Abstract

This study presents a novel sustainable approach to desalination by integrating tidal energy with reverse osmosis (RO) technology, enhanced by Kenics static mixers (KSM) to improve mass transfer. A three-dimensional computational fluid dynamics (CFD) model analyzes the optimized ROKSM configuration, featuring three rows of KSM at a 30° twist angle, achieving a 1.6-fold increase in the Sherwood number (from 8.5 to 13.6 at Re = 300) and a 23% increase in water flux (from 13 to 16 L/m²h) by reducing concentration polarization. However, this comes with a 4.7-fold increase in pressure drop, partially mitigated by Energy Recovery Devices (ERDs), resulting in a net specific energy consumption of 2.2–2.5 kWh/m³. Tidal energy from global sites (600–1700 kW) provides feed pressures of 17–80 bar, with energy storage and pressure regulation ensuring stable RO operation despite tidal fluctuations. Techno-economic analysis indicates a potential levelized cost of water (LCOW) reduction of 15–20% (to 0.45–0.65 $/m³) under realistic conditions, though challenges in intermittency and costs require further validation. The integrated approach, validated with less than 5% error against experimental data, demonstrates significant potential for sustainable freshwater production, offering a scalable solution for coastal regions worldwide.

Similar content being viewed by others

Introduction

Water scarcity is an escalating global issue, intensified by climate change, population growth, and industrialization. Desalination, especially through RO, has emerged as a practical solution to this problem by converting seawater into potable water1,2. However, the energy-intensive nature of traditional desalination processes presents significant economic and environmental challenges3,4. To address these challenges, coupling tidal energy plants with desalination plants to produce drinking water is a promising approach. Tidal energy plants harness the power of ocean tides to generate electricity. Tidal stream generators, also known as tidal energy converters (TECs), extract energy from the kinetic motion of tidal currents and function similarly to underwater wind turbines, capturing the energy from moving water to generate electricity5,6. Tidal stream generators are installed in areas with strong tidal currents, such as narrow straits, estuaries, or between islands because of their high energy potential and minimal environmental impact7. Tidal stream generators are particularly suitable for small to medium-scale applications due to their relatively low installation costs and minimal environmental impact compared to other methods8.

Several studies have been done in the field of RO and tidal energy optimisation9,10. Wu et al.11 focused on a hybrid Multi-Effect Distillation (MED) and RO desalination plant in a large coastal steel enterprise in Northeast Asia, China. The optimized hybrid system demonstrated significant performance improvements, achieving a recovery rate of approximately 54.22%, an average product water cost of 0.5582 US$/m³, and energy consumption of 1.015 kgce/m³, translating to an equivalent carbon emission of 2.49 kg/m³, exhibiting superior energy-saving efficiency, lower operational costs, and reduced carbon emissions compared to standalone or alternative hybrid systems. Qudah et al.12 conducted a study focused on powering a small-scale RO unit using the differential evolution algorithm, specifically tailored to the local weather data of Dhahran, Saudi Arabia. The findings revealed a 4.67% reduction in the levelized cost of energy. Furthermore, the cost of water when selling surplus energy to the grid decreased by between 14.5% and 15.5%. Additionally, when surplus energy was utilized for further desalination, the cost of water was lowered by approximately 18–22%. Ali et al.13 assessed the techno-enviro-economic aspects of a hybrid renewable energy system designed to power an RO/Well unit with a capacity of 500 m³/day in the Salbukh region of Riyadh, Kingdom of Saudi Arabia. Using Homer software, the study identifies an optimal system configuration that includes photovoltaics, wind turbines, fuel cells, a reformer, an electrolyzer, a hydrogen tank, and a battery. The results showed that the optimal hybrid system decreased the cost of energy by almost 26%. Gao et al.14 examined the application of magnetization pretreatment in the RO process with the aim of reducing scale formation and improving water flux. Their findings demonstrated that magnetization effectively slowed the decline in water flux during the RO process and enhanced flux recovery following cleaning. Additionally, magnetization increased the solubility of carbonate solutions, which contributed to a reduction in carbonate scaling. The Ryznar Stability Index further indicated improved solubility and a decrease in scaling tendencies. Shakibi et al.15 conducted an exploration of a groundbreaking hybrid system that combines power generation, cooling, freshwater production, and hydrogen production, utilizing geothermal systems in Australia as a case study. They assessed the system from energy, exergy, and economic viewpoints. To optimize the system’s operation, an artificial neural network was implemented, and the study compared the accuracy of four different neural networks in terms of optimizing and predicting system performance. The findings revealed an improvement in exergy efficiency of 16.01%, alongside a reduction in the payback period of 13.62%. Xu et al.16 investigated the application of coastal acoustic tomography (CAT) technology to evaluate the spatial and temporal variations in the ocean environment for tidal energy extraction. CAT technology was proposed to assess the ocean environment through sound wave signal transmission between multiple stations. The study examined the tidal energy distribution around the Liuheng channel using a three-station mirror-type acoustic tomography experiment. The findings indicated that the spatial distribution of tidal energy could be indirectly calculated via reciprocal travel time, providing a reference for tidal energy evaluation. This method is suitable for assessing the spatial and temporal distribution of tidal energy in small waterways, bays, and complex coastal areas. Skiarski et al.17 analyzed the operation and optimization of tidal barrage power plants, which generate clean electricity by utilizing tidal range variations. The study offered a critical analysis of various strategies to optimize tidal barrage operations. It focused on employing optimization schemes, utilising the barrage models and opportunities for further improvement.

While feed spacers have been extensively studied for concentration polarization (CP) mitigation in RO membranes, achieving flux enhancements through turbulence promotion18,19, they often introduce uneven flow distributions and increased fouling propensity. In contrast, Kenics static mixers (KSM) offer a novel alternative with helical elements that induce radial mixing and vortex formation, potentially providing more uniform mass transfer and lower biofouling risks. This study positions KSM as a complementary enhancement to spacers, integrating them with tidal energy for the first time to address both energy and mass transfer challenges in sustainable desalination.

