Abstract

With the growing emphasis on sustainability and circular economy principles in industrial sectors, the effective utilization of waste-derived and abundantly available natural resources has become imperative. Renewable lignocellulosic fibers such as jute fiber (JF), banana fiber (BaF), coconut coir (CC), and pineapple leaf fiber (PALF) serve as viable reinforcements for developing eco-friendly polymer composites. In this study, hybrid natural fiber (NF) composites were fabricated using the hand lay-up method with varying weight percentages of alkaline-treated JF, CC, BaF, and PALF. Alkaline treatment improved fiber–matrix interfacial bonding by reducing hydroxyl groups and enhancing surface roughness, which significantly contributed to improved mechanical and thermal performance. Mechanical testing revealed that the composite containing 20% JF, 20% CC, and 10% PALF exhibited superior properties, achieving a tensile strength of 85.8 MPa, flexural strength of 134.5 MPa, impact strength of 23.3 J/m2, and hardness of 72.6 Shore D. Fourier transform infrared spectroscopy (FTIR) confirmed successful alkaline treatment through reduced hydroxyl group intensity and improved fiber–matrix compatibility. Atomic force microscopy (AFM) further revealed increased surface roughness (Ra = 31.43 nm), indicating enhanced interfacial adhesion. To predict mechanical performance, machine learning (ML) regression models including linear regression, multilinear regression, decision tree, and random forest were developed using experimental data. Among these, the random forest model demonstrated the highest predictive capability, achieving R2 values of 0.968 for tensile strength, 0.939 for flexural strength, 0.941 for impact strength, and 0.962 for hardness, along with the lowest error metrics (mean absolute error and root mean squared error). These results highlight its suitability for accurate prediction of mechanical properties in fiber-reinforced composites. Furthermore, dynamic mechanical analysis (DMA) revealed enhanced viscoelastic behaviour in treated fiber composites, while thermogravimetric analysis (TGA) confirmed excellent thermal stability up to 690 °C in JF/CC/PALF-reinforced samples.

Similar content being viewed by others

Introduction

Natural fibers are among the most eco-friendly materials, offering several advantages over synthetic alternatives1. Broadly defined, they are fibers that are neither artificial nor synthetic, and can be derived from both plant and animal sources2. Recently, significant attention has been directed toward utilizing natural fibers such as flax, jute fiber (JF), sisal, and oil palm, from renewable and non-renewable resources, in composite fabrication. Cellulose-based fibers are commonly classified into grass and reed fibers (e.g., rice, wheat, corn), core fibers (e.g., kenaf, hemp, JF), leaf fibers (e.g., abaca, sisal, pineapple), and bast fibers (e.g., ramie, JF, flax, kenaf, hemp)3. Their key benefits—light weight, low cost, reduced wear on processing equipment, favourable mechanical properties (tensile and flexural modulus), improved surface finish in molded composites, and their renewable and abundant availability have driven growing interest in their application as reinforcements in polymer matrices4. Additionally, natural fibers offer flexibility in processing, biodegradability, and minimal health risks, making them attractive reinforcements. Strong yet lightweight, they can be incorporated into polymers to produce natural fiber-reinforced polymer composites (NFPCs) with high specific strength and stiffness5. However, their inherent drawbacks cannot be overlooked. Composed of cellulose, lignin, hemicellulose, pectin, and waxy components, natural fibers readily absorb environmental moisture, leading to weak fiber–polymer bonding. Furthermore, chemical incompatibility between fibers and polymer matrices hinders effective interfacial adhesion, resulting in poor stress transfer and limited mechanical performance. To address these issues, specific fiber surface treatments are essential. Such modifications often involve functional groups that react with fiber structures, reducing moisture absorption and significantly improving fiber–matrix compatibility6. Like any other material, NFPCs also have disadvantages, including low heat stability, variability in fiber quality, poor fiber–matrix interfacial interaction due to polarity mismatch, and significant moisture absorption. The chemical incompatibility between natural fibers and polymer matrices results in weak coupling, leading to ineffective stress transfer across the interface. To overcome this limitation, natural fibers require chemical treatments, where reagent functional groups react with fiber structures to modify their composition and improve interfacial bonding7. The primary goal of such surface treatments is to enhance fiber–matrix adhesion and stress transferability in composites. For instance, Al Mahmud et al.8 reported that introducing a ‘Rubik’s layer’ in epoxy composites reinforced with JF, BaF, and coconut fibers significantly improved interfacial adhesion. This modification enhanced tensile strength, stiffness, bending resistance, and impact performance by increasing the composite’s load-carrying capacity, flexibility, and structural integrity. The incorporation of natural fibers with a Rubik’s layer significantly enhanced durability, energy absorption capacity, and impact resistance. Using compression moulding, Balaji et al.9 investigated hybrid polymer composites comprising epoxy (E) reinforced with sisal (SF), banana fiber (BaF), coconut coir (CC), and a sisal/banana/coir (SBCF) combination. Five laminates were fabricated with stacking sequences of E, E/SF, E/CC, E/BF, and E/SBCC, using 30% fiber (SF, BF, or CC) with 70% epoxy and, in the hybrid laminate, 10% of each fiber with 70% epoxy. Among them, E/SF composites exhibited superior properties, achieving tensile and flexural strengths of 28.26 MPa and 57.90 MPa, respectively. In comparison, BaF composites reached 21.6 MPa (tensile) and 32.38 MPa (flexural), while CC composites achieved 22.19 MPa (tensile) and 36.79 MPa (flexural). Further, Sumesh et al.10 explored the use of biowaste-derived fillers—banana fiber fly ash (BFA), coir fly ash (CFA), and pineapple fly ash (PFA) in epoxy composites reinforced with 30% sisal and pineapple fibers. Incorporating 1–4 wt% of these fillers improved fiber–matrix adhesion, with tensile strength increasing to 23.78–33.79 MPa, compared to 20.45 MPa for the unfilled composite. Adding BFA, PFA, and CFA filler powders resulted in flexural strength improvements of 22.11%, 13.92%, and 11.46%, respectively. Thiagamani et al.11 investigated epoxy hybrid composites reinforced with jute (J), kenaf (K), and banana fibers (B) in various stacking sequences using compression moulding, alongside control samples of pure epoxy, pure J, pure K, and pure B. The results revealed that pure BaF composites outperformed the hybrids in tensile strength (41 MPa), interlaminar shear strength (18 MPa), flexural strength (67 MPa), and Shore D hardness (86). Among the hybrids, KBJJBK composites achieved a maximum tensile strength of 34 MPa and flexural strength of 54 MPa, while BJKKJB composites recorded the highest hardness (87), intralaminar shear strength (17 MPa), lowest water absorption (8%), and minimal thickness swelling (2%). Meanwhile, machine learning (ML), a subfield of artificial intelligence (AI), employs statistical and probabilistic techniques to uncover hidden patterns in complex datasets and improve performance through learning. ML has emerged as a powerful tool for designing and optimizing new materials across diverse applications12. ML has recently demonstrated effectiveness across diverse disciplines, particularly in materials science, extending well beyond its theoretical boundaries13. Karamov et al.14 applied artificial neural networks, random forest, and gradient boosting models to predict mechanical properties, reporting that gradient boosting decision tree algorithms achieved the best performance for fracture toughness, with mean squared error (MSE) below 10% of the average value—well within experimental error. Such data-driven methods uncover complex patterns in large datasets, enabling advanced prediction and interpretation. Researchers have successfully employed ML to forecast ductile strength, hardness, and elastic constants with high accuracy15,16. These studies highlight ML’s potential not only to enhance material performance and deepen understanding of material behaviour but also to guide the design of innovative materials. Importantly, ML extends predictive capability to anisotropic, composite, and heterogeneous material systems, beyond conventional homogeneous and isotropic materials. This adaptability underscores the versatility of ML and its broad applicability in contemporary materials science research. However, despite these advancements, the use of ML in natural fiber hybrid composites remains limited, particularly for predicting mechanical performance based on experimental testing criteria. Regression analysis uses existing training data to fit a curve and determine the best course of action for continuous value problems. It simulates a reciprocal relationship between the parameters based on the mistake that the trained model predicts. When making predictions about problems with continuous nature—that is, issues with huge or infinite solutions regression methods are employed17. Five regression methods, including polynomial regression, bagging regression, random forest, XGBoost, and gradient boosting, were trained and assessed using standard error metrics and five-fold cross-validation, as shown by Kumar et al.18. Out of the models mentioned above, the random forest model performed the best (R2 = 0.92, mean absolute error (MAE) = 1.64), surpassing both the ensemble and conventional models. In a related study, Escalante-Tovar et al.19 evaluated support vector machine (SVM), decision tree, and random forest approaches for predicting tensile, flexural, and impact strength of hybrid natural fiber composites, using experimentally derived datasets for model training and validation. The results clearly indicated that the random forest model exhibited superior predictive accuracy, achieving R2 values of 0.98, 0.97, and 0.96 for tensile, flexural, and impact strengths, respectively. In contrast, decision tree and SVM models demonstrated comparatively lower performance across all metrics, reinforcing the effectiveness and reliability of random forest for modelling the behaviour of fiber-reinforced composites. In a related study, Kumar et al.20 enhanced the mechanical performance of 3D-printed ABS parts by incorporating glass fibers between layers. Optimal printing parameters (250 °C nozzle, 80 °C bed temperature, and 60% infill) produced the highest tensile strength of 39 MPa. Using a machine learning model based on classification and regression trees (CART), the study revealed that infill density was the most influential factor in strength prediction. Experimental validation further confirmed strong interlayer bonding and overall material quality, demonstrating how ML-driven approaches can improve manufacturing reliability for practical applications. Building upon such advancements, the present work addresses an existing research gap, as no prior studies have explored the mechanical performance of composites reinforced with four natural fibers. For the first time, the mechanical characteristics of four-fiber reinforced epoxy matrices are systematically investigated, examining properties such as flexural, ductile, impact, and hardness. Furthermore, a linear regression-based machine learning approach was applied to model and predict these properties based on experimental mechanical data, thereby offering novel insights into the complex interactions governing natural fiber hybrid composites.

