Abstract

Environmental damage caused by colored effluents poses a threat to the environment, as vast amounts of harmful water contamination are regularly discharged into water sources. The hybrid nanocomposite was successfully synthesized using hydrothermal and thermal treatment methods. A prepared hybrid nanostructure metal composite material, utilizing gallic acid (GA@ZnO-AC), was synthesized and employed for the treatment of methylene blue (MB) in an aqueous environment via adsorption. FTIR, SEM-EDX, BET, and XRD analyses were performed on the hybrid composite. The ZnO, ZnO-AC, and GA@ZnO-AC have a BET surface area of 3.7360, 491.8929, and 467.51 m2/g, pore volume of 0.004039, 0.286580, and 0.247606 cm3/g, and average pore diameter of 4.3240, 2.3304, and 2.1185 nm, respectively. TGA and TEM results indicate that the material is thermally stable due to its phase transition and exhibits a nano-scale shape. The adsorptive performance of nanocomposites ZnO-AC and GA@ZnO-AC for MB removal was significantly influenced by contact time (60 min), temperature (298 K), adsorbent dosage (60 mg (ZnO-AC), 50 mg (GA@ZnO-AC)), and pH (11). The percentage absorbed MB was 98.61% for ZnO-AC and 98.30% for GA@ZnO-AC at their optimum condition. The Langmuir isotherm showed that ZnO-AC and GA@ZnO-AC had the highest adsorption capacities of 153.85 mg/g and 175.44 mg/g, respectively, at 298 K. Isotherm, kinetics, and thermodynamics studies showed that the results fitted the Redlich-Peterson and PSO models, which indicated a spontaneous, feasible, exothermic, and physisorption process. This study presents a low-cost hybrid material that addresses environmental concerns related to the removal of dyes from aqueous media.

Similar content being viewed by others

Introduction

Environmental pollution is a major cause of premature death and disease worldwide. Pollution has been a significant threat to both people and nature throughout history, largely due to rapid population growth and the establishment of permanent communities1. The environmental degradation and scarcity of natural resources have motivated worldwide efforts to limit contamination2,3. Water contamination is significantly higher than air and soil, representing 46.05 to 63.03% of overall problems caused by contaminants4. In general, water contaminants are classified as inorganic or organic. Organic pollutants include organic solvents, dyes, herbicides, insecticides, and pharmaceuticals5,6. Inorganic contaminants include fertilizers, metals, acids, salts, and alkalis7. The harmful effects of pollutants can lead to carcinogenicity, toxicity, and mutagenicity; additionally, the ecological integrity of living species can be compromised8. Pollution-related complications include conjunctivitis, gastrointestinal diseases, congenital anomalies, neurological illnesses, allergic reactions, and genetic alterations9. New approaches are required to eradicate these hazardous contaminants from the environment. Adsorption is one of the most widely used strategies for contaminant removal10. Developing composites, tubes, and nanoscale materials as adsorbents has received much attention in nanotechnology11.

Dyes, among the most significant contaminants, have garnered considerable interest over the past few years. Excessive levels of dyes in water and soil can destroy plants, aquatic ecosystems, and public health12. Exposure to dyes can cause respiratory, skin, liver, digestive, renal, and cancer problems13. Dyes like methylene blue, methyl orange, and eosin yellow are more likely to cause health issues14. The adverse effects of MB are vomiting, nausea, mental difficulties, and even irreversible eye injuries15. Hence, the treatment of MB in wastewater has attracted special attention in recent years.

Researchers have made every effort to eliminate these contaminants because they have a detrimental impact on the environment. Every alternative was explored to develop technology that would reduce the dye contamination of water16. These technologies utilize advanced oxidation, membrane filtration, integrated treatment processes, ozonation, biological, or physicochemical processes; however, each has total or partial restrictions17. Among these methods, adsorption is a revolutionary, cost-effective, and easy-to-run process with dependable performance18.

Bamboo is a biomass resource that is both versatile and renewable19,20. Bamboo grows rapidly and is readily available in huge quantities, and its chemical content makes it appropriate for synthesising activated carbon21. Alpha cellulose and lignin make up 40–50% and 20–26% of bamboo, respectively, on average22. Lignin and cellulose contribute to the generation of macropores and micropores, respectively, by activated carbon21.

Various materials, including compost, resins, bagasse, kaolinite, agricultural waste, metal oxides, coal, ash, and activated carbon, are utilized as adsorbents for removing specific organic compounds and heavy metals from aquatic environments. However, some adsorbents exhibit limited adsorption efficiency due to their low adsorption capacities and surface areas23.

Magnetic nanoadsorbents serve as effective adsorbents to address the issue of adsorbent particles passing through filters, which can result in secondary pollution in the environment23,24,25,26. Among these magnetic nanoadsorbents, cobalt ferrite (CoFe2O4) nanoparticles, characterized by their high adsorption capacity, excellent magnetic properties, and significant surface area, have garnered interest for their application in water treatment processes23,27. The addition of CMC to nanocomposite synthesis increased the adsorbent surface area, which resulted in more active sites for metronidazole removal. Magnetized nanocomposite has a large specific surface area and can be used to remove contaminants from water sources23. According to Amirmahani et al., chitosan, derived from natural organic matter, can be used as a surface adsorbent in the wastewater and water treatment industries due to its high adsorption capacity28.

The synthesis of nanocomposites can result in adsorbents with enhanced adsorption capabilities. Loading nanostructure onto activated carbon to create nanocomposites will enhance its adsorptive characteristics. The nanocomposites possess a high regeneration and reusability capacity, allowing them to be used numerous times without losing their adsorption efficacy. Due to the extensive use of MB dye, there is a significant need to develop economical methods for removing this hazardous pollutant.

Zinc oxide (ZnO) is an affordable, readily available, high electron mobility, high adsorption capacity, environmentally friendly, non-toxic, chemically and physically stable photocatalyst that is biocompatible29,30,31,32. Therefore, integrating the adsorption properties of ZnO with the specific features of these materials might provide a considerable advantage by improving the adsorption efficiency of the nanocomposites, as it increases the overall surface area available for contaminant adsorption33,34,35. Amirmahani et al. utilize a chitosan-Zinc oxide (ZnO) nanocomposite and chitosan to adsorb the reactive red 198 (RR 198) dye from contaminated water. The result showed that the maximum adsorption capacity (qm) obtained from the Langmuir model was 172.41 mg/g at the operating conditions (reaction time: 40 min, temperature: 25 °C, pH: 4, adsorbent dose: 1 g/L)35. In another investigation, Akpomie et al. investigated the adsorption of celestine blue (CEB) using a biogenic-chemically mediated synthesis of a composite (ZnO@ACP). The results showed that the impregnation of ZnONPs onto the biomass enhanced the spontaneity of the process and exhibited endothermic features, with high CEB desorption of 81.3% from the dye-loaded ZnO@ACP, as well as efficient reusability, demonstrating the efficacy of the prepared nanocomposite for CEB adsorption36. Nasiri et al. used CoFe2O4@CMC/HZSM-5 to remove metronidazole (MNZ) from synthetic and real samples, achieving 94% and 85% efficiency, respectively23. This suggested that the magnetic nanohybrid adsorbent is suitable for treating metronidazole in both synthetic and real media. In another investigation by Nasiri et al., a modified magnetic nano-biocomposite based on zeolite (CoFe2O4@CMC@HZSM-5) was employed to remove Pb(II)27. The result showed 75% and 96% efficiency for real and synthetic samples, respectively.

Phenolic acids are the most common secondary metabolic products in plants. They are distinguished by their rich anti-carcinogenic activities, anti-inflammatory, anti-allergic, antioxidant, and chemical structure37,38. Phenolic acids are classified into two types: derivatives of cinnamic acid (ferulic acid, caffeic acid, p-coumaric acid) and derivatives of benzoic acid (ellagic acid, gallic acid, vanillic acid, p-hydroxybenzoic acid)39,40. Phenolic acids conjugated with zinc oxide are antioxidant drugs that display antioxidant characteristics and are being investigated for their potential as antioxidant drugs41,42. Gallic acid, a naturally occurring phenolic compound found in plants, is indeed gaining traction as a biosorbent due to its abundance and affordability compared to commercial adsorbents43. Its effectiveness is further enhanced by its strong chelating properties, which allow it to bind with metal ions and other pollutants44. Metal ions coordinate with natural phenolic ligands to form supramolecular complexes, resulting in stable structures that preserve the ligands’ active adsorption sites while enhancing the adsorption performance of unmodified materials. Metal ion-gallic acid (GA) networks are particularly well-known among metal-organic frameworks (MOFs) due to their extraordinary stability, biological activity, and excellent adsorption capacity45. MPNs have received considerable attention due to their universal adhesive capabilities, broad compatibility, and environmental friendliness, which make them highly successful for modifying adsorbent surfaces45. Similar investigations have been carried out using various adsorbents to remove a range of dyes. El-Shorbagy investigated the adsorption of methylene blue through the grafting of phenolic acids (caffeic and/or gallic acids) on chitosan38. In another study, Salih et al. investigated the adsorption of methylene blue (MB) and rhodamine B (RhB) by magnesium-doped CoFe2O4 nanoparticles–SiO2–3-aminopropylethoxysilaneallic acid magnetic nanocomposite46. The results show 95.3% for RhB and 98.6% for MB, and after five cycles, the adsorption was 79.6% for RhB and 82.5% for MB.

The conductive nature of AC and gallic acid can increase the adsorptive performance of the GA@ZnO-AC nanocomposite. Biocompatibility is a crucial characteristic of adsorbents, as it enables the effective removal of pollutants from waste effluent while minimising negative environmental impacts46.

In this study, we aimed to exploit the photocatalytic properties of gallic acid and ZnO, along with the adsorptive properties of activated carbon (AC) derived from bamboo, by introducing ZnO nanostructures into the AC and gallic acid through a combination of hydrothermal, cross-linking, and heat treatment methods. The primary justification for this research is that, to the best of our knowledge, no publications have been found that employ this method to synthesise ZnO-AC and GA@ZnO-AC nanocomposites. AC and gallic acid were cross-linked with ZnO nanostructure to develop enhanced characteristics relevant to the newly developed synthesized GA@ZnO-AC. Additionally, gallic acid is an oxidizing agent that minimizes the potential harmful influence on the environment and humans. Furthermore, it has never been used to remove MB dye pollutants. The novel adsorbents are distinguished by their complex chemical structure and the presence of several active hydroxyl groups, which function as cationic pollution adsorbents.

