Abstract

Large-scale rock burst disasters often occur in high-stress and deep-buried tunnels, due to challenges in accurate forecasting and the lack of clarity regarding the underlying mechanisms largely. This study combined on-site stress drilling tests, coupled finite and discrete element simulations, and theoretical calculations to examine unloading damage, rockburst evolution, and deformation failure of the high-stress and deep-buried Xuefengshan No.1 tunnel. The initial geo-stress characteristics were inversed to explore the unloading damage evolution and failure mechanism. The influences of stress distribution, displacement development, and energy release on the stability and rock burst risk of surrounding rock masses were analyzed. The rock burst risks along this tunnel were assessed by the energy method and stress intensity ratio method comprehensively. The findings revealed that displacement convergence and stress release caused by unloading during tunnel excavation were most prominent at the tunnel invert and the arch waist on both sides. The displacement of the rock mass within the unloading zone exhibited a symmetrical distribution along the tunnel axis, with displacement gradually decreasing radially outward. The deep-buried granite and slate sustained greater damage during the rockburst compared to sandstone. There were approximately 6500 m of the Xuefengshan No.1 tunnel, accounting for 55.7% of its total length, possessing potential rock bursts, predominantly at weak to moderate levels. The likelihood of rock bursts increased with burial depth, with a marked rise in risk when the depth exceeded 300 m. The results of this study could provide valuable insights into the geo-stress characteristics and rockburst risk assessment for high-stress and deep-buried tunnels.

Similar content being viewed by others

Introduction

High-energy and large-scale disasters often occur in deep-buried tunnels due to the challenging environmental conditions and intense excavation disturbances, as well as the unclear mechanism driving such disasters1. The main problems associated with high-stress tunnel excavation include large deformations, rock bursts, and shock bumps. These problems have always been a central focus of research, both domestically and internationally2,3,4,5. Rockburst, a distinctive geological hazard in high-stress areas, refers to the violent release of significant amounts of elastic strain energy stored originally in hard, brittle rock layers. This energy release can cause rock blocks or fragments to detach from the rock mass through various mechanisms such as bursting, ejection, peeling, loosening, or throwing, often triggered by excavation disturbances6,7. The occurrence of rock bursts depends on two primary conditions: (1) the ability of the rock mass to store substantial energy and exhibit a strong ejection tendency during failure, and (2) the presence of a high-stress concentration in the surrounding area8. With the increasing number of deep underground engineering projects, the severity of engineering disasters caused by rock bursts is expected to rise. As a result, predicting the mechanisms of rockbursts, assessing their likelihood of occurrence, and estimating the intensity of rockburst activity have become critical scientific problems in deep tunnel excavation, mineral resource extraction, and underground engineering construction9,10,11.

The stress distribution within the rock mass plays a critical role in evaluating and assessing rockbursts in tunnels. The initial stress state field, formed by the weight and structural forces acting on the rock mass, serves as an indirect indicator of rockburst risk. This parameter is essential for rock burst risk assessment and also forms the basis for studying the mechanical properties of surrounding rock masses following tunnel excavation12,13,14,15. While in-situ tests can provide accurate measurements of initial geo-stress levels, practical limitations such as unfavorable site conditions and insufficient funding can often prevent the widespread use of such methods, leading to incomplete representations of the initial stress field16,17. At present, the inversion analysis has become a widely accepted alternative for obtaining reliable estimates of the initial geo-stress field. This approach relies on data gathered from on-site stress measurements, geological structural conditions, and other relevant factors18,19,20. In terms of tunnel rock mass unloading damage, Labious et al.21and Zhou et al.22investigated the spatial and temporal effects of the mechanical behavior of surrounding rock masses during tunnel excavation. A large number of other scholars have expanded upon these findings, examining the mechanical effects, strength changes, deformation characteristics, and crack development in rock mass unloading. This body of work has contributed to a relatively comprehensive theoretical framework for excavation unloading research, particularly from the perspective of energy evolution23,24,25,26,27,28,29. Wang et al.30and Meng et al.31analyzed the energy release and conversion mechanisms in rock masses subjected to cyclic loading and unloading, identifying the laws governing stress release and energy release during rock mass failure. In deep-buried tunnels, the unloading excavation and geo-stress redistribution could result in significant horizontal stress concentration at the base of the rock mass before a breakthrough, leading to the accumulation of elastic strain energy. However, the rapid release of this energy, combined with a transient unloading rebound in the surrounding rock masses, can induce severe rockburst failures in adjacent zones. Due to the complexity and expense associated with indoor rockburst tests32,33, numerical simulation methods are increasingly preferred for investigating rockburst failure modes and mechanisms in the tunnels. The particle flow code (PFC), as an emerging numerical analysis method, has been widely adopted for studying fundamental issues, such as the basic properties of rock materials, the dynamic response of particulate matter, and the fracture processes in rock media34,35,36. For example, Li et al.37employed PFC simulations to investigate the microscopic fracture characteristics and failure patterns associated with unloading-induced rock bursts under different stress conditions. These simulations provide an effective means of discriminating and verifying rock bursts. Wu et al.38extended these efforts by simulating rockburst failure processes through PFC, demonstrating its effectiveness in distinguishing and verifying rockburst occurrences. Similarly, Huang et al.39used the discrete element method to simulate rock fracture processes under varying confining pressures, analyzing the mechanisms of fracture and the shape effects on granite. In terms of rockburst risk assessment, Zhou et al.40developed a strength assessment method based on a circular grey objective decision model, incorporating variable weights and considering multiple factors such as rock mass structure and geological conditions. This model achieved favorable results in assessing rockburst strength. Additionally, Zhang et al.41proposed a Bayesian model with incremental learning capabilities, which demonstrated high accuracy in predicting rockburst risks and was validated in a tunnel along the CZ railway. Sajjad et al.42developed an intelligent classification model that used key predictive variables to forecast rockburst occurrences. Despite these advances, current research on the evolution and assessment of rock bursts in long-distance and deep-buried tunnels with complex geological conditions remains in the exploratory stage. Although these existing studies can provide important insights into rockburst mechanisms, further investigation is still needed to fully understand the behavior and risk factors associated with rockbursts in such environments.