Methodology

System description and integration

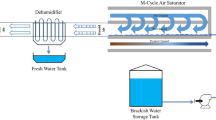

The proposed Reverse Osmosis Tidal Energy-Kenics Static Mixer (ROTE-KSM) system integrates tidal stream generators with RO membranes enhanced by Kenics static mixers (KSM) to improve mass transfer and reduce concentration polarization (CP). Tidal energy is harnessed using underwater tidal stream generators, which convert kinetic energy from tidal currents into electricity via turbines similar to wind generators20. These devices are deployed in high-current areas such as narrow straits, estuaries, or between islands, providing predictable power outputs ranging from 600 to 1700 kW across global sites21. The generated electricity powers high-pressure pumps, delivering feed pressures of 17–80 bar to the RO unit, sufficient for seawater desalination22,23.

To manage tidal intermittency (semidiurnal cycles with peak flows every 6–12 h), the system incorporates battery energy storage systems (sized at 20–50% of peak load, based on NREL projections24 and variable frequency drives (VFDs) for pumps, ensuring stable operation. Excess energy during peaks is stored or used for auxiliary processes, while pressure regulation maintains consistent RO inlet conditions.

The RO process involves pretreatment (filtration to remove particulates), high-pressure pumping, and membrane separation25. Seawater feed (salinity ~ 13 mol/m³ NaCl, equivalent to 35 g/L) enters the membrane module at 25 °C and Re 100–300. KSM elements are installed in the feed channel to induce helical mixing, disrupting the boundary layer and enhancing mass transfer. The optimized configuration features three rows of KSM at a 30° twist angle, as determined from parametric studies. Permeate is collected at fluxes of 13–16 L/m²h, while brine is routed through Energy Recovery Devices (ERDs) with 95% efficiency to recover pressure energy, reducing net specific energy consumption (SEC) to 2.2–2.5 kWh/m³. Table 1 describes the process of the optimized RO plant coupled with the tidal stream generator.

This integrated design leverages tidal’s renewable nature for sustainable desalination, with KSM addressing CP limitations in standard RO. Process simulations were conducted using Aspen Plus for flowsheet validation, confirming energy balances and flux predictions.

Synergistic integration of tidal energy and KSM (ROTE-KSM) system combines tidal energy integration with KSM-enhanced RO to achieve a sustainable and efficient desalination process. Tidal energy powers the high-pressure pumps, while KSM improves mass transfer efficiency, resulting in higher water flux and reduced energy consumption per unit of freshwater produced. This synergistic approach not only addresses the energy demands of RO but also enhances membrane performance, offering a scalable solution for sustainable freshwater production in coastal regions. Figure 1 represents a plot plant of the proposed model.

CFD model setup

The CFD analysis of the ROKSM system was conducted using a three-dimensional framework to evaluate mass transfer enhancement and hydrodynamic performance. The computational domain represents the RO module with integrated Kenics static mixers (KSM), and the following details clarify the setup and assumptions.

This study explores the mass transfer performance of a ROTE system integrated with KSM through a three-dimensional CFD model. The analysis primarily examines the Sherwood number and pressure drop under various conditions, including the static mixer twist angle, Reynolds number, and the number of mixer rows. Specifically, the number of static mixer rows ranges from 1 to 3, the twist angle varies between 30° and 90°, and the Reynolds number is considered from 100 to 300. The ROTE has dimensions of 30 mm in length, 1 mm in height, and 4 mm in width. Figures 1(a), 1(b), and 1(c) illustrate the different configurations: ROTE without KSM, ROTE with a single row of KSM (designated as ROKSM), and ROKSM with three rows, all set at a twist angle of 30°. Each ROKSM configuration comprises five KSM elements, each with a thickness of 0.5 mm and a length of 5 mm. Figure 2 represents the configurations of ROTE with KSM by different rows and without KSM.

The geometry is defined in a Cartesian coordinate system (x, y, z), where:

-

x is the axial direction along the flow path (length of the channel),

-

y is the transverse direction across the channel width,

-

z is the vertical direction representing the channel height.

The channel dimensions are 0.2 m (length, x), 0.05 m (width, y), and 0.002 m (height, z), with KSM elements (twist angle 30°, diameter 0.01 m) inserted at three rows along the x-axis. In practice, RO membranes are typically rounded (spiral-wound modules); however, for computational efficiency, the model simplifies the membrane as a flat channel. The KSM is integrated between two flat membrane layers, and this approximation neglects curvature effects, which are assumed to have a minor impact on mass transfer due to the small channel height relative to the membrane radius (typically 0.1–0.2 m in spiral-wound modules).

For modelling ROKSM, the model is assumed to be three-dimensional and laminar due to the low Reynolds number. The feed flow is considered incompressible and isothermal. According to these assumptions, the equations of continuity, momentum, and mass transfer are illustrated in Table 2. In the equations of Table 2, c is the concentration of salt, u is the velocity vector, p is pressure, ρ is density, D is the mass transfer diffusion coefficient of salt, and µ is the viscosity of the flow.

Where u is the velocity vector, p is pressure, µ is viscosity, ρ is density, f is body forces, C is species concentration, D is diffusion coefficient, and S is source term (zero in bulk flow).

The CFD model solves the Navier-Stokes equations for incompressible flow and the convection-diffusion equation for mass transfer. The flow is initially assumed to be laminar, consistent with a Reynolds number (Re) of 300, defined as \(\:Re=\frac{\rho\:\nu\:{D}_{h}}{\mu\:}\), where ρ is fluid density (1025 kg/m³ for seawater), v is average velocity (0.1 m/s), Dh is hydraulic diameter (0.004 m), and µ\muµ is dynamic viscosity (0.001 Pa·s), representing the ratio of inertial to viscous forces. The Sherwood number (Sh), defined as \(\:Sh=\frac{k{D}_{h}}{D}\), where k is the mass transfer coefficient and D is the diffusion coefficient (1.6 × 10–3 m2/s for NaCl), indicates the dimensionless mass transfer rate.

However, the insertion of KSM with a 30° twist angle disrupts the laminar flow, creating localized regions of higher velocity and potential turbulence due to the helical structure. To assess this, the primary model employs a laminar flow assumption, validated against experimental data with errors less than 5% as the overall Re remains below the transition threshold (~ 2000 for rectangular channels). A sensitivity analysis using the k-ε turbulence model was conducted to evaluate localized turbulence effects, revealing that turbulent viscosity increases by up to 15% near the KSM but does not significantly alter the Sherwood number (difference < 2%) or water flux predictions. Thus, the laminar model is deemed sufficient for the current analysis, though future studies may refine this with a hybrid approach for higher Re.

