Abstract

The manufacturing industry’s continuous digital intelligence transformation has triggered an extensive discussion on the environmental impact. In order to further explore this relationship, the panel data of 30 provinces in China from 2011 to 2021 is used in this analysis, the index system of digital intelligent transformation of manufacturing industry is constructed from two aspects of digitalization and intelligence of manufacturing industry, and the principal component analysis method is used to calculate. The two-way fixed effect model is used to analyze its impact on energy consumption and carbon emissions. The results show that the level of digital intelligence transformation of manufacturing industry in the eastern region is relatively high. In addition, the digital intelligence transformation of the manufacturing industry has a U-shaped impact on the scale and intensity of energy consumption and carbon emissions, and there is a positive linear relationship between the digital intelligence transformation of the manufacturing industry and the energy consumption structure. Further research has found that the impact of different regions and digital transformation indicators on energy consumption and carbon emissions is heterogeneous. This study establishes a foundation for quantitative analysis of the digital intelligence transformation of manufacturing industry, and makes up for the deficiency of existing research that pays more attention to linear relationship. It provides both theoretical basis and policy recommendations for energy conservation and emission reduction in manufacturing.

Similar content being viewed by others

Introduction

The content of greenhouse gases, such as carbon dioxide, has continued to rise, and climate problems have become increasingly serious. Major economies worldwide have formulated policies aimed at reducing carbon emissions and conserving energy to jointly advance low-carbon and environmentally friendly development. China is the world ‘s leading energy consumer and carbon dioxide emitter. In 2020, it announced its intention to strive to achieve peak carbon emissions by 2030 and carbon neutrality by 2060. According to the MEIC-China CO2 emissions database, in 2021, China ‘s total carbon emissions exceeded 10 billion tons, of which manufacturing accounted for 33.56%. Additionally, from 1997 to 2021, the manufacturing energy consumption in China increased from 780 million to 2.9 billion tons. In 2021, manufacturing energy consumption accounted for 55.73% of the total energy consumption. These data show that manufacturing carbon emissions and energy consumption accounted for a large share of the total emissions. Controlling China’s manufacturing carbon emissions and promoting green, energy-saving, and low-carbon development are particularly important for achieving the dual-carbon goal1,2,3. The digital intelligence of the manufacturing industry integrates the core features of digitization and intelligence. Data-driven methods comprehensively upgrade and innovate the manufacturing industry to achieve more efficient, intelligent, and accurate operations. Digitalization and greening of the manufacturing industry complement each other, and the transformation of digital intelligence will also bring about changes in carbon emissions and energy consumption. Therefore, studying the impact of the digital intelligence transformation of manufacturing on energy consumption and carbon emissions provides a scientific basis for the government to formulate more effective regulatory policies under the dual carbon target, guide the rational allocation of digital investment in the manufacturing industry, and promote the realization of sustainable development goals.

The digital intelligent transformation of the manufacturing industry refers to the systematic transformation process of reconstructing the production mode, operation mode, and value chain of the manufacturing industry through the deep integration of digital technology and intelligent manufacturing technology to achieve efficiency improvement, cost reduction, and competitiveness enhancement. With information technology innovation as the driving force, the industrial Internet and other digital technologies are deeply integrated with the manufacturing industry4,5 promoting revolutionary changes in industrial structure and production methods and continuously improving the development level of traditional manufacturing6,7,8. Existing research on the digital intelligent transformation of the manufacturing industry first examined the meaning9 statistical measurement10 and influencing factors11. The second is the impact of digital intelligence transformation on the environment12,13which is still controversial and can be divided into three aspects: (1) Digital intelligence transformation can dramatically lower carbon emissions and energy consumption through information technology and automated processes14,15,16. (2) According to some studies, the digitalization process may intensify, raising energy demand and, therefore, carbon emissions17,18. (3) Despite these controversies, some studies have demonstrated that there is no immutable linear correlation between digital intelligence transformation and carbon emissions. A long-term analysis of the two could reveal either an inverted or positive U-shaped curve16,19. These controversies may result from the use of different methods to measure digital intelligence transformation and from regional differences.

The current research is mostly biased towards the digitalization of manufacturing and intelligent transformation of manufacturing. The measurement of the digital intelligence transformation of the manufacturing industry is mostly from a micro perspective, measured by indicators such as the frequency of digital intelligence words, and very few studies measure the digital intelligence transformation of the manufacturing industry from the provincial level. However, previous studies have usually focused on how the transformation of digital intelligence changes the single indicator of energy consumption or carbon emissions, and there are few comprehensive investigations on energy conservation and emission reduction respectively4,5. Carbon emissions and energy consumption are important factors in environmental pollution. The relationship between them is mutually reinforcing and tightly interconnected. To solve the disputes and fill in the blanks, this study focuses on the definition of digital intelligence transformation of the manufacturing industry at the provincial level, analyzes the development level of digital intelligence region, and focuses on the impact of digital intelligence transformation of the manufacturing industry on energy consumption and carbon emissions, broadens the research perspective, and combines carbon emissions and energy consumption, which is helpful to solve more comprehensively how digital intelligence transformation affects energy conservation and emission reduction. Owing to the different characteristics of different regions, the study of regional heterogeneity helps China ‘s provincial level to judge the stage of the transformation and development of manufacturing intelligence, as well as the impact on energy conservation and emission reduction, to formulate corresponding investment strategies and regulatory policies to help the manufacturing industry play a more efficient role in energy conservation and emission reduction.

The format of the paper is as follows: the theoretical analysis and research hypotheses are presented in Sect. 2; the research methods and data are described in Sect. 3; Sect. 4 provides empirical results and analysis; Sect. 5 offers a discussion; and the policy implications are concluded in Sect. 6.

