Abstract

The quality of the machined surface and reduced carbon footprint are crucial factors for the operational effectiveness and lifetime of the manufactured components. Direct energy deposition (DED) can be employed to create large and complex metal parts, but low-dimensional accuracy usually requires finishing by a subtractive process. The present work deals with the sustainability assessment and machinability analysis in the machining of laser-melted titanium-based composites (TiC–Ti64-ELI) for the aviation sector. In this regard, the milling experiments were performed under distinct environmentally friendly cooling conditions. The results were analyzed in terms of environmental concerns, such as carbon emissions and specific cutting energy, as well as machining quality characteristics, including surface roughness and tool wear. The results indicate that cryogenic cooling with the carbon dioxide (Cryo-CO2) technique with laser-melted titanium composites can significantly lower carbon emissions while maintaining high-quality performance standards required in aviation applications. The desirability function was employed to obtain the best speed-feed combinations and environmental conditions for milling TiC–Ti64-ELI. The derived optimal conditions are Vc = 60 m/min, fr = 0.082 mm/rev, and Cryo-CO2 cooling. In addition, sustainable assessment was employed to study the effectiveness of environmental conditions.

Similar content being viewed by others

Introduction

Sustainable manufacturing involves optimising energy and resource efficiency, reducing waste production, and converting available resources into goods with small harmful environmental impact 1. It emphasises the need to maintain the quality of both the process and the output and promotes improved personal wellness. Since it started about 20 years ago, sustainable manufacturing has evolved to fulfill the demands of the manufacturing industry for ecological balance, reduced health risks, environmental protection, energy efficiency, and economic viability. To achieve sustainable manufacturing, all aspects of a product’s life cycle from design and production to disposal must be considered. With the goal to minimise the product’s environmental impact and maximise its economic benefits, sustainable practices are carried out 2. By using sustainable manufacturing practices, manufacturers can reduce their environmental impact, increase their competitiveness, and deliver long-term value to their stakeholders3.

The increasing global energy consumption has led to a demand for lightweight structural materials with high specific strength to meet rising energy needs. Titanium matrix composites (TMCs) offers a promising solution because they exhibit remarkable specific strength, Young’s modulus, high-temperature stability, and corrosion resistance, making them appropriate for practical engineering applications4. Reinforcing nanoscale additives in TMCs improves their inherent properties, particularly under challenging conditions. The incorporation of a small amount of uniformly dispersed nanoscale reinforcements can significantly improve the properties of nanocomposites5. Among the ceramic particles used in TMCs, TiC is particularly noteworthy owing to its exceptional chemical stability and seamless compatibility with the Ti matrix. Promising materials for the aircraft and aerospace sectors are TiC-particle-reinforced TMCs. Due to the high specific strength, modulus, and superior creep resistance of TiC particles at extreme temperatures, TiC-TMCs show superior durability6. Nevertheless, TiC-TMCs are often challenging materials to manufacture. During traditional cutting, the elevated hardness of TiC and the lesser thermal conductivity of Ti alloys cause significant tool wear and poor surface finish7. AM provides the benefit of achieving the desired shapes of complex parts by using refractory ceramic particles8. AM in metal forming includes advanced techniques, mainly Powder Bed Fusion (PBF) and DED. The DED process involves depositing a metal powder or wire and using a high-powered beam, such as an electron beam or a laser, to melt and fuse the material as it is applied, making it suitable for fixing and adding material to existing components. Selective Laser Melting (SLM), a type of PBF, employs a laser to melt metal powder, creating highly detailed parts with excellent layer-by-layer mechanical properties. Both DED and SLM offer distinct advantages for fabricating complex geometries and high-quality metal parts9. Nonetheless, the surface finish of parts produced via AM tends to be lower than that of those formed conventionally. Fortunately, when dealing with AM-produced parts, machining allowances can be minimized, thereby reducing post-treatment expenses. Various AM parameters yield parts with distinct microstructures10. In order to provide efficient and accurate manufacturing, measurement is crucial for maintaining quality, confirming tolerances, optimising machining parameters, and minimising errors during and after AM.

Shunmugavel et al. investigated the machinability comparison between SLM- and wrought-fabricated Ti64 alloys. The findings revealed that the machining of SLMed Ti resulted in higher cutting forces, subsequently increasing the cutting heat and leading to greater chip/tool abrasion11. Nasr et al. fabricate Gr/Ti64 nanocomposites with distinct graphene (Gr) percentage using a high-frequency induction heating process. The influence of Gr reinforcement on the milling of Ti64 nanocomposite was analyzed. At high Vcs (50–75 m/min), and 0.6 wt% Gr/Ti64 nanocomposites achieve the lowest surface irregularity12. Li et al. examined the machinability of CNT-TMCs fabricated using diverse methods. The post-milling results show variations in machinability based on tool wear, cutting force, and surface morphology. These differences are mainly due to CNT agglomeration and TiC particles formed in situ in the Ti matrices13. The primary challenges and issues limiting the machinability of Ti-MMCs include severe tool wear, poor quality machined surfaces, and limited tool life. Using carbide and cubic boron nitride (CBN) inserts, Niknam et al.14. reported turning Ti-MMCs under different cutting conditions. Based on statistical analysis and experimental results, cutting parameters could only regulate the Ra and VB when CBN inserts were employed14. Cutting fluids (CFs) are important for machining high-performance products across aerospace, power generation, and automotive industries. They are important in lessening cutting heat and friction, improving surface quality, and boosting machining efficiency by removing chips and debris15. These fluids are subject to bacterial growth, contain toxic elements, and cause contamination, thereby impacting operator health16. Additionally, they require extra resources for recycling, increasing energy consumption, and constituting 17% of production costs. To address these issues, manufacturers must minimize CF usage and explore alternative solutions17. In this context, different CF methods, such as MQL and cryogenic (cryo) coolants, are being explored as substitutes. MQL has emerged as a promising technique for applying CFs owing to its environment-friendly nature and cost-effectiveness18. Better known as semi-dry machining, MQL involves combining a tiny amount of nontoxic biodegradable oil with high-pressure gases and directing it to the machining of alloys19,20. End-milling of Ti alloys, specifically Ti, with MQL has been extensively studied to improve the machining performance while addressing environmental and health concerns. MQL has been shown to be effective in reducing surface roughness (Ra), milling forces, and tool wear, and, in some cases, it outperforms the traditional flood cooling method21. Sun et al. explored various cooling methods and determined that MQL achieved outstanding lubrication performance, particularly prolonging tool life and decreasing radial and tangential forces22. Zan et al. conducted experimental investigations to examine the effects of different MQL parameters on the end-milling of Ti64. The nozzle’s angle was the main variable affecting the experimental results23. There was a clear relationship between the nozzle angle and the milling forces. Park et al. employed image processing methods and a confocal microscope to measure the size and volume of droplets in the desired distribution. The spray parameters were then improved by using these discoveries. According to the investigation, the ideal distance between the nozzles was around 50 mm, while increased air pressure resulted in less wetting of the cutting surface24. This study does have certain drawbacks, burr formation and tool vibration are highly influenced by the air fluid’s direction and pressure in MQL25. For efficient L/C, MQL characteristics like the amount of oil, air pressure, and nozzle location are crucial26.

