Abstract

The correct selection of material with adequate characteristics for bearing races has been troublesome owing to the wide availability of materials with different sets of characteristics. In the same context, the present work deals with selection of the best composite formulation using multi-criteria decision making (MCDM) method among the set of prepared composite alternatives. The preference selection index (PSI) method was utilized in ranking alternatives under uncertain (fuzzy) environment. Four hybrid Zinc alloy (ZA-27) nanocomposite reinforced with varying wt% of micro SiC and nano TiO2 were fabricated using stir casting technique, and different performance characteristics are examined to select the best composite formulation for bearing races. The rationale for selecting this combination of materials stems from the enhanced hardness and thermal resistance provided by micro SiC particles, while TiO2 contributes to improved wear resistance and reduced friction, critical for enhancing the performance and longevity required in bearing application. The results demonstrate significant improvements in the mechanical and tribological properties of the composites, with A-1 composite sees 107% increase in tensile strength, a 78% increase in hardness, and 24% enhancement in wear resistance compared to the unreinforced ZA-27 alloy. Finally, it was concluded that A-1 (having 2.5 wt% SiC and 2.5 wt% TiO2 as reinforcement) composite formulation comes out as the best alternative among available options, which was validated by fuzzy TOPSIS and fuzzy VIKOR approaches, for the bearing races application.

Similar content being viewed by others

Introduction

In the design and development of any specific bearing (roller, cylindrical etc.), bearing races are an integral and one of the important elements guiding the balls to ride and support. A significant amount of care and effort is needed in the design of bearings when selecting appropriate ball and bearing race material. Improper material selection of bearing races can result in an increase in rolling contact stress, damping capacity reduction, can shorten the fatigue life or can result in failure or fracture of components during functioning1. Selecting the optimal material for bearing races (inner and outer) can reduce the wear and risk of component failure can be reduced. Furthermore, the increase in rolling contact stress is mainly attributed to the material property of the components interfacing the rollers. Considering the aforementioned issue in bearing races, selection of suitable or best material for bearing race part seems to play a significant role in decreasing the wear and enhancing the fatigue life of bearings. Earlier, commercial brass bronze was utilized for bearing races which are now replaced by zinc alloys (ZA) as the leading material and are becoming progressively significant. These materials have several important properties like high temperature stability, wear resistance and improved fatigue strength, high tensile strength etc., which make them a promising solution for bearing race application. Moreover, hard filler particles addition to matrix material is one of the key solutions for enhancing the aforementioned characteristics appropriate for use in automobile and aerospace applications2. However, material selection for this component has been surrounded by several constraints. The design personnel and engineers must deal with large number of criteria depending upon the type of application. In addition, there are many important properties that need to be taken care of while selecting reinforcement materials like shape, size, orientation, morphology, and synergy between the filler and base matrix. Moreover, the use of hybrid metal alloy composites is widely accepted having distinct fillers shape and size, which significantly enhances the performance mandatory for any specific application that may not be possible in case of monolithic composites.

Shastry et al. studied metal alloy composite taking ZA 27 as matrix reinforced with alumina of size varying from 50 to 90 μm. The results suggested that damping capacity and dynamic modulus are increased as percentage of reinforcement increases3. ZA composite reinforced with 80 μm size TiO2 filler particles were prepared by Patnaik et al., showing an uptrend in wear resistance characteristics with addition of TiO2 filler. The results showed that 8wt. % TiO2 reinforced ZA composite have maximum wear resistance performance among all prepared formulations4. Similarly, stir-casted hybrid ZA composite was prepared by reinforcing different wt% of rice husk ash (RHA), silicon carbide and graphite with particles size in micro ranges. The study recommended finally that fracture toughness increased on increasing RHA content but at the expense of minimizing ultimate tensile strength and hardness5. Further, the ZA hybrid composite considering TiBr micro particles and BN nano particles were prepared and sliding wear tests show that sliding wear resistance enhances with more refinement in the microstructure of the composite6. Rajmohan showed an enhancement in physico-mechanical characteristics of stir cast hybrid ZA composite with micro SiC and nano CuO fillers with decrease in surface roughness of the prepared composite formulations7. Till date, the researchers have reinforced ZA-27 alloy with alumina, SiC, TiB2, TiBr, quartz particulate, ZrO2 and fly-ash (with the particle size in between 0 and 10 wt.-%) with wide application in automotive and space applications8,9,10. In addition, the other reinforcements such as BN11, Gr12, WC13,14 were also beneficial in enhancing the physio-mechanical and tribological characteristics of hybrid composites.

The current study focusses on examining the addition of hybrid reinforcement of silicon carbide (SiC) and titanium dioxide (TiO2) by different weight% to the ZA 27 alloy by measuring their properties like void contents, micro-hardness, ultimate tensile strength, flexural strength, and impact strength for bearing races. It is worth clarifying that TiO2 contributes to enhanced tribological properties, such as reduced friction and increased wear resistance. Also, the SiC’s particles’ hardness and thermal stability further strengthen characteristics required for bearing races application as demonstrated by Yadav et al.15. Together, TiO2 and SiC offer a combination of advantages that individual materials may not provide, making them ideal for use in automotive application where durability and performance are critical16,17. Since each fabricated composite has its own properties depending on the requirement of each individual criterion, it mandates to choose optimal composite formulation which significantly fulfils the need of specific application. Similarly, Keiser et al.18 have selected bearing material considering wear resistance as important criteria for its utilization in molten chloride salt. Gangwar and Pathak19 in their study considered physio-mechanical and wear characteristics for appropriate selection of bearing materials exercising fuzzy VIKOR methodology. They revealed that higher interfacial bonding between marble dust-reinforced particles and base alloy matrix improves the wear resistance and other mechanical properties of the developed bearing material, which is critical in bearing application. Conventionally, several experiments or users’ experiences were utilized for correct selection of material or replacement of existing ones with superior performance. Nevertheless, to prevent the wrong selection of adequate material, the use of multi-criteria decision making (MCDM) methods were highly suggested20. MCDM methods help in examining, sorting, and ranking of available alternatives on the basis of individual criterion effective for specified application and removes inefficient alternatives21. Thus, thorough understanding of some MCDM techniques is required to enhance the decision capability among material scientists for selection of correct material based on different material properties.