The current study aims to develop a novel ZnO-AC and GA-ZnO-AC nanocomposite for the adsorption of methylene blue from aqueous media. Additionally, various factors were investigated to determine the optimal conditions for the highest adsorption of MB. Furthermore, the kinetic model, isotherm, and thermodynamics were investigated to identify the process mechanism.

Experimental

Materials and methods

Activated carbon (AC) derived from Bamboo was purchased from Eva Chem, Malaysia. Chemicals, including zinc chloride (98%), gallic acid (97.5–102.5%), and methylene blue, were purchased from Sigma-Aldrich. Sodium hydroxide (98%) and hydrogen chloride (37%) were obtained from Merck KGaA, Darmstadt, Germany. Maize grains were brought from the shop at Miri, Sarawak, Malaysia.

Preparation of ZnO nanostructure

ZnO was synthesized using the method described by Eskikaya et al.47, with modifications. Firstly, 250 ml of 0.5 M ZnCl2 was slowly reacted with 1 M NaOH and stirred continuously until a white precipitate formed, indicating the formation of ZnO nanostructures using the hydrothermal method and a pH of 8–9. The resulting mixture was placed in a water bath at 90 °C for 4 h and then left to cool at room temperature in the dark. The resulting powder was thoroughly washed with distilled water several times, dried overnight at 60 °C, and then calcined in a furnace at 500 °C for 3 h.

Preparation of ZnO-AC nanocomposite

The following approach was used to prepare the ZnO-AC nanostructure. Five grams of ZnO nanostructure was added to 100 mL of distilled water and stirred for 10 min at 90 °C. Then 7 g of AC was added and stirred for 30 min at 90 °C. Subsequently, 50 mL of maize extract solution (MES) was added slowly and mixed for another 30 min. The mixture was allowed to settle overnight, then transferred to an oven and dried at 60 °C for 72 h.

Preparation of GA@ZnO-AC nanocomposite

5 g of ZnO nanostructure was added to 100 mL of distilled water and stirred for 10 min at 90 °C. Then, 0.02 M gallic acid (GA) (0.340 g) was dissolved in 50 mL of distilled water and added dropwise; the mixture was then continuously stirred for an additional hour. 7 g of AC was added and stirred for 30 min at 90 °C. Subsequently, 50 mL of maize extract solution (MES) was added slowly and mixed for another 30 min. The mixture was allowed to settle overnight, then transferred to an oven and dried at 60 °C for 72 h. Figure 1 illustrates the novel GA@ZnO-AC.

Preparation of maize grain extract solution

The maize grain extract solution was prepared according to the method described by Ndagijimana et al.48 approach with some modifications. The maize grains were sorted out to remove stones and unwanted materials. Then, it was soaked in a container containing 500 mL of tap water for 4 days to ferment. It was then wet-milled into a slurry and sieved through a muslin cloth to obtain the maize extract solution. The solution was left at room temperature for 24 h to settle and decant. Finally, the maize extract solution (MES) was stored in a refrigerator for further use as a cross-linker. Figure 2 illustrates the process flow for preparing MES.

Batch equilibrium adsorption studies

200 mg of MB dye was dissolved in 200 mL of deionized water in a beaker to prepare a stock solution (1000 mg/L). The MB dye serial dilution was prepared at concentrations ranging from 30 to 70 mg/L. 50 mg of the prepared GA@ZnO-AC was measured and put into each conical flask containing 100 mL of MB at temperatures of 298, 308, 318, and 328 K, respectively, while maintaining the initial pH of the MB solution. The mixture was then stirred at 120 rpm and maintained at a controlled temperature for 180 min. The MB concentrations were measured at time intervals using a UV spectrophotometer (model DR2800, Hach) at a wavelength of 663 nm. After the process, the quantity adsorbed at time intervals, equilibrium, as well as percentage removal, were obtained by Eqs. (1–3) below:

Where \({C}_{t},\) \({C}_{e}\) and \({C}_{o}\) represent final, equilibrium, and initial concentration of MB (mg/L), V = volume of MB dye (L), w = weight (g) of the material, and qt and qe = quantity of MB adsorbed at a time interval and equilibrium, respectively (mg/g).

Results and discussion

Characterization

XRD

Figure 3 shows the phase composition of AC, ZnO nanostructure, ZnO-AC, and GA@ZnO-AC as determined by powder X-ray diffraction (PXRD). The XRD crystallinity pattern of AC shows two broad diffraction backgrounds corresponding to 2θ = 26.59° and 43.75° in the spectrum, which are attributable to the (002) and (100) crystal planes. This suggests that carbon has graphitised and formed an amorphous structure (JCPDS 00-056-0159). The XRD crystalline pattern of ZnO nanostructure, ZnO-AC, and GA@ZnO-AC nanocomposite showed the hexagonal pattern of ZnO and wurtzite type structure, exhibited peaks at 31.43°, 34.66°, 36.47°, 47.58°, 56.88°, 63.11°, 67.97°, and 69.12° which matches to the indexing (100), (002), (101), (102), (110), (103), (112), and (201) lattice faces (JCPDS No. 36–1451). The peaks at 31.43°, 34.66°, and 36.47° are characteristic of ZnO, and this became noticeable. The XRD diffraction pattern of the ZnO-AC nanocomposite exhibited peaks at 24.84°, 31.81°, 34.54°, 36.34°, 44.68°, 47.51°, 56.62°, 62.83°, and 67.99°. The appearance of ZnO and AC on the nanocomposite material indicates that the cross-linking method for incorporating AC into ZnO was successful49,50. The peaks of ZnO at 47.58° and 56.88° disappeared after the material was activated and doped with ZnO, indicating that the materials had successfully crosslinked. Additionally, activated carbon peaks at 26.59° and 43.75° were observed on the ZnO-AC nanocomposite. The XRD diffraction pattern of GA@ZnO-AC nanocomposite exhibited peaks at 24.84°, 31.81°, 34.54°, 36.34°, 47.51°, 49.39°, 51.01°, 54.20° 56.62°, 62.83°, and 67.99°. The emergence of GA, ZnO, and AC on the nanocomposite material demonstrates the successful incorporation of AC and GA into ZnO. Gallic acid peaks are not shown in the XRD diffraction pattern of GA@ZnO-AC nanocomposite because gallic acid is no longer present as a crystalline material in the GA@ZnO-AC but exists in the amorphous state51,52. Likewise, the peaks of ZnO at 47.58° and 56.88° disappeared after the material was activated, indicating that the material had successfully crosslinked. In addition, activated carbon peaks at 26.59° are observed on the GA@ZnO-AC nanocomposite.

Brunauer–Emmett–Teller (BET)

The results in Fig. 4a–d revealed that the synthesised nanocomposite showed type IV isotherm characteristics with a clear hysteresis loop that occurred at relatively high pressure with an area diameter between 2 and 50 nm. Figure 4a–d shows that the pore volume of AC, ZnO, ZnO-AC, and GA@ZnO-AC were 0.0040, 0.2866, 0.2476, and 0.5571 cm3/g, the surface area of 3.7360, 491.8929, 467.5148, and 1036.5882 m2/g, and the average pore diameter were 4.3240, 2.3304, 2.1185, and 2.1496 nm, respectively. The surface area of ZnO nanostructures increases when they are impregnated with AC, while the surface area decreases upon adding gallic acid to ZnO-AC. This suggests that a small amount of gallic acid may have been deposited on the surface, while the majority is absorbed into the pores53. Even though there is a decline in the surface area of GA@ZnO-AC due to pore blockage by gallic acid, it is postulated that the increased number of active hydroxyl ions (OH−) and the carboxylic group from gallic acid may act as the additional adsorption sites, which can promote the adsorption capacity of GA@ZnO-AC38. Furthermore, GA can effectively remove contaminants from wastewater, minimise the negative influences of contaminants on the environment, and reduce secondary pollutants during the degradation process44. The BET results also revealed increased pore volume, while the adsorption average pore decreases with the introduction of activated carbon and gallic acid on the ZnO nanostructure.

SEM/EDX analysis

Figure 5a–d depicts the surface structures of activated carbon (AC), ZnO nanostructure, ZnO-AC, and GA@ZnO-AC. Figure 5a shows the structure of AC, which exhibits a heterogeneous surface with well-developed pores and several cavities54,55. AC’s well-developed pores may be linked to the loss of volatile substances in CO and CO2, and the intercalation of the potassium element into the generated char prior to analysis56. AC had larger holes on the sample surface, indicating increased porosity. The SEM structure of ZnO in Fig. 5b revealed a nanosheet-like structure. Figure 5c shows the ZnO-AC structure, which suggests the homogeneous and reasonably consistent disposition of ZnO nanostructure on the AC’s surface57. It also showed an arrangement of particles with various spherical masses, aggregated and large pore sizes. The micrograph of GA@ZnO-AC is shown in Fig. 5d. It revealed a regular and crystal-like structure, as well as the presence of particles of various spherical forms that were aggregated and porous. It also revealed the presence of white spots and a spherical shape of gallic acid on the material’s surface. In Fig. 5a, the elemental composition of the activated carbon contains C, O, F, Si, S, and Cl with weight composition of 94.54, 3.49, 1.41, 0.32, 0.11, and 0.13wt%, respectively. The EDX data in Fig. 5b showed a large amount of Zn (52.66 wt%) and O (26.44 wt%). This confirms the successful fabrication of the ZnO nanostructure. The EDX profile of the ZnO-AC is represented in Fig. 5c, indicating a new peak of Zn with a weight composition of 2.57wt%. The weight composition of oxygen (O) increased from 3.49wt% to 5.45wt% with the addition of ZnO nanostructure, showing the presence of ZnO on the AC’s surface58. Figure 5d shows the EDX profile of GA@ZnO-AC, which reveals a new peak corresponding to Zn with a weight composition of 1.49 wt%. The weight composition of oxygen (O) increases from 3.49 up to 5.26wt% with the addition of ZnO nanostructure and gallic acid, showing the existence of gallic acid and ZnO on the AC’s surface. It was also observed that the weight composition of silicon (Si) decreased from 0.32 to 0.22%. This may be related to the existence of GA on the AC’s surface.