Liquid nitrogen (LN2) and cryo-CO2, two liquefied gases, are commonly used in cryo-machining, a state-of-the-art technique that replaces traditional cutting methods. The continued retention of the tool’s sharp cutting edges through the use of cryo fluids during cutting produces better surface quality27. This technique has become more well-known in the last few years because of its capacity to generate accurate and superior cuts28. The usage of cryo CO2 in the end milling of Ti64 was explored by Shokrani et al. to disclose the challenges linked with the cutting of these materials, including poor surface integrity and short tool life. According to the findings, end milling of Ti64 with cryocooling substantially improves surface integrity29. Cryo CO2 cooling has been shown to significantly lessen the cutting heat, cutting forces, and Ra in relation to dry and flood cooling conditions30. Jamil et al. investigated the effect of tool wear and Ra performance in the turning of Ti64 with cryo coolant. The trials exposed that CO2-snow cooling minimized Ra and tool wear31. Although cryo-CO2 cooling has demonstrated improvements in machining performance, but it is also significant to note that the cooling capabilities and effects on machining parameters can differ between cryo-CO2 and LN2 32. Due to the large number of parameters involved in machining, the Response Surface Methodology (RSM) is used to model and analyze the results, helping identify optimal conditions with fewer experiments. It saves time and cost while improving accuracy in process optimization. It includes the following general stages: screening, modelling, and optimisation33,34. A high degree of system knowledge can be achieved by the sequential experimentation strategy built into this methodology, provided that the non-technical and technical problems in the experimental phases are appropriately handled35. The less complex desirability-based techniques are simple to apply, understand, and adaptable to the preferences of the decisionmaker36.

The existing literature highlights ongoing investigations into machining methods for conventional Ti64 and TMC. There is no literature focused on the machinability of DED processed TiC–Ti64-ELI with distinct cutting environments. AMed TMC materials pose unique challenges owing to their poor machinability, prompting the need for further study. This investigation focuses on 3 stages: (1) Investigation on machinability, (2) Optimization, and (3) Sustainability assessment. This research investigates the machinability of DED-processed TiC–Ti64-ELI by employing coated TiAlN carbide cutting tools with distinct lubricant cooling approaches. Specifically, it explores the cryo environment and compares it with alternative machining conditions (dry, flood, and MQL).

Materials and methods

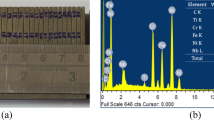

Fabrication of TMC

Pre-alloyed Ti64-ELI powder with particle sizes ranging from 45 to 100 μm is the matrix material. It was supplied by TLS Technik GMbH & Co, Germany. For strengthening the matrix, Stanford Advance Material having − 140 + 325 mesh size TiC powder was utilized. In Fig. 1, the powder morphologies of Ti64-ELI and TiC are displayed. Figure 1a shows the Ti64-ELI particles that were smooth and spherical. In contrast, the TiC powder shown in Fig. 1b was coarse particles with irregular shapes. The samples were obtained by depositing them on a Ti64 base plate that had been washed with acetone and served as the substrate. The production of all samples was carried out on an IPG fibre laser (λ = 1073 nm) processing system that was combined with a KUKA robot (Fig. 1c). For the purpose of delivering the Ti64-ELI and TiC particles through the carrier gas while the deposition was taking place, a GTV powder system (D-57629) that was fitted with two powder feed hoppers were utilised. The ratio of powder weight (Wt.) for Ti64-ELI had been selected to be 94 Wt.%, while the ratio for TiC was set at 6 Wt.%. Throughout the deposition operation, the powder carrier gas was blown at a rate of 1.5 l/min. To protect the produced samples from oxidation, argon gas was employed. Gas flow rate of 12 l/min and beam diameter of 2 mm were the process parameters maintained during sample deposition, with the energy density of 90 J/mm2,37. The fabricated sample is presented in Fig. 1d.

Machining of TiC–Ti64-ELI

In this work, the milling experiments were performed on TiC–Ti64-ELI using a tungsten carbide (WC) insert with TiAlN coating. This coating was employed because of its ability to withstand the challenging conditions during TiC–Ti64-ELI machining. This material has applications across diverse industries, including spacecraft and nuclear plants, where components demand high-performance characteristics and exceptional reliability. This insert was complemented by a BAP300R tool holder, ensuring stability and optimal performance throughout the milling process. Full information concerning the experimental setup, including specifications and parameters, is presented in Table 1. Moreover, the cutting parameters employed in the milling process are not randomly chosen but are carefully determined. They are based on the procedures provided by the tool insert manufacturers and are informed by existing research literature, ensuring that the milling operation is conducted under optimized conditions. Figure 2 presents the workflow of the investigation.

Cutting environments

Dry machining

Dry machining is often used as an ecologically friendly alternative as a reason of the absence of CFs, which can contribute significantly to manufacturing expenses, constituting up to 17% of the total cost38. However, despite its cleanliness, dry machining faces challenges related to productivity, low surface finish, and increased cutter wear. The absence of L/C results in elevated temperatures during the machining process, imposing limitations on the process variables and ultimately impacting production.