This study took the high-stress and deep-buried Xuefengshan No.1 tunnel project as the research background and employed a combination of on-site stress drilling tests, coupled finite and discrete element simulations, and theoretical calculations to analyze the stress distribution characteristics of surrounding rock masses in this tunnel. The research investigates the influences of stress evolution, displacement development, and energy release on the stability of surrounding rock masses during tunnel construction, with particular emphasis on the failure mechanisms involved. Besides, both the energy method and the stress-strength ratio method were employed to comprehensively assess and predict the rock burst risk level throughout the entire tunnel.

Assessment theory of rock bursts

Energy method

From an energy perspective, the internal energy changes in deeply buried rock masses typically progress through four distinct stages during loading and unloading. They were energy input, energy accumulation, energy dissipation, and energy release. In the initial stage, the rock mass system absorbs external energy, which is stored as elastic strain energy within the rock masses. During unexpected disturbances, such as excavation, a portion of this energy is irreversibly dissipated as the plastic deformation, while the stored elastic energy remains reversible. When the accumulated energy reaches a level sufficient to generate new fractures and microvoids in the rock masses, the instability and failure of surrounding rock masses shall occur. At this point, the remaining energy is predominantly released as the kinetic energy. The energy-based approach is a crucial method for assessing rockburst risk since it can evaluate the energy variations in surrounding rock masses in response to unloading excavation and stress changes. Commonly applied techniques within this framework include the elastic strain energy method (Wet), the energy impact performance method, the rock mass brittleness method, and the rockburst potential method. Among these, the elastic strain energy index method43is the most widely used and practical. Polish scholar Kidybinshi first proposed this method and indicated that the rockburst phenomenon was the result of the sudden release of elastic strain energy accumulated in the surrounding rock under high initial stress conditions. By analyzing the elastic strain energy of rock mass, Wet, the probability and intensity of rock bursts could be assessed. As illustrated in Fig. 1, the elastic strain energy index is typically defined as the ratio of the stored elastic energy to the dissipated energy in surrounding rock masses.

Where point A represents the peak stress of the rock mass. ϕsp represents the elastic strain energy, corresponding to the area enclosed by AOC, and ϕst denotes the dissipated strain energy, represented by the area enclosed by AOB.

The Polish national standard defines specific rockburst risk levels based on thresholds of Wet. A value of Wet≥5.0 indicates a high likelihood of severe rockburst occurrence, while values 2.0 ≤ Wet<5.0 suggest the potential for rock bursts of moderate to low intensity. For Wet<2.0, the risk of rock burst is considered minimal.

The elastic strain energy index (Wet) is commonly used to evaluate the amount of elastic energy that a rock mass can store before. This index is typically calculated by measuring the accumulation and release of strain energy in a rock mass during a compression test. The magnitude of this index reflects the energy storage capacity of the rock as it approaches the fracture point. If significant damage or plastic deformation occurs during the loading process, some of the strain energy is released prematurely. This early release reduces the overall accumulation of elastic strain energy, resulting in a lower energy output during the unstable fracture phase. Consequently, this suggests that the rock fracture will likely occur gradually rather than suddenly, thereby lowering the likelihood or intensity of rockbursts. Conversely, if the rock mass undergoes minimal damage or energy release before fracture, its elastic strain energy index would be higher, leading to a greater release of energy during fracture, which increases the probability and severity of rock bursts.

The stress-strength ratio method

There are mainly two methods for using strength theory to evaluate the initial stress in tunnels, including the stress-strength ratio method and the strength-stress ratio method. Among them, the stress-strength ratio method is particularly focused on identifying rock bursts caused by high geo-stress conditions and can provide clear criteria for assessing the severity of such events. This method focuses on two main aspects: analyzing the actual stress experienced by the surrounding rock masses in tunnels and considering the inherent strength of the rock itself. The determination of the stress on the surrounding rock depends on factors such as the tunnel’s shape and the homogeneity of the surrounding rock masses. For tunnels with regular circular or elliptical shapes and uniform surrounding rock properties, theoretical calculations, grounded in classical rock mechanics theory, are typically employed to estimate the actual stress experienced by the rock mass. These calculations can also predict the distribution of stress at different positions around the tunnel using analytical solutions. To streamline the calculation process in practical applications, especially when the tunnel’s design is circular and the horizontal and vertical stresses are unequal, specific formulas can be applied to quickly estimate the stress status of surrounding rock masses. These formulas usually account for stress concentration effects, the depth at which the tunnel is buried, and the properties of the rock mass. The formula for calculating the stress-strength ratio for surrounding rock in tunnels incorporates these factors44:

Where σr represents the radial stress; σθ denotes the circumferential stress, and τrθ refers to the shear stress between the radial and circumferential directions; σv is the vertical geo-stress while k is the ratio of horizontal to vertical initial geo-stress, commonly known as the lateral pressure coefficient. The term r/r0 is the ratio of the polar diameter (r) of the point to the tunnel radius (r0), and θ is the polar angle.