Materials and methods

Selection of fibers, matrix and use of hybridization

The selection of jute fiber (JF), banana fiber (BaF), coir fiber (CC), and pineapple leaf fiber (PALF) in this study was driven by their abundant availability, low cost, renewable nature, and favorable mechanical properties. Each fiber provides distinct reinforcement benefits: JF and PALF impart high tensile strength, CC contributes toughness and impact resistance, while BaF enhances ductility. Epoxy resin was employed as the matrix material owing to its excellent mechanical strength, thermal stability, chemical resistance, and proven compatibility with natural fibers. The strategic hybridization of these fibers was adopted to harness their complementary characteristics, thereby enabling synergistic reinforcement effects that enhance the overall strength, durability, and versatility of the developed composite system.

The suppliers of JF, CC, BaFs, and PALF were Marvel Fibers, located in Coimbatore, Tamil Nadu, India. Epoxy (LY 556) was selected as the matrix substance. The epoxy and the hardener HY-951 are supplied by Supreme Chemicals Pvt. Ltd., located in Hyderabad, Telangana, India. Table 1 represents the attributes of natural fibers.

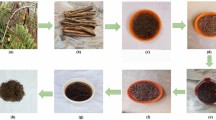

Extraction process of natural fibers

The raw fibers such as BaF, JF, CC, and PALF were initially peeled to remove the outer layer of the stem without damaging the fiber surface. Subsequently, the fibers were thoroughly washed with pressurized water to eliminate residual organic impurities and surface contaminants. Following cleaning, the fibers were sun-dried outdoors for eight hours to reduce moisture content. The dried long fibers were then cut into uniform lengths of approximately 15–20 mm using scissors to ensure consistency in the composite preparation. The use of short fibers facilitates uniform distribution within the matrix and promotes stable composite properties by enhancing resin adherence and minimizing defects.

Chemical treatment of natural fibers

Chemical treatment of natural fibers is a widely employed method to enhance fiber–polymer matrix interfacial bonding. This process reduces the abundance of hydroxyl (–OH) functional groups on the fiber surface while simultaneously increasing surface roughness, thereby improving adhesion between the fibers and the polymer matrix23. As a result, chemically treated natural fiber composites typically exhibit superior tensile, flexural, impact, and interlaminar shear properties compared to their untreated counterparts.

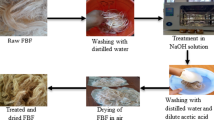

Alkaline (NaOH) treatment

Alkaline treatment using sodium hydroxide (NaOH) is a widely adopted technique for modifying the surface of natural fibers in composite applications. This process effectively removes non-cellulosic amorphous constituents such as lignin, hemicellulose, waxes, and oils from the fiber surface, thereby exposing crystalline cellulose. The exposure of cellulose not only enhances the surface roughness of the fibers but also promotes superior mechanical interlocking with the polymer matrix. In addition, the treatment reduces the abundance of hydrophilic hydroxyl groups, leading to lower moisture absorption and improved dimensional stability of the composites over time. A 5% NaOH solution was selected for this study as it provides an optimal balance: sufficiently strong to activate and clean the fiber surface without compromising its structural integrity. Concentrations above 5–10% often result in excessive delignification and cellulose degradation, reducing fiber strength, whereas concentrations below 3% may not induce adequate surface modification. Guided by both literature precedent and experimental validation, 5% NaOH was thus chosen to ensure effective fiber–matrix bonding while preserving mechanical performance. In practice, JF, BaF, CC, and PALF fibers were immersed in a 5% NaOH aqueous solution at 30 °C for 1 h, followed by thorough rinsing with distilled water until the wash water reached a neutral pH. The treated fibers were then dried in a hot-air oven at 70 °C for 24 h to ensure complete removal of residual moisture24.

Selection of hand lay-up method

The hand lay-up technique was selected for composite fabrication owing to its simplicity, cost-effectiveness, and adaptability in accommodating varied fiber orientations and compositions. This method also enables better control over fiber distribution and placement, making it particularly suitable for small- to medium-scale experimental investigations. Its advantages align well with the objectives of the present study, which aimed to optimize the mechanical performance of hybrid natural fiber composites through controlled fiber hybridization.

Fabrication process of hybrid composite samples

The fabrication of natural fiber-reinforced epoxy composites using the hand lay-up method was carried out through a series of systematic steps to ensure uniform fiber dispersion, proper resin impregnation, and effective curing. In this process, four natural fibers—jute fiber (JF), banana fiber (BaF), coir fiber (CC), and pineapple leaf fiber (PALF)—were employed as reinforcements in an epoxy resin matrix. The alkali-treated fibers were thoroughly rinsed with distilled water to remove residual NaOH, followed by oven drying at 60–80 °C for several hours to minimize moisture content and improve adhesion. A wooden mould with dimensions of 200 × 25 × 5 mm3 was used for specimen preparation25. To facilitate easy demoulding, the inner surfaces of the mould were coated with paraffin wax or a suitable release agent. The epoxy resin was prepared by mixing with HY951 hardener in a 10:1 weight ratio, ensuring homogeneous blending for optimal curing. The fibers were then placed in the mould cavity according to the required composition and orientation, followed by the gradual pouring and uniform distribution of the resin mixture. A roller was employed to remove trapped air bubbles and promote effective resin penetration into the fibers. After lay-up, the mould was closed and subjected to room-temperature curing for 24 h, followed by post-curing in a hot-air oven at 60 °C for 2 h to achieve enhanced cross-linking and mechanical stability. The epoxy–hardener mixture was mechanically stirred for 45–60 min to ensure homogeneous consistency and to initiate the chemical reaction necessary for curing26. The alkali-treated fibers (JF, BaF, CC, and PALF) were cut into lengths of 15–20 mm and uniformly arranged within the mould, either in discrete layers or in hybrid stacking sequences, depending on the experimental design. The resin–hardener blend was then gradually poured over the fibers, ensuring complete wetting of the reinforcements. A roller was employed to apply gentle pressure and eliminate entrapped air bubbles, a critical step to prevent void formation that could compromise the structural integrity of the composites. Following the lay-up, the mould was left undisturbed at room temperature for 24 h to allow sufficient curing. For enhanced cross-linking and improved mechanical performance, post-curing at slightly elevated temperatures (≈ 60 °C for several hours) was also performed in selected cases. After curing, the composite laminates were carefully demoulded and their edges were trimmed to achieve uniform dimensions. The composition of the fabricated samples is presented in Table 2, while the fabrication process is illustrated in Fig. 127.

