Abstract

Printed electronics (PE) present a promising alternative to conventional photolithography by enabling rapid prototyping with reduced costs, material waste, and enhanced design flexibility and advantages, particularly relevant for high-frequency microwave applications. This study presents the design, fabrication, and evaluation of two microstrip low-pass filters (LPFs) with cutoff frequencies of 2.60 GHz and 3.55 GHz serving as representative components for microwave circuits, using three additive manufacturing techniques: Direct-Write (DW), Screen Printing (SP), and Aerosol Jet Printing (AJP). Over 60 filter samples were fabricated and measured to systematically assess performance across different printing methods. The LPFs were designed and analyzed through electromagnetic simulations, complemented by an LC equivalent circuit model based on actual device dimensions to better understand their behavior. Measured frequency responses showed strong agreement with simulations, validating the effectiveness of all three printing methods. Each technique demonstrated unique trade-offs between resolution, fabrication complexity, and electrical performance, emphasizing the need to tailor method selection to specific application requirements. This paper offers valuable insights into the design, analysis, and fabrication of RF and microwave circuits using printed electronics, highlighting the strengths and limitations of each technique. It serves as a practical guide for researchers in selecting suitable methods for high-frequency applications.

Similar content being viewed by others

Introduction

Printed electronics (PE) is a transformative technology that fabricates electronic components by depositing functional materials onto substrates. Compared to traditional photolithography, PE reduces production costs, minimizes material waste, and enables flexible, lightweight devices1. Recent advancements have expanded the applications of PE into high-frequency domains2,3,4. However, designing microwave circuits remains challenging due to impedance matching, signal propagation, and minimizing high-frequency losses. Recently, advanced designs have been introduced in the field of high-frequency applications, including low-pass filters5,6,7, power amplifiers8, power dividers9,10, antennas11, and sensors12, demonstrating significant improvements in performance and efficiency. These advancements in high-frequency circuit design align well with the capabilities of printed electronics, which offer new opportunities for fabricating microwave components with greater flexibility and cost efficiency; however, this alignment may require careful consideration depending on the specific printing method employed. Unlike conventional subtractive fabrication methods such as photolithography, PE techniques like dispenser printing (which is called Direct-Write), SP, and AJP enable rapid prototyping and customized circuit production with minimal material waste. Using these techniques, researchers have successfully developed various RF and microwave components, demonstrating their potential for high-frequency applications13,14,15. For instance, in13, a microwave sensor was designed and fabricated using AJP technology, employing a single-layer coplanar waveguide structure for biomedical purposes. This study emphasizes AJP’s potential in creating high-frequency sensors that hold promise for future applications in medical diagnostics. Similarly, in14, a stretchable RF strain sensor was fabricated using screen printing technology. The sensor, designed with a half-wavelength patch resonating at 3.7 GHz, illustrates the capability of screen printing to produce flexible RF components ideal for wearable electronics. In15, dispenser printing was applied for the fabrication of high-frequency microwave antennas. The study highlighted how this additive manufacturing technique enables the creation of precise, customizable components for RF applications. In their work, a UHF RFID dipole antenna was printed directly onto the curved interior surface of a car mirror housing, demonstrating the suitability of dispenser printing for conformal, high-frequency applications in complex environments.

This work provides a comparative analysis of three PE techniques to evaluate their suitability for fabricating high-frequency circuits and to highlight method-specific trade-offs, including effects from dimensional variations, surface roughness, and frequency-dependent losses. In this paper, two LPFs were designed and followed by the fabrication process. Over 60 samples using three different printing techniques: Direct-Write printing, SP, and AJP, were fabricated and measured. A total of 60 samples were produced, with 10 of each LPF type per printing method. These investigations aimed to assess the performance and reliability of the fabricated LPF circuits as high-frequency components and to evaluate the feasibility of these printing technologies and materials for microwave applications.

Materials and methods

Low-pass filters are essential in modern communication systems, primarily for suppressing high-frequency noise components. With ongoing progress in filter design techniques, compact configurations that maintain high efficiency have become increasingly feasible. In this study, to address the challenges associated with the fabrication process, two low-pass filter structures are proposed that utilize triangular and rectangular resonators. These geometries are selected due to their structural simplicity and completeness, enabling straightforward implementation as full circuits suitable for printed fabrication methods. The use of basic resonator shapes, which are prevalent in high-frequency circuit design, further supports their practicality.

