Abstract

Norfloxacin (NOFX), a common fluoroquinolone antibiotic, has recently raised significant concerns due to its adverse effects on both humans and the aquatic environment. In this work, a CuS-ZnS p-n heterojunction was introduced with graphene oxide (GO) sheets using a simple solvothermal technique. ZnS nanoparticles (NPs) have a hexagonal crystal phase and a cubic morphology. In contrast, CuS NPs have a cylindrical shape, and GO has wrinkled flakes. Under visible light, the ZnS/CuS/GO nanocomposite’s exceptional hydrogen generation rate and remarkable photodegradation properties were caused by its variable bandgap. It was discovered that the optimal conditions for NOFX drug’s breakdown were 50 mg of catalyst and 10 ppm of drug concentration at 30 °C, pH 10, and 300 W Xenon light. The efficiency of drug degradation rose from around ~ 19% to about ~ 86% which is consistent with first-order reaction kinetics. Nanocomposite has outstanding structural stability and can be recycled 5 times, with a noticeable decrease in photocatalytic effectiveness from ~ 86% to ~ 80%. Additionally, to assess the hydrogen production efficiency of the synthesised samples in the presence of sodium thiosulphate, which served as the sacrificial agent, photocatalytic water splitting tests were conducted. Hydrogen generation efficiency was found to be minimum for ZnS (276 µmol/g/h) in 120 min, which was enhanced to 452 µmol/g/h for ZnS/CuS/GO nanocomposite.

Similar content being viewed by others

Introduction

The use of antibiotics as drugs to protect individuals and livestock against various infections has increased over the past few years1. Antibiotics released from healthcare facilities are progressively becoming more destructive to the marine ecosystem2. According to a recent investigation, traces of antibiotics have been found in rivers. Because of their negative impact on the activity of bacteria, fluoroquinolones (FQs) are not degradable in biological wastewater treatment systems. Furthermore, the continuous interaction between FQs and bacterial cultures resulted in resistance against these drugs3. There are reports of the noticeable presence of several antibiotics, including ofloxacin, sulfamethoxazole, and norfloxacin (NOFX) in water bodies. NOFX is widely utilised to treat gram-positive and gram-negative infections caused by bacteria in humans and animals. The ubiquity and increasing amount of NOFX in aquatic environments may encourage the growth of antibiotic-resistant infections caused by microbes, making the current antimicrobial regimen ineffectual. However, because of its slow breakdown, NOFX particles accumulate in water bodies, which is highly harmful to human well-being and also upsets the sensitive equilibrium of the ecosystem4,5. Many methods, such as membrane filtering, adsorption, wastewater therapy (both physical and chemical), advanced oxidation procedures (AOPs), reversible osmosis, electrocoagulation, treatment with biological agents, exchange of ions, and microbial breakdown technology, have been thoroughly researched and used for eliminating antibiotics via different mediums6,7,8,9,10,11,12. Since the quinolone ring found in NOFX is stable, it is difficult to break down completely. This prevents standard techniques from effectively breaking down the medication. Additionally, photocatalysis is thought to be the most effective and environmentally friendly method for eliminating antibiotics from the water reservoir. Since light is a sustainable form of power due to its abundance, solar-light-responsive photocatalysts become an economical approach13. Due to its unmatched excellence, eco-friendliness, high efficiency, and outstanding stability, photocatalytic breakdown using semiconductors as photocatalysts is thought to have potential as a successful treatment approach for residual antibiotics14,15,16. Effective and environmentally friendly methods for the removal of reactive material using NPs in conjunction with photocatalytic breakdown are now being proven17. In recent years, considerable research has been conducted on the application of semiconductor-based substances in the breakdown of environmental contaminants when exposed to UV radiation18. ZnS, an n-type semiconductor with a wide band gap ~ 2.6–4.6 eV, is currently being thoroughly investigated as a semiconductor in different fields such as photocatalysis, monitoring and imagery because of its significant characteristics such as visible-light responsiveness, optimal band sites, increased thermal as well as chemical resistance, non-toxic manufacturing and cost-effectiveness19,20,21. Nevertheless, the combined effect of photogenerated electron-hole pairs, as well as the reduction in visible light, prevents these photocatalysts from being used on a broad scale22. Due to reduced toxic content, water stability, increased surface area, economic viability, biocompatibility, and chemically inert nature, dopant modifications using transition metal ions are crucial23,24,25. Copper sulphide (CuS), a p-type semiconductor with a large band gap, has drawn a lot of interest due to its distinctive optical and electric characteristics26,27 along with other chemical and physical attributes28,29. Therefore, ZnS and CuS were used to construct a facile heterojunction for effective photocatalytic degradation of organic drugs like NOFX. In a photocatalytic system, a p-n heterojunction was created by combining ZnS NPs with CuS, and the photocatalytic efficiency was achieved by the excitation of electrons and holes30,31. One of the most useful two-dimensional (2D) nanomaterials is graphene oxide (GO), which has an extensive surface area, good mechanical properties, resistance to high temperatures, and rapid electron transmission32,33. Several reports indicate that self-agglomeration of graphene prevents specific photocatalysts from ever achieving excellent performance. Enhancing the removal of graphene layers and improving their characteristics can be achieved through the incorporation of additional NPs into the layered structure of graphene34,35,36. Consequently, the conductivity and photocatalytic capabilities of the graphene layers can also be enhanced by the incorporation of such p-n heterojunctions37,38. To support the metal sulphide layer’s photocatalytic efficacy for practical uses, integrating them is a vital strategy.

