Abstract

This study aims to determine the feasibility of producing sustainable geopolymer bricks with industrial waste, such as fly ash and GGBS. The experimental investigations have been conducted at varying sodium hydroxide (NaOH) molarity (4 M, 6 M, 10 M, 12 M), GGBS incorporation levels (0%, 5%, 10%, 15%, 20%), curing temperatures (ambient, 60 °C, 80 °C, 120 °C), and curing durations (7, 14, and 28 days) to examine physical and mechanical properties of geopolymer bricks. The findings demonstrated a notable increase in compressive strength with elevated GGBS content, with a peak strength of 49.63 MPa at 20% GGBS, 10 M NaOH molarity, and a curing temperature of 80 °C after 28 days. Elevated curing temperatures improve the compressive strength, and attain its maximum value at 120 °C; however, 80 °C was identified as the optimal setting for balancing mechanical performance and energy efficiency. Moreover, the augmented quantity of GGBS enhanced bulk density and durability while reducing porosity and water absorption. In optimal conditions, microstructural analyses employing energy dispersive X-ray spectroscopy (EDX) and scanning electron microscopy (SEM) revealed enhanced geopolymer gel development and a more compact matrix formation. Comparative analysis of SEM pictures and EDS data indicates that the high concentration of Ca and Si contributes to the dense microstructure and abundant C-S-H area. Geopolymer bricks exhibit enhanced strength owing to their significant C-S-H composition. The study concludes that the integration of industrial waste ashes, specifically with 10 M NaOH, 20% GGBS, and curing at 80 °C, yields high strength geopolymer bricks with enhanced microstructural properties, suggesting their viability as an environmentally sustainable substitute for conventional construction materials.

Similar content being viewed by others

Introduction

Brick is one of the oldest construction materials, with a history spanning several millennia. From ancient civilizations to contemporary architecture, bricks have been employed as a versatile and durable building material, with continual advancements in their manufacturing processes and applications. Due to its durable, fire resistance, and aesthetic appeal characteristics, these bricks remain among the most extensively used materials in the construction industry today1. Due to the huge demand of this traditional building material; recent research has focused on developing alternative brick types using industrial waste, particularly in the form of geopolymer bricks2. Since the bricks have long served as one of significantly important construction building materials, the ongoing developments in materials science and construction technologies suggested that the geopolymer bricks could emerge as a viable and widely adopted alternative construction building material. This is largely attributed to the numerous advantages of geopolymer bricks offer over the conventional bricks, including improved environmental sustainability, enhanced mechanical strength, greater energy efficiency, and increased long-term durability3. Considering the utilization of industrial waste materials or by-products, such as fly ash, GGBS and others, geopolymer bricks may offer an environmental sustainable substitute for conventional construction materials by minimizing the depletion of natural resources, which also significantly reduces energy consumption during its production as compared to traditional bricks.

In this context, copper mine tailings have been emerged as a material for brick production. By combining copper mine tailings with varying percentages of Ordinary Portland Cement (OPC), these tailing-based bricks have shown improved compressive strength and reduced water absorption as the OPC content increased4. Further, Roy et al.5 and Liu et al.6 used gold mill tailing and wastewater sludge, respectively, in combination with OPC to make geopolymer bricks, and found it has better performance than the clay bricks. After introducing the geopolymerization concept by Davidovits7several researchers have reported successful geopolymerization of aluminosilicate rich materials, such as fly ash, ground granulated blast furnace slag (GGBS), red mud, iron ore tailing, mine tailing, metakaolin, rice husk ash, glass waste, limestone dust, wood sawdust, welding flux slag, ferrochrome ash, farming waste, ceramic dust waste, oyster shell, cotton waste. These materials have shown their potential as effective binders, offering a significantly lower carbon footprint compared to traditional cement-based binders8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24. The use of GGBS improves the workability of concrete by reducing water demand, permeability and heat of hydration25. Moreover, it was also reported that the geopolymer bricks and concrete requires elevated curing temperatures for the geopolymerization process along with an appropriate concentration of alkali activators. These conditions result in high compressive strength with low water absorption capacity18,21,26,27,28. Thus, it can also be stated that recycling of industrial and agriculture waste into brick production not only enhances materials performance but also contributes to environmental sustainability by reducing the ecological impact of construction materials19,22. For example, copper mine tailing bricks are fabricated using sodium hydroxide (NaOH) solutions with concentration of 10 M and 15 M, under varying water-cement ratios, forming pressures, and curing temperatures ranging from 8 to 18%, 0–35 MPa and 60o−120 °C, respectively. It has been reported that copper mine tailing bricks meet the requirements of ASTM guidelines for brick formation using geopolymerization techniques. Researchers have found that the optimum range of NaOH concentration and curing temperature for achieving the best results is 5–15 M and 23–120 °C, respectively19,24,29,30,31,32,33,34,35,36,37,38,39.

Additionally, a geopolymer brick developed using fly ash or the combinations of fly ash and bottom ash with alkali activator have shown a promising result under varying forming pressure. These bricks were found to meet the criterion of conventional concrete bricks as outlined by Israeli standard39. Diop and Grutzeck40 developed a geopolymer brick using NaOH concentration of 4 M, 8 M and 12 M, and curing temperature of 40 °C, 80 °C and 120 °C. The maximum compressive strength of brick was reported corresponding to 4 M and 8 M NaOH mixes at 40 °C, while the 12 M NaOH mix showed highest strength at 80 °C. Mohsen and Mostafa41 developed kaolin clay based geoploymer bricks using NaOH and Na2SiO3 mixtures as alkali activators. The bricks activated with alkali solution exhibits significantly higher compressive strength than those activated with NaOH alone. It was also noticed that the compressive strength increased from room temperature to 75 °C, but decreased as the curing temperature increase from 75 °C to 150 °C. Ahmad et al.42 designed a fly ash based geoploymer brick with Na2SiO3/NaOH ratio of 2.5 and 12 M NaOH concentration. The mechanical performance of this brick was evaluated under molding pressures of 0, 20, and 40 MPa, curing conditions at both ambient and elevated temperatures, and curing durations of 7 and 28 days. It was reported that under ambient curing with increased molding pressure, the strength improved by more than 180%; however, under elevated curing temperature, the compressive strength increased only by 72% with molding pressure of 20 MPa. A summary of existing literature on the design and performance of geopolymer bricks and geopolymer concrete is presented in Table 1. Although substantial research has been conducted on fly ash-based geopolymer systems43,44,45,46,47,48,49continued investigation is necessary for the advancement of geopolymer bricks ensuring its widespread and reliable application in the construction industry.