Analysis of the influencing mechanism

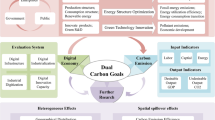

Manufacturing digital intelligence transformation of manufacturing industry and carbon emissions

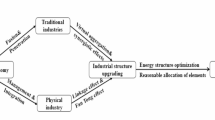

In the early stage of the digital intelligence transformation in manufacturing, the application of digital intelligence technology showed obvious efficiency improvements. By promoting technology spillovers and knowledge accumulation, it stimulates green innovation and saves carbon emissions during the R&D process, and the entire industrial structure is promoted towards a more low-carbon and sustainable direction20,21. With regard to enterprise R&D, management, manufacturing, and market operations, it optimizes the use of resources and production processes22. Through intelligent detection, the accuracy of information is improved, resource demand is forecasted, timely and effective adjustments are made, unnecessary pollutant emissions and waste of resources are reduced, and thus the intensity of carbon emissions23,24. Furthermore, digitization fosters the growth of new clean industries25which fundamentally reduces pollutant emissions and presents the manufacturing sector with previously unheard-of opportunities for high-quality, environmentally friendly development. However, with the advancement of digital intelligence transformation, the efficiency improvement effect brought by digital intelligence has gradually become smaller, and the scale effect of economic scale expansion has gradually become more important. In addition, the digital infrastructure itself is a high-energy carrier, and the rapid update of electronic and electrical equipment and devices also produces a large amount of heat in the manufacturing industry, which requires a cooling system to dissipate heat26. The transformation of digital intelligence requires the introduction of more automation and intelligent equipment; however, the maintenance and management of equipment are still in the stage of industrial 2.0, which can easily cause waste of resources and lead to a rebound in total carbon emissions.

Hypothesis 1

The manufacturing digital intelligence transformation has a U-shaped relationship with the scale and intensity of carbon emissions, which decreases first and then increases.

Manufacturing digital intelligence transformation and energy consumption

The impact of the digital intelligence transformation of manufacturing on energy consumption also presents complex dynamic interactions. In the early stage, digital technology penetrates rapidly, efficiency improvement and structural optimization dominate, and unit energy consumption decreases. Manufacturing companies use more energy-efficient production and R&D equipment investments to replace outdated production machines and advanced technology to replace traditional processes, prompting them to achieve green production and transformation27. Digital technology is applied to the entire process of energy development, processing, transmission, conversion, distribution, and final utilization to optimize resource allocation28,29,30 and reduce waste generation31,32. Digital technology is integrated into the energy supply and demand sides to predict and control the consumption and circulation of energy production, transportation, and use to realize real-time collection of production data, thus formulating more scientific and accurate energy management strategies, promoting business process reengineering, and improving productivity and economic output33. However, when the transformation process of digital intelligence reaches the later stage, the technological dividend decreases, the energy rebound effect gradually appears, the improvement of energy efficiency leads to the decrease of energy use cost, stimulates enterprises to expand production or consumers to increase demand34 offsets some energy saving, and the marginal effect of energy saving and emission reduction is gradually reduced. In addition, digital intelligence technology has continuously spawned new formats and increased energy demand, leading to an increase in total energy consumption and intensity.

However, for the energy consumption structure, the transformation of digital intelligence promotes clean energy substitution, applies clean energy to technical equipment in the manufacturing process, reduces dependence on the combustion of traditional coal and other high-energy fuels, helps improve the utilization rate of renewable energy, and makes more efficient use of environmental resources by accelerating the creation of new energy technologies35. The marginal cost of clean energy, such as wind, solar, and electricity, is close to zero. Digitization further reduces operation, maintenance, and transaction costs. It generates less energy consumption and fewer emissions. The scale effect has little impact on the energy consumption structure, and the efficiency improvement effect has always dominated the scale effect. Therefore, the digital transformation of the manufacturing industry can promote the optimization of the energy consumption structure. A specific theoretical logic diagram is shown in Fig. 1. In light of this, the following hypothesis is proposed:

Hypothesis 2

The manufacturing digital intelligence transformation has a positive U-shaped relationship with the scale and intensity of energy consumption, and can optimize the energy consumption structure.

Methods and data

Model building

Ehrlich and Holdren (1971)36 proposed the IPAT model, which is used to study the human disturbance factors of environmental pollution. They believe that population growth, improvement of material living standards, and scientific and technological progress of resource development and utilization are the root causes of increasing environmental pressure. In addition, previous studies have found that pollution emissions are affected by various other factors8. Therefore, combined with the IPAT model and previous research, the following specific models were constructed:

\(I\,=\,F\left( {P,A,T,Other{\text{ }}Variables} \right)\)

Where I represents the impact on the environment, represented by energy consumption (Ec) and carbon emissions (Ce). P, A, and T are population, affluence, and technical level, respectively, expressed by population size, living standards, and technological innovation. Other variables represent other effects on carbon emissions. In order to study the impact of manufacturing digital intelligence transformation on carbon emissions, the manufacturing digital intelligence transformation is taken as another variable affecting carbon emissions, and its square term is added together in order to observe the existing nonlinear relationship. In addition, manufacturing scale and foreign investment were selected as control variables related to energy consumption and carbon emissions. The following equations are obtained:

Ec is expressed by energy consumption scale, energy consumption structure and energy consumption intensity respectively, and Ce is carbon emission scale and carbon emission intensity respectively. DIM, PS, LS, TI, MC and FDI represent manufacturing digital intelligence transformation, population size, living standard, technological innovation, manufacturing scale and foreign direct investment respectively, \(\:{a}_{0}\) is a constant term; \(\:{\mu\:}_{t}\) is a time fixed effect; \(\:{v}_{i}\) is an individual fixed effect; and \(\:{\epsilon\:}_{it}\) is a random error term.

Variables selection

Explained variables

-

(1)

Energy consumption. Based on Wang et al. (2022)30 and Yang et al. (2022)8energy consumption scale (TEC), energy consumption structure (ECS), and energy consumption intensity (ECE) are selected as surrogate variables. Total energy consumption serves as a representation of TEC. ECS is depicted by the proportion of natural gas consumption to total energy consumption, as natural gas is a clean energy source, the energy consumption structure is better the higher the natural gas percentage. ECE refers to the energy consumption per unit of GDP. The lower the value is, the higher the energy efficiency is.