Experimental studies on ZnS/CuS/GO ternary composites with photocatalytic activity on the drug NOFX are not available. The creation of ZnS/CuS p–n heterojunction facilitates the effective removal of photoinduced charge carriers and is responsible for improved photocatalytic activity. Consequently, ZnS/CuS/GO stands out as one of the best catalysts for the photocatalytic degradation of many drugs. This inspired us to work on ZnS/CuS/GO nanocomposite, highlighting its importance in drug degradation for a safer environment. In this study, the synthesis of GO, ZnS, and CuS was done by the modified Hummers method and the sol-gel method, respectively. In contrast to traditional physical and chemical techniques, which frequently need hazardous solvents, elevated temperatures, and costly apparatus, the present synthesis method provides a more straightforward, economical, and ecologically sustainable option. Specifically, this study’s synthesis method reduces energy utilisation and harmful byproducts. Although the particle sizes produced by chemical precipitation and hydrothermal techniques are comparable to the current method’s scalability and biocompatibility, the current method is a more environmentally friendly choice for photocatalytic applications. A novel ternary nanocomposite of ZnS/CuS/GO was prepared, and it was found that the ZnS/CuS/GO nanocomposite increases the visible-light photocatalytic decomposition of antibiotics effectively. The effectiveness of photocatalytic processes was improved to ~ 86% using ZnS/CuS/GO hybrid catalyst, with around ~ 67% increase. In addition to this, the photocatalytic degradation mechanism and the effect of various parameters on photocatalysis are also discussed. Furthermore, the photocatalyst’s stability and reusability in its as-synthesised form are also investigated. Nanocomposite has outstanding structural stability and can be recycled 5 times, with a decrease in photocatalytic effectiveness from 86 to 80%. For large-scale environmental applications, this decreases waste output and improves cost-effectiveness. ZnS/CuS composites serve two purposes: (i) monitoring the environment and (ii) remediation. Besides photocatalysis, these can also be employed for colourimetric pollutant detection. The nanocomposite was also examined for photocatalytic water-splitting ability for the production of hydrogen gas, a renewable energy fuel. Figure 1 shows the structure and properties of NOFX.w The synthesis process is straightforward, low-temperature, and employs water-based solvents, which may allow for scalability. Because no high-energy equipment is needed, scale-up can be done economically. But some of the challenges include keeping the dispersion of NPs on GO constant at higher volumes, along with maintaining material yield, batch consistency, managing and recovering nanomaterials when using them extensively. For commercial feasibility, more work is required on pilot-scale experiments and actual water sample testing. While using this composite for degrading NOFX, there are concerns about toxicity and possible effects on the environment because of its small size and capacity to produce reactive oxygen species (ROSs), which can be harmful to aquatic creatures and microbes. Even at low quantities, copper’s toxic effects, which are caused by copper ions produced from CuS, can be detrimental to marine life. The persistence of NPs in soil and water settings may allow them to bioaccumulate in living things and have long-term ecological implications. Also, environmental pollution may result from improper disposal of ZnS/CuS/GO nanocomposites, which raises the possibility of environmental dispersion. At the same time, we carefully manage the toxicity and ecological risk by using enclosed or controlled spaces and creating strategies for recovering and recycling the nanocomposite after usage to avoid contaminating the environment. It can be recovered by centrifugation or filtration after its use. To stop metal ion leaching, used materials need to be carefully handled as hazardous waste. It is advised to recycle or immobilise the catalyst on solid supports to reduce disposal problems and enhance sustainability. When done in large quantities, GO synthesis from graphite using a modified Hummers’ process is still scalable and economical. Compared to noble metal-based photocatalysts, the procedure is more cost-effective because the precursors for ZnS and CuS are available at low cost. Low capital and operational costs are further supported by the use of aqueous solvents and the lack of high-vacuum or high-pressure equipment. This approach has the potential to be scaled up at a reasonable cost.

Experimental details

Materials, methods, and instruments

All the chemicals used for the synthesis were of analytical grade; therefore, no additional purification was required. The study employed analytical grade zinc chloride (ZnCl2), sodium sulfide (Na2S), copper acetate (Cu(CH3COO)2), sodium thiosulfate (Na2S2O3), graphite, potassium permanganate (KMnO4), distilled water, sulphuric acid (H2SO4), and hydrogen peroxide for the synthesis of ZnS, CuS and GO, respectively. NOFX (used as a pollutant) is a laboratory-grade reagent. A water-soluble solution of HCl and NaOH was used to modify the pH of buffer solutions. Distilled water was used to dilute the stock solution to create drug solutions at different concentrations. The compound’s crystalline structure and phase were determined using the X-ray diffraction (BRUKER D8 ADVANCE diffractometer) technique. SEM was used to assess the morphology of the synthesised samples (SUPRA55VP-4132 CARL ZEISS). UV-Vis spectra of the synthesised samples were acquired using a SHIMADZU UV-2600 spectrophotometer. Catalysis results were recorded using a UV-1900I-SHIMADZU twin-beam spectrophotometer.

Synthesis of ZnS NPs

Synthesis of ZnS NPs was carried out using the sol-gel method. This involved dissolving 14.5 g of zinc chloride (0.1063 mol) in 100 mL of distilled water and adding dropwise a solution of 9.55 g of sodium sulfide (0.224 mol), which was prepared by adding sodium sulfide to distilled water. White precipitates were formed after one hour of stirring, maintained at 80 °C. To collect the product, the resultant mixture was centrifuged at 6000 rpm. Finally, it was rinsed using distilled water and 100% ethanol to remove any remaining contaminants.

Synthesis of GO nanosheets

GO was typically made from pure graphite powder by the modified Hummers method. 27 ml of H2SO4 and 3 ml of phosphoric acid (H3PO4) were mixed in the volume ratio of 9:1 and stirred for a few minutes. Later, 0.225 g of graphite flakes were introduced into the mixture while stirring, followed by 1.32 g of the KMnO4 addition to the solution. The mixture was stirred for about 2 h till it became dark green. Once the solution was cooled to room temperature, deionised water containing 10 ml of 30% H2O2 was slowly poured into it. The mixture was then made to stand overnight so that a solid precipitate could be obtained by decantation to remove contaminants and metal ions. The product was washed seven times in a 5% warm HCl solution. To get the black powder, the solution was filtered, washed with ethanol, and then centrifuged for 30 min at 4000 rpm. Ultimately, the resulting powder was dried for 24 h at 80 °C to produce pure black GO nanosheets.