Moreover, the geopolymer bricks made from aluminosilicate-rich industrial byproducts like fly ash, GGBS, and mine tailings offer low carbon emission, reduced energy consumption, and enhanced strength compared to traditional clay bricks. Most of the existing studies on geopolymer bricks have primarily focused either on fly ash-based geopolymer brick or the use of individual industrial by-products such as red mud, GGBS, or mine tailings. However, limited research has systematically examined the combined effect of both GGBS and sand content in geopolymer brick formulations. The use of sand and GGBS together changes the microstructure, durability, and strength of geopolymer bricks under a variety of activator and curing conditions. The interaction between sand and calcium-rich GGBS influences the compressive strength, porosity, and water absorption. Therefore, this research aims to investigate the optimal response of mix design, at different amount of GGBS and fly ash content (keeping sand content fixed), on the properties of geopolymer bricks, under varying sodium hydroxide molarity levels, curing temperatures, and curing durations. The tests were performed at different NaOH concentrations (4, 6, 10, and 12 M), curing temperatures (room temperature, 60 °C, 80 °C, and 120 °C), curing periods (7, 14, and 28 days) and GGBS percentages (0, 5, 10, 15 and 20%). These amounts of molarity, curing temperature, and GGBS percentage were chosen to strike a balance in improving the performance of geopolymer bricks, and ensuring its viable and scalable production.

Materials, sample Preparation and testing procedure

Materials

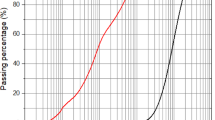

The materials used in this study are fly ash, sand, GGBS and alkali activator (NaOH and Na2SiO3). The fly ash was collected from Kanti thermal power plant, Bihar. Based on the elementary chemical composition in fly ash, shown in Table 2, it is categorised as class F fly ash as per ASTM-C618-2273. Figure 1 presents the particle size of fly ash, which consist of silt (0.002–0.075 mm) and clay (< 0.002 mm) in the order of 78.55% and 21%, respectively, with very minimal quantity of sand (0.45%). GGBS produced at very high temperature (≥ 1500 °C) as a by-product of iron production industries; consisting silica, alumina, and calcium are the major constituents. It contains Si/Al ratio is 2.02 (refer Table 2). The particle size distribution of GGBS, presented in Fig. 1, indicates that GGBS consist of sand, silt and clay in the order of 3.92%, 82.72% and 13.36%, respectively. Based on the particle size gradation both fly ash and GGBS comes in the category of silty-clay or silty-soil particle. The particle size of sand is also presented in Fig. 1, which consist of fine, medium and coarse sand of grade zone-II, as per IS 272074. The specific gravity of sand, fly ash and GGBS was found to be 2.64, 2.11 and 2.82, respectively.

Sodium hydroxide (NaOH) and sodium silicate (Na2SiO3) solution have been used an alkali activator for geopolymerization process7. NaOH is commonly available in solid form as a flake and pellet and, the solution of which is prepared in the laboratory using distilled water. Since the reaction between NaOH and water is exothermic in nature, the solution was kept for 24 h at room temperature to make it cool. Further, Na2SiO3, also known as water glass due to its viscous, transparent, and colourless characteristics, is a key alkaline activator used in the synthesis of geopolymer bricks. It is stable either in alkaline or in neutral solutions, which enhances the workability as well as consistency of geopolymer mixes. Na2SiO3 facilitates polymerization into a three ways, making dense structure of aluminosilicate, increasing compressive strength and creating a robust binding matrix in geopolymer bricks. To prepare the alkaline solution of NaOH and Na2SiO3, the mass ratio of Na2SiO3 to NaOH was kept 2.524,29,32–33,75–76. During mixing of both the solution of NaOH and Na2SiO3, the silicate ions and hydrogen ions mixed in acidic solution and produce a silicic acid, which converts into silica gel, a hard glassy substance, after heating77.

Further, since liquid (i.e., solution) to solid material (L/Sm) ratio plays a critical role in controlling the properties of geopolymers that influences setting time, workability, strength and microstructures, several researchers has studied the effect of L/Sm ratio (ranging from 0.42 to 0.5819,24,29–30,32–36,78−79) on the compressive strength of geopolymer. It was reported that the compressive strength of geopolymer decreases with increasing L/Sm ratio; whereas, initial and final setting time increases with increasing L/Sm ratio. For the present study, the L/Sm ratio was chosen 0.33 to prepare fly ash based geoploymer bricks, since the literature suggest that the L/Sm ratio should lies in between 0.3 and 0.831.

Sample Preparation technique

To prepare the sample of fly ash-based geopolymer bricks, all the raw materials, such as fly ash, GGBS, and sand, were properly mixed with alkali activator. Figure 2 presents all the steps and experimental procedure that has been followed to prepare the geopolymer bricks. A total of 720 geopolymer bricks were prepared to assess its performance at different alkali activator’s molarity levels i.e., 4 M, 6 M, 10 M, and 12 M. The weight of solid materials was taken as 3 times weight of liquid (i.e., solution of water, NaOH and Na2SiO3).

After proper mixing of solid material with solution, poured into the mould of dimensions 205(± 5) ×95(± 5) ×95(± 5) mm, which is slightly higher than the standard size (190 × 90 × 90 mm) of clay brick as per IS 349580. The air present in the wet geopolymer mixture was removed using a vibratory table, and then left in the mold to solidify for 24 h. Subsequently, following the similar step, several specimens have been prepared at different concentration of alkali activator and at different percentage of GGBS, mentioned in Table 3. After dismantling the brick from mold, and then kept for curing at room temperature (RT), 60 °C, 80 °C and 120 °C for 24 h, and then dry weight (air dried weight for RT, whereas; oven dried for other temperatures) of brick is measured. These temperature-cured bricks were further tested at 7, 14 and 28 days of air curing to determine the compressive strength of fly ash-based geopolymer bricks blended with GGBS and sand.

Testing procedure

The compressive strength of fly ash-based geopolymer brick, prepared at varying content of fly ash (i.e., 70, 65, 60, 55, and 50%) and GGBS (i.e., 0, 5, 10, 15, and 20%) with fixed content of sand (i.e., 30%) mentioned in Table 3, was estimated using UCS testing machine (AIM-317E-DG-1-T-C1) of capacity 2000 kN (IS: 12894, 2002)81. Further, to assess durability and resistance to water penetration, water absorption tests were performed to find out the amount of water absorb by geopolymer bricks under submerged condition. Since the excessive water absorption may affect the structural integrity and life of geopolymer bricks, this test is utmost important to check the passiveness and quality of the brick. It can be calculated using Eq. (1) following IS1077:199282; wherein W1 is weight of dry brick at 105 °C in oven and W2 is the weight of wet brick after immersion. The bulk density of the geopolymer brick was estimated using Eq. (2) following IS1077: 13,75783. The value of bulk density and water absorption reported in this study are the average value of three results.