In the same context, the use of MCDM techniques in material selection were major research goals among researchers working in different engineering domains. Over the last decade, researchers proposed graph theory and matrix approach, TOPSIS method, grey relation analysis (GRA) and ELECTRE approach as MCDM methods for material selection in contrasting environment and thermal conductor applications22,23,24,25. Likewise, a novel VIKOR technique was proposed for evaluating optimal alternative having improved performance and characteristics required in knee replacement for bio-medical application26. Gangwar et al. applied a novel AHP based MOORA approach for optimizing and selecting best nano-hydroxyapatite reinforced dental composites alternative considering different physico-mechanical and thermal characteristics27. Singh et al. adopted hybrid entropy-ELECTRE II method for exploring different natural fibers-based composites as an alternative for braking application considering tribological properties and provides final ranking of prepared composite for maximum benefits28. Maniya and Bhatt introduced preference selection index (PSI) for optimal material selection considering conflicting criteria among a set of available options without assigning relative weights among considered criteria29. Few works applied analytic hierarchy process (AHP) technique for enhancing the capability of material selection automobile body parts30,31. The material selection for bumper beams development was performed using AHP and PROMETHEE technique under fuzzy environment32. Similarly, the method of extended TOPSIS was employed under fuzzy environment for choosing optimal material in additive manufacturing application33. Recently, a unified PROMETHEE under fuzzy system was offered for selecting best material in application of automotive panel34. For enhanced understanding and exploration of key advantages, weaknesses and differences of these MCDM methods, researchers can refer to35,36,37.

Based on past research, it is evident that very few works have been performed to utilize preference selection index techniques under fuzzy environment in choosing optimal ZA-27 hybrid composite formulations. The proposed technique of fuzzy PSI is logical and user-friendly in optimal zinc alloy hybrid composite formulation selection. In addition, unlike previous studies, which often focus on individual reinforcement effects or deterministic decision-making approaches, our work uniquely developed the ZA-27/SiC/TiO2 hybrid nanocomposite and evaluation in terms physical, mechanical and tribological characterization, which is not available in literature. The results of the proposed technique will certainly enhance productivity and aid in minimizing cost without providing relative weights to any individual criteria. In the same context, the present work focused on preparing a series of composite formulations with different wt% of micro powders of silicon carbide (SiC) and nano powder of titanium dioxide (TiO2). Different important characteristics of these formulations were measured, and ranking performed using proposed PSI methodology under fuzzy environment. Finally, sensitivity analysis was also performed to validate the adequacy of results.

Material and methods

Synthesis of bearing races material

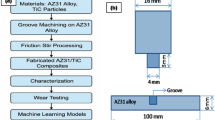

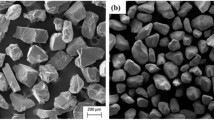

This study utilized ZA 27 zinc alloy (see Table 1) as base matrix in ingot form for samples preparation utilizing varying weight% of SiC particles (micro) and TiO2 particles (nano) as filler, with size of 60 μm and 40–60 nm, respectively. The weight% (0, 2.5, 5 and 7.5) of micro SiC and nano TiO2 reinforced zinc (ZA 27) alloy hybrid composite (A0, A1, A2 and A3) are prepared employing stir casting technique as shown in Fig. 1. In stir casting the matrix material is poured in preheated graphite crucible and leads to heated about 30–40 °C temperature above its melting point. Vacuum environment was used to avoid any oxidation of molten metal with environment. Reinforcements were added and stirred with stirrer which attached with motor, rotated at 800 rpm for 30–40 s. after homogeneous mixing molten metal was poured into mould (190 × 40 × 10 mm3). The nano TiO2 powder shows good strength and an exceptionally high hardness of 9339 kg/ mm2 as well as toughness making it a suitable candidate for reinforcement. In addition, it possesses low density of 3.87 g/cc which shows better wettability and wear properties when mixed with ZA 27 alloy.

Different samples of alloy composite were prepared using stir casting technique. For which the filler materials and base alloy were weighted, and magnesium particles were added for enhancing wettability and bonding between base matrix and filler material. The ZA-27 alloy particles were poured in preheated graphite crucible and heated till its molten state is realized. As the molten state is attained, the two filler materials were added based on weighed quantity. The motor driven stirrer made of mild steel utilized for stirring the molten mixture thoroughly. During composite samples synthesis adequate attention was given to avoid sedimentation of reinforcement in liquid metal. Post adequate blending of base alloy and filler material, the prepared mixture was carefully poured into aluminium mould of required dimension. The different composite formulation was taken out from aluminium mould and permitted for cooling in atmospheric condition. The prepared samples designation with composition details are provided in Table 2.

For hybrid nanocomposite, as shown in Fig. 2 (a), the EDS results showed that the percentage of aluminium and oxygen is higher than zinc but in ZA 27 alloy the major constituent is zinc. From this it could be concluded that macrosegregation may had occurred in pure ZA 27 alloy. Moreover, from Fig. 2 (b-d) showed satisfactory percentage of elements which was required as per composition. From this it can be attributed that nano TiO2 particles and micro SiC particles have sufficiently good bond with matrix.

The Archimedean principle39 was utilized for determining the density determination of the fabricated composite while the void fraction is evaluated using below Eq. (1),

where \(\:{\rho\:}_{t}\), \(\:{\rho\:}_{e}\) are theoretical and experimental density of the manufactured samples.

The Vicker hardness tester of FH-10 series was employed for determining micro-hardness based on ASTM E92-16. For better visualization and examination of indentation in sample, a USB based camera, or microscope was used with 10X magnification for better details. The hardness values measured were an average of 10 readings for each composite formulation. Similarly, the tensile tests on different composite samples were performed according to carried out as per ASTM standard E8 on Instron 3369 UTM. The dimensions of tensile test samples are 12.4 mm gauge length, 3 mm width and 2.8 mm thickness and were according to ASTM standard E8 for metal matrix composite. Similarly, flexural test was performed as per ASTM-E290 and 3 point bending test were performed considering span of 45 mm. For determining impact strength, Charpy test for specimens was used and sample was prepared according to ASTM E23. All the properties were taken as an average of 10 readings for each sample.

