Abstract

3D quadrangular rotary braiding is one vital technique of high efficiency and flexibility to manufacture preforms for composites. However, the use of this technique is limited to fabricating a few traditional braided fabric structures, which is attributed to the lack of knowledge of its process. Therefore, a model is proposed to simulate the braiding process so as to develop new processes and corresponding fabric structures. First, yarn interlacement patterns under individual propelling of the horn-gear and switch are depicted, which preliminary supplies a reference to the selection of process parameters. Then, the braiding process is digitized based on a novel mixed coordinate system, which constructs the relation between the process and carrier path. Combined with the algorithm transforming carrier path to yarn trajectories, the process-structure model is established. Afterward, the effect of horn-gear and switch movement on the yarn interlacement pattern is illustrated, which further clarifies the utilization principle of braiding process parameters. Several interesting novel braided structures including the surface-core structure are found, which shows the potential of this technique. At last, a new multi-layer interlock structure is created by modifying part of the process parameters of traditional 3D braided structure, which verifies the correctness of above model and effects.

Similar content being viewed by others

Introduction

3D braided composites have become one kind of critical engineering materials in aerospace, aeronautic and automotive industries due to their excellent mechanical properties such as delamination resistance and impact tolerance1. As one technique to manufacture 3D braided preforms, the 3D rotary braiding process is gaining more and more attention for its flexibility to manufacture complex braided structures with high efficiency2,3.

In the 3D rotary braiding process, carrier configuration and carrier path are parameters deciding the braided fabric structures and thus influencing the mechanical properties of their composites. In order to design and manufacture desirable preforms, it is vital to understand their effects on fabric structures and explore potential braided structures.

As to the traditional 3D rotary braiding machine, carriers travel along determinate paths, thus primary works are concentrated on the carrier configuration. Tada et al.4 proposed an approach to translate traditional 3D braided structures into machine processes including the optimum carrier number and horn-gear arrangement. By doubling the number of braiding yarns, Wang et al.5 presented a new one-carry-two full five-directional braided composite which has a distinct meso-structure. To avoid carrier collisions, Meng et al.6,7 established a mathematical model that can get reasonable carrier arrangement based on the carrier path in both circular and square rotary braiding processes.

When it comes to modern rotary braiding machines, the use of individually controlled switches allows the control of carrier path. Therefore, the carrier path is gaining more concentration. Kyosev et al.8 developed a simulation tool to get the fabric structure manufactured from variable carrier paths. Subsequently, the concept of extended horn-gear9 and carrier delay method10 were proposed for the change of braiding patterns. In our previous work, a model11 for the 3D hexagonal process was constructed, therefore several basic rules for the adoption of braiding process parameters and interesting fabric structures were found. Yang et al.12 made an optimization on the switch mechanism of 3D hexagonal braiding machine, and resulted fabric structures were simulated and fabricated. Aiming at manufacturing variable-section braiding structures, Shao et al.13 proposed a method for the track structure splicing.

Nowadays, simulation has become an effective and essential approach to develop processes for novel fabric structures14,15,16,17,18, and softwares have been developed such as the TexMind which can help pattern designing. As to the 3D quadrangular rotary braiding machine with a 3Tex switch mechanism19, the process becomes more complicated due to the special switch mechanism. It is noted that the rotation angle and rotation direction of horn-gears and switches have neglectful effects on the carrier path and resulting fabric structures, which are not demonstrated in previous works.

Therefore, this paper aims to build a model for simulating the 3D quadrangular rotary braiding process so as to investigate the effects of braiding process parameters and explore potential fabric structures. The rest of this paper is organized as follows. Section 2 introduces the 3D quadrangular rotary braiding process. Section 3 demonstrates the process-structure model. Section 4 illustrates the investigation on novel processes and corresponding fabric structures. Conclusions are summarized in Sect. 5.

The 3D quadrangular rotary braiding process

The 3D quadrangular rotary braiding process studied in this paper depends on the machine construction shown in Fig. 1, in which horn-gears are assembled on the plate in configuration of rows and columns while switches are placed between them. Due to the special switch mechanism, each horn-gear can hold up to four carriers simultaneously. During the braiding process, horn-gears and switches rotate to push carriers rotating around them thereby yarns connected to carriers are manipulated to form specific interlacing preforms.

