Abstract

This paper explores the surface characteristics of Inconel 718 following a composite surface enhancement process that combines heat treatment, ultrasonic impact, and solid particle-water jet (HT-UIT-SPEWJ). The research focuses on analyzing the impact of various process parameters on the microstructure, surface roughness, microhardness, residual stress, and XRD patterns of the treated material. The results indicate that after HT-UIT-SPEWJ treatment, the Inconel 718 surface predominantly features “crater-like” formations and debris adhesion. There is a notable inverse relationship between surface roughness and aging temperature, with aging temperature emerging as the most critical factor affecting surface roughness. The surface roughness initially decreases and then increases with the ultrasonic shock frequency, reaching its lowest value of 1.552 μm at 140 Hz. A similar trend is observed with jet pressure, where surface roughness decreases initially and then increases. In addition, the study reveals that the surface microhardness and residual compressive stress of the specimens are significantly improved after treatment, and both show a positive correlation with aging temperature. Microhardness exhibits an initial rise, followed by a decrease and another increase as ultrasonic shock frequency increases, while residual compressive stress peaks at -1027.47 MPa at 120 Hz before decreasing. Similar patterns are observed with varying jet pressures for both microhardness and residual compressive stress. The HT-UIT-SPEWJ treatment induces considerable residual compressive stress, penetrating depths greater than 250 μm, and results in prominent diffraction peaks corresponding to γ(111), γ(200), and γ(220) in the treated specimens.

Similar content being viewed by others

Introduction

Nickel-based superalloys are prized for their exceptional performance in high-temperature environments, thanks to their remarkable strength, fatigue resistance, and corrosion and oxidation resistance. These attributes make them ideal for use in demanding applications such as aerospace, automotive manufacturing, and gas turbines, including engine turbine blades and integrally bladed rotors1,2,3,4. However, as operational conditions become more rigorous, these components increasingly face issues like deformation, cracking, or damage, which can lead to significant safety hazards and economic losses5,6.

Research has established that defects such as deformation, cracks, and damage typically initiate on the surface of components, particularly in areas with poor surface quality. Nickel-based superalloys, known for their machining challenges, can see improved surface integrity through modifications in chemical composition, thereby enhancing their machinability7,8,9. The microstructure of these alloys predominantly consists of tetragonal γ” and face-centered cubic γ’ strengthening phases, which provide high strength across a wide temperature range10,11,12. Additionally, the δ phase, primarily found along grain boundaries, acts as a “pinning” mechanism to prevent grain coarsening. However, the δ phase also introduces notch sensitivity when present in small quantities and can weaken the material if excessive, affecting the surface integrity of components13,14,15. The morphology and quantity of the δ phase are largely influenced by the heat treatment (HT) process. By altering the internal structure’s morphology and distribution or modifying the surface chemical composition, the mechanical properties of components can be significantly enhanced, stresses relieved, and surface integrity improved, thus extending component lifespan16,17,18. For instance, Lee et al. studied Inconel 718 through solution and aging treatments, examining the relationship between aging temperature, precipitate behavior, and mechanical properties. Their findings revealed that an increase in the size and quantity of γ” and γ’ phases at 718 °C improved strength and hardness but reduced toughness, with the formation of numerous small precipitates at grain boundaries leading to intergranular fracture19. Li et al. explored the effects of magnetic abrasive finishing (MAF) and subsequent heat treatment on the surface quality and mechanical properties of rapid prototyped Inconel 718. Their results indicated that the MAF process significantly reduced surface roughness and, when followed by appropriate HT, notably enhanced mechanical properties, yielding significant residual compressive stress and grain refinement20. While heat treatment processes can optimize the distribution of elements and precipitate phases, thus improving the machinability and mechanical properties of nickel-based superalloys, they still fall short of meeting the requirements of increasingly complex service environments. Persistent issues such as excessive grain growth, surface oxidation, and microstructural non-uniformity continue to affect the surface integrity of components21,22,23. To further enhance surface integrity, improve microstructure and stress states, and significantly boost fatigue life and crack resistance, mechanical surface strengthening processes have gained traction24,25. For example, ultrasonic impact treatment (UIT) can refine grains and introduce residual compressive stress, reducing crack initiation and propagation. Meng et al. proposed ultrasonic-assisted laser peening (ULP) technology to enhance the fatigue resistance of 2024-T351 aluminum alloy, combining ultrasonic peening (UP) and laser peening (LP) to refine grains and increase dislocation density, thereby significantly improving residual compressive stress and microhardness, and inhibiting crack formation and propagation26. Similarly, laser peening (LP) can greatly enhance the microstructure of materials, introduce significant residual compressive stresses, and achieve precise control over treated areas and energy input. However, LP can create a substantial heat-affected zone, and the process is costly27. Water jet peening (WJP), known for being environmentally friendly, accessible, and cost-effective, has seen widespread application. For instance, Zhang et al. explored the effects of WJP on residual stress, surface roughness, and fatigue life of Inconel 718, demonstrating that WJP induced significant residual compressive stress, thereby markedly improving fatigue performance28. In conclusion, while heat treatment remains a traditional and essential method for enhancing the performance of nickel-based superalloys by improving mechanical and fatigue properties, it has limitations regarding surface integrity, residual stress control, and microstructural uniformity. These shortcomings manifest in issues such as surface oxidation, excessive grain growth, and uneven microstructure at high temperatures29,30,31. Research indicates that ultrasonic impact surface strengthening technology (UIT) offers unique benefits in grain refinement, plastic deformation, and residual compressive stress, further enhancing the grains32. Meanwhile, WJP also contributes significantly to plastic deformation and residual compressive stress in samples33. However, reports on the composite surface strengthening of UIT-SPEWJ are limited, and the interaction between this composite process and traditional heat treatment on the surface integrity of nickel-based superalloys remains unclear.