Determination of tribological properties

The specific wear rate was evaluated as per ASTM G99 standards using DUCOM TR281-M wear analyzer standards at room temperature40. The specific wear rate was calculated by the following Eqs. (2),

where \(\:{W}_{s}\) is the specific wear rate in µm3/N.µm, \(\:\rho\:\) is the density of sample, \(\:{F}_{c}\) is the normal contact load, \(\:M\) is the mass loss, \(\:V\) is the sliding velocity, and \(\:T\) is the test duration. The wear volume was assessed by scanning stylus profilometry. For coefficient of friction measurement, a fretting wear analyser DUCOM TR281-M was used on which the flat sample was made to oscillate with linear movement at constant frequency and amplitude with the help of stepper motor. The movement of sample was monitored by LVDT, and frictional force was measured by piezoelectric transducer. Change in tangential force was recorded and subsequently coefficient of friction was determined with the help of computer system. The outline of proposed techniques and workflow is shown in Fig. 3.

The fuzzy preference selection index (PSI) methodology

This section presents a description on fuzzy Preference selection index (PSI) which was recently created for finding solutions to non-trivial multi-variate problems. The PSI method is easy to comprehend and free from assigning weights to attributes. The application of PSI approach is evident in literature that is applicable in volatile and non-trivial problem solving. The real-life application involves uncertainty and incomplete data which becomes challenging for a decision maker to assign a specific rating to an alternative. To this end, fuzzy set were integrated with PSI that provides values in between 0 and 1 with varying membership rates. The fuzzy logic concept is comparable with human reasoning and applicable for prediction where incomplete information exists. In addition, fuzzy theory provides better evaluations and superiority in transforming linguistic variables into fuzzy values. In current work, a robust approach is implemented combining PSI under fuzzy environment for improvement in decision making process.

Generally, fuzzy membership functions are employed in different applications under an uncertain environment41. However, the triangular membership function is utilized more than trapezoidal functions owing to higher ease in calculation. Additionally, for subjective and imprecise information, the triangular fuzzy set proves to be an effective way of formulating decision-making problems42.

Consequently, PSI methodology under fuzzy environment employed for realizing improved solution in material selection and used for precise ranking of available alternatives. The steps of fuzzy PSI methodology are described below in detail.

Step 1: Initially, the materials are sorted considering relevant attributes agreement.

Step 2: Formulation of MCDM problem in matrix format.

Step 3: Linguistic terms and corresponding fuzzy number for each criterion and material are defined and tabulated as shown in Tables 3 and 4.

Step 4: The fuzzy value for attributes and corresponding weight are defined for individual decision makers.

Step 5: The aggregated fuzzy ratings \(\:{F}_{ijk}\) is evaluated with respect to each individual criterion \(\:{C}_{j}\) and can be expressed as Eqs. (3),

The aggregated fuzzy weight of each criterion can be calculated as Eqs. (4),

Step 6: The Center of area (COA) technique utilized for determination of best non-fuzzy performance value (BNP) using below Eqs. (5),

Step 7: Formulation of normalized decision matrix.

Step 8: Formulation of weighted normalized decision matrix by multiplying individual element of the normalized decision matrix with \(\:{U}_{jk}\) obtained in Step 5.

Step 9: Determination of overall preference value \(\:{P}_{j}\) and preference variation value (\(\:{V}_{j}\)) using the following Eq. (6) and Eqs. (7),

where \(\:{\varOmega\:}_{j}=(1-{V}_{j})\) in the above equation and \(\:{R}_{j}=\frac{1}{n}\sum\:{R}_{ij}\).

Step 10: The preference selection index value (\(\:{\omega\:}_{i}\)) for every alternative has been calculated by using Eq. (8), as given below.

Step 11: Lastly, the composite formulations are sorted as per PSI index values and ranked accordingly.

Results and discussions

Criterion evaluation

Different physico-mechanical and tribological testing of ZA-27 hybrid nanocomposites were executed and treated as individual criteria. The properties include density (C1), void fraction (C2), hardness (C3), tensile strength (C4), flexural strength (C5), impact strength (C6), coefficient of friction (C7), wear rate (C8) and wear volume (C9). The rule of mixture is employed for calculating density, while Archimedes’ principle determined the void fraction % for different composites. Table 5 shows the effect of hybrid filler concentration on the void fraction and density for prepared composite formulations. It was observed that void fraction and density of micro SiC and nano TiO2 reinforced hybrid nanocomposites decrease and increase respectively with increase in weight% of micro SiC and nano TiO2. Precisely, when 2.5 wt% each micro SiC and nano TiO2 was added to pure ZA27 alloy, the void contents increased from 0.174 to 0.636 which is approximately 265%. On further increase in micro SiC and nano TiO2 each to 5 wt %, void contents tend to increase from 0.636 to 3.278 which is approximated as 415%. When percentage of micro SiC and nano TiO2 was increased to 15%, 7.5% each, the void contents further increased by 41%. The observed uptrend in void fraction may be due to higher contact area resulting from higher particulate content43. In addition, increasing the stirring time during fabrication increases void contents. Also, stirring time increases when reinforcements is increased, for thorough mixing of reinforcements and matrix44. The above-mentioned reasons could possibly be responsible for the increase in void content.

Figure 4 shows strong reliance of different characteristics on the varying composition of micro SiC and nano TiO2 particles. From Fig. 2, when 2.5 wt% of each micro SiC and nano TiO2 was added to pure ZA27 alloy, the hardness increased from 41.2 HV to 73.38 HV which is approximately 78%. On further increase in micro SiC and nano TiO2, each to 5 wt%, hardness tends to decrease from 73.38 HV to 30.29 HV which is approximated as 59%. When the percentage of micro SiC and nano TiO2 increased to 15% and 7.5% respectively, the hardness further decreased by 2%. The standard deviation of micro-hardness for 0%, 5%, 10% and 15% was 6.37, 5.13, 4.22 and 3.55 respectively. When solidification transpire owing to mismatches in coefficient of thermal expansion (CTE) and elastic modulus (EM) of matrix and nanoparticle, there is generation of geometrically necessary dislocations (GND) around each particle. These particles act as a strong and resistant barrier that hinders the movement of dislocations. This results in work hardening and strengthens nanocomposite as given by Orowan strengthening mechanism45.