Norwegian scholar Russenes was the first to propose the stress-strength ratio method for predicting rockbursts45. This method considers both the initial stress and the inherent strength of surrounding rock masses. However, since rock bursts originate from the sidewalls of tunnels, where r = r0, there are

Where µ is the Poisson’s ratio of the surrounding rock; σi (i = 1,2,3) denotes the maximum, intermediate, and minimum principal stresses in order.

The stress strength ratio Wb, as defined by Eq. (9), could be determined by the maximum principal stress and the unconfined compressive strength of surrounding rock masses.

Where σc is the unconfined compressive strength of surrounding rock masses.

The risk of rock bursts in surrounding rock masses is typically assessed by evaluating the stress strength ratio. Commonly accepted standards for this evaluation are as follows: when Wb<0.2, it indicates the absence of a rockburst; when 0.2 ≤ Wb<0.3, a weak rockburst is expected; when 0.3 ≤ Wb<0.55, it signifies a moderate rockburst; and when Wb≥0.55, a strong rockburst is anticipated.

Simulations of unloading excavation and rockburst evolution

The geo-stress inversion of the site

Geological conditions of the project

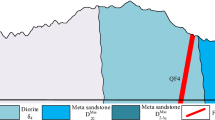

The Xuefengshan No.1 tunnel is a double-track railway tunnel located between Longhui County and Xupu County in Hunan Province, China. The up and down lines have a horizontal distance of 5 m. The tunnel entrance is situated at route marker DK243 + 255, while the exit is at DK254 + 925, giving the tunnel a total length of 11,670 m. The tunnel’s interior gradient is designed with an uphill slope of 9.2‰ from the entrance to DK249 + 500, followed by a downhill slope of 4.6‰ from DK249 + 500 to the exit. The maximum burial depth of the tunnel reaches 800 m. Figure 2 illustrates a three-dimensional topographic map of the area surrounding the Xuefengshan No.1 tunnel, The figure shows the topography and corresponding altitude distribution of the Xuefengshan No.1 tunnel.

The Xuefengshan No.1 tunnel is situated at the northern boundary of the Xuefengshan’s uplift zone, a region characterized by significant tectonic activity and a history of multiple major geological movements. Within the smaller section of the tunnel lies the Shishuikeng anticline structure, while the exit section intersects with the Jixiang Village anticline. The remaining areas predominantly feature monocline rock formations. These rock layers typically dip towards the west and slightly to the northwest, with dip angles ranging from 30° to 70°. A detailed breakdown of the geological formations in these Three positions is provided in Table 1.

The area of the Xuefengshan No.1 Tunnel had rich geological layers from the surface to deep underground. The rock compositions included from the Quaternary to the older geological periods. The outermost layer was the Quaternary Holocene alluvial layer (Q4Ql + Pl), which was a layer formed by modern river erosion and sedimentation, containing relatively new surface sediments. The following stratum was the residual slope layer of the Upper Pleistocene (Q3Ql + el). It was composed of older erosion materials that might be part of higher terrain. Under these newer sedimentary layers, the bedrock layers of the Cambrian period appeared successively, including the Jinjiadong Formation (Z2j) and the three sections of the Hongjiang Formation (Z1hj), Heling Formation (Z1h), Guanyintian Formation (Z1g), and Changtan Formation (Z1c3, Z1c2, Z1c1). These bedrock layers revealed the older geological history and tectonic changes in the region. The Mobin and Tianjing Formations of the Qingbaikou System were respectively manifested in the second section (Qbmb2), the first section (Qbmb1), the fourth section (Qbt4), the third section (Qbt3), the second section (Qbt2), and the first section (Qbt1). At the same time, the Shiqiaopu Formation (QbS) and the Plain Formation of the Jixian System (Jxb) were also part of this complex geological structure.

Results of geo-stress inversion

On-site geo-stress testing

Following the on-site testing requirements and principles for measuring point layout, three representative sections of the Xuefengshan No.1 tunnel were selected for initial stress testing. The on-site stress measurement was conducted using the drilling core stress relief method, while the rock’s elastic modulus and Poisson’s ratio were calibrated through confining pressure tests on sampled rock cores. The measurement points were chosen at a depth of 600 m section of DK249 + 950, 700 m section of DK250 + 850, and 800 m section of DK246 + 750. The on-site geo-stress measurement at these points utilized the CSIROHID Cell digital hollow enclosure stress detector. Boreholes were strategically arranged at designated measurement points, and equipped with stress gauges to measure surrounding rock stress. Figure 3 illustrates the process of on-site drilling. The coordinates of these measuring points, along with the thickness of the overlying rock, are provided in Table 2. The calculated stress components of the original rock mass are shown in Table 3.

Calculation model and parameters

To assess the influence of stress distribution, a nonlinear Mohr-Coulomb elastoplastic constitutive model was used in FLAC3D software to simulate a mechanical representation of surrounding rock masses. As illustrated in Fig. 4, the numerical model dimensions for geo-stress inversion were 120 m×100 m×120 m in the horizontal, axial, and vertical directions of the tunnel. The different colors in Fig. 3 represent the different regions of the inversion model, namely the tunnel, the zone with significant and smaller impacts of tunnel excavation. The equivalent radius of the tunnel excavation section was established at 7.15 m, and the influence zone of the tunnel excavation was defined as 5 times the tunnel’s diameter. The minimum and maximum sizes of triangle elements were 1.0 and 5.0 m. The macro material properties of surrounding rock masses including granite, slate, and sandstone were listed in Table 4, which was determined based on geological and measured data that accurately reflect the actual geological conditions.