Flood machining

Traditionally, emulsion-based CFs have been utilized in manufacturing to achieve a favorable dimensional precision by reducing the thermal enlargement of the workpiece (W/p). However, it fails to mitigate tool wear, particularly for challenging materials. Moreover, the sustainability of these fluids is compromised by various factors.

-

Bacterial growth poses health risks to workers.

-

Oil particles sticking to chips necessitate recycling.

-

The chemical reaction of oil particles turns into injurious gases at high temperatures, causing air pollution.

-

Large energy and space requirements for fluid circulation, storage and recycling.

Given these drawbacks, it is imperative to compare the cutting efficiency of traditional cutting oil with sustainable alternatives such as MQL and cryo-cutting, particularly for difficult-to-cut materials. In this study, flood cutting was performed at a CF flow rate of 2.75 l/min. The CF, comprising 2% of mineral oil in water, was delivered through a 6 mm diameter coolant pipe positioned at a 2 cm standoff distance.

MQL machining

MQL is a sustainable method, due to the minimal use of cutting oil. This method delivers oil particles to the cutting zone in mist form, eliminating the need for chip recycling associated with traditional methods. By misting the oil, MQL enhances lubrication at the cutting region and exhibits superior penetrability compared to flood cooling39. However, MQL is dependent on process variables, including (1) Type of cutting oil, (2) Nozzle tip distance, (3) Oil flow rate, (4) Nozzle diameter, and (5) Air pressure. Optimizing these parameters is crucial; a higher air pressure generates finer droplets, while a closer nozzle tip distance ensures effective wetting of the cutting zone. In this study, a 6-bar air pressure with a 20 mm minimum nozzle tip distance was chosen for mist generation. The sesame cutting oil was selected because of its superior productivity, biodegradability, and storage stability. The acid composition of sesame oil is presented in Table 2. The nozzle assembly, equipped with a 2 mm diameter nozzle, disperses mist onto the rake face, ensuring optimal lubrication during machining operations.

Cryogenic machining

Cryo machining is used as an eco-friendly substitute to the conventional emulsion-based CFs. Unlike emulsion-based fluids, cryo-fluids leave no residue on the W/p or chip, thus eliminating the need for secondary cleaning and chip recycling. Although safety precautions are necessary when handling cryo-fluids, they still do not have harmful effects on workers’ health. Cryo-machining is particularly effective for machining superalloys, yielding benefits in terms of surface integrity, cutting force, and tool wear. It aligns with sustainability criteria by addressing the economic, environmental, and social aspects. This study analyzed and compared CO2-based cryo cutting with other L/C techniques based on machinability indicators. The cryo-CO2 was supplied to the cutting area through a thermoplastic pipe and a nozzle. A 2 mm nozzle opening positioned at a 20 mm standoff length from the rake side was used to supply cryo-CO2.

Measurement of responses

Arithmetic Ra was evaluated using a Mitutoyo tester . The median Ra was examined using Eq. 141.

where Lm signifies the measured distance, and y indicates the deviation from the nominal surface. Five measurements were taken from the machined surface at different locations, excluding the lowest and highest values, to enhance precision. The surface topography was analyzed using a Taylor Hobson-made Talysurf 3D profilometer with the help of Taly Map software. Video measuring device OPTIV was employed to measure the flank wear on the tool insert. The Vb is measured at three different places of the flank face, and the average was taken as Vb in this investigation . The Specific Cutting Energy (SCE) in joule per square millimeter (J/mm3) was computed using Eqs. 2 and 342.

where the Material Removal Rate (MRR) and depth of cut (DOC) in millimeters were utilized. Power consumption was evaluated by measuring the total power across the three phases using an HTC-made clamp analyzer. The power consumed by the CNC machine was measured across the three phases were recorded using the analyzer. Equation 4 explains the calculation for CE resulting from SEC during the machining processes of TiC–Ti64-ELI. India’s carbon emissions factor (CEF) sourced from the Ministry of Power’s annual reports, stands at 0.721 kg-CO2/kWh has been considered because the machining experiments were performed in India43. Specific energy consumption (SEC) in metal cutting operations is a critical factor that is influenced by the choice and application of coolants. Coolants serve to reduce the friction, thereby potentially lessening energy consumption and improving cutting efficiency44. SEC total during machining is determined by summing up the energy utilized during standby mode (Tstdby), air cut (Taircut), cutting operation (Tcutting)45. The cutting time is determined by factors such as machining allowance, cut length, fr, and Vc when milling. SECt can be computed using the subsequent formulas Eqs. 5–7.

Results and discussions

Specific cutting energy

Global energy demand continues to rise each year, with the manufacturing sector accounting for nearly 20% of total annual consumption. Consequently, this sector significantly contributes to global CO2 emission. A substantial portion of this energy is consumed during the machining processes conducted by machine tools in manufacturing42. Adjusting operational parameters can potentially reduce energy consumption, but such alterations must be approached carefully due to potential impacts on cost and production capacity46. SCE represents the energy essential to eliminate a unit volume of material during metal cutting. It directly influences both energy usage and MRR. Generally, minimizing SCE is desirable, achieved by either increasing MRR with the same energy input or reducing energy consumption for a given material removal. Lowering SCE not only enhances energy efficiency but also aids in reducing CE. Adjusting cutting parameters can influence SCE, while L/C strategies also play a crucial role. It’s imperative to select CFs that are sustainable and environmentally friendly without compromising operator health. The cooling rate and steady-state temperatures achieved can vary, which may influence the choice of coolant for specific machining objectives. This study focuses on investigating the impact of L/C strategies on SCE.

In Fig. 3, the SCE outcomes are showed concerning distinct feed-speed combinations for each cooling medium. Cryo-CO2 exhibits the lowest SCE, followed by MQL, flood, and dry cutting conditions. SCE is linked with various energy components, including plastic deformation energy (SCEPD), frictional energy at the material/tool interface (SCEFriE), and energy necessary for chip formation and surface movement (SCEForE). The total SCE is a summation of these factors, Eq. 842.