Synthesis of CuS NPs

CuS was synthesised by dissolving 0.082 mol (7.84 g) copper acetate and 0.129 mol (20.39 g) sodium thiosulfate separately in 100 ml of distilled water each. A change in the mixture’s colour from yellow to brown and then to dark green was observed. The solution was stirred continuously for 6 h at 90 °C, forming a greenish-black precipitate. After solution cooling, the precipitate was filtered and washed with distilled water to remove unreacted ions, and the resulting product was then dried in an oven at 60 °C.

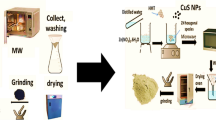

Synthesis of zns/cus/go ternary nanocomposite

To achieve a uniform dispersion, synthesised GO, CuS, and ZnS were separately dispersed in deionised water via a stoichiometric mixture along with stirring for 15 min. CuS, ZnS, and GO dispersions were well-dispersed at the stoichiometric ratio. After stirring the mixture for 2 h at room temperature, the nanocomposite is filtered and dried in a hot air oven at 80 °C. The synthesis scheme is depicted in Fig. 2.

Kinetics of synthesis

The kinetics of nanocomposite synthesis are vital to refining the end product’s physicochemical characteristics and catalytic efficacy. Achieving desired morphology, particle size distribution, and compositional uniformity in synthesis methods, where reaction conditions are usually milder and less harmful to the environment, makes kinetic control even more essential. ZnS and CuS NPs are most likely nucleated and grown on the GO surface either simultaneously or sequentially during the process. GO’s functional groups (such as –OH, –COOH, and epoxide) can interact with metal ions, leading to heterogeneous nucleation, which makes it a reactive surface as well as a stabilising scaffold. Numerous factors influence this process, including concentration of precursors (Zn2+ and Cu2+), pH, which influences ion complexation and hydrolysis, and diffusion and crystallisation rates, which are influenced by reaction temperature and duration. The rate-determining phase in this study is thought to be either the diffusion of ions towards nucleation sites on GO or the reduction/hydrolysis of metal precursors. These procedures are usually slower, which avoids harsh heating or powerful reducing chemicals, and the creation of NPs is more homogeneous and regulated. Furthermore, by adsorbing ions or stabilising intermediate species, GO may slow down or moderate the growth kinetics and avoid uncontrollable aggregation.

Results and discussion

Morphological properties

SEM microscopy was used to examine the material’s morphology. SEM images of ZnS NPs synthesised through the sol-gel method are displayed in Fig. 3a-b, where agglomeration seems to have taken place during synthesis due to the increased surface energy of NPs. According to the SEM results, the fragments were cubical, further demonstrating the uniformity of the dimensions and shape. SEM image of GO illustrates its normal texture. Figure 3c indicates that the morphological behaviour is somewhat thicker near the periphery than at the centre. As the reaction period increases to a sufficient level, the quantity of oxygen functional molecules decreases. GO sheets were half-folded and wrinkled with a few layers within them, and this can be attributed to the interaction between the imperfections in the structure and oxygen’s properties in the fundamental plane of GO with sp3 carbon cores. The aggregation of multilayers is due to the thin sheets of graphene, which tend to be connected39,40. The formation of flake-like morphology with holes that vary in size between a few µm and ~ 1000 nm on its outermost layer, revealed by the micrographs obtained from the SEM (Fig. 3d). SEM images of CuS indicated that the following three steps might be involved in the production of CuS nanostructures, including a significant quantity of CuS core particles created during the solvothermal method involving copper-thiourea compounds in the solutions. Next, the core components were aggregated, and eventually, the fragments were assembled into larger fragments. Furthermore, the homogenous synthesis of CuS NPs with both growing and nucleating stages in a regulated way with a clearly defined shape was made easier by an elevated temperature of 150 °C. When the reaction period was increased, the initially formed nanostructures expanded into new structures after the nucleation stage and also uniformly aligned themselves to a clearly defined cylindrical-like form. One important consideration that must be made during the synthesis is the stability of the nanomaterials. Intense interactions between molecules, such as π-π interactions as well as van der Waals interactions, are well recognised to have a role in the agglomeration of nanostructures.

The exterior surface of the cylindrical CuS was found to be like flowers, as shown in Fig. 3e–f, composed of several interlocking and slightly bent flakes with width variations. SEM images of nanocomposite ZnS/CuS/GO, as shown in Fig. 4, have a typical characteristic of clumping together. The outermost layer appeared to be a little uneven. The microscopic images demonstrate that the crystallised ZnS NPs are clumped together. According to the morphology, primary building units with a variety of alignments combine to generate the synthesised ZnS nanocomposite ensembles. Additionally, irregularly shaped NPs were formed as a result of the spontaneous accumulation of NPs. The microscopy image (Fig. 4a-b) exhibits non-homogeneities in particle size arrangement. It is evident from the larger-scale picture (Fig. 4c) that the substantial NPs are aggregates of the smaller fragments. The compositional results (EDS analysis) are given in the ESI file.

Structural analysis

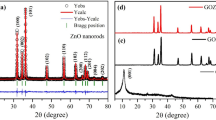

XRD was used to determine the crystal arrangement and the average crystallite sizes of the synthesised samples. By oxidising graphite, a substance called GO was formed, as evidenced by the signal near 2θ = 10–11°. GO is a sp3 hybridised framework made up of multiple layers of carbon. These are generated by the amount of oxygen in the functional groups, making them hydrophilic along with extended interconnected layers. A prominent as well as well-defined scattering signal of GO can be seen at 2θ = 10.6°, which corresponds to the (001) basal plane with a d-separation of 0.961 nm (Fig. 5a). XRD arrangement of the CuS nanocrystals, shown by comparing it with JCPDS database number #01-078-0876, suggests that it is associated with a hexagonal CuS phase. Significant diffraction peaks can be corresponding to the elevated crystal diffraction planes i.e. (002), (004), (100), (101), (102), (103), (006), (105), (008), (110), (108), (109), (116), (208) and (212) respectively.