In addition, microscopic/spectroscopic techniques, such SEM, EDS and XRD, were performed to investigate the change in microstructures or in phase concentration to understand the behavioural changes of the geopolymer bricks prepared as well as tested at different conditions such as curing temperature, curing period and alkali activator concentration.

Results and discussion

Impact of geopolymerization, curing temperature and GGBS content on compressive strength

Figure 3 presents the variation of compressive strength of fly ash-GGBS geopolymer bricks at different NaOH concentration, different combination of GGBS, and different curing temperature, obtained on 7 days of curing periods. Figure 3a indicates that the compressive strength of geopolymer increases with increasing molarity of alkali activator i.e., from 6 M to 10 M; however, further increases in molarity, i.e., from 10 M to 12 M, shows strength reduction for all the percentage variations of GGBS. This might be due to the proper dissolution of silica and alumina from fly ash and GGBS, up to 10 M NaOH solution, accelerate the geopolymerization and gel formation thereby makes a dense geopolymer matrix structure resulting enhanced compressive strength. However, further increase of NaOH solution, i.e., at 12 M, the reduction in compressive strength might be due to the overabundance of Na⁺ ions that reduce the formation of aluminosilicate hydrate gel leads to weak microstructural bonding84,85. The compressive strength of geopolymer brick was also found to be increase with increasing amount of GGBS, corresponding to any morality. However, the alkali activator of molarity 10 M can provide the maximum compressive strength of geopolymer bricks irrespective to the addition GGBS. Similar findings have been reported by Kumar et al.59.

Figure 3b presents the variation of compressive strength of geopolymer bricks corresponding to different temperatures Room Temperature (RT), 60 °C, 80 °C and 120 °C. The compressive strength geopolymer brick, corresponding to 80 °C, is significantly higher than that of RT and 60 °C. Further, increase in temperature from 80 °C to 120 °C, the rate of improvement in compressive strength is not so significant, and therefore it can be stated that the strength beyond 80 °C is marginally affected by temperature. Based on the outcome corresponding to 80 °C, it can be stated that curing temperature of 80 °C promotes quick formation of N-A-S-H and C-A-S-H gel by accelerating ion (Na⁺, Al³⁺, and Si⁴⁺) mobility, leading to faster setting and high early strength. EDS analysis also support this since favourable Ca/Si ratio, but SEM demonstrates a compact, cohesive microstructure with few unreacted particles. This enhanced strength at an optimal curing temperature of 80 °C in an indication of balanced kinetics reaction and decreased microcracking. Overall, it can be stated that the higher value of compressive strength of geopolymer bricks can be obtained corresponding to 10 M solution and 80 °C. Similar results were observed corresponding to all variation of GGBS59.

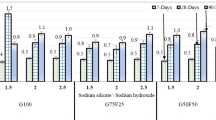

Figure 3c presents the variation of compressive strength of geopolymer bricks corresponding to the different percentage of GGBS observed on 7 days at 80 °C. The results indicate that the compressive strength increases with increasing GGBS and, the maximum value of compressive strength of geopolymer bricks was observed corresponding to 10 M solution. Further, the investigations have been extended for 14 days and 28 days of curing period to understand the impact of curing period on compressive strength of geopolymer. It can be seen from Fig. 4a and b that the curing period, of 14–28 days, does not impact significantly in comparison to percentage GGBS. It can also be seen that the compressive strength of geopolymer increases drastically within 5% of GGBS; however further increase in GGBS from 5 to 20%, the incremental rate of compressive strength is not so significant.

Impact of curing period on compressive strength

Figure 5 present the effect of curing period (i.e. 7, 14, 28 days) on the compressive strength of geopolymer bricks, prepared at 10 M. Figure 5a shows the variation of compressive strength of bricks tested at RT, and it can be noticed that the compressive strength of geopolymer bricks increases with increasing curing period. It can also be seen that the rate of increase in compressive strength is significantly higher corresponding to 5% GGBS at RT. Similar observations was reflected at the temperature of 60 °C, 80 °C and 120 °C shown in Fig. 5b, c and d, respectively. Moreover, the compressive strength of fly ash geopolymer bricks with 0% GGBS was found to be 5.38 MPa at 28 days, which is relatively higher than the minimum acceptable value of compressive strength of clay brick i.e., 3.75 MPa. Further, the compressive strength of geopolymer bricks with 20% GGBS, on 28 days at RT, found to be 17% higher than the maximum compressive strength (i.e., 35 MPa) of clay brick. The compressive strength of geopolymer bricks with 0% GGBS at 60 °C was found to be 6.02, 5.8 and 7.83 MPa corresponding to the curing period of 7, 14 and 28 days, which is also relatively higher than the minimum acceptable value (i.e., 3.75 MPa) of clay bricks.

However, at 80 °C, the compressive strength geopolymer bricks with 0% GGBS was found to be 9.21, 9.29 and 9.43 MPa corresponding to the curing period of 7, 14 and 28 days, which is nearly 2.5 times higher than the minimum acceptable value (i.e., 3.75 MPa) of clay bricks. This might be due to the rate of formation of N-A-S-H and C-S-H gels is faster within 7 days of curing period which is responsible for the early strength of geopolymers. Further increase in curing period i.e., 14 days or 28 days, though the strength has increased but the rate of this increment is relatively lesser than the strength obtained at 7 days. Thus, it can be stated that with prolong curing (i.e., 14 days or 28 days) of geopolymer induce microstructural refinement by breaking down of unreacted fly ash and GGBS, thereby facilitating more gel formation resulting dense matrix of geopolymer with less porosity that signify enhanced structural integrity. Moreover, as the percentage GGBS increased, the compressive strength of geopolymer bricks becomes nearly equal or higher than the maximum strength (i.e., 35 MPa) of conventional clay bricks86. This can be attributed to the fact that, with an increase in GGBS content, the formation of calcium-rich gels (such as C–S–H and C–A–S–H) also increases, which significantly contributes to strength gain and results in a denser, more compact microstructure, thereby enhancing the compressive strength.

Bulk density characteristics

Bulk density of a material reflects how closely the particles are associated. Figure 6 presents the variations of bulk density with increasing percentage of GGBS at different molarity ranging from 4 to 12 M. It can be seen that the bulk density of geopolymer bricks are marginally affected by amount of GGBS. However, the results indicate that the GGBS particles and the concentration of alkali activator contribute to form a denser matrix of materials.