When examining the impact of cutting strategies on SCE, it is critical to evaluate each energy phase. In dry conditions, the absence of L/C results in increased heat in the cutting area. As an outcome, material softening occurs, which reduces the energy essential for plastic deformation. However, the absence of cooling accelerates cutter wear, necessitating additional energy for surface formation. MQL is widely recognized to reduce friction by creating an oil film at the chip-tool junction; however, it is evident that tool wear primarily impacts cutting energy, which is consistent with the findings of SCE. The cryo-CO2 cooling is proposed to sustain cutter geometry by mitigating temperature-induced cutter failures, thereby maintaining SCE at a consistent level. Furthermore, the decrease in SCE with the adoption of cryo-CO2 is attributed to lessened friction, enhanced heat dissipation facilitated by cryo-coolant.

Carbon emission

Carbon emissions analysis is a critical tool for assessing the environmental sustainability of metal cutting operations. It allows for the quantification of greenhouse gases produced during machining processes, which is essential for identifying areas where improvements can be made to reduce environmental impact47. Interestingly, while advancements in tool materials and Vcs have increased productivity, they have also led to higher temperatures and associated losses in resources and product quality. The use of sustainable CFs and optimized cutting parameters has been identified as necessary to align with green economy principles and reduce \({C}_{E}\)48. Moreover, the integration of CE considerations into the optimization of cutting parameters has been proposed as a method to balance environmental and economic objectives in manufacturing49. From a study by Kanan et al.50, the friction between the carbide end mill cutter and the W/p generates heat. This heat triggers oxidation of the carbide in the TiAlN-coated cutter, leading to the release of CO and CO2 into the atmosphere due to the presence of oxygen.

When carbide reacts with oxygen incompletely, it produces CO (Eq. 8), and when it undergoes complete combustion, it generates CO2 (Eq. 9). Furthermore, CE during cutting is also attributed to the surrounding air, which comprises 417 ppm of CO2 due to global warming and climate variation.

Figure 4 presents the CE outcomes concerning distinct feed-speed combinations for each cooling medium. Metal cutting procedures affect CE depending on cooling methods. Due to friction, dry machining without CF produces high heat and tool wear. This increases energy use and tool replacements, which increase CE. Flood cooling, which continuously applies a huge amount of CF, reduces cutting heat and extends tool life. The energy needed to produce, use, and dispose of CFs makes this process environmentally troublesome and increases CE. MQL uses an aerosol to supply a small amount of lubricant to the cutting area for sustainability. This technique reduces friction and heat, extending tool life and energy use. Thus, MQL minimizes fluid production and operating energy usage CE. Eco-friendly cryo cooling with CO2 is notable. This approach uses liquid CO2 to rapidly cool the cutting area through the phase transition from liquid to gas. CO2 is often derived from industrial emissions, recycling carbon, and reducing atmospheric CO2. Its improved cooling, energy savings, and low CE make it a highly efficient and ecologically beneficial metal cutting procedure.

Machinability analysis

Surface roughness

Ra is a crucial factor in defining the quality of machining and significantly affects the performance of machined components51. Although conventional knowledge suggests that lower Vcs lead to better surface finishes, modern machining technology and the understanding of phenomena such as BUE formation have revealed a more complex relationship between cutting parameters and surface integrity. The necessity for precise control of Ra emphasizes its critical importance in metal cutting processes52,53. Each cooling methods were evaluated at two Vcs (30 and 60 m/min) and two frs (0.08 and 0.1 mm/rev), with Ra values recorded for each combination.

Figure 5 presents the variation in Ra under distinct feed-speed combinations. Dry machining exhibited the highest Ra values, with Ra ranging from 1.95 to 2.33 μm. The flood machining showcased improved surface finish compared to dry machining, with Ra ranging from 1.51 to 1.68 μm. MQL demonstrated further enhancement in surface quality, with Ra values ranging from 1.08 to 1.21 μm. Notably, cryo-CO2 machining emerged as the superior coolant, yielding the lowest Ra values across all conditions. With Ra ranging from 0.95 to 1.1 μm, Cryo-CO2 machining consistently outperformed other coolants. The results exposed significant variations in Ra across the distinct cutting environments and parameters. Dry machining consistently yielded higher Ra values, particularly evident at lower Vcs and higher frs. In contrast, flood machining consistently produced superior surface finishes, displaying lower Ra values across dry condition. MQL machining exhibited intermediate performance, with variations depending on the specific combination of Vc and fr. Cryo-CO2 machining indeed stood out as a notable performer in terms of Ra during the milling operation. The effectiveness of Cryo-CO2 arises from its ability to rapidly absorb heat through the process of phase change from liquid to gas, leveraging its latent heat of vaporization. This inherent cooling capability helps in reducing the heat at the cutting area, which, in turn, contributes to minimizing thermal deformation and improving surface finish. While Cryo-CO2 may not directly provide lubrication like traditional lubricants, its cooling effect indirectly influences friction between the cutting tool and W/p, resulting in improved surface quality.

3D surface topography of TiC–Ti64-ELI at a Vc = 60 m/min and fr = 0.10 mm/rev, under distinct cooling condition (Generated using MountainsSPIP Academic 10, https://www.digitalsurf.com/).

Figure 6 presents the 3D surface topography of unmachined and machined faces of TiC–Ti64-ELI with distinct coolants. It is observed that there is a strong correlation between the cutting environments and the quality of the machined face. Dry machining, lacking any external cooling or lubrication subjected to frictional heat during chip formation. This intense heat softens the machined surface of the TiC–Ti64-ELI, promoting adhesion and buildup of material on the cutting tool. As the BUE grows, it acts like an uneven protrusion, scraping the machined surface and resulting in a rougher finish with deeper valleys and higher peaks. Flood cooling, by introducing an abundant amount of coolant, effectively reduces friction and heat at the cutting area. This minimizes thermal softening and BUE formation, leading to a smoother surface finish related to dry machining. While MQL offers some L/C, reduces friction, it is more effective than flood cooling in managing heat, particularly for challenging materials like TiC–Ti64-ELI. Reduced peaks and valleys are seen in MQL compared to the flood condition. Cryo-CO2 cooling stands out due to its unique properties. The extremely low temperature of Cryo-CO2 significantly reduces heat and friction at the cutting junction. This not only minimizes thermal softening and BUE formation but also strengthens the machined surface by a phenomenon known as tribo-chemical strengthening. At these low temperatures, the interaction between the cutting tool and W/p can create a thin, hardened layer on the machined face.