Tensile, flexural, impact and hardness test

For tensile testing, flat specimens were prepared according to ASTM D638 standards, with dimensions of 115 mm in length, 15 mm in width, and 7 mm in thickness, and a gauge length of 70 mm28. Tests were conducted at a crosshead speed of 10 mm/min using a universal testing machine (UTM) (MCS/UTE-1 T, KVS Materials Testing Lab, Hyderabad, Telangana, India). A total of six specimens were tested under five consistent loading conditions, and tensile strength was calculated from the load–displacement curves. The applied strain rate was maintained at 1.389 × 10⁻5 s⁻1 to evaluate the mechanical response at the specified loading rate. Flexural testing was also carried out using the same UTM in accordance with ASTM D638 standards. The specimens had dimensions of 100 mm in length, 15 mm in width, and 7 mm in thickness. The obtained flexural strength values were derived from the recorded load–deflection data. Flexural testing was carried out using a three-point bending setup on a universal testing machine (MCS/UTE-1T, KVS Materials Testing Lab, Hyderabad, Telangana, India). The test was performed with a support span of 60 mm, a crosshead speed of 10 mm/min, and six specimens, following ASTM D790 standards. Impact strength, a key property reflecting the toughness of a material, was evaluated using the Charpy impact method. Fracture tests were conducted on an FIE 02/2021–1624 ASTM IT30 impact testing machine (KVS Materials Testing Lab, Hyderabad, Telangana, India) in accordance with ASTM D256. The specimen dimensions were 55 × 20 × 10 mm3, and six samples were tested. Hardness testing was performed using Shore-D hardness equipment (50293 HTR-I, KVS Materials Testing Lab, Hyderabad, Telangana, India) according to ASTM D2240. A load of 44.45 N was applied with an indenter of 1.40 mm tip diameter and a 30° cone, extending up to 2.54 mm. For each specimen, at least six readings were taken at different points, and the average hardness value was calculated.

Characterization techniques

The morphological characteristics of the fabricated composites were examined using a scanning electron microscope (SEM) (JEOL JSM-5300LV) operated at 10 kV (Shikag’s Engineering Labs Pvt. Ltd., Hyderabad, Telangana, India). Fourier transform infrared (FTIR) spectroscopy was performed using a Shimadzu 8400S spectrometer with a high resolution of 0.85 cm−1 over the spectral range of 400–4000 cm−1 (Shikag’s Engineering Labs Pvt. Ltd., Hyderabad, Telangana, India)29. Atomic Force Microscopy (AFM) analysis was carried out using a commercial NT-MDT system (Russia) available at Shikag’s Engineering Labs Pvt. Ltd., Hyderabad, Telangana, India. Gold-coated cantilevers with Si3N4 tips (CSG 10, NT-MDT) were employed, having a tip radius of curvature of 35° and a cantilever spring constant of 0.1 N/m, without additional functionalization. Data acquisition and processing were conducted using a Park XE-70 AFM equipped with XEI image processing software30. The scanner provided a scan range of 10 μm × 10 μm in the x–y directions and 70 μm in the z direction.

Dynamic mechanical analysis and thermogravimetric analysis

Dynamic mechanical analysis (DMA) was conducted in accordance with ASTM D4065-12 (2009) to evaluate the viscoelastic behavior of the natural fiber (NF) composites. The test was performed using a TA Instruments DMA Q800 analyzer (Shikag’s Engineering Labs Pvt. Ltd., Hyderabad, Telangana, India) on specimens with dimensions of 60 × 12 × 3 mm330. Thermogravimetric analysis (TGA) was carried out using an EXSTAR TG/DTA 7000 thermal analyzer (Shikag’s Engineering Labs Pvt. Ltd., Hyderabad, Telangana, India). The samples were heated in the temperature range of 30–700 °C at a constant heating rate of 10 °C/min under both air and nitrogen atmospheres in separate runs. For each measurement, approximately 5 mg of composite material was placed in a 5 mm diameter alumina crucible and heated from 300 to 900 °C at a linear rate of 10 °C/min with a nitrogen flow rate of 50 cm3/min30.

Machine learning models used

In this study, machine learning (ML) techniques were employed to predict the mechanical properties of hybrid natural fiber composites. Linear regression (LR) and multiple linear regression (MLR) were applied to model the relationship between one or more input variables and the target property, under the assumption of linear dependence. Decision tree regression (DTR), a rule-based approach, was utilized to capture nonlinear interactions by constructing a hierarchical decision structure. Random forest regression (RFR), an ensemble of multiple decision trees, was further implemented to improve prediction accuracy and minimize overfitting through result averaging. These algorithms were selected for their robustness in handling multivariable datasets and were employed to estimate tensile strength, flexural strength, impact strength, and hardness based on fiber composition and treatment.

Model evaluation methods by machine learning

In this study, key evaluation metrics including relative absolute error (RAE), root mean squared error (RMSE), and the coefficient of determination (R2) were used to assess the predictive accuracy of the machine learning models for mechanical properties. Among these, R2 is particularly important as it quantifies the proportion of variability in the experimental data explained by the predictions. A higher R2 indicates a stronger agreement between predicted and observed values, and is mathematically expressed as:

The R2 value ranges from 0 to 1, with values closer to 1 indicating a stronger correlation between predicted and experimental results. Here, \(yi\) denotes the observed value and ŷᵢ the predicted value; R2 = 1 represents a perfect fit, while R2 = 0 indicates no explanatory power31. To further assess model accuracy, error metrics such as mean squared error (MSE), root mean squared error (RMSE), and mean absolute error (MAE) were employed. These quantify the average deviation between predictions and actual values, where lower values denote higher accuracy. The corresponding formulas are:

In these formulations, ‘yi’ and ‘\(\widehat{y}i^{\prime}\) denote the actual and predicted values, respectively, while nnn is the total number of samples. MSE, RMSE, and MAE share the same unit as the target variable, making them directly interpretable. Lower values indicate better agreement between predictions and experimental results. Together, R2, MSE, RMSE, and MAE provide a robust basis for evaluating the predictive accuracy and reliability of the machine learning models. Machine learning provides efficient and cost-effective tools for modelling the complex, heterogeneous behaviour of natural fiber composites32. Algorithms such as linear regression, decision tree, and random forest are employed to capture relationships between fiber composition and mechanical properties. In this study, these models are applied to predict tensile, flexural, impact strength, and hardness, serving as the basis for performance evaluation. Based on the insights of Mulenga et al.33, ML models are highly relevant for predicting and optimizing the mechanical properties of natural fiber composites. Techniques such as linear regression, decision tree, and random forest effectively capture complex, nonlinear relationships between material composition and performance, and have been recognized for their robustness in handling variability and uncertainty in bio-composites. This establishes a clear methodological basis for the subsequent discussion on model performance metrics. Hamzat et al.34 demonstrated the strong predictive capability of ML models for estimating the flexural strength of fiber-reinforced composites, with random forest and gradient boosting achieving R2 values of 0.979 and 0.974, respectively. Building on these findings, the present study employs linear regression, decision tree, and random forest models to predict key mechanical properties.

Results and discussion

Mechanical properties of neat epoxy samples

The fundamental mechanical performance of neat epoxy resin is illustrated in Fig. 2a and b. The material exhibits a tensile strength of 47.5 MPa, flexural strength of 55.2 MPa, and hardness of 53 Shore D, along with a tensile modulus of 1.2 GPa, flexural modulus of 2.4 GPa, and impact strength of 6 J/m2. These values reflect the intrinsic behavior of epoxy as a thermoset polymer, governed by its dense cross-linked molecular structure. While this configuration provides dimensional stability, rigidity, and moderate stiffness, it also imparts a relatively brittle character, particularly under high loads or impact forces. The absence of fiber or filler reinforcement limits its ability to resist deformation and dissipate energy, as indicated by the moderate tensile and flexural moduli and comparatively low impact strength. Thus, neat epoxy is well-suited for applications where rigidity and shape retention are prioritized, but its limited toughness underscores the need for reinforcement. Benchmarking these properties against hybrid composites enables a clear quantification of the improvements in strength, stiffness, and energy absorption achieved through fiber hybridization.