A central design constraint involves minimizing the line width to align with fabrication capabilities. The direct-write printer available in the laboratory cannot reliably produce line widths smaller than 300 µm. Accordingly, this limitation has been integrated into the design to ensure compatibility with all three selected printing techniques, which will employ an identical circuit layout. Maintaining a consistent layout across methods facilitates a fair comparison in terms of both fabrication quality and functional performance. To ensure a systematic evaluation, the same filter layout was fabricated using three different printing techniques. In the following sections, the materials and processes involved in each method are described in detail.

Substrate

The proposed microstip filters are optimized for high-frequency applications and will be evaluated in subsequent sections. For the fabrication process, polyethylene terephthalate (PET) foil Mylar A is selected as the substrate. Mylar A offers several advantages that make it well-suited for this experimental work: it is lightweight, cost-effective, and readily available, making it an attractive choice for prototyping and scalable production. Its semi-flexible nature allows for potential integration into conformal or flexible electronic systems, while still maintaining sufficient mechanical stability for reliable circuit operation. Given these characteristics, Mylar A is considered a promising alternative substrate for high-frequency applications. Its detailed specifications are summarized in Table 1.

Printing technologies

A typical microstrip structure consists of three primary layers: a dielectric substrate positioned between a conductive ground plane on the bottom and a signal-carrying conductive strip on the top surface16. A visual representation of the basic additive printing process is shown in Fig. 1, which includes a diagram illustrating the printing setup and substrate configuration. This figure highlights the precise deposition of conductive ink onto the substrate, ensuring that the printed circuits conform to the intended microstrip structure.

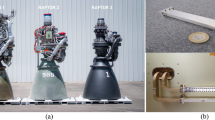

Three different printing machines were used in this study. A Nordson EFD Pro Plus dispenser was used for the Direct-Writing process. An Ekra E2 screen printer was employed for screen printing (SP), and an Optomec AJ-300 system was used for aerosol jet printing (AJP). These printing machines are shown in Fig. 2. Detailed descriptions of the three printing methods, including their operating principles and key process parameters, are provided in the Supplementary Information (SI). In addition, complete details of the port assembly are discussed in the SI and illustrated in Fig. S1.

Design and simulation

In this study, a triangular-shaped resonator is used as the main part of both LPFs’ design. The triangular resonator is chosen for its practical and analytical advantages. As a derivative of the square resonator, it can be easily analyzed using well-known square resonator principles. It also introduces a deep transmission zero, which improves stopband selectivity and achieves sharper transition band characteristics in the stopband. Moreover, its geometric complexity presents fabrication challenges for printed electronics, making it a good candidate for assessing the capabilities of different printing methods. Two types of low-pass filters were designed using this resonator. Their design and corresponding simulation results, performed using Agilent Advanced Design System (ADS) 2021, version 1.0, and discussed in the following sections. All simulations were performed using Perfect Electric Conductor (PEC) conductors to eliminate conductor loss and provide a consistent baseline for comparison among the three printing technologies. This approach isolates the fabrication effects, such as surface roughness and ink conductivity, from the electromagnetic design. However, the filters in this work were not optimized. The objective was to create basic and printable low-pass structures that could be reliably fabricated using three different printing methods (Direct Write, Screen Printing, and Aerosol Jet). This required us to work within the fabrication constraints, particularly the minimum printable line width and spacing, which limited the design options. For readers interested in fully optimized, high-performance microwave filters, we refer to our earlier publications5,7,19,20.

Compact low-pass filter (CLPF) design

Figure 3(a) illustrates the proposed Triangular Resonator (TR) along with its dimensions, while Fig. 3(b) presents its electromagnetic (EM) frequency response. This resonator can create a deep transmission zero at 6.74 GHz. As seen in Fig. 3(b), the original TR lacked adequate suppression in the stopband. To achieve superior out-of-band suppression and mitigate unwanted harmonics, it is necessary to introduce additional transmission zeros within the stopband region. As a result, a rectangular-shaped resonator cell is incorporated into the existing design, improving the stopband performance, and the prototype Compact LPF (CLPF) is formed. Figure 3(c) illustrates the proposed layout structure of the prototype CLPF and its dimensions, while the EM frequency response is depicted in Fig. 3(d). As shown, the stopband performance has improved, though some unwanted harmonics remain.

As shown in Fig. 3(d), the prototype CLPF exhibits some unwanted harmonics near the stopband region. To eliminate these harmonics and extend the stopband, attenuator units are commonly added in series with the resonators. The final proposed CLPF structure is depicted in Fig. 4(a), with its frequency response shown in Fig. 4(b). It generates a deep transmission zero at 12.83 GHz, achieving an attenuation level of nearly −60 dB. This addition improves attenuation and broadens the stopband width (SBW), providing better suppression of unwanted harmonics.