As the trend shows in Fig. 4, the tensile strength of hybrid nanocomposite increases from 67.125 MPa to 138.758 MPa which is approximated as 107% increment. This is even more than double as compared to unreinforced alloy when 2.5 wt% of each micro SiC and nano TiO2 were added. Further increase in micro SiC and nano TiO2 each to 5% tensile strength tends to decrease by 109%. When the percentage of micro SiC and nano TiO2 is increased to 15%, 7.5% each, the tensile strength further decreases by 7%. Firstly, the increase in tensile strength is attributed to enough nanoparticles which are well distributed in matrix and act as obstacles to the movement of dislocations during loading of composites. These dislocation lines loop around the particles inspite of cutting through them which results in higher tensile strength. Also, during solidification, dislocations are created around particles due to elastic modulus (EM) mismatch and coefficient of thermal expansion (CTE) mismatch between matrix and particles which thereby contribute to increase in tensile strength as given by Orowan strengthening mechanism46. Increase in strength also depends upon the grain size and volume fraction of nanoparticles as given by Hall-Petch strengthening which have contributed for nano as well as micro particles. As the base matrix grain size decreases, the value of tensile strength increases. Also, the grain size of matrix depends upon nano-particle size and its weight%. Till addition of 2.5 wt% of TiO2 nano particle and 2.5 wt% of SiC microparticles the tensile strength increases. The increase in Ultimate tensile strength when reinforcement is increased from 0 to 5% can be attributed to the above given reasons. An increase of 10–15% reinforcement provides a lower trend for tensile strength; the possible reasons could be the agglomeration of nano TiO2 and micro SiC particles with higher wt% and grain boundary saturation47.

The flexural strength of hybrid nanocomposite increases by 106% which is even more than double as compared to unreinforced alloy when 2.5 wt% of each micro SiC and nano TiO2 was added. On further increase in micro SiC and nano TiO2 each to 5% flexural strength tends to decrease by 186%. When the percentage of micro SiC and nano TiO2 is further increased to 15%, 7.5% each the flexural strength increases by 8% but still is less than pure ZA 27 alloy. Further, the increase in reinforcement reduces tensile strength of the prepared composite. The possible reasons could be voids contents, agglomeration of nano particles, non-uniform distribution of particles in matrix, inadequate bonding between matrix and particles, etc. The property enhancement majorly depends on distribution of particulates and grain size. If particles are added beyond the limit, grains get saturated and further enhancement of strength will not occur. More than particles, grain refinement does not occur by subdivision of grains, capability of micro SiC and nano TiO2 to nucleate matrix grains decreases, no pinning effect of dislocations occur at nano particles which strengthens the composite48. Hence, the addition of micro SiC and nano TiO2 to 5 wt% to pure ZA27 gives preeminent result for flexural strength.

As the trend shows in Fig. 4, hybrid nanocomposite impact strength is decreasing by reinforcement to pure ZA 27 alloy, though the decrease is negligible. Impact strength decreases by 0.07% when 2.5 wt% of each micro SiC and nano TiO2 was added. On increase in micro SiC and nano TiO2 each to 5% impact strength tends to decrease by 0.24%. When the percentage of micro SiC and nano TiO2 was further increased to 15%, 7.5% each, the impact strength decreased by 0.04%. The slight decrease in impact strength with the addition of micro SiC and nano TiO2 filler particles can likely be attributed to the embrittling effect these particles have on the material. The micro-sized SiC particles, known for their hardness, may restrict dislocation movement, while the nano-sized TiO2 particles can create localized stress concentrations. This combination may impede the material’s ability to deform plastically, leading to reduced toughness and slight embrittlement49. Hence, the addition of micro SiC and nano TiO2 to pure ZA27 gives no increase in impact strength. Considering the results, pure ZA 27 shows the best result for impact strength.

SEM images of fractured surfaces of ZA 27 alloy and hybrid nanocomposites are shown in Fig. 5. From Fig. 5 (a), it can be seen from the fractography, no dimples are observed in fractured surfaces. This demonstrates that fracture had occurred in brittle manner or through brittle cleavage mechanism. The fractured surfaces of samples were smooth and bright suffered little deformation and no necking. Figure 5 (b) indicates that 5 wt% reinforced hybrid nanocomposite exhibits more plastic deformation than the other composites and pure ZA 27 alloy. It is also for this reason that 5 wt% reinforced hybrid nanocomposite attained higher ultimate tensile strength. These nanocomposite materials possess large amount of dislocation movement barriers and have a low tendency for work hardening. From Fig. 5 (b) crack growth and its propagation can be seen clearly visible through which fracture may have commenced and progressed. Flat and smooth surfaces indicate brittle fracture but in Fig. 5 (b), a slight number of dimples was observed. As the wt% of reinforcements have increased, the brittleness of composites increases as seen from Fig. 5 (c) and (d). The formation of steps, smooth surfaces and tear ridges clearly indicates the brittle fracture.

Figure 6 illustrates the effect of micro SiC and nano TiO2 content on coefficient of friction, wear rate and wear volume of the manufactured nanocomposite at normal load of 6 N, frequency of 6 Hz and sliding distance of 110 μm. It is evident that as the percentage of reinforcements increased, coefficient of friction decreased. This could probably happen because of the presence of hard dispersoids which act as barrier between counter body and composite. It does not allow direct contact of metal to the counter body. Also because of breakage of thin oxide film from sample surface and asperities deform plastically which requires high stress that had led to abrupt changes in coefficient of friction. From Fig. 6, when micro SiC and nano TiO2, 2.5 wt% each, was added to pure ZA27 alloy, the wear rate decreased from 0.05204 to 0.03951 which is approximately 24%. On further increase in micro SiC and nano TiO2 each to 5 wt%, wear rate tends to decrease from 0.03951 to 0.03378 which is approximated as 15%. When the percentage of micro SiC and nano TiO2 increased to 15%, 7.5% each, the wear rate further decreased by 49%. The wear rates of composites are less than that of unreinforced alloy. During the fretting test the sliding of specimen in each direction i.e. back and forth motion, the asperities of surfaces first adhered because of mechanical interlocking and then broken. The building and breaking of thin oxide layer were simultaneous process48. Soft matrix phase is removed by hard steel balls through plastic ploughing and grooving and as the percentage of reinforcements were increased, the wear losses reduced.