Geo-stress inversion analysis

The initial geo-stress field primarily consisted of the self-weight stress field and the structural stress field. When conducting the simulation on the self-weight stress of surrounding rock masses along the tunnel, the zero-displacement boundary conditions were applied to the lateral and bottom surfaces of the stress inversion model in the x, y, and z directions. Considering that the composition of geo-stress primarily included self-weight stress and structural stress, a unit displacement boundary condition was applied normally to the boundary surfaces with a constant node velocity of 0.00005 m/s following 10,000 calculation steps. Then, these calculated stress of measurement points located at the same position were compared with the on-site measurement results of these points. Since the whole inversion model was considered the same lithology and employed the ideal elastic model, the displacement boundary conditions for each boundary could be determined by multiple regression analysis. Taking the case of the model buried with a depth of 600 m as an example, the final velocity boundary in the X, Y, and Z directions was applied at 5.5e-7 m/s, 8.5e-7 m/s, and 1.85e-7 m/s, respectively. Similarly, different final velocity boundaries in the X, Y, and Z directions were also applied to the model buried with a depth of 700 and 800 m. The stress cloud map in the z-direction of the tunnel calculated by FLAC3D software is shown in Fig. 5. Based on the mechanical properties and structural characteristics of rock layers, it was evident that rock masses with greater burial depth, higher hardness, and a higher elastic modulus were capable of storing more stress. Ground stress measurements at three stress relief drilling points are presented in Table 5. The inversion regression results showed that the simulated and measured values were closely aligned, with an error margin of less than 18%. The trend and overall distribution of the two datasets were consistent, accurately reflecting the stress state of the surrounding rock in the tunnel. These findings suggest that the stress field derived for the Xuefengshan No.1 tunnel area through inversion regression is both reasonable and reliable. Additionally, the principal stress values of the surrounding rock exhibited a nearly linear increase with the burial depth. The vertical principal stress was found to be equal to or slightly greater than the gravitational stress exerted by the overlying rock layer per unit area. The principal stress followed a pattern of σx>σy>σz, indicating that the initial stress field of the surrounding rock was primarily dominated by horizontal structural stress. The average stress exceeded 20 MPa, classifying the Xuefengshan No.1 tunnel as a high-stress tunnel.

Unloading damage evolution

The displacement and stress variations during tunnel excavation at burial depths of 600, 700, and 800 m simulated by software were analyzed, as shown in Fig. 6. It was observed that the tunnel underwent significant ‘necking’ and stress redistribution after the unloading process. The plastic zone within the loosened surrounding rock was mainly concentrated at four 45-degree angles; expanding outward and forming an overall butterfly shape. The plastic zone in the upper section of the tunnel was generally larger than that in the lower section. A noticeable displacement convergence occurred at the inverted arch and the arch waists on both sides of the tunnel, where the most substantial stress release was recorded. The surrounding rock at the arch crown exhibited a sinking trend, while the rock at the arch shoulders and arch waists on both sides moved, creating a squeezing effect toward the center. This resulted in an ‘arching’ effect that enhanced the bearing capacity of the arch crown and limited displacement developments. This displacement pattern was consistent with the distribution of the principal stress values from geo-stress testing, which indicated a distribution of σx>σy>σz, and aligned with the typical horizontal structural stress-dominant behavior in tunnels. As the burial depth increased, notable differences in displacement and stress release were observed across various surrounding rock types. The sandy slate layer at a burial depth of 800 m exhibited the greatest displacement and stress changes, with values reaching 8.2 mm and 45.97 MPa, respectively.

Numerical simulation of rock bursts

Coupling model and parameters

The model sizes for the rockburst simulation were consistent with those used in the geo-stress inversion model as mentioned. Since rockburst is a large deformation phenomenon, this study embedded particle flow code in FLAC3D software and developed a simulation model by coupling finite element and discrete element methods. A discrete element model was employed to represent the regions where the rockburst was likely to occur. It was well known that there was still no unified calculation method for the transform between macro and meso parameters. The conventional way to determine them was by the trial-and-error procedure based on some limited experimental data. Table 6 listed microscopic parameters for the discrete element model, such as particle size, contact mode, and stiffness ratio. These parameter values were similarly determined by following the same procedure based on the indoor experimental data of rock masses with different geological lithologies. The remaining portion of the model adopted a finite element tetrahedral mesh, with element sizes ranging from 0.2 m to 0.4 m. The calculation parameters for this region were identical to those of the geo-stress inversion model. The initial and boundary conditions at the interface between the finite and discrete zones were conversed by the homogenization method, thereby creating a rockburst model that integrated both macroscopic and microscopic scales.

In the model, the tunnel’s axis was oriented along the Y-axis, while the axes perpendicular to it were designated as the X-axis and Z-axis. As shown in Fig. 7, the model dimensions were uniform in both the horizontal and vertical directions, measuring 120 m each, whereas the tunnel’s axial dimension extended to 100 m. The discrete model featured minimum and maximum particle sizes of 0.2 m and 0.4 m, respectively. A Python program was utilized to map the particle reaction forces at the coupling boundaries of the discrete domain to the nodes of finite element mesh. Simultaneously, the node velocities from the finite domain at these coupling boundaries were mapped to the particles in the discrete domain. This methodology ensured that stress and velocity were transmitted instantaneously across the coupled boundary between the continuous and discrete domains. During the simulation, displacement constraints were applied to the left, right, and lower boundaries of the model, while vertical loads were imposed on the upper boundary to simulate the pressure exerted by the overlying soil layer. The magnitude of the applied load was determined based on the burial depth of the tunnel and the geological conditions. Three typical cross-sections, corresponding to the stress measurements obtained on-site, were selected to track the process of the rock burst and the failure evolution of the surrounding rock in the tunnel. Based on the calculated stress inversion results, an analysis was conducted on the energy release, crack propagation, and deformation development of the surrounding rock in the tunnel, taking into account lithological compositions and burial depths. Furthermore, the study discussed the stress disturbances affecting the surrounding rock and the potential occurrence of rock bursts within the tunnel.