As seen in Fig. 4(b), the simulation results show that the −3 dB cut-off frequency is 2.6 GHz. The return loss is 13 dB, showing good signal reflection characteristics in the passband. The stopband width extends from 3.68 GHz to 21 GHz, providing a broad range of harmonic suppression. Additionally, the compact size of the low-pass filter is 8.72 × 23 mm2, making it suitable for space-constrained applications while maintaining effective filtering characteristics.

Folded low-pass Filter (FLPF) Design

Another triangular-shaped resonator is depicted in Fig. 5(a). Due to circuit size reduction, the transmission line has been folded from both sides, giving the structure the name Folded Triangular Resonator (FTR). The related Electromagnetic (EM) frequency response is shown in Fig. 5(b). As shown in Fig. 5(b), the designed FTR exhibits a transmission zero around 6.51 GHz. This transmission zero is critical, as it influences the sharpness of the lowpass filter’s transition band and the location of the cut-off frequency. Additionally, this folded structure exhibits a narrow stopband, which will need adjustment in the subsequent steps. In the next step, double rectangular structures are incorporated into the proposed FTR, as illustrated in Fig. 5(c), and the prototype FLPF has been formed. The dimensions of these structures are also indicated in the figure (all measurements are in millimeters). The corresponding frequency response is shown in Fig. 5(d).

As shown in Fig. 5(d), unwanted harmonics in the 10 GHz to 18 GHz range can adversely affect the performance of the designed LPF. To mitigate this issue, two suppressing cells will be added to the prototype FLPF. These suppressing cells are carefully designed to minimize the interference caused by the mentioned unwanted harmonics, thereby enhancing the overall effectiveness of the designed LPF. The final FLPF design and its frequency response are illustrated in Fig. 6(a) and (b), respectively, demonstrating a significant reduction in these harmonics.

Based on several specification factors, the performance of the discussed LPFs are listed and summarized in Table 2. It can be observed that the proposed LPFs provide good performance in stopband rejection and passband insertion loss.

To better realize the behavior of the designed filters, the LC models for these circuits are calculated and illustrated in Fig. 7(a) and (b). The proposed LC parameters (Inductances and Capacitances) are calculated using Eq. 1 and Eq. 2, and the lossless line and open-end concepts16,19. These values were calculated directly from the physical dimensions without optimization. The LC equivalent circuit model enables a simpler analysis of the resonator’s behavior compared to the full-wave solution based on Maxwell’s equations.

where:

For \(\raisebox{1ex}{$w$}\!\left/ \!\raisebox{-1ex}{$h$}\right.\le 1\) :

For \(\raisebox{1ex}{$w$}\!\left/ \!\raisebox{-1ex}{$h$}\right.\ge 1\) :

Also, λg denotes the guided wavelength at cut-off frequency (fc), Zs is the characteristic impedance of the lines, and ɛre is the effective permittivity16. In addition, the calculated LC parameters are reported in Tables 3 and 4, respectively.

Figure 8(a) and (b) show the comparison between the LC model and EM simulation results for the CLPF and FLPF, respectively. As observed, the approximate LC model captures the general shape of the response and correctly predicts the locations of poles and zeros. Although a slight frequency shift exists, this is inherent to lumped-element approximations, which do not account for distributed effects. Nevertheless, the overall response pattern remains consistent with the EM results at lower frequencies, making the LC model a useful conceptual tool without requiring full-wave EM analysis. By applying these models along with Kirchhoff’s voltage and current laws in the frequency domain, the transfer functions and approximate locations of the transmission zeros can be derived, which this analysis is out of the main concept of this work. For further details, refer to7,20.

Measurement and analysis of CLPF

A collection of the real photographic images of the fabricated CLPF using Direct-Write printing, Screen Printing (SP), and Aerosol Jet Printing (AJP) are shown in Fig. 9(a), (b), and (c), respectively. For detailed information on the assembly of the input and output ports, please refer to the (SI) file.

Figure 10 presents a comparison between the simulated and measured frequency responses of the CLPF fabricated using three different printing techniques: Direct-Write (DW), Screen Printing (SP), and Aerosol Jet Printing (AJP). Subfigures (a)–(f) show the performance of the fabricated samples alongside their corresponding simulations. Each fabrication method was used to produce 10 circuits.

As observed in the previous comparison figures, the results for S11 and S12 across the three different printing technologies show acceptable agreement with simulations at lower frequencies, with some minor mismatches remaining within acceptable limits. Additionally, all three technologies demonstrate the ability to follow the simulation trends to some extent. However, significant mismatches are observed at higher frequencies, exceeding the acceptable matching margin. These discrepancies may arise from various factors, which will be analyzed in detail in the subsequent sections to identify their root causes and assess their impact on the overall circuit performance. While 10 samples were fabricated for each method, one AJP sample failed after fabrication, and only 9 samples were successfully tested mentioned in subfigures 10(e) and (f).