The water flux across an RO membrane is governed by the difference between the applied pressure and the osmotic pressure, adjusted for permeate pressure26:

where i is the van’t Hoff factor (≈ 2 for NaCl), cw is the wall concentration (mol/m³), R is the gas constant (8.314 × 10⁻⁵ bar.m³/mol.K), and T is the absolute temperature.

Concentration polarization increases cw relative to the bulk concentration (cb), quantified by the concentration polarization factor (CPF):

The wall concentration is related to the mass transfer coefficient (k) via the boundary layer model.

where D is the diffusion coefficient, and dc/dy is the concentration gradient at the membrane surface.

The Sherwood number is defined as shown in Eq. 5:

where Lc is the characteristic length (e.g., channel height or hydraulic diameter), and k is the mass transfer coefficient. Sh quantifies the efficiency of mass transfer, reducing concentration polarization in the ROKSM system.

To link osmotic pressure to Sherwood number, the mass transfer at the membrane surface should be considered. The water flux J also drives solute convection toward the membrane, balanced by diffusion away from it. The steady-state mass transfer equation is:

where cp is the permeate concentration (≈ 0 mol/m³ for RO, as permeate is nearly pure water). Combining with the mass transfer coefficient:

Equation 8 resulted from Eq. 7:

The osmotic pressure is:

Equation (1) is unconventional because osmotic pressure is not typically expressed directly as a function of Sh. The Sherwood number influences cw via the mass transfer coefficient, which indirectly affects π. By Eq. (10):

With:

The water flux, J, is determined by the hydraulic permeability, L, the pressure difference between the feed side (P) and the permeate side (Pp), and the osmotic pressure, which is calculated using the Van’t Hoff factor, f, where Sh is the Sherwood number, D is the diffusion coefficient and ΔC is the concentration difference across the membrane. For NaCl, f has a value of 4955 Pa per mol/m³26. The essential data of the present CFD model are available in Table 3.

The boundary conditions for the model are the inlet velocity and the inlet salt concentration, which are specified at the inlet of the membrane. An outlet pressure defined as a pressure condition is applied at the outlet, and a no-flux boundary condition, \(\:n.(D\nabla\:c\:+\:uc)\:=\:0\), is considered for salt on the membrane surfaces. Additionally, Eq. 1 for the two membrane surfaces is used to describe the mass transfer of water in the fluid flow26.The remaining boundary condition is the no-slip condition. Figure 3 presents the boundary condition of the proposed model.

Results and discussion

Model verification and validation

Figure 4(a) illustrates the mesh domain of the present CFD model. This system uses an unstructured mesh due to the existence of KSM in the RO. For mesh independence analysis, Fig. 4(b) illustrates the mass transfer coefficient as a function of the number of elements. According to the results, after 300,000 elements, the variation in the mass transfer coefficient is not significant; thus, this mesh is used for calculations.

For validation of mass transfer in the RO, Fig. 4(c) presents a comparison of mass transfer from this study and the study by Li et al.26 as a function of inlet velocity. The inlet concentration of salt in the RO is 13 mol/m2, and the feed pressure is 13.6 bar. According to the results, the average relative error between the present model and the data from Li et al. is less than 5%, indicating good agreement.

To the best of our knowledge, no previous study has investigated RO with KSM. Therefore, to validate the flow characteristics of an RO system with a spacer, the present study utilizes the data from Kavianipour et al.19, who examined a submerged spacer in an RO system. Figure 4(d) presents a comparison of the pressure drop between the current study and the data reported by Kavianipour et al. across different Reynolds numbers. The results indicate that the average relative error between the present model and the data from Kavianipour et al. is less than 2%, demonstrating strong agreement.

Concentration and velocity distribution of RO and kenics static mixers (ROKSM)

Figure 5 illustrates the velocity and concentration distributions in the RO feed channel at Re = 300. The subfigures are: (a) velocity distribution in ROKSM, showing enhanced mixing due to helical elements; (b) velocity distribution in standard RO, with more laminar flow and boundary layer buildup; (c) concentration distribution in ROKSM, demonstrating reduced wall concentration (indicating lower CP); and (d) concentration distribution in standard RO, with higher wall concentration and pronounced CP layer. These profiles confirm that KSM disrupts the boundary layer, reducing CP factor (CPF) from 1.038 in standard RO to 1.015 in ROKSM, leading to improved mass transfer.

In the velocity distributions (Fig. 3a and b), the ROKSM process (Fig. 5a) exhibits a more complex and varied color pattern, indicating enhanced mixing induced by the KSM elements. The static mixers disrupt the laminar flow, creating regions of higher velocity and turbulence, which are absent in the standard RO process (Fig. 5(b)). In Fig. 5(b), the standard RO shows a predominantly uniform blue-green pattern, suggesting a more consistent but lower velocity profile, typical of laminar flow without mixing elements. This contrast highlights KSM’s role in promoting a more dynamic flow, which can reduce stagnant zones and enhance mass transfer.

The concentration distributions (Figs. 5(c) and 5(d)) further elucidate the effect of KSM on solute behavior. In the ROKSM process (Fig. 5(c)), the concentration varies between 13 and 16 mol/m³, with a more uniform distribution across the channel, indicating effective mixing that mitigates solute accumulation near the membrane surface. The presence of KSM elements disrupts the concentration boundary layer, preventing the pronounced red zones (higher concentrations) seen in the standard RO process (Fig. 5(d)), where concentrations reach up to 16 mol/m³ near the outlet. The standard RO shows a clear gradient, with increasing concentration along the flow path, reflecting severe concentration polarization due to the lack of mixing. This qualitative difference supports of reduction in concentration polarization with ROKSM, as the uniform concentration profile reduces the risk of fouling and enhances membrane performance.

As mentioned, Fig. 5 shows velocity distributions in (a) ROKSM and (b) standard RO, and concentration distributions in (c) ROKSM and (d) standard RO, confirming reduced CP in ROKSM.