Simulation of rock burst in tunnel

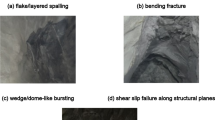

Figures 8 and 9, and 10 show the simulation results of rock bursts occurring inside tunnels calculated in FLAC3D, in which various lithological types and burial depths were considered. An analysis of the displacement contours of the rock mass in the longitudinal section of the tunnel at different time steps reveals that the range of unloading effects from tunnel excavation consistently expands as the calculation steps increase. The particle displacement surrounding the tunnel demonstrates a symmetrical distribution along the tunnel’s axis, gradually diminishing radially outward. Notably, changes in displacement are more pronounced in the rock mass near the axis. Given that the tunnel excavation represents an instantaneous unloading process, the abrupt emergence of a free surface along the tunnel’s side wall inevitably triggers a series of mechanical responses. Specifically, the radial stress within the tunnel experiences a sharp decline, while the axial stress remains relatively constant, and the tangential stress increases. These changes can lead to significant stress concentration. Consequently, the bond between the free surface and adjacent particles is disrupted, leading to the progressive development of cracks. As depicted in the figures, a substantial number of spherical particles undergo significant displacement at the tunnel’s bottom plate and top arch due to the release of elastic strain energy. As the unloading effect progresses, a large number of particles are ejected from the free surface and the surrounding rock, culminating in the occurrence of rock bursts. The displacement contour of the tunnel cross-section shown in Fig. 11 indicates numerous instances of particle ejection within the red area of the palm face, corresponding to the release associated with tunnel excavation. The displacement distribution pattern observed during the rockburst further underscores the ongoing impact of tunnel excavation on the stability of the surrounding rock. This suggests that the dynamic characteristics related to stress release and adjustment of the surrounding rock continue throughout the excavation process. A comparison of the failure modes of surrounding rock across different lithological types and burial depths indicates that the damage sustained by granite and slate, characterized by superior rock properties and greater hardness, is generally more extensive than that observed in sandstone during rock bursts.

Discussions

Rockburst assessment using the energy method

The potential and intensity of rock bursts in surrounding rocks can be assessed by analyzing the elastic strain energy index Wet of the surrounding rocks. Here the total initial and final elastic strain energies were calculated following the below equation in PFC where the strain energy was supposed to be stored in particle contacts.

Where Nc was the number of contacts; \(\left| {F_{i}^{n}} \right|\)and\(\left| {F_{i}^{s}} \right|\)were the amplitude normal and shear forces; \({k^n}\)and\({k^s}\)were the normal and shear stiffness.

By applying the energy method, strain energy release process curves for surrounding rocks of varying lithologies and burial depths were calculated as shown in Fig. 12. It shows the discrete element simulation part of the energy unloading and release process and the energy accumulation and release amount before and after the occurrence of tunnel rock burst. The energy method analysis and prediction results are shown in Table 7, where the strain energy is automatically recorded in the modeling process. The results of the elastic strain energy index Wet indicate that there shall be a high likelihood occurrence of rockburst in the tunnel. In the selected three cases, the basic conditions for rockburst were all met, with the possibility of severe rockburst in some instances. Specifically, granite at a burial depth of 600 m showed a high probability of severe rockburst, slate at approximately 700 m exhibited moderate rockburst potential, and Sandstone demonstrated no rockburst. The strain energy release process curves in Fig. 12 also presented that the energy release curves for granite buried at 600 m and slate buried at 700 m indicate slower changes and lower energy release, which suggested a higher retention of elastic strain energy and a greater risk of rock burst. In contrast, sandstone buried at 800 m exhibited greater energy release, significantly reducing the potential risk of rock bursts.

By the above method, the rock burst levels along the entire Xuefengshan No.1 tunnel, with a section position spacing of 100 m, were analyzed. The blue solid triangles in the figure indicate three representative cross-sections chosen for the numerical simulation discussed above. The results of the elastic strain energy index are presented in Fig. 13. It also roughly shows the lithological distribution of the strata along the tunnel. The stress levels of these four types of rock masses in the tunnel are as follows: granite was 82 ~ 100 MPa, sandstone was 65 ~ 88 MPa, slate was 66 ~ 84 MPa, and sandy slate was 83 ~ 93 MPa. As shown in this figure, 8.6% of the tunnel sections exhibited high rock burst levels, 40.5% showed moderate to low levels, and 50.9% displayed no rock bursts. In sections where rock bursts were likely to occur, the predominant rock types were granite, sandy slate, and feldspar quartz sandstone. The granite was slightly weathered, with a hard texture and relatively intact block structure. In contrast, the sandy slate and feldspar quartz sandstone were in unconformable contact, characterized by highly developed fractures and rock fragmentation within the contact zone. These geological conditions resulted in a dispersed distribution of rock burst risk levels. Additionally, the risk level of rock bursts appeared to correlate with the burial depth; the deeper the burial depth, the higher the associated risk.

Rockburst assessment using the strength theory

To consider the influence of the lining thickness and other structural factors, the outer equivalent radius of the tunnel was set at 7.15 m. Given the relatively small tunnel diameter compared to its burial depth, a uniformly distributed load was applied to simulate the boundary conditions of the overlying surrounding rock. The horizontal and vertical stresses within the surrounding rock were derived from the on-site drilling measurements and geo-stress field analysis, conducted through finite difference simulation. Subsequently, the tangential stresses were calculated using Eq. (2) to (9), with consideration given to the influence of the second principal stress (σ2) in estimating the stress levels that could potentially trigger rock bursts in the surrounding rock. Finally, the risk and severity of rock bursts at various tunnel sections were assessed based on established rock burst criteria.