It can also be noticed that the bulk density corresponding to 10 M and 12 M concentration is relatively higher as compared to 4 M and 6 M concentration for the range of 0–5% GGBS. Although, the higher bulk density generally reflects higher porosity; however, in the process of geopolymenrization, the formation of C-S-H, C-A-S-H and N-A-S-H gels in the pores of geopolymer matrix reduces pore volume and fill the voids, thereby creating a denser internal structure which leads to the enhanced compressive strength. It can also be noticed that the bulk density corresponding to 20% GGBS not affected significantly by changing NaOH concentration. Overall, the bulk density of geopolymer bricks was found to be in the range of 1.42 g/cc to 1.88 g/cc, which is similar in the range as reported by Singh et al.51.

Water absorption characteristics

The water absorption phenomenon by brick gives an idea about its durability, surface porosity and the construction performance. The increasing water absorption property of bricks resulting in strength reduction; thereby a potential damage of structures. Therefore, to understand the controlled level of water absorption is quite important for long term durability of geopolymer bricks. Figure 7a indicates that the water absorption of geopolymer brick, at 6 M molarity, increases with increasing GGBS and decreases with increasing temperature from RT to 80 °C; whereas, at 10 M molarity, the water absorption of geopolymer brick was found to be increased with increasing GGBS and curing temperature (i.e., from RT to 120 °C), presented in Fig. 7b. This increase in water absorption is mainly associated with the increase in porosity due to the increase in unreacted part of fly ash and GGBS; the amount of unreacted particle increased (and hence porosity also) with increasing GGBS content at lower molarity (≤ 10 M). Si-Hui et al. (2020)87 have also noticed similar phenomenon while preparing geopolymer bricks. Moreover, at 12 M molarity, the water absorption of geopolymer brick was found to be decreased with increasing GGBS, whereas the same increased marginally with temperature from RT to 120 °C, shown in Fig. 7c. This is mainly due to the enhanced formation of aluminosilicates i.e., C-A-S-H gel at higher concentration (12 M) of alkali activator, which is responsible to make a dense structure of brick with less porosity, thereby reduced water absorption and improved compressive strength of geopolymer88. More importantly, the of geopolymer bricks, prepared at 6 M, 10 M and 12 M, reflect significantly lesser water absorption (as per IS 1077:199282) than the conventional clay brick and OPC-based concrete blocks shown in Table 4.

Figure 7 also infer that with increasing percentage of GGBS, the pore space might be increased due to the shape of fly ash and GGBS resulting in higher water absorption phenomenon. The water absorption of geopolymer bricks was found to be higher at higher temperature (120 °C), corresponding to 10 M and 12 M, also indicating the possibility of increase in pore space. Overall, it can be stated that the water absorption of geopolymer bricks are affected by molarity of alkali activator, which reflecting that there is an increase in C-S-H or C-A-S-H gel that might absorb little more amount of water within range of molarity 4-10 M.

Microstructural analysis of geopolymer brick

Impact of percentage GGBS: SEM and EDS analysis

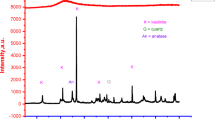

Scanning Electron Microscopy (SEM) is commonly used to investigate the microstructure, phase composition, and geopolymerization to identify the structural bond made by the additive in the geopolymer brick. Figure 8 shows SEM image and EDS spectrum, at 10 M, for different compositions of GGBS in geopolymer bricks. It can be seen that as the percentage GGBS increases, Ca component increases. It can also be seen from Fig. 8(a-e) that with increasing percentage of GGBS, the geopolymer matrix displays a dense as well as compact structure with confined microstructure and less pore space. The formation of dense and homogeneous microstructures improves the mechanical properties of geopolymer bricks51,88. Energy Dispersive Spectroscopy (EDS) spectrum, presented in Fig. 8 (a-e), shows that all mixes contain Calcium (ca.), Silicon (Si), Aluminium (Al) and other elements. This could be due variations in the distribution of GGBS. The presence of elements like Al, Mg and S in EDS indicates the availability of GGBS or Fly ash in geopolymer. By comparing SEM image and EDS, it can also be concluded that high amount of Ca and Si are responsible to form dense microstructure and rich region of C-S-H. Due to rich region of C-S-H, geopolymer brick achieve more strength. The high amount of Ca shown in EDS indicate a region in geopolymer matrix with higher concentration of Ca (OH)2. Moreover, it can be stated that the coupling phenomenon of C-S-H (calcium silicate gel), C-A-S-H (calcium aluminosilicate gel) and N-A-S-H (sodium aluminosilicate gel) during the geopolymerization of Fly ash and GGBS are responsible for the improvement of compressive strength of geopolymer. It can also be seen from Table 5 that the ratio of Ca/Si, Ca/Al and Ca/(Al + Si) increases with increasing amount of GGBS, which also indicates that the strength of fly ash-GGBS based geopolymer majorly imparted by the formation of C-S-H, C-A-H and C-A-S-H gel. Similar observations have also been reported by Ma et al.89.

Based on EDS results, the Ca/Al, Al/Si and Na/(Si + Al) ratio were also estimated to emphasize the gel formation hypothesis, shown in Table 5. It can be seen that the Ca/Al ratio increases (from 0.0374 to 0.635) with increasing amount of GGBS, which might lead to the formation of C-A-H gel causing strength improvement. However, the dataset of Al/Si and Na/(Si + Al) ratio does not reflect any significant trend but the impact of N-A-S-H gel on the strength characteristics cannot be denied due to the hybridization of N-A-S-H and C-A-S-H gel.

Impact of alkali activator concentration: SEM and EDS analysis

Figure 9 presents SEM image and EDS spectrum of 50FA:30 S:20G geopolymer prepared at 6 M and 10 M. The SEM image, at 10 M morality, indicates a more uniform and dispersed structure of geopolymer, which suggest more controlled growth process. The higher concentration might facilitate more even distribution of reactants, leading to more consistent growth across the material. Therefore, the higher molarity geopolymer leads to a higher concentration of precursor molecules, resulting in more nucleation sites during the formation process. This can lead to a more uniform distribution of fly ash or GGBS particles. Moreover, the compressive strength of geopolymer prepared at 10 M was found to be higher than that of 6 M, this is mainly attributed to the improvement in Ca and Si content during geopolymerization (refer Table 5); which resulting in the excess amount of formation of C-S-H and C-A-S-H gel, followed by C-S-H, C-A-S-H and N-A-S-H gel.