-

(2)

Carbon emissions. Similar to energy consumption, carbon emissions scales (TCE) and carbon emission intensity (CEE) were selected as substitute variables. TCE was expressed as the total carbon emissions in manufacturing, and CEE was expressed as carbon emissions per unit of GDP, aiming to explore the effectiveness of the digital intelligence transformation in manufacturing industry in promoting carbon reduction.

Core explanatory variables

Digital intelligence transformation of the manufacturing industry (DIM). Digital intelligence transformation is the upgrading and reconstruction of digitization and intelligence, which reflects the linkage effect of digitization and intelligence. The digital intelligent transformation of the manufacturing industry is based on digitization, highlighting the standardized governance of data and the intelligent design of algorithms, drawing on the innovative achievements of digital technology and intelligent technology, carrying out technological innovation based on massive data resources, and applying high-level intelligent algorithms to promote the creation of intelligent scenarios, forming super-strong perception ability and value-added ability, and then driving the whole industry to improve quality and efficiency and transformation and upgrading. To more fully express the digital intelligent transformation of the manufacturing industry, the index system of digital intelligent transformation of the manufacturing industry was constructed by selecting indicators from both digital and intelligent aspects.

In terms of digital indicators, Lyu et al. (2023)37 and Yang et al. (2022)8 are used to measure the four dimensions of manufacturing digital infrastructure construction, manufacturing digital innovation ability, manufacturing digital application ability and manufacturing sustainable development ability. Digital infrastructure construction is the embodiment of digital investment and network construction ability of manufacturing industry, which is comprehensively considered through the number of domain names and Internet broadband access ports. In addition, digital innovation capability reflects the absorption and transformation of emerging technologies by manufacturing enterprises, including the input level of digital products and the intensity of R&D investment. Digital application ability reflects the combination and application of advanced technology and traditional industrial practice in all aspects of manufacturing industry, and measures the growth of e-commerce, patent application and innovation of new products in manufacturing industry. The ability of sustainable development reflects the improvement of digital green development and ecological benefits of manufacturing industry.

In terms of intelligent indicators, referring to the research of Li and Ling (2023)38 and Yang et al. (2019)39 the intelligence is measured from two aspects: intelligent basic input of manufacturing industry and intelligent benefit of manufacturing industry. The intelligent basic investment of manufacturing industry includes the investment of personnel and intelligent equipment. The intelligent benefit reflects the improvement of intelligent manufacturing efficiency from two aspects of market profit and market efficiency of intelligent equipment. Table 1 lists these indicators in detail. The principal component analysis method and the average sum of the two dimensions are used to calculate the comprehensive level of digital and intelligent transformation of manufacturing industry in each province.

Control variables

In order to reduce the interference of other factors and prevent the deviation caused by missing variables, referring to other studies21,40 the following control variables are selected.

(1) Population size (PS): The increase in population will bring more energy demand, resource consumption and waste emissions, resulting in increased energy consumption and carbon emissions, which are measured by the logarithm of the number of people in each province. (2) Living standard (LS): Higher living standards pay more attention to low-carbon consumption patterns, which will reduce energy consumption and carbon emissions, using the per capita GDP of each province. (3) Technological innovation (TI):Energy consumption per unit of production decreases as technical innovation in energy utilization increases. The quantity of patent applications that are granted to a province is referred to as technological innovation. (4) Manufacturing scale (MC): The energy consumption in the region is proportional to the number of manufacturing industries, which is expressed by the logarithm of the number of manufacturing industries above the scale of each province. (5)Foreign direct investment (FDI): Multinational companies will bring advanced clean technology and management experience, reduce energy consumption and carbon emissions through technology spillover effects, expressed as the ratio of import and export trade to GDP.

Data source

This study selected the panel data of 30 provinces in China (except Tibet, Hong Kong, Macao, and Taiwan) from 2011 to 2021, and the data involved were from the China Statistical Yearbook, China Energy Statistical Yearbook, China Industrial Statistical Yearbook, provincial statistical yearbooks, and CEADs databases. For individual indicators, missing data for individual years were supplemented by interpolation. The descriptive statistics for every variable are presented in Table 2.

Results

Evaluation of digital intelligence transformation in manufacturing

The principal component analysis method is used to measure the level of manufacturing digital intelligence transformation (DIM) in each province. Figure 2 shows the spatial distribution of the DIM values of each province in 2011, 2016 and 2019 and the average annual growth rate (AAGR=(DIM value in 2021/DIM value in 2011)^(1/10)-1) of each province during this period.

The evaluation results show that China ‘s manufacturing industry is widely distributed and that the digital intelligence transformation of manufacturing is increasing every year in most provinces. The level of manufacturing digital intelligence transformation has spatial distribution characteristics that are high in the east and low in the west. Generally, the eastern regions exhibit the highest levels of digital intelligence transformation, followed by the central regions; in contrast, the western region has a low overall development level of digital intelligence transformation because of its remote location. A substantial disparity persists between provinces; for instance, Guangdong’s value of 0.843 is 8.6 times that of Xinjiang’s 0.098, and eastern coastal provinces manufacturing has seen a greater degree of digital intelligence transformation than western inland provinces. Owing to the strong economic foundation and advantages of manufacturing scale, convenient transportation, strong technical foundation, and policy support, the eastern coastal areas provide the fundamental prerequisites for digital intelligence transformation. Regarding average annual growth rates, the highest among all regions is in the Central region, which shows a high potential for digitization, followed closely by the Eastern and Western regions. The northeastern regions showed slower annual growth rates.

Figure 3 is the box line diagram and violin diagram of the manufacturing digital intelligent transformation in the four major regions and the whole country. It can be seen that the development of the four major regions is quite different. Among them, the eastern region is higher than the national average, and the western region and the northeast region are lower than the national average. The quartile spacing in the eastern region is larger than that in other regions, and the violin ' trailing ' is longer, indicating that there is a large gap in the level of manufacturing digital intelligent in the eastern provinces, which may be due to the large differences in infrastructure, data resources and policy environment in the early stage of manufacturing digital intelligent in the eastern provinces. The positive skewness of the sequence distribution of the development level of manufacturing digital intelligence transformation in the central region is obvious, and the median is close to the lower quartile line, indicating that the level of manufacturing digital intelligence transformation in most parts of the central region is relatively high, and the regional differences are large. The distance between the upper cut-off point and the upper quartile in the western region is long, indicating that the western region has great development potential. The quartile range in Northeast China is narrow, and the peak part of the violin body is wide, indicating that the manufacturing digital intelligence transformation is in the middle of the province to maintain a small gap.