This study proposes a UIT-SPEWJ composite strengthening process based on heat treatment. To assess the effects of different process parameters on the surface integrity of Inconel 718, we systematically examined the surface morphology, surface roughness, surface and subsurface microhardness34,35,36, residual stress, and XRD patterns of Inconel 718 after HT-UIT-SPEWJ composite surface strengthening through orthogonal experiments. The research also analyzed the microstructural evolution of specimens following HT-UIT-SPEWJ composite surface strengthening.

UIT-SPEWJ composite surface strengthening process

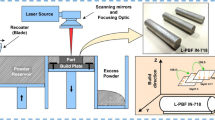

The working principle of the UIT-SPEWJ composite surface strengthening process is illustrated in Fig. 1. Initially, the specimen is securely clamped, and an UIT device mounted on a three-axis sliding rail is employed. Ultrasonic waves are transmitted through a sensor to the ultrasonic device head, which houses a piezoelectric ceramic element that converts electrical energy into mechanical vibrational energy. This vibrational energy is then conveyed to the working surface through a vibrating mechanism, inducing plastic deformation on the specimen’s surface. The same UIT needle, moving at a consistent speed along the three-axis rail, as shown in Fig. 1(a), performs the UIT strengthening on the surface of the Inconel 718 nickel-based superalloy specimen, resulting in uniformly distributed UIT pits.Following the ultrasonic surface strengthening process, the specimen is re-clamped and positioned in a water jet CNC machine. The water jet nozzle is fixed perpendicular to the specimen’s surface at a predetermined standoff distance. High-pressure water is generated by a pump and directed into the nozzle’s mixing chamber. The pressure differential within the nozzle creates suction, drawing in a substantial number of solid particles along with a small amount of air into the mixing chamber. The high-pressure water flow is thoroughly mixed with solid particles and air in the nozzle mixing chamber, forming a high-speed, high-energy-density composite jet. This jet is further accelerated in the nozzle contraction section and stabilized in the cylindrical section, after which it impinges concentrically on the specimen surface, thereby inducing additional plastic deformation and microstructural refinement of the surface layer, as shown in Fig. 1(b). The combined action of ultrasonic impact and water jet can construct a gradient microstructure on the specimen surface, thus enhancing the mechanical properties and corrosion resistance of the material, as shown in Fig. 1(c).

Experimental equipment and methods

Materials

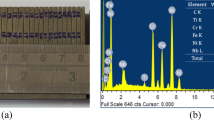

The material utilized in this study is the Inconel 718 nickel-based superalloy. To guarantee the precision and reliability of the experimental data, the chemical composition of Inconel 718 was quantitatively assessed using an energy-dispersive spectrometer. The mass fractions of the chemical elements are detailed in Table 1, while the corresponding mechanical properties are presented in Table 237.

Heat treatment process

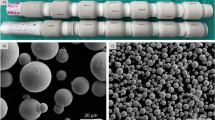

In the experimental process, the Inconel 718 specimens were subjected to an interrupted aging heat treatment using an SX2-4-10 box-type resistance furnace, as illustrated in Fig. 2. The procedure consisted of three stages. In the first stage (solution treatment), the specimens were heated to 1052 °C, held for 1 h, and then water-quenched to room temperature. In the second stage (first-step aging), the specimens were reheated to the designated aging temperature of 650 °C, 670 °C, 690 °C, or 710 °C and held for 8 h to promote the initial precipitation of strengthening phases. In the third stage (second-step aging), the specimens were furnace-cooled to 620 °C, held for 8 h, and finally air-cooled to room temperature. This interrupted heat treatment, combining solution treatment and double aging, was designed to optimize the precipitation behavior and microstructural evolution of the alloy, thereby achieving superior comprehensive mechanical properties. The comprehensive heat treatment parameters are depicted in Fig. 2 and summarized in Table 3.

As a precipitation-hardenable alloy, the performance of Inconel 718 is heavily dependent on the phases that precipitate during heat treatment38,39. Utilizing JMatpro software, the phases present in Inconel 718 and their respective precipitation amounts were calculated based on the chemical composition outlined in Table 1. The resulting Continuous Cooling Transformation (CCT) and Time-Temperature-Transformation (TTT) diagrams are displayed in Fig. 3. These diagrams indicate that the primary precipitated phases in Inconel 718 at elevated temperatures include the γ’ phase, γ” phase, δ phase, Laves phase, and σ phase. The main strengthening phases are the γ’ phase, γ” phase, and δ phase. Specifically, the precipitation temperature ranges are 537–670°C for the σ phase, 536–775°C for the γ” phase, 641–727°C for the γ’ phase, and 625–800°C for the δ phase. Table 4 summarizes the common phases in Inconel 718 and their impact on the material, as reported in the literature40,41,42,43.