The average crystallite size (D) could be determined via the commonly used Debye-Scherrer formula.

It is given in the form of an equation where k is the form factor, and β is the full width at half maximum (FWHM) expressed in radians. According to the calculations, the average crystallite size was found to be ~17.7 nm. (Fig. 5).

The ZnS (JCPDS card number #01-083-2234) crystal system is associated with a hexagonal phase. The obtained diffraction peaks at twoθ readings, 27.65, 28.07, 28.56, 29.15, 47.64, and 56.39, correspond to the d-spacings of 3.222, 3.175, 3.122, 3.060, 1.907, and 1.630 Å, respectively. The peaks are determined to originate from the (104), (015), (0018), (017), (112), and (1118) crystal planes (Fig. 5). According to the Scherrer Eq. (1), the substance with a higher degree of crystalline character will have larger particles. The noise observed in the structure of diffraction patterns can perhaps be explained by the degradation of crystallisation caused by significant sulphur imperfections (vacant positions) in the compound. In the case of ZnS/CuS/GO nanocomposite, the peak positions of the ZnS, CuS, and GO are present, confirming the formation of the nanocomposite. The peaks of ZnS, CuS, and GO slightly shifted in the case of ZnS/CuS/GO nanocomposite as compared to individual components (Fig. 5).

Photocatalytic activity studies

UV-visible spectroscopy results of the synthesized samples are represented by Fig. S1 (electronic supplementary information file). Fig. S2. (a) Photocatalytic water splitting by ZnS, CuS, and ZnS/GO/CuS nanocomposite in the presence of sodium thiosulfate. (b) The bar diagram shows hydrogen production rates. ZnS/CuS/GO nanocomposite was examined in the presence of visible light as a photocatalyst for the NOFX degradation. Following the photocatalysis process, a stock combination for the drug pollutant was created by combining 20 mg of NOFX drug powder with 1000 mL of distilled water. Once the mixture was stirred for 30 min, it was then shifted to a Xenon lamp (light source) to establish a balance between the two processes of sorption and desorption. A xenon lamp possesses high illumination intensity in the visible part of the spectrum. These can provide a wide range of light, making them ideal for a variety of commercial and research uses. Utilising two 250 W Xenon lamps with an effective wavelength of 420 nm, the absorbance of the supernatant of NOFX was determined to be 275 nm. For the photocatalytic investigation, to measure the absorbance at the appropriate wavelengths, a small volume of samples was taken periodically and analysed under the UV-Vis spectrum. The optimisation of catalyst dose, concentration, temperature, and pH value was proved to be effective for the breaking down of the NOFX drug. The degradation efficiency was examined at various ZnS/CuS/GO concentrations (20–50 mg) to find the optimum catalyst dose required for the enhanced photodegradation of the drug. The pH was also adjusted while maintaining a consistent pollutant concentration. The degradation of the drug was examined using different parameters, and the following formula was utilised to determine the degradation percentage.

Where C0 denotes the starting concentration and Ct denotes the end concentration at time t.

Effect of catalyst dose

The effect of the nanocomposite material on the photodegradation of the NOFX drug was examined by changing its dosage in the presence of light. Since the quantity of catalyst directly influences the rate of modification, photocatalyst dosage is an essential variable in the photocatalytic breakdown of the contaminants. The catalyst concentration in the current investigation was varied from 20 to 50 mg. At constant pollutant concentrations, the photocatalyst dosage significantly affected the decomposition of NOFX. The photocatalytic breakdown efficiency of NOFX was enhanced considerably by the ZnS/CuS/GO composite, rising from ~19% of the nanocomposite in 30 min to ~86% of the ZnS/CuS/GO nanocomposite under the Xenon lamp irradiation conditions with a duration of less than 2.5 h. This improvement is due to the synergistic interactions of ZnS, GO, and CuS, which collectively increase light absorption and electron-hole separation. Figure 6a makes it evident that when the weight of catalysts increases, the rate of pollutant degradation also increases. This can be attributed to the medium that is being used, as it introduces more photoactive sites. The radical ions generated due to the presence of photocatalytic sites are responsible for the breakdown. The rate of catalyst degradation increases with an increase in catalyst quantity. As more active sites were available to facilitate absorption of light and catalytic activity, increasing the amount of catalyst can initially speed up the reaction. As a result, more effective collisions and reactions take place at the same time. After a certain point, the reaction rate may not be significantly increased by raising the catalyst amount. This can be attributed to the fact that the catalyst may already be absorbing all available light, and beyond that, there is no improvement in light absorption efficiency, which causes the saturation effect.

Effect of drug concentration

To determine the effect of the drug’s concentration, the amount of nanocomposite was kept constant, and the concentration of the drug was varied (10, 20, 30, and 40 ppm). As illustrated in Fig. 6b. It became evident that when the drug concentration was increased, the progression of drug breakdown slowed down, which indicated a high breakdown efficiency at small starting concentrations. Two factors that contributed to this efficiency decline with an increase in drug concentration are (i) When the initial dosage of a drug increases, a significant number of chemical molecules will be consumed over the composite surface. This results in a decrease in the number of active sites and increases the occupied space of the catalyst surface, which further reduces the generation of OH• radicals. (ii) When the concentration of the drug increases, only a few photons reach the catalyst surface. This prevents most of the light from reaching the outermost layer of the catalyst, which results in a decline of the photoexcitation process of the catalyst, and a slow degradation rate is observed in the later stages of the experiment.