Effect of Reynold number and row of KSM

Figure 6 compares the Sherwood number, pressure drop, and concentration distribution for different Reynolds numbers (Re) and the number of rows of the KSM. Figure 6(a) shows that the Sherwood number increases with an increase in the Reynolds number. The condition with three rows of KSM showed the highest Sherwood number, indicating better mass transfer performance compared to one row of KSM and without KSM. According to Fig. 6(a), the Sherwood number (Sh) is significantly higher in the ROKSM system compared to the standard RO process, especially with three rows of KSM. At Re = 300, the Sherwood number for ROKSM with three rows is approximately 1.6 times of the standard RO process. Even with one row of KSM, the Sherwood number is 1.3 times of the standard RO process. Figure 6(a) shows that the ROKSM system enhances mass transfer efficiency by up to significantly compared to the standard RO process, with three rows of KSM providing the best performance. Figure 6(b) represents that the pressure drop increased with an increase in the Reynolds number. The condition with three rows of KSM showed the highest pressure drop, indicating higher resistance to flow compared to one row of KSM and without KSM. At Re = 300, the pressure drop for ROKSM with three rows is approximately 4.7 times of the standard RO process. With one row of KSM, the pressure drop is 1.5 times of the standard RO process. While ROKSM improves mass transfer, it increases the pressure drop which is a trade-off that must be managed. Figure 6(c) depicts the concentration profile along the RO system enhanced with KSM (ROKSM) at Re of 100, 200, and 300, while Fig. 6(d) shows the same for a standard RO system without KSM.

The main findings underscore the effectiveness of KSM in improving RO performance. ROKSM reduces concentration polarization as evidenced by the lower outlet concentration. Higher Re values improve mixing in ROKSM, smoothing the concentration profile and reducing peaks, while in standard RO, they exacerbate polarization due to the lack of mixing. However, this comes with a higher pressure drop, a trade-off that requires further optimization. The lower osmotic pressure in ROKSM enhances the net driving force for water flux.

The incorporation of KSM in the ROKSM configuration enhances mass transfer by disrupting the laminar flow typical of standard RO systems, as evidenced by the complex velocity patterns in Fig. 5(a). This disruption creates localized turbulence, which reduces the concentration boundary layer near the membrane surface, lowering concentration polarization and increasing the Sherwood number to (Fig. 6(a)). However, the KSM’s twisted geometry increases flow resistance, leading to a pressure drop approximately 4.7 times higher than that of standard RO at Re = 300 (Fig. 6(b)). This trade-off arises because the enhanced mixing requires additional energy to overcome the increased frictional losses within the feed channel. The 30-degree twist angle optimizes mixing by maximizing flow disruption, but it also results in the highest pressure drop, necessitating a careful balance between mass transfer gains and energy costs.

The ROKSM system increases water flux by 23%, from 13 L/m2 h for standard RO to 16 L/m²h at Re = 300, driven by reduced concentration polarization due to enhanced mixing by Kenics static mixers. The CFD model (Sect. 4) shows this through concentration profiles, with ROKSM exhibiting a uniform distribution ranging from 13 to 16 mol/m³, compared to standard RO’s pronounced gradient reaching 22 mol/m2 at the outlet wall. The outlet wall concentration is 13.5 mol/m³ for ROKSM and 16 mol/m2 for standard RO, with a bulk concentration of 13 mol/m2 (Table 3).

This reduction in wall concentration lowers the osmotic pressure, which, per Eq. (1), increases water flux. The hydraulic permeability is 2.74 m/h/bar, and the feed pressure is assumed at 60 bar, with a permeate pressure of 1 bar. The salt diffusion coefficient is 1.6 × 10–3m²/s, and the channel height is 1 mm (Table 3). The Sherwood number for ROKSM is 13.6, compared to 8.5 for standard RO, indicating enhanced mass transfer that reduces solute buildup at the membrane surface. The CFD model, validated with less than 5% error, confirms that ROKSM’s higher Sherwood number and lower wall concentration directly contribute to the 23% flux increase, as visualized in Fig. 5(c) compared to Fig. 5(d).

Investigating the impact of the angle of KSM

Sherwood number is an indicator of mass transfer performance. Higher Sherwood numbers represent better mass transfer efficiency. According to Fig. 7(a), the Sherwood number increased with the Reynolds number for all conditions. The KSM at a 30-degree angle showed the highest Sherwood number, indicating the best mass transfer efficiency. The KSM at a 90-degree angle showed a lower Sherwood number compared to the 30-degree angle but still higher than without KSM.

Figure 7(b) shows that the pressure drop increased with the Reynolds number for all conditions. The KSM at a 30-degree angle showed the highest pressure drop, indicating the greatest resistance to flow. The KSM at a 90-degree angle represented a lower pressure drop compared to the 30-degree angle but higher than without KSM.

Figure 7 shows that the KSM at a 30-degree angle provides the best mass transfer efficiency, as indicated by the highest Sherwood number. This suggests that the 30-degree angle is more effective at promoting mixing and enhancing mass transfer. In terms of flow resistance, the KSM at a 30-degree angle also results in the highest pressure drop, indicating increased resistance to flow. This is a trade-off that must be considered when optimizing the process.

The angle of the KSM has a significant impact on both mass transfer efficiency and flow resistance. While a 30-degree angle provides the best mass transfer, it also increases the pressure drop. Therefore, the angle should be optimized based on the specific requirements of the process, balancing mass transfer efficiency and flow resistance. Overall, the analysis highlights the importance of the angle of the KSM in optimizing the RO process. Adjusting the angle can significantly impact the performance, and careful consideration is needed to achieve the desired balance between efficiency and resistance. Figure 8 represents the velocity and concentration distribution for different 30- and 90-degrees positions of the mixers.

Integration of tidal energy with ROKSM desalination

In this section, the effect of integrating ROKSM with tidal energy is investigated (ROTE-KSM). First, the range of power that can be harnessed from tidal energy is determined. This power is then utilized to drive a feed pump. The outlet pressure of the pump is considered the feed flow pressure, which is then supplied to the ROTE-KSM system. Table 4 represents the several tidal stream generator sites according to their capacity and scale. Figure 6 illustrates the outlet pressure of the pump as a function of different tidal power sites, considering a flow rate range between 300 and 1000 m³/h. This figure is generated using Aspen Plus V12.