Measurement and analysis of FLPF

Another collection of the real photographic c images of the fabricated FLPF using Direct-Write (DW) printing, Screen Printing (SP), and AJP are shown in Fig. 11(a), (b) and (c), respectively. For detailed information on the assembly of the input and output ports, including attachment methods, please refer to the (SI) file.

Figure 12 illustrates the comparison between simulated and measured frequency responses of the FLPF fabricated using 3 different printing techniques. Subfigures 12(a)–(f) display the frequency performance of the fabricated filters against their simulated counterparts. A total of 10 samples were fabricated for each printing method.

As demonstrated in Fig. 12, at lower frequencies, both S11 and S12 show acceptable agreement between simulation and fabrication results, with all samples exhibiting similar behavior. However, one sample, as shown in subfigures 12 (c) and (d), deviates with a different pattern. This issue was investigated and found to be related to a problem in the line printing process. At higher frequencies, discrepancies are observed in both S11 and S12 across all three technologies, which are discussed further in the following sections.

Analysis of performance discrepancies at higher frequencies

As shown in Figs. 10 and 12, noticeable differences were observed between the simulated results and the actual fabricated ones, especially at higher frequencies above 10 GHz, which happened in all of the mentioned printing technologies for both LPFs. There are several reasons for these discrepancies. While the polymeric matrix filled with conductive micro-particles, can influence the accuracy of the fabrication process, the choice of substrate also plays a crucial role in achieving optimal performance. At higher frequencies, various substrate properties critically influence the performance of fabricated circuits. Among these, the loss tangent (tanδ) and dielectric constant (εr) are particularly significant21. The loss tangent quantifies the dielectric material’s intrinsic energy dissipation as heat during electromagnetic wave propagation. As the frequency increases, dielectric losses become more significant, leading to greater signal attenuation. Similarly, variations in the dielectric constant can introduce impedance mismatches and signal distortions. To explore this further, all-pass transmission lines related to CLPF and FLPF using DW printing technology are fabricated, as shown in Fig. 13. Also, a comparison between their simulation and measuring results are shown in Figs. 14 and 15, respectively.

Performance problems and degradation observed beyond 10 GHz in both the all-pass lines and the proposed low-pass filters (LPFs) suggest that the limitation may originate from the substrate’s frequency-dependent behavior. Although PET (Mylar A) is widely used for flexible electronics, its dielectric properties are not well-suited for high-frequency applications above ~ 10 GHz. These findings highlight the importance of proper substrate selection in RF and microwave circuit design. A comparison of commonly used rigid and flexible substrates, including their dielectric constant (εr) and loss tangent (tanδ) across frequencies, is provided in Table S1 (SI file).

Analysis of dimensional accuracy in different technologies

Figures 16 and 17 show microscopic photos of fabricated CLPF and FLPF with the exact dimensions marked, respectively. To compare the performance of the three fabrication technologies (DW Printing, SP, and AJP), key dimensions of the fabricated samples are measured and compared to the simulated values.

For a better comparison, similar dimensions were used across the three printing methods. This helped reveal how accurately each method could reproduce the intended design and where errors might occur. Tables 5 and 6 show the percentage difference between the simulated and fabricated dimensions. These differences highlight the practical limits of each method and show where improvements are needed. This analysis can guide future engineers and researchers in choosing the right printing method for high-frequency applications by showing how each technique behaves after printing and curing.

To make the comparison more meaningful, two key parameters, W and H, were selected and compared for analysis across all three printing technologies. These parameters were chosen because they represent important features such as the sharpness of edges, the width, and the length of elements, and they are repeated in both CLPF and FLPF. By focusing on these dimensions, it was possible to evaluate not only the overall accuracy of each method but also their ability to recreate detailed shapes. You can find the exact dimensions for these two parameters in the Table. 7.

Among the three different printing technologies, the largest differences between the fabricated and simulated dimensions were observed in the DW printing technology. Figure 18(a) illustrates a microscopic photo of the fabricated sample using DW printing technology and marked W and H parameters. Dimensional mismatches occur during the printing process, and dimensional reductions are required to compensate for material spreading. While this isn’t an issue for straight structures, sharp angles can be affected, leading to inaccuracies. To maintain the correct shape, contour lines must remain parallel to the original design. However, this also means the edges may shift from their intended position. The printing process of a sharp angle in DW technology is shown in Fig. 18(b); the red lines represent the original contour, while the white lines indicate the filling process.