Effect of temperature

The removal of the NOFX drug by photo-catalysis utilising ZnS/CuS/GO nanocomposite at different temperature intervals was examined. The experiment was conducted at a concentration of 10 ppm for 180 min at optimal pH with 50 mg of nanocomposite. As the temperature was increased, the absorbance of the NOFX drug declined substantially (Fig. 6c).

Effect of pH

The pH of the solution greatly influences the photocatalytic water-soluble oxidation of organic substances. This is because it affects the amount of charge, dimensions, and locations of both the valence and conduction bands of the catalyst. Degradation studies were carried out at different pH values (2.0–12.0) using NOFX at constant concentration along with 50 mg of nanocomposite at room temperature for 3 h. The impact of pH level on NOFX breakdown over time is shown in Fig. 6d. The graph showed that the photocatalytic breakdown of NOFX proceeded more quickly at basic pH as opposed to acidic pH levels (Fig. 6d). The highest levels of adsorption, along with degradation, occurred at a pH of 10–11. The breakdown of the photocatalyst was increased as the pH was raised. The rate of drug adsorption and desorption is reduced at greater pH levels. The photocatalytic reduction activity was considerably lower in the basic situation, particularly at pH 12. The primary cause for this phenomenon is the outermost charge of the nanocomposite catalyst and NOFX41. Two ionising functional groups are present in NOFX, i.e., the 3-carboxyl group and N4 of the piperazine moieties. These functional groups cause a pair of distinct ionisation parameters, pKa1 (pH = 6.34), resulting from the reduction of protons of the carboxyl group moiety, and pKa2 (pH = 8.75) as a result of the protonation process of N4 within the piperazinyl moiety. As a result, NOFX exhibited zwitterionic activity across these two levels of pH, as well as positively charged behaviour below pH 6.34 and a negatively charged behaviour over pH 8.75. Both NOFX and ZnS/CuS/GO nanocomposites are regulated by the positive charge in the acidic solution. Similar charges exhibit repelling action, limiting NOFX’s ability to interact with the outermost layers of the nanocomposite and lowering the extent of degradation. The attractive interaction between the nanocomposite and the deprotonated carboxyl group moiety accelerated the breakdown mechanism. The most effective and efficient NOFX breakdown was achieved at pH levels that are slightly over the pKa2, or in the range of 9.5–10.5. Higher concentration of hydroxide anion (OH−) acts as the precursor for hydroxyl radicals (OH•), which are produced during photocatalysis. The production of OH• will increase with an increase in OH− ion concentration. The degradation efficiency drops beyond this pH due to the negative charges of NOFX and the nanocomposite repelling each other. Therefore, pH 10 was determined to be the ideal pH for further investigations.

Influence of morphology on photocatalytic activity

Their particle size and shape largely determine the photocatalytic efficiency of nanocomposites. ZnS/CuS/GO nanocomposite in this work shows a heterogeneous distribution of nanosized particles. The material’s surface area, light absorption capabilities, and behaviour of charge carriers are all directly impacted by these morphological characteristics. Smaller particles possess a larger surface-to-volume ratio, which considerably increases the active sites available for photocatalytic processes. This improves the interaction between the catalyst surface and reactive oxygen species (ROS) like •OH and O2•⁻ as well as the adsorption of NOFX molecules. Furthermore, smaller particle sizes minimise the recombination and increase the effectiveness of charge separation by reducing the distance that the produced electrons and holes must traverse. The shape of particles also influences the interactions of light with the surface. The reactivity of materials can be increased by adding particles with irregular or sharp-edged morphologies, thereby improving light scattering and absorption. Furthermore, different crystallographic facets may be exposed differently by anisotropic forms. Some of these facets may have better photocatalytic activity because of suitable surface energies or reactive site density.

Degradation efficiency

The ideal conditions, such as pH 10, temperature 30 °C, drug concentration 10 ppm, and amount of nanocomposite 50 mg, are taken for degradation efficiency. NOFX breakdown rate increased from ~19% of nanocomposite in 30 min to ~86% of nanocomposite as the illumination duration was less than 2 h, as shown in the plot (time vs. % degradation) in Fig. 7.

Reaction kinetics

The kinetic studies have provided insight into the process and the degradation performance of the photocatalyst. It also offers evidence for how well the photocatalysis is functioning. The study was conducted under ideal conditions regarding the NOFX medication treatment (Fig. 8). It is possible to use the first-order kinetics approach by calculating ln C0/Ct vs. t linearly:

where C0 and Ct are the drug concentrations at time 0 and t, respectively, and k represents the first-order rate constant. The calculated k is represented by the slope of the linear fit, which is 0.97124 h-1, whereas a high correlation coefficient (R2 = 0.98791) demonstrates the suitability of the first-order kinetic model.

Additionally, the significant relationship between time and the logarithmic concentration rate is confirmed by the high Pearson’s r value (0.96808). Because of the synergistic interactions between ZnS (active sites), CuS (light sensitiser), and GO (charge transfer mediator), the nanocomposite exhibits improved photocatalytic activity, evidenced by its high rate constant. The nanocomposite’s ability to degrade antibiotics effectively in aqueous conditions was demonstrated by its ~ 86% breakdown.