From Figs. 7 and 8, the worn surfaces and scar area are more severe in pure ZA 27 alloy as compared to composites and it had subsequently decreased as percentage of reinforcements increased. Matrix material was removed by hard steel balls through grooving and micro-ploughing action, allowing hard ceramic particles to directly meet steel balls which resisted wear. Particles loosened up after more effect of counter-body; got cracked and ultimately left the matrix in form of fine debris50. There is also spreading of tribo-chemical residues produced during fretting. At pure ZA 27 it can observed that the tribo-layer completely covers the worn surface. Scratches are produced on worn surfaces, but the extent of scratches is least in 15 wt% reinforced hybrid metal alloy nanocomposite and maximum in pure ZA 27. These hard particles prevent surface fractures by abrasion due to formation of wear debris, which is a major factor of wear mechanism. During sliding and increased concentration of hard ceramic particles, wear rate and wear volume was less because these reinforcements prevented the crack propagation. Micro-cracks also seemed to get reduced on increase in percentage of reinforcements. Wear rate decreases which is a function of concentration of particles51.

When the relation between wear volume and wear depth was studied it was found that as the percentage of reinforcements were increased, wear volume and depth of wear decreased. The variation of wear volume and wear depth of base alloy and hybrid nanocomposite as function of micro SiC and nano TiO2. Figure 8 shows the wear depth of pure ZA 27 alloy and hybrid nanocomposite. The blue portion represents the depth of wear in the scar area. It can be concluded from the graph that as the reinforcements are added to pure ZA 27 alloy wear depth has decreased. Wear is at least in 15 wt% reinforced composite and maximum in pure ZA 27 alloy. Finally, from the above results it is evident that as the reinforcement SiC + TiO2 particulates increases by wt%, the wear rate and wear losses decrease along with decrease in coefficient of friction from 0.75 to 0.25 with reinforcement addition.

Fuzzy PSI material optimization

This section presents material selection and optimization for bearing races utilizing newly developed fuzzy PSI methodology. The selection of composite depends on different criteria such as tensile strength, density, hardness, impact strength, wear volume, coefficient of friction and wear rate. The higher-the-better criteria aims to realize higher value i.e., density, hardness, tensile strength, flexural and impact strength while void content, wear rate, wear volume and coefficient of friction governs lower-the-better. Based on the discussions in previous sections, it is obvious that none of the alternatives satisfy all criteria, which makes it relevant to employ fuzzy PSI techniques for optimization and selection of the best alternative composite material.

Tables 6 and 7 show linguistic variables and their fuzzy values for a particular attribute implemented. In addition, Tables 8 and 9 reports significance rating for each composite formulation based on evaluation criteria. Further, combined fuzzy levels were evaluated related to individual criteria. Table 10 shows an aggregated fuzzy matrix calculated for material ratings and criterion weights. De-fuzzification results were reported in Table 11 based on the importance of criterion and material ratings for realizing crisp values. Finally, normalization and weighted normalization is performed for transforming decision matrix into compatible form based on outcome desired either higher-the-better or lower-is-better and reported in Tables 12 and 13. Equation 6 is utilized for calculating preference variation values (\(\:{V}_{j}\)) as specified below:

\(\:{V}_{1}\)= 0.8893, \(\:{V}_{2}\)= 0.9376, \(\:{V}_{3}\)= 0.9878, \(\:{V}_{4}\)= 0.976, \(\:{V}_{5}\)= 0.9639, \(\:{V}_{6}\)= 0.9737, \(\:{V}_{7}\)= 0.9588, \(\:{V}_{8}\)= 0.9588, \(\:{V}_{9}\)= 0.9684.

The values of overall preference values (Pj) for various criteria are calculated below:

\(\:{P}_{1}\)= 0.1030, \(\:{P}_{2}\)= 0.1086, \(\:{P}_{3}\)= 0.1144, \(\:{P}_{4}\)= 0.1130, \(\:{P}_{5}\)= 0.1116, \(\:{P}_{6}\)= 0.1128, \(\:{P}_{7}\)= 0.1122, \(\:{P}_{8}\)= 0.1122, \(\:{P}_{9}\)= 0.1121.

The overall PSI values (\(\:{\omega\:}_{i}\)) were determined and Table 14 reports ranking of composite formulations. Thus, composite formulations were ranked, and results show that A1 is the best ranked composite formulation, the composites A3 and A2 are ranked as second and third preferred formulations. The composite formulation A0 is least preferred and thus, least suitable among available composite formulations. Therefore, the composition of ZA-27 alloys with 2.5 wt% SiC and 2.5 wt% TiO2 (i.e., A1) comes out as the optimal composite formulation.

For confirming the efficacy of hybrid fuzzy PSI technique for optimal composite selection, the results are equated to classical AHP, and two fuzzy methods like fuzzy TOPSIS52 fuzzy VIKOR53 methodology. Table 15 presents the composite ranking order for different alternatives for various techniques and proves that all techniques predict A1 is the optimal composite material for specific applications.