As expected, an increase in flow rate results in a decrease in outlet pressure. For a power input of 600 kW, the outlet pressure ranges between 55 and 17 bar. At 1000 kW, the pressure varies from 91 to 28 bar, while for 1700 kPa, it ranges between 153 and 46 bar. In all three cases, the generated pressure is sufficient for RO applications. However, it is important to note that RO membranes have an upper-pressure limit due to structural constraints. With this renewable energy source, the primary concern is the minimum pressure required to effectively utilize tidal energy for pressure generation and overcome the osmotic pressure of the feed flow. Some studies consider the maximum feed pressure to be below 80 bar. Therefore, in this study, we investigate feed pressures ranging between 17 and 80 bar, which falls within the pressure range available from tidal power. The minimum and maximum pressures within this range are presented in Fig. 9.

To clarify the integration of tidal energy with the ROKSM system, we define an operating condition for the primary CFD analysis at Re = 300, where key results are reported (Sherwood number of 13.6, 23% flux increase from 13 to 16 m/h). For a 10,000 m2/day (3.65 million m³/year) desalination plant, we select a feed flow rate of 500 m2/h (within 300–1000 m2/h, Sect. 5.4) and a feed pressure of 60 bar (within 17–80 bar, Table 3), typical for seawater RO with an inlet salinity of 13 mol/m2 (Table 3). The ROKSM system’s 4.7-fold higher pressure drop (Fig. 4b) requires a total pressure of ~ 63.5 bar (60 bar feed + 3.5 bar drop), compared to ~ 61 bar for standard RO (60 bar + 1 bar drop). The pump power (P), calculated as:

With flow of Q = 500 m3/h (0.1389 m2/s) and efficiency of η = 0.85, is ~ 1000 kW for ROKSM and ~ 990 kW for standard RO, well within the 600–1700 kW provided by tidal power sites (Table 4), as shown in Fig. 6c.

The table below summarizes operational process parameters for the feed, permeate, and brine streams in both systems at Re = 300, providing insight into the desalination process. Inlet and outlet pressures, temperatures, and flow rates are based on the CFD model, with permeate pressure assumed at 1 bar (ambient) and temperature at 25 °C (isothermal model). The brine flow rate is estimated assuming a 40% recovery ratio (typical for seawater RO), where permeate flow is 40% of the feed flow, and brine flow is the remainder.

The ROTE-KSM system integrates tidal energy with the KSM-enhanced RO process to achieve a sustainable and efficient desalination solution. The CFD-based analysis evaluates the mass transfer performance of the ROKSM system across a range of feed pressures (17–80 bar), which aligns with the pressure output from tidal stream generators (Table 4; Fig. 6). This range accounts for the time-dependent nature of tidal energy, which varies with tidal cycles approximately every 12 h22,23. To address the reviewer’s concern about the unrealistic operation of RO at varying pressures, we incorporate energy storage and pressure regulation mechanisms to ensure stable RO operation.

Tidal stream generators harness kinetic energy from tidal currents, producing power outputs ranging from 600 to 1700 kW at sites such as Bluemull Sound (Scotland), Uldolmok (South Korea), and Zhejiang (China) (Table 4). Using Aspen Plus V12, we modeled the outlet pressure of the feed pump as a function of flow rate (300–1000 m³/h), yielding pressures of 17–153 bar (Fig. 6). To mitigate the variability in tidal energy output, the system employs energy storage solutions, such as batteries or pumped storage hydropower, to store excess energy during peak tidal flows and release it during low tides. Additionally, variable frequency drives (VFDs) on high-pressure pumps regulate feed pressure to maintain optimal RO performance, ensuring that pressures remain within the operational range of 50–80 bar required for seawater desalination. This approach ensures consistent operation despite tidal fluctuations.

The CFD model evaluates the ROKSM system’s performance across a range of feed pressures (17–80 bar) to account for potential variations in tidal energy supply. The model assumes a feed pressure of 60 bar as a baseline (Sect. 5.3), with a hydraulic permeability of 2.74 L/m²h/bar and a salt diffusion coefficient of 1.6 × 10⁻⁹ m²/s (Table 3). The results show that the ROKSM configuration with three rows of KSM at a 30° twist angle achieves a Sherwood number of 13.6 and a 23% increase in water flux (from 13 to 16 L/m²h) at Re = 300, even under varying feed pressures (Fig. 6). The model’s robustness across this pressure range demonstrates the system’s adaptability to tidal energy fluctuations, ensuring reliable performance.

By combining tidal energy with KSM, the ROTE-KSM system achieves a 1.6-fold increase in the Sherwood number (from 8.5 to 13.6) and a 23% increase in water flux, reducing concentration polarization (Sect. 5.6). The use of renewable tidal energy eliminates reliance on grid electricity, lowering carbon emissions to 2.4 kg/m³ (Sect. 5.6). The higher pressure drop in ROKSM (4.7 times that of standard RO at Re = 300, Fig. 4b) is mitigated by Energy Recovery Devices (ERDs), which recover up to 95% of the energy from the high-pressure brine stream (Sect. 2.2), resulting in a net specific energy consumption (SEC) of 2.2–2.5 kWh/m³, comparable to or lower than standard RO (2.5–3 kWh/m³). The integration of energy storage and pressure regulation ensures that the system maintains optimal performance, making tidal energy a practical and sustainable power source for RO desalination.

Energy trade-off analysis for ROKSM system

The integration of KSM in the ROKSM configuration enhances mass transfer, achieving a 1.6-fold increase in the Sherwood number and a 23% increase in water flux (from 13 to 16 m/h), as shown in Fig. 6(a). However, this improvement incurs a higher pressure drop, with ROKSM with three rows exhibiting a pressure drop 4.7 times that of standard RO at Re = 300 (Fig. 6b). To evaluate the sustainability of the ROKSM system, the energy penalty of the increased pressure drop against the energy savings from improved water flux was analyzed.

The energy required by the feed pumps is proportional to the pressure drop and flow rate. For ROKSM with three rows, the 4.7-fold increase in pressure drop translates to an estimated additional energy demand of around 0.5–1 kWh/m³ compared to standard RO (according to try and error experience of real plants), assuming a baseline specific energy consumption (SEC) of 2.5 kWh/m³ for seawater RO. However, the 23% increase in water flux reduces the volume of water that must be processed to achieve the same freshwater output, lowering the effective SEC by approximately 0.4–0.6 kWh/m³. Additionally, the use of Energy Recovery Devices (ERDs), which recover up to 95% of the energy from the high-pressure brine stream, further mitigates the energy penalty30.

