Abstract

The stability criterion based on the characterization of rock masses can be used to advance deep underground engineering projects. A key geomechanical criterion in geotechnical engineering is rock quality designation (RQD), which assesses risk for engineering design success criteria. Time, cost, and credibility constraints make it difficult to accurately estimate RQD. Point-scale data makes engineering design less precise and confusing, while traditional drilling for RQD estimation are expensive and time-consuming. An innovative geophysical approach to 2D and 3D RQD estimation is presented in this study. It provides easier, faster, and cheaper access to geomechanical volumetric data. So far, no other work has used non-invasive CSAMT to estimate RQD over 1 km depth in a highly diverse rock setting. The suggested approach provides a more precise and thorough evaluation of the rock’s integrity for the effective installation of the neutrino detector 700 m below ground. The results are significant because they help us make sense of complicated geological situations, estimate the likelihood of early collapse, and build deep underground structures safely, steadily, and affordably. Our approach leads to more objective indices, helps in the development of more accurate geotechnical structures, and reduces inconsistencies between appropriate geomechanical models and sparse data.

Similar content being viewed by others

Introduction

The success of every geotechnical project hinges on the accuracy of the evaluations of the underlying geological layers1,2. When planning underground structures, it is necessary to have a reliable assessment of the rock’s unit bearing capacity3,4. A complete understanding of the carrying capacities of the underlying geological layers is necessary for assessing the technical challenges prior to the start of construction5. An underground structure displays numerous obstacles due to the extremely variable circumstances6. Structural sinking typically occurs when the strength of the rock unit is miscalculated7,8. In order to safeguard the subterranean construction, it is necessary to conduct a thorough assessment of the rock unit’s potential. Nevertheless, accurately assessing the rock mass’s capacity to bear a specific load is among the trickiest parts of geotechnical investigations9,10,11,12.

Recently, the design of buildings has made extensive use of particular rock mass engineering parameters. The rock quality designation (RQD), geological strength index (GSI), rock structure rating (RSR), modulus of elasticity (E), uniaxial compressive strength (UCS), Q-system, slope mass rating (SMR), rock core index (RCI), rock mass rating system (RMR), rock mass integrity coefficient (Kv), and rock mass index (Rmi) are the main indices used to assess the quality of rock units13,14,15,16,17,18,19,20,21,22. RQD gives crucial geological insights of the underlying strata by evaluating the basement rock’s bearing capacity. It also provides numerical data and suggestions for appropriate geotechnical construction23,24. The accurate geomechanical parameter RQD is therefore essential for practically underground building projects. Traditional drilling can gather rock mechanical characteristics from coring via lab tests and on-site assessments to gain a thorough geological understanding of the targeted location25,26. Boreholes provide more accurate geological information, but generating a thorough 2D (two dimensional) analysis is a laborious task with serious disadvantages2,27. The high cost of each drill test makes it impractical and unsafe to dig holes all over the place. Traditional drilling methods may be inaccurate while evaluating the rock masses due to the site-specific nature24. Additionally, schedule and budgetary limitations make it difficult to get geological data, particularly when conducting on-site testing. Furthermore, it might not be feasible to conduct testing in areas with steep terrain and deep depths. Because of exceedingly challenging circumstances, non-intrusive approaches need to be utilized when drilling is not practical. Such techniques offer the required subsurface knowledge using RQD, making sure the advancement of geotechnical infrastructure.

However, geophysical research offers a more rapid, less costly, non-invasive, non-corrosive, and simple ways for assessing the underlying geological layers via two and three dimensions28,29,30,31,32,33,34,35. In diverse settings, these are by far the best techniques for gathering underground geological data36. Potential remedies include seismic surveys, the ERT (electrical resistivity tomography) technique, and the CSAMT (controlled source audio-frequency magnetotellurics) approach6,20,24. In recent years, CSAMT has emerged as the best geophysical method in terms of both suitability and affordability in the pursuit of exhaustive geological information at extraordinarily deep depth during hard rock studies37,38,39,40,41. Cheaper, faster, and more responsive to low-resistive rocks, CSAMT is the way to go in challenging topographical situations compared to other geophysical research methods40. CSAMT subsurface examinations are more comprehensive than those offered by most other geophysical methods, such as ERT, and can penetrate to a depth of 1 km6,10. Another advantage of CSAMT over conventional geophysical research is its wider resistivity range when compared to other geophysical parameters2. Because of this, CSAMT is an effective tool for exploring the incredibly diverse topographical features and performs better when employing empirically based methodologies.

Several studies suggest a meaningful relationship between geomechanical and geophysical characteristics42,43,44,45,46. Numerous factors influence geophysical and geomechanical characteristics, including pore-spacing, fracture, fluid content, weathering degree, joints, permeability, rock type, fault, rock modification, lithology type, and saturation4,19. This study is the first to use the CSAMT technique to construct 2D RQD models (obtained from a 2D CSAMT survey) and 3D RQD models (obtained from either a complete 3D CSAMT survey or making a unidirectional 3D CSAMT survey using 2D CSAMT surveys) in a highly diversified environment with a wide variety of rock types and significant depths. Only a small number of boreholes will be drilled utilizing the suggested research at appropriate places throughout the project area. Following that, it’s possible to conduct a more trustworthy CSAMT study to evaluate the vast research domain. By immediately connecting geophysical and borehole data, the RQD could be derived throughout the entire site under examination, without the need for drilling tests. From these equations, 2D and 3D dimensional RQD images are produced for the entire research region. This method would cut down on expensive boreholes required to get a comprehensive and perceptive evaluation of subsurface rock units.