Furthermore, to confirm and validate the fuzzy PSI results of material selection, sensitivity analysis is employed. The stability of ranking order is examined using sensitivity analysis related to weights of the criterion54]– [55. The sensitivity analysis typically validates the results and methodology adopted qualitatively and quantitatively in decision making due to undefined input values. The possible settings combination needed to execute sensitivity analysis comprises of different viable arrangements of weights such that each criterion is distributed in the complete array of linguistic scale. A total of 16 different combinations were formulated performing sensitivity analysis on corresponding weights distribution. The variation of criteria weight varies the final ranking of individual ranking which is reported in Table 16. The criteria weights utilized are (0.0, 0.1, 0.2), (0.1, 0.2, 0.3), (0.2, 0.35, 0.5), (0.4, 0.5, 0.6), (0.5, 0.65, 0.8), (0.7, 0.8, 0.9) and (0.8, 0.9, 1.0) for first seven trials, while final 9 trials have highest criteria weight set as (0.8, 0.9, 1.0) and lowest criteria weight as (0.0, 0.1, 0.2) for other remaining criteria. In the first trial, higher (0.2) weights are assigned to important criteria such as hardness, tensile strength, wear rate and wear volume and coefficient of friction while lower weights are designated for other criteria. The weights are provided to criteria considering bearing races performance and making sure the total weights add up to 1. Further, normalized weighted scores are calculated and finally PSI index value was found. Based on PSI score the ranking was provided to individual composite formulations. Similar procedure was followed for all trials by changing the weights to criteria. Figure 9 shows the variation in ranking by altering the weights for different criteria.

From Table 16, it was realized that A1 composite formulation has achieved the best ranking in 13 out of 16 trials. Moreover, A3 choice has the best PSI index of 1 trial only. It was also revealed that with higher weightage to hardness, wear rate and coefficient of friction, the A1 formulation was selected as best choice for bearing races application followed by A3 composite formulation. It is worth noting that A1 has maximum PSI value when the weights are provided to hardness, wear rate and coefficient of friction as was the case in trial 7 while other criteria have zero weightage. The results of sensitivity analysis validate the results of fuzzy PSI and confirm alternative A1 as the top priority (90.00%) composite formulation. The alternative A1 is also relatively insensitive (Table 16) to different criteria weights as clear from the results of sensitivity analysis. The A1 composite formulation developed is likely a result of balanced reinforcement concentrations, favorable wettability, optimal dispersion during processing, and good interfacial bonding. The wettability and processing conditions are the most critical parameters controlling the distribution of SiC and TiO₂ in the ZA matrix, ensuring uniform distribution and effective enhancement of the composite properties. The final ranking depends on PSI values results attained through sensitivity analysis and may be expressed: A1 > A3 > A2 > A0, confirming efficacy and robustness of adopted fuzzy PSI methodology. The proposed fuzzy-based decision-making method offers significant potential for practical application in industrial settings. By capturing expert opinions through fuzzy membership functions, the approach enables more consistent and transparent evaluation of complex criteria, such as material performance, cost, and durability—factors commonly encountered in manufacturing environments. This methodology can be integrated into material selection processes for tribological applications, particularly in industries like automotive, aerospace, and mechanical engineering, where multi-criteria decisions are routine. Moreover, the model can support early-stage design, supplier evaluation, and quality control, and it is adaptable for implementation within digital decision-support tools in CAD/CAM or MES platforms. Its flexibility and scalability make it a promising framework for guiding real-world industrial decisions under uncertainty.

Conclusions

This paper presents the selection of optimal formulation based on mechanical and tribological characteristics of micro SiC and nano TiO2 reinforced bearing races material (ZA-27 alloy). The composite formulations were based on varying wt% of micro SiC and nano TiO2 and analyzed for physico-mechanical and tribological properties. By integrating expert knowledge with fuzzy logic, this work offers a practical and adaptable tool that can assist engineers and managers in making informed, consistent, and justifiable decisions when selecting hybrid materials for tribological applications. The following conclusions are drawn from current study.

-

1.

After analyzing different properties, it was found that addition of micro SiC and nano TiO2 improves the physical, mechanical and tribological characteristics positively.

-

2.

The ZA27 alloy composite with 2.5 wt% of each micro SiC and nano TiO2 shows an upsurge in hardness from 41.2 HV to 73.38 HV which is approximately 78%, owing to strong nanoparticles, which act as a strong and resistant barrier that hinders the movement of dislocations, while the tensile strength of hybrid nanocomposite increases from 67.125 MPa to 138.758 MPa seeing almost 107% jump from unreinforced alloy owing to strong interfacial bonding between matrix and reinforcement.

-

3.

With increase in the reinforcement SiC + TiO2 particulates wt%, the wear rate and wear losses decrease along with decrease in coefficient of friction from 0.75 to 0.25. The primary reason may be attributed to establishment of harder surface layer that resists plastic deformation and material removal under loading.

-

4.

It was also found that composite sample A1 (ZA-27 alloy + 2.5 wt% SiC + 2.5 wt% TiO2) is ranked as best alternative material having maximum PSI score of 0.8259. The A0 alternative comes out as a minimum favored composite material with the lowest PSI value of 0.6855. Additionally, the best combination of criteria is realized for maximizing physio-mechanical properties and minimizing tribological properties using hybrid methodology.

-

5.

For validation of proposed fuzzy PSI approach, sensitivity analysis was employed to confirm the stability and robustness of the technique by altering weights of different criteria.

The primary limitation of this research involves lack of investigation on the influence of temperature and long-term wear behavior, that would provide valuable insights and may be a good avenue for future research. Future work may also be aimed at employing other multi-criteria decision-making techniques hybridizing with fuzzy module for optimizing composite formulations for various applications. In addition, investigating a broader range of operational conditions will be considered in future studies to expand the practical understanding of the material’s tribological response.

Data availability

Data will be shared on requests to the corresponding author.

References

Kumar, N. & Satapathy, R. K. Bearings in aerospace, application, distress, and life: a review. J. Fail. Anal. Prev. 23 (3), 915–947 (2023).

Şap, S., Değirmenci, Ü., Usca, Ü. A. & Uzun, M. Tribological behaviors and mechanical properties of novel Al-5Cu hybrid composites under dry sliding conditions. Proc. Institution Mech. Eng. Part. C: J. Mech. Eng. Sci. 238 (15), 7690–7704 (2024).

Sastry, S., Krishna, M. & Uchil, J. A study on damping behaviour of aluminite particulate reinforced ZA-27 alloy metal matrix composites. J. Alloys Compd. 314 (1–2), 268–274 (2001).