Although both horn-gear rotation and switch rotation can change the carrier position, the effects of them on the yarn interlacement are distinct due to the quantity of carriers surrounding them. As shown in Fig. 2a, each switch can hold up to two carriers which are distributed around the circumference. Thus, the switch rotation angle can only be multiples of 180° to avoid movement interferences. When the switch rotates half a circle, two carriers exchange their position which leads to the common skew interlacement pattern20. When the switch rotates one circle, carriers rotate one circle returning to their initial position, which results in an “arm-in-arm” curved interlace pattern. When the switch continues to rotate, yarns will be intertwined together to form a wick-like structure. If there is only one carrier surrounding the switch, the switch rotation greater than 180° will not lead to a helpful positional change of carriers but introduces twisting into yarns.

As to horn-gears which can hold more carriers, the effect is quite different. While only one or two carriers are configured around each horn-gear, the effect is as same as that of switches. However, if more than two carriers are configured around each horn-gear, yarns form the common skew interlacement pattern when the horn-gear rotation angle is not greater than 180° while yarns are wound together when the angle is greater than 180°, which is shown in Fig. 2b. Therefore, in order to make yarns interlace together rather than twist together, the horn-gear rotation angle should be not greater than 180° and the switch rotation angle should be not greater than 360°.

Aforementioned analyses illustrate the yarn interlacement pattern under individual propelling of the horn-gear or switch, which preliminarily provides a reference for the selection of braiding movement parameters. However, in the braiding process, carriers move under the joint action of horn-gears and switches, thus each yarn interlaces with other yarns in multiple positions and the interlacement pattern changes with the horn-gear rotation direction, horn-gear rotation angle, switch rotation direction, switch rotation angle and their combination. Therefore, it is vital to establish a mathematical model to predict yarn trajectories based on the braiding process parameters.

Process-structure model for the 3D rotary braiding process

The braiding process in this paper specifically refers to the braiding movement which decides the fabric topology, thus the yarn tension is omitted. The braiding movement includes three parts namely horn-gear rotation, switch rotation and lifting motion. Among them, horn-gear and switch rotation jointly determine the carrier path on the braiding machine and thus yarns are interlaced to form corresponding patterns under the traction of carriers. The lifting motion determines the height of the forming plane thus determines the geometric parameters such as braiding angle and pitch length, but has no influence on the fabric structure. Therefore, in this section, the relation between the process and carrier path will be first established, and the fabric structure will be subsequently constructed according to the carrier path. Since the fabric structure is only related to the rotation direction and rotation angle of horn-gears and switches, and has nothing to do with the rotation speed or acceleration, the context will focus on the analysis of rotation direction and rotation angle.

Relation between the process and carrier path

The carrier path is made up of arcs around horn-gears and switches due to their actuation. Therefore, the position, direction and size of these arcs are determined by the movement of adjacent horn-gears and switches. In order to get the motion path of carriers, a coordinate system is established to describe the carrier position and build the adjacent relationship between carriers and horn-gears, switches.

It is noted that horn-gears are arranged in rows and columns like a lattice. As we know, each point in the lattice can be expressed as \(\vec {{\varvec{R}}}=m\vec {{\varvec{a}}}+n\vec {{\varvec{b}}}\) in which \(\vec {{\varvec{a}}}\) and \(\vec {{\varvec{b}}}\) are lattice basis vectors and m and n are integers. Aiming to map the horn-gear and switch movement parameters to matrix elements, the coordinate system is constructed as shown in Fig. 3, in which the coordinate origin is set outside the horn-gear array and the half length of basis vectors is utilized as unit length, which makes the coordinate values of horn-gears and switches to be positive integers. In this coordinate system, the position of horn-gears is expressed by the coordinate of their rotation center (m, n), in which m and n are even numbers. Similarly, the position of switches is expressed by the coordinate of their rotation center (p, q), in which the sum of p and q is an odd number. Since carriers are placed in the slots around horn-gears, their position is represented by (x, y,θ), in which x and y are coordinates of the surrounded horn-gear andθ is the angle required for the carrier to rotate clockwise around the horn-gear to reach X-axis, 0 ≤ θ < 360°. The value of θ depicts the relative position of carriers to the surrounded horn-gear, which decides the carrier movement direction when the adjacent switch rotates half a circle. This direction is described by a vector (u, v), in which u = cosθ, v = sinθ. The coordinates and direction vectors of labeled carriers in Fig. 3 are shown in Table 1. Consequently, the position relations between carriers and horn-gears, switches are established, which can be concluded that the motion of carrier (x, y,θ) is decided by horn-gear (x, y) and switch (x + u, y + v). Therefore, providing the current carrier coordinate and movements of relative horn-gear and switch, the subsequent carrier coordinate after braiding movements can be calculated.