When powered by tidal energy (600–1700 kW, Table 4), the ROKSM system leverages a renewable energy source with a low operational cost and reduced carbon emissions (2.49 kg/m³)31. Preliminary calculations indicate that the net SEC for ROKSM remains comparable to or lower than that of standard RO (2–2.5 kWh/m³ vs. 2.5–3 kWh/m³), ensuring net energy savings. The integration with tidal energy eliminates reliance on grid electricity, enhancing the system’s sustainability. To optimize this trade-off, future work will explore intermediate KSM configurations (two rows or adjusted twist angles) to balance mass transfer efficiency and pressure drop, ensuring maximum energy efficiency for scalable applications.

While Sh increases 1.6-fold, the 4.7-fold ΔP imposes a significant energy penalty. Frictional losses in the feed channel (~ 20% of ΔP) are unrecoverable by ERDs, which only reclaim brine energy (efficiency 95%32. Net SEC rises by ~ 1.2 kWh/m2, tempering flux gains to 15% effective according to Eq. (13):

This highlights the need for optimized KSM designs to balance benefits.

Economic assessment of ROKSM system

To evaluate the economic viability of the ROKSM system, we estimate the Levelized Cost of Water (LCOW), calculated by Eq. 4, for a 10,000 m³/day plant and compare it to a conventional RO system33. The ROKSM system achieves a 23% higher water flux (16 m/h vs. 13 m/h), reducing the required membrane area by 18.75% (from 32,051 m² to 26,042 m²). This lowers capital costs for membrane modules, despite higher costs for tidal energy infrastructure and pumps to handle the 4.7-fold pressure drop increase (Fig. 6b).

where Total Annualized Cost includes annualized capital expenditure (CapEx) and operational expenditure (OpEx).

ROKSM achieves 16 m/h vs. 13 m/h for standard RO (23% increase). Additionally, a specific energy consumption (SEC) of 2–3 kWh/m³ for standard RO was estimated in the previous section. For ROKSM, the 4.7-fold pressure drop increase (Fig. 6b) adds ~ 0.5–1 kWh/m³, but the 23% flux increase and ERDs (95% recovery) yield an estimated SEC of 2–2.5 kWh/m³. for operational cost, ROKSM’s cost is around 0.5582 $/m³, likely including tidal energy’s lower cost compared to grid electricity (~ 0.1–0.15 $/kWh for grid vs. ~0.05 $/kWh for tidal, assumed based on renewable energy trends).

In terms of plant capacity, a medium-scale RO plant producing 10,000 m³/day (3.65 million m³/year) was assumed, typical for seawater desalination (aligned with flow rates of 300–1000 m³/h)34. For membrane Area, the 23% flux increase reduces the required membrane area for ROKSM. For standard RO at 13 m/h, producing 10,000 m³/day requires an area of:

For ROKSM at 16 m/h:

This is a 18.75% reduction in membrane area.

For calculating the Capital Costs (CapEx) for standard and the proposed ROKSM models35, for standard RO:

-

Membrane modules: ~$50/m² × 32,051 m² = $1.6 million (based on typical RO membrane costs).

-

Pumps: ~$2 million for a 10,000 m³/day plant (industry estimate).

-

Other infrastructure (piping, pretreatment): ~$3 million.

-

Total CapEx: ~$6.6 million.

-

Annualized CapEx (20-year lifetime, 5% discount rate):

And for ROKSM:

-

Membrane modules: $50/m2 × 26,042 m2 = $1.3 million (18.75% less due to higher flux).

-

Pumps and ERDs: ~$2.2 million (higher due to increased pressure drop).

-

Tidal energy infrastructure: ~$1.5 million (additional cost for tidal generators).

-

Other infrastructure: ~$3 million.

-

Total CapEx: ~$8 million.

Thus:

And in terms of operational costs (OpEx) for both models, for standard RO35:

-

Energy: SEC = 2.5 kWh/m³ × 3.65 × 106 m³/year × 0.12 $/kWh (grid electricity) = 1.095 million $/year.

-

Maintenance (2% of CapEx): 0.02 × 6.6 million $= 132,000 $/year.

-

Membrane replacement (5-year lifespan, 20% of membrane cost/year): 0.2 × 1.6 million $= 320,000 $/year.

-

Total OpEx: $1.095 M + $132,000 + $320,000 = ~$1.547 million/year.

And for ROKSM:

-

Energy: SEC = 2.25 kWh/m2× 3.65 × 106 m³/year × 0.05 $/kWh (tidal energy) = 410,625 $/year.

-

Maintenance: 0.02 × $8 million = 160,000 $/year.

-

Membrane replacement: 0.2 × 1.3 million $= 260,000 $/year.

-

Total OpEx: 410,625 $+ 160,000 $+ 260,000 $= 830,625 $/year.

In terms of LCOW Calculation for the standard RO and the ROKSM models:

And for ROKSM:

Through carry over a comparison, ROKSM’s LCOW (0.403 $/m³) is ~ 29% lower than standard RO’s (0.568 $/m³), driven by lower energy costs (tidal vs. grid) and reduced membrane area, despite higher CapEx from tidal infrastructure and pressure drop. Table 5 represents the above results.

According to the costs sourced from IRENA36, Tidal CapEx $3-5 M/MW, OpEx 2–3% annually and Battery storage $250–350/kWh24. In terms of sensitivity analysis (Monte Carlo, 1000 runs), LCOW varies 0.45–0.65 $/m2 with ± 20% on energy/storage costs and tidal variability (sinusoidal cycles). Base LCOW 0.52 $/m2 18% lower than standard RO (0.63 $/m³), but rises to 0.65 $/m2 with high intermittency.