Photocatalytic degradation mechanism

The proposed photocatalytic degradation mechanism of NOFX by ZnS/CuS/GO nanocomposite is given as a model. A semiconductor photocatalyst is stimulated when exposed to photons having energy equivalent to or greater than the band gap energy42. Consequently, the excited state of the semiconductor nanocomposite leads to the formation of the charge carriers, i.e., an electron-hole pair, on the composite surface. This is the first step in a prospective process for the degradation of NOFX43. In a nanocomposite, the charge carriers of CuS move to the GO conduction band upon exposure to visible light. Therefore, the photoexcited electrons as well as holes are transferred among the CuS and GO layers via firmly connected ZnS (Fig. 9). Positive holes are thus formed in the CuS valence band. Instead of functioning as an electron receiver, the exfoliated GO layers successfully stop the e and h+ mixing44,45,46. Thus, interaction of electrons in the conductive band within the GO layers with the dissolved oxygen leads to the generation of radicals composed of superoxide anion (O2−) and reactive hydroxyl free radicals (OH.). In the presence of visible radiations, the highly reactive hydroxy free radicals efficiently degrade the adsorbed drug molecules47,48. Simultaneously, CuS and ZnS positively charged vacancies within the valence band combine using molecules of water to produce highly reactive hydroxy free radicals49,50. Thus, when exposed to visible light, such hydroxy free radicals easily break down the NOFX drug. The effective photocatalytic drug removal within a small period is facilitated by the large surface area as well as ultra-fast hole and electron transport ability of the nanocomposites. Table 1 shows the degradation of the NOFX drug using different photocatalysts along with their optimum conditions and mode of synthesis.

Reliability and stability

Reusability tests are mentioned in Fig. 10. For a catalyst to break down various pollutants in wastewater discharges, stability and reusability are essential qualities since these influence the catalyst’s affordability and viability. Reusability tests over five successive photocatalytic cycles were used to assess the stability. The nanocomposite was collected, washed, and utilized again under similar parameters, completing each cycle. By the 5th cycle, the degradation efficiency has decreased from 86 to 82%, confirming the strong photocatalytic stability. Surface oxides, like CuO and ZnO, are formed during the photocatalytic degradation. Efficiency was not considerably affected by slight variations in uniform surface compositions with partial oxidations following photocatalysis. Instead, these might have contributed to the ongoing degrading activity by slightly altering the surface-active sites.

The degradation efficiency values indicated reliable performance and little variability over cycles with a standard deviation of ± 2.1%. The repeatability of the photocatalytic behavior of ZnS/CuS/GO composite is confirmed by low deviation. Environmental variables like temperature, ionic strength, and pH also influence stability. When exposed to light, ZnS and CuS are known to partially oxidize or photo-corrode, particularly in acidic or highly oxidative situations. By preventing particle agglomeration and promoting improved charge separation, the addition of GO to the nanocomposite is anticipated to enhance the stability and lower the risk of photo-corrosion.

Furthermore, the reaction was performed in the presence of sodium thiosulfate serving as a sacrificial agent. It was evident from the photocatalytic water splitting experiment that the maximum amount of hydrogen was obtained from ZnS/CuS/GO nanocomposite, which is about 452 µmol/g/h, while the pure ZnS and CuS showed 276 µmol/g/h and 309 µmol/g/h of hydrogen production, respectively, as summarized in Table 2. The enhanced hydrogen production rate was obtained when a ternary ZnS/CuS/GO nanocomposite was used as a photocatalyst due to the development of a p-n heterojunction interface between them, which leads to the enhancement of electron-hole pair separation at the interface.

Conclusion

ZnS/CuS/GO nanocomposite was effectively synthesized using a straightforward sol-gel technique, and XRD and SEM confirmed its crystallinity and nanoscale characteristics. Photocatalytic effectiveness was increased by the creation of a p-n heterojunction made possible by the homogeneous decorating of CuS and ZnS NPs by GO layers. Better charge separation and the synergistic interactions between ZnS, GO, and CuS are responsible for the much higher activity of the nanocomposite as compared to its constituent parts. When NOFX was exposed to 300 W Xenon light, the best photocatalytic degradation results were obtained at a drug concentration of 10 ppm, a catalyst loading of 50 mg, and a pH of 10. Nanocomposite followed first-order kinetics and reached a ~ 86% degrading efficiency in 2 h. The production of ROSs, improved surface area, and effective charge separation are all responsible for the increased photoactivity. Using Na2SO3 as a sacrificial agent, the nanocomposite also showed encouraging hydrogen evolution capabilities (452 µmol/g/h) during photocatalytic water splitting. These results demonstrate the potential of ZnS/CuS/GO nanocomposites as an economical and effective photocatalyst for applications in sustainable energy and environmental remediation.

Data availability

The datasets generated and/or analyzed during the current study are available in the [Deepak Kumar] repository. Any additional data can be provided upon request by the corresponding author.

References

Khetan, S. K. & Terrence, J. Collins. Human pharmaceuticals in the aquatic environment: A challenge to green chemistry. Chem. Rev. 107 (6), 2319–2364 (2007).

Duong, H. et al. Occurrence, fate and antibiotic resistance of fluoroquinolone antibacterials in hospital wastewaters in Hanoi, Vietnam. Chemosphere 72 (6), 968–973 (2008).

Li, Y., Bi, E. & Chen, H. Sorption behavior of Ofloxacin to kaolinite: Effects of pH, ionic strength, and Cu (II). Water Air Soil Pollut. 228, 1–10 (2017).

Lei, M., Bing, Y. & Nandong, X. A review on environmental behaviors and ecotoxicology of fluoroquinolone antibiotics. Asian J. Ecotoxicol. 2, 76–88 (2015).

Trovo, A. G. et al. Degradation of the antibiotic amoxicillin by photo-Fenton process–chemical and toxicological assessment. Water Res. 45 (3), 1394–1402 (2011).

Julkapli, N., Muhd, S., Bagheri S. & Bee Abd hamid. Recent advances in heterogeneous photocatalytic decolorization of synthetic dyes. The Sci. World J. 692307 (2014).

Bibi, S. et al. Photocatalytic degradation of malachite green and methylene blue over reduced graphene oxide (rGO) based metal oxides (rGO-Fe3O4/TiO2) nanocomposite under UV-visible light irradiation. J. Environ. Chem. Eng. 9 (4), 105580 (2021).