Tensile attributes of hybrid composite samples

The tensile behaviour of the hybrid composites is governed by fiber type, content, and interfacial compatibility with the epoxy matrix. As shown in Fig. 3a, tensile strength increases with fiber loading and peaks in sample S-5, highlighting the optimized fiber synergy. Jute fiber (JF) plays the most dominant role in enhancing tensile strength due to its rough surface morphology and improved interfacial adhesion with the epoxy matrix after alkali treatment, which facilitates efficient stress transfer. Banana fiber (BaF), present in S-1, S-3, and S-6, does not directly elevate tensile strength to the same extent as JF or PALF, but contributes by improving ductility, energy absorption, and crack resistance, thereby enhancing damage tolerance. Coir fiber (CC), included in S-2, S-5, and S-6, further contributes to toughness and crack-bridging, redistributing stresses and delaying premature failure despite its relatively lower stiffness. The tensile strength improvement from 74.7 MPa in S-2 to 85.8 MPa in S-5 reflects the synergistic effect of combining fibers with complementary properties. Among them, pineapple leaf fiber (PALF) plays a crucial role in S-4, S-5, and S-6, where its high cellulose content and crystalline structure provide excellent load-bearing capacity and stiffness, significantly reinforcing tensile performance. The optimized composition of S-5 demonstrates a well-balanced combination of stiffness, toughness, and interfacial adhesion, making it the most effective formulation.

This behaviour indicates that PALF can effectively compensate for reductions in JF content while sustaining or even enhancing the composite’s performance. The improvement in stiffness and load-bearing capacity in samples with higher PALF content is primarily attributed to efficient stress distribution and enhanced crack resistance, particularly when fiber alignment during layup is favourable. The hybrid fiber system enables a synergistic effect, where the complementary properties of different fibers balance one another: CC contributes toughness, BaF improves ductility, while PALF provides stiffness and JF contributes high strength, resulting in composites with well-rounded mechanical behaviour. Interfacial adhesion plays a decisive role in tensile performance. JF exhibits strong chemical affinity with epoxy, enabling rapid stress transfer and minimizing fiber pull-out, whereas PALF shows slightly weaker interfacial compatibility but compensates with its intrinsic strength and stiffness. When interfacial bonding is improved, especially via alkali treatment, stress transfer becomes more efficient, leading to significant enhancement in tensile characteristics. Moreover, as fiber content increases—particularly with higher JF loadings—a larger portion of the applied tensile load is carried by the stiffer, stronger fibers rather than the weaker epoxy matrix. This efficient load transfer mechanism, as highlighted by Reddy et al.27, is the fundamental reason behind the observed improvement in tensile strength. However, exceeding the optimal fiber loading threshold can lead to fiber agglomeration, poor resin wetting, and void formation, all of which compromise interfacial adhesion and reduce the overall mechanical performance of the composite. Figure 3b illustrates the stress–strain responses of different hybrid systems, highlighting the influence of fiber combinations. In sample S-1, the high JF content produced a steep stress–strain curve, reflecting strong tensile strength but greater brittleness. In contrast, sample S-2 exhibited a more gradual curve with improved ductility due to the crack-bridging effect of CC. In S-3, the inclusion of BaF contributed modestly to stiffness, resulting in a more linear stress–strain profile and slightly higher tensile limits. Samples S-4 and S-5, where JF was reduced to 20% and PALF increased to 20% or 10%, displayed improved stiffness but lower plastic deformation, suggesting a strength–ductility trade-off. The enhanced tensile strength observed in these systems may also be attributed to the increased crystallinity of NaOH-treated fibers35. Notably, S-6 benefited from BaF’s stiffness contribution, showing higher stress at lower strain levels but reduced toughness. Overall, reductions in fiber content or inadequate fiber dispersion lowered load-bearing efficiency, promoting stress localization, microcrack initiation, and premature failure36. Furthermore, excessive fiber incorporation increased the number of fiber ends and interfaces, which acted as stress concentrators and ultimately decreased the composite’s modulus and strength. Cracking often initiates at weak locations, particularly when interfacial bonding is compromised. Hu and Lim37 reported that alkali treatment significantly enhanced the tensile properties of hemp fiber-reinforced PLA compared to untreated counterparts. Similarly, Peng et al.38 observed that cellulose particles with higher lignin content improved composite tensile strength more effectively than those with lower lignin levels. Yan et al.39 examined coir fiber-reinforced epoxy composites and found that a 5 wt% alkali treatment increased tensile strength by 17.8% relative to untreated composites. In another study, alkali treatment of pineapple leaf fiber (PALF) using different NaOH concentrations (1, 3, 5, and 7%, w/v) revealed that 5% NaOH yielded the most pronounced improvement, enhancing tensile strength by 28% compared to untreated samples40. Collectively, these findings emphasize that fiber–matrix interaction, fiber dispersion, and the intrinsic physical properties of reinforcements are key determinants of tensile performance41,42,43. Therefore, optimizing fiber content, surface modification, and composite design is critical for achieving desirable strength and toughness in hybrid systems. The strain-at-break results varied across the samples, reflecting differences in ductility. Samples S-5 and S-6 exhibited higher fracture strain values, indicating superior ductility and an ability to withstand greater elongation prior to failure. In particular, S-5 combined this ductility with excellent tensile strength, demonstrating a well-optimized hybrid structure. The incorporation of 5% NaOH alkaline treatment further enhanced the mechanical performance, with tensile strength reaching 88.8 MPa. This improvement is primarily attributed to improved fiber–matrix adhesion, as alkaline treatment removes hemicellulose, lignin, and surface waxes, thereby increasing cellulose exposure and surface roughness. These modifications promote stronger mechanical interlocking and more efficient stress transfer at the interface. The tensile modulus values also varied with fiber composition and treatment. The highest modulus was observed in sample S-5, containing 20% jute, 20% coir, and 10% PALF, where coir’s inherent rigidity and PALF’s reinforcing capacity acted synergistically to improve stiffness. Conversely, S-1 displayed a notable reduction in tensile modulus due to the absence of coir, which, with its high lignin content, contributes significantly to stiffness and resistance to elastic deformation. These results underscore the importance of balanced fiber combinations and surface treatment in achieving optimal tensile strength, modulus, and ductility in hybrid natural fiber composites.

Flexural attributes of hybrid composite samples

The flexural strength behavior of the manufactured hybrid epoxy composites shows a strong correlation between fiber composition and bending resistance, as illustrated in Fig. 4a. JF emerges as the most significant natural reinforcement due to its high tensile strength, large aspect ratio, and strong interfacial adhesion with the epoxy matrix. The effective fiber–matrix bonding facilitates efficient stress transfer during bending, thereby minimizing fiber pull-out and crack initiation while enhancing resistance to flexural deformation. Samples S-1, S-2, and S-3, each containing 30 wt% JF, consistently exhibited flexural strength values of approximately 130 MPa. This result confirms that JF acts as the primary load-bearing reinforcement, effectively resisting tensile and compressive stresses on opposite faces of the bent composite beam. The high cellulose content of JF (above 60%) and its aligned microfibrillar structure further contribute to stiffness and resistance against both elastic and plastic deformation under bending loads. The auxiliary fibers, including BaF, CC, and PALF, enhance the overall mechanical performance of the composite but play a secondary role in determining its flexural strength. In Sample S-1, the combination of 10% BaF and 10% PALF with 30% JF produced a well-balanced composite with superior flexural strength and improved damage tolerance. The combination of these fibers likely enhanced fracture-arresting capability, as BaF and PALF improved the matrix’s energy dissipation during flexure, despite their weaker individual interfacial bonding with epoxy compared to JF. Flexural strength remained comparable in S-2 and S-3 when CC and BaF were introduced, highlighting that maintaining 30 wt% JF content is essential for achieving superior bending performance, regardless of the secondary fiber type. This finding reinforces the premise that JF is the dominant contributor to flexural strength, whereas secondary fibers primarily influence properties such as impact resistance, matrix toughness, and crack-bridging efficiency. Samples S-4 and S-6, with reduced JF content (20 wt%), exhibited lower flexural strength (~ 125 MPa). Although PALF in these samples partially compensated for the reduction due to its high intrinsic tensile modulus and elevated cellulose content (up to 82%), its relatively weaker bonding with epoxy compared to JF limited its efficiency in transferring bending loads. Consequently, reduced fiber–matrix contact lowered the load-bearing capacity under flexure, resulting in the observed strength decrease. The performance discrepancy can be further explained by compositional differences among fibers. For instance, PALF has a significantly higher cellulose content (70–82%) than BaF (48–50%) and a lower lignin content (4.6–12%) compared to BaF (19.17%). High cellulose levels typically enhance stiffness and load-bearing capacity, whereas lower lignin promotes fiber flexibility and reduces interfacial stress concentrations. These compositional variations may account for the superior flexural performance of PALF-rich composites44,45. The relatively narrow range of flexural strength values observed among the samples suggests that the epoxy matrix plays a critical role in maintaining stress distribution within the composite. Owing to its thermosetting nature, inherent stiffness, and excellent adhesive properties, epoxy ensures uniform load transfer and minimizes localized stress concentrations, even with varying fiber compositions. Notably, Sample S-5, which contained a higher overall fiber fraction, exhibited superior flexural stress, consistent with previous reports46,47. The increased fiber–matrix interactions and overall stiffness at higher fiber loading demand greater energy to initiate and propagate bending deformation. In this configuration, CC likely contributes to toughness, while PALF and JF act as the primary reinforcements, providing tensile strength and rigidity that enhance flexural resistance and delay structural failure. These results emphasize the importance of fiber selection, chemical compatibility, and optimized weight fractions in designing hybrid composites for improved flexural performance. Strong fiber–matrix adhesion, particularly in the case of JF, remains critical for achieving superior bending resistance. Fiber strength and fiber–matrix adhesion were significantly improved after alkali treatment, as reported by Sedan et al.48. Incorporating fibers with comparable mechanical and physical properties enhanced the composite’s load-bearing response, as demonstrated in the most balanced samples (S-1 to S-3). A reduction in JF content below the optimal level consistently led to decreased flexural strength, underscoring the critical role of JF in providing effective reinforcement. Future strategies to further enhance flexural performance may include surface modification of secondary fibers (e.g., PALF or BaF) to improve interfacial bonding, as well as advanced fiber hybridization techniques aimed at optimizing spatial distribution and alignment within the matrix to maximize mechanical synergy. Conversely, reducing the JF fraction diminishes composite efficiency, reaffirming its importance in achieving optimal mechanical performance. The experimental results for all composite samples are presented in Table 3.