The SEM images of the machined faces of TiC–Ti64-ELI with different coolants are displayed in Fig. 7. Dry cutting resulted in significant adhered material, scratches, and smearing due to high temperature during machining. Flood cooling somewhat reduced the temperature and provided lubrication, even though some adhesion, scratches, and smearing were seen on the milled face. MQL further minimized these issues with efficient heat removal and lubrication through a fine mist. Cryo-CO2 cooling proved to be the most effective, as its extreme cooling capability drastically reduced thermal loads, minimized material adhesion, and prevented surface defects. This superior cooling and hardening effect led to the best surface finish and tool life among all the tested environments, highlighting cryo-CO2 as the optimal choice for milling TiC–Ti64-ELI.

Flank wear

Flank wear is a critical factor in metal cutting as it straight away impacts the tool life and the quality of the milled face. Studies consistently show that Vb is a predominant mode of tool degradation, affecting operational conditions and outcomes of machining processes54. Luo et al.55 highlight the impact of operational conditions, such as Vc, and Zhao et al.56 suggest that tool geometry and edge preparation can influence the rate of Vb, thereby affecting tool life. Jozić et al.57 points out that at high Vcs, the tool may fail due to other forms of wear before Vb becomes critical. Figure 8 presents the variation in Vb under distinct feed-speed combinations. Across all environmental conditions, Cryo-CO2 machining exhibited the lowest Vb values, with the highest recorded value of 0.097 mm observed at 60 m/min and 0.1 mm/rev. In contrast, dry machining consistently yielded the highest Vb values, with the highest recorded value of 0.191 mm observed at 60 m/min and 0.1 mm/rev. Comparatively, Flood machining and MQL fall between these extremes. Flood cutting resulted in lower Vb values than dry machining, but higher than Cryo-CO2 cutting, with the highest recorded value of 0.141 mm observed at 60 m/min and 0.1 mm/rev. Similarly, MQL exhibited lower Vb values than dry and flood machining but higher Vb values than Cryo-CO2 cutting, with the highest recorded value of 0.126 mm observed at a Vc of 60 m/min and a fr of 0.1 mm/rev.

Figure 9 displays the SEM images of the tool under different environmental conditions. The dry cutting results in significant friction between the tool and W/p. This friction causes elevated heat, which is worsened by the lack of a medium to dissipate heat. The elevated temperature leads to thermal softening of TiC–Ti64-ELI, increasing the tendency for the material to adhere to the tool’s face, forming a BUE. The adhesion and subsequent detachment of the material cause surface irregularities on the W/p and contribute to tool chipping. Additionally, the high thermal and mechanical stresses promote abrasion, as the adhered particles act as abrasive elements, wearing down the cutting tip of the tool and reducing its lifespan. Flood cooling helps to dissipate and absorb the heat produced in the cutting area. This cooling effect lowers the heat and reduces the thermal expansion and softening of TiC–Ti64-ELI. The lubrication provided by the CF diminished the friction and the resultant wear. Consequently, adhesion and abrasion were less pronounced than those in dry cutting. However, some level of cutter wear persists due to the incomplete elimination of the thermal stresses and mechanical friction. The tool still experiences wear, although at a slower rate, resulting in an improved surface quality and extended tool life than under dry condition.

MQL effectively combines L/C with minimal fluid usage. The application of a lubricant reduces the heat at the cutting area, thereby lessening the heat loads and mitigating adhesion. The thin film of the lubricant lowers the friction between the tool-W/p junction, significantly reducing abrasive wear. Thus, MQL lessens cutter wear and enhances the surface quality of the W/p compared with both flood and dry conditions. The physical mechanism of MQL ensures efficient temperature removal and provides lubrication, thereby enhancing the efficiency of the TiAlN-coated inserts. Cryo-CO2 cooling was employed to achieve extremely low temperatures at the cutting area. The CO2 transitions from liquid to gas upon contact with the cutting area, absorbing a substantial amount of heat and thereby drastically reducing the temperature. This extreme cooling effect minimizes thermal expansion and effectively prevents adhesion. The hardened W/p surface, owing to cryo-cooling, also contributed to less abrasive wear. Additionally, the low temperature preserves the sharpness of the cutting tip and extends the tool life.

Determination of key parameters for sustainable milling

A popular statistical optimisation technique for handling multi-response problems in a variety of industrial and other fields is the desirability function method. It is efficient and minimises response mismatches compared to other optimisation approaches. Minimising the SEC, CE, Ra, and VB is the primary goal of the current work, which follows the conventional procedure for applying the desirability function technique. The number of input factors and response goals currently being employed in this study is displayed in Table 3. The input parameters, Vc (30–60 m/min) and fr (0.08 mm/rev − 0.10 mm/rev), have been varied across the entire parameter range. Figure 10a shows the ramp function graphs for the optimal parameters, whereas Fig. 10b shows the desirability values for the responses and control factors. A higher desirability of 0.975 is attained at a Vc of 60 m/min, fr of 0.082 mm/ rev, and cryo-CO2 condition. The desirability function method yielded the following predicted ideal values: 9.396 J/mm3, 0.00076, 0.949 μm, and 0.0918 mm, respectively. Figure 11 presents the desirability under varied cooling conditions at distinct stages for all the environmental conditions used in this investigation. Therefore, the SEC, CE, Ra, and Vb measurements obtained during this optimisation are appropriate for the TiC–Ti64-ELI precise machining. Validation tests are then carried out, and Table 4 presents the findings; the errors of SEC, CE, Ra, and Vb are in the range of 0.15%, 0.39% 0.21% and 0.22%, respectively, when compared with the experimental values for the same input parameters.

Sustainability assessment

The decision matrix is introduced to study the effect of each cooling condition. A tool for ranking and analysing a list of possibilities according to different criteria is a decision matrix59. It is especially helpful in situations where multiple competing aspects need to be considered, as is frequently helpful in the case when choosing a machining method. Figure 12 presents the process flow of the decision matrix.