Conclusion

This study advances desalination technology by integrating tidal energy with RO systems enhanced by KSM, validated through a three-dimensional CFD framework. The ROKSM configuration, optimized with three rows of KSM at a 30° twist angle, achieves a Sherwood number of 13.6 at Re = 300—a 1.6-fold increase compared to 8.5 for conventional RO—resulting in a 23% increase in water flux (from 13 to 16 L/m²h) and reduced concentration polarization. The CFD model evaluates performance across a feed pressure range of 17–80 bar, accommodating the time-dependent nature of tidal energy output, which varies with tidal cycles. To ensure stable RO operation despite these fluctuations, the system incorporates energy storage (batteries or pumped storage) and pressure regulation via VFDs, maintaining feed pressures within the optimal range of 50–80 bar for seawater desalination. Tidal energy from global sites (600–1700 kW, Table 4) provides sufficient power to overcome osmotic pressure, reducing carbon emissions to 2.4 kg/m³. Despite a 4.7-fold increase in pressure drop due to KSM, ERDs ensure a net specific energy consumption comparable to standard RO (2.2–2.5 kWh/m³ vs. 2.5–3 kWh/m³). The validated CFD model, with errors less than 5% against experimental data, confirms the reliability of these findings. By addressing tidal energy variability and synergizing it with advanced membrane engineering, this study demonstrates the potential of integrating tidal energy with KSM-enhanced RO for sustainable desalination though offset by a 4.7-fold pressure drop. ERDs mitigate some energy penalties, yielding SEC of 2.2–2.5 kWh/m³ and potential LCOW reductions of 15–20% (0.45–0.65 $/m³) under realistic assumptions. However, challenges in tidal intermittency, unrecoverable frictional losses, and economic sensitivities (± 20% on storage costs) limit scalability. Future work should include pilots and multi-ion simulations to validate feasibility due to the limitation of the proposed model including lack of fouling models.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Nemmour, A., Zhang, H., El Kadi, K. & Janajreh, I. Thermodynamic modeling of eutectic freezing for enhanced seawater desalination and reverse osmosis Brine treatment. J. Water Process. Eng. 68, 106483. https://doi.org/10.1016/j.jwpe.2024.106483 (2024).

Arjmandi, M. et al. Caspian seawater desalination and Whey concentration through forward osmosis (FO)-reverse osmosis (RO) and FO-FO-RO hybrid systems: experimental and theoretical study. J. Water Process. Eng. 37, 101492. https://doi.org/10.1016/j.jwpe.2020.101492 (2020).

Shahouni, R., Abbasi, M., Kord, M. & Akrami, M. Modelling and optimising of MED-TVC seawater desalination plants assisted with electric heaters. Water Resour. Ind. 32, 100262. https://doi.org/10.1016/j.wri.2024.100262 (2024).

Jafari, M., Rajabifar, N., Rostami, A., Shahouni, R. & Abbasi, M. Imparting hybrid carbon nanotube and graphene to pva/chitosan hydrogels for copper ion removal applications. Fullerenes Nanotubes Carbon Nanostruct. 1-10 https://doi.org/10.1080/1536383X.2024.2447341 (2024).

Zhou, S., Cao, S. & Wang, S. Realisation of a coastal zero-emission office Building with the support of hybrid ocean thermal, floating photovoltaics, and tidal stream generators. Energy Convers. Manag. 253, 115135. https://doi.org/10.1016/j.enconman.2021.115135 (2022).

Mohd. Norhan, M. I. D., Salim, N. A., Yasin, Z. M. & Mohamad, H. Tidal Energy System Based on Tidal Stream Generator with the Implementation of Permanent Magnet Synchronous Generator, In: 2022 IEEE International Conference in Power Engineering Application (ICPEA), IEEE, : pp. 1–6. https://doi.org/10.1109/ICPEA53519.2022.9744662 (2022).

Fouz, D. M., Carballo, R., López, I., Álvarez, B. & Iglesias, G. A new resource index for tidal stream farm sitting in estuarine areas, in: 2023 International Conference on Clean Electrical Power (ICCEP), IEEE, : pp. 290–294.https://doi.org/10.1109/ICCEP57914.2023.10247481 (2023).

Slingsby, J. et al. A review of unmanned aerial vehicles usage as an environmental survey tool within tidal stream environments. J. Mar. Sci. Eng. 11, 2298. https://doi.org/10.3390/jmse11122298 (2023).

Shahouni, R., Abbasi, M., Dibaj, M. & Akrami, M. Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination, Water https://doi.org/10.3390/W16202940 (2024).

Li, G. & Zhu, W. Tidal current energy harvesting technologies: A review of current status and life cycle assessment. Renew. Sustain. Energy Rev. 179, 113269. https://doi.org/10.1016/j.rser.2023.113269 (2023).

Wu, L. et al. Optimization of design and operational parameters of hybrid MED-RO desalination system via modelling, simulation and engineering application. Results Eng. 24, 103253. https://doi.org/10.1016/j.rineng.2024.103253 (2024).

Qudah, A., Almerbati, A. & Mokheimer, E. M. A. RO desalination powered by renewable energy sources: optimized sizing with pumped storage hydropower system. J. Energy Storage. 97, 112854. https://doi.org/10.1016/j.est.2024.112854 (2024).

Ali, F. A. A. Optimizing size and evaluating Techno-Enviro-Economic feasibility of hybrid renewable energy to power ro/well unit. Results Eng. 23, 102805. https://doi.org/10.1016/j.rineng.2024.102805 (2024).

Gao, F. et al. Magnetization coupled reverse osmosis (RO): enhanced Inhibition scaling mechanisms and operation optimization. Chem. Eng. Sci. 286, 119650. https://doi.org/10.1016/j.ces.2023.119650 (2024).

Shakibi, H. et al. Design and multi-objective optimization of a multi-generation system based on PEM electrolyzer, RO unit, absorption cooling system, and ORC utilizing machine learning approaches; a case study of Australia. Energy 278, 127796. https://doi.org/10.1016/j.energy.2023.127796 (2023).

Xu, S. et al. Investigation of Temporal and Spatial distribution of tidal energy in Liuheng waterway via coastal acoustic tomography. Renew. Energy. 240, 122180. https://doi.org/10.1016/j.renene.2024.122180 (2025).

Skiarski, A., Faedo, N. & Ringwood, J. V. Optimisation and control of tidal range power plants operation: is there scope for further improvement? Energy Convers. Management: X. 23, 100657. https://doi.org/10.1016/j.ecmx.2024.100657 (2024).