Impact attributes of hybrid composite samples

The fiber–matrix interfacial bonding, fiber type and distribution, and intrinsic mechanical properties of individual fibers have a pronounced influence on the impact strength of natural fiber–reinforced epoxy composites. As shown in Fig. 4b, varying the proportions of JF, CC, BaF, and PALF alters the energy absorption capacity and resistance to crack propagation under sudden impact loading. Specimens S-1, S-2, and S-3, each containing 30 wt% JF, exhibited moderate-to-high impact strength values of 16.1 J/m2, 17.6 J/m2, and 19.9 J/m2, respectively. The presence of JF, with its high cellulose content, moderate elongation at break, and aligned fibrillar microstructure, facilitates stress transfer and partial energy dissipation under dynamic loading. However, while JF contributes significantly to flexural strength, its relatively low strain-to-failure and high stiffness restrict plastic deformation, thereby limiting its ability to enhance impact resistance. By contrast, impact strength increased substantially in composites with higher CC content. For instance, despite a reduced JF fraction, Sample S-5 (with 20 wt% CC) exhibited the highest impact strength (23.3 J/m2). The superior performance of CC can be attributed to its high lignin content (~ 45%) and inherent toughness, which enhance fracture resistance and energy dissipation through mechanisms such as fiber pull-out and matrix cracking. The cell wall porosity and surface roughness of CC enhance mechanical interlocking with the epoxy matrix, providing stronger anchorage and resistance to impact-induced crack propagation. These observations are consistent with previous reports47, which emphasize fiber pull-out and frictional sliding as key mechanisms contributing to improved energy absorption with increasing fiber loading. The incorporation of 10 wt% BaF in S-1 and S-3 markedly increased impact strength (from 16.1 J/m2 in S-1 to 19.9 J/m2 in S-3). Although less stiff than JF, BaF possesses considerable flexibility and tensile strength, enabling it to act as a toughening agent by dissipating impact energy through mechanisms such as microcrack deflection and plastic deformation. The moderate improvement in impact resistance indicates that BaF’s lower rigidity allows more efficient deformation under high strain, complementing JF’s stiffness and producing a synergistic enhancement in toughness. PALF, despite its high cellulose content (70–82%) and excellent stiffness, shows relatively poor interfacial bonding with epoxy due to its elevated lignin content and waxy surface layer48. This weak bonding reduces stress transfer efficiency and can lead to premature delamination under impact. Nevertheless, higher PALF content, as in S-4 and S-6 (20 wt% PALF), improved impact strength to 20.4 J/m2, suggesting that PALF contributes to initial impact resistance and overall composite stiffness. While PALF is less effective than CC in arresting crack propagation, its intrinsic stiffness and moderate strain-to-failure allow it to serve as a stiffening phase under high-velocity loading conditions. It is evident that while JF primarily enhances flexural strength, CC and BaF are more effective in improving impact resistance owing to their superior energy absorption capacities. The progressive increase in impact strength from S-1 to S-3 highlights the cumulative contribution of secondary fibers such as BaF and CC in blunting crack tips, dissipating strain energy, and delaying fracture propagation. Despite incorporating different dominant secondary fibers (PALF in S-4 and CC in S-5), both samples exhibited comparable impact strengths (20.4 J/m2 and 23.3 J/m2, respectively). This suggests that PALF contributes through stiffness-driven energy absorption, whereas CC is more effective in toughness-governed failure mechanisms. The distinct responses under impact emphasize the importance of fiber–matrix compatibility and fracture mechanics behaviour, where fiber stiffness, pull-out resistance, and debonding energy act in combination. The maximum impact strength achieved in this study (23.3 J/m2) aligns well with previously reported values for natural fiber hybrid composites. However, the composite that was 35 wt% loaded and had treated fibers for strong interface bonding achieved the highest impact strength (59.27 J/m2). The outcome demonstrated that PALF is appropriate for uses needing impact resistance and vibration damping49. As supported by earlier studies50, the pull-out process, combined with interfacial friction and fiber debonding, accounts for a substantial portion of impact energy absorption. With higher fiber content, greater force is required to disengage fibers from the matrix, thereby improving the composite’s resistance to impact-induced failure. The impact strength behaviour of the hybrid composites is governed by the complex interplay among fiber stiffness, interfacial adhesion, and fracture energy dissipation mechanisms. An optimal balance, as observed in S-3 and S-5, arises from the combination of JF’s load-bearing capacity with the toughening effect of CC or BaF, resulting in composites with superior impact resistance. Although less dominant, PALF contributes notably to composite stiffness and resistance to fracture initiation. Furthermore, the incorporation of 5% NaOH alkaline treatment had a significant influence on the impact strength of the hybrid composites. The recorded value of 15 kJ/m2 demonstrated an enhanced ability to absorb and dissipate energy under sudden loading, which can be attributed to improved fiber surface roughness, more uniform fiber dispersion, and deeper matrix penetration.

Tensile and flexural modulus of hybrid composite samples

Figure 5 presents a comparative analysis of the tensile and flexural modulus for six composite samples (S-1 to S-6), measured in GPa. Across all samples, the flexural modulus is consistently higher than the tensile modulus, which is typical of fiber-reinforced composites due to stress distribution during bending, where surface fibers predominantly resist the applied load. Among the samples, S-3 exhibited the highest flexural modulus (4.3 GPa) and a correspondingly high tensile modulus (3.7 GPa), indicating well-balanced mechanical performance attributed to optimal fiber dispersion, strong interfacial bonding, and effective hybridization. S-2 also demonstrated enhanced tensile stiffness (3.8 GPa), reflecting efficient axial load-bearing capacity. In contrast, S-5 and S-6 showed a notable reduction in tensile modulus (2.7–2.8 GPa), likely due to increased porosity, weak fiber–matrix interaction, or insufficient fiber content. The consistently higher flexural modulus, particularly in S-3 and S-5, underscores their superior resistance to bending loads, making them suitable for applications such as automotive panels, construction materials, and structural reinforcements.

Hardness attributes of hybrid composite samples

As shown in Fig. 6, the hardness results are strongly correlated with the intrinsic stiffness, tensile strength, and interfacial adhesion properties of the constituent natural fibers. Hardness, which reflects a material’s resistance to localized plastic deformation, is governed not only by fiber stiffness but also by the efficiency of stress transfer from the matrix to the fibers, the quality of the fiber–matrix interfacial bonding, and the overall composite microstructure.