Patnaik, A., Mamatha, T. G., Biswas, S. & Kumar, P. Damage assessment of Titania filled zinc–aluminum alloy metal matrix composites in erosive environment: A comparative study. Mater. Des. (1980–2015). 36, 511–521 (2012).

Alaneme, K. K. & Ajayi, O. J. Microstructure and mechanical behavior of stir-cast Zn–27Al based composites reinforced with rice husk ash, silicon carbide, and graphite. J. King Saud University-Engineering Sci. 29 (2), 172–177 (2017).

Palanivel, R., Dinaharan, I., Laubscher, R. F. & Davim, J. P. Influence of Boron nitride nanoparticles on microstructure and wear behavior of AA6082/TiB2 hybrid aluminium composites synthesized by friction stir processing. Mater. Design. 106, 195–204 (2016).

Rajmohan, T., Palanikumar, K. & Arumugam, S. Synthesis and characterization of sintered hybrid aluminium matrix composites reinforced with nanocopper oxide particles and microsilicon carbide particles. Compos. Part. B: Eng. 59, 43–49 (2014).

Owoeye, S. S., Folorunso, D. O., Oji, B. & Borisade, S. G. Zinc-aluminum (ZA-27)-based metal matrix composites: a review Article of synthesis, reinforcement, microstructural, mechanical, and corrosion characteristics. Int. J. Adv. Manuf. Technol. 100 (1–4), 373–380 (2019).

Mitrović, S. et al. Tribological potential of hybrid composites based on zinc and aluminium alloys reinforced with SiC and graphite particles. Tribology Ind. 34 (4), 177–185 (2012).

Thandalam, S. K., Ramanathan, S. & Sundarrajan, S. Synthesis, microstructural and mechanical properties of ex situ Zircon particles (ZrSiO4) reinforced metal matrix composites (MMCs): a review. J. Mater. Res. Technol. 4 (3), 333–347 (2015).

Şap, S., Değirmenci, Ü. & Usca, Ü. A. Impact of Boron nitride and silicon carbide on tribological properties of Al-3Gr-based hybrid composites. J. Brazilian Soc. Mech. Sci. Eng. 45 (10), 510 (2023).

Şap, S. Mechanical and tribological behaviour of novel Al–12Si-based hybrid composites. Mater. Test. 65 (4), 560–577 (2023).

Değirmenci, Ü. Mechanical and tribological behavior of a hybrid WC and Al2O3 reinforced Al–4Gr composite. Mater. Test. 65 (9), 1416–1436 (2023).

Usca, Ü. A., Şap, S., Uzun, M., Giasin, K. & Pimenov, D. Y. Evaluation of mechanical and tribological aspect of self-lubricating Cu-6Gr composites reinforced with SiC–WC hybrid particles. Nanomaterials 12 (13), 2154 (2022).

Yadav, M., Kumaraswamidhas, L. A., Kumar, A., Khan, T. Y. & Baig, U. Erosion behavior of Al–SiC and Al–WC MMCs via powder metallurgy under solid particle impingement. Sci. Rep. 14 (1), 29533 (2024).

Singh, P., Singh, R. K. & Das, A. K. Influence of ceramic reinforcements on mechanical properties and high-temperature sliding wear behaviour of heat-treated Al6082–SiC–TiO2 composites developed by stir-casting process. Multiscale Multidisciplinary Model. Experiments Des. 7 (2), 1339–1356 (2024).

Usca, Ü. A., Şap, S., Uzun, M. & Değirmenci, Ü. Determination of mechanical and tribological properties of vacuum sintered hybrid reinforced Al-4Cu composites. J. Compos. Mater. 58 (26), 2799–2815 (2024).

Keiser, J. R. et al. Material selection and corrosion studies of candidate bearing materials for use in molten chloride salt. J. Solar Energy Eng. 145(2), 021001 (2023).

Gangwar, S. & Pathak, V. K. Preliminary evaluations on development and material selection of high temperature vacuum casted marble dust-reinforced silicon-bronze alloy material for bearing applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 235(1), 131–148 (2021).

Yadav, S., Pathak, V. K. & Gangwar, S. A novel hybrid TOPSIS-PSI approach for material selection in marine applications. Sādhanā 44 (3), 58 (2019).

Jahan, A., Edwards, K. L. & Bahraminasab, M. Multi-criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design (Butterworth-Heinemann, 2016).

Rao, R. V. A material selection model using graph theory and matrix approach. Mater. Sci. Engineering: A. 431 (1–2), 248–255 (2006).

Shanian, A. & Savadogo, O. A material selection model based on the concept of multiple attribute decision making. Mater. Design. 27 (4), 329–337 (2006).

Jee, D. H. & Kang, K. J. A method for optimal material selection aided with decision making theory. Mater. Design. 21 (3), 199–206 (2000).

Chan, J. W. & Tong, T. K. Multi-criteria material selections and end-of-life product strategy: grey relational analysis approach. Mater. Design. 28 (5), 1539–1546 (2007).

Bahraminasab, M. & Jahan, A. Material selection for femoral component of total knee replacement using comprehensive VIKOR. Mater. Design. 32 (8–9), 4471–4477 (2011).

Gangwar, S., Yadav, S. & Pathak, V. K. Optimized selection of nanohydroxyapatite-filled dental restorative composites formulation for best physico‐mechanical, chemical, and thermal properties using hybrid analytical hierarchy process‐multi‐objective optimization on the basis of ratio analysis approach. Polym. Compos. 42 (8), 3841–3856 (2021).

Singh, T., Pattnaik, P., Pruncu, C. I., Tiwari, A. & Fekete, G. Selection of natural fibers based brake friction composites using hybrid ELECTRE-entropy optimization technique. Polym. Test. 89, 106614 (2020).

Maniya, K. & Bhatt, M. G. A selection of material using a novel type decision-making method: preference selection index method. Mater. Design. 31 (4), 1785–1789 (2010).