Although the DW method showed acceptable scattering results, it struggled with forming sharp edges and fine details, making it less ideal for complex designs. In contrast, AJP offered the highest precision, with printed shapes closely matching the simulations. Its accuracy in reproducing fine features made it the most reliable option. SP fell in between—better than DW in accuracy, but not as precise as AJP. As representative cases, post-simulations were performed for one CLPF and one FLPF design using their measured dimensions after fabrication. The corresponding results are provided in the SI file.

Analysis of scattering parameters in different technologies

The performance of all three printing technologies can be observed in Fig. 19, where the scattering parameters (S11 and S12) are compared against the simulated patterns.

As seen, all of the mentioned technologies demonstrated deviations and discrepancies with simulated parameters at frequencies above 10 GHz, which can be related to the substrate limitation at high frequencies, which was examined and explained in the previous section. For the SP technology, greater deviations from the expected trends are observed in the S11 parameters of both CLPF and FLPF, indicating that it struggles to accurately replicate the simulated performance. Although the magnitude of the S11 parameter is less than −10 dB, this deviation shows limitations in the technology’s ability to control certain design or fabrication variables that affect the reflection behavior, and this problem can be seen in both CLPF and FLPF. Also, for S12, a little mismatch is observed in FLPF at lower frequencies for screen printing technology, as well, where the transmission characteristics differ significantly from the simulated pattern. Notably, these mismatches in S11 and S12 further confirm inconsistencies in the screen printing overall performance. In contrast, DW printing and AJP technologies demonstrate significantly better alignment with the simulated results for both S11 and S12. Their scattering parameters closely follow the expected patterns, showcasing their ability to retain the intended electromagnetic properties during fabrication. This consistency across both CLPF and FLPF suggests that DW printing and AJP technologies are more reliable and precise, making them better suited for applications that demand high accuracy and performance.

Analysis of printed conductors in different technologies

At microwave and millimeter-wave frequencies, factors such as conductor thickness, width, and surface roughness directly influence signal propagation, conductor loss, and impedance matching. In determining the performance of printed conductors, various aspects can be examined. Among them, three main factors are considered in this section.

Cross-sectional height profiles

Details of the printed conductor edges and the cross-sectional height profiles of the printed conductors in different printing technologies are shown in Fig. 20, and reported in the Table. 8. Technology DW exhibits the thickest conductor (8.662 µm) with a moderate width (312.602 µm), resulting in the largest cross-sectional area (1738.611 µm2). This larger volume contributes to lower RF resistance, which can help reduce conductor losses and improve power handling. Technology SP, with a slightly thinner height (7.157 µm) but a wider trace (316.485 µm), shows a moderate cross-sectional area (1459.721 µm2), potentially balancing impedance control and conductor loss more effectively. In contrast, Technology AJP produces the thinnest conductor (2.859 µm) with the widest trace (332.532 µm), leading to a significantly smaller cross-sectional area (863.386 µm2).

Skin effect

At high frequencies, the skin effect forces current to flow primarily near the conductor’s surface, reducing the effective conducting cross-section. This phenomenon is highly dependent on conductor thickness. The skin depth (δ) is given by22:

where:

f = Frequency (Hz), μ = Permeability of the material (H/m), μ0 = Permeability of free space (H/m), σ = Electrical conductivity (S/m), ρ = Resistivity = 1/σ (Ω.m), and π = 3.14.

As frequency increases, the skin depth decreases, causing more of the current to flow along the surface of the conductor. This results in higher resistance and increased power loss due to the reduced effective cross-sectional area available for current flow. The impact of the skin effect is more significant in materials with higher resistivity and lower thickness, making it a critical factor in the design of high-frequency circuits and transmission lines. The skin depth values for silver at 1 GHz, 10 GHz, and 20 GHz are approximately 2.01 μm, 0.63 μm, and 0.45 μm, respectively. For silver: ρ = 1.59 × 10−8 (Ω⋅m), µ = µr \(\times\) μ0 = 4π × 10−7 H/m. (µr = 1, since silver is non-magnetic).

In the DW method, where the conductor is thicker, the skin depth remains within the conductor body, allowing for a larger conducting area, thereby reducing losses. Conversely, in AJP, the thinner conductor results in the skin depth exceeding its total thickness, forcing the current into a more constrained path, and increasing resistance and losses. This makes DW more favorable for high-frequency applications in terms of skin effect management. A summary analysis of the skin effect across various printing technologies is presented in the Supplementary file and Table. S2.