Our research bridges the gap between reliable geomechanical models and inadequate drilling via the provision of 2D and 3D RQD models that more accurately predict rock mass properties when compared to previous studies. The estimation of RQD using CSAMT has never been done before. Furthermore, for a variety of rock types in a very diverse environment, this work is the first of its kind to obtain 2D and 3D models of RQD at depths greater than 1 km. The main objectives of this study were to: (1) quickly predict geotechnical parameter RQD with 2D and 3D measurements using CSAMT; (2) precisely evaluate the instability of rock masses for useful engineering projects at great depths in difficult geological conditions; (3) cut down on the number of costly drilling required to obtain the subsurface geological data; and (4) encourage the use of non-invasive geophysical techniques for deep subsurface studies as an alternative to expensive drilling.

Methods

The current study aimed to estimate RQD for 2D and 3D assessment of rock unit stability throughout the project territory using readily available borehole data in combination with a non-invasive CSAMT approach. A flowchart depicting the primary stages of this procedure is shown in Fig. 1.

Study area

This investigation was carried out in Kaiping City, South China, in order to develop the deep underground neutrino detector (Fig. 2). Since the project site is in a monsoon system, the majority of the 1985 mm of precipitation that falls there each year occurs during the summer. Bodies of water, including rivers, surround the Kaiping region. The geomorphology of the research site is characterized by low, somewhat cut, and significantly depleted hills and mountains. The terrain in the north is somewhat lower than that in the south. The region has a number of noteworthy characteristics: a range of elevations between 46 and 438 m above sea level, a lot of vegetation, extensive weathering of rocky rocks, and generally gentle to steep terrain slopes47. The three most notable mountains are Jixinshan, Dashishan, and Qilongding. The summit of Xikeng, which is situated in the southern portion of the study site, is the highest point in the landscape at 548.9 m. At an elevation of around 7.7 m, the northeastern portion of the location under investigation is traversed by the Yongkouwei River.

The research site has Jurassic, Permian, Carboniferous, Devonian, Indosinian, Caledonian, and Yanshanian intrusive rocks, Quaternary, Ordovician, and Cambrian strata, and a few Paleogene strata. The three main lithologies found are sandstone, granite, and hornstone (Fig. 2). The Kaiping concave fault and fold systems, which are fairly complex due to the influence of magmatic processes and diverse structures, are the main geological characteristics in the examined region48. The different tectono-geological stages can be displayed in the production of jointed fissure structures, with the local tectonic lines lining up with the fault strike, primarily in the northeast orientation47. The location of the examined area is depicted in Fig. 2, which includes drilling tests (W1–W6), simplified geological conditions, and geophysical profiles (A–F).

CSAMT survey

Principle

CSAMT has been widely used in geotechnical studies2,26,37,39. For CSAMT surveys, one place emits a controlled electric signal into the ground from a distance, and another place monitors the electric and magnetic fields29,49. There is a mathematical relationship between the reflected depth and the frequency because different fields propagate at different depths in the subsurface structure41. It uses the fact that different rocks have different electrical conductivities to track changes in magnetic field intensity and main field potential50. Fourier transformations are employed to obtain the signal frequency components once the EM field fluctuations time series have been acquired51.

CSAMT makes use of an artificially controlled field source. The electromagnetic field component of the electric dipole source can be measured using current electrodes 1–2 km apart. Batteries or suitable places can be used to position the transmitter and connections that connect it to the current electrodes. The distances between the transmitter and receiver from the field source, which are typically 5–10 km, are determined by geological conditions and DOI (depth of investigation). The field source can be described by an estimated plane wave. We can determine the subsurface resistivity by splitting horizontally and orthogonally the magnitudes of magnetic/electric field. The subsurface geology-related resistivities are influenced by a number of factors, including fault fragmentation, water saturation, lithological changes in stratigraphic structures, pore fluid, porosity, rock types, etc2,52. Geological structures with a depth of 20–1000 m can be evaluated using CSAMT with a vertical resolution of 5–20%. DOI is determined by transmission frequency and subsurface resistivity. Higher DOI is usually obtained by decreasing frequency and increasing subsurface resistivity6. The station spacing, which is normally between 10 and 200 m, determines the lateral resolution. The strength of the received signal rises with the station-interval size53. At each station, a portable receiver can be used to process, amplify, filter, and record the signal. When signals are transmitted, they are picked up by magnetic-field sensors and pairs of electrodes, which are short grounded dipoles. When conducting CSAMT surveys, it is important to minimize the influence of potential sources of noise, such as radio transmitters, metal fences, and power lines. Modeled resistivity data can be displayed as a cross section, fence, 3D drawing, or plan.