Hambali, A., Sapuan, S. M., Ismail, N. & Nukman, Y. Material selection of polymeric composite automotive bumper beam using analytical hierarchy process. J. Cent. South. Univ. Technol. 17 (2), 244–256 (2010).

Mayyas, A. et al. Using quality function deployment and analytical hierarchy process for material selection of body-in-white. Mater. Design. 32 (5), 2771–2782 (2011).

Ilangkumaran, M., Avenash, A., Balakrishnan, V., Kumar, S. B. & Raja, M. B. Material selection using hybrid MCDM approach for automobile bumper. Int. J. Ind. Syst. Eng. 14 (1), 20–39 (2013).

Anand, M. B. & Vinodh, S. Application of fuzzy AHP–TOPSIS for ranking additive manufacturing processes for microfabrication. Rapid Prototyp. J. 24 (2), 424–435 (2018).

Gul, M., Celik, E., Gumus, A. T. & Guneri, A. F. A fuzzy logic based PROMETHEE method for material selection problems. Beni-Suef Univ. J. Basic. Appl. Sci. 7 (1), 68–79 (2018).

Emovon, I. & Oghenenyerovwho, O. S. Application of MCDM method in material selection for optimal design: A review. Results Mater. 7, 100115 (2020).

Rahim, A. A., Musa, S. N., Ramesh, S. & Lim, M. K. A systematic review on material selection methods. Proc. Institution Mech. Eng. Part. L: J. Materials: Des. Appl. 234 (7), 1032–1059 (2020).

Singh, R. et al. A historical review and analysis on MOORA and its fuzzy extensions for different applications. Heliyon (2024).

Sheikh, K. A., Khan, M. M. & Dey, A. Optimizing wear resistance of ZA-27 alloy through analytical modelling: A study on the effect of titanium carbide content, load, and speed. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol.13506501241257738. (2024).

Tunç, S. A., Çanakçı, A., Karabacak, A. H., Çelebi, M. & Türkmen, M. Effect of different PCA types on morphology, physical, thermal and mechanical properties of AA2024-B4C composites. Powder Technol. 434, 119373 (2024).

ASTM, G. 99–95a Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus (ASTM International, 2000).

Nadeem, A., Rizvi, A. A. & Noor, M. Y. Applying a Higher Number of Output Membership Functions to Enhance the Precision of a Fuzzy System (IEEE Transactions on Emerging Topics in Computational Intelligence, 2024).

Yu, H. Research on the urban green transportation development level evaluation based on the triangular pythagorean fuzzy multiple attribute decision making. J. Intell. Fuzzy Syst. (Preprint), 1–19 (2024).

Akbari, M. K., Baharvandi, H. R. & Shirvanimoghaddam, K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des.(1980–2015) 66, 150–161 (2015).

Ezatpour, H. R., Sajjadi, S. A., Sabzevar, M. H. & Huang, Y. Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Design. 55, 921–928 (2014).

Sharma, S. C., Girish, B. M., Somashekar, D. R., Kamath, R. & Satish, B. M. Mechanical properties and fractography of zircon-particle-reinforced ZA-27 alloy composite materials. Compos. Sci. Technol. 59 (12), 1805–1812 (1999).

Li, Z. G. Fabrication of in situ TiB2 particulates reinforced zinc alloy matrix composite. Mater. Lett. 121, 1–4 (2014).

Matin, A., Saniee, F. F. & Abedi, H. R. Microstructure and mechanical properties of mg/sic and AZ80/SiC nano-composites fabricated through stir casting method. Mater. Sci. Engineering: A. 625, 81–88 (2015).

Alizadeh, M. Strength prediction of the arbed Al/Al2O3/B4C nano-composites using Orowan model. Mater. Res. Bull. 59, 290–294 (2014).

Abdollahi, A., Alizadeh, A. & Baharvandi, H. R. Dry sliding tribological behavior and mechanical properties of Al2024–5 wt.% B4C nanocomposite produced by mechanical milling and hot extrusion. Mater. Design. 55, 471–481 (2014).

Akhtar, F. & Guo, S. J. Microstructure, mechanical and fretting wear properties of TiC-stainless steel composites. Mater. Charact. 59 (1), 84–90 (2008).

Kim, J. S., Lee, K. M., Cho, D. H. & Lee, Y. Z. Fretting wear characteristics of titanium matrix composites reinforced by titanium boride and titanium carbide particulates. Wear 301 (1–2), 562–568 (2013).

Han, F., Alkhawaji, R. N. & Shafieezadeh, M. M. Evaluating sustainable water management strategies using TOPSIS and fuzzy TOPSIS methods. Appl. Water Sci. 15 (1), 4 (2025).

Singh, D. P., Avikal, S. & Singh, H. Approach for the Selection of Material for Construction Under Fuzzy. Advances in Materials Engineering: Select Proceedings of ICFAMMT 2024. Vol. 377. (2025).

Dewangan, S., Gangopadhyay, S. & Biswas, C. K. Study of surface integrity and dimensional accuracy in EDM using fuzzy TOPSIS and sensitivity analysis. Measurement 63, 364–376 (2015).

Gangwar, S., Sharma, S. & Pathak, V. K. Preliminary evaluation and wear properties optimization of Boron carbide and molybdenum disulphide reinforced copper metal matrix composite using adaptive Neuro-fuzzy inference system. J. Bio-and Tribo-Corrosion. 7 (1), article4 (2021).

Funding

Open access funding provided by Manipal University Jaipur.

Author information

Authors and Affiliations

Contributions

Swati Gangwar: Writing – original draft, Visualization, Validation, Supervision, Software, Conceptualization. Sugandha Singh: Writing – review & editing, Visualization, Validation, Methodology, Investigation, Vimal Kumar Pathak: Writing – review & editing, Visualization, Validation, Software, Project administration, Methodology, Investigation, Formal analysis, Data curation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Gangwar, S., Singh, S. & Pathak, V.K. Optimal selection of SiC and TiO2 reinforced ZA27 hybrid nanocomposite exercising PSI approach under fuzzy environment for bearing application. Sci Rep 15, 31499 (2025). https://doi.org/10.1038/s41598-025-16827-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16827-3