Surface roughness

Surface roughness is an important factor in high-frequency performance because a rougher surface can cause more signal scattering and losses. Based on the cross-sectional height profiles shown in Fig. 20, among the three methods, screen printing has the roughest surface, direct writing has a moderately rough surface, and Aerosol Jet printing has the smoothest surface. Since screen printing has the highest roughness, it could introduce more losses at higher frequencies. DW is somewhat better in this regard, but its surface is still not perfectly smooth. On the other hand, AJP’s smooth surface helps reduce roughness-related losses, but because its conductors are much thinner, it still suffers from higher resistance, which affects its overall performance at high frequencies. These findings highlight the need for a careful selection of printing technology based on RF circuit requirements. Each method presents trade-offs, and the optimal choice will depend on the available fabrication methods and technical resources for printing and fabrication.

Results and discussion

Utilizing printed electronics in high-frequency applications requires careful planning and attention to detail. To ensure optimal performance and reliability, designers and fabricators should consider several key factors. Based on the findings of this scientific report, some recommendations are suggested as follows:

Printing technology selection

Selecting an appropriate printing technology for high-frequency applications requires careful consideration of resolution and dimensional accuracy. Designers must understand the limitations of each method and adapt their layouts accordingly. Early decisions about the printing and fabrication techniques are essential, as different methods such as Direct-Write (DW), Aerosol Jet Printing (AJP), screen printing (SP), and gravure printing offer varying levels of precision. In this study, the DW technology available in our lab (dispenser-based) was limited to a minimum line width of approximately 300 μm, making it unsuitable for finer transmission lines. This resolution constraint significantly impacts design flexibility and must be addressed during the early design phase. Among the three evaluated methods, AJP demonstrated the highest dimensional accuracy, closely aligning with simulated geometries. SP showed moderate performance, while DW had the largest deviations from the intended design. By aligning design requirements with the capabilities of the chosen printing method, the performance and reliability of printed RF circuits can be significantly improved.

Ink conductivity considerations

Another consideration is the different silver inks employed in the three printing technologies. Each ink exhibits distinct conductivity values, which directly influence insertion loss and overall device performance. Since the simulations in this work were based on PEC models for consistency across methods, these variations were not explicitly incorporated into the analysis. For reference, the measured resistivity values of the inks are summarized in Table S3 (SI file). This factor is critical for accurate prediction and must be carefully considered in future design-oriented studies.

Design and printing considerations

Printing high-frequency circuits requires special attention to several factors, such as dimensional accuracy, thermal expansion, printing inaccuracies, and material shrinkage or expansion, as even minor variations can significantly impact circuit performance. High-frequency circuits are highly sensitive to small changes in printed dimensions, which can cause frequency shifts. Variations in dimensions and other parameters should be minimized through precise fabrication and design compensations. As a brief overview, a comparison between the initial design, post-fabrication simulation, and measurement results of the two LPFs is presented in Fig. S2 (SI file). Once the right printing methods and materials, like ink and substrate, are chosen, it’s recommended that simple transmission lines be printed, considering minimum resolutions and printing limitations, to check the properties of the printed lines. This helps evaluate how the selected ink interacts with the chosen substrate, including factors like surface tension and wettability, which influence ink adhesion and flow. It also helps identify any shrinking or spreading during printing and curing. This simple test gives designers very useful information to finalize the design and make adjustments based on the limitations of the chosen materials and printing technology and by applying some modifications during the design phase, the final fabricated results can be brought closer to the desired values. In this study, all simulations were carried out using Perfect Electric Conductor (PEC) models to provide a common baseline for fair comparison among the three printing technologies. Since the focus was on relative performance rather than absolute material properties, this approach was sufficient for the comparative analysis. However, it is noted that incorporating the effective conductivity of the printed conductors would lead to a more accurate agreement between simulations and measurements.

Surface quality

Surface roughness in printed conductors is generally higher than that of traditional copper etching, leading to increased conductor losses at high frequencies. Achieving smoother surfaces depends on factors such as ink formulation (particle size, shape, and wetting behavior), curing conditions, and the choice of printing technology and substrate. Materials with higher silver content or semi-sinterable pastes are also preferable to reduce losses in porous printed structures. In this study, surface quality was compared across three printing methods while the relationship between surface roughness and other parameters could be explored in future works. As discussed, SP showed the roughest surfaces, DW had moderate roughness, and AJP provided the smoothest finish. Despite its smoothness, AJP suffers from higher resistance due to thinner conductors, while SP, with its rougher surface, may cause greater losses at higher frequencies. DW printing offers a balanced compromise but still presents surface challenges.