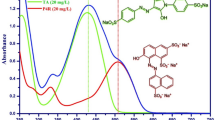

FTIR analysis

Figure 6a–d shows the FTIR spectrum of activated carbon (AC), gallic acid (GA), ZnO nanostructure, ZnO-AC, and GA@ZnO-AC. The FTIR spectrum of the AC functional group is found in 3763.34 cm−1, 2314.68 cm−1, 2094.76 cm−1, 1649.57 cm−1, and 1453.66 cm−1 as presented in Fig. 6a. The IR spectra exhibit an absorption band at 3763.34 cm−1, corresponding to the –OH stretching vibration of the –OH groups in hemicellulose, cellulose, and lignin. The peak at 2314.48 cm−1 corresponded to the C=C stretching vibration, whilst peaks at 2072.40 cm−1 and 1649.59 cm−1 were related to the aliphatic C–H group and the C =O stretching vibration of the hemicellulose and –COOH group, respectively59,60. The peak at 1453.66 cm−1 indicated the presence of C aromatic lignin61. Pure gallic acid (GA) spectrum was observed at peaks 3488.79 cm−1, 3231.60 cm−1, 1699.67 cm−1, 1621.39 cm−1, 1610.21 cm−1, 1539.39 cm−1, 1445.39 cm−1, 1371.66 cm−1, 1297.11 cm−1, 868.46 cm−1, 760.38 cm−1, and 708.19 cm−1, respectively, as shown in Fig. 5b. Absorption peaks at 3488.79 cm−1 and 3231.60 cm−1 are due to the stretching of hydroxyl groups (–OH)62. The absorption peak at 1699.67 cm−1 indicates carboxyl (C =O) stretching of the COOH group63,64. The 1539.39 cm−1 and 1445.39 cm−1 peaks correspond to C=C aromatic stretching65. Peaks were also observed at 1297.11 cm−1, attributed to the C–O stretching vibration. The peaks at 868.46 cm−1, 760.38 cm−1, and 708.19 cm−1 are C-H bending65. The following peaks was observed in ZnO 3488.79 cm−1, 2429.56 cm−1, 2031.40 cm−1, 1894.24 cm−1, 1617.66 cm−1, 1047.38 cm−1, 898.28 cm−1, and 715.65 cm−1, respectively as presented in Fig. 6c. The peak at 3488.79 cm−1 corresponds to the –OH stretching vibration of the hydroxyl groups66, whereas peaks at 2429.56 cm−1 and 2031.40 cm−1 represent the C =C stretching vibration59. The peak at 1894.24 cm−1 might be due to asymmetric and symmetric stretching vibrations of CH2 bonds60. The peak at 1047.38 cm−1 was related to the C–H bending vibration. The 898.28 cm−1 and 715.65 cm−1 peaks are –C=O–C stretching67. The FTIR spectral range (4000–650 cm−1) shows no Zn transmittance peak. The peak for Zn can be observed at 572 cm−1, as reported by Dada et al.59. The following peaks were observed in ZnO-AC, which are 3596.88 cm−1, 2299.77 cm−1, 2031.40 cm−1, 1606.48 cm−1, 1047.38 cm−1, 898.28 cm−1, and 715.65 cm−1, respectively, as shown in Fig. 6d. A peak at 3596.88 cm−1 was assigned to the O–H stretching vibration68. The peaks were spotted at 2299.77 cm−1 and 2031.40 cm−1, corresponding to the C = C stretching vibration. The peak at 1606.48 cm−1 was assigned to the stretching mode of C =O in the oxalate64. The 898.28 cm−1 and 715.65 cm−1 peaks are –C=O-C stretching67. The FTIR spectra of GA@ZnO-AC at 3865.33 cm−1, 3712.43 cm−1, and 3466.42 cm−1 are linked to the O–H stretching vibration of the OH−groups as presented in Fig. 6e. The 2310.95 cm−1 and 2131.40 cm−1 peaks correspond to the C=C stretching vibration. The peaks at 1703.39 cm−1, 1546.85 cm−1, and 1397.75 cm−1 correspond to C=C aromatic stretching69. The peak at 1034.27 cm−1 was due to C–H bending vibration. The peak at 719.38 cm−1 corresponds to C=O–C stretching67.

TEM analysis

The TEM images of ZnO-AC and GA@ZnO-AC are presented in Fig. 7a–b. In Fig. 7a, the ZnO-AC exhibits a spherical shape, which is evident due to the strong attraction between the particles. This attraction is a result of van der Waals force and dipole-dipole interaction, resulting in the aggregation of individual particles to some extent. The TEM images of the ZnO nanocomposite with spherical morphology show that the material is uniform and quite monodisperse70. The average particle sizes range from 28.77 to 78.06 nm. In Fig. 7b, the agglomerated surfaces of GA@ZnO-AC were observed to have diminished after impregnation of GA on the surface of ZnO-AC. It shows that GA@ZnO-AC was successfully synthesized. The average particles ranged from 25.05 to 52.54 nm.

Thermogravimetric (TGA) analysis

The thermogravimetric (TGA) and derivative thermogravimetric (DTG) analyses used to investigate the thermal stability of the materials produced are presented in Fig. 8a through d. The TGA curve for Activated carbon (AC), as presented in Fig. 8a, shows that the weight of the AC began to decrease at 93.33 to 111 °C (15%). According to the DTG curve, the highest weight loss of 24.25% occurred at 800 °C. This is due to the breakdown of cellulose and hemicellulose71. The TGA and DTG curves for ZnO exhibited three distinct weight loss stages, as seen in Fig. 8b. A weight loss of 1.3% was detected between 25 and 147.3 °C, attributed to the evaporation of water content59. The second weight loss was 1.9% between 147.3 and 182 °C. A reduction was observed between 182 and 214 °C, resulting in a 2% weight loss. Another stage of weight loss was recorded between 182 and 270.67 °C, and between 270.67 and 449.67 °C, corresponding to 1% and 1.3%, respectively. A significant weight loss was observed between 449.67 and 565 °C, accounting for 14.22% weight loss due to the breakdown and removal of organic groups72. Finally, weight loss of 2.53% was observed between 565 and 800 °C. The TGA and DTG curve for ZnO-AC nanocomposite was presented in Fig. 8c. There is a 17% weight loss between 25 and 156 °C due to water evaporation. The second weight loss was 0.71% between 155 and 189.33 °C. The third weight loss of 4.12% between 189.33 and 713 °C is due to the breakdown of hemicellulose, cellulose, and lignin73,74. The final stage of decline was observed between 713 and 800 °C, resulting in a weight loss of 2.97%, which may indicate additional breakdown of lignin73. The TGA and DTG curve for GA@ZnO-AC nanocomposite was presented in Fig. 8d. The first stage of weight loss, a 16.6% decrease between 25 and 161.67 °C, s related to the evaporation of water59. The second weight loss was 1%, which occurred between 161.67 and 200 °C. The third weight loss of 4.21% between 200 and 725.67 °C is due to the breakdown of hemicellulose, cellulose, and lignin73,74. The final step was observed from 725.67 to 800 °C, resulting in a 2% weight loss, which could represent further breakdown of lignin74.

Effect of adsorption parameter

Influence of contact time and initial concentration

The adsorption efficiency of ZnO-AC and GA@ZnO-AC for the removal of methylene blue (MB) was examined by adjusting the initial MB concentration (30–70 mg/L) and contact time (0–180 min) in a batch experiment at 298 K, with other operation parameters kept constant. As shown in Figs. 9(a) and 9 (b), the MB dye is rapidly taken up by both ZnO-AC and GA@ZnO-AC within the first 20 min and then processed at a slower pace, eventually reaching equilibrium at 60 min. This could be attributable to the fast adsorption of MB onto the adsorbent’s accessible active sites. At low concentrations, practically all MB molecules were adsorbed onto the adsorbent surface. However, at higher concentrations, the adsorbent surface was rapidly saturated with MB75.

Effect of pH and pH(PZC)

Figure 9c–f shows the effect of pH and point of zero charge pH(PZC) of ZnO-AC and GA@ZnO-AC. Figure 9c–d depicts the pHpzc values of 7.25 for ZnO-AC and 7.15 for GA@ZnO-AC. This indicates that at pH values greater than 7.25 and 7.15, ZnO-AC and GA@ZnO-AC have a negative charge, allowing them to adsorb more methylene blue dye. Figure 9e, f depicts the effect of pH values ranging from 2 to 11 for ZnO-AC and GA@ZnO-AC. The finding showed that the percentage of MB removed with ZnO-AC and GA@ZnO-AC nanocomposites increases as the pH increases from 2 to 11. The highest percentage of MB was attained at pH 11, whereas the lowest percentage removal was achieved at pH 2. The percentage removal and adsorption capacity when the pH varied from 2 to 11 were 97.71-115.04 mg/g and 83.75–98.61% for ZnO-AC at 60 mg, and 101.48-137.63 mg/g and 72.49–98.30% for GA@ZnO-AC at 50 mg. This is mostly due to the adsorbent’s zero-point charge (pHzpc) of 7.25 and 7.15. This suggests that the ZnO-AC and GA@ZnO-AC become more negatively charged, which causes the electrostatic attraction between adsorbents and MB dye, leading to a rise in the removal of MB dye59,76,77. At a pH below the zero-point charge (pH < pHpzc), the adsorbent’s surface charge is dominated by protonation, resulting in hydrogen ions. This reduces MB removal due to greater competition between the H− on the active sites of the adsorbents and the MB cations78,79. Thus, electrostatic repulsion interactions between positively charged MB and positively charged adsorbent active surfaces generate the MB’s low percentage removal and adsorption capability59,80.

Influence of temperature

Temperature is a crucial controlling parameter in dye treatment, as most textile dye effluent is generated at extremely high temperatures. The study evaluated the effect of temperature on the uptake of MB by ZnO-AC and GA@ZnO-AC nanocomposites to determine the nature of the adsorption process. The experiment was conducted at various temperatures (298, 308, 318, 328, and 338 K) and under optimum conditions (initial concentration = 70 mg/L; speed = 200 rpm, time = 60 min; adsorbent dosage = 60 mg (ZnO-AC), 50 mg (GA@ZnO-AC), and volume = 100 mL, respectively). Figure 9g–h depicts how the adsorption capacity and percentage removal of MB decrease as temperature rises. These trends support the idea that adsorption is more effective at lower temperatures and less effective at higher ones78. This shows that the process is exothermic81,82. As the temperature increased from 298 to 338 K, the percentage of MB dye removal and adsorption capacity decreased from 115.04 to 113.72 mg/g and 98.61–97.47% for ZnO-AC (Fig. 9(g)) and 137.63-135.51 mg/g and 98.30-95.36% for GA@ZnO-AC (Fig. 9(h)), respectively. The lower the temperature of a gas molecule, the lower its kinetic energy, and hence the molecules move slower. Molecules travelling at lower speeds are easily adsorbed. Hence, the lower temperature favours physical adsorption.