UIT-SPEWJ experimental method

After heat treatment, the Inconel 718 specimens were subjected to UIT using a KZUIT-20 C ultrasonic strengthening device. The ultrasonic amplitude was set to 5 μm, and a cylindrical impact pin with a diameter of 2 mm was employed. To investigate the effect of different conditions on surface integrity, the ultrasonic shock frequency (USF) was adjusted to 100, 120, 140, and 160 Hz. During UIT, the KZUIT-20 C device was mounted on a three-axis sliding rail to perform impacts at fixed intervals, thereby achieving discrete surface treatment. Discrete surface UIT refers to applying point impacts on the material surface with predetermined spacing, generating regularly arranged impact pits. Although discrete at the microscopic scale, the overlapping plastic strain zones between adjacent pits lead to the formation of a nearly uniform plastically deformed layer at the macroscopic level. In this study, the longitudinal spacing of impact pits was set to 5 mm and the transverse spacing to 2 mm, as illustrated in Fig. 1(a). Following the UIT process, the specimens were secured in a water jet CNC machine using 120-mesh SiC particles as the abrasive medium. The gemstone nozzle had a central hole diameter of 0.8 mm, as shown in Fig. 1(b). The nozzle standoff distance was set to 10 mm, with a movement speed of 300 mm/min and a track spacing of 0.8 mm. The jet pressure (JP) was varied at 20, 25, 30, and 35 MPa. Jet pressure plays a crucial role in the SPEWJ surface strengthening process as it directly influences the kinetic energy of the jet and consequently the degree of erosion on the specimen surface. To evaluate the impact of the HT-UIT-SPEWJ composite surface strengthening on the surface integrity of Inconel 718 specimens and to optimize the process parameters, a Taguchi method was used for experimental design. The key variables in this design included aging treatment temperature(ATT), ultrasonic shock frequency(USF), and jet pressure(JP). Four levels of each parameter were selected based on practical conditions, as detailed in Table 5, with the L16 orthogonal test matrix presented in Table 6.

Characterization methods

The characterization methods employed for the specimens after HT-UIT-SPEWJ composite surface strengthening are illustrated in Fig. 4. Initially, the surface microstructure of the treated specimens was examined using a Hitachi S-3400 N field-emission scanning electron microscope. Surface roughness was assessed using a JD520 surface roughness tester, with measurements taken at five randomly selected locations over a sampling length of 10 mm. The average of these measurements was used to determine the surface roughness Ra.Microhardness was measured using a SHSiWI microhardness tester from Shanghai S&V Instruments. The specimen was positioned on the tester platform with the indenter axis aligned perpendicularly to the surface. The measurements were conducted under a load of 200 g with a holding time of 15 s. At each depth, the microhardness was measured three times to obtain the average value. First, the surface microhardness of the strengthened specimen was tested, followed by measurements taken every 25 μm along a line perpendicular to the strengthened surface. After multiple measurements, the average values were calculated to determine the microhardness distribution along the depth direction until the values tended to stabilize. Residual stress was measured using an X-ray stress analyzer, focusing on both the surface and the depth direction perpendicular to the strengthened surface. The sin²ψ method with ψ angles ranging from 135° to 143° was applied to ensure the accuracy and reliability of the results. Residual stress measurements were performed on the strengthened surface and along the depth direction perpendicular to the surface. At each depth, no fewer than three measurements were taken, and the average value was used to obtain the residual stress distribution of the surface and subsurface of the Inconel 718 specimens. Phase analysis was also performed on the composite surface-strengthened specimens, with the measurement parameters set as follows: 2θ range of 20 ~ 90° and a scanning rate of 2°/min. This phase analysis aimed to identify the phases present after the HT-UIT-SPEWJ process and evaluate their potential impact on the material’s performance.

Results and discussion

Orthogonal experiment analysis

Table 7 outlines the orthogonal experimental results, detailing the surface roughness, microhardness, and residual stress of Inconel 718 after HT-UIT-SPEWJ treatment. From these results, an intuitive analysis table was generated, which is presented in Table 8.

To systematically evaluate the effects of ATT, USF, and JP on surface roughness, microhardness, and residual stress, an analysis of variance (ANOVA) was conducted on the orthogonal experimental results in Table 7, and the results are presented in Table 9. In single-factor ANOVA, the total variation can be decomposed as:

Where:

SST:total sum of squares,

SSfactor:sum of squares due to the factor,

SSE:error sum of squares.

The mean square (MS) is calculated as:

The F value is defined as:

Significance is judged by the p-value:

P < 0.05: significant,

P < 0.01: highly significant,

P ≥ 0.05: not significant.

The results indicate that ageing temperature has a highly significant effect (p < 0.01) on all three response indicators and serves as the dominant factor; USF exhibits a significant influence (p < 0.05) only on surface roughness, while its effects on microhardness and residual stress are not significant; JP does not reach the significance level (p > 0.05) for any of the three indicators.

Additionally, range analysis was performed to further evaluate the relative influence of each factor (Table 10). The results demonstrate that the range values (R) of ageing temperature are the largest for all three response indicators, highlighting its predominant role. Frequency ranks second in influencing roughness, while pressure ranks second for hardness and residual stress. These observations are consistent with the ANOVA results.