Data acquisition

The CSAMT data was collected along 6 profiles (A–F) with a total of 122 sounding places and 5825 m of profile length. The distance between each station was 50 m. A DOI of 1300 m was reached in the CSAMT survey. Scalar measurements were taken using the TM Mode. These measurements take the electric and magnetic fields in two directions: parallel to the measuring line and perpendicular to it. When performing EMAP observations, it is made sure that the locations of observations are interconnected consecutively and that the measurement points are 50 m from the electrode. We used Gain mode X1 in combination with the 50 Hz linear filter. The emission current’s minimum current ranges from 2.6 to 4.5 A at 7680 Hz, while its maximum current ranges from 12 to 18 A at 1 Hz. The CSAMT data was gathered using a V8 multifunction receiver and a TXU-30 transmitter manufactured in Phoenix, Canada. A geophysical approach Up to 1000 V of transmission voltage, 20 A of current at 1000 V, and 40 A of current at 500 V can all be supported by the TXU-30 multi-function transmitter with a 30 kilowatt output. This GPS-capable transmitter is ideal for in-depth research because it works with domestic three-phase 220 V alternators. The working frequency ranged from 1 to 7680 Hz, and 34 frequency points were used in total. The V8 multifunction receiver can not only gather data but also keep an eye on the data from additional secondary receiving units. For this, the primary receiving box includes three channels and three tracks. The transmitter and receiver were 9.2 to 12.4 km apart. The non-polarized electrode was used to record the electric field signal. The signal from the magnetic fields is recorded via AMTC-30 (High-frequency AMT/CSAMT magnets operating between 10,000 Hz and 0.1 Hz) inductive magnetic sensor. After obtaining three orthogonal magnetic field components and two orthogonal electric field components at each point, the tensor measurement was carried out. The specific places of measurement were obtained via the American Trimble Company’s XH dual-frequency GPS receiver. The CSAMT object detection line was measured using the Hi-Tech V30GNSS RTK system. Modern GPS technology allows the location precision range to approach sub-meter level. A computer program determined the orientation and distance between each survey point and line of survey, and then transmitted those results to a GPS or RTK device. The RTK or GPS navigational function was used to locate the measuring points of the survey lines.

A 3–5% system quality check was performed on the spots along the measurement lines, and it was found that the distribution of inspection points was generally even. With an RMS of less than 5%, an error tolerance of adjacent points on the profile of less than 10, a relative elevation tolerance of 1.67 mm, and a plane tolerance of 2.33 mm, the system quality check was successful and produced data that satisfied the design requirements for this task. High-quality data was gathered at the project site because there was no electrical or human disturbance. The attributes of the investigated site were derived from the analysis of the CSAMT data10. Following the elimination of data distortion, a curve analysis was conducted. The static modifications were implemented utilizing a Hanning window spatial filtering method, which is based on curve analysis and geological understanding. Therefore, the gathering of precise data interpretation/processing was made easier by high-quality geophysical data.

Data processing

Canadian Phoenix’s CMTPro Version software was utilized for the data processing phase54. Among the many functions performed by this program are the following: removing inaccurate measuring point curves, adjusting electrode locations, automatically smoothing observed curves, creating CMT files from source current, reference track data, and V8 data, and lastly, creating AVG files. The CSAMT-SW algorithm, depicted in Fig. 3, was utilized to carry out the 2D inversion55.

These are the most important parts of CSAMT-SW: (1) Change data from an AVG file to the D format; (2) Creating, modifying, and importing CHK file into D format; (3) Cleaning up the D file by hand by eliminating troublesome sectors, jump points, near-field data, and interpolation; (4) To process the smoothing, use the D file. Various static correction approaches yielded inversion results that were, upon comparison, very comparable; (5) There are four alternative static correction processes, and the resulting files are D, H, K, and Z; (6) To convert to text files, we use BOSTICK inversion and near field correction; (7) Quasi-2D inversion: In order to generate resistivity-depth section data consisting of finite layers, this approach directly applies the CSAMT global field model (ID), which combines transition and near fields, to the measured data from CSAMT. The data in the D file was subjected to Bostick inversion53, with the outputs stored as * _BOS.DAT and * _BSS.DAT, respectively. The data format of the D file is converted and saved in a newly produced * _M. DMT text file in compliance with the requirements of the 2D inversion model of CSAMT. The inversion method is employed to fit the produced models to the measured data until the maximum number of iterations or RMS error has been reached; in this case, it was 5 iterations. Within the context of the local geology and the peculiarities of the datasets, the most appropriate processing/inversion algorithms reduced the errors of the models and developed a reliable resistivity model (2D) of CSAMT. The final inversion model provided us with a better understanding of the geological features beneath the surface by displaying changes in resistivity.

Estimation of rock quality designation (RQD)

Rock engineering commonly makes use of RQD, a fundamental geomechanical index initially proposed by Deere (1964) at the University of Illinois in the US. This parameter is crucial for the effective execution of many geotechnical design procedures, such as s construction of dams, mining of rock masses, stability of slopes, excavation, and more24,25. It might classify and characterize rock masses according to collapse norms. Any overestimation of RQD can cause the project to go over budget and the engineering structure to collapse4,56. Because of this, RQD functions as the principal geomechanical index to determine the structural soundness of the rocks in geotechnical study57. It is typically determined by means of a large-scale excavation program. RQD is defined by the digging process and the core’s transport to the laboratory58. Before engineering facilities are built, it is common practice to employ this efficient geomechanical parameter for load-bearing assessments of foundation rock. It gives engineering rock a numerical rating of how reliable it is. Overall assessment of fracture degree is provided by RQD. The core samples (taken from drills) with take-up rates are used by RQD to evaluate the hard rock quality. In other words, the subsurface rock is continuously sampled by continuously acquiring rock cores through a 75 mm diameter double-layered tube59. Traditionally, NX-size cores with a diameter of 54.7 mm were used to obtain the borehole-based RQD. A sum of all hard core pieces longer than 4 inches (10 cm) are added together and then divided with overall core run length. When calculating RQD, hard rock pieces shorter than 10 cm or 4 inches in length and pieces of soft rocks longer than 10 cm or 4 inches are not taken into account. Since RQD gives the quantity of rock cores recovered from the boreholes, it is measured in percentage units (%). As a result, RQD offers a high-integrity rock mass (in %) that may be recovered through a drilling interval. The RMR and Q systems, among others, use RQD to categorize rock masses. It is common practice to use the following equation to derive RQD from borehole rock samples60:

RQD stands for rock quality designation, expressed as a percentage (%). Firstly, a total of 37 RQD measurements were obtained by applying Eq. 1 to 6 boreholes with depths ranging from 10 to 200 m as shown in Fig. 4a.

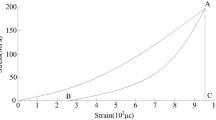

After that, 37 RQD values derived from boreholes were empirically linked with 37 resistivity values obtained from selected CSAMT soundings. For instance, A5 was the fifth sounding for 200 m on surveyed line A with W1, C8 was the eighth sounding for 350 m along C with W2, D2 was the second sounding for 50 m with D and W3, D15 was the fifteenth sounding for 700 m on surveyed line D with W4, E15 was the fifteenth sounding across profile E with W5 at 700 m, and E21 was the 21st sounding on surveyed line E with W6 for a 1000 m distance (Fig. 4a). From the CSAMT-borehole correlations, we were able to derive the following equations (Fig. 4b):

where Ωm is used to measure the inverted or true resistivity ρ, represented as Res. Initially, Eq. 2 was created using 37 resistivity-RQD measurements (Fig. 4b). But as Eq. 2 only provides a weak empirical connection (R2 = 0.80), it cannot reliably predict RQD. For the purpose of obtaining more precise RQD, the resistivity-RQD values were divided into two robust empirical correlations (R2 = 0.90 and R2 = 0.99, Fig. 4b) to formulate Eqs. 3 and 4. The experimentally determined Eq. 3 was utilized to evaluate three granite types: substantially weathered/fractured, partially weathered/fractured, and fresh granite, using RQD values of 50–100% and electrical resistivity above 700 Ωm. The evaluation of sandstone and hornstone was carried out using Eq. 4, with RQD ranging from 0 to 50% and a resistivity below 700 Ωm. Last but not least, the RQD parameter, a predicted geomechanical feature present in all A-F geophysical profiles, was modeled in 2D and 3D using the SKUA-GOCAD (Version: 22 build 2022.06.20) programs61,62.

The evaluation of moderately weathered/fractured granite (MW/FG), hornstone (HS), poorly weathered/fractured granite (PW/FG), sandstone (SS), and fresh granite (FG) was carried out using 37 resistivity-RQD data points at 10–200 m depths. The data was collected from 6 drilled tests (W1–W6) and the associated resistivity (ρ) was calculated from CSAMT soundings (A5 represents sounding number 5 along profile A, C8 indicates sounding number 8 along profile C, D2 indicates sounding 2 along profile D, D15 demonstrates hearing 15 along profile D, E15 reveals sounding 15 along profile E, and E21 displays sounding number 21 on surveyed line E), (a) Resistivity data points corresponding to drilling-based RQD, (b) Geophysical-borehole correlation.

Results

Geophysical-borehole correlation

Based on the various ranges of rock quality designation (RQD) and electrical resistivity, the combined data from six CSAMT profiles and six boreholes was used to limit the underground formation into numerous discrete strata, as shown in Table 1. The subsurface geotechnical models were constructed using the geological settings of the study area and CSAMT-borehole data. These models included five distinct geological layers: hornstone, sandstone, fairly weathered granite or moderately fractured granite, complete fresh/integral granite, and poorly weathered granite or weakly fractured granite. Resistivity below 350 Ωm and RQD between 0 and 25% were taken into consideration for sandstone; hornstone was subjected to resistivity ranging from 350 to 700 Ωm and RQD ranging from 25 to 50%; electrical resistivity between 700 and 1000 Ωm and RQD between 50 and 75% were taken into consideration for moderately fractured or weathered granite; resistivity between 1000 and 1500 Ωm and RQD between 75 and 90% were taken into consideration for poorly or weakly fractured/weathered granite; and RQD values ranging from 90 to 100% and resistivity values above 1500 Ωm were employed for integral granite rock. We assigned a very high grade to fresh granite, a high grade to lightly weathered/fractured granite, a medium grade to moderately weathered/fractured granite, a low grade to hornstone, and a very low rank to sandstone in the subsurface geomechanical model Thus, fresh or integrated granite is the best surface to build a civil structure on, while the sandstone in the research region is the worst possible surface.