Influence of adsorbent dose

The effect of ZnO-AC and GA@ZnO-AC nanocomposite dosage on MB dye adsorption was examined under optimum conditions, and the results are presented in Fig. 9i–j. An increase in the ZnO-AC dosage from 30 to 60 mg resulted in 70.79–98.61% uptake of MB dye, as shown in Fig. 9i. Furthermore, increasing the adsorbent dosage resulted in a decrease in MB removal83. This finding could be attributed to the fact that, at lower ZnO-AC nanocomposite doses, the MB dye molecules compete for adsorption with limited adsorption sites on the adsorbents78,84. Likewise, increasing the GA@ZnO-AC dosage from 30 to 50 mg resulted in 66.72–98.30% removal of MB dye, while further increasing it from 50 to 80 mg caused a reduction in MB dye uptake, as shown in Fig. 9(j). The phenomenon may be associated with the notion that a greater number of adsorptive sites were generated at increased adsorbent dosage. However, the utilisation of these sites is limited at certain concentrations of MB dye solution85,86. However, overlapping adsorption sites or overcrowding of the adsorbent can cause screening effects, resulting in no further increase in the percentage removal of the MB dye78,87.

Adsorption influence of (a, b) contact time, (c, d) Point of zero charges, (e, f) pH, (g, h) temperature, (i, j) adsorbent dosage of methylene blue removal on ZnO-AC and GA@ZnO-AC nanocomposite (initial concentration = 70 mg/L; speed = 200 rpm, time = 60 min; adsorbent dosage = 60 mg (ZnO-AC), 50 mg (GA@ZnO-AC), and volume = 100 mL, respectively).

Isotherm studies

Developing an appropriate isotherm model for adsorption is essential to designing and optimising adsorption processes. In an equilibrium adsorption state, the isotherm determines the distribution of adsorbed molecules between the solid and liquid phases. The adsorption experimental data were fitted to four isotherms, including the Dubinin–Radushkevich (D–R), Temkin, Freundlich, and Langmuir models, as shown in Eqs. 4–7.

Where \({q}_{s}\) is the maximum sorption capacity, \({q}_{e}\) is the quantity of pollutant adsorbed per unit weight of the adsorbent (mg/g), \({K}_{T}\) is the Temkin constant (L/g) and \({B}_{T}\) is heat of adsorption (J/mol), 1/n is adsorption intensity and \({K}_{f}\) is Freundlich, \({K}_{L}\) and \({q}_{m}\) are the Langmuir constant (L/g) and maximum adsorption capacity (mg/g).

Table 1; Fig. 10a–d show that the adsorption of MB onto ZnO-AC is more suitable for the Langmuir model, suggesting a monolayer adsorption process. The Langmuir (< 0.97), Freundlich (< 0.94), Temkin (0.92), and Dubinin–Radushkevich (0.79). The highest adsorption capacities were 153.85, 151.52, 147.06, and 138.89 mg/g at 298, 308, 318, and 328 K, respectively. The separation factor (RL), as determined by Eq. (8), predicts the favorability of the adsorption process.

Where \({K}_{L}\) Denotes the Langmuir constant (L/g), and Co (mg/L) represents the initial concentration of MB dye. The RL number indicates whether the adsorption process is favorable (0 < RL < 1), unfavorable (RL > 1), linear (RL = 1), or irreversible (RL = 0)88.

The RL value is the dimensional constant separation factor or equilibrium constant, indicating the form and type of the isotherm. The RL values obtained at different temperatures were 0.7109 (298 K), 0.6573 (308 K), 0.6643 (318 K), and 0.6275 (328 K). The RL results obtained were < 1, suggesting favorability of the Langmuir isotherm89,90,91. Likewise, Table 1; Fig. 11a–d show the adsorption isotherm parameter values determined from the MB adsorption linear plots on GA@ZnO-AC. The Langmuir models fit the adsorption data well, suggesting monolayer adsorption. The Langmuir model (R2 < 0.98) best explains the adsorption of MB onto the GA@ZnO-AC surface, followed by the FreundliR2 c h (< 0.97), TemkR2 i n (< 0.96), and Dubinin–RadushkeviR2 c h (< 0.80) models. Furthermore, the highest adsorption capacities were 175.44, 172.41, 144.93, and 140.85 mg/g at 298, 308, 318, and 328 K, respectively. Freundlich isotherm resulted in n values greater than one. A value larger than one implies suitable adsorption92,93. According to the Temkin and D-R models, the adsorption system is physisorption and characterized by weak van der Waals forces (E and BT < 8 kJ/mol)94,95,96. The positive value of the heat of adsorption of the Temkin isotherm (BT) indicates that it is exothermic, which also agrees with the effect of temperature82. In summary, the adsorption isotherm study revealed that the Langmuir isotherm best described the adsorption of MB onto the adsorbent. This indicated that the nature of the adsorption is monolayer and homogeneity81,92. For comparison, Table 4 presents the qmax values for various adsorbents used in previous studies for MB adsorption. The adsorbents used in this work (ZnO-AC and GA@ZnO-AC) exhibit high adsorption capabilities.

Kinetic studies

The kinetic study of MB dye solution onto ZnO-AC and GA@ZnO-AC was investigated using four kinetic models (pseudo-first order (PFO), pseudo-second-order (PSO), intra-particle diffusion model, and Elovich’s Equation) as shown in Eqs. 9–12.

Where \({q}_{e}\)and \({q}_{t}\)are the quantities adsorbed at equilibrium and over a given time interval. \({K}_{1}\) is PFO constant, \({K}_{2}\) is PSO constant, \({K}_{ip}\) is constant (mg/g \({min}^{1/2}).\) C is the adsorbent thickness, \({\alpha }_{e}\) and \({\beta }_{e}\) are the initial adsorption rate (mg/g. min) and desorption constant (g/mg).

Table 2; Fig. 12a–d for ZnO-AC and Table 2; Fig. 13a–d for GA@ZnO-AC revealed that the adsorption behaviour of MB on ZnO-AC and GA@ZnO-AC was best fitted by the pseudo-second-order with R2(0.9993) and R2 (0.9979), respectively. In addition, the calculated adsorption capacity (qe, cal) values for the pseudo-second-order were more closely aligned with the adsorption experimental capacity (qe, exp) values at various concentrations97,98,99. Therefore, the result suggested that the rate-limiting step may be the chemisorption process involving electrostatic interactions100. Figures 12c and 13c show that the linear graph for intraparticle diffusion does not pass through the origin due to the variances in the mass transfer between the initial and final stages of the adsorption of MB. This implies that the process is multi-step and involves diffusion adsorption into the interior and external surfaces101. Furthermore, the Elovich model adsorption rate constant (α) values at various concentrations were higher than the desorption rate constant (β), indicating that MB adsorption onto ZnO-AC and GA@ZnO-AC was higher at the initial stage. This implies a higher adsorption rate than desorption102,103. The model was supported by lower values of SSE and χ2, all of which followed the second pseudo-second order. When the plot of four adsorption kinetics models was compared, the adsorption data fit perfectly with the pseudo second order model, indicating that the adsorption process is governed by chemisorption104, which involves the sharing or exchange of surface electrons between the active sites of adsorbent material and MB molecules in the solution105.

Adsorption thermodynamics study

Adsorptive thermodynamics of GA@ZnO-AC and ZnO-AC were carried out at temperatures (298–328 K) to determine the value of enthalpy change (ΔH°), entropy change (ΔS°), and Gibbs free energy (ΔG°), which were determined using Eqs. 13–16, respectively106,107,108,109,110.

Where \(\varDelta G\) is Gibb’s free energy (KJ/mol), R and T are the gas constant (8314 J mol), and Absolute temperature. \({K}_{d}\) is the equilibrium constant, \({q}_{e}\)and \({C}_{e}\)are quantity adsorbed and concentration at equilibrium, \(\varDelta S\) and \(\varDelta H\) are the change in entropy (KJ/mol. K) and enthalpy (KJ/mol).

The temperature-dependent graph was used to determine the enthalpy change (ΔH°) and entropy change (ΔS°). Figure 14a–b shows the slope and intercept of In Kd vs. 1/T, which were used to calculate ΔS° and ΔH°. Table 3 presents the thermodynamic results for the absorption of MB on ZnO-AC and GA@ZnO-AC. The negative value of ΔG° across all temperatures suggests a spontaneous and feasible process. The degree of spontaneity of the adsorption process decreases with increasing temperature111. The adsorption of MB dye onto ZnO-AC and GA@ZnO-AC is physisorption since ΔGo values are within the range of 0 to −20 kJ/mol112,113,114,115. Table 3 shows that ZnO-AC and GA@ZnO-AC adsorb MB dye more efficiently at lower temperatures, as indicated by an increase in ΔG° values116. The negative values of ΔH° indicate an exothermic process of MB dye adsorption onto the adsorbents (GA@ZnO-AC and ZnO-AC). The negative values of ΔS° imply less randomness of the adsorbed MB dye at the adsorbent-solution interface during the adsorption process. This suggests a stable system with no structural changes at the liquid-solid interface117.

Comparison of the adsorption of MB with various nanocomposites

The percentage removal and adsorption capacity of MB with adsorbents are itemized in Table 4. Table 4 shows that ZnO-AC and GA@ZnO-AC materials are more effective in removing MB compared to other adsorbents. It further indicates that methylene blue can be removed from wastewater using adsorption techniques with different adsorbent materials.

Cost evaluation of preparation of ZnO-AC and GA@ZnO-AC

Cost is one of the main elements that can attract industrialists to adsorbents. Researchers rarely report this because their primary focus is on the performance of the adsorbent. The current application of nanocomposites as a prospective and viable material for environmental cleanup has accelerated the need for cost estimates in assessing the material’s cost-effectiveness125. As a result, Table 5 presents the cost of developing ZnO, GA@ZnO-AC, and ZnO-AC for MB dye treatment through various steps, including reagent costs (zinc chloride, hydrogen chloride, sodium hydroxide, and ethanol), electricity costs (hotplate, oven, centrifuge, and furnace), and the cross-linking process. According to Bello et al.126the cost of commercial activated carbon is at least USD 259.50 per kilogram. As a result, its exorbitant cost limits its long-term use and availability. ZnO-AC and GA@ZnO-AC are cost-effective due to the low or no cost of the starting material.