Ahmad, I. et al. Lanthanum-zinc binary oxide nanocomposite with promising heterogeneous catalysis performance for the active conversion of 4-nitrophenol into 4-aminophenol. Coatings 11 (5), 537. (2021).

Kashif, M. et al. Organic sensitization of graphene oxide and reduced graphene oxide thin films for photovoltaic applications. Int. J. Energy Res. 45 (6), 9657–9666 (2021).

Aravind, M. et al. Critical green routing synthesis of silver NPs using Jasmine flower extract for biological activities and photocatalytic degradation of methylene blue. J. Environ. Chem. Eng. 9 (1), 104877 (2021).

Hussain, S. et al. Charge storage in binder-free 2D-hexagonal CoMoO4 nanosheets as a redox active material for pseudocapacitors. Ceram. Int. 47 (6), 8659–8667 (2021).

Saleem, M. et al. Experimental and theoretical study of highly porous lignocellulose-assisted metal oxide photoelectrodes for dye-sensitized solar cells. Arab. J. Chem. 14 (2), 102937 (2021).

Shurbaji, S., Huong, P. T. & Talal Mohammed Altahtamouni. and. Review on the visible light photocatalysis for the decomposition of ciprofloxacin, norfloxacin, tetracyclines, and sulfonamides antibiotics in wastewater. Catalysts 11(4), 437 (2021).

Oseghe, E. O. & Augustine, E. Ofomaja. Facile microwave synthesis of pine cone derived C-doped TiO2 for the photodegradation of Tetracycline hydrochloride under visible-LED light. J. Environ. Manag. 223, 860–867 (2018).

Tobajas, M., Belver, C. & Rodriguez, J. J. Degradation of emerging pollutants in water under solar irradiation using novel TiO2-ZnO/clay nanoarchitectures. Chem. Eng. J. 309, 596–606 (2017).

Ponnaiah, S. et al. Efficacious separation of electron–hole pairs in CeO2-Al2O3 nanoparticles embedded GO heterojunction for robust visible-light driven dye degradation. J. Colloid Interface Sci. 512, 219–230 (2018).

Shamsipur, M. & Hamid Reza Rajabi. Study of photocatalytic activity of ZnS quantum dots as efficient nanoparticles for removal of methyl violet: Effect of ferric ion doping. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 122, 260–267 (2014).

Rajabi, H. R. & Farsi, M. Effect of transition metal ion doping on the photocatalytic activity of ZnS quantum dots: Synthesis, characterization, and application for dye decolorization. J. Mol. Catal. A: Chem. 399, 53–61 (2015).

Chang, L. et al. A highly sensitive fluorescent turn-on biosensor for glycoproteins based on boronic acid functional polymer capped Mn-doped ZnS quantum Dots. Anal. Chim. Acta. 995, 91–98 (2017).

Rajabi, H. et al. Fast sonochemically-assisted synthesis of pure and doped zinc sulfide quantum Dots and their applicability in organic dye removal from aqueous media. J. Photochem. Photobiol., B. 181, 98–105 (2018).

Pandey, V. et al. Nitrogen donor ligand for capping ZnS quantum dots: A quantum chemical and toxicological insight. RSC Adv. 9 (49), 28510–28524 (2019).

Sharma, S. et al. Carbon quantum Dot supported semiconductor photocatalysts for efficient degradation of organic pollutants in water: A review. J. Clean. Prod. 228, 755–769 (2019).

Abha, K. et al. Photoluminescence sensing of bilirubin in human serum using L-cysteine tailored manganese doped zinc sulphide quantum Dots. Sens. Actuators B 282, 300–308 (2019).

Patel, J. et al. Mn-doped ZnS quantum dots–an effective nanoscale sensor. Microchem. J. 155, 104755 (2020).

Wang, Y. et al. Cu-Mn codoped ZnS quantum dots-based ratiometric fluorescent sensor for folic acid. Anal. Chim. Acta 1040, 136–142 (2018).

Naşcu, C. et al. Spray pyrolysis deposition of CuS thin films. Mater. Lett. 32, 2–3 (1997).

Takase, K. et al. Electrical resistivity and photoluminescence spectrum of layered oxysulfide (LaO) CuS. Solid State Commun. 123 (12), 531–534 (2002).

Paul, P. P., Thomas, B., Rauchfuss, Scott, R. & Wilson General synthesis of metalloid polysulfide complexes from the elements: Structures of Sb2S152-and InS8 (N-MeIm)-. J. Am. Chem. Soc. 115 (8), 3316–3317 (1993).

Grijalva, H. et al. Amorphous and crystalline copper sulfides, CuS. J. Mater. Chem. 6 (7), 1157–1160 (1996).

Rameshbabu, R., Ravi, P. & Sathish, M. Cauliflower-like cus/zns nanocomposites decorated g-C3N4 nanosheets as noble metal-free photocatalyst for superior photocatalytic water splitting. Chem. Eng. J. 360, 1277–1286 (2019).

Venugopal, G. et al. Efficient visible-light piezophototronic activity of ZnO-Ag8S hybrid for degradation of organic dye molecule. J. Phys. Chem. Solids. 143, 109473 (2020).

Devi, L. & Gomathi Impact of preparative pH conditions on the structure and morphology of graphene oxide-CoFe2O4 composite: Exploration of adsorption isotherm models and photocatalysis. Surf. Interfaces. 14, 175–183 (2019).

Ghosh, U. & Pal, A. Graphitic carbon nitride-based Z scheme photocatalysts: Design considerations, synthesis, characterization and applications. J. Ind. Eng. Chem. 79, 383–408 (2019).

Diaz-Angulo, J. et al. Coupling of heterogeneous photocatalysis and photosensitized oxidation for diclofenac degradation: Role of the oxidant species. J. Photochem. Photobiol. A 383, 112015 (2019).

Khan, S. & Anudeep Kumar, N. Ternary photocatalyst based on conducting polymer doped functionalized multiwall carbon nanotubes decorated with nanorods of metal oxide. Mater. Sci. Eng. B 243, 86–95 (2019).