PALF, with its high tensile modulus, cellulose crystallinity, and low microfibril angle, makes a substantial contribution to the hardness of the composites, particularly in samples S-4, S-5, and S-6, where its loading is higher. The rigidity of PALF enhances the composite’s resistance to indentation by acting as a barrier against localized plastic deformation of the epoxy matrix. This effect is especially evident when PALF replaces or supplements less rigid fibers, thereby improving resistance to mechanical wear and penetration forces. JF, owing to its good fiber–matrix adhesion and moderate stiffness, offers the dual advantage of enhancing hardness while preserving ductility. Its lignocellulosic structure, coupled with strong chemical affinity for epoxy, facilitates efficient load transfer under localized stress. Notably, even when the JF content in S-4, S-5, and S-6 is reduced to 20 wt%, the composites retain high hardness. This observation suggests that JF’s strong interfacial bonding with epoxy compensates for its reduced fraction, enabling the matrix to effectively harness the reinforcing effect of the fibers in resisting indentation. BaF and CC, in contrast, possess lower inherent stiffness compared to PALF and JF. Nevertheless, they contribute to improved toughness and resistance to microcrack initiation, thereby supporting the overall hardness of the composites. Their role is more pronounced in dissipating energy during impact or cyclic loading rather than directly enhancing resistance to indentation. Both BaF and CC contain significant amounts of lignin, which reduces brittleness and marginally enhances surface hardness by stabilizing the matrix against microfracture propagation under indenter pressure. The progression from sample S-1 to S-5 highlights the synergistic benefits of fiber hybridization, where fibers with distinct mechanical profiles complement one another to enhance surface hardness. For instance, in S-4, the higher PALF content (20 wt%) compensates for the reduced JF fraction by imparting rigidity, while CC contributes ductility and energy dissipation, resulting in a balanced hardness response. The observed increase in hardness with CC incorporation (from S-1 to S-5) indicates that, although CC is less stiff than PALF or JF, its high lignin content and surface roughness promote effective mechanical interlocking with the epoxy matrix. This enables CC to strengthen the composite without compromising stiffness, demonstrating that toughness and hardness are not mutually exclusive in natural fiber composites. Thus, the combined fiber system of JF, PALF, BaF, and CC governs not only the overall mechanical resilience but also the surface durability of the hybrid composites. The interfacial synergy between stiff fibers such as PALF and JF and more energy-absorbing fibers such as CC and BaF produces hybrid composites with tailored hardness characteristics, suitable for semi-structural applications requiring both strength and wear resistance. The measured hardness value of 72.6 Shore D is consistent with values reported for alkali-treated coir–flax–epoxy composites (71–75 Shore D), as noted by Yan et al.39. However, in sample S-6, where both JF and BaF are present at 20 wt%, a decrease in hardness was observed. This reduction can be attributed to the fiber crowding effect, where excessive fiber volume fractions promote fiber–fiber interactions rather than effective matrix encapsulation. Such conditions lead to localized stress concentrations at fiber ends or edges, the formation of resin-rich zones, and poor load distribution, thereby reducing resistance to indentation. Moreover, high fiber loading can hinder resin infiltration during processing, resulting in voids and diminished composite integrity51. By contrast, the incorporation of 5% NaOH alkaline treatment had a pronounced positive effect on hardness, with the treated composites achieving a value of 97 Shore D. This enhancement can be ascribed to improved fiber surface roughness, stronger fiber–matrix adhesion, and better load transfer, which collectively impart higher surface resistance and structural rigidity. The improvements in tensile strength (88.8 MPa), flexural strength (127.41 MPa), impact strength (15 kJ/m2), and hardness (97 Shore D) observed in this study are consistent with the findings of Mulenga et al.51, who reported comparable enhancements in natural fiber–reinforced composites through the incorporation of sisal fibers and fly ash fillers. Their study demonstrated increases of up to 130% in tensile strength, 386% in flexural strength, 17% in impact strength, and a substantial rise in hardness from 58.63 to 153.73 N/mm2, thereby validating the synergistic benefits of fiber reinforcement and surface treatment in improving composite performance.

Comparison between neat epoxy and composite samples

The mechanical performance of natural fiber-reinforced epoxy composites, including those containing JF, BaF, CC, and PALF, is primarily governed by fiber–matrix adhesion, fiber strength, and microfibrillar structure52. PALF exhibits superior tensile strength compared to CC due to its high cellulose content (70–82%) and low microfibrillar angle (8–14°), which enhances stress transfer within the composite. BaF, with its lignin-rich structure (5–15%), contributes to improved impact resistance, whereas jute provides moderate performance owing to its balanced cellulose (61–71%) and hemicellulose (14–20%) content. CC, characterized by higher lignin content (30–45%) but lower cellulose (32–43%), shows reduced tensile strength (95–230 MPa) yet offers greater toughness. In the tested hybrid composites (C1–C6), increasing PALF content (e.g., C5: 20 wt%) raised tensile strength to 85 MPa and flexural strength to 134 MPa, attributed to its high modulus and effective interfacial bonding with epoxy. Banana fiber improves impact resistance (e.g., C6: 22 J/m2) due to its ductility, while higher fiber loading (e.g., C6: 20 wt% BaF) enhances hardness (66 Shore D) through denser fiber packing. By comparison, neat epoxy exhibits a tensile strength of approximately 48 MPa and a modulus of 2–3 GPa, highlighting the 40–180% improvement achieved through fiber reinforcement. All composite configurations demonstrate marked enhancements, with tensile strength values ranging from 68 (C1) to 85 MPa (C5). This enhancement can be attributed to improved fiber–matrix stress transfer and mechanical interlocking provided by the fibrous reinforcement. Neat epoxy exhibits a low tensile modulus of 1.1 GPa, reflecting its limited stiffness under uniaxial loading. In contrast, the composites show increased stiffness, with tensile moduli ranging from 2.35 (C4) to 3.75 GPa (C2), indicating greater resistance to elastic deformation. Flexural strength also improved markedly, rising from 55 in neat epoxy to 134 MPa in C5, demonstrating the hybrid composites’ ability to withstand bending forces without fracture or delamination. Similarly, the flexural modulus increased from 2.4 GPa in neat epoxy to over 4.05 GPa (C3), highlighting the influence of fiber content and orientation on flexural resistance. Composite hardness ranged from 47 to 66 Shore D, exceeding that of neat epoxy (53 Shore D), with C6 reaching 66 Shore D, indicative of enhanced surface stiffness. Finally, the impact strength of neat epoxy was 6 J/m2, whereas the composite samples achieved significantly higher values, peaking at 22 J/m2 in C6. These results confirm that fiber reinforcement substantially improves energy absorption capacity, a critical property for applications involving impact or dynamic loading.