Baseline regression analysis of digital intelligence transformation of manufacturing industry on energy consumption

According to formula (1) and (2), regression analysis using time individual two-way fixed effect model, the conclusion of the impact of digital intelligence transformation on energy consumption are displayed in Table 3. Among them, the result of adding no control variables is in column (1) (3) (5), and column (2) (4) (6) adds control variables. It is clear that the first-order coefficient of DIM is negative, whereas the second-order coefficient is positive and significant, according to the results of Models (1) and (2). This represents that digital intelligence transformation of manufacturing industry and energy consumption scale have a nonlinear relationship, showing a positive U-curve that decreases first and then increases. Then, according to the method of Lind and Mehlum41Utest was used to test the U-shaped relationship. The result was significantly positive at the 1% level, which verified the U-shaped relationship. According to the vertex coordinate formula of the univariate quadratic function, the inflection point was 0.379, as shown in Fig. 4. Therefore, when the DIM is less than 0.379, enhancing digitalization of manufacturing industry will reduce energy consumption scale. To maximizing the energy-saving benefits brought by digital intelligence transformation, we ought to hasten its adoption in the manufacturing. Combined with Table 2, for the entire country, the current national average does not exceed the inflection point value. Accelerate the manufacturing sector’s digital intelligence transformation, will help bring down the amount of energy used. However, the gap between provinces is wide, the degree of influence on the scale of energy consumption also shows a clear imbalance. At present, only a few provinces in the eastern region have exceeded 0.379. That might occur when the manufacturing industry experiences a swift development in its digital intelligence transformation, the energy saving brought about by it is less than the energy consumption due to its economic growth. When it reaches a certain extent, it causes the amount of energy consumed to rise.

Similarly, Models (3) and (4) exhibit that the level of DIM on energy consumption intensity also exhibits a positive U-shape curve impact, which first decreases and then increases. When lower than the inflection point of 0.618, increasing the level of digital intelligence can reduce intensity energy consumption intensity. In 2021, only Guangdong province has crossed the inflection point, indicating that China’s manufacturing still needs to go through a faster digital intelligence transformation at this point. For provinces less than the inflection point, it is feasible to efficiently minimize the consumption of energy by speeding up the digital intelligence transformation. Moreover, the effects of digital intelligence transformation of manufacturing industry on energy consumption has a marginal diminishing effect. When DIM < 0.379, the intensity and scale of energy consumption can be reduced by improving the digital intelligence level of the manufacturing industry. When 0.379 ≤ DIM < 0.618, the development of digital intelligence transformation can reduce the intensity of energy consumption, but not the scale of energy consumption; when DIM ≥ 0.618, improving the level of digital intelligence transformation of manufacturing industry will not reduce the intensity and scale of energy consumption.

The coefficient of the quadratic term of DIM is not significant, which indicates that there is no U-shaped relationship between the digital intelligence transformation of manufacturing industry on the energy consumption structure, and it is further tested by the linear model, and the results are shown in Models (7). The coefficient of DIM is significantly positive. Therefore, the level of digital intelligent transformation of manufacturing industry can significantly optimize the energy consumption structure.

The possible reason is that when the transformation and development of digital intelligence in manufacturing industry is at a low level, it can give full play to the advantages brought by digital technology and have a better effect of energy saving and emission reduction. With the improvement of the level of digital intelligence, the impact on the scale of energy consumption gradually decreases, resulting in the effect of energy saving less than the level of unit output, and then the energy consumption per unit of GDP is no longer reduced. The excessive development of digital intelligence will also lead to the excessive consumption of energy resources, resulting in the increase of total energy consumption. However, the industrial structure transformation brought about by digital intelligence can enable manufacturing enterprises to gradually use new clean energy, continuously carry out energy transformation, and continuously optimize the energy consumption structure.

Baseline regression analysis of digital intelligence transformation of manufacturing industry on carbon emissions

Table 4 shows the final results of the benchmark regression. Similar to the model in Table 3, the conclusions of Models (2) and (4) display that the digital intelligence transformation process has a negative first-order coefficient and a positive second-order coefficient, all of these coefficients are significant. It clearly demonstrates that the manufacturing digital intelligence transformation possesses a U-curve effect on the carbon emissions intensity and scale, which decreases first and then increases. The inflection points are 0.599 and 0.528, respectively, as shown in Fig. 5.

For carbon emissions scale, the average value of the country and the four major regions has not reached the peak value at this stage, indicating that improving DIM at this stage is conducive to reducing carbon emissions nationwide and even in various regions. However, for each province, and only Guangdong and Jiangsu provinces crossed the inflection point, and the remaining provinces are below the inflection point value during the analysis period. It shows that the development level of each province is very different, as so does the impact on carbon emissions scale. Similar to energy consumption, when digital intelligence development rises to a certain level, while digital intelligence transformation promotes economic growth, it may offset some of the emission reduction efforts due to technological upgrading and efficiency improvement, thereby increasing carbon emissions. In addition, for carbon emission intensity, at present, the inflection point value is not exceeded by the average values for the whole country and the four major regions. At present, the DIM has improved, and the digital intelligence emission reduction effect has been fully utilized.

There is also a marginal diminishing effect in the nonlinear relationship among manufacturing digital intelligence transformation and carbon emissions. Specifically, when DIM < 0.528, improving the manufacturing digital intelligence transformation is beneficial to reducing carbon emissions scale and decreasing carbon emissions intensity; when 0.528 ≤ DIM < 0.599, improving the level of digital intelligence transformation of manufacturing industry is conducive to reducing carbon emissions scale, but cannot reduce the carbon emissions intensity. When DIM ≥ 0.599, accelerating the manufacturing digital intelligence transformation could not lower the scale and intensity of carbon emissions.