Surface roughness and microstructure

Figure 5 illustrates the effects of varying HT-UIT-SPEWJ composite surface strengthening parameters on the surface quality and roughness of Inconel 718. As depicted in Fig. 5(a), after aging treatment, the UIT creates impact pits of specific depths on the surface of Inconel 718. These pits are subsequently smoothed by the solid particle erosion water jet (SPEWJ), forming the final surface after composite strengthening. When the ATT is set at 650 °C, the surface roughness measures 2.223 µm. As the temperature rises to 710 °C, the surface roughness decreases by 0.97 µm, indicating an inverse relationship between surface roughness and aging temperature (Fig. 5(b)). Additionally, after HT-UIT-SPEWJ treatment, the sample surface exhibits features such as “craters” and debris adhesion. The analysis in Tables 8 and Fig. 5(f) demonstrates that the aging temperature significantly influences the surface roughness of Inconel 718 following composite strengthening. It is noted that the γ’ phase in Inconel 718 typically precipitates at temperatures between 900 °C and 1050°C44,45. When solution-treated at 1052 °C for 1 hour, the coarse primary γ’ phase dissolves, leading to a more uniform and fine solid solution. This process promotes secondary precipitation of γ’ and γ” phases during subsequent aging, which are critical strengthening phases in Inconel 71846,47. According to the Continuous Cooling Transformation (CCT) and Time-Temperature-Transformation (TTT) diagrams in Fig. 3, aging at 650 °C results in the formation of γ’ and γ” phases in Inconel 718. As the aging temperature increases, these phases further develop and stabilize, enhancing the alloy’s strength and hardness. When the UIT-SPEWJ composite surface strengthening is applied, the process modifies surface stress based on the material’s hardness and strength. Inconel 718 containing γ′ and γ″ phases exhibits high strength and hardness after aging treatment, which enables it to effectively resist the surface deformation induced during the UIT-SPEWJ composite strengthening process, thereby leading to the generation of residual compressive stress and grain refinement. As a result, with increasing ATT, the alloy demonstrates improved surface quality. Figure 5(c) shows that the surface roughness of Inconel 718 initially decreases and then increases as the UIT frequency rises. At a frequency of 140 Hz, the surface roughness reaches a minimum of 1.552 μm, though “craters” and debris adhesion remain visible. During UIT, the high-frequency vibrations of the impact needle create small, dense pits on the surface due to localized plastic deformation and microstructural changes. The ultrasonic frequency greatly influences the distribution of impact energy, leading to variations in pit size and depth. At lower frequencies, concentrated impact energy results in larger or deeper pits, which the subsequent SPEWJ treatment cannot fully smooth, leaving noticeable marks and higher surface roughness. As the ultrasonic frequency increases, the impact energy becomes more evenly distributed, resulting in smaller, shallower pits48. When Inconel 718 undergoes SPEWJ treatment, the jet effectively smooths the impact pits, enhancing surface quality. However, at 160 Hz, the smaller pit size intensifies the erosion effect of the water jet. The solid abrasive particles at higher speeds cause secondary damage around existing pits, increasing surface roughness. Figure 5(e) highlights the effect of JP on the surface roughness of Inconel 718 after HT-UIT-SPEWJ treatment. At 20 MPa, the surface roughness measures 1.68 μm. As the JP increases to 25, 30, and 35 MPa, the surface roughness values are 1.566, 1.671, and 1.862 μm, respectively, indicating that surface roughness initially decreases and then increases with rising JP. At 35 MPa, the surface shows distinct “craters” and debris adhesion. This occurs because higher JP delivers greater impact energy at increased speeds, leading to significant erosion. While the UIT pits are smoothed out, additional micro-damages occur, raising roughness. Additionally, at higher speeds, solid particles may shatter and adhere to the surface.

Effects of HT-UIT-SPEWJ Process Parameters on Surface Roughness and Morphology of Inconel 718: (a) Schematic Diagram of Surface Formation on Inconel 718; (b) Effect of Aging Temperature on Surface Roughness; (c) Effect of UIT Frequency on Surface Roughness; (d) Surface Morphology of Inconel 718 After HT-UIT-SPEWJ Treatment; (e) Effect of JP on Surface Roughness; (f) Range Analysis of Orthogonal Experiment.

Surface and subsurface microhardness analysis

Figure 6 illustrates the impact of various HT-UIT-SPEWJ composite surface strengthening parameters on the microhardness of Inconel 718’s surface and subsurface layers. As indicated in Table 2, the initial microhardness of untreated Inconel 718 ranges from 439 to 445 HV. After the HT-UIT-SPEWJ composite treatment, the surface microhardness increases significantly, with values ranging from 480 to 565 HV, depending on the specific parameters used. In Fig. 6(a), the surface microhardness of Inconel 718 is recorded at 484 HV when the aging temperature is 650°C. The data shows a positive correlation between surface microhardness and aging temperature. As the temperature is increased to 710°C, the surface microhardness rises to 560 HV. Based on the equilibrium phase diagram of Inconel 718 in Fig. 3, it can be inferred that at 650 °C, both the σ phase and γ” phase are present, with the γ’ phase beginning to precipitate. As the aging temperature rises to 710 °C, the γ’ and γ” phases become more stable. During aging, the primary strengthening mechanism is the formation of fine, dispersed precipitates within the Inconel 718 matrix, which enhances the material’s strength49,50. At lower aging temperatures, the formation of γ’ and γ” phases is insufficient, but as the temperature increases, the precipitates grow larger and are more uniformly distributed throughout the matrix. These larger, uniformly distributed precipitates effectively impede dislocation movement, thereby increasing the material’s hardness. Figure 6(b) depicts the influence of USF on the surface microhardness of Inconel 718 following HT-UIT-SPEWJ treatment. Initially, the surface microhardness increases, then decreases, and finally increases again as the USF rises. At 100 Hz, the surface microhardness is at its lowest, measuring 514.43 HV. When the frequency is increased to 120 Hz, the microhardness rises by 16.23 HV compared to 100 Hz. At frequencies of 140 Hz and 160 Hz, the surface microhardness values are relatively similar, recorded at 526.46 HV and 527.81 HV, respectively. The analysis suggests that at lower ultrasonic frequencies, the impact energy is more concentrated on the sample surface, which is insufficient to cause significant grain refinement or an increase in dislocations51. As the ultrasonic frequency increases, the impact energy is more evenly distributed across the surface, leading to greater plastic deformation. Subsequent SPEWJ surface strengthening intensifies the plastic deformation, resulting in grain refinement and increased microhardness. However, with further increases in ultrasonic frequency, the surface roughness of the Inconel 718 sample decreases (as shown in Fig. 5), which affects the material’s mechanical properties and reduces surface hardness. Figure 6(c) shows the effect of JP on the surface microhardness of Inconel 718 after HT-UIT-SPEWJ treatment. The microhardness values are recorded at 528.02 HV, 535.43 HV, 524.15 HV, and 511.82 HV for JP of 20, 25, 30, and 35 MPa, respectively. This indicates that the surface microhardness of Inconel 718 initially increases and then decreases as JP rises. With the increase of JP, the impact kinetic energy of the jet on the material surface is enhanced. Within a certain pressure range, the additional impact energy induces a higher density of dislocations, resulting in more pronounced plastic deformation and work hardening, thereby leading to an increase in microhardness. However, as the JP continues to rise, excessive impact energy causes an increase in surface roughness as well as the formation of microcracks and material erosion, which in turn leads to a reduction in microhardness. Figure 6(d) illustrates the variation in microhardness along the depth direction of Inconel 718 samples under different process parameters. The microhardness generally decreases from the surface toward the interior and then stabilizes. The greatest hardening layer depth of 500 µm is observed at an aging temperature of 710 °C, while the depth is 318 µm when the USF is 100 Hz.