Substrate selection

The substrate material plays a crucial role in the electrical performance of microwave circuits, particularly through its dielectric constant (εr) and loss tangent (tan δ). While flexible substrates like PET (Mylar A) offer advantages such as flexibility and lightweight, they tend to introduce instability at high frequencies. As demonstrated in this work, Mylar A showed notable performance limitations above 10 GHz, primarily due to higher dielectric losses and variability in material properties. These issues can lead to increased signal attenuation and performance degradation. Additionally, it is recommended that prior to design and simulation, the dielectric properties of the selected substrates (εr and tanδ) be experimentally characterized, as this would improve prediction accuracy and reduce discrepancies between simulation and measurement during the main experiments.

High-frequency performance of printed microstrip lines is strongly influenced by substrate-side characteristics, such as surface roughness, adhesion, and the interaction between substrate and printed ink24,25. While all samples used the same PET Mylar A substrate, the current study did not systematically investigate these factors. We acknowledge that substrate-side contributions can affect field distribution and insertion loss, and recommend detailed characterization in future works to further improve prediction accuracy and device performance.

Evaluating trade-Offs

In high-frequency applications, it is very important to carefully evaluate the trade-offs between selected material properties, methods, printing resolution, conductivity, and fabrication feasibility. Each design decision can significantly affect both the electrical and mechanical performance of the circuit. For instance, while higher conductivity materials may improve signal transmission, they might also come with challenges such as increased fabrication complexity or cost. Similarly, selecting a printing method with higher resolution can enhance dimensional accuracy but may be limited by material properties or the equipment’s capabilities. By understanding these trade-offs and making informed decisions, designers can achieve optimal performance while maintaining the practical feasibility of the design process.

Conclusions

Printed Electronics (PE) is a growing area in electronics that allows circuits to be made in new ways, using low-cost, flexible, and lightweight materials. Instead of traditional methods that remove material to create patterns, PE builds circuits by adding material only where needed. This scientific report demonstrated the design, simulation, and fabrication of two microstrip low-pass filters using three distinct Printed Electronics (PE) technologies: Direct-Write printing, Screen Printing (SP), and Aerosol Jet Printing (AJP). Over 60 samples were fabricated (10 samples of each filter type per printing technique), and tested to evaluate the feasibility, performance, and repeatability of these additive manufacturing methods for high-frequency circuit applications. Despite resolution limitations inherent to each technology, the filters were successfully implemented with essential high-frequency features, including discontinuities and different geometries. Among the three methods, DW printing demonstrated the best agreement between simulated and measured results, along with reliable electrical performance. Throughout this report, various challenges and questions arose, leading to valuable insights. The findings suggest that printed electronics, particularly DW printing, offer a promising approach for the development of flexible and high-frequency electronic components. The results presented in this paper provide a foundation for further exploration, offering new possibilities for cost-effective and adaptable circuit fabrication in high-frequency electronics.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Wiklund, J. et al. A review on printed electronics: Fabrication methods, inks, substrates, applications and environmental impacts. J. Manuf. Mater. Process. 5, 89. https://doi.org/10.3390/jmmp5030089 (2021).

Lotfi, S., Janda, M., Reboun, J. & Blecha, T. Microstrip resonators on polyethylene terephthalate substrates realized by direct-write technology. Flex. Print. Electron. 9, 015014. https://doi.org/10.1088/2058-8585/ad3117 (2024).

Neermann, S., Franke, J., Sippel, M., Lomakin, K., & Gold, G. Reliability of Printed Microwave Electronics. Proc. Electron. Compon. Technol. Conf., 1791–1796. https://doi.org/10.1109/ECTC32696.2021.00283 (2021).

Taksala Devapriya, A. & Robinson, S. Development of microwave components using additive manufacturing: A review. IETE J. Res. 70, 7670–7686 (2024).

Abdipour, A., Abdipour, A. & Lotfi, S. A lowpass filter with sharp roll-off and high relative stopband bandwidth using asymmetric high-low impedance patches. Radioengineering 24, 712–716 (2015).

Vali, S. K. & Rao, K. S. Design of wide stopband lowpass filter using defected ground structure. Microsyst. Technol. 30, 721–728 (2024).

Hayati, M. et al. A compact simple microstrip lowpass filter based on elliptical analyzed resonator. Frequenz 76, 247–254 (2022).

Lotfi, S., Roshani, S., Roshani, S., & Shirzadian Gilan, M. A planner Doherty power amplifier with harmonic suppression with open and short-ended stubs. Frequenz 76, 121–130 (2022).