Robustness test

Four aspects of the test are adopted to confirm the accuracy and dependability of the conclusion. (1) For each variable in the 1% quantile on both sides of the tail, after eliminating outliers and then regression, as shown in Table 5. (2) Qinghai Province and Xinjiang Province, which started late and developed slowly in the digital transformation of manufacturing industry, are excluded and then returned, as shown in Table 6. (3) Considering the endogenous problem between variables, the two-stage least squares (2SLS) instrumental variable method is used for testing, using the first-order lag of the explanatory variable as the instrumental variable. The results are shown in Table 7, The Kleibergen-Paap rk LM statistics are significant at the 1% level, indicating that there is no problem of insufficient identification of instrumental variables. The Cragg-Donald Wald F statistic is greater than the Stock-Yogo weak ID test critical values of 10% maximal IV size, indicating that the instrumental variable is valid and rejects the assumption of weak instrumental variables. In the regression results, the coefficients of DIM and DIM2 are significant, and are consistent with the benchmark regression results, which proves that the results are reliable. (4) Further, the system GMM is used to deal with the endogenous problem. The results in Table 8 show that AR (1) is less than 0.1 and AR (2) is greater than 0.1, indicating that the random error term has first-order autocorrelation, but there is no second-order autocorrelation, which satisfies the premise that the GMM model does not have sequence correlation for the disturbance term. The Hansen test value is greater than 0.1, indicating that the instrumental variables are proved to be effective through the over-identification test, and the regression results are consistent with the benchmark regression. the robustness test demonstrates that the significance and coefficient symbols of each variable correspond to those of the benchmark regression, and the conclusion is further verified.

Heterogeneity analysis

Affected by factors such as regional resource status and development stage, the specific influence of the manufacturing digital intelligence transformation presents differentiated characteristics. Consequently, the influence of the digital intelligence transformation of manufacturing industry, energy consumption, and carbon emissions in various regions was studied. Table 9 shows the regression results between regions in detail.

In the eastern region, no significant non-linear relationship is observed between the digital transformation of manufacturing industry and energy consumption and carbon emissions. There is a significant positive U-shaped relationship between the transformation of manufacturing intelligence in the central region and the scale of energy consumption and carbon emissions, with inflection points of 0.283 and 0.348. At present, the average value of the central region is located on the left side of the inflection point, and the total carbon emissions and energy consumption can be reduced by accelerating the transformation of digital intelligence. In the central region, the relationship between digital intelligence transformation and energy consumption intensity and carbon emission intensity is not obvious. The digital intelligence transformation in the western region only has a significant positive U-shaped relationship with carbon emission intensity, and the inflection point is 0.180. In 2021, although the average value of the western region exceeds the inflection point value, half of the provinces have not yet reached it, and carbon emission intensity can still be reduced through digital intelligence transformation. In Northeast China, there is a positive U-shaped relationship between the transformation of digital intelligence and the scale and intensity of energy consumption. In addition, there is a positive U-shaped relationship between the transformation of digital intelligence and the scale and intensity of carbon emissions. On the other hand, in the eastern and western regions, the digital intelligence transformation of the manufacturing industry can significantly optimize the energy consumption structure, while in the central region, it shows a relationship of inhibiting the energy consumption structure, and the influence relationship in the northeast region is not obvious.

The possible reason is that the manufacturing industry in the eastern region has a high degree of digital intelligence transformation, and has gradually shifted from high-energy-consuming traditional industries to technology-intensive industries. These industries have high energy efficiency, and the marginal effect brought by digital intelligence is limited. It is difficult to further significantly reduce energy consumption and carbon emissions. The central region is in a period of rapid economic development. Although digital intelligence transformation can reduce the total amount of carbon emissions, the demand for economic growth and industrial expansion makes the effect on carbon emission intensity not obvious. However, the current energy structure in the central region is still dominated by coal power. Although digital intelligence reduces carbon emissions per unit of GDP by optimizing the production process, it has limited improvement in the energy structure.

For each inflection point value, the inflection point in the central region is lower than the national average. This can be attributed to the region’s high proportion of energy-intensive industries and its heavy reliance on energy consumption, which diminishes the promoting effect of digital and intelligent transformation on energy conservation and emission reduction, thereby resulting in a smaller inflection point. The western region is in the stage of large-scale construction of digital facilities. Although DIM may contribute to reducing carbon emission intensity, the scale effect partially offsets the emission reduction benefits, leading to an inflection point for carbon emission intensity that is lower than the national average. Among all regions, the northeast region exhibits the smallest inflection point. This is primarily due to its climatic characteristics, which drive high energy demand. However, the current level of DIM remains relatively low, limiting its capacity to transform traditional industrial energy consumption. Consequently, the inflection point appears furthest to the left.

Regression analysis of sub-indicators of digital intelligence transformation in manufacturing industry

In order to further study the specific impact of the digital intelligent transformation of manufacturing industry on energy conservation and emission reduction, taking manufacturing digitization and manufacturing intelligence as independent variables. The regression results are shown in Table 10.

There are significant nonlinear effects between manufacturing digitization and energy consumption intensity, carbon emission intensity and carbon emission scale. Among them, manufacturing digitization has a positive U-shaped relationship with energy consumption intensity, carbon emission intensity and carbon emission scale, and manufacturing digitalization can significantly optimize the energy consumption structure. The possible reason is that in the early stage of digital intelligence transformation, digital intelligence transformation of manufacturing industry can effectively reduce energy consumption intensity and carbon emission scale and intensity through technological innovation, resource allocation efficiency improvement, industrial structure upgrading and other ways. But with the deepening of digital intelligence transformation, the increase in productivity may lead to more carbon emissions and energy consumption while bringing more output, and the effect of energy conservation and emission reduction is gradually weakened. The intelligence of manufacturing industry has a positive U-shaped relationship with the scale of carbon emissions, which decreases first and then increases, and the intelligent manufacturing industry has a positive effect on the energy consumption structure. Similarly, the development of intelligence may promote the transformation of the production process. Advanced technology and automation equipment replace the procedural labor of traditional industries, improve the efficiency of information transmission, promote the improvement of energy efficiency and the application of clean energy technology, optimize energy consumption structure and promote the reduction of carbon emissions. With the further development of intelligence, the dependence of stable technical system forms a state of carbon lock-in, which hinders the innovation of low-carbon technology. In addition, the energy rebound effect weakens the effect of intelligent energy saving and emission reduction, which leads to the increase of carbon emission scale and can no longer continue to optimize the energy structure.