The stress distribution of the surrounding rock was analyzed by selecting points at 100-meter intervals along the whole tunnel, which spans 11,670 m. As shown in Fig. 14, the stress characteristics of the surrounding rock at the arch crown, the arch shoulder (inclined at a 45° angle), and the arch waist were found to vary following changes in the burial depth of the tunnel. The stress level at the arch waist was notably higher than that at both the arch shoulder (45° angle) and the arch crown, aligning with the results from on-site stress measurements.

The stress-strength ratio method was also employed to calculate the stress-strength ratio index Wb at each measurement point. The maximum value at the selected points was considered representative of the stress level. Discrimination analysis, using this index to assess the risk of rock bursts within the tunnel, is illustrated in Fig. 15. The analysis identified three points as having a high risk of rock bursts, spanning approximately 299 m, or 2.6% of the total tunnel length. Additionally, 49 points were classified as having a moderate risk of rock bursts, covering around 4819 m, equivalent to 41.9% of the tunnel. 21 points were categorized as having a low risk, extending across 2059 m, or 17.9% of the total tunnel length. Finally, the length of sections deemed to have no risk of rock bursts was about 4324 m, constituting 37.6% of the tunnel. Upon comparison with the tunnel’s burial depth distribution, it becomes evident that areas of moderate rockburst risk predominantly correspond to sections with greater burial depth. This observation suggests that the burial depth is likely the most significant factor affecting the occurrence of rock bursts in the tunnel.

Comparative analysis of these two assessment methods

The occurrence of rock bursts is influenced not only by external stress conditions but also by the intrinsic physical properties of the rock mass, such as its hardness and integrity. For example, while soft rocks under high-stress conditions may exhibit a high stress-strength ratio, they typically experience significant plastic deformation rather than rock bursts. Therefore, in assessing the risk of rock bursts in the surrounding rock, it is crucial to comprehensively evaluate both the type of rock mass and the extent of crack development. This study integrates the stress-strength ratio with the elastic strain energy method to account for stress levels, strength conditions, and the structural characteristics of the tunnel in the discriminant analysis of rock burst risk. The comprehensive assessment results for each section of the tunnel are presented in Table 8.

By combining the data from Figs. 13 and 15; Table 8, it is evident that the application of different rock burst criteria results in notable variations in assessment outcomes, reflecting differing tendencies in discrimination. Both methods indicate that when the burial depth exceeds approximately 300 m, the possibility of rock bursts rises significantly with the burial depth. Meanwhile, the stress-strength ratio method identifies a greater proportion of sections with weak to moderate rockburst risk compared to the energy method, which tends to classify more sections with high risk. On the contrary, although the energy method provides a straightforward evaluation based on the elastic strain energy index and can reflect some essential information for rock burst prediction, it only considers the properties of the rock mass itself. As a matter of fact, the storage of elastic strain energy is just a necessary condition for rock bursts. More additional factors, including geo-stress level, lithology, and other forms of energy release (e.g. acoustic or thermal energy) should also be taken into account. Consequently, there should be an underestimation in rock burst risk levels evaluated by the energy method solely. The stress-strength ratio method primarily focuses on the interaction between the mechanical properties of rock masses and their geo-stress. It can effectively evaluate whether the rock mass has failed. However, it does not explain the failure modes of rock masses. To more accurately predict rockburst risk, the rockburst assessment method should incorporate limits on the compressive strength of rock masses and consider the influence of structural planes within the rock masses. Therefore, it should be more favorable for comprehensive rock burst analysis by integrating multiple assessment methods with considerations of geo-stress, lithology, and other relevant factors.

On the whole, the assessment and early warning systems for rock bursts primarily rely on qualitative interpretations at home and abroad. Since the influencing factors of rock bursts are numerous and complex, the documented studies only provide a limited number of criteria and methods. It is very essential to adopt a comprehensive approach that considers various influencing factors and the measured data from on-site testing to evaluate the rock burst risk level of surrounding rock masses in underground engineering practices.

Conclusion

This study combined on-site stress drilling tests, coupled finite and discrete element simulations, and theoretical calculations to examine unloading damage, rockburst evolution, and deformation failure of the high-stress and deep-buried Xuefengshan No.1 tunnel. The analysis focused on the effects of stress evolution, displacement development, and energy release on the stability of surrounding rock masses during the tunnel excavation. The differences in rock burst assessment methodologies, specifically comparing the energy method to the stress intensity ratio method, were discussed. Some main conclusions were drawn as follows:

-

1.

The geo-stress inversion results indicated that the principal stresses of surrounding rock masses in the tunnel followed the distribution pattern of σx > σy > σz, where x, y, and z denoted the directions of the tunnel cross-section and tunnel axis and the direction perpendicular to the ground. A discrepancy of less than 18% between the measured and inversed values suggested that the Xuefengshan No.1 tunnel was mainly governed by horizontal structural stress.

-

2.

Significant inward displacement and convergence changes were observed at the inverted arch and the arch waists on both sides of the tunnel. The surrounding rock at the arch crown showed a sinking trend. The plastic zones within surrounding rock masses were mainly concentrated at four 45-degree angles, forming a butterfly-shaped distribution, and their area at the arch crown was greater than the inverted arch.

-

3.

The unloading deformation of surrounding rock masses exhibited a pronounced symmetrical distribution along the tunnel direction and a gradual decrease in the radial direction. The failure of surrounding rock masses in the tunnel always initialized with the significant displacement at the arch crown and inverted arch of the tunnel. The rock masses would be ejected from the free surface at a certain velocity when the rockburst occurred. Granite and slate seemed to experience more severe damage during the rockburst compared to sandstone.