Cost analysis

Cost analysis is one of the significant important aspects to evaluate the economic feasibility for the production of geopolymer bricks that will help in identifying the most cost effective raw materials among fly ash, GGBS, sand and additives. Therefore, considering the current market rate of raw materials used in this study, provided in Table 6, are studied to ensure a realistic assessment of production cost under prevailing market conditions.

The estimated cost of geopolymer bricks of dimension 210 mm×100 mm×100 mm are compared with the traditional bricks of size 190 mm×100 mm×100 mm. The cost of fly ash bricks (without GGBS and sand) was found to be 14.92 INR, which is like the cost reported by Singh at al51. However, the cost of geopolymer bricks with 20% GGBS was found to be 22.26 INR. Thus, it can be stated the cost of geopolymer bricks may increase depending on the cost of fly ash, GGBS and alkali activators. However, for present study, due to free availability of industrial byproducts ‘Fly ash and GGBS’, the cost of geopolymer brick is majorly depending on the cost of alkaline solution. The cost of geopolymer brick is relatively higher than the traditional brick, which can be reduced by large-scale production, and thereby utilization of industrial wastes such as fly ash and GGBS will deliver substantial economic and environmental benefits. This includes reduction in production cost through waste valorization, low energy consumption due to ambient curing, and significant reduction in carbon emission. This way of industrial waste valorization promotes a circular economy by reducing landfill waste and hence, minimizing environmental impact. Thus from cost perspective, it can be stated that the Fly ash and GGBS-based geopolymer bricks are not only environment friendly but also economically viable. The low production cost, energy efficiency, and long-term durability make them a significant alternative to the traditional building materials, especially in sustainable and large-scale construction project.

Summary and conclusions

The feasibility of producing fly ash-based geopolymer bricks using waste materials (such as GGBS and fly ash) was systematically evaluated through an analysis of the effects of geopolymerization parameters such as alkali activator concentration, GGBS content, and curing temperature on key properties, such as compressive strength, microstructural characteristics, water absorption, and bulk density. Based on the experimental investigations, the following significantly important conclusions have been drawn.

-

Geopolymer brick specimens activated with 10 M NaOH solution exhibited superior compressive strength relative to those prepared with 4 M, 6 M, and 12 M solutions. The highest compressive strength of 49.63 MPa was achieved with 10 M NaOH, 20% GGBS, and 80 °C curing, confirming optimal conditions for gel formation and densification. However, similar performance in mixes with 15% GGBS or slightly lower molarity indicates a performance range, not a fixed optimum. An increased GGBS content contributed to enhanced structural stability, improved microstructural refinement, and elevated compressive strength. Based on these findings, a 10 M alkali concentration is identified as optimal for geopolymer brick fabrication.

-

Furthermore, compressive strength improved with increasing curing temperature from ambient conditions up to 120 °C, with an optimal curing temperature of 80 °C identified for optimal performance. Measured performance of 80 °C curing is 0.141 MPa per °C, a strength gain of 0.0228 MPa per kJ/kg when normalized by energy intake.

-

Geopolymer bricks cured at 6 M, 10 M, and 12 M molarities demonstrated significantly reduced water absorption compared to conventional clay bricks, indicating improved durability and reduced porosity.

-

The bulk density of geopolymer bricks formulated with 10 M and 12 M concentrations was notably higher than those prepared with 4 M and 6 M solutions, correlating with increased GGBS content and microstructural densification.

Although utilizing industrial wastes, such as fly ash and GGBS, to produce geopolymer bricks offers significant economic and environmental advantages, comprehensive investigations are required to assess their practical applicability. Moreover, challenges related to environmental safety, including toxicity, recycling potential, and long-term durability, must be thoroughly addressed. Additionally, exploring cost-reduction strategies could enhance the economic viability and market acceptance of geopolymer bricks. Preliminary cost assessments indicate that a single geopolymer brick (210 mm × 100 mm × 100 mm) incurs a marginally higher cost compared to a traditional brick of identical dimensions. However, cost efficiencies can be achieved through optimized production techniques and process improvements. Overall, the widespread adoption of geopolymer bricks has the potential to substantially mitigate fly ash accumulation while promoting its valorization as a sustainable building material.

Data availability

The data of this study have already been provided in this manuscript. However, it will also make available from the corresponding author upon reasonable request.

References

Gencel, O. et al. Properties of bricks with waste ferrochromium slag and zeolite. J. Clean. Prod. 59, 111–119. https://doi.org/10.1016/j.jclepro.2013.06.055 (2013).

Das, D., Gołąbiewska, A. & Rout, P. K. Geopolymer bricks: the next generation of construction materials for sustainable environment. Constr. Build. Mater. 445, 137876. https://doi.org/10.1016/j.conbuildmat.2024.137876 (2024).

Shubbar, A. A., Sadique, M., Kot, P. & Atherton, W. Future of clay-based construction materials – A review. Constr. Build. Mater. 210, 172–187. https://doi.org/10.1016/j.conbuildmat.2019.03.206 (2019).

Morchhale, K., Ramakrishnan, N. & Dindorkar, N. Bulk. Utilisation of copper mine tailings in production of bricks. J. Institution Eng. (India) Part. CV Civil Eng. Div. 87, 13–16 (2006).

Roy, S., Adhikari, G. R. & Gupta, R. N. Use of gold mill tailings in making bricks: a feasibility study. Waste Manage. Res. J. Sustainable Circular Econ. 25, 475–482. https://doi.org/10.1177/0734242X07076944 (2007).

Liu, Z. et al. Utilization of the sludge derived from dyestuff-making wastewater coagulation for unfired bricks. Constr. Build. Mater. 25, 1699–1706. https://doi.org/10.1016/j.conbuildmat.2010.10.012 (2010).

Davidovits, J. Geopolymer Chemistry and Applications (Geopolymer Institute, 2008).

Habert, G., Billard, C., Rossi, P., Chen, C. & Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 40, 820–826. https://doi.org/10.1016/j.cemconres.2009.09.031 (2009).

Verma, M. et al. Geopolymer concrete: a material for sustainable development in Indian construction industries. Crystals 12, 514. https://doi.org/10.3390/cryst12040514 (2022).

Luhar, S., Rajamane, N. P., Corbu, O. & Luhar, I. Impact of incorporation of volcanic Ash on geopolymerization of eco-friendly geopolymer composites: A review. IOP Conf. Ser. Mater. Sci. Eng. 572 (012001). https://doi.org/10.1088/1757-899X/572/1/012001 (2019).

Siddika, A., Hajimohammadi, A., Mamun, M., Alyousef, R. & Ferdous, W. Waste glass in cement and geopolymer concretes: A review on durability and challenges. Polymers 13, 2071. https://doi.org/10.3390/polym13132071 (2021).