As shown in Fig. 4, when the horn-gear rotates, carriers are still located around the initial horn-gear, which means the X and Y coordinate values of carriers don’t change. However, the relative position of carriers to the horn-gear changes, which can be represented as the change ofθ values. In order to make sure that the angle value conforms to aforementioned definition, the remainder operation is carried out on the angle values. Consequently, the formula of carrier movement around horn-gears is expressed as

wherein k represents the braiding motion consequence, mh is the horn-gear rotation angle in which the positive number means counterclockwise rotation and the negative number means clockwise rotation.

When the switch rotates, the change of carrier position depends on the switch rotation angle. As shown in Fig. 5, if the rotation angle is odd multiples of 180°, the value of x, y andθ will change simultaneously in which the growth direction of x and y values is identical to the direction vector and the value of θ becomes the remainder of 360°. If the rotation angle is even multiples of 180°, obviously the carrier will rotate around switches several circles and finally get back to the initial position, which means the value of x, y andθ will not change. Therefore, the formula of carrier movement around switches is expressed as

wherein ms is the switch rotation angle in which the positive number means counterclockwise rotation and the negative number means clockwise rotation.

While a single carrier is taken as the object, its movement is only related to the horn-gears and switches it surrounds. However, it is noted that the motion of these horn-gears and switches also acts on other surrounding carriers. As to total carriers taking part in the braiding process, their movements are not only related to the horn-gear and switch movements but also related to the arrangement of horn-gears and switches. Therefore, the movement parameter of horn-gears and switches in every braiding step is actually a two-dimensional matrix in which the location of elements is determined by the arrangement of horn-gears and switches. Considering that horn-gear and switch movements vary in the braiding process, the movement parameter is one three-dimensional matrix about the braiding step.

Taking the horizontal and vertical coordinates of horn-gears and switches as the number of rows and columns of the matrix respectively, the motion parameter matrix of the braiding machine shown in Fig. 3 can be written as

wherein mh and ms are movement parameters of horn-gears and switches in the kth step of the braiding process and the element whose value is zero represents the position without horn-gear or switch distribution. Obviously, the matrix size is decided by the arrangement of braiding machine. The matrix size is (2n + 1)×(2m + 1) when the horn-gears are arranged in m×n. Usually, switches are not installed at the periphery of braiding machines, which makes all periphery elements to be 0.

Relation between the carrier path and fabric structure

When carriers move on the braiding plate, yarns on the carriers move in the space and interlace together to form integrated fabrics. Therefore, the fabric structure can be obtained by combining yarn trajectories.

The formation of yarn trajectories is shown in Fig. 6, in which the preform underside plane, the forming plane and the plane of yarn outlet are parallel with each other. Before the braiding movement, yarn terminals are connected to the carrier at point A and the fabric at point respectively. When the braiding movement begins, the terminal connected with the fabric maintains static while the other terminal moves from point A to point B due to the traction from the carrier, which makes the yarn have a certain orientation under yarn tension. After interlacing with other yarns, the yarn segment \({\text{A''B'}}\) above the forming plane turns into a new part of the fabric and the current forming plane becomes the new preform underside plane. By such cyclic movements, yarns are constantly braided into the fabric. Therefore, the yarn trajectory can be obtained by combining the newly formed yarn segments (\({\text{A''B'}}\)) in every step.