Discussion

Based on the panel data of 30 provinces in China (except Tibet, Hong Kong, Macao, and Taiwan) from 2011 to 2021, this study uses principal component analysis to measure the level of digital intelligence transformation of the manufacturing industry in each province, constructs a two-way fixed effect model, and explores the relationship between the digital intelligence transformation of the manufacturing industry and energy consumption and carbon emissions. Based on this, the heterogeneity between regional and digital intelligence transformation indicators is analyzed. The following conclusions were drawn:

The development level of digital intelligence in China ‘s manufacturing industry shows an overall trend of high in the east and low in the west, but each region has maintained a certain growth momentum. The eastern coastal areas provide the basic premise for the transformation of digital intelligence with their strong economic foundation and manufacturing scale, convenient transportation, strong technical foundation, and policy support. The western region started late, the digital intelligence infrastructure is backward, and R&D investment, talent investment, and policy support are low, but the growth of some provinces and cities is more obvious. The digital intelligence development in the manufacturing industry in the western region is increasing. Under the dual promotion of policy and investment, it shows great development potential.

The transformation of digital intelligence in the manufacturing industry has a significant impact on energy consumption and carbon emissions. There is a positive U-curve impact on the energy consumption scale, intensity, carbon emission scale, and intensity. There is a positive linear relationship between the digital intelligent transformation of the manufacturing industry and the energy consumption structure. This conclusion provides a new empirical basis for the academic discussion on the environmental impact of the digital transformation of the manufacturing industry from the aspects of energy saving and emission reduction.

Further analysis of regional heterogeneity is required. In the eastern region, owing to the more developed technical economy and the impact of the manufacturing industry structure, DIM can only increase the proportion of clean energy but has no significant impact on other indicators. The high dependence on coal in the central region and the solidification of the energy structure of the industry have led to a negative impact of DIM on the energy consumption structure. However, owing to the optimization of the production process by digital intelligence technology, the total energy consumption and carbon emissions are reduced. The digital intelligence of the manufacturing industry in the western region started late, and the decline in the total energy consumption caused by digital intelligence has not significantly changed the energy consumption caused by scale expansion. Currently, DIM levels in Northeast China are low, and technical effects play a leading role. However, owing to the characteristics of the manufacturing industry and regional climate, the overall energy structure has not been significantly improved.

Additionally, the digitization of the manufacturing industry has a significant impact on energy consumption intensity, carbon emission scale, and carbon emission intensity, showing a U-shaped curve that first decreases and then increases, optimizing the energy consumption structure. There is a positive U-shaped relationship between manufacturing intelligence and the carbon emission scale, and a positive linear effect on the energy consumption structure. Digitization has reached a mature promotion stage. The expansion of manufacturing digitization benefits from the support of digital infrastructure and applications, which helps reduce energy consumption and carbon emission intensities. Intelligent is still in its early stages. Currently, intelligence is mostly used in experimental or small-scale scenarios, which do not immediately improve production efficiency and resource utilization efficiency. A wide-scale carbon reduction has not yet been formed; therefore, its impact on carbon emission intensity is limited.

This study conducted a lot of work in theoretical and empirical analysis; however, there are still some shortcomings. Specifically, (1) using the principal component method to calculate the results of the digital intelligence transformation of the manufacturing industry in the range of 0–1, there may be insufficient identification of differences. In the future, a more comprehensive evaluation can be achieved by constructing a more refined mathematical evaluation system and optimizing the calculation methods. (2) There are significant differences in socio-economic conditions among cities in different provinces. Therefore, when complete and available county-level data are available, the research may be more accurate and in-depth. Future research can use panel data from prefecture-level cities to consider the heterogeneity between cities and improve the robustness of the research.

Conclusions

This study focuses on the influence of the digital intelligence transformation of manufacturing industry on carbon emissions and energy consumption. The level of digital intelligence transformation of manufacturing industry is evaluated. Then, using regression analysis, as is found that the manufacturing digital intelligence transformation has a nonlinear and linear relationship with energy consumption and carbon emissions. After considering the study findings, the following suggestions are provided:

First, optimize the overall layout of digital intelligence transformation and promote regional coordinated development. The research results show that there are differences in the process of digital intellectualization transformation in various regions. The state should advocate industrial linkage with surrounding areas, strengthen interconnection and synchronization among various production areas, give full play to regional resource advantages and industrial characteristics, avoid deviating from the actual pursuit of ' large and complete ' development model, and coordinate dislocation development. The process of digital intelligence transformation in the central and western regions is slow. It is necessary to combine the advantages of ecology, energy, electricity and other resources, seize the major national strategic opportunities such as “East Number West Calculation” transform the resource advantages into industrial advantages, consolidate the construction of digital infrastructure within the manufacturing industry, and build a manufacturing cluster with regional characteristics. The eastern region uses its advantages in digital technology and location to focus on promoting high-tech manufacturing. The high-low matching will form a pattern of mutual echo, coordinated development and complementary advantages of the manufacturing industry in the eastern and western regions, and jointly promote the digital transformation of the manufacturing industry.