Morphological study of hybrid composite samples

To further investigate the microstructural characteristics and failure mechanisms of natural fiber (NF)-reinforced epoxy composites, optical and scanning electron microscopy was performed on the fractured surfaces of tensile-tested samples (Fig. 7, S-1 to S-6). The morphological analysis reveals that natural fibers were generally well distributed and embedded within the epoxy matrix across all samples, indicating uniform fiber dispersion during processing. However, variations in fiber–matrix adhesion, matrix continuity, and void content among the samples led to distinct failure behaviors that correlate with their mechanical performance. Severe matrix degradation and pronounced fiber pull-out were observed in sample S-1 (Fig. 7), reflecting poor interfacial adhesion between the fibers and the epoxy matrix. This weak bonding is likely due to the hydrophilic nature of untreated fibers and the hydrophobic character of the epoxy resin, which hinders strong interfacial connections, resulting in inefficient load transfer, fiber debonding, and matrix fracture under tensile stress. The presence of fiber rupture further indicates stress concentration at weak interfaces, causing premature failure. In contrast, the fractured surface of sample S-2 (Fig. 7) exhibits less matrix damage, suggesting stronger fiber–matrix interaction. The predominance of matrix-controlled failure with minimal fiber detachment indicates that the fiber–matrix bond remained largely intact during tensile loading, and the matrix properties governed the observed fracture behavior. This observation suggests enhanced fiber–matrix compatibility in sample S-2, likely resulting from optimized fiber processing or more favourable fiber loading. Sample S-3 (Fig. 7) exhibits localized fiber degradation and fragmented fiber particles, indicating that fiber variability in length, aspect ratio, and surface quality is critical for maintaining microstructural integrity. Non-uniform fiber properties lead to uneven stress distribution, creating localized stress concentrations that promote microcrack formation and fiber rupture. The presence of untreated or inadequately treated fibers further exacerbates these effects by limiting mechanical interlocking and chemical interaction with the matrix. In sample S-4 (Fig. 7), interfacial voids and fiber pull-out are evident, highlighting a common issue in natural fiber composites: insufficient matrix wetting of the fibers. Poor resin infiltration during manufacturing, especially in hand lay-up or low-pressure processes, can generate micro voids that act as stress concentrators, promoting debonding under tensile loading and weakening the composite. Additionally, the inherent incompatibility between hydrophilic fibers and hydrophobic epoxy remains a contributing factor to premature fiber–matrix separation. In contrast, Sample S-5 (Fig. 7) exhibits a markedly improved morphology, characterized by strong interfacial adhesion, minimal void content, and fiber fracture rather than pull-out, reflecting superior load transfer and composite integrity. This study indicates that fiber–matrix adhesion was significantly enhanced, likely due to the alkali treatment of the natural fibers. Alkalization removes surface impurities and hemicellulose, roughening the fiber surface and improving both mechanical interlocking and chemical interaction with the epoxy matrix. The improved tensile and impact properties of this sample reflect more efficient stress transfer across the fiber–matrix interface, contributing to higher mechanical strength. However, despite relatively high fiber loading (20 wt% JF and BaF), the morphology of sample S-6 (Fig. 7) shows fiber crowding and potential agglomeration, leading to fiber–fiber interactions and stress concentrations at fiber ends. This reduces load distribution efficiency and promotes localized matrix cracking. When fiber volume exceeds an optimal threshold, the matrix may fail to fully wet all fibers, resulting in partial resin infiltration, increased voids, and compromised composite integrity. These microstructural characteristics directly contribute to the observed reduction in impact strength for S-6, as excessive fiber content hinders energy absorption and crack-arrest mechanisms. Overall, the morphological data support the mechanical performance trends, particularly the impact strength results: samples with 20 wt% JF and CC (e.g., S-5) exhibit the most favorable microstructure, characterized by well-bonded fibers, minimal voids, and continuous fiber–matrix interaction, correlating with higher energy absorption under impact loading. This improvement is attributed to enhanced fiber–matrix adhesion, which facilitates more efficient stress absorption under dynamic loading. Conversely, the reduction in impact strength observed in S-6, despite increased BaF content, results from weakened interfacial bonding and reduced load transfer efficiency caused by excessive fiber loading and fiber crowding effects53. The morphological analysis underscores the critical role of interfacial adhesion, fiber surface treatment, optimal fiber volume fraction, and void minimization in governing the mechanical performance of bio-composites. Chemical treatment, appropriate fiber loading, and improved processing techniques enhance the compatibility between natural fibers and the epoxy matrix, promoting uniform fiber dispersion, microstructural homogeneity, and superior tensile and impact performance. Figure 7 (S-6) clearly shows fiber pull-out from the matrix under tensile loading, a common failure mode associated with insufficient interfacial bonding. The presence of detached fibers and rough fracture surfaces indicates that the adhesion between hydrophilic natural fibers and the hydrophobic epoxy resin was inadequate, leading to poor stress transfer across the interface under mechanical loading. This morphological observation aligns with the tensile test results, which show reduced tensile strength in sample S-6, indicating that insufficient fiber–matrix adhesion significantly diminishes the composite’s load-bearing capacity. Poor interfacial bonding promotes fiber slippage rather than cohesive matrix failure or fiber fracture, reflecting inadequate matrix–fiber connection. Consequently, applied tensile stress is not effectively transferred from the matrix to the fibers, resulting in premature debonding and fiber pull-out instead of efficient fiber reinforcement. A primary cause of this interfacial failure is insufficient surface treatment of the natural fibers. Without appropriate chemical modifications—such as alkali treatment, silane coupling, or plasma activation—the fiber surfaces retain non-cellulosic contaminants, including waxes, pectins, and lignin, which impede adhesion and stress transfer54.

These surface contaminants hinder intimate contact between the fibers and the matrix, preventing the formation of the chemical or mechanical interlocks necessary for strong adhesion. Although fiber pull-out can increase fracture surface roughness and superficially appear to enhance energy dissipation, in this context it represents a suboptimal failure mode. Fibers disengage from the matrix without effectively contributing to stress resistance, compromising not only tensile strength but also overall composite stiffness and structural integrity, particularly under prolonged or cyclic loading where interface durability is critical.

FTIR spectroscopy of hybrid composite samples

The alkaline-treated hybrid natural fiber-reinforced epoxy composite sample (S-5) was analyzed using FTIR spectroscopy to investigate the chemical interactions and structural modifications in the lignocellulosic fibers resulting from the treatment. The recorded spectra, shown in Fig. 8, span the 500–4000 cm−1 range, capturing functional groups relevant to both the fiber constituents and the epoxy matrix. Absorption peaks at 2921 cm−1 and 2867 cm−1 correspond to stretching vibrations of aliphatic –CH2 and –CH3 groups, respectively, indicating the presence of saturated hydrocarbon chains in both the cellulose backbone and the epoxy polymer matrix. Peaks at 1243 cm−1 and 782 cm−1 are attributed to C–O stretching vibrations in the epoxide ring, confirming the characteristic structure of the epoxy resin. Absorptions at 1673 cm−1 and 1564 cm−1 correspond to C=C stretching vibrations in the aromatic benzene rings of the epoxy backbone, demonstrating retention of the aromatic structure post-curing55. The broad absorption band centered at 3456 cm−1, associated with O–H stretching vibrations in cellulose and hemicellulose, exhibits notable changes upon alkaline treatment, reflecting modifications to the fiber surface chemistry. Treatment with NaOH causes the O–H stretching band to narrow and shift toward 3700 cm−1, indicating a reduction in hydroxyl group density. This shift results from the partial replacement of hydroxyl groups with acetyl or alkali-reactive groups, which decreases fiber hydrophilicity and enhances compatibility with the hydrophobic epoxy matrix. The reduction in intensity and breadth of the 3500–3000 cm−1 band reflects the removal of amorphous hemicellulose and lignin, both of which contain free –OH groups. This chemical purification through alkaline delignification exposes crystalline cellulose, promoting improved fiber–matrix interfacial interaction via increased surface roughness and reactivity56. Additionally, the treatment modifies the fiber surface chemistry, enhancing hydrophobic interactions with the matrix and reducing water absorption—both critical factors for improving composite dimensional stability and mechanical performance. The FTIR analysis confirms that alkaline treatment significantly alters the chemical composition and surface functionality of the natural fibers, thereby strengthening interfacial bonding with the epoxy resin in sample S-5.

Surface topographical analysis of hybrid composite sample

The surface topography of the alkali-treated hybrid natural fiber composite (sample S-5) was examined using atomic force microscopy (AFM), producing high-resolution two-dimensional (2D) and three-dimensional (3D) images without physically damaging the fiber surface (Fig. 9). AFM analysis revealed distinct surface morphological features in the natural fiber composite (NFC) structure of sample S-5. The average surface roughness (Ra) was 31.43 nm, indicating the presence of residual surface contaminants such as fragmented lignin or unremoved amorphous cellulose. These surface irregularities are often associated with incomplete fiber treatment or uneven chemical modification during alkaline processing57. Table 4 summarizes the roughness parameters of sample S-5. The root mean square (RMS) roughness (Rq) of 39.54 nm confirms the nanoscale undulations on the fiber surface, which serve as critical indicators of potential interfacial adhesion with the epoxy matrix. Increased surface roughness enhances mechanical interlocking, thereby improving stress transfer efficiency between the fibers and the matrix under mechanical loading. Additional topographical parameters, such as skewness (Rsk = – 0.821 nm) and kurtosis (Rku = 3.612 nm), provide further insight into the distribution and nature of surface features. The negative skewness indicates a predominance of valleys over peaks, while a kurtosis value greater than three signifies a leptokurtic surface distribution, characterized by sharper features and more pronounced peaks and valleys attributes often favourable for anchoring at fiber–matrix interfaces. The average peak height (Rz = 193.52 nm) and maximum profile height (Rt = 170.98 nm) reveal significant nanoscale surface undulations, highlighting the heterogeneous topography of the fibers. When embedded in a thermosetting polymer such as epoxy, these features can enhance wetting behaviour and interfacial bonding strength56. However, the presence of residual lignin or surface contaminants, as reflected by Ra and Rq, may still limit optimal chemical bonding, suggesting that further surface modification—via silanization, plasma treatment, or enzymatic processing—could improve fiber compatibility with hydrophobic polymer matrices. AFM analysis confirms that, although alkaline-treated fibers in sample S-5 exhibit increased roughness conducive to mechanical interlocking, additional refinement of surface chemistry and purity could further enhance reinforcing performance. Careful optimization of surface treatment protocols for natural fibers in structural epoxy composites can thus lead to improved load transfer and overall composite durability.