-

4.

The energy method and the stress-strength ratio method demonstrated strong consistency in assessing the potential for rock bursts in the tunnel. Both of them indicated that there were approximately 6,500 m of the Xuefengshan No.1 tunnel facing rockburst risk from weak to moderate, accounting for 55.7% of the total tunnel length. A clear correlation was observed between rockburst risk level and burial depth when it exceeded 300 m.

-

5.

The stress-strength ratio method compared with the energy method would provide a more stringent classification of the risk levels. It is advisable to conduct a comprehensive analysis that integrates multiple approaches and accounts for various factors to achieve a more thorough understanding of rock burst risk. The results of this study could provide valuable insights into the geo-stress characteristics and rockburst risk assessment for high-stressed and deep-buried tunnels.

Data availability

Data will be made available on request and can be obtained by contacting Xiaohua Zhang (email:202362261281@njtech.edu.cn).

References

Wu, Z. J., Li, M. Y. & Weng, L. Thermal-stress-aperture coupled model for analyzing the thermal failure of fractured rock mass. Int. J. Geomech. 20 (10), 1–22 (2020).

Li, J. X., Zhang, R., Huang, L., Zou, Y. L. & Fang, Y. J. Study on instability mechanism and disposal measures of brittle fractured surrounding rock area in high geo-stress Tunne. Chin. J. Undergr. Space Eng. 14 (5), 1345–1351 (2018).

Zhang, G. H., Jiao, Y. Y. & Wang, H. Outstanding issues in excavation of deep and long rock tunnels: a case study. Can. Geotech. J. 51 (9), 984–994 (2014).

Yang, J. M. & Li, F. J. Study on construction scheme of shallow embedded bias tunnel underpassing a nature reserve. Railway Invest. Surveying. 49 (3), 116–122 (2023).

Yin, J. W. et al. Research on construction technology of maoxian tunnel crossing maowen-Wenchuan active fracture section[J]. Railway Invest. Surveying. 49 (3), 131–138 (2023).

Cheng, B. R., Feng, X. T. & Fu, Q. Q. Integration and high precision intelligence microseismic monitoring technology and its application in deep rock engineering. Rock. Soil. Mech. 41 (7), 2422–2431 (2020).

Li, T., Feng, X. T. & Wang, R. Characteristics of rockburst location deflection and its microseismic activities in a deep tunnel. Rock. Soil. Mech. 40 (7), 2847–2854 (2019).

Pan, J. L., Ren, F. H. & Cai, M. F. Effect of joint density on rockburst proneness of the elastic-brittle-plastic rock mass. Shock Vib., (17), 1–9 (2021).

Yang, W. B. et al. Collaborative treatment technology for landslide and tunnel diseases at the entrance section of the tashao village tunnel in baoji-lanzhou high-speed railway. Railway Invest. Surveying. 49 (2), 1–7 (2023).

Cao, B. et al. Application of 3D laser scanning technology in line and slope adjustment of high-speed railway shield tunnels. Railway Invest. Surveying. 49 (4), 53–58 (2023).

Zhang, X. J. et al. Research on key technologies of advanced geological prediction in TBM construction of deep-buried long tunnel. Railway Invest. Surveying. 49 (3), 48–55 (2023).

Zhang, L. Q., Yue, Z. Q., Yang, Z. F., Qi, J. X. & Liu, F. C. A displacement-based back-analysis method for rock mass modulus and horizontal in-situ stress in tunneling—illustrated with a case study. Tunn. Undergr. Space Technol. 21 (6), 636–649 (2006).

Jin, C. Y. et al. Study on refined back-analysis method for stress field based on in situ and disturbed stresses. Int. J. Geomech. 21, 04021141 (2021).

Kou, H. et al. Distribution characteristics of in situ stress field for a deep-buried tunnel in the fault area. Int. J. Geomech. 23, 04023074 (2023).

Li, G. et al. Stress field determination from local stress measurements by numerical modelling. Int. J. Rock. Mech. Min. Sci. 46 (1), 138–147 (2009).

Li, H., Li, C. B., Liu, Y. P., Han, G. & Zhao, Q. H. Geostress field characteristics of high steep canyon slope in Southwest China. Rock. Soil. Mech. 37 (Supp. 1), 482–488 (2016).

Wang, C. H. & Xing, B. R. A new theory and application progress of the modified hydraulic test on pre-existing fracture to determine in-situ stresses. Rock. Soil. Mech. 38 (5), 1289–1297 (2017).

Zhang, M., Huang, J., Ju, N. P., Zhang, Y. L. & Zhang, G. Z. Inverse analysis on in-situ stress field of super-long and deep buried tunnel in Chuan-Zang railway. Chin. J. Undergr. Space Eng. 15 (04), 1232–1238 (2019).

Fu, H. L., Li, L., Zhang, G. Q. & Zhang, J. B. Inverse analysis on initial stress field based on peripheral displacement convergence. J. Railway Sci. Eng. 13 (02), 301–308 (2016).

He, M. W., Zhou, Z. & C. & Application of the ridge regression in the backanalysis of a virgin stress field. Bull. Eng. Geol. Environ. 80 (3), 2215–2235 (2021).

Labiouse, V., Sauthier, C. & You, S. Hollow Cylinder Simulation experiments of galleries in Boom Clay formation. Rock. Mech. Rock. Eng. 47 (1), 43–55 (2014).

Zhou, J. et al. Mechanism of surrounding rock failure in impact stress and in-situ stress in circular tunnel[J]. Geomech. Geophys. Geo-Energy Geo-Resour. 9, 165 (2023).