2D modeling of rock mass quality

By using Eqs. 3 and 4 based on geophysical-borehole correlation, 2D CSAMT models may be efficiently converted into 2D RQD models (Fig. 5). In contrast to the scant drill data, geophysical-based 2D RQD models offer a thorough and accurate description of rock unit integrity for depths ranging from 0 to 1300 m across the whole studied area (Figs. 6 and 7). The following is an evaluation of the rock unit strength along profile A: Between 400 and 1200 m deep and 600 and 1060 m wide, completely integral granite was marked. At distances of 40–160 m and 430–1150 m, a layer of weakly weathered/fractured granite, 200–400 m thick, is observed encircling the fresh granite. The evaluation of the poorly fractured or weathered granite involved a 100–450 m thick layer of moderately weathered/fractured granite around it at depths of 0–1300 m and lengths of 0–180 m, 390–1200 m, and 1300–1450 m. At depths of 200–800 m and distance of 230–380 m, a 100–300 m thick layer of sandstone is analyzed. Hornstone makes up the remaining profile at depths between 0 and 1300 m, especially between 0 and 500 m and between 1200 and 1450 m distance. The following is the evaluation of rock unit stability along profile B: Fresh granite is assessed between 400 and 700 m, more precisely between 0 and 200 m and between 350 and 450 m. At depths of 100–800 m and distance of 0–450 m, a 200–400 m thick layer of badly weathered/fractured granite surrounds the fresh granite. The whole profile is analyzed to study the moderately weathered and fractured granite around the poorly weathered and fractured granite. There is a 200–300 m thick hornstone layer found between 0 and 300 m distance, especially between 230 and 450 m. There is also another 100–200 m thick hornstone layer beneath 800 m with 0–200 m and 300–400 m distance. Along this profile, there is no discernible sandstone. The following is an evaluation of the rock unit strength along profile C: Between 200 and 600 m in depth and between 200 and 600 m in distance, a fresh granite layer that is about 200 m thick is found. Along the whole profile, the freshly formed granite is surrounded by badly weathered and fragmented granite at depths of 150–800 m. Furthermore, the poorly weathered/fractured granite is surrounded by a 100 m thin layer of moderately weathered/fractured granite, which is 300 m thick and measured at 0–400 m at the bottom and 550–650 m at the top. The rest of the profile is mostly made up of hornstone, with a 150 m thick layer of sandstone situated between 20 and 140 m and between 450 and 510 m distance. The following is the rock mass quality study along profile D: At depths of 200–700 m, more precisely between 50 and 350 m and 520–600 m, a fresh granite layer that is 100–400 m thick is investigated. Additionally, a 250 m thick, weathered or weakly fractured granite that is 0–650 m away from this fresh granite is examined. Furthermore, the poorly weathered or cracked granite is surrounded by a 100 m thin layer of moderately weathered or fractured granite, and a 300 m thick layer of moderately fractured or weathered granite was assessed for 0–400 m distance. Hornstone makes up remainder of the measured line, with a 300 m thick layer of sandstone at the summit, between 650 and 700 m. The following is the evaluation of the rock unit reliability along profile E: Between depths of 200 and 450 m and distance of 250 and 400 m, there is a fresh granite layer that is roughly 250 m thick. This fresh granite is surrounded by 200–405 m of weakly weathered/fractured rock, which is estimated to be between 50 and 500 m deep and 100–980 m away. Furthermore, the weakly weathered/fractured granite is surrounded by a 120 m thin layer of moderately weathered/fractured granite, and a 300 m thick layer of moderately fractured or weathered granite was revealed with depths of 150–450 m and distances of 350–850 m, spanning from 1100 to 1300 m. The rest of the profile is made up of hornstone, including sandstone, which is found between 450 and 1300 m depth at 1000–1400 m distance and between 0 and 1200 m depth at 0–200 m distance. Along profile F, rock unit strength is evaluated as follows: A fresh granite layer that is roughly 450 m thick is seen between 150 and 600 m depth in a horizontal range of 50 to 200 m, and between 300 and 600 m depth in a range of 700 to 900 m distance. A 400–600 m thick layer of badly weathered or cracked granite surrounds this fresh granite, and it is measured from the surface to depths of 0–300 m and 500–1150 m. Moderately weathered or fractured granite makes up the remaining portion of the profile, which contains a 300 m thick layer of hornstone that extends from the surface to depths of 350–800 m and 1000–1150 m. The findings from the integrated 2D RQD models, which are shown in Figs. 6 and 7, show that rock unit stability often increases upward, with the core regions primarily being characterized by the highest grade integral granite.

The conversion of 2D CSAMT models (for six profiles A–F) into 2D RQD models and the interpretation of these 2D RQD models, using geophysical-borehole correlation, make it easier to evaluate four faults (F1–F4), fresh granite (FG), hornstone (HS), poorly weathered/fractured granite (PW/FG), sandstone (SS), and moderately weathered/fractured granite (MW/FG). The 2D models were generated by the software SKUA-GOCAD (Version: 22 build 2022.06.20).

Evaluation of the integrated 2D RQD models (generated by the software SKUA-GOCAD (Version: 22 build 2022.06.20)) that include four faults (F1–F4) and five different geological rock units: sandstone (SS), fresh granite (FG), hornstone (HS), poorly weathered/fractured granite (PW/FG), and moderately weathered/fractured granite (MW/FG).