Influence of HT-UIT-SPEWJ composite surface strengthening parameters on the microhardness of Inconel 718 surface and subsurface layers: (a) Effect of aging temperature on surface microhardness of Inconel 718; (b) Effect of USF on surface microhardness of Inconel 718; (c) Effect of JP on surface microhardness of Inconel 718; (d) Effect of HT-UIT-SPEWJ composite surface strengthening parameters on the cross-sectional microhardness of Inconel 718.

Residual stress

Figure 7 illustrates the effects of various HT-UIT-SPEWJ composite surface strengthening parameters on the residual stress distribution within the surface and subsurface layers of Inconel 718. The HT-UIT-SPEWJ composite surface treatment predominantly induces compressive residual stress in Inconel 718, with surface residual compressive stress values ranging from 920 to 1100 MPa, depending on the processing conditions. Figure 7(a) highlights the relationship between ATT and surface residual stress in Inconel 718 following HT-UIT-SPEWJ treatment. A positive correlation is observed between ATT and surface residual compressive stress, with the maximum stress value of 1095.93 MPa occurring at an ATTof 710°C. This suggests that γ’ and γ” are the main strengthening phases in the Inconel 718 matrix. As the ATT increases, the solubility of these precipitates rises, leading to their re-precipitation and growth within the lattice52,53. Higher ATT facilitate the coarsening and growth of these phases, thereby enhancing the material’s hardness and strength. This improvement in mechanical properties allows the sample to better absorb and transfer the impact load during UIT-SPEWJ treatment, resulting in increased plastic deformation and elevated residual compressive stress on the surface. Figure 7(b) presents the effect of USF on the surface residual stress of Inconel 718 after HT-UIT-SPEWJ treatment. The surface residual compressive stress initially increases and then decreases as the USF rises, with the highest stress of −1027.47 MPa observed at 120 Hz. The increased ultrasonic frequency enhances both the energy and the area affected by the ultrasonic waves, leading to more significant residual compressive stress and microplastic deformation on the surface and subsurface layers. Following the SPEWJ surface treatment, additional stress release and transformation occur, further increasing the residual compressive stress. However, as the frequency continues to rise, surface roughness increases, and stress relaxation and microcracks may develop, leading to a reduction in residual compressive stress. Figure 7(c) illustrates the influence of JP on the surface residual stress of Inconel 718 after HT-UIT-SPEWJ treatment. The recorded residual compressive stress values at JP of 20, 25, 30, and 35 MPa are − 1011.62, −1030.91, −1008.06, and − 1000.61 MPa, respectively, indicating an initial increase followed by a decrease in stress as JP rises. The analysis suggests that after the UIT surface treatment, significant plastic deformation and residual compressive stress are induced on the surface. The subsequent SPEWJ treatment further amplifies plastic deformation, increasing residual compressive stress. However, excessive JP can lead to over-deformation, surpassing the material’s elastic limit, causing stress relaxation and redistribution54,55,56, which ultimately reduces the residual compressive stress on the surface of the Inconel 718 samples. Figure 7(d) shows the variation in residual stress along the depth direction of Inconel 718 samples under different processing parameters. The HT-UIT-SPEWJ composite surface treatment induces substantial residual compressive stress, with an influence depth exceeding 250 µm. The residual compressive stress decreases progressively with increasing depth from the surface.

Effects of HT-UT-SPEWJ composite surface strengthening process parameters on the surface and sub-surface residual stress of Inconel 718 :(a) Effects of ATT on the surface residual stress of Inconel 718; (b) The effect of USF on the surface residual stress of Inconel 718; (c) The influence of JP on the surface residual stress of Inconel 718; (d) Influence of HT-UIT-SPEWJ composite surface strengthening process parameters on the residual surface stress of Inconel 718.

XRD analysis

Figure 8 illustrates the influence of various HT-UIT-SPEWJ composite surface strengthening parameters on the XRD patterns of Inconel 718 samples. The treated samples exhibit prominent diffraction peaks corresponding to γ(111), γ(200), and γ(220) phases. Notably, no significant diffraction peaks associated with the δ phase are observed in the treated Inconel 718 samples. Additionally, the γ’ and γ” phases are not distinctly detected, likely due to their specific crystal structures—γ’ with an L12-type face-centered cubic structure and γ” with a D03-type tetragonal structure57,58, both of which are aligned with the γ phase structure.When the ATT is increased to 710 °C, the intensity of the γ diffraction peak at approximately 45° is more pronounced compared to the intensity at 650 °C. Similarly, the peak intensities at an USF of 120 Hz and a JP of 25 MPa are significantly higher than those under other parameter settings. As shown in Fig. 8, when the ATT is 710 °C, the diffraction intensity of the γ(111) main peak is significantly higher than that at 650 °C, indicating that a higher ATT promotes ordering and preferred orientation of the γ matrix. Meanwhile, under the conditions of an USF of 120 Hz and a JP of 25 MPa, the diffraction peak intensity is also markedly enhanced. Compared with a lower frequency (100 Hz) and a higher JP (35 MPa), these parameters are more favorable for the formation of stable dislocation structures and stress field distributions, thereby increasing the diffraction intensity. These results indicate that the HT-UIT-SPEWJ composite process parameters have a significant influence on the phase integrity and peak intensity evolution of Inconel 718.