Manikandan, P. & Vasugi, V. A critical review of waste glass powder as an aluminosilicate source material for sustainable geopolymer concrete production. Silicon 13, 3649–3663. https://doi.org/10.1007/s12633-020-00929-w (2021).

Abdellatief, M., Elrahman, M. A., Abadel, A. A., Wasim, M. & Tahwia, A. Ultra-high performance concrete versus ultra-high performance geopolymer concrete: mechanical performance, microstructure, and ecological assessment. J. Building Eng. 79, 107835. https://doi.org/10.1016/j.jobe.2023.107835 (2023).

Von Bahr, B. et al. Experiences of environmental performance evaluation in the cement industry. Data quality of environmental performance indicators as a limiting factor for benchmarking and rating. J. Clean. Prod. 11, 713–725. https://doi.org/10.1016/S0959-6526(02)00126-9 (2003).

Huntzinger, D. N. & Eatmon, T. D. A life-cycle assessment of Portland cement manufacturing: comparing the traditional process with alternative technologies. J. Clean. Prod. 17, 668–675. https://doi.org/10.1016/j.jclepro.2008.04.007 (2008).

Amin, S. K., El–Sherbiny, S. A., El–Magd, A. A. M. A., Belal, A. & Abadir, M. F. Fabrication of geopolymer bricks using ceramic dust waste. Constr. Build. Mater. 157, 610–620. https://doi.org/10.1016/j.conbuildmat.2017.09.052 (2017).

El-Naggar, K. A. M., Amin, S. K., El-Sherbiny, S. A. & Abadir, M. F. Preparation of geopolymer insulating bricks from waste Raw materials. Constr. Build. Mater. 222, 699–705. https://doi.org/10.1016/j.conbuildmat.2019.06.182 (2019).

Ferone, C., Colangelo, F., Cioffi, R., Montagnaro, F. & Santoro, L. Mechanical performances of weathered coal fly Ash based geopolymer bricks. Procedia Eng. 21, 745–752. https://doi.org/10.1016/j.proeng.2011.11.2073 (2011).

Ahmari, S. & Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 29, 323–331. https://doi.org/10.1016/j.conbuildmat.2011.10.048 (2011).

Ahmari, S. & Zhang, L. Durability and leaching behavior of mine tailings-based geopolymer bricks. Constr. Build. Mater. 44, 743–750. https://doi.org/10.1016/j.conbuildmat.2013.03.075 (2013).

Kumar, P., Pratap, B., Sharma, S. & Kumar, I. Compressive strength prediction of fly Ash and blast furnace slag-based geopolymer concrete using convolutional neural network. Asian J. Civil Eng. 25, 1561–1569. https://doi.org/10.1007/s42107-023-00861-5 (2023).

Pratap, B., Kumari, P., Rao, B. H. & Mondal, S. Mechanical and durability performance of fly Ash on bauxite residue and ground granulated blast slag based geopolymer composite. Iran. J. Sci. Technol. Trans. Civil Eng. 48, 3213–3229. https://doi.org/10.1007/s40996-024-01425-6 (2024).

Turgut, P. & Algin, H. M. Limestone dust and wood sawdust as brick material. Build. Environ. 42, 3399–3403. https://doi.org/10.1016/j.buildenv.2006.08.012 (2006).

Venugopal, K., Radhakrishna, N. & Sasalatti, V. Development of alkali activated geopolymer masonry blocks. IOP Conf. Ser. Mater. Sci. Eng. 149, 012072. https://doi.org/10.1088/1757-899x/149/1/012072 (2016).

Amran, Y. H. M., Alyousef, R., Alabduljabbar, H. & El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 251, 119679. https://doi.org/10.1016/j.jclepro.2019.119679 (2019).

Jamil, N. H. et al. Influences of SiO2, Al2O3, CaO and MgO in phase transformation of sintered kaolin-ground granulated blast furnace slag geopolymer. J. Mater. Res. Technol. 9, 14922–14932. https://doi.org/10.1016/j.jmrt.2020.10.045 (2020).

Luhar, I. & Luhar, S. A comprehensive review on fly Ash-Based geopolymer. J. Compos. Sci. 6, 219. https://doi.org/10.3390/jcs6080219 (2022).

Silva, G. et al. Analysis of the production conditions of geopolymer matrices from natural Pozzolana and fired clay brick wastes. Constr. Build. Mater. 215, 633–643. https://doi.org/10.1016/j.conbuildmat.2019.04.247 (2019).

Apithanyasai, S., Nooaek, P. & Supakata, N. The utilization of concrete residue with electric Arc furnace slag in the production of geopolymer bricks. Eng. J. 22, 1–14. https://doi.org/10.4186/ej.2018.22.1.1 (2018).

Ahmari, S. & Zhang, L. Utilization of cement kiln dust (CKD) to enhance mine tailings-based geopolymer bricks. Constr. Build. Mater. 40, 1002–1011. https://doi.org/10.1016/j.conbuildmat.2012.11.069 (2012).

Sukmak, P., Horpibulsuk, S. & Shen, S. L. Strength development in clay–fly Ash geopolymer. Constr. Build. Mater. 40, 566–574. https://doi.org/10.1016/j.conbuildmat.2012.11.015 (2012).

Abdullah, M. M. A., Ibrahim, W. M. W. & Tahir, M. F. M. in Elsevier eBooks 273–287 (2015). https://doi.org/10.1016/b978-1-78242-305-8.00012-7. https://doi:10.1016/B978-1-78242-305-8.00012-7.

Zawrah, M. F., Gado, R. A., Feltin, N., Ducourtieux, S. & Devoille, L. Recycling and utilization assessment of waste fired clay bricks (Grog) with granulated blast-furnace slag for geopolymer production. Process Saf. Environ. Prot. 103, 237–251. https://doi.org/10.1016/j.psep.2016.08.001 (2016).

Guo, X., Shi, H., Chen, L. & Dick, W. A. Alkali-activated complex binders from class C fly Ash and Ca-containing admixtures. J. Hazard. Mater. 173, 480–486. https://doi.org/10.1016/j.jhazmat.2009.08.110 (2009).

Chen, C., Li, Q., Shen, L. & Zhai, J. Feasibility of manufacturing geopolymer bricks using Circulating fluidized bed combustion bottom Ash. Environ. Technol. 33, 1313–1321. https://doi.org/10.1080/09593330.2011.626797 (2011).

Kumar, A. & Kumar, S. Development of paving blocks from synergistic use of red mud and fly Ash using geopolymerization. Constr. Build. Mater. 38, 865–871. https://doi.org/10.1016/j.conbuildmat.2012.09.013 (2012).