Mechanisms of adsorption

The mechanism influencing the interaction of the MB molecule adsorption on ZnO-AC and GA@ZnO-AC was investigated using pH and intraparticle diffusion. The pH influence on the adsorptive efficiency of ZnO-AC and GA@ZnO-AC towards MB showed that the electrostatic interaction was the key mechanism governing the adsorption reaction. When the pH solution exceeded the PZC (7.15) for ZnO-AC and the PZC (7.25) for GA@ZnO-AC, the adsorption sites on ZnO-AC and GA@ZnO-AC became positively charged, enabling a strong electrostatic interaction with the positively charged cationic MB. The interaction between the positively charged ions on the surface of adsorbent (ZnO-AC and GA@ZnO-AC) and the negatively charged ions of the MB enhanced the adsorption capability of the adsorbent (ZnO-AC and GA@ZnO-AC) to MB108,127. When proton acceptor and proton donor groups are activated, carboxylic and hydroxyl groups on the surface of the adsorbent connect with MB via hydrogen bonding128,129. MB might potentially adsorb on the adsorbent’s outer layer via π-π stacking108,130. Thus, the actual diffusion process during adsorption is often determined by intraparticle diffusion. The dominance of intra-particle diffusion as the rate-governing step is investigated by plotting qt against t1/2, which gives a straight line passing through the origin. The intercept provides information on the boundary layer thickness (Ci, mg/g), while the slope of this line indicates the rate constant of intra-particle diffusion (k_id, mg/g/min1/2). Regarding the adsorption of MB dye by adsorbent (ZnO-AC and GA@ZnO-AC), Figs. 12c, 13c show that the linear graph for intraparticle diffusion does not pass through the origin due to the variances in the mass transfer between the initial and final stages of the adsorption of MB. This implies that the process is multi-step and involves diffusion adsorption into the interior and external surfaces101.

Effect of adsorbent recycling and reuseability

In an environmentally friendly application process, the reuse and recovery of adsorbents is economically necessary. This study evaluated the regeneration process by desorbing MB dye from the surfaces of ZnO-AC and GA@ZnO-AC, nanocomposites, after adsorption with an ethanol solution. Ethanol is employed to increase the polarity of the solvent, thereby disrupting the electrostatic interaction between the adsorbents and MB. Figure 15 indicates that the removal efficacy of MB dyes onto ZnO-AC and GA@ZnO-AC at the first stage was 98.04% (GA@ZnO-AC), 98.45% (ZnO-AC) and after four regenerations still was 87.79% (GA@ZnO-AC) and 71.09% (ZnO-AC), which elucidates that the adsorbents have excellent recycling and regeneration performance. Furthermore, GA@ZnO-AC exhibits higher removal efficacy than ZnO-AC at four regeneration cycles due to the presence of gallic acid. In addition, the presence of gallic acid enhances the chemical stability, enabling the GA@ZnO-ACo to maintain its structural and magnetic properties throughout this period124.

Conclusion

In this study, ZnO, ZnO-AC, and GA@ZnO-AC nanocomposites were prepared and analyzed by BET, XRD, FTIR, TGA, TEM, and SEM-EDX, with effective application as a nanostructure for treating MB from aqueous media. The ZnO-AC and GA@ZnO-AC nanostructures have demonstrated significant potential as an effective material in removing MB. The optimum conditions for MB adsorption onto ZnO-AC and GA@ZnO-AC were determined to be a pH of 11, a contact time of 60 min, a concentration of 70 mg/L, and an adsorbent dosage of 60 mg ZnO-AC. and 50 mg GA@ZnO-AC. The highest adsorption capacity and percentage removal were 153.85 mg/g. and 98.61% for ZnO-AC, 175.44 mg/g and 98.30% for GA@ZnO-AC, respectively. The maximum monolayer adsorption capacity obtained from adsorbents (ZnO-AC and GA@ZnO-AC) was higher than that obtained from other adsorbents. The adsorption process obeyed the Langmuir isotherm, and the kinetics study was better fitted to PSO than PFO kinetics, indicating the role of both the adsorbent and MB in the adsorption process. The negative values of ΔH°, ΔS°, and ΔG° confirmed that the adsorptive removal of MB onto ZnO-AC and GA@ZnO-AC was less random, exothermic, and feasible. The reusability investigation demonstrated a remarkable percentage removal of MB after five cycles, indicating their stability and potential for industrial treatment on a large scale. The research produced a hybrid nanocomposite that is both cost-effective and ideal for use as a high-performance adsorbent, making a significant contribution to addressing the environmental issues of dye adsorption from wastewater.

Data availability

All data generated or analyzed during this study are included in this article.

References

Ajibade, F. O. et al. Environmental pollution and their socioeconomic impacts, in Microbe Mediated Remediation of Environmental Contaminants, 321–354 (Elsevier, 2021). https://doi.org/10.1016/B978-0-12-821199-1.00025-0.

Li, X. et al. A developed method of water pollution control based on environmental capacity and environmental flow in Luanhe river basin. Water (Basel). 14 (5), 730 (2022).

Long, C. et al. Applications of carbon dots in environmental pollution control: a review. Chem. Eng. J. 406, 126848. https://doi.org/10.1016/j.cej.2020.126848 (2021).

Huang, Y., Mi, F., Wang, J., Yang, X. & Yu, T. Water pollution incidents and their influencing factors in China during the past 20 years. Environ. Monit. Assess. 194 (3), 182. https://doi.org/10.1007/s10661-022-09838-4 (2022).

Akhtar, A. B. T., Naseem, S., Yasar, A. & Naseem, Z. Persistent organic pollutants (POPs): Sources, types, impacts, and their remediation, pp. 213–246. (2021). https://doi.org/10.1007/978-981-15-5499-5_8

Rawat, K. Organic pollutants in wastewater and its remediation approaches using graphene adsorbent. Int. J. Agricult. Appl. Sci. 2(2), 8–13 (2021). https://doi.org/10.52804/ijaas2021.222

Mishra, S. et al. Biofilm-mediated bioremediation is a powerful tool for the removal of environmental pollutants. Chemosphere 294, 133609. https://doi.org/10.1016/j.chemosphere.2022.133609 (2022).

Novikau, R. & Lujaniene, G. Adsorption behaviour of pollutants: Heavy metals, radionuclides, organic pollutants, on clays and their minerals (raw, modified and treated): A review. J. Environ. Manag. 309, 114685. https://doi.org/10.1016/j.jenvman.2022.114685 (2022).

Yaashikaa, P. R., Kumar, P. S. & Karishma, S. Review on biopolymers and composites—Evolving material as adsorbents in removal of environmental pollutants. Environ. Res. 212, 113114. https://doi.org/10.1016/j.envres.2022.113114 (2022).

Lan, D. et al. Adsorptive removal of organic dyes via porous materials for wastewater treatment in recent decades: A review on species, mechanisms and perspectives. Chemosphere 293, 133464. https://doi.org/10.1016/j.chemosphere.2021.133464 (2022).

Jawed, A., Saxena, V. & Pandey, L. M. Engineered nanomaterials and their surface functionalization for the removal of heavy metals: A review. J. Water Process. Eng. 33, 101009. https://doi.org/10.1016/j.jwpe.2019.101009 (2020).

Khan, W. U., Ahmed, S., Dhoble, Y. & Madhav, S. A critical review of hazardous waste generation from textile industries and associated ecological impacts. J. Indian Chem. Soc. 100 (1), 100829. https://doi.org/10.1016/j.jics.2022.100829 (2023).

Balali-Mood, M., Naseri, K., Tahergorabi, Z., Khazdair, M. R. & Sadeghi, M. Toxic mechanisms of five heavy metals: Mercury, lead, chromium, cadmium, and arsenic, Front Pharmacol 12 (2021). https://doi.org/10.3389/fphar.2021.643972

Mbuyamba, N. S., Tshilanda, D. D., Mpiana, T. P., Ngbolua, K. T. N. & Kaki, C. Assessment of arsenic, lead, mercury and cadmium pollution in soils, sediments and mining residues of the Lite-Bala site using the GRADSOD approach. Open. J. Soil. Sci. 15 (02), 136–155. https://doi.org/10.4236/ojss.2025.152007 (2025).

Yang, Y. et al. Hydrogels for the removal of the methylene blue dye from wastewater: A review. Environ. Chem. Lett. 20 (4), 2665–2685. https://doi.org/10.1007/s10311-022-01414-z (Aug. 2022).

Munir, M. et al. Jul., Effective adsorptive removal of methylene blue from water by didodecyldimethylammonium bromide-modified brown clay. ACS Omega 5 (27), 16711–16721 (2020). https://doi.org/10.1021/acsomega.0c01613

Mansouri, F., Chouchene, K., Roche, N. & Ksibi, M. Removal of pharmaceuticals from water by adsorption and advanced oxidation processes: State of the Art and trends. Appl. Sci. 11 (14), 6659. https://doi.org/10.3390/app11146659 (2021).

Moosavi, S. et al. Application of efficient magnetic particles and activated carbon for dye removal from wastewater. ACS Omega 5(33), 20684–20697 (2020). https://doi.org/10.1021/acsomega.0c01905

Iroegbu, A. & Ray, S. Bamboos: From bioresource to sustainable materials and chemicals. Sustainability 13 (21), 12200 (2021). https://doi.org/10.3390/su132112200

Hada, S. et al. An overview on biomass of bamboo as a source of bioenergy. In Biotechnology for biofuels: A sustainable green energy solution 241–265 (Springer, 2020). https://doi.org/10.1007/978-981-15-3761-5_10.

Negara, D. N. K. P., Nindhia, T. G. T., Surata, I. W., Sucipta, M. & Hidajat, F. Activated carbon characteristics of Tabah bamboo that physically activated under different activation time. IOP Conf. Ser. Mater. Sci. Eng. 539 (1), 012011. https://doi.org/10.1088/1757-899X/539/1/012011 (2019).

Choy, K. K. H., Barford, J. P. & McKay, G. Production of activated carbon from bamboo scaffolding waste—process design, evaluation and sensitivity analysis. Chem. Eng. J. 109, 1–3. https://doi.org/10.1016/j.cej.2005.02.030 (May 2005).