Abdipour, A. & Makki, S. V. A. D. Miniaturized equal/unequal Wilkinson power dividers capable of harmonic suppression utilizing microstrip π-shaped resonators modified by lumped elements. Sci. Rep. 14, 7337. https://doi.org/10.1038/s41598-024-57940-z (2024).

Jamshidi, M. B. et al. An intelligent digital twinning approach for complex circuits. Appl. Soft Comput. 154, 111327 (2024).

Qin Hua, A., Yang, C. F., Li, J. W., Lan, Q. S., Yun, L. J., & Xia, Y. L. Design of Rectangular Microstrip Patch Antenna Based on Dual Neural Network Model. IETE J. Res. (2025).

Chen, C.-C., Tai, C.-C. & Liu, C.-L. The microwave microstrip sensor design for noncontact thickness measurement of copper-clad laminate. IEEE Sens. J. (2024).

Piekarz, I. et al. Additively manufactured microwave sensor for glucose level detection in saliva. Sci. Rep. 14, 28235. https://doi.org/10.1038/s41598-024-79867-1 (2024).

Jeong, H. & Lim, S. A stretchable radio-frequency strain sensor using screen printing technology. Sensors 16, 1839 (2016).

Xu, D. et al. Flexible low-profile UWB antenna on polyimide film based on silver nanoparticle direct-write dispenser printing for wireless applications. J. Mater. Sci. Mater. Electron. 34, 1297 (2023).

Hong, H. J. & Lancaster, M. J. Microstrip Filters for RF/Microwave Applications. Vol. 7, Wiley, (2011).

Lotfi, S., Janda, M. & Blecha, T. Study of flexible printed transmission lines realized by direct-write printing technology. 46th Int. Spring Sem. Electron. Technol. (ISSE), 1–5 (2023).

Cherukhin, I., Gao, S. P. & Guo, Y. Fully Flexible Polymer-Based Microwave Devices: Materials, Fabrication Technique, and Application to Transmission Lines. IEEE Trans. Antennas Propag. 69, 8763–8777. https://doi.org/10.1109/TAP.2021.3083855 (2021).

Lotfi, S. & Hayati, M. Compact low-pass filter with ultra-wide stopband using analysed triangular-shaped resonator. Electron. Lett. 53, 1050–1052 (2017).

Karimi, G., Lotfi, S. & Siahkamari, H. Design of microstrip lowpass filter with sharp roll-off using elliptical and radial resonators. Frequenz 71, 349–356 (2017).

Lee, T.-N. et al. Characterization of low-loss dielectric materials for high-speed and high-frequency applications. Materials 15, 2396 (2022).

Pozar, D. M. Microwave Engineering. 4th edn. Wiley, (2012).

Roshani, S. et al. Design and fabrication of a compact microstrip hybrid ring coupler with harmonic reduction for L-band radar system. Sci. Rep. 15, 1–12 (2025).

Gold, G. & Helmreich, K. A physical surface roughness model and its applications. IEEE Trans. Microwave Theory Tech. 65, 3720–3732. https://ieeexplore.ieee.org/document/7932148 (2017).

Sepaintner, F., et al. Characterization of additively produced RF-structures on low-cost PCB materials based on inkjet technology for industrial applications up to 80 GHz. IEEE Trans. Components Packag. Manuf. Technol. 11, 2077–2088. https://ieeexplore.ieee.org/document/9564049 (2021).

Lotfi, S., Janda, M. & Blecha, T. Utilization of direct-write for the realization of a Microstrip resonator on a flexible substrate. 46th Int. Spring Sem. Electron. Technol. (ISSE), 1–4 (2023).

Acknowledgements

This research was supported by the Student Grant Agency of the University of West Bohemia in Pilsen under grant No. SGS-2024-008, titled "Materials and Technologies for Electrical Engineering".

Funding

Student Grant Agency of the University of West Bohemia in Pilsen,SGS-2024-008,SGS-2024-008,SGS-2024-008,SGS-2024-008

Author information

Authors and Affiliations

Contributions

Saeedeh Lotfi and Tomas Blecha conceived the study. Saeedeh Lotfi performed the design, simulations, and analysis, and wrote the manuscript. Saeedeh Lotfi and Tomas Blecha performed the measurements. Martin Janda fabricated the circuits and contributed to manuscript revision. Tomas Blecha and Jan Reboun supervised the project and contributed to manuscript revisions. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lotfi, S., Janda, M., Reboun, J. et al. Comparative analysis of printed electronics technologies in RF and microwave circuits. Sci Rep 15, 39422 (2025). https://doi.org/10.1038/s41598-025-22948-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-22948-6