-

The objective of considering this process is to distinguish each environmental cutting strategy with quantitative values.

-

For a machining process, the environmental conditions (dry, flood, MQL, and cryo-CO2) are the alternatives considered in this approach.

-

CE, SCE, surface finish, and tool life are the parameters taken into consideration in place of the criteria.

-

Give each criterion a weight on a scale of 1 to 5, where 5 is the most significant. Table 5 presents the weight of each criterion.

-

On a scale of 1 to 10, where 10 represents the highest level of performance, evaluate each alternative in relation to each criterion. Table 5 presents the scores of each alternative. Figure 13a presents the deviation of scores in relation to alternatives and the criterion.

-

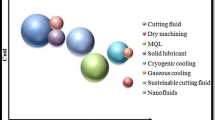

The alternative with the highest total weighted score is considered the best option for milling. Figure 13b shows cryo-CO2 with the highest score of 126, followed by MQL (108), flood (86), and dry (58) cutting strategies.

Conclusions

The influence of several environmental conditions on the machinability and sustainability of TiC–Ti64-ELI was investigated in this work. Under varied machining conditions (dry, flood, MQL, and cryo-CO2), the focus was set on evaluating the SCE, CE, Ra, and Vb. In addition, optimization with the desirability approach and sustainability with the decision matrix were performed. The following are the inferences from the findings:

-

The lowest SCE was observed in cryo-CO2 cooling, followed by MQL, flood, and dry cutting environmental conditions. The fact that cryo cooling is the most energy-efficient technology, it efficiently reduces the quantity of energy needed for material removal, thereby improving the overall efficiency of the machining process.

-

In contrast with dry, flood, and MQL approaches, the utilisation of cry-CO2 cooling in the machining of TiC–Ti64-ELI resulted in a statistically significant reduction in CE. This is in line with the principles of green manufacturing, which emphasise cryo cooling as an environmentally friendly solution that contributes to reducing the carbon footprint of cutting processes.

-

Cryo-CO2 cooling produced the best surface finish, with the lowest Ra values (Ra ranging from 0.95 to 1.1 μm). This superior performance is attributed to the excellent heat dissipation provided by the cryo coolant, which minimizes thermal deformation on the machined surface.

-

It was noted that cryo-CO2 cooling resulted in the least amount of Vb, which therefore considerably extended the tool’s life and maintained its geometry. For ensuring constant machining performance and high-quality surface finishes over a lengthy period of time, this is necessary.

-

Cryo-CO2 drastically reduced temperatures, preventing adhesion and abrasive wear while preserving the sharpness of cutting edges. Flood cooling offered improved conditions compared to dry cutting, mitigating thermal stresses and enhancing surface finish. MQL demonstrated efficient heat removal and lubrication, reducing abrasive wear and enhancing surface integrity, though not as effectively as cryo-CO2 cooling.

-

Multi-objective optimization with the help of the desirability function helps to find out the optimal cutting condition to get the best surface quality and minimize sustainable issues. The derived optimal conditions are Vc = 60 m/min, fr = 0.082 mm/rev, and Cryo-CO2 cooling.

-

Cryo-CO2 cooling offers a comprehensive solution for sustainable manufacturing, as it not only significantly reduces CE and SCE but also enhances social responsibility by minimizing the ecological footprint of machining operations. Moreover, its ability to extend tool life and reduce the frequency of tool changes leads to lower operational costs and increased productivity, contributing to overall cost savings. Furthermore, the lessened Ra and reduced tool wear achieved under cryo-CO2 cooling condition result in higher quality machined components, thereby enhancing the technological performance of the milling process and ensuring superior product quality.

-

A decision matrix is included to evaluate each cutting strategy with CE, SCE, surface finish, and tool life. Cryo-CO2 cooling condition outperformed with a score of 126, followed by MQL, flood, and dry cutting strategies. This assessment suggests that for milling, cryo-CO2 cooling condition is the best solution.

Data availability

The datasets used and/or analysed during the current study will be available from the corresponding author on reasonable request.

Abbreviations

- AM:

-

Additive manufacturing

- BUE:

-

Built-up edge

- C E :

-

Carbon emission

- CEF :

-

Carbon emission factor

- CF:

-

Cutting fluid

- Cryo:

-

Cryogenic

- DED:

-

Directed energy deposition

- fr :

-

Feed rate

- L/C:

-

Lubrication and cooling

- MQL:

-

Minimal quantity lubrication

- MRR:

-

Material removal rate

- PBF:

-

Powder bed fusion

- Ra:

-

Surface roughness

- SCE:

-

Specific cutting energy

- SEC:

-

Specific energy consumption

- SLM:

-

Selective laser melting

- Ti:

-

Titanium

- Tstdby :

-

Standby mode

- Taircut :

-

Air cut

- Tcutting :

-

Cutting operation

- TiC:

-

Titanium carbide

- TMC:

-

Titanium matrix composite

- Vc:

-

Cutting speed

- W/p:

-

Workpiece

References

Ross, N. S. et al. Carbon emissions and overall sustainability assessment in eco-friendly machining of Monel-400 alloy. Sustain Mater. Technol 37 (2023).

Pruhs, A., Kusch, A., Woidasky, J. & Viere, T. Design for circularity in manufacturing industries–operationalisation and decision support. Resour Conserv. Recycl. 202 (2024).

Ahmadi-Gh, Z. & Bello-Pintado, A. Why is manufacturing not more sustainable? The effects of different sustainability practices on sustainability outcomes and competitive advantage. J. Clean. Prod. 337, 130392 (2022).

Kim, M. K. et al. Strategies and outlook on metal matrix composites produced using laser powder bed fusion: A review. Metals (Basel) 13 (2023).

Paramsothy, M. Nanocomposites: Nanoscience and nanotechnology (nanoscale phenomena) in advanced composites. Nanomaterials 12, 10–13 (2022).

Karadimas, G. & Salonitis, K. Ceramic matrix composites for aero engine applications—a review. Appl. Sci. 13 (2023).

Li, G., Chandra, S., Rahman Rashid, R. A., Palanisamy, S. & Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 75, 72–99 (2022).