Nasiri, A., Heidari, M. R., Javid, N. & Yazdanpanah, G. New efficient and recyclable magnetic nanohybrid adsorbent for the metronidazole removal from simulated wastewater. J. Mater. Sci. Mater Electron. 33(33), 25103–25126 (2022). https://doi.org/10.1007/S10854-022-09216-3

Amirmahani, N., Mahmoodi, N. O., Bahramnejad, M. & Seyedi, N. Recent developments of metallic nanoparticles and their catalytic activity in organic reactions. J. Chin. Chem. Soc. 67 (8), 1326–1337 (2020). https://doi.org/10.1002/JCCS.201900534

Amirmahani, N., Rashidi, M. & Mahmoodi, N. O. Synthetic application of gold complexes on magnetic supports. Appl. Organomet. Chem. 34 (5). https://doi.org/10.1002/AOC.5626 (2020).

Abolghasemi, S., Nasiri, A., Hashemi, M., Rajabi, S. & Rahimi, F. Magnetic nanocomposites: innovative adsorbents for antibiotics removal from aqueous environments–a narrative review, Appl. Water Sci. 15(2), 1–54, Feb. (2025). https://doi.org/10.1007/S13201-025-02360-1/FIGURES/17

Nasiri, A., Malakootian, M. & Javid, N. Modelling and optimization of lead adsorption by CoFe2O4@CMC@HZSM-5 from aqueous solution using response surface methodology, Desalination Water Treat 248, 134–148 (2022). https://doi.org/10.5004/DWT.2022.28046

Amirmahani, N., Mahdizadeh, H., Seyedi, N., Nasiri, A. & Yazdanpanah, G. Synthesis and performance evaluation of chitosan/zinc oxide nanocomposite as a highly efficient adsorbent in the removal of reactive red 198 from water. J. Chin. Chem. Soc. 70(4), 869–878 (2023). https://doi.org/10.1002/JCCS.202200514

Wu, H. et al. Three-dimensional zinc oxide decorated with cadmium sulfide nanoparticles heterogenous nanoarchitectures with expedited charge separation toward efficient photocatalytic degradation of organic pollutants. Mater. Sci. Eng. B. 292, 116459. https://doi.org/10.1016/J.MSEB.2023.116459 (2023).

Garg, S. & Goel, N. Encapsulation of heavy metal ions via adsorption using cellulose/zno composite: First principles approach. J. Mol. Graph Model. 124, 108566. https://doi.org/10.1016/j.jmgm.2023.108566 (Nov. 2023).

Shrestha, P. et al. Dec., Decoration of zinc oxide nanorods into the surface of activated carbon obtained from agricultural waste for effective removal of methylene blue dye. Materials 13(24), 5667 (2020). https://doi.org/10.3390/ma13245667

Ong, C. B., Ng, L. Y. & Mohammad, A. W. A review of ZnO nanoparticles as solar photocatalysts: synthesis, mechanisms and applications. Renew. Sustain. Energy Rev. 81, 536–551. https://doi.org/10.1016/j.rser.2017.08.020 (Jan. 2018).

Hadian, D., Alni, A., Patah, A., Handayani, N. & Zulfikar, M. A. Efficient removal of Pb(II) ion using Tio2/Zno/Sio2 nanocomposite from aqueous solutions via Adsorption-Photocatalysis process. Sains Malays. 53 (5), 1133–1147. https://doi.org/10.17576/jsm-2024-5305-13 (May 2024).

Motitswe, M. G., Badmus, K. O. & Khotseng, L. Application of reduced graphene oxide-zinc oxide nanocomposite in the removal of Pb(II) and Cd(II) contaminated wastewater. Appl. Nano 5(3), 162–189 (2024). https://doi.org/10.3390/applnano5030012

Amirmahani, N., Mahdizadeh, H., Seyedi, N., Nasiri, A. & Yazdanpanah, G. Synthesis and performance evaluation of chitosan/zinc oxide nanocomposite as a highly efficient adsorbent in the removal of reactive red 198 from water. J. Chin. Chem. Soc. 70(4), 869–878. https://doi.org/10.1002/JCCS.202200514;CTYPE:STRING:JOURNAL. (2023).

Akpomie, K. G. & Conradie, J. Synthesis, characterization, and regeneration of an inorganic–organic nanocomposite (ZnO@biomass) and its application in the capture of cationic dye. Sci. Rep. 10 (1), 1–12. https://doi.org/10.1038/S41598-020-71261- (2020).

El-Shorbagy, H. G., El-Kousy, S. M., Elwakeel, K. Z. & El-Ghaffar, M. A. A. Eco-friendly chitosan condensation adduct resins for removal of toxic silver ions from aqueous medium. J. Ind. Eng. Chem. 100, 410–421 (2021). https://doi.org/10.1016/J.JIEC.2021.04.029

El-Shorbagy, H. G. Efficient removal of methylene blue dye from aqueous medium utilizing eco-friendly Chitosan adsorbents. J Dispers Sci. Technol (2024). https://doi.org/10.1080/01932691.2024.2381038.

Badria, F. A. & Badria, F. A. Phenolic compounds—chemistry, synthesis, diversity, non-conventional industrial, pharmaceutical and therapeutic applications 26 (2022). https://doi.org/10.5772/INTECHOPEN.94825

da Silva, A. P. G., Sganzerla, W. G., John, O. D. & Marchiosi, R. A comprehensive review of the classification, sources, biosynthesis, and biological properties of hydroxybenzoic and hydroxycinnamic acids. Phytochem. Rev. 24(2), 1061–1090 (2023). https://doi.org/10.1007/S11101-023-09891-Y

Vera, J. et al. Antioxidant activity as an indicator of the efficiency of plant extract-mediated synthesis of zinc oxide nanoparticles. Antioxidants 12, 784 (2023). https://doi.org/10.3390/ANTIOX12040784

Nska, L. R. et al. Elicitation and enhancement of phenolics synthesis with zinc oxide nanoparticles and LED light in lilium candidum L. Cultures in vitro. Agron. 1313, (6), 1437. https://doi.org/10.3390/AGRONOMY13061437 (2023).

Kuppusamy, S., Thavamani, P., Megharaj, M. & Naidu, R. Bioremediation potential of natural polyphenol rich green wastes: A review of current research and recommendations for future directions. Environ. Technol. Innov. 4, 17–28 (2015). https://doi.org/10.1016/J.ETI.2015.04.001

Lima, J. P. P., Tabelini, C. H. B. & Aguiar, A. A review of Gallic Acid-Mediated Fenton processes for degrading emerging pollutants and dyes. Molecules 2023. 28(3), 1166. https://doi.org/10.3390/MOLECULES28031166 (2023).

Santoso, S. P. et al. Unlocking the potential of Gallic Acid-Based metal phenolic networks for innovative adsorbent design. Molecules 30 (6), 1218. https://doi.org/10.3390/MOLECULES30061218/S1 (2025).

Salih, S. J., Abd Ali, L. I. & Hamad, W. M. Novel synthesis and characterization of magnesium-doped CoFe2O4 nanoparticles–SiO2–3-aminopropylethoxysilane–gallic acid magnetic nanocomposite for effective removal of cationic dyes. Arab. J. Chem. 17 (3), 105647 (2024).

Eskikaya, O. et al. Synthesis of two different zinc oxide nanoflowers and comparison of antioxidant and photocatalytic activity. Chemosphere 306, 135389. https://doi.org/10.1016/J.CHEMOSPHERE.2022.135389 (2022).

Ndagijimana, P. et al. Simultaneous removal of ibuprofen and bisphenol A from aqueous solution by an enhanced cross-linked activated carbon and reduced graphene oxide composite. Sep. Purif. Technol. 299, 121681 (2022). https://doi.org/10.1016/J.SEPPUR.2022.121681

Naciri, Y. et al. Facile synthesis, characterization and photocatalytic performance of Zn3(PO4)4 platelets toward photodegradation of Rhodamine B dye. J. Environ. Chem. Eng. 6 (2), 1840–1847. https://doi.org/10.1016/J.JECE.2018.02.009 (2018).

Oluwasogo, D. A. et al. Biosynthetic modulation of carbon-doped ZnO for rapid photocatalytic endocrine disruptive remediation and hydrogen evolution. J. Clean. Prod. 394, 136393. https://doi.org/10.1016/J.JCLEPRO.2023.136393 (2023).

W. Heng et al. Insights into cocrystallization and coamorphization engineering techniques in the delivery of traditional chinese medicine: Formation mechanism, solid-state characterization, and improved pharmaceutical properties. Cryst. Growth Des. 22(8), 5110–5134 (2022). https://doi.org/10.1021/ACS.CGD.1C01352/ASSET/IMAGES/MEDIUM/CG1C01352_0019.GIF

Singh, D., Singh Maniyari Rawat, M., Semalty, A. & Semalty, M. Gallic acid-phospholipid complex: Drug incorporation and physicochemical characterization. Lett Drug Des. Discov. 8 (3), 284–291 (2011). https://doi.org/10.2174/157018011794578240

Petrisor, G. et al. Mesoporous silica materials loaded with gallic acid with antimicrobial potential. Nanomaterials 12 (10) (2022). https://doi.org/10.3390/NANO12101648

Wang, A., Xu, W., Sun, Y., Sun, K. & Jiang, J. Heterogeneous activated carbon with graphitized shell and hydrophilic pores integrating high conductivity and pore affinity for excellent rate performance supercapacitors. Fuel 310, 122410. https://doi.org/10.1016/J.FUEL.2021.122410 (Feb. 2022).

Jasri, K. et al. Mesoporous activated carbon produced from mixed wastes of oil palm frond and palm kernel shell using microwave radiation-assisted K2CO3 activation for methylene blue dye removal: Optimization by response surface methodology. Diam. Relat. Mater. 131, 109581. https://doi.org/10.1016/J.DIAMOND.2022.109581 (2023).

Yuan, J. et al. Preparation of N, O co-doped carbon nanotubes and activated carbon composites with hierarchical porous structure for CO2 adsorption by coal pyrolysis. Fuel 333, 126465. https://doi.org/10.1016/J.FUEL.2022.126465 (2023).