3D modeling of rock mass quality

The 3D RQD exterior visualization shown in Fig. 8 (a, b) provided an exhaustive evaluation of rock unit reliability. The northern region’s ground surface, the eastern region’s depths of 0–400 m, the southern region’s depths of 1200–1300 m, and the western region’s depths of 400–800 m were all used to evaluate fresh granite. Poorly weathered granite was found along profile A at 705–1105 m, surveyed line B at 85–155 m, geophysical traverse D at 105–165 m, 275–305 m, and 525–575 m, along profile E at 135–175 m and 305–355 m, and CSAMT line F at 105–305 m and 705–905 m, excluding areas surrounding fresh granite. Moderately weathered granite was assessed along profile A at distances of 105–205 m, 395–770 m, and 1045–1185 m; profile B at 0–85 m and 185–365 m; profile C at 0–45 m, 205–245 m, 345–405 m, and 545–645 m; profile D at 0–35 m, 155–215 m, 335–415 m, 495–515 m, and 595–625 m; profile E at 0–45 m, 115–135 m, 175–195 m, 315–335 m, 375–795 m, and 1145–1295 m; and surveyed line F at 95–125 m, 295–395 m, 695–790 m, and 955–1115 m. The following areas were used to evaluate the sandstone: profile A at 245–295 m, profile C at 425–495 m, profile D at 645–705 m, profile E at both 245–295 m and 905–975 m, and profile F at 0–25 m of distance. The remaining area along profiles A–F was assessed using hornstone.

A thorough analysis of rock unit assessment from a 3D RQD internal perspective is provided in Fig. 8 (c, d). Granite was only evaluated using profile A at a distance of 845–945 m. Poorly fractured granite was identified along profiles A and F at 705–1095 and 705–1145 m, respectively. Granite that was moderately fractured was assessed at the following distances: surveyed line F with 0–705 m and 995–1155 m; profile A with 545–660 m and 1105–1185 m; profile B with 0–90 m; profile C with 0–89 m; profile D with 0–345 m; and profile E with 400–790 m. Following that, hornstone was delineated by survey line E at 205–400 m and 845–1045 m, profile A at 0–545 m and 1195–1450 m, profile B at 105–455 m, profile C at 75–645 m and profile D at 345–700 m. Only profile E was used to evaluate sandstone for 0–195 m and 995–1405 m distances. The 3D RQD data, displayed in Fig. 8, show that the interior is mostly made up of granite, which is fresh rock encircled by worn or cracked rock. The quality of the rock unit deteriorates steadily as viewed from above. This makes it possible to use 3D RQD modeling to accurately and thoroughly appraise the rock unit reliability.

The 3D RQD models (generated by the software SKUA-GOCAD (Version: 22 build 2022.06.20)) with RQD on a color scale changing from dark red to dark blue, including four faults (F1–F4) and five different geological rock units: fresh granite (FG), hornstone (HS), poorly weathered/fractured granite (PW/FG), sandstone (SS), and moderately weathered/fractured granite (MW/FG), for (a) 3D RQD with outer insight, (b) Interpreted 3D RQD with outer insight, (c) 3D RQD with inner insight, and (d) Interpreted 3D RQD with inner insight.

Rock mass quality assessment at depths

Because of the restricted drilling data, the measured RQD in this investigation is unable to appraise the rock mass reliability below 200 m. For the purpose of conducting a faster, more accurate, and thorough evaluation of rock unit reliability, a strong correlation between drilling and CSAMT data was developed to determine RQD down to 1300 m. Figure 9 illustrates and analyses the predicted RQD at depths of 0, 200, 600, 1000, and 1300 m. Criteria for evaluating the subsurface at a depth of 1300 m were as follows: Fresh granite, which makes up around 2% of the subsoil in the central and southwestern regions, is measured. Hornstone, which makes about 28% of the subsoil, is examined by the eastern and western parts that surround fairly fragmented granite. In the central sections, moderately fragmented granite made up around 27% of the subsurface. In the middle and southwest parts of the region, where there was weakly fragmented granite, about 21% of the subsurface was analyzed. In the eastern region, the majority of subsurface assessments were carried out on sandstone, which accounted for 22% of the entire. The following standards were applied in order to comprehend the subsurface at a depth of 1000 m: Sandstone made up 21% of the subsurface in the eastern areas. In the central and northern sections, 22% of the subsurface was exposed due to poor fractured granite. 28% of the subsurface in the centre and southwestern areas was exposed as moderately fragmented granite. In the eastern and western regions, 27% of the subsurface was found to be hornstone around moderately fragmented granite. Lastly, 2% of the subsurface was made up of fresh granite that was marked in the middle. We used these criteria to interpret the subterranean conditions at a depth of 600 m: In the middle, northern, and northwest sections, fresh granite was examined with 20% of the subsurface; in the central regions, moderately fractured granite was evaluated with 10% of the subsurface; in the central, northern, and northwest sections, poorly fractured granite was delineated with 25% of the subsoil; with the southwestern and eastern parts, hornstone was primarily marked by 25% of the subsoil; and with the eastern regions, sandstone was evaluated with 20% of the subsurface. The subterranean layers are examined at a depth of 200 m while taking into account: The majority of the subsurface was defined by integral granite, which accounted for 15% of the total; moderately cracked granite, which accounted for 27% of the subsoil, was primarily evaluated in the central portions; weakly broken granite was found to make up about 21% of the subsoil in the central and northwest sections; hornstone, which accounted for 27% of the subsurface, was discovered in the southern and southeastern regions; and sandstone, which accounted for 10% of the subsoil, is analyzed with the southwestern and eastern portions. From the surface above, the followings are ascertained at a depth of 0 m: 37% of the central regions’ surface was rated as moderately worn granite, while 16% of the subterranean area, primarily in the center and northern portions, was evaluated as poorly weathered granite. 12% of the subsoil was revealed by fresh granite in the northern regions; Sandstone was mostly analyzed in the inner and southern areas, accounting for 9% of the surface, whereas hornstone was found in the southeastern and southwestern portions, comprising 26% of the surface. Figure 9 illustrates how the thickness of fresh granite reduces from top to bottom. For technical construction, middle parts down to 600–700 m offer the best conditions. The lowest-grade rock mass is found in the eastern and western regions, particularly below 700 m in depth.