Based on the above analyses, an algorithm is presented to transform the carrier path to yarn trajectory, which consists of three steps: (1) adding height values to convert the carrier path into yarn path; (2) constructing the control polygon by discretizing the yarn path and connecting the midpoints of each discrete line segment; (3) fitting the control polygon to obtain the yarn trajectory. An example is taken to depict the relation between carrier path and yarn trajectory, which is shown in Fig. 7. As shown in Fig. 7a, under the joint action of four horn-gears and four switches, the carrier departs from point A, passes through points B, C, D, E, F, G, H and finally returns to the starting point A in the form of circular arcs, which constitutes the carrier path. Based on predetermined rotation speeds of horn-gears and switches, the time at each point is calculated. Assume the initial height is 0 and the height decreases as the braiding movement goes on, then the height value after each rotation movement is obtained based on the time and lifting velocity. By adding decreasing height values to each point in turn, the yarn path is obtained, which is shown in Fig. 7b. The yarn path can reflect the movement trajectory of yarns, however, there are discontinuous cusps in it, which cannot represent the real appearance of yarns. Actually, the yarn is so flexible that it becomes smooth under tension and squeezing. Therefore, curve fitting is adopted to transform the yarn path into yarn trajectory. Since the distribution of each yarn segment is fixed and no longer affected by the braiding process when it becomes one part of the fabric, it can be expressed that the trajectory of each yarn segment is only determined by the yarn carrier movement before and after it, thus the B-spline curve with local control property is utilized to carry out this transformation. The quadratic B-spline curve is determined by three control points, starting at the midpoint of first two control points and ending at the midpoint position of last two control points, which will not cause too much change in the yarn extension direction. Therefore, the quadratic B-spline curve is selected to generate the yarn trajectory. The control points are set to be the midpoints of each arc segment so that it can maintain the yarn extension direction. Before calculating the midpoints, arcs greater than 90° are discretized to be segments of 90°. It can be seen from Fig. 7 that the calculated yarn trajectory is smooth and can represent the yarn extension direction as well.

Investigation on the 3D rotary braided fabric structures

Effect of horn-gear and switch movement on the yarn interlacement pattern

In the fabric, yarns interlace with each other to form various interlacement patterns due to the differences in braiding motion. Although the fabric is made up of numerous yarns and the interlacement situation is complex, as long as the interlacement pattern resulting from every two interlaced yarns is correct, the interlacement situation in the whole fabric is correct. Therefore, in order to verify the correctness of above algorithm and investigate the effect of horn-gear and switch movement on the yarn interlacement pattern, yarn interlacement patterns under different movement conditions are tested.

In the rotary braiding process, the interlacement pattern of two adjacent yarns is determined by relative horn-gears and switches. Therefore, a minimum unit which is large enough to get yarns interlaced is employed, in which there are two horn-gears and one switch between them. In the test, horn-gear 1 and 2 rotate a certain angle, then the switch rotates a certain angle, and at last two horn-gears rotate a certain angle. Since the arcs greater than 90° are discretized to be multiple segments of 90° in the algorithm, the horn-gear rotation angle greater than 90° will not affect the interlacement pattern, thus the horn-gear rotation angle is set to be 90° in this test. As shown in Table 2, there are totally eight movement direction combinations for this minimum unit, in which “CW” represents clockwise rotation and “CCW” represents counterclockwise rotation. The cases when the switch rotation angle is 180° and 360° are tested and depicted separately.

When the switch rotation angle is 180°, test results are shown in Fig. 8. In order to show the interlacement pattern much more clearly, the cylinder around yarn trajectory is used to show the yarn and the color varying from blue to red represents the height varying from higher to lower. It is seen that the eight interlacement patterns are quite different due to various rotation direction schemes and they can be divided into three types. In the first type, which is shown in Fig. 8a, h, although carriers exchange the horn-gears they follow, yarns do not interlace but stack together because the horn-gears and switch have the same rotation direction. In the second type, when horn-gears have the same rotation direction and the switch has the opposite, yarns surround each other to form an “arm-in-arm” structure, which is shown in Fig. 8b, g. This structure is similar to the structure formed by warp yarns and weft yarns in plain weave fabrics, but the interlaced yarns are not perpendicular. When it comes to the third type, horn-gears have opposite rotation directions, thus yarns interlace with each other to form the typical skew structure20 and the positional relationship between two yarns in the height direction becomes opposite due to the change of switch rotation direction, which is shown in Fig. 8c–f. For instance, the yarn extending from left to right is located at the below of the other yarn in Fig. 8c but located at the above in Fig. 8d. Upon comparison of Fig. 8a–h, it is evident that both the first or the latter four schemes encompass the aforementioned three types of interlacement patterns. It suggests that the combination of horn-gear rotation direction, rather than horn-gear rotation direction, decides the diversity of yarn interlacement pattern. In other words, when the rotation direction relationship between adjacent horn-gears is decided, the diversity of fabric structures keep unchanged whether a certain horn-gear rotates clockwise or counterclockwise.

