerated Solvent Extraction, in Oil Extraction and Analysis. 25–38 (AOCS Publishing, 2019).

Yang, H., Comstock, K. & Lopez, L. Comparison of Soxhlet and accelerated solvent extraction for leachable and extractable analysis of packing material. Thermo Sci. Application Note. 1108, 1–9 (2014).

Denery, J. R. et al. Pressurized fluid extraction of carotenoids from haematococcus pluvialis and Dunaliella Salina and Kavalactones from Piper methysticum. Anal. Chim. Acta. 501 (2), 175–181. https://doi.org/10.1016/j.aca.2003.09.026 (2004).

Hossain, M. B. et al. Optimisation of accelerated solvent extraction of antioxidant compounds from Rosemary (Rosmarinus officinalis L.), marjoram (Origanum Majorana L.) and oregano (Origanum vulgare L.) using response surface methodology. Food Chem. 126 (1), 339–346. https://doi.org/10.1016/j.foodchem.2010.10.076 (2011).

Parry, J. et al. Characterization of cold-pressed onion, parsley, cardamom, mullein, roasted pumpkin, and milk Thistle seed oils. J. Am. Oil Chem. Soc. 83, 847–854. https://doi.org/10.1007/s11746-006-5036-8 (2006).

Ramadan, M. F. et al. Rediscovery of cold pressed cardamom (Elettaria cardamomum L.) oil: a good source of fat-soluble bioactives with functional and health-enhancing traits. Rend. Lincei Scienze Fis. E Naturali. 33 (3), 631–642. https://doi.org/10.1007/s12210-022-01081-w (2022).

Arpitha, S., Srinivasan, K. & Sowbhagya, H. B. Anti-inflammatory effect of resin fraction of cardamom (Elettaria cardamomum) in carrageenan-induced rat paw edema. PharmaNutrition 10, 100165. https://doi.org/10.1016/j.phanu.2019.100165 (2019).

Zhang, H., Seck, H. L. & Zhou, W. Inactivation of Salmonella typhimurium, Escherichia coli O157:H7, Staphylococcus aureus, and Listeria monocytogenes in cardamom using 150 KeV low-energy X-ray. Innovative Food Sci. Emerg. Technol. 67, 102556. https://doi.org/10.1016/j.ifset.2020.102556 (2021).

Allaf, T. et al. Impact of instant controlled pressure drop pre-treatment on solvent extraction of edible oil from rapeseed seeds. Oilseeds Fats Crops Lipids. 21 (3), A301. https://doi.org/10.1051/ocl/2014002 (2014).

Besombes, C. et al. Pressure, temperature and processing time in enhancing camelina sativa oil extraction by instant controlled Pressure-Drop (DIC) texturing pre-treatment. Grasas Y Aceites. 71 (3), 365. https://doi.org/10.3989/gya.0337191 (2020).

Shin, H. Y. et al. Thermal stability of fatty acids in subcritical water. J. Anal. Appl. Pyrol. 98, 250–253. https://doi.org/10.1016/j.jaap.2012.08.003 (2012).

Mkaouar, S. et al. Instant controlled pressure drop (DIC) effect on compositional analysis of Olive leaves (Olea Europaea L). J. Food Meas. Charact. 16 (2), 1494–1501. https://doi.org/10.1007/s11694-021-01257-2 (2022).

Jablaoui, C. et al. Comparison of expander and instant controlled Pressure-Drop DIC technologies as thermomechanical pretreatments in enhancing solvent extraction of vegetal soybean oil. Arab. J. Chem. 13 (10), 7235–7246. https://doi.org/10.1016/j.arabjc.2020.08.005 (2020).

Shen, X. et al. Stearic acid metabolism in human health and disease. Clin. Nutr. 44, 222–238. https://doi.org/10.1016/j.clnu.2024.12.012 (2025).

Bouallegue, K. et al. Impact of texturing/cooling by instant controlled pressure drop DIC on pressing and/or solvent extraction of vegetal oil. Int. J. Eng. Res. Sci. 2 (1), 12 (2016).

Abbas Ali, M. et al. Effect of heating on oxidation stability and fatty acid composition of microwave roasted groundnut seed oil. J. Food Sci. Technol. 54, 4335–4343. https://doi.org/10.1007/s13197-017-2904-1 (2017).

Nagy, K. et al. Investigating the thermal stability of Omega fatty Acid-Enriched vegetable oils. Foods 13 (18), 2961. https://doi.org/10.3390/foods13182961 (2024).

Bouallegue, K. et al. Texturing and instant cooling of rapeseed as pretreatment prior to pressing and solvent extraction of oil. Food Bioprocess Technol. 9 (9), 1521–1534. https://doi.org/10.1007/s11947-016-1734-x (2016).

Eikani, M. H., Khandan, N. & Feyzi, E. Enhancing bio-oil extraction using instant controlled pressure drop texturing. Food Bioprod. Process. 117, 241–249. https://doi.org/10.1016/j.fbp.2019.06.008 (2019).

Schwingshackl, L. & Hoffmann, G. Monounsaturated fatty acids, Olive oil and health status: a systematic review and meta-analysis of cohort studies. Lipids Health Dis. 13, 1–15. https://doi.org/10.1186/1476-511X-13-154 (2014).

Froyen, E. & Burns-Whitmore, B. The effects of Linoleic acid consumption on lipid risk markers for cardiovascular disease in healthy individuals: A review of human intervention trials. Nutrients 12 (8), 2329. https://doi.org/10.3390/nu12082329 (2020).

Imamura, F. et al. Effects of saturated fat, polyunsaturated fat, monounsaturated fat, and carbohydrate on glucose-insulin homeostasis: a systematic review and meta-analysis of randomised controlled feeding trials. PLoS Med. 13 (7), e1002087. https://doi.org/10.1371/journal.pmed.1002087 (2016).

Danthiir, V. et al. The older people, omega-3, and cognitive health (EPOCH) trial design and methodology: a randomised, double-blind, controlled trial investigating the effect of long-chain omega-3 fatty acids on cognitive ageing and wellbeing in cognitively healthy older adults. Nutr. J. 10, 1–18. https://doi.org/10.1186/1475-2891-10-117 (2011).

Oppedisano, F. et al. The anti-inflammatory and antioxidant properties of n-3 pufas: their role in cardiovascular protection. Biomedicines 8 (9), 306. https://doi.org/10.3390/biomedicines8090306 (2020).

Acknowledgements

The first author, Giselle D. Teresa-Martínez, gratefully acknowledges Secretaría de Ciencia, Humanidades, Tecnología e Innovación (SECIHTI) for granting scholarship No. 1048242.

Author information

Authors and Affiliations

Contributions

G.T.M and P.R.C wrote the main manuscript, and prepared figures and tables. M.A.M and C.T.P did the statistical analysis. A.C.M supervised the whole project. All authors revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Teresa-Martínez, G., Rodriguez-Castillo, P., Alonzo-Macías, M. et al. Changes in cardamom (Elettaria cardamomum) fatty acid composition induced by instant controlled pressure drop technology. Sci Rep 15, 28755 (2025). https://doi.org/10.1038/s41598-025-14431-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14431-z