Xie, J., Wang, J., Rao, R., Wang, C. & Fang, C. Effects of combined usage of GGBS and fly Ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. B Eng. 164, 179–190. https://doi.org/10.1016/j.compositesb.2018.11.067 (2018).

Yaseri, S., Verki, V. M. & Mahdikhani, M. Utilization of high volume cement kiln dust and rice husk Ash in the production of sustainable geopolymer. J. Clean. Prod. 230, 592–602. https://doi.org/10.1016/j.jclepro.2019.05 (2019).

Freidin, C. Cementless pressed blocks from waste products of coal-firing power station. Constr. Build. Mater. 21, 12–18. https://doi.org/10.1016/j.conbuildmat.2005.08.002 (2005).

Diop, M. B. & Grutzeck, M. W. Low temperature process to create brick. Constr. Build. Mater. 22, 1114–1121. https://doi.org/10.1016/j.conbuildmat.2007.03.004 (2007).

Mohsen, Q. & Nasser Yosef Mostafa. Investigating the possibility of utilising low kaolinitic clays in production of geopolymer bricks. Ceram.-Silik. 54 (2), 160–168 (2010).

Ahmad, M. et al. Physico-mechanical performance of fly Ash based geopolymer brick: influence of pressure – temperature – time. J. Building Eng. 50, 104161. https://doi.org/10.1016/j.jobe.2022.104161 (2022).

Nath, P. & Sarker, P. K. Effect of GGBFS on setting, workability and early strength properties of fly Ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 66, 163–171. https://doi.org/10.1016/j.conbuildmat.2014.05.080 (2014).

Singh, B., Rahman, Paswan, R. & Bhattacharyya, S. K. Effect of activator concentration on the strength, ITZ and drying shrinkage of fly ash/slag geopolymer concrete. Constr. Build. Mater. 118, 171–179. https://doi.org/10.1016/j.conbuildmat.2016.05.008 (2016).

Saha, S. & Rajasekaran, C. Enhancement of the properties of fly Ash based geopolymer paste by incorporating ground granulated blast furnace slag. Constr. Build. Mater. 146, 615–620. https://doi.org/10.1016/j.conbuildmat.2017.04.139 (2017).

Rafeet, A., Vinai, R., Soutsos, M. & Sha, W. Guidelines for mix proportioning of fly ash/ggbs based alkali activated concretes. Constr. Build. Mater. 147, 130–142. https://doi.org/10.1016/j.conbuildmat.2017.04.036 (2017).

Islam, A., Alengaram, U. J., Jumaat, M. Z., Bashar, I. I. & Kabir, S. M. A. Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete. Constr. Build. Mater. 101, 503–521. https://doi.org/10.1016/j.conbuildmat.2015.10.026 (2015).

Phoo-Ngernkham, T., Maegawa, A., Mishima, N., Hatanaka, S. & Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 91, 1–8. https://doi.org/10.1016/j.conbuildmat.2015.05.001 (2015).

Lee, N. K. & Lee, H. K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 47, 1201–1209. https://doi.org/10.1016/j.conbuildmat.2013.05.107 (2013).

Yadav, U. S. & Jha, A. K. Enhancing mechanical characteristics of fly Ash and fly Ash–Stone dust using geopolymerization technique. J. Hazard. Toxic Radioact. Waste. 29 https://doi.org/10.1061/jhtrbp.hzeng-1416 (2025).

Singh, S. B., Maiti, P. R. & Mohanty, S. Development of filler-free and ambient-cured fly Ash based geopolymer brick utilizing low molar concentration of activating solution. Case Stud. Constr. Mater. e04032 https://doi.org/10.1016/j.cscm.2024.e04032 (2024).

Sowmyashree, T., Muralidhara, S., Sharif, A. & Mohammed, V. Lecture Notes Civil Eng. 451–461 doi:https://doi.org/10.1007/978-981-99-2552-0_36 (2023).

Pawar, A. S. et al. Experimental study on assessment of fly Ash and GGBS based Geo-polymer mortar with brick waste as replacement to fine aggregates. IJRPR 3 (Issue 6), pp102–107 (2022).

Shewale, P. et al. Experimental study on assessment of fly Ash and GGBS based geopolymer mortar with brick waste replacement to fine aggregates. Int Res. J. Eng. Technol : 1392–1398. (2022).

Tarek, D. et al. Building envelope optimization using geopolymer bricks to improve the energy efficiency of residential buildings in hot arid regions. Case Stud. Constr. Mater. 17, e01657. https://doi.org/10.1016/j.cscm.2022.e01657 (2022).

Ahmed, M. M. et al. Fabrication of thermal insulation geopolymer bricks using ferrosilicon slag and alumina waste. Case Stud. Constr. Mater. 15, e00737. https://doi.org/10.1016/j.cscm.2021.e00737 (2021).

Madani, H., Ramezanianpour, A. A., Shahbazinia, M. & Ahmadi, E. Geopolymer bricks made from less active waste materials. Constr. Build. Mater. 247, 118441. https://doi.org/10.1016/j.conbuildmat.2020.118441 (2020).

Lavanya, B., Kuriya, P. D., Suganesh, S., Indrajith, R. & Chokkalingam, R. B. Properties of geopolymer bricks made with flyash and GGBS. IOP Conf. Ser. Mater. Sci. Eng. 872, 012141. https://doi.org/10.1088/1757-899x/872/1/012141 (2020).

Kumar, R., Das, P., Beulah, M. & Arjun, H. R. in IntechOpen eBooks (2020). https://doi.org/10.5772/intechopen.81748

Ganesh, A. C., Muthukannan, M., Aakassh, S., Prasad, N. & Subramanaian, B. Energy efficient production of geopolymer bricks using industrial waste. IOP Conference Series Materials Science and Engineering 872, 012154 (2020). https://doi.org/10.1088/1757-899x/872/1/012154

Youssef, N., Lafhaj, Z. & Chapiseau, C. Economic analysis of geopolymer brick manufacturing: a French case study. Sustainability 12, 7403. https://doi.org/10.3390/su12187403 (2020).

Balakrishnan, N., Usha, S. & Thomas, P. K. Lecture Notes Civil Eng. 279–290 doi:https://doi.org/10.1007/978-3-030-26365-2_27 (2019).

Youssef, N. et al. Reuse of waste bricks: a new generation of geopolymer bricks. SN Appl. Sci. 1 https://doi.org/10.1007/s42452-019-1209-6 (2019).

Pavithra, N., Divya, G., Suganthi, M. & Omprakash, S. Experimental study on the behaviour of geopolymer bricks. Int. J. Civil Eng. Technol. (IJCIET). 9 (2), 87–95 (2018).