When the switch rotation angle is 360°, results are shown in Fig. 9. If horn-gears and the switch have the same rotation direction, yarns interlace together to form the “arm-in-arm” structure, which is shown in Fig. 9a and h. If horn-gears have the same rotation direction and the switch has the opposite, both yarns revolve one circle around the other yarn to form closed loops thus yarns wind with each other, which is shown in Fig. 9b and g. If two horn-gears have different rotation directions, only one yarn revolves one circle around the other yarn to form a closed loop so yarns wind together too but the winding angle is smaller, which is shown in Fig. 9c–f. Compared to the situation when switch rotation angle is 180°, the switch rotation angle which is 360° don’t generate any new yarn interlacement patterns except for yarn winding situations.

Compared to the actual situation, it is proved that this yarn trajectory generation algorithm can accurately depict yarn interlacement patterns under different movement conditions. Analyzing above results, it can be deduced that the rotation movement of horn-gears and switches changes the extension direction of yarns and the amount of this change decides the yarn interlacement pattern. For instance, when the switch rotation angle is 360°, although both two horn-gears rotate clockwise in rotation direction schemes (a) and (b) in Table 2, it is the difference in switch rotation direction that results in various yarn interlacement patterns in Fig. 9a and b. As shown in Fig. 10, both two carriers belonging to horn-gear HG-1 rotate clockwise from point A to point B, then rotate one circle back to point B, and ultimately rotate clockwise to point C. When the switch rotates clockwise, the carrier path is composed of AB, BD, DE, EB and BC, which is shown in Fig. 10a. In the carrier path, there are bends in segments ABD and EBC. When the yarn is tightened by the tension, the bends in segment ABD and EBC turn to be straight thereby opening the closed loop BDEB forming by the switch rotation, and then forming the “arm-in-arm” interlacement pattern with the other yarn. When it comes to the movement scheme b) in Table 2, the switch rotates counterclockwise, which is shown in Fig. 10b. Under this condition, the closed loop is tightened by the yarn tension, which results in the yarn winding. According to above analyses, it can be predicted that yarns will wind with each other no matter what the rotation direction combination of horn-gears and the switch is when the switch rotation angle is greater than 360°. In other words, compared to the interlacement patterns when the switch rotation angle is 180°, the switch rotation angle which is equal to or greater than 360° does not generate new yarn interlacement patterns except for yarn winding patterns. Thus, considering yarn winding is harmful to the performance of fiber-reinforced composites, the context will concentrate on the analysis of fabric structures when the switch rotation angle is 180°.

Simulation and verification of the fabric structures

In order to reveal the effect of braiding motion on the fabric structure and explore new structures, a simulation interface is developed based on the yarn trajectory algorithm, which is shown in Fig. 11. This simulation interface can generate the trajectory of appointed yarns based on braiding movement parameters and carrier configuration imported by sliders and radio buttons on the interface or excel spreadsheet.

According to the analyses in Sect. 4.1, when the switch rotation angle is 180°, there are three yarn interlacement patterns namely no interlacement, “arm-in-arm” interlacement and the typical skew interlacement. In this section, fabric structures under these three corresponding rotation direction combinations and different horn-gear rotation angles are simulated, which are shown in Table 3. In this simulation, the 4 × 4 horn-gear arrangement is adopted to fully reflect the influence of braiding motion on the fabric reinforcement form.

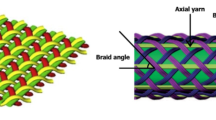

The simulation results are shown in Fig. 12, in which the color varies from blue to red represents the height varies from higher to lower. In fabric A, there are 10 yarn groups with no interlacement, in which one group winds clockwise around the periphery of the fabric and the other 9 groups twist in the interior. In fabric B, yarns move back and forth along the X or Y axis and interlace with the yarns whose extension direction is perpendicular to theirs. Compared with fabric A, it is the horn-gear rotation movement of 180° that divides carriers following each horn-gear into two groups moving towards perpendicular directions, which let corresponding yarns interlace together. Yarns in fabric B can get through the whole thickness and they are parallel to the surface, which is similar to 3D surface-core braided fabrics which can reduce the impair resulting from the cut edge to their composites. In fabric C, there are 10 yarn groups and among them one group winds clockwise around the periphery of the fabric, which is similar to fabric A. However, the other 9 groups in fabric C interlace with adjacent groups to form an integrated “arm-in-arm” structure. In fabric D, there are also 8 yarn groups and the yarn extension direction is similar to fabric B, but yarns in the same group interlace with each other and each yarn is floating over another yarn to form a 2D plain braided structure. Meanwhile, the skew interlacement between different yarn groups links 2D braided layers together to form an entirety. Fabric E is the typical 3D braided structure in which yarns get through the whole thickness in 45° direction with the surface and yarns belonging to different groups interlace with each other. In fabric F, there are 8 yarn groups and the extension direction is similar to fabric D. Also, yarns in the same group interlace with each other to form 2D braids and yarns in different groups interlace to connect these 2D braided layers together. The difference between fabric D and F is that yarns in the same group in fabric F are floating over three yarns which forms the Hercules(3/3) braided structure21.