Mechanism of HT-UIT-SPEWJ composite surface strengthening

Figure 9 illustrates the strengthening mechanism of Inconel 718 samples modified through HT-UIT-SPEWJ composite surface treatment. The aging process, followed by air cooling, promotes the formation of precipitates, which enhances the material’s mechanical properties. As shown in Fig. 3, the primary precipitates in Inconel 718 are the γ’ and γ” phases. During the initial stages of aging, fine γ” phase precipitates, typically in spherical or disk shapes, contribute significantly to the alloy’s strengthening. As the ATT increases, the γ’ phase forms, further boosting the alloy’s strength and hardness. Upon completing the aging process, high-frequency UIT surface strengthening induces plastic deformation in the surface and subsurface regions, generating significant residual compressive stress. This process refines the grains, leading to a more uniform microstructure, and the accumulation of deformation energy increases dislocation density, thereby enhancing the samples’ hardness and mechanical properties. When high-pressure water jetting is applied to the ultrasonically strengthened Inconel 718 surface, the impact of the high-speed jet causes localized plastic deformation in the material’s surface and near-surface regions. Unlike UIT, water jetting continuously delivers kinetic energy over a larger area, resulting in a more uniformly deformed layer that penetrates deeper into the sample’s surface. This high-pressure water jetting not only further intensifies surface plastic deformation but also optimizes and reorganizes the refined grain and dislocation structures. Following UIT surface strengthening, a residual compressive stress layer is already present on the material’s surface. The SPEWJ surface treatment further enhances residual compressive stress in the surface and subsurface regions, with the release and transformation of this stress contributing to increased hardness and the inhibition of crack formation and propagation.

Conclusions

The surface quality, roughness, microhardness, residual stress, and XRD patterns of Inconel 718 were evaluated under various process parameters after undergoing HT-UIT-SPEWJ composite surface treatment. The main findings are summarized as follows:

(1)The HT-UIT-SPEWJ treatment resulted in surface features such as “crater” formations and debris adhesion. Surface roughness exhibited an inverse relationship with ATT. At 650 °C, surface roughness was 2.223 µm, which decreased by 0.97 µm as the ATT increased to 710°C. Aging temperature had the most significant impact on surface roughness, with γ’ and γ” phases as the main precipitates. As USF increased, surface roughness initially decreased, reaching a minimum of 1.552 µm at 140 Hz, and then increased. Similarly, at a JP of 20 MPa, surface roughness was 1.68 µm, and it initially decreased before increasing as the JP rose.

(2)The microhardness of the sample surface improved considerably after HT-UIT-SPEWJ treatment, ranging from 480 to 565 HV depending on the process parameters. Surface microhardness showed a positive correlation with ATT, peaking at 560 HV at 710 °C. As USF increased, surface microhardness initially rose, then decreased, and rose again. With increasing JP, surface microhardness initially increased before declining. Microhardness decreased from the surface towards the interior before stabilizing. The maximum hardening layer depth was 500 μm at 710 °C, while at 100 Hz USF, the depth was 318 μm.

(3)The HT-UIT-SPEWJ treatment induced significant residual compressive stress in Inconel 718, with surface stress values ranging from 920 to 1100 MPa across different parameters. A positive correlation was observed between ATT and surface residual compressive stress, with a peak of 1095.93 MPa at 710 °C. As USF increased, surface residual compressive stress initially increased, peaking at −1027.47 MPa at 120 Hz, before decreasing. Residual compressive stress values at JP of 20, 25, 30, and 35 MPa were − 1011.62, −1030.91, −1008.06, and − 1000.61 MPa, respectively. The treatment induced significant residual compressive stress, with an influence depth exceeding 250 μm.

(4)The HT-UIT-SPEWJ treatment resulted in prominent diffraction peaks corresponding to γ(111), γ(200), and γ(220), with no significant δ phase diffraction peaks observed. Similarly, no significant γ’ and γ” phases were detected. At an ATT of 710 °C, the intensity of the γ diffraction peak around 45° was higher compared to that at 650°C. Additionally, at an USF of 120 Hz and a JP of 25 MPa, the diffraction peak intensity was notably higher compared to other process parameters.

Data availability

All data generated or analysed during this study are included in this published article.

References

T.R, S. et al. High-reliability repair of single-crystal Ni-base Superalloy by selective electron beam melting[J]. Materials & Design,2022,224.

Yuanguo, T., Nong, G. & Philippa, R. Oxidation induced crack closure in a nickel base superalloy: A novel phenomenon and mechanism assessed via combination of 2D and 3D characterization[J]. Materials Science & Engineering A,2022,861.

Rongrong, W. et al. Compound purification of nickel base Superalloy cutting waste through special cleaning agent attached to ultrasonic stirring[J]. Journal of Cleaner Production,2022,378.

K,Kumar, N. T. B. N. & Abhijith, A. K. S, et al. Assessment of the post-dynamic recrystallization effects on the overall dynamic recrystallization kinetics in a Ni-base superalloy[J]. Journal of Alloys and Compounds,2023,930.

Guo, H. et al. Microstructure, wear, and corrosion resistance of HVOF WC24-Cr3C257-NiCr19 coating[J].Tribology International,2025,211110806-110806.

Junyan, Z. et al. Nacre-Mimetic nanocomposite aerogels with exceptional mechanical performance for thermal superinsulation at extreme Conditions.[J]. Advanced materials (Deerfield Beach, Fla.),2023,35(29).