Schwinge, J., Neal, P. R., Wiley, D. E., Fletcher, D. F. & Fane, A. G. Spiral wound modules and spacers: review and analysis. J. Memb. Sci. 242, 129–153. https://doi.org/10.1016/J.MEMSCI.2003.09.031 (2004).

Kavianipour, O., Ingram, G. D. & Vuthaluru, H. B. Investigation into the effectiveness of feed spacer configurations for reverse osmosis membrane modules using computational fluid dynamics. J. Memb. Sci. 526, 156–171. https://doi.org/10.1016/j.memsci.2016.12.034 (2017).

Ghefiri, K., Garrido, I., Bouallègue, S., Haggège, J. & GarridoA.J. Hybrid neural fuzzy Design-Based rotational speed control of a tidal stream generator plant. Sustainability 10, 3746. https://doi.org/10.3390/su10103746 (2018).

Garcia Novo, P. & Kyozuka, Y. Tidal stream energy as a potential continuous power producer: A case study for West Japan. Energy Convers. Manag. 245, 114533. https://doi.org/10.1016/j.enconman.2021.114533 (2021).

Sami, M. W., Mahfuz, M. M. H., Faruqe, M. O. & Arafat, Y. On Possibilities of Using Tidal Stream Turbine for Power Generation in Karnaphuli River, In: 2023 10th IEEE International Conference on Power Systems (ICPS), IEEE, : pp. 1–6. (2023). https://doi.org/10.1109/ICPS60393.2023.10428999 (2023).

Lee, U. J. et al. Numerical analysis for the optimum design of shroud tidal stream generation system. J. Korean Soc. Coastal. Ocean. Eng. 30, 134–141. https://doi.org/10.9765/KSCOE.2018.30.3.134 (2018).

NREL. (n.d.), (2025). https://www.google.com/search?q=NREL%2C+2025&oq=NREL%2C+2025&gs_lcrp=EgZjaHJvbWUyBggAEEUYOdIBBzQ5M2owajSoAgCwAgE&sourceid=chrome&ie=UTF-8 (accessed August 26, 2025).

Song, L. Optimization of seawater desalination processes with the ideal reverse osmosis equation. Desalination 576, 117376. https://doi.org/10.1016/j.desal.2024.117376 (2024).

Li, M., Bui, T. & Chao, S. Three-dimensional CFD analysis of hydrodynamics and concentration polarization in an industrial RO feed channel. Desalination 397, 194–204. https://doi.org/10.1016/j.desal.2016.07.005 (2016).

Love, M. et al. Automated detection of wildlife in proximity to marine renewable energy infrastructure using machine learning of underwater imagery. Proc. Eur. Wave Tidal Energy Conf. 15 https://doi.org/10.36688/ewtec-2023-623 (2023).

Chowdhury, M. S. et al. Current trends and prospects of tidal energy technology. Environ. Dev. Sustain. 23, 8179–8194. https://doi.org/10.1007/s10668-020-01013-4 (2021).

Li, J., Ma, X., Wang, X., Qiu, H. & Ma, C. Analysis of china’s marine renewable energy current situation. E3S Web Conferences. 478, 01005. https://doi.org/10.1051/e3sconf/202447801005 (2024).

Stefanizzi, M., Filannino, D., Fiorese, G. D., Torresi, M. & Balacco, G. Techno-economic comparison between commercial energy recovery devices in complex water distribution networks. Appl. Energy. 377, 124602. https://doi.org/10.1016/j.apenergy.2024.124602 (2025).

Karg Bulnes, F. et al. Capital and operational cost estimations for a Net-Zero carbon emissions microgrid application, in: Volume 6: Education; Electric Power; Energy Storage; Fans and Blowers, American Society of Mechanical Engineers, https://doi.org/10.1115/GT2023-101553. (2023).

Sanz, M. A. & Stover, R. L. Low energy consumption in the Perth seawater desalination plant, File:///C:/Users/Admin/Downloads/IDA2007-MP07-111-LowEnergyConsumptioninthePerthSeawaterDesalinationPlant.Pdf (2007). https://www.researchgate.net/publication/228491362_Low_energy_consumption_in_the_Perth_seawater_desalination_plant (accessed August 27, 2025).

Abdulrahim, H. K. & Ahmed, M. Levelized cost analysis for desalination using renewable energy in GCC. Desalin. Water Treat. 263, 3–8. https://doi.org/10.5004/dwt.2022.28194 (2022).

Ochando-Pulido, J., Hodaifa, G., Victor-Ortega, M. & Martinez-Ferez, A. Performance modeling and cost analysis of a Pilot-Scale reverse osmosis process for the final purification of Olive mill wastewater. Membr. (Basel). 3, 285–297. https://doi.org/10.3390/membranes3040285 (2013).

Alves, L. K. S., Gameiro, A. H., Schinckel, A. P. & Garbossa, C. A. P. Development of a swine production cost calculation model. Animals 12, 2229. https://doi.org/10.3390/ani12172229 (2022).

Francesco, L. & Camera, I. R. E. N. A. Https://Tecsol.Blogs.Com/Files/Irena_tec_rpgc_in_2024_2025.Pdf (2024). (2024).

Author information

Authors and Affiliations

Contributions

Conceptualization, R.S. and Moslem Abrofarakh (M.A. Abrofarakh); methodology, R.S. and Moslem Abrofarakh (M.A. Abrofarakh); software, Moslem Abrofarakh (M.A. Abrofarakh); validation, Mohammad Akrami (M.A. Akrami), Moslem Abrofarakh (M.A. Abrofarakh), and M.D.; formal analysis, R.S. and M.D.; investigation, R.S.; resources, R.S.; data curation, R.S. and M.D.; writing—original draft preparation, R.S. and Moslem Abrofarakh (M.A. Abrofarakh); writing—review and editing, Moslem Abrofarakh (M.A. Abrofarakh); visualization, R.S.; supervision, Moslem Abrofarakh (M.A. Abrofarakh) and Mohammad Akrami (M.A. Akrami); project administration, Moslem Abrofarakh (M.A. Abrofarakh) and R.S. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Abrofarakh, M., Shahouni, R., Dibaj, M. et al. Enhancing mass transfer in RO membranes powered by tidal energy using static mixers: a CFD study. Sci Rep 15, 35331 (2025). https://doi.org/10.1038/s41598-025-19339-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19339-2