Saleh, T. A., Alhooshani, K. R. & Abdelbassit, M. S. A. Evaluation of AC/ZnO composite for sorption of dichloromethane, trichloromethane and carbon tetrachloride: Kinetics and isotherms. J. Taiwan Inst. Chem. Eng. 55, 159–169 (2015). https://doi.org/10.1016/J.JTICE.2015.04.004

Norozi, K., Mansouri, M., Karamian, E. & Maleki, B. Activated carbon/ZnO-Ni Nanoflower composite as an efficient photocatalyst for enhanced degradation of reactive red 120 dye under LED light. Feb https://doi.org/10.21203/RS.3.RS-2472573/V1 (2023).

Dada, A. O. et al. Zinc oxide decorated plantain Peel activated carbon for adsorption of cationic malachite green dye: Mechanistic, kinetics and thermodynamics modeling. Environ. Res. 252, 119046. https://doi.org/10.1016/J.ENVRES.2024.119046 (Jul. 2024).

Md Salim, R., Asik, J. & Sarjadi, M. S. Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena Leucocephala bark. Wood Sci. Technol. 55 (2), 295–313. https://doi.org/10.1007/S00226-020-01258-2/TABLES/1 (s2021).

Kang, D. et al. Carbon fibers derived from oleic Acid-Functionalized lignin via thermostabilization accelerated by UV irradiation. ACS Sustain. Chem. Eng. 9, 5204–5216. https://doi.org/10.1021/ACSSUSCHEMENG.1C00574/SUPPL_FILE/SC1C00574_SI_001.PDF (2021).

Aminu, I. et al. Adsorption isotherms and kinetic studies of Congo-Red removal from waste water using activated carbon prepared from jujube seed. Am. J. Analyt. Chem. 11 (1), 47–59. https://doi.org/10.4236/AJAC.2020.111004 (Jan. 2020).

Malakootian, M., Hashemi, M., Toolabi, A. & Nasiri, A. Investigation of nickel removal using poly(amidoamine) generation 4 dendrimer (PAMAM G4) from aqueous solutions. J. Eng. Res. 6(2). (2018). https://kuwaitjournals.org/jer/index.php/JER/article/view/3360

Intarasuwan, K., Amornpitoksuk, P., Suwanboon, S. & Graidist, P. Photocatalytic dye degradation by ZnO nanoparticles prepared from X2C2O4 (X = H, Na and NH4) and the cytotoxicity of the treated dye solutions. Sep. Purif. Technol. 177, 304–312 (2017).

Nazim, V. S., El-Sayed, G. M., Amer, S. M. & Nadim, A. H. Functionalized SnO2 nanoparticles with Gallic acid via green chemical approach for enhanced photocatalytic degradation of citalopram: Synthesis, characterization and application to pharmaceutical wastewater treatment. Environ. Sci. Pollut. Res. 30 (2), 4346–4358. https://doi.org/10.1007/S11356-022-22447-5/FIGURES/9 (2023).

Loo, W. W., Pang, Y. L., Wong, K. H., Lim, S. & Mah, S. K. Adsorption-photocatalysis of organic dyes using empty fruit bunch activated carbon-metal oxide photocatalyst. IOP Conf. Ser. Mater. Sci. Eng. 458 (1), 012042. https://doi.org/10.1088/1757-899X/458/1/012042 (Dec. 2018).

Ong, C. B., Mohammad, A. W., Rohani, R., Ba-Abbad, M. M. & Hairom, N. H. H. Solar photocatalytic degradation of hazardous congo red using low-temperature synthesis of zinc oxide nanoparticles. Process Saf. Environ. Prot. 104, 549–557. https://doi.org/10.1016/J.PSEP.2016.04.006 (2016).

Saini, J., Garg, V. K., Gupta, R. K. & Kataria, N. Removal of orange G and Rhodamine B dyes from aqueous system using hydrothermally synthesized zinc oxide loaded activated carbon (ZnO-AC). J. Environ. Chem. Eng. 5 (1), 884–892. https://doi.org/10.1016/J.JECE.2017.01.012 (2017).

Mo, X. et al. Activation and deactivation characteristics of sulfonated carbon catalysts. J. Catal. 254 (2), 332–338. https://doi.org/10.1016/J.JCAT.2008.01.011 (2008).

Saramas, D. & Ekgasit, S. Nano-zinc oxide-doped activated carbon from popped rice and its application for feed additive. Eng. J. 25 (3), 41–50 (2021).

Zhang, S., Fan, X. & Xue, J. A novel magnetic manganese oxide Halloysite composite by one-pot synthesis for the removal of methylene blue from aqueous solution. J. Alloys Compd. 930, 167050 (2023).

Mashrai, A., Khanam, H. & Aljawfi, R. N. Biological synthesis of ZnO nanoparticles using C. albicans and studying their catalytic performance in the synthesis of steroidal pyrazolines. Arab. J. Chem. 10, S1530–S1536 (2017).

Conde-Rivera, L. R., Suarez-Escobar, A. F., Marin-Perez, J. J., Junco-Rodriguez, M. J. & Lopez-Suarez, F. E. TiO2 supported on activated carbon from tire waste for ibuprofen removal. Mater. Lett. 291, 129590. https://doi.org/10.1016/J.MATLET.2021.129590 (2021).

Awasthi, M. K. et al. Refining biomass residues for sustainable energy and bio-products: an assessment of technology, its importance, and strategic applications in circular bio-economy. Renew. Sustain. Energy Rev. 127, 109876. https://doi.org/10.1016/J.RSER.2020.109876 (2020).

Moradi, O., Pudineh, A. & Sedaghat, S. Synthesis and characterization agar/go/zno NPs nanocomposite for removal of Methylene blue and Methyl orange as Azo dyes from food industrial effluents. Food Chem. Toxicol. 169, 113412. https://doi.org/10.1016/J.FCT.2022.113412 (2022).

He, H. et al. Exploring green and efficient zero-dimensional carbon-based inhibitors for carbon steel: from performance to mechanism. Constr. Build. Mater. 411, 134334 (2024).

Pasgar, A., Nasiri, A. & Javid, N. Single and competitive adsorption of Cu2+ and Pb2+ by tea pulp from aqueous solutions, Environ. Health Eng. Manag. 9 (1), 65–74 (2022). https://doi.org/10.34172/EHEM.2022.08

Olafadehan, O. A., Bello, V. E., Amoo, K. O. & Bello, A. M. Isotherms, kinetic and thermodynamic studies of methylene blue adsorption on Chitosan flakes derived from African giant snail shell. Afr. J. Environ. Sci. Technol. 16 (1), 37–70. https://doi.org/10.5897/AJEST2021.3065 (2022).

Bouyahia, C. et al. Influence of extraction techniques on the adsorption capacity of methylene blue on sawdust: Optimization by full factorial design. Mater. Sci. Energy Technol. 6, 114–123. https://doi.org/10.1016/J.MSET.2022.12.004 (2023).

Wang, F. et al. Adsorption of bisphenol A on peanut shell biochars: The effects of surfactants. J. Chem. 2019 (1), 2428505. https://doi.org/10.1155/2019/2428505 (2019).

Adeoye, J. B. et al. Adsorptive removal of cadmium (II) and Asensic (III) ion from aqueous solution using zeolite Y synthesized from Kaolin. In International Conference on Science, Engineering and Business for Sustainable Development Goals, SEB-SDG 2023 (2023). https://doi.org/10.1109/SEB-SDG57117.2023.10124495

Edet, U. A. & Ifelebuegu, A. O. Kinetics, isotherms, and thermodynamic modeling of the adsorption of phosphates from model wastewater using recycled brick waste. Processes 2020. 8 (6), 665. https://doi.org/10.3390/PR8060665 (2020).

Abrishamkar, S., Mohammadi, A., De La Vega, J., Wang, D. Y. & Kalali, E. N. Layer-by-layer assembly of Calixarene modified GO and LDH nanostructures on flame retardancy, smoke suppression, and dye adsorption behavior of flexible polyurethane foams. Polym. Degrad. Stab. 207, 110242. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2022.110242 (2023).

Davarcı, D., Duyar, C. & Zorlu, Y. 3D Ag(I) coordination polymer constructed from a flexible pyridyloxycyclotetraphoshazene linker: Synthesis, crystal structure and dye adsorption properties. Polyhedron 231, 116250. https://doi.org/10.1016/J.POLY.2022.116250 (2023).

Rostamian, M. et al. Introducing a bio sorbent for removal of methylene blue dye based on flexible poly(glycerol sebacate)/chitosan/graphene oxide ecofriendly nanocomposites. Chemosphere 289, 133219. https://doi.org/10.1016/J.CHEMOSPHERE.2021.133219 (2022).

Alghamdi, A. A. et al. Efficient adsorption of lead (ii) from aqueous phase solutions using polypyrrole-based activated carbon. Materials (Basel) 12 (12) (2020). https://doi.org/10.3390/ma12122020

Benzaoui, T., Selatnia, A. & Djabali, D. Adsorption of copper (II) ions from aqueous solution using bottom Ash of expired drugs incineration. Adsorpt. Sci. Technol. 36, 1–2 (2018).

Chuenpratoom, T., Hemavibool, K., Rermthong, K. & Nanan, S. Removal of lead by Merlinoite prepared from sugarcane Bagasse Ash and kaolin: Synthesis, isotherm, kinetic, and thermodynamic studies. Molecules. 26 (24), 7550 (2021). https://doi.org/10.3390/MOLECULES26247550 (2021).

Elmorsi, T. M., Mohamed, Z. H., Shopak, W. & Ismaiel, A. M. Kinetic and equilibrium isotherms studies of adsorption of Pb (II) from water onto natural adsorbent. J. Environ. Prot. (Irvine Calif.). 5 (17), 1667–1681 (2014).

Musah, M. et al. Adsorption kinetics and isotherm models: A review. CaJoST 4 (1), 20–26 (2022).

Wang, J. & Guo, X. Adsorption isotherm models: Classification, physical meaning, application and solving method. Chemosphere 258, 127279. https://doi.org/10.1016/j.chemosphere.2020.127279 (2020).

Takele, T., Angassa, K., Abewaa, M., Kebede, A. M. & Tessema, I. Adsorption of methylene blue from textile industrial wastewater using activated carbon developed from H3PO4-activated Khat stem waste. Biomass Convers. Biorefin. 15 (3), 4085–4108. https://doi.org/10.1007/S13399-023-05245-Y/METRICS (Feb. 2023).

Dimbo, D. et al. Methylene blue adsorption from aqueous solution using activated carbon of Spathodea campanulata. Results Eng. 21, 101910. https://doi.org/10.1016/J.RINENG.2024.101910 (2024).