Simulated fabric structures resulted from braiding process parameters in Table 3.

Based on above simulations, it is seen that various fabric structures can be obtained by changing the movement parameters of horn-gears and switches. In fabrics A and C, yarns extend in the local area. However, yarns in fabric B, D, E and F extend along specific directions getting through the whole thickness and turn back when they reach the boundaries, which forms the 3D reinforcement. These simulations depict several fabric structures consisting of the extension direction of yarns in the periphery and interior as well as the interlacement among yarns. Combining the effect of horn-gear and switch movement on yarn interlacement patterns in Sect. 4.1, it is realized that novel fabric structures can be created by modifying movement parameters based on above structures.

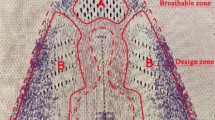

As shown in Fig. 13a, limited by the braiding trajectory, there are inevitably gaps on the surface of traditional rectangular multi-layer interlock braided fabrics, which results in defects between layers. To avoid these defects, a novel rectangular multi-layer interlock braided fabric is proposed based on fabric E in Fig. 12, which is shown in Fig. 13b. By setting the rotation angle of switches between horn-gear columns to be 360°, carriers turn back to the horn-gears they initially follow and the braiding trajectory is restricted to layers separated by these switches. Thus, in this novel multilayer fabric, yarns in each layer interlace together to form a 2D braided structure, meanwhile yarns in adjacent layers interlock together according to the “arm-in-arm” pattern, which avoids the gaps between layers. Also, various interesting novel fabric structures can be obtained based on this method.

Two kinds of rectangular multilayer interlock braided fabrics: (a) the traditional one7, (b) the novel one.

In order to verify above analyses of fabric reinforcement forms, a quadrangular rotary braiding machine is set up, which is shown in Fig. 14a. In this braider, the 4 × 4 horn-gear arrangement is adopted, which means it can hold 64 carriers and 25 axial yarns simultaneously. After yarn hanging, yarns can be automatically braided into fabrics to a maximum length of 400 mm based on the movement parameters of horn-gears and switches. 3D braided fabrics, multilayer interlock braided fabrics and 2D braided fabrics are fabricated using carbon fiber and glass fiber, which is shown in Fig. 14b. The 3D braided fabric corresponds to fabric E in Fig. 12, in which the glass fiber tracer yarn diagonally passes through the thickness of the fabric and interspersed between each surface. The multilayer interlock fabric corresponds to the fabric in Fig. 13b, in which carbon or glass fiber bundles extend in their own layer and interlace with those yarns in adjacent layers. By making the switches corresponding to interlock points static in the braiding process of the multilayer interlock fabric, the yarn interlock is destructed thus the integrated multilayer fabric becomes four separated 2D fabrics, which is shown in Fig. 14a and b. It also can be seen that the fabric cross-section varies according to the different fabric structures, which supplies a way to the regulation of the shape and properties of composites without adding or decreasing yarns.

Conclusions

In this paper, a process-structure model for the 3D quadrangular rotary braiding is developed and its potential to manufacture novel fabric structures is investigated. First, the effect of horn-gear and switch movement on yarn interlacement patterns is revealed, and the horn-gear rotation angle is suggested to be not greater than 180° and the switch rotation angle is suggested to be not greater than 360° to avoid yarn twisting, meanwhile, the switch rotation angle of 360° is recommended only when it is used to connect layers. Second, several interesting fabric structures such as the surface-core-like structure B and arm-in-arm structure C are obtained through the simulation, which shows the quadrangular rotary braiding can fabricate distinct fabrics by changing the process parameters. Third, a novel multilayer interlock braided fabric is created by modifying part of the process parameters based on above typical structures and the effect of horn-gear and switch movement, which represents a new way to obtain desirable reinforcements for composites.

This paper focuses on building the connection between braiding movements and fabric topology but omits the process parameters which influence the fabric geometry. Further, an integrated model considering rotation speeds of horn-gears and switches, lifting velocity and yarn tension will be constructed to predict the geometric information of fabrics.