Wu, K. Q., He, M. M., Yuan, Z. Y., Ma, X. D. & Ma, C. C. Investigating dynamical stress adjustment induced by transient excavation in a deep-buried tunnel[J]. Int. J. Geomech. 24, 04024218 (2024).

Chen, R. P. et al. Upward soil arching effect under unloading: mechanism, theory and engineering application. Transp. Geotech. 47, 101276 (2024).

Chen, Z. Q., He, C., Dong, W. J. & Jiang, C. W. Investigation on failure mechanism and time-delay fracturing behavior of hard-rock tunnel under extremely high geostress state. Tunn. Undergr. Space Technol. 148, 105767 (2024).

Zheng, K. Y. et al. A computational method for tunnel energy evolution in strain-softening rock mass during excavation unloading based on triaxial stress paths. Comput. Geotech. 169, 106212 (2024).

Shen, J. H. et al. Deformation and fracture featuresof unloaded rock mass. Chin. J. Rock. Mech. Eng. 22 (12), 2028–2031 (2003).

Gao, S., Zhang, L. M., Wang, Z. Q. & Cong, Y. Study of deformation and energy properties of marble unloading failure. Chin. J. Rock. Mech. Eng. 33 (S1), 2808–2813 (2014).

Meng, Q. B. et al. Effects of acoustic emission and energy evolution ofrock specimens under the uniaxial cyclic loading and unloading compression. Rock. Mech. Rock. Eng. 49 (10), 3873–3886 (2016).

Wang, C. L. et al. Stress energy mechanism for rock failure evolution basedon damage mechanics in hard rock. Rock. Mech. Rock. Eng. 53 (07), 1–17 (2019).

Meng, Q. B., Liu, J. E. & Huang, B. X. Efects of confning pressure and temperature on theenergy evolution of rocks under triaxial cyclic loading and unloading conditions. Rock. Mech. Rock. Eng. 55 (08), 773–798 (2022).

Xu, Y. N. et al. Simulation testing and mechanism studies on rock burst. Chin. J. Rock. Mech. Eng. 21 (10), 1462 (2002).

Tian, B. Z., Liu, S. J., Zhang, Y. B., Liang, P. & Liu, X. X. Laboratory simulation of temporospatial evolution characteristics of infrared radiation in the process of rockburst in granite tunnel. Rock. Soil. Mech. 37 (03), 711–718 (2016).

Xin, X. K., Meng, Q. B., Pu, H. & Wu, J. Y. Theoretical analysis and numerical simulation analysis of energy distribution characteristics of surrounding rocks of roadways. Tunn. Undergr. Space Technol. 147, 105747 (2024).

Chen, X. Z. & Yu, H. T. Rockburst prediction for deep tunneling near fault based on the PD-BEM method. Tunn. Undergr. Space Technol. 147, 105725 (2024).

He, M. M. et al. Numerical simulation of rock bursts triggered by blasting disturbance for deep-buried tunnels in jointed rock masses. Comput. Geotech. 161, 105609 (2023).

Li, Y. B., Zhou, Y., Wu, S. C. & Wang, C. Deformation and failure of surrounding rock of circular tunnel using coupled continuous-discrete method. Chin. J. Rock. Mech. Eng. 34 (9), 1849–1858 (2015).

Wu, S. C., Zhou, Y. & Gao, B. Study of unloading tests of rock burst and PFC3D numerical simulation. Chin. J. Rock. Mech. Eng. 29 (S2), 4082–4088 (2010).

Huang, F., LI, T. Y., Gao, X. Y., Yang, X. & Lin, Z. Study on the macro-micro failure mechanism of granite and its geometryeffect under the different conditions of confining pressure by discreteelement. J. Chin. Coal Soc. 44 (3), 924–933 (2019).

Zhou, X. L. et al. Evaluation of rock burst intensity based on annular grey target decision-making model with variable weight. Arab. J. Geosci. 12 (2), 43–55 (2019).

Zhang, Q. H. et al. A semi-naïve bayesian rock burst intensity prediction model based on average one-dependent estimator and incremental learning. Tunn. Undergr. Space Technol. 146, (2024).

Sajjad, A., Kourosh, S. & Sayyed, H. M. Developing intelligent classification models for rock burst prediction after recognizing significant predictor variables, Sect. 2: Designing classifiers. Tunn. Undergr. Space Technol. 84, 235–258 (2019).

Kidybinski, A. Bursting liability indices of coal. Int. J. Rock. Mech. Min. 18 (2), 295–304 (1981).

Panet, M. & Guenot, A. Analysis of convergence behind the face of a tunnel. In Brighton 197–204 DOI: 10.1016/0148–9062(83)91744-8 (1982).

Russenes, B. F. Analysis of rock spalling for tunnels in steep valley sides. In Norwegian (1974).

Acknowledgements

The research was conducted with funding provided by the Key Program of the National Natural Science Foundation of China (Grant No. 42330704) and the National Natural Science Foundation of China (Grant No.41902282).

Author information

Authors and Affiliations

Contributions

Conceptualization, G.X.; Funding acquisition, Z.W. and S.W; Resources, G.X.; Val-idation, X.Z and D.X.; Writing—original draft, G.X. and X.Z.; software, X.P.Writing—review & editing, X.Z. All authors haveread and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiang, G., Zhang, X., Wang, S. et al. Unloading damage evolution and rockburst risk assessment of Xuefengshan No.1 tunnel by combining multiple approaches. Sci Rep 15, 2016 (2025). https://doi.org/10.1038/s41598-025-85417-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-85417-0

Keywords

This article is cited by

-

Energy dissipation and dilation processes of rock mass under incremental cyclic loading and unloading

Scientific Reports (2025)