Fongsamootr, T., Thawon, I., Tippayawong, N., Tippayawong, K. Y. & Suttakul, P. Effect of print parameters on additive manufacturing of metallic parts: performance and sustainability aspects. Sci. Rep. 12, 1–12 (2022).

Armstrong, M., Mehrabi, H. & Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 84, 1001–1029 (2022).

Deckers, J., Vleugels, J. & Kruth, J. P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 5, 245–260 (2014).

Shunmugavel, M., Polishetty, A., Goldberg, M., Singh, R. P. & Littlefair, G. Tool wear and surface integrity analysis of machined heat treated selective laser melted Ti-6Al-4V. Int. J. Mater. Form. Mach. Process. 3, 50–63 (2016).

Nasr, M. M., Anwar, S., Al-Samhan, A. M., Abdo, H. S. & Dabwan, A. On the machining analysis of graphene nanoplatelets reinforced Ti6Al4V matrix nanocomposites. J. Manuf. Process. 61, 574–589 (2021).

Li, G., Munir, K., Wen, C., Li, Y. & Ding, S. Machinablility of titanium matrix composites (TMC) reinforced with multi-walled carbon nanotubes. J. Manuf. Process. 56, 131–146 (2020).

Niknam, S. A., Kamalizadeh, S., Asgari, A. & Balazinski, M. Turning titanium metal matrix composites (Ti-MMCs) with carbide and CBN inserts. Int. J. Adv. Manuf. Technol. 97, 253–265 (2018).

Ross, N. S. et al. Role of sustainable cooling/lubrication conditions in improving the tribological and machining characteristics of Monel-400 alloy. Tribol. Int. 176, 107880 (2022).

Vishal, R., Sworna Ross, N., Manimaran, K., Gnanavel, B. K. & G. & Impact on machining of AISI H13 steel using coated carbide tool under vegetable oil minimum quantity lubrication. Mater. Perform. Charact. 8, 527–537 (2019).

Ishfaq, K. et al. Progressing towards sustainable machining of steels: A detailed review. Material (Basel) 14, 1–47 (2021).

Viswanathan, R., Ramesh, S. & Subburam, V. Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Meas. J. Int. Meas. Confed. 120, 107–113 (2018).

Manikanta, J. E., Abdullah, M., Ambhore, N. & Kotteda, T. K. Analysis of machining performance in turning with trihybrid nanofluids and minimum quantity lubrication. Sci. Rep. 15, 1–12 (2025).

Mia, M. et al. Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Meas. J. Int. Meas. Confed. https://doi.org/10.1016/j.measurement.2018.02.016 (2018).

Narayanan, S.V., Benjamin D, M., MV, H., Keshav, R. & Raj, D.S. A combined numerical and experimental investigation of minimum quantity lubrication applied to end milling of Ti6Al4V alloy. Mach. Sci. Technol. 25, 209–236 (2020).

Sun, J. et al. Effects of coolant supply methods and cutting conditions on tool life in end milling titanium alloy. Mach. Sci. Technol. 10, 355–370 (2006).

Zan, Z. et al. Investigation of MQL parameters in milling of titanium alloy. Int. J. Adv. Manuf. Technol. 116, 375–388 (2021).

Park, K. H., Olortegui-Yume, J., Yoon, M. C. & Kwon, P. A study on droplets and their distribution for minimum quantity lubrication (MQL). Int. J. Mach. Tools Manuf. 50, 824–833 (2010).

Zheng, X., Liu, Z., Chen, M. & Wang, X. Experimental study on micro-milling of Ti6Al4V with minimum quantity lubrication. Int. J. Nanomanuf. 9, 570–582 (2013).

Tawakoli, T., Hadad, M. J. & Sadeghi, M. H. Influence of oil mist parameters on minimum quantity lubrication—MQL grinding process. Int. J. Mach. Tools Manuf. 50, 521–531 (2010).

Mia, M. Multi-response optimization of end milling parameters under through-tool cryogenic cooling condition. Measurement 111, 134–145 (2017).

Jebaraj, M., Kumar, P. & Anburaj, R.. Effect of LN2 and CO2 coolants in milling of 55NiCrMoV7 steel. J. Manuf. Process. (2020). https://doi.org/10.1016/j.jmapro.2020.02.040

Shokrani, A., Dhokia, V. & Newman, S. T. Investigation of the effects of cryogenic machining on surface integrity in CNC end milling of Ti–6Al–4V titanium alloy. J. Manuf. Process. 21, 172–179 (2016).

Jebaraj, M. & Kumar, M. P. End milling of DIN 1.2714 die steel with cryogenic CO2 cooling. J. Mech. Sci. Technol. 33, 2407–2416 (2019).

Jamil, M. et al. Heat transfer efficiency of Cryogenic-LN2 and CO2-snow and their application in the turning of Ti-6AL-4V. Int. J. Heat. Mass. Transf. 166, 120716 (2021).

Pušavec, F., Grguraš, D., Koch, M. & Krajnik, P. Cooling capability of liquid nitrogen and carbon dioxide in cryogenic milling. CIRP Ann. https://doi.org/10.1016/j.cirp.2019.03.016 (2019).

Surya, M. S. Optimization of machining parameters while turning AISI316 stainless steel using response surface methodology. Sci. Rep. 14, 1–12 (2024).

Davoodi, B. & Eskandari, B. Tool wear mechanisms and multi-response optimization of tool life and volume of material removed in turning of N-155 iron-nickel-base superalloy using RSM. Meas. J. Int. Meas. Confed. 68, 286–294 (2015).

Mia, M. Mathematical modeling and optimization of MQL assisted end milling characteristics based on RSM and Taguchi method. Measurement 121, 249–260 (2018).

Costa, N. R., Lourenço, J. & Pereira, Z. L. Desirability function approach: A review and performance evaluation in adverse conditions. Chemom Intell. Lab. Syst. 107, 234–244 (2011).

Ramasobane, P., Mashinini, M. P. & Masina, B. N. Nano mechanical study on a single layer TiC/TI6Al4V-ELI composite manufactured with laser metal deposition. MATEC Web Conf. 388, 03005 (2023).