Geophysical-based RQD mapping (generated by the software SKUA-GOCAD (Version: 22 build 2022.06.20)) at different depths, including (a) RQD distribution at 0, 200, 600, 1000, and 1300 m depths (RQD on a color scale increasing from dark red to dark blue), and (b) Analysis of RQD at 0, 200, 600, 1000, and 1300 m depths for four faults (F1–F4), fresh granite (FG), hornstone (HS), poorly weathered/fractured granite (PW/FG), sandstone (SS), and moderately weathered/fractured granite (MW/FG).

Evaluation of faults

Four major faults, designated F1, F2, F3, and F4, are found in the project region based on the 2D and 3D RQD models, as shown in Figs. 5, 6, 7, 8 and 9. Low resistivity and RQD measurements, notably resistivity < 1000 Ωm and RQD < 75%, were used to identify these faults. The NW-SE orientated fault F1 was found 300 m away along profile A. F1 has a thickness of 200 to 400 m and is 1300 m deeper. Along profile A, 1300 m to the northwest-southeast, is where fault F2 was defined. With a thickness and width of 200–300 m, F2 stretches 1300 m deeper. Fault F3 was assessed for of 1050 m distance alongside line E, which is orientated NE-SW. F3, which is situated 1300 m below sea level, is 250–350 m wide and thick. A fault, F4, was located 450 m away along profile F in the northwest-southeast direction. F4 is thicker and wider by 150–250 m and 1300 m depth. F1 is assessed in the west, and F2–F4 are found in the east. The building plan should avoid the fault zones depicted since the indicated faults yield the most badly graded rock unit. The centre regions are perfect for engineering construction and provide high-quality rock mass.

Comparison of the predicted and measured RQD

A thorough and methodical assessment of rock unit strength throughout the project area is revealed by the RQD based on CSAMT. The RQD findings (Figs. 5, 6, 7, 8 and 9) demonstrate that: Fresh and fractured/weathered granite are inspected in the middle parts; Hornstone is distinguished mainly in the eastern, southern, and western regions between weathered and fractured granite and sandstone. Sandstone undergoes a full analysis in the eastern regions and a partial evaluation in the western ones. Borehole RQD data provide incompatible mapping of subsurface layers for appraising the rock unit reliability. The drilling results do correspond with the CSAMT data in a few locations near the drills with depths of 200 m. Therefore, the measured RQD (obtained via drills) yields imprecise assessments of rock mass stability over a wide region, in contrast to the predicted RQD.

The drill-RQD and the CSAMT-RQD were compared in order to determine the percentage inaccuracy for the selected measurements (Table 2). When W1 (well number one) is empirically connected to A5 (5th sounding along surveyed line A), Eqs. 3 and 4 yield a %error of 5 and 3, respectively, at depths of 25 m and 115 m, while Eq. (2) yields a %error of 21 and 3, respectively. With a depth of 10 and 130 m, the integration of C8 (sounding 8 along profile C) and W2 (well number two) yields a %error of 22 and 7, respectively, when using Eqs. < link rid="eqn2”>2</link> and 2 and 5 when using Eqs. 3 and 4. The addition of W3 (well number three) and D2 (sounding second on line D), at a depth of 85 and 150 m, results in a %error of 4 and 4 according to Eq. 2, and 3 and 0 according to Eqs. 3 and 4, respectively. W4 (well number four) and D15 (15th sounding at line D) are integrated to produce %errors of 83 and 20 using Eqs. 2 and 25 and 7 using Eqs. 3 and 4, with corresponding depths of 25 and 85 m. With equivalent depths of 60 and 200 m, the integration of W5 (well number four) and E15 (15th sounding at line E) yields %errors of 3 and 3 via Eqs. 3 and 4 and 4 and 7 via Eq. 2. Additionally, the addition of W6 (well number six) and E21 (the 21st sounding on line D) yields a %error of 4 and 3 according to Eqs. 3 and 4, and 29 and 24 according to Eq. 2, with corresponding depths of 80 and 120 m. The comparison described above so indicates that there is less error between the projected and obtained RQD. This comparison also makes it clear that Eqs. 3 and 4 provide more accuracy than Eq. 2.