Second, according to local conditions, make full use of digital intelligence transformation to reduce the carbon emissions. In regions where the transformation of digital intelligence is still on the left side of the inflection point of energy conservation and emission reduction, it is crucial to accelerate the development of digital technology infrastructure, drive new technological progress, build an efficient energy system, and increase green energy consumption. Vigorously develop the green low-carbon high-end equipment manufacturing industry, focus on the layout of national strategic emerging industries, increase the proportion of high-tech manufacturing industries, and promote the manufacturing industry to be more low-carbon and green. In the region where DIM is within the inflection point range of energy saving and emission reduction, relevant policies are formulated to focus on improving the indicators that have not reached the inflection point, make full use of the benefits brought by the digital transformation of the manufacturing industry, and promote regional energy savings and emission reductions. In areas where the digital transformation of the manufacturing industry is near the inflection point, it is necessary to continue to give full play to the comparative advantages of the digital transformation of the manufacturing industry, promote the research and utilization of energy-saving and emission-reduction technologies, and strive to achieve greater marginal benefits. Simultaneously, considering the rebound effect of energy use and carbon emissions, focusing on the balance between economic growth and environmental protection, avoiding overexploitation and expanding the scale of emissions, reducing the carbon emissions of manufacturing to a lower level, promoting the sustainable development of manufacturing, and promoting the realization of dual carbon goals are essential.

Third, innovate the energy consumption mode of manufacturing enterprises and data centers. Manufacturing enterprises use digital technology to optimize energy production and consumption, supply and demand; install grid intelligent control system; real-time monitoring and collecting energy consumption data; improve energy management efficiency. Traditional energy enterprises should speed up the deep integration with digital technology, build a digital energy industry cluster with strong competitiveness, use digital technology to enable energy power generation, reduce power generation costs, advocate the creation and deployment of new energy technologies, and amplify the spillover effects of these technological advances. For the data center with high energy consumption, in one aspect, the “East Number West Calculation” initiative must be put into action to direct the western region to undertake the computing power demand with the goal of improving overall energy efficiency. In addition, it is equally essential to innovate the data center’s energy consumption model. adopt low-carbon site selection, digital technology to reduce heat energy consumption, eliminate high-energy equipment, and boost clean energy consumption to enhance the green development status of the current digital center.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Chen, Y., Li, Q. & Liu, J. Innovating sustainability: VQA-Based AI for carbon neutrality challenges. J. Organizational End. User Comput. (JOEUC). 36 (1), 1–22. https://doi.org/10.4018/JOEUC.337606 (2024).

Wang, Y., Wang, T., Wang, W. & Hou, Y. Collaborative application of deep learning models for enhanced accuracy and prediction in carbon neutrality anomaly detection. J. Organizational End. User Comput. (JOEUC). 36 (1), 1–25. https://doi.org/10.4018/JOEUC.340385 (2024).

Ran, J., Zou, G. & Niu, Y. Deep learning in carbon neutrality forecasting: A study on the SSA-Attention-BIGRU network. J. Organizational End. User Comput. (JOEUC). 36 (1), 1–23. https://doi.org/10.4018/JOEUC.336275 (2024).

Zhang, L. et al. Digital economy, energy efficiency, and carbon emissions: evidence from provincial panel data in China. Sci. Total Environ. 852, 158403. https://doi.org/10.1016/j.scitotenv.2022.158403 (2022).

Lin, B. & Zhou, Y. Does the internet development affect energy and carbon emission performance? Sustainable Prod. Consum. 28, 1–10. https://doi.org/10.1016/j.spc.2021.03.016 (2021).

Bhujabal, P., Sethi, N. & Padhan, P. C. ICT, foreign direct investment and environmental pollution in major Asia Pacific countries. Environ. Sci. Pollut. Res. 28 (31), 42649–42669. https://doi.org/10.1007/s11356-021-13619-w (2021).

Thiede, S. Environmental sustainability of cyber physical production systems. Procedia CIRP. 69, 644–649. https://doi.org/10.1016/j.procir.2017.11.124 (2018).

Yang, Z. et al. Digitalization and carbon emissions: how does digital City construction affect china’s carbon emission reduction? Sustainable Cities Soc. 87, 104201. https://doi.org/10.1016/j.scs.2022.104201 (2022).

Zhang, Y. & Wang, J. Research on influencing factors and path of digital intelligence transformation of manufacturing enterprises. Kybernetes 53 (2), 752–762. https://doi.org/10.1108/K-06-2023-1042 (2024).

Zou, L., Li, W., Wu, H., Liu, J. & Gao, P. Measuring corporate digital intelligence transformation: methodology, indicators and applications. Sustainability 16, 4087. https://doi.org/10.3390/su16104087 (2024).

Wang, Y. & Su, X. Driving factors of digital intelligence transformation for manufacturing enterprises: A multi-case study from China. Int. J. Technol. Manage. 87 (2–4), 229–253. https://doi.org/10.1504/IJTM.2021.120932 (2021).

Wang, B. et al. How does artificial intelligence affect high-quality energy development? Achieving a clean energy transition society. Energy Policy 186114010. https://doi.org/10.1016/j.enpol.2024.114010 (2024).

Huang, C. & Lin, B. Promoting decarbonization in the power sector: how important is digital transformation? Energy Policy. https://doi.org/10.1016/j.enpol.2023.113735 (2023). ,182.

Zeng, Y., Xu, X., Zhao, Y. & Li, B. Impact of digital economy on the upgrading of energy consumption structure: evidence from Mainland China. Sustainability 15, 5968. https://doi.org/10.3390/su15075968 (2023).

Gao, J., Xu, N. & Zhou, J. Does digital intelligence transformation contribute to corporate carbon emissions reduction? Empirical evidence from China. Sustainability 15 (18), 13414. https://doi.org/10.3390/su151813414 (2023).

Zheng, R. et al. How does digitalization drive carbon emissions? The inverted U-shaped effect in China. Environ. Impact Assess. Rev. 102, 107203. https://doi.org/10.1016/j.eiar.2023.107203 (2023).

Salahuddin, M. & Alam, K. Internet usage, electricity consumption and economic growth in australia: A time series evidence. Telematics Inform. 32 (4), 862–878. https://doi.org/10.1016/j.tele.2015.04.011 (2015).

Raheem, I. D., Tiwari, A. K. & Balsalobre-Lorente, D. The role of ICT and financial development in CO2 emissions and economic growth. Environ. Sci. Pollut. Res. 27, 1912–1922. https://doi.org/10.1007/s11356-019-06590-0 (2020).