Waghmareonkar, D. & Hake, S. L. Evaluate properties of fly Ash based geopolymer bricks. IRJET 5 (6), 1–9 (2018).

Kejkar, R. B., Wanjari, S. P., Sharma, D. & Rajankar, R. Experiment investigation and physical performance of geopolymer fly Ash bricks. IOP Conf. Ser. Mater. Sci. Eng. 431, 092005. https://doi.org/10.1088/1757-899x/431/9/092005 (2018).

Banupriya, C., John, S., Suresh, R., Divya, E. & Vinitha, D. Experimental investigations on geopolymer bricks/paver blocks. Indian J. Sci. Technol. 9 https://doi.org/10.17485/ijst/2016/v9i16/92209 (2016).

Subramani, T. & Sakthivel, P. Experimental investigation on flyash based geopolymer bricks. METHODOLOGY 5, 5 (2016).

Hwang, C. L. & Huynh, T. P. Evaluation of the performance and microstructure of ecofriendly construction bricks made with fly Ash and residual rice husk Ash. Adv. Mater. Sci. Eng. 2015, 1–11. https://doi.org/10.1155/2015/891412 (2015).

Faheem, M. T. M. et al. Application of clay - based geopolymer in brick production: a review. Adv. Mater. Res. 626, 878–882 (2012). https://doi.org/10.4028/www.scientific.net/amr.626.878

Mastura, W. I. W., Kamarudin, H., Nizar, I. K., Abdullah, M. M. A. B. & Mohammed, H. The effect of curing time on the properties of fly Ash-Based geopolymer bricks. Adv. Mater. Res. 626, 937–941. https://doi.org/10.4028/www.scientific.net/amr.626.937 (2012).

Sahu, A., Kumar, S., Srivastav, A. & Anurag, H. Experimental investigation on the performance of ground granulated blast furnace slag and copper slag blended recycled aggregate concrete exposed to elevated temperatures. J. Building Eng. 112531 https://doi.org/10.1016/j.jobe.2025.112531 (2025). Apr. 2025, doi: 10.1016/j.jobe.2025.112531.

American Society for Testing and Materials. Committee C-9 on Concrete and Concrete Aggregates. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete (ASTM international, 2008).

Indian Standard 2720-4:1985. Methods of test for soils, Part 4: Grain size analysis. Bureau of Indian Standard (BIS) New Delhi, India.Reaffirmed (2006).

Naggar, K. M. E. et al. Performance of geopolymer insulation bricks synthesized from industrial waste. Minerals 14, 977. https://doi.org/10.3390/min14100977 (2024).

Deraman, L. M., Abdullah, M. M. A., Ming, L. Y., Ibrahim, W. M. W. & Tahir, M. F. M. Mechanical properties on geopolymer brick: A review. AIP Conf. Proc. https://doi.org/10.1063/1.5002235 (2017).

Matinfar, M. & Nychka, J. A. A review of sodium silicate solutions: structure, gelation, and syneresis. Adv. Colloid Interface Sci. 322, 103036. https://doi.org/10.1016/j.cis.2023.103036 (2023).

Puertas, F., Palacios, M. & Vázquez, T. Carbonation process of alkali-activated slag mortars. J. Mater. Sci. 41, 3071–3082. https://doi.org/10.1007/s10853-005-1821-2 (2005).

Chen, C. et al. Mechanical activation of coal gasification slag for one-part geopolymer synthesis by alkali fusion and component additive method. Constr. Build. Mater. 411, 134585. https://doi.org/10.1016/j.conbuildmat.2023.134585 (2023).

Indian Standard 3495. Method of Tests of Burnt Clay Building Bricks (Bureau of Indian Standard (BIS) New Delhi, 1992).

Indian Standard 12894. Pulverized Fuel ash-lime Bricks Specification (Bureau of Indian Standard (BIS) New Delhi, 2002).

Indian Standard 1077. (Reaffirmed 2008) Common burnt clay building bricks-Specifications. Bureau of Indian Standard (BIS) New Delhi, India. (1993).

Indian Standard 13757. (Reaffirmed 2007) Burnt clay fly ash building bricks-Specification. Bureau of Indian Standard (BIS) New Delhi, India. (1992).

Hardjito, D., Wallah, S. E., Sumajouw, D. M. & Rangan, B. V. Fly ash-based geopolymer concrete. Australian J. Struct. Eng. 6 (1), 77–86 (2005).

Temuujin, J., Minjigmaa, A., Lee, M., Chen-Tan, N. & Van Riessen, A. Characterisation of class F fly Ash geopolymer pastes immersed in acid and alkaline solutions. Cem. Concr. Compos. 33, 1086–1091. https://doi.org/10.1016/j.cemconcomp.2011.08.008 (2011).

Gencel, O. et al. Manufacturing of fired bricks derived from wastes: utilization of water treatment sludge and concrete demolition waste. 30th conference on our world in concrete & structures. Vol. 24.. (2005).

Si-Huy, N., Thanh-Tam, L. T. & Trong-Phuoc, H. Effects of NAOH concentrations on properties of the thermal power plant Ashes-Bricks by alkaline activation. J. Wuhan Univ. Technology-Mater Sci. Ed. 35, 131–139. https://doi.org/10.1007/s11595-020-2236-2 (2020).

Shilar, F. A., Ganachari, S. V., Patil, V. B., Khan, T. M. Y. & Khadar, S. D. A. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case Stud. Constr. Mater. 16, e01014. https://doi.org/10.1016/j.cscm.2022.e01014 (2022).

Ma, C. K., Awang, A. Z. & Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 186, 90–102. https://doi.org/10.1016/j.conbuildmat.2018.07.111 (2018).

Acknowledgements

Authors are very thankful to the Department of Civil Engineering of both the institutes, Motihari College of engineering Motihari, Bihar and National Institute of Technology Patna, Bihar, for providing the facilities to conduct the experiments during this study.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

GAA: Conceptualization, Methodology, Lab work, Formal analysis, Writing-original draft preparation; SSK: Conceptualization, Methodology, Formal analysis, Writing-Review and editing, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ansari, G.A., Kumar, S.S. Geopolymerization of fly ash and GGBS for sustainable industrial waste utilization. Sci Rep 15, 34318 (2025). https://doi.org/10.1038/s41598-025-16574-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16574-5

Keywords

This article is cited by

-

Efficiency of Palm Oil Fuel Ash, Sugarcane Bagasse Ash and GGBS-Based Alkali Activated Binders in the Stabilisation of Expansive Soil

Indian Geotechnical Journal (2025)