Discussion

The construction of subterranean engineering structures primarily relies on a comprehensive assessment of rock mass quality. The classification of rock mass competence is based on a number of geotechnical parameters. RQD, RCI, UCS, GSI, Rmi, RSR, SMR, E, Q-system, and RMR are the most precise and practical engineering indices utilized in these assessments; these are all typically assessed using boreholes14,17,18,19,20,21. The traditional approaches, however, have a number of drawbacks, including being costly, intrusive, time-consuming, requiring heavy equipment, providing point-scale data, allowing measurements at shallow depths, lacking volumetric data, being unable to explore the entire site for extensive coverage, and not being able to be carried out in steep topographic areas. To address the limitations of conventional methods, the proposed approach turns to geophysical methods for indirect estimation of geomechanical parameters. Geophysical approaches can serve as a valuable and cost-effective complement to a test-boring research program. Unlike borings, geophysical surveys provide the quick and cost-effective exploration of extensive areas. They represent average conditions along an alignment or within an area, rather than along the confined vertical line at a specific site as observed in a digging. Geophysical data can assist in identifying optimal locations for future drill holes and offer insights to infer foundation conditions between current drill sites. These data are valuable for identifying anomalies in bedrock surfaces and at interfaces between strata. The expense of conducting geophysical surveys is frequently lower than that of drilling; thus, the prudent application of both geophysical techniques and drilling can yield the necessary information at a reduced overall cost. While geophysical fieldwork is comparatively cost-effective, the interpretation of results is complex and requires specialization. To ensure test results are useable and accurate, correlations must be established locally using exploration data from borings.

Based on the goals and needs of the investigation, the most appropriate geophysical approach is chosen. For hard rock assessment in varied environments, the most effective geophysical methods include seismic, ERT, and CSAMT, whereas other options are less efficient or less accurate. Some geophysical methods, including CSAMT, ERT, and VES, measure resistivity across a wide range of values, which gives them an advantage. Wide ranges of geophysical parameter values are the primary determinant of empirical equation accuracy in empirical-based research such as this one. In electrical methods, resistivity is quantified in Ωm, exhibiting a broader range of values compared to other geophysical parameters such as seismic velocity, magnetism, and gravity, etc. A specified range of resistivity values (in Ωm) is used to evaluate each geological layer or rock mass. Therefore, as compared to other geophysical parameters with narrow ranges, geological layers having a large range of resistivity values are more accurately evaluated. In hard rock investigations, 2D/3D resistivity measurements from ERT and CSAMT yield more comprehensive and precise assessments of subsurface formations than 1D VES. ERT is a near-surface geophysical method that offers subsurface assessments mostly at shallow depths, typically within the range of 0–200 m. The main purpose of conducting CSMAT surveys is to investigate the deep subsurface structures. With CSAMT, a site can be explored to a depth of 1 km or even deeper. The geological background in the project region is markedly diverse, with granite prevailing at shallow depths, while hornstone and sandstone dominate at greater depths; thus, extensive depth exploration is crucial for the deep underground construction of engineered structures. Therefore, based on the aforementioned considerations, CSAMT was selected as the optimal geophysical method for this study.

The CSAMT-based RQD enables a thorough evaluation of rock unit properties at large depth. Using a specific set of values for RQD, the rocks are classified into five main categories, including hornstone, sandstone, moderately weathered/fractured granite, fresh granite, and poorly weathered/fractured granite. A number of factors contribute to the low quality of rock masses, including type of lithology, influence of water, fractures, faults, and the presence of stratification (contact/boundary between two distinct rock masses, such as SS-HS, HS-MW/FG, MW/FG-PW/FG, and PW/FG-FG)63. Another possibility is that the drilling process itself will hit and erode the rock mass, creating plastic zones64. The particular parameter ranges are determined by taking into account the local environment and rock composition. A rock unit’s RQD-resistivity range is relative rather than fixed, and site-to-site variances may arise. However, the proposed approach can be used to obtain specific resistivity-RQD ranges for any specific area. Generally, 5–8 boreholes spanning the entire area with respect to the rock unit characteristics, with at least 5 measurements per borehole, can be used to construct a trustworthy empirical equation. Most significantly, the RQD-resistivity range and the quantity of geophysical-borehole measurements have an impact on the empirical equation’s dependability. Additional datasets utilized in correlation analysis can be used to calculate geomechanical indices more accurately. In the majority of datasets, the difference between the actual and projected RQD was less than 10% (Table 2), indicating a high degree of precision. However, the extremely low RQD is the reason for the severe 25% inaccuracy in the correlation between D15 and W4 at 25 m depth provided in Table 2. Smaller numbers are more likely to contain errors than larger ones. The key reason for the trustworthy results was the suitable drill placements (which include all five types of rocks). The use of multiple equations (Eqs. 3 and 4 for five layers) for different rock units (as seen in Table 2) to compute RQD is more accurate than using Eq. (2) for each rock mass unit. However, distinct empirical equations work better when each rock mass unit has access to adequate borehole observations.

We can get resistivity surveys in many different flavors, including 1D, 2D, 3D, and even 4D. A horizontal and uniform geology is assumed by 1D resistivity studies. This presumption restricts the analysis of resistivity changes to the vertical plane. Since such a site is uncommon, a 1D survey is rarely required. Additionally, when we just need an average value with depth, 1D is the way to go. 2D resistivity surveys represent a significant advancement; however, they remain reliant on an approximation of 3D space. A 2D survey uses a single line of electrodes and is based on the premise that the geology under study extends indefinitely and unchanged in a direction perpendicular to the line of electrodes. Without presumptions, 3D resistivity surveys measure in every direction with an electrode grid and thus allow us to get a 3D subsurface model. Although 3D surveys may have the potential to provide a more realistic model than 1D or 2D, however a 2D survey is the most closely related alternative. Making a unidirectional 3D survey using 2D surveys is an excellent way to balance these two types (2D and 3D). Here, a few 2D survey profiles are used to sweep an area, and the data is then combined to approximate 3D. This study conducted just a 2D CSAMT survey, from which 3D CSAMT data