Wang, X. Y. & Li, J. Y. Did the digital economy effectively promote energy conservation and CO 2 reduction? China Popul. Resour. Environ. 32 (11). https://doi.org/10.12062/cpre.20221022 (2022).

Guo, Z., Xiang, Y., Zhou, K., Fu, L. & Song, Y. How does the digital intelligence transformation affect the carbon emissions of manufacturing enterprises in china?? The perspective of green technology innovation. Sustainability 16 (8), 3184. https://doi.org/10.3390/su16083184 (2024).

Li, Y. et al. Energy structure, digital economy, and carbon emissions: evidence from China. Environ. Sci. Pollut. Res. 28, 64606–64629. https://doi.org/10.1007/s11356-021-15304-4 (2021).

Lange, S., Pohl, J. & Santarius, T. Digitalization and energy consumption. Does ICT reduce energy demand? Ecol. Econ. 176, 106760. https://doi.org/10.1016/j.ecolecon.2020.106760 (2020).

Goralski, M. A. & Tan, T. K. Artificial intelligence and sustainable development. Int. J. Manag Educ. 18, 100330. https://doi.org/10.1016/j.ijme.2019.100330 (2020).

Ren, S. Y., Hao, Y., Xu, L., Wu, H. T. & Ba, N. Digitalization and energy: how does internet development affect china’s energy consumption? Energy Econ. 98, 20. https://doi.org/10.1016/j.eneco.2021.105220 (2021).

Cheng, Y., Zhang, Y., Wang, J. J. & Jiang, J. X. The impact of the urban digital economy on china’s carbon intensity: Spatial spillover and mediating effect. Resour. Conserv. Recycl. 189, 9. https://doi.org/10.1016/j.resconrec.2022.106762 (2023).

de Sousa Jabbour, A. B. L., Jabbour, C. J. C., Foropon, C. & Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 132, 18–25. https://doi.org/10.1016/j.techfore.2018.01.017 (2018).

Birdsall, N. & Wheeler, D. Trade policy and industrial pollution in Latin america:where are the pollution havens. J. Environ. Dev. 25 (2), 137–149. https://doi.org/10.1177/107049659300200107 (1993).

Myovella, G., Karacuka, M. & Haucap, J. Digitalization and economic growth: a comparative analysis of sub-Saharan Africa and OECD economies. Telecomm. Policy. 44 (2), 101856. https://doi.org/10.1016/j.telpol.2019.101856 (2020).

Li, G. & Liao, F. Input digitalization and green total factor productivity under the constraint of carbon emissions. J. Clean. Prod. 377, 134403. https://doi.org/10.1016/j.jclepro.2022.134403 (2022).

Wang, J. Q., Ma, X. W., Zhang, J. & Zhao, X. Impacts of digital technology on energy sustainability: China case stud. Appl. Energy. 323, 119329. https://doi.org/10.1016/j.apenergy.2022.119329 (2022).

Zhang, S., Ma, X. & Cui, Q. Assessing the impact of the digital economy on green total factor energy efficiency in the post-COVID-19 era. Front. Energy Res. 9, 798922. https://doi.org/10.3389/fenrg.2021.798922 (2021).

Hwang Young Kyu. The synergy effect through combination of the digital economy and transition to renewable energy on green economic growth: empirical study of 18 Latin American and Caribbean countries. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2023.138146 (2023). ,418.

Wang, J., Wang B,Dong, K. & Dong, X. How does the digital economy improve high-quality energy development? The case of China. Technol. Forecast. Social Change 184. https://doi.org/10.1016/j.techfore.2022.121960 (2022).

Berkhout, F. & Hertin, J. De-materialising and re-materialising: digital technologies and the environment. Futures 36 (8), 903–920. https://doi.org/10.1016/j.futures.2004.01.003 (2004).

Alam, M. W. & Murad, M. W. The impacts of economic growth, trade openness and technological progress on renewable energy use in organization for economic co-operation and development countries. Renew. Energy. 145, 382–390. https://doi.org/10.1016/j.renene.2019.06.054 (2020).

Ehrlich, P. R. & Holdren, J. P. Impact of population growth. Science 171 (3977), 1212–1217. https://doi.org/10.1126/science.171.3977.1212 (1971).

Lyu, Y., Zhang, L. & Wang, D. The impact of digital intelligence transformation on low-carbon development of manufacturing. Front. Environ. Sci. 11, 1134882. https://doi.org/10.3389/fenvs.2023.1134882 (2023).

Li, X. & Ling, J. The impact of manufacturing intelligence on green development efficiency: A study based on Chinese data. Sustainability 15, 7553. https://doi.org/10.3390/su15097553 (2023).

Yang, H., Li, L. & Liu, Y. The effect of manufacturing intelligence on green innovation performance in China. Technological Forecast. Social Change. https://doi.org/10.1016/j.techfore.2022.121569 (2022). ,178.

Ma, Q., Tariq, M., Mahmood, H. & Khan, Z. The nexus between digital economy and carbon dioxide emissions in china: the moderating role of investments in research and development. Technol. Soc. https://doi.org/10.1016/j.techsoc.2022.101910 (2022). ,68.

Lind, T. J. & Mehlum, H. With or without U? The appropriate test for a U-shaped relationship. Oxf. Bull. Econ. Stat. 72 (1), 109–118. https://doi.org/10.1111/j.1468-0084.2009.00569.x (2010).

Acknowledgements

The Research was supported by the following foundations: Major research projects in humanities and social sciences in universities in Hebei Province (Grant No. ZD202418).

Author information

Authors and Affiliations

Contributions

Qiqi Sun, Siyan Liu, Lili Feng and Gang Lu wrote the main manuscript text . All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, Q., Liu, S., Feng, L. et al. Nonlinear relationship between digital and intelligent transformation and energy conservation and emission reduction in China. Sci Rep 15, 29814 (2025). https://doi.org/10.1038/s41598-025-15821-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-15821-z