Hu, Q. & Zhang, Z. Application of Dubinin–Radushkevich isotherm model at the solid/solution interface: A theoretical analysis. J. Mol. Liq. 277, 646–648 (2019).

Al-Ghouti, M. A. & Da’ana, D. A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 393, 122383. https://doi.org/10.1016/j.jhazmat.2020.122383 (2020).

Sadeghi, M., Moradian, M., Tayebi, H. A. & Mirabi, A. Removal of penicillin G from aqueous medium by PPI@SBA-15/ZIF-8 super adsorbent: Adsorption isotherm, thermodynamic, and kinetic studies. Chemosphere 311, 136887. https://doi.org/10.1016/J.CHEMOSPHERE.2022.136887 (2023).

Kul, A. R., Aldemir, A., Alkan, S., Elik, H. & Çalışkan, M. Adsorption of basic blue 41 using Juniperus excelsa: Isotherm, kinetics and thermodynamics studies. Environ. Res. Technol. 2 (3), 112–121 (2019).

Gabriela, C., Simona, B., Maria, H. & Arch Kinetic and equilibrium studies on adsorption of Reactive Blue 19 dye from aqueous solutions by nanohydroxyapatite adsorbent. Environ. Prot., 42, 3–11, (2016).

Ofomaja, A. E., Naidoo, E. B. & Pholosi, A. Intraparticle diffusion of cr (VI) through biomass and magnetite coated biomass: A comparative kinetic and diffusion study. S. Afr. J. Chem. Eng. 32 (1), 39–55 (2020).

Mohamed Nasser, S., Abbas, M. & Trari, M. Understanding the rate-limiting step adsorption kinetics onto biomaterials for mechanism adsorption control. Prog. React. Kinetics Mech. 49 (2024). https://doi.org/10.1177/14686783241226858/ASSET/E6F515F2-D5A5-472C-89AF-644B278E27B2/ASSETS/IMAGES/LARGE/10.1177_14686783241226858-FIG4.JPG

Pathania, D., Sharma, S. & Singh, P. Removal of methylene blue by adsorption onto activated carbon developed from ficus carica Bast. Arab. J. Chem. 10, S1445–S1451 (2017).

Kim, S. H., Kim, D. S., Moradi, H., Chang, Y. Y. & Yang, J. K. Highly porous biobased graphene-like carbon adsorbent for dye removal: Preparation, adsorption mechanisms and optimization. J. Environ. Chem. Eng. 11 (2), 109278 (2023).

Obayomi, K. S. et al. Green synthesis of graphene-oxide based nanocomposites for efficient removal of methylene blue dye from wastewater. Desalination 564, 116749 (2023).

Abewaa, M., Adino, E. & Mengistu, A. Preparation of Rumex abyssinicus based biosorbent for the removal of Methyl orange from aqueous solution. Heliyon 9 (12), e22447. https://doi.org/10.1016/J.HELIYON.2023.E22447 (2023).

Mengistu, A., Abewaa, M., Adino, E., Gizachew, E. & Abdu, J. The application of Rumex abyssinicus based activated carbon for brilliant blue reactive dye adsorption from aqueous solution. BMC Chem. 17 (1), 1–24. https://doi.org/10.1186/S13065-023-01004-2/PEER-REVIEW (2023).

Zhang, M. et al. High and fast adsorption of Cd(II) and Pb(II) ions from aqueous solutions by a waste biomass based hydrogel. Sci. Rep. 10(1), 1–13 (2020). https://doi.org/10.1038/s41598-020-60160-w

Bhuyan, M. A. H., Carvalheiras, J., Novais, R. M. & Luukkonen, T. Adsorption of Pb(II) from synthetic wastewater with alkali-activated blast furnace slag and lignin composite. Clean. Eng. Technol. 27, 101033. https://doi.org/10.1016/J.CLET.2025.101033 (2025).

Adeoye, J. B. et al. Rapid adsorptive removal of eosin yellow and methyl orange using zeolite Y. Sci. Rep. 13 (1), 1–15. https://doi.org/10.1038/S41598-023-48675-4 (2023).

Harrou, A., Gharibi, E., Nasri, H. & Ouahabi, M. E. Thermodynamics and kinetics of the removal of methylene blue from aqueous solution by raw kaolin. SN Appl. Sci. 2 (2), 1–11 (2020). https://doi.org/10.1007/S42452-020-2067-Y/TABLES/1

Sibhat, W. T. et al. Effect of Ethiopian Kaolin treatment on the performance of adsorptive removal of methylene blue dye. Results Chem. 13, 102027. https://doi.org/10.1016/J.RECHEM.2025.102027 (2025).

Wang, Z. et al. Efficient adsorption of methylene blue from aqueous solution by graphene oxide modified persimmon tannins. Mater. Sci. Eng. C Mater. Biol. Appl. 108, 110196. https://doi.org/10.1016/j.msec.2019.110196 (2020).

Shah, J. A. et al. Melia Azedarach activated carbon and its novel TiO2 nanocomposite for chemisorption and photodecoloration of reactive orange 16: Isotherm and kinetic modeling. Curr. Anal. Chem. 17 (1), 107–119 (2021).

Kasbaji, M. et al. Implementation and physico-chemical characterization of new alkali-modified bio-sorbents for cadmium removal from industrial discharges: Adsorption isotherms and kinetic approaches. Process Biochem. 120, 213–226 (2022).

Yadav, M. K., Gupta, A. K., Ghosal, P. S. & Mukherjee, A. Remediation of carcinogenic arsenic by pyroaurite-based green adsorbent: Isotherm, kinetic, mechanistic study, and applicability in real-life groundwater. Environ. Sci. Pollut Res. Int. 27 (20), 24982–24998. https://doi.org/10.1007/s11356-020-08868-0 (2020).

Kang, H. J. & Kim, J. H. Adsorption kinetics, mechanism, isotherm, and thermodynamic analysis of Paclitaxel from extracts of taxus chinensis cell cultures onto Sylopute. Biotechnol. Bioprocess Eng. 24, 513–521 (2019).

Phatthanakittiphong, T. & Seo, G. T. Characteristic evaluation of graphene oxide for bisphenol A adsorption in aqueous solution. Nanomaterials 6 (7), 128 (2016). https://doi.org/10.3390/NANO6070128

Nuengmatcha, P., Mahachai, R. & Chanthai, S. Thermodynamic and kinetic study of the intrinsic adsorption capacity of graphene oxide for malachite green removal from aqueous solution. Orient. J. Chem. 30 (4), 1463–1474. https://doi.org/10.13005/OJC/300403 (2014).

Ahmadi, S. & Adaobi Igwegbe, C. Removal of methylene blue on zinc oxide nanoparticles: nonlinear and linear adsorption isotherms and kinetics study. igwegbe. Nat. Sci. 38 (1), 289–303 .

Golestani, N., Nasiri, A. & Hashemi, M. CoFe2O4@ MC/AC as an efficient and recyclable magnetic nanohybrid adsorbent for the metronidazole removal from simulated wastewater: bioassays and whole effluent toxicity. Desalin. Water Treat. 280, 312–329 (2022).

Tju, H., Taufik, A. & Saleh, R. Adsorption of methylene blue using Fe3O4/CuO/ZnO/nanographene platelets (NGP) composites with various NGP concentration. J. Phys. Conf. Ser., 12019. (2016).

Zango, Z. U. et al. Effective removal of methylene blue from simulated wastewater using ZnO-Chitosan nanocomposites: Optimization, kinetics, and isotherm studies. Molecules 27 (15), 4746. https://doi.org/10.3390/molecules27154746 (2022).

Yu, F. et al. ZnO/biochar nanocomposites via solvent free ball milling for enhanced adsorption and photocatalytic degradation of methylene blue. J. Hazard. Mater. 415, 125511. https://doi.org/10.1016/j.jhazmat.2021.125511 (2021).

Tara, N. et al. Nigella sativa-Manganese Ferrite-Reduced graphene Oxide-Based nanomaterial: A novel adsorbent for water treatment. Molecules 28 (13), 5007. https://doi.org/10.3390/molecules28135007 (2023).

Tahseen, Z. S., Rashid, B. Z., Ali, S. H., Kaka, K. N. & Salih, S. J. Next-generation Ni-doped CoFe2O4@ SiO2-NH2-gallic acid nanocomposites: Synergistic effects of functionalization for advanced dye removal and antibacterial applications. J. Hazard. Mater. Adv. 18, 100686 (2025).

GadelHak, Y., El-Azazy, M., Shibl, M. F. & Mahmoud, R. K. Cost Estimation of synthesis and utilization of nano-adsorbents on the laboratory and industrial scales: A detailed review. Sci. Total Environ. 875, 162629. https://doi.org/10.1016/j.scitotenv.2023.162629 (2023).

Bello, O. S., Adegoke, K. A., Sarumi, O. O. & Lameed, O. S. Functionalized locust bean pod (Parkia biglobosa) activated carbon for Rhodamine B dye removal. Heliyon 5 (8), e02323. https://doi.org/10.1016/j.heliyon.2019.e02323 (2019).

Wang, Y. et al. Novel environmental-friendly nano-composite magnetic attapulgite functionalized by Chitosan and EDTA for cadmium (II) removal. J. Alloys Compd. 817, 153286. https://doi.org/10.1016/J.JALLCOM.2019.153286 (2020).

Liu, Z., He, W., Zhang, Q., Shapour, H. & Bakhtari, M. F. Preparation of a GO/MIL-101 (Fe) composite for the removal of Methyl orange from aqueous solution. ACS Omega. 6 (7), 4597–4608 (2021).

Wang, F. et al. Sorption behavior and mechanisms of organic contaminants to nano and microplastics. Molecules 25 (8), 1827 (2020).

Hu, X., Li, Z., Ge, Y., Liu, S. & Shi, C. Enhanced π–π stacks of aromatic ring-rich polymer adsorbent for the rapid adsorption of organic dyes. Colloids Surf. Physicochem. Eng. Asp. 643, 128782. https://doi.org/10.1016/J.COLSURFA.2022.128782 (2022).

Acknowledgment

The authors express their gratitude for the financial support received from the Curtin Malaysia Collaborative Research Scheme 2022 (CMCR, cost center 004036). Additionally, the authors extend their thanks to Curtin University Malaysia for the support provided through the Curtin Malaysia Postgraduate Scholarship (CMPRS).

Author information

Authors and Affiliations

Contributions