Weinert, K., Inasaki, I., Sutherland, J. W. & Wakabayashi, T. Dry machining and minimum quantity lubrication. CIRP Ann. Manuf. Technol. 53, 511–537 (2004).

Hamran, N. N. N., Ghani, J. A., Ramli, R. & Haron, C. H. C. A review on recent development of minimum quantity lubrication for sustainable machining. J. Clean. Prod. 268, 122165 (2020).

Ni, J., Cui, Z., Wu, C., Sun, J. & Zhou, J. Evaluation of MQL broaching AISI 1045 steel with Sesame oil containing nano-particles under best concentration. J. Clean. Prod. 320, 128888 (2021).

Şap, S. Machining and energy aspect assessment with sustainable cutting fluid strategies of Al–12Si based hybrid composites. Int. J. Precis Eng. Manuf. Technol. 11, 33–53 (2024).

Gupta, M. K. et al. Comparison of tool wear, surface morphology, specific cutting energy and cutting temperature in machining of titanium alloys under hybrid and green cooling strategies. Int. J. Precis Eng. Manuf. Technol. https://doi.org/10.1007/s40684-023-00512-9 (2023).

Khanna, N., Airao, J., Kshitij, G., Nirala, C. K. & Hegab, H. Sustainability analysis of new hybrid cooling/lubrication strategies during machining Ti6Al4V and inconel 718 alloys. Sustain. Mater. Technol. 36, e00606 (2023).

Fernando, W. L. R., Karunathilake, H. P. & Gamage, J. R. Strategies to reduce energy and metalworking fluid consumption for the sustainability of turning operation: A review. Clean. Eng. Technol. 3, 100100 (2021).

Zhou, Q. et al. Understanding the machining induced tribological mechanism of Hastelloy-X under sustainable cooling/lubrication conditions. Int. J. Adv. Manuf. Technol. 123, 973–983 (2022).

Linares, P., Pintos, P. & Würzburg, K. Assessing the potential and costs of reducing energy demand. Energy Transit. 1 (2017).

Soori, M., Ghaleh Jough, F. K., Dastres, R. & Arezoo, B. Sustainable CNC machining operations, a review. Sustain. Oper. Comput. 5, 73–87 (2024).

Schultheiss, F., Zhou, J., Gröntoft, E. & Ståhl, J. E. Sustainable machining through increasing the cutting tool utilization. J. Clean. Prod. 59, 298–307 (2013).

Zhou, G., Lu, Q., Xiao, Z., Zhou, C. & Tian, C. Cutting parameter optimization for machining operations considering carbon emissions. J. Clean. Prod. 208, 937–950 (2019).

Kanan, M. et al. Analysis of carbon footprints and surface quality in green cutting environments for the milling of AZ31 magnesium alloy. Sustain 15 (2023).

Ross, N. S. et al. A new intelligent approach of surface roughness measurement in sustainable machining of AM-316L stainless steel with deep learning models. Meas. J. Int. Meas. Confed. 230, 114515 (2024).

Brinksmeier, E., Preuss, W., Riemer, O. & Rentsch, R. Cutting forces, tool wear and surface finish in high speed diamond machining. Precis Eng. 49, 293–304 (2017).

Ahmed, Y. S., Fox-Rabinovich, G., Paiva, J. M., Wagg, T. & Veldhuis, S. C. Effect of built-up edge formation during stable state of wear in AISI 304 stainless steel on machining performance and surface integrity of the machined part. Materials (Basel) 10 (2017).

Natasha, A. R., Ghani, J. A., Che Haron, C. H. & Syarif, J. The influence of machining condition and cutting tool wear on surface roughness of AISI 4340 steel. IOP Conf. Ser. Mater. Sci. Eng. 290 (2018).

Luo, X., Cheng, K., Holt, R. & Liu, X. Modeling flank wear of carbide tool insert in metal cutting. Wear 259, 1235–1240 (2005).

Zhao, T., Zhou, J. M., Bushlya, V. & Ståhl, J. E. Effect of cutting edge radius on surface roughness and tool wear in hard turning of AISI 52100 steel. Int. J. Adv. Manuf. Technol. https://doi.org/10.1007/s00170-017-0065-z (2017).

Jozić, S., Lela, B. & Bajić, D. A. New mathematical model for flank wear prediction using functional data analysis methodology. Adv. Mater. Sci. Eng. 138168 (2014).

Gupta, M. K. et al. Tool wear patterns and their promoting mechanisms in hybrid cooling assisted machining of titanium Ti–3Al–2.5V/grade 9 alloy. Tribol. Int. 174, 107773 (2022).

Montenero, K., Kelble, C. & Broughton, K. A quantitative and qualitative decision-making process for selecting indicators to track ecosystem condition. Mar. Policy 129, 104489 (2021).

Acknowledgements

This article was supported by the European Union under the REFRESH—Research Excellence For REgion Sustainability and High-tech Industries project number CZ.10.03.01/00/22_003/0000048 via the Operational Programme Just Transition. The authors also thank the Department of Science and Innovation (DSI) for funding through the Collaborative Program in Additive Manufacturing (CPAM). The Council for Scientific and Industrial Research is thanked for laboratory equipment support. The author Ritu Rai would also like to acknowledge the financial support provided by the Minister of Science and Higher Education under the ‘Regional Initiative of Excellence Program’ project RID/SP/0041/2024/01.

Author information

Authors and Affiliations

Contributions

N.S.R.: Conceptualization, Methodology, Software, Writing original draft; P.T.:Methodology, Resources, Visualization, Reviewing original draft; B.N.M: Resources, Funding, Reviewing original draft; P.L.: Methodology, Resources; P.M.M.: Conceptualization, Methodology, Funding, Reviewing original draft; B.J.A.: Visualization, Reviewing original draft; R.R.: Analysis, Writing original draft; A.N.:Analysis, Funding, Reviewing original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ross, N.S., Tema, P., Masina, B.N. et al. Precision measurement and sustainable assessment in milling of additively manufactured TiC–Ti64-ELI composites. Sci Rep 15, 33382 (2025). https://doi.org/10.1038/s41598-025-18310-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18310-5