Hui, L. et al. Review on Fatigue of Additive Manufactured Metallic Alloys: Microstructure, Performance, Enhancement and Assessment Methods.[J]. Advanced Materials (Deerfield Beach, Fla.),2023,36(17),1-57.

Shaochuan, L. et al. Influence mechanism of abrasive belt wear on fatigue resistance of TC17 grinding surface[J]. Engineering Failure Analysis,2022,141.

S,P.E. C,N., F. S, et al. Fatigue failure mechanisms for AlSi10Mg manufactured by L-PBF under axial and torsional loads: the role of defects and residual stresses[J]. International Journal of Fatigue,2022,162.

Zhao, B. et al. Study on chip formation and surface integrity of nickel-based Superalloy inconel 718 by laser assisted micro-cutting[J]. Journal of Manufacturing Processes,2024,113.

Guo, H. et al. Study on performance of laser cladding of 60 wt%WC-Ni coating with ultrasonic/temperature composite energy field[J]. J. Alloys Compd., 1034181344–1034181344. (2025).

J, P. S. M. et al. Role of void nucleation at primary-γ’/γ interface on strain softening of nickel base superalloy 720Li[J]. Journal of Alloys and Compounds,2023,958.

Richa, G. et al. Transformation of borides in directionally solidified nickel base Superalloy and its mechanical response[J]. J. Alloys Compd. ,2023,952.

Zhihang, Z. et al. Insights into the effect of γ′- or γ′′-precipitated phase types on resistance against harmful atoms of heterogeneous interface in nickel-based superalloys[J]. J. Mater. Res. Technol. ,2023,26.

Z, J. S. & T.A., P. Effects of nitride precipitation on delta phase formation in additively manufactured nickel superalloys[J]. J. Alloys Compd. ,2024,976.

Arthur, F. et al. Effect of annealing twins, strain-recrystallization processing and δ-phase fraction on microtexture and evaluation of mechanical properties of nickel-based Superalloy 718[J]. Materials Science & Engineering A,2023,881.

PeiZhi, Y. et al. Evolution of microstructure and δ phase in an aging-treated nickel-based Superalloy during hot compression[J]. Materials Characterization,2023,200.

Yu, H. et al. Influence of initial heat treatment on microstructure evolution and mechanical properties during cold rolling and annealing of Hastelloy X[J]. Journal of Alloys and Compounds,2024,981.

Gu, B. et al. Effects of ultrasonic impact on residual Stress, Microstructure, and electrochemical properties of Q690 welded Joint[J]. J. Mater. Eng. Perform. 2025 (prepublish):1–16 .

Liqun, L. et al. Evaluation of the ATI 718Plus Repaired by Laser Metal Deposition Under Heat Treatment Regimes: Microstructures, Mechanical properties, and their heterogeneity[J]. Materials Science & Engineering A,2023,885,86-101.

Ho, G. L. et al. Evaluation of precipitation phase and mechanical properties according to aging heat treatment temperature of inconel 718[J]. J. Mater. Res. Technol. ,2023,27.

Kun, L. et al. Hybrid post-processing effects of magnetic abrasive finishing and heat treatment on surface integrity and mechanical properties of additively manufactured inconel 718 superalloys[J]. J. Mater. Sci. Technol. ,2022,128.

Wang J J,Han W Z, Wang C Z et al. Effect of rejuvenation heat treatment on serrated flow behavior and fracture mechanism of nickel-based superalloys[J]. Trans. Nonferrous Met. Soc. China 2025, 35(5):1603–1618 .

Yuhui, T. & B. S L,M. N, H. Managing the inevitable microstructural and property heterogeneity in powder bed fusion Ti-6Al-4V parts via heat treatment[J]. J. Alloys Compd., 969. (2023).

Ghaemifar S,Roostaei M, Zamani R M et al. Tailoring microstructure, tensile properties, and creep resistance of additively manufactured inconel 718 Superalloy by post heat treatment[J]. Trans. Nonferrous Met. Soc. China 2025, 35(6):1890–1906 .

Chen, H. et al. Thermo-mechanical fatigue behavior and microstructure evolution of 4Cr5Mo3V hot work die steel[J]. Int. J. Fatigue ,2024,183.

Pengfei, S. et al. Strategy and Mechanism To Improve the Fatigue Properties of Ti6Al4V ELI Alloy by Microstructure Modulation Combined with Surface Strengthening process[J]. Materials Science & Engineering A,2024,892,1-15.

Xiankai, M. et al. Vibration fatigue performance improvement in 2024-T351 aluminum alloy by ultrasonic-assisted laser shock peening[J]. Int. J. Fatigue ,2023,168.

Wang, C. et al. Effects of laser shock processing on microstructure and mechanical properties of K403 nickel-alloy[J]. Materials & Design,2016,89.

Zhang, P. et al. Inconel 718 alloy strengthening mechanism and fatigue life of microtexture-induced microjet coupled with cavifying water jet[J]. Vacuum,2024,222.

Zehua, L. et al. Regulating Microstructure and Improving Precipitation Hardening Response of fine-grained Mg-RE-Ag hot-extruded Alloy by Extreme short-time Heat treatment[J]. Materials Science & Engineering A,2024,892,1-12.

Xu, J. et al. Effects of the substitution of Si by P on crystallization behavior, soft magnetic properties and bending ductility of FeSiBCuPC alloys[J]. J. Alloys Compd., 816. (2020).

Cuiping, W. et al. Development of novel ferritic steels strengthened by the Co16X6Si7-G phase: A theoretical and experimental study[J]. Materials & Design,2022,222.

Wang, Y. et al. Adhesion improvement and strengthening mechanisms of ultrasonic adhesive-impact bonding process for CFRP/Ni bonded joints[J]. Surfaces and Interfaces,2024,46.