Data availability

The code used during the current study is available from the corresponding author on reasonable request.

References

Gu, Q. et al. Structural modeling and mechanical characterizing of three-dimensional four-step braided composites: A review. Compos. Struct. 207, 119–128 (2019).

Li, X. et al. Research status of 3D Braiding technology. Appl. Compos. Mater. 1–11 (2022).

Zhengxi, Z. et al. Advanced composite preform forming technology for structures and its digitization: A review. Thin Wall Struct. 113053 (2025).

Tada, M. et al. Structure and machine Braiding procedure of coupled square braids with various cross sections. Compos. Appl. S. 32 (10), 1485–1489 (2001).

Wang, Y. et al. Novel processing technology and mesoscopic geometric modeling of a new three-dimensional (3D) braided composite and the study on its longitudinal mechanical properties. Compos. Struct. 251, 112525 (2020).

Meng, Z. et al. Modeling and analysis of the carrier arrangement in three-dimensional circular Braiding. Tex. Res. J. 88 (1), 49–58 (2018).

Du, C. et al. Modeling and analysis of the carrier arrangement in square rotary Braiding. Tex. Res. J. 89 (19–20), 4208–4219 (2019).

Kyosev, Y. Numerical modelling of 3D Braiding machine with variable paths of the carriers. Appl. Compos. Mater. 25 (4), 773–783 (2018).

Kyosev, Y. & Glebner, P. Extended Horn gears in 3D maypole braiding: theoretical analysis, gear arrangement and prediction of the floating length. J. Tex. Fibrous Mater. 1, 1–7 (2018).

Glessner, P. & Kyosev, Y. Carrier delay-based method for development of the tracks for the transitions between patterns on 3D Braiding machines with continuous rotating Horn gears. Tex. Res. J. 91 (23–24), 2833–2845 (2021).

Mei, H. et al. Process modelling of 3D hexagonal braids. Compos. Struct. 252 (4), 112679 (2020).

Yang, X. et al. Design optimization of a three-dimensional hexagonal Braiding technique. Tex. Res. J. 95 (7–8), 688–704 (2024).

Shao, G. et al. Track design and realization of Braiding for three-dimensional variably shaped cross-section preforms. J. Eng. Fiber Fabr. 16 (10), 1485–1489 (2021).

Yang, X. et al. Fiber-level automatic modeling strategy of 3D rotary braided preform based on motion information. Compos. Struct. 354, 118832 (2025).

Li, J. et al. A matrix computing method for visualizing switchless controlled 3D hexagonal-annular rotary Braiding process architecture. Polym. Compos. 44 (10), 6616–6633 (2023).

Ren, C. et al. Topology-based parametric modeling of three-dimensional hexagonal braids for advanced composite structures. Tex. Res. J. 95 (1–2), 64–78 (2024).

Ding, C., Gu, X. & Lu, C. Simulation of the hexagonal 3D Braiding process for stent preforms. Tex. Res. J. 94 (5–6), 691–703 (2024).

Du, C. et al. Numerical analysis of composite preform structure based on flat cross-linked Braiding. J. Ind. Text. 53, 1–22 (2023).

Li, X. et al. Research status of 3D Braiding technology. Appl. Compos. Mater. 29 (1), 147–157 (2022).

Ma, Z., Zhang, P. & Zhu, J. Investigation of the classification and properties of three-dimensional textile fabrics. J. Eng. Fiber Fabr. 14, 1–11 (2019).

Kyosev, Y. Braiding Technology for Textiles: Patterning of Braided Products (Elsevier, 2015).

Funding

This study is financially supported by National Natural Science Foundation of China (52405383), Natural Science Foundation of Shandong Province (ZR2023QE292, ZR2022QE253) and Support Plan for Outstanding Youth Innovation Team in Universities of Shandong Province (2022KJ311).

Author information

Authors and Affiliations

Contributions

Haiyang Mei and Zhenyu Han, conceptualization. Haiyang Mei, Shouzheng Sun, Jiale Ding, Jingjing Zhang and Changping Feng, investigation. Zhenyu Han, supervision. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mei, H., Sun, S., Ding, J. et al. A model for simulating the 3D quadrangular rotary braiding process. Sci Rep 15, 31148 (2025). https://doi.org/10.1038/s41598-025-16119-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-16119-w