Son, S. et al. Understanding the relative efficacies and versatile roles of 2D conductive nanosheets in hybrid-type photocatalyst. Appl. Catal. B. 257, 117875 (2019).

Fu, J. et al. Hollow CoSx polyhedrons act as high-efficiency Cocatalyst for enhancing the photocatalytic hydrogen generation of g-C3N4. ACS Sustain. Chem. Eng. 6 (2), 2767–2779 (2018).

Chang, C. J., Wei, Y. H. & Wen-Shyong, K. Free-standing CuS–ZnS decorated carbon nanotube films as immobilized photocatalysts for hydrogen production. Int. J. Hydrog. Energy 44, 30553–30562 (2019).

Dreyer, D. R. et al. The chemistry of graphene oxide. Chem. Soc. Rev. 39 (1), 228–240 (2010).

Shen, J. et al. One step synthesis of graphene oxide– magnetic nanoparticle composite. J. Phys. Chem. C 114 (3), 1498–1503 (2010).

Ling, C. et al. Enhanced removal of sulfamethoxazole by a novel composite of TiO2 nanocrystals in situ wrapped-Bi2O4 microrods under simulated solar irradiation. Chem. Eng. J. 384, 123278 (2020).

Pouretedal, H. et al. Nanoparticles of zinc sulfide doped with manganese, nickel and copper as nanophotocatalyst in the degradation of organic dyes. J. Hazard. Mater. 162 (2-3), 674–681 (2009).

Sun, L. et al. ZnS nanoparticles doped with Cu (I) by controlling coordination and precipitation in aqueous solution. J. Mater. Chem. 9, 1655–1657 (1999).

Lyu, J. et al. Removal of Tetracycline by BiOBr microspheres with oxygen vacancies: Combination of adsorption and photocatalysis. J. Phys. Chem. Solids. 129, 61–70 (2019).

Qian, R. et al. Charge carrier trapping, recombination and transfer during TiO2 photocatalysis: An overview. Catal. Today 335, 78–90 (2019).

Mallick, A. et al. High figure of merit p-type transparent conducting thin film based on solution processed CuS-ZnS nanocomposite. J. Alloys Compd. 770, 813–822 (2019).

Yang, X. et al. Template-directed synthesis of photocatalyst-encapsulating metal–organic frameworks with boosted photocatalytic activity. ACS Catal. 9 (8), 7486–7493 (2019).

González-Casamachin, D. et al. Visible-light photocatalytic degradation of acid Violet 7 dye in a continuous annular reactor using zno/ppy photocatalyst: Synthesis, characterization, mass transfer effect evaluation and kinetic analysis. Chem. Eng. J. 373, 325–337 (2019).

Pedrosa, M. et al. N/S-doped graphene derivatives and TiO2 for catalytic ozonation and photocatalysis of water pollutants. Chem. Eng. J. 348, 888–897 (2018).

Chen, F. et al. Surfactant-free synthesis of homogeneous nano-grade cadmium sulfide grafted reduced graphene oxide composite as a high-activity photocatalyst in visible light. Ceram. Int. 45 (11), 14376–14383 (2019).

Zhao, Y. et al. Green and efficient photodegradation of Norfloxacin with CsPbBr3-rGO/Bi2WO6 S-scheme heterojunction photocatalyst. Colloids Surf., A. 626, 127098 (2021).

Behera, A. et al. Construction of isoenergetic band alignment between cds QDs and CaFe2O4@ZnFe2O4 heterojunction: A promising ternary hybrid toward Norfloxacin degradation and H2 energy production. J. Phys. Chem. C. 123 (28), 17112–17126 (2019).

Dong, W. et al. Optimized removal of antibiotics over Cd0.5Zn0.5S/NiCo-LDH: Constructing a homojunctions-heterojunctions composite photocatalyst. J. Environ. Chem. Eng. 10 (6), 108624 (2022).

Ji, M. et al. Highly efficient visible-light-driven water splitting for H2 evolution and degradation of ECs using CdS/ZnIn2S4 S-scheme heterojunction with built-in electric field. Fuel 374, 132444 (2024).

Patel, J. et al. Assessing the photocatalytic degradation of fluoroquinolone norfloxacin by Mn: ZnS quantum dots: Kinetic study, degradation pathway and influencing factors. Nanomaterials 10 (5), 964 (2020).

Zhao, Y. et al. Bi2WO6/AgInS2 S-scheme heterojunction: Efficient photodegradation of organic pollutant and toxicity evaluation. J. Mater. Sci. Technol. 170, 200–211 (2024).

Acknowledgements

This project was funded by the Deanship of Scientific Research (DSR) at King Abdulaziz University, Jeddah, under grant no. (IPP: 688-829-2025). The authors, therefore, acknowledge with thanks DSR for technical and financial support."Authors also acknowledge the support provided by the University Centre for Research and Development Centre, Chandigarh University, Mohali-140413, Punjab, India, for sample characterisations.

Author information

Authors and Affiliations

Contributions

Shakshi Singh, Nagaraju Sunnam, Fiona Elza Correya, and Deepak Kumar: Data curation, Writing and Experimental work. Ritika Soni, Kulwinder Singh, Prasad Eknath Lokhande, Seepana Praveenkumar, and Malini Shashank Bapat: Research methodology, Formal analysis, and Visualization. Suresh Ghotekar, Deepak Kumar, Nabisab Mujawar Mubarak, and Faisal Abnisa: Formal analysis, Manuscript review, and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Singh, S., Sunnam, N., Correya, F.E. et al. Synergistic effects of heterojunction graphene oxide nanocomposites in photocatalytic degradation of norfloxacin and hydrogen generation via water splitting. Sci Rep 15, 33220 (2025). https://doi.org/10.1038/s41598-025-18060-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18060-4