Zhou, Z. et al. Effect of ultrasonic impact treatment on the surface integrity of nickel alloy 718[J]. Advances in Manufacturing,2020(prepublish).

Shaochuan, L. et al. Multi-dimensional ultrasonic-assisted belt grinding on the surface integrity of inconel 718[J]. Journal of Manufacturing Processes,2023,102.

Jeong, W. T. et al. Effects of Ultrasonic Treatment on Mechanical Properties and Microstructure of Stainless Steel 308L and Inconel 718 Functionally Graded Materials Fabricated Via double-wire Arc Additive manufacturing[J]. Materials Science & Engineering A,2024,896,1-13.

Shen, C. et al. Effect of heat treatment on microstructure and mechanical properties of Mg-6Gd-3Y-0.5Zr alloy fabricated by wire Arc additive manufacturing[J]. Journal of Alloys and Compounds,2024,986.

Sun, P. et al. Effect of Heat Treatment on Microstructure evolution, Strengthening Mechanisms and Mechanical Properties of Zn Modified Al–Mg Alloys with Sc and Zr additions[J]. Materials Science & Engineering A,2024,896,1-11.

Liu, B. et al. Fine grains with high-density annealing twins and precipitates inducing favorable strength and excellent plasticity in laser powder bed fusion-fabricated inconel 718 via deep cryogenic and heat treatments[J]. J. Mater. Sci. Technol. ,2024,187.

Yiting, Z., Liangyun, L. & Quanqiang, S. Microstructural evolution and precipitated phase characteristics in the fusion zone for the as-repaired inconel 718 alloy by directed energy deposition additive manufacturing[J]. Materials Characterization,2023,204.

Rong, R. et al. Two-stage annealing treatment to uniformly refine the microstructure, tailor δ precipitates and improve tensile properties of inconel 718 alloy[J]. Journal of Alloys and Compounds,2022,927.

Naiyuan, X. et al. Role of δ-phase on mechanical behaviors of additive manufactured inconel 718: detailed microstructure analysis and crystal plasticity Modelling[J]. International Journal of Plasticity,2023,168.

Wenhao, C. et al. The precipitation behavior effect of δ and γ phases on mechanical properties of laser powder bed fusion inconel 718 alloy[J]. Materials Characterization,2022,194.

Yufeng, Z. et al. Passive behavior of laser directed energy deposited inconel 718 after homogenization and aging heat treatment[J]. Corrosion Science,2022,205.

Liu, G. et al. Enhanced wear resistance of Ti reinforced inconel 718 Superalloy manufactured by laser directed energy deposition[J]. Materials Characterization,2024,209.

Yufeng, Z. et al. Synergistic effect of transpassive film and gamma double prime phase on the electrochemical dissolution behavior of inconel 718 manufactured by laser directed energy deposition[J]. Materials Characterization,2023,204.

Xin, C. et al. Acceleration mechanism of abrasive particle in ultrasonic Polishing under synergistic physical vibration and cavitation: numerical study[J]. Ultrasonics Sonochemistry,2023,101.

Ghorpade, A. & Prakash U,Joshi, S. Effect of heat treatments on strengthening mechanisms in electron beam melted Superalloy inconel 718[J]. Materials Science & Engineering A,2024,895.

Xiao, T. et al. An Investigation of Precipitation Strengthened Inconel 718 Superalloy after Triode Plasma nitriding[J]442 (Surface & Coatings Technology, 2022).

Jiandong, W. et al. Effects of layer-by-layer ultrasonic impact treatment on microstructure and mechanical properties of 304 stainless steel manufactured by directed energy deposition[J]. Additive Manufacturing,2023,68.

Jie, S. A. et al. Unusually high room and elevated-temperature tensile properties observed in direct aged wire-arc directed energy deposited inconel 718[J]. Scientific Reports,2023,13(1).

Junmyoung, J. & Donghyun V,Hwan, S. L. Precipitation kinetics of secondary phases induced by heat accumulation in the deposit of inconel 718[J]. Additive Manufacturing,2022,55.

Vasudevan, B., Nagarajan L & L N., et al. Experimental study, modeling, and parametric optimization on abrasive waterjet drilling of YSZ-coated inconel 718 superalloy[J]. J. Mater. Res. Technol. ,2024,29.

Yu, L. et al. Mechanism for Stress Relaxation Behavior of the Residual Stress Improving Treatments with Water Jet Peening and buffing[J] (Materials Science & Engineering A, 2020).

Ping, Z. et al. Influence of SiC pellets water jet peening on the surface integrity of 7075-T6 aluminum alloy[J]. Vacuum,2022,196.

Jacco, S. & D V,E. T G,U. M, S. Crystal structure and morphology of the bright orange γ-phase of pigment red 53:2 from XRPD, DFT + D and TEM[J]. Dyes and Pigments,2021(prepublish).

Lee, T. et al. Crystal structure and piezoelectric characteristics of various phases near the triple-point composition in PZ-PT-PNN system[J]. J. Eur. Ceram. Soc. ,2020,40(5).

Funding

The authors gratefully acknowledge the financial support provided by various organizations. In particular, they wish to thank the National Natural Science Foundation of China (Grant Nos. 51705270) and the Research Start-up Fund of Guangdong Ocean University.

Author information

Authors and Affiliations

Contributions

The design of the overall scheme was completed by Zhang Ping.The design of the simulation scheme was completed by Yue Xiujie. Data extraction was completed by Jiang Xiaomin. Language modification was completed by Wang Youqiang.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yue, X., Wang, Y., Zhang, P. et al. Investigation of surface integrity in inconel 718 enhanced by heat treatment, ultrasonic impact and multi-media jet processing. Sci Rep 15, 34123 (2025). https://doi.org/10.1038/s41598-025-20533-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-20533-5