Selection of ML models

Linear regression, multilinear regression, decision tree regression, and random forest regression were selected due to their established effectiveness in regression-based prediction tasks, particularly in materials science and composite performance modelling. Linear and multilinear regression serve as interpretable baseline models, enabling the evaluation of linear relationships between fiber composition and mechanical properties. Decision tree regression provides a non-linear modelling approach, capable of capturing complex interactions between variables. Random forest regression, as an ensemble method, further improves prediction accuracy and generalization by mitigating overfitting. The use of this diverse set of models allows for comparative assessment and ensures robust prediction of composite behaviour based on experimental data. All data preprocessing, model training, and evaluation were performed using the python programming language in the Google Colaboratory (Colab) environment.

Linear regression model using ML to predict mechanical attributes

This study utilized experimental data on mechanical properties, with six data points recorded for each input parameter: tensile strength, flexural strength, impact strength, and hardness. The data flow for machine learning in fiber-reinforced hybrid composites is illustrated in Fig. 10. Linear regression, a widely used statistical method, determines the relationship between a dependent variable and one or more independent variables58. In this approach, the least squares method minimizes the mean squared error between predicted and observed values. In natural fiber-reinforced composites, the dependent variable typically represents the mechanical properties of the material, such as tensile strength, flexural strength, impact strength, and hardness. The model assumes a linear relationship between dependent and independent variables, allowing prediction of how changes in fiber composition or other parameters affect composite performance. Moreover, linear regression facilitates both optimization and prediction of composite material attributes, making it a valuable tool for the design and development of high-performance, environmentally friendly fiber composites.

ML linear regression model for predicting tensile strength

The projected values closely match the real values, indicating that the linear regression model has efficiently captured the link among the input variables and the tensile strength, as shown in Fig. 11a.

Small deviations observed in the first few samples, such as the differences between actual and predicted values for S-1 and S-2, can be attributed to inherent variability or noise in the experimental data. In contrast, the near-perfect agreement for samples S-3, S-4, S-5, and S-6 indicates that the model was effectively trained, with minimal overfitting or underfitting. This consistency demonstrates that the linear regression model successfully captures the underlying trends in the dataset and can reliably predict tensile strength for this set of hybrid composites. Overall, these results confirm the model’s applicability and accuracy, highlighting a strong correlation between the experimental data and the predictions generated by the linear regression approach.

ML linear regression model for predicting flexural strength

The comparison of anticipated and actual flexural strength values demonstrates high model performance and a close fit between the model and the observed data, as shown in Fig. 11b. In this situation, the predicted values are almost identical to the actual ones, with only minor deviations. For example, in S-1, the actual flexural strength is 127.4, whereas the anticipated value is 129.28, indicating a 1.88-point difference. Similarly, the predictions for S-2 (129.6 real vs. 130.96 expected) differ by only 1.36, which is a tiny difference. The fact that Samples S-3, S-4, S-5, and S-6 have perfect alignment between actual and anticipated values implies that the linear regression model has captured the link between input variables and flexural strength very well. The model appears to generalize well for these data, demonstrating the accuracy and dependability of its predictions. In machine learning terminology, this result indicates that the linear regression technique was successful in reducing the error (or residuals) between real and predicted values to an extremely low level. Minor discrepancies in the initial few samples could be attributed to small variances or noise in the data, which is typical of real-world datasets. Overall, the model’s ability to forecast flexural strength with such precision indicates that it has effectively learned the underlying trends and is likely to perform well in similar situations.

ML linear regression model for predicting impact strength

The predicted values closely match the actual values, indicating that the linear regression model effectively captured the underlying relationship between the input variables and impact strength, as shown in Fig. 12a. For S-1, the actual impact strength is 16.1 J/m2, while the predicted value is 18.62 J/m2, yielding a difference of 2.52 J/m2. Similarly, S-2 shows a discrepancy of 2.73 J/m2 between the actual (17.6 J/m2) and predicted (20.33 J/m2) values. In contrast, the predicted values for samples S-3, S-4, S-5, and S-6 perfectly align with the actual measurements, demonstrating high prediction accuracy. This suggests that the model is well-calibrated and has successfully learned the relationship between the input features and impact strength for these samples.

The minor deviations observed in the first two samples can be attributed to natural variability or inherent noise in the experimental data. Overall, these results confirm that the linear regression model provides a reliable and accurate prediction of impact strength based on the given input parameters.

ML linear regression model for predicting for hardness

Figure 12b shows that the predicted hardness values closely match the actual measurements, with only minor deviations. For instance, S-1 has an actual hardness of 64.3 Shore D and a predicted value of 66.16 Shore D, resulting in a slight difference of 1.86. Similarly, S-2 exhibits a 2.16-point disparity between the actual (65.8) and predicted (67.96) values. These small deviations fall within an acceptable range, indicating good model performance. The predicted values for Samples S-3, S-4, S-5, and S-6 perfectly match the actual values, demonstrating 100% prediction accuracy. This alignment suggests that the linear regression model effectively captured the relationship between the input variables and hardness, producing accurate and reliable predictions. The minor discrepancies in the first two samples can be attributed to natural variability or noise in the experimental data, a common occurrence in real-world applications. Overall, these results confirm that the model is both reliable and effective for predicting hardness, exhibiting a high degree of accuracy and generalizability within this dataset.

Evaluation of performance metrics

The results provide a comparison of experimental and anticipated values based on four assessment metrics: R2, MAE, MSE, and RMSE. Table 5 illustrates the performance evaluation findings for each model of mechanical features, as well as the various metrics.

The performance of machine learning models across different mechanical properties of natural fiber composites exhibits varying levels of accuracy and prediction error. For tensile strength, the linear regression model achieved an R2 value of 0.953, explaining approximately 95.3% of the variance. This is supported by relatively low error metrics, with MAE = 0.823, MSE = 1.306, and RMSE = 1.142, indicating highly accurate predictions with minimal error. For flexural strength, the R2 value decreased to 0.775, reflecting a reduced capacity to capture variability. Error metrics were MAE = 0.824, MSE = 1.117, and RMSE = 1.056, slightly higher than for tensile strength, suggesting a moderately accurate model fit. In predicting impact strength, the model yielded an R2 of 0.801, with MAE = 0.834, MSE = 1.092, and RMSE = 1.044, indicating moderate accuracy and comparable prediction errors to flexural strength. For hardness, the model achieved an R2 of 0.835, explaining roughly 83.5% of the variance; however, MAE = 0.862, MSE = 1.303, and RMSE = 1.141 were relatively higher, suggesting slightly lower predictive precision compared to the other properties. Other models, including multilinear regression, decision tree regression, and random forest regression, were also applied using similar approaches, and their performance metrics were similarly evaluated to compare predictive efficiency.

Prediction of mechanical attributes from ML (Multilinear, Decision tree and Random forest regression) models

Tensile strength comparison between ML models

Tensile strength ratings ranged from 71.3 to 85.8 MPa. Figure 13 displays a comparison of tensile strength between actual and predicted ML models. The linear and multilinear regression models generate identical forecasts for all samples, closely matching the actual values, particularly for S-3 to S-6. However, both significantly underestimate S-1 and S-2. The decision tree model makes perfect or near-exact predictions for the majority of samples, albeit it repeats the same value (77.5 MPa) for several samples, as is typical of its discrete decision-based splitting. The random forest model produces the smoothest and most realistic forecasts, with values that are very near to the actual tensile strength in all samples. This indicates that the random forest model generalizes better and avoids overfitting.

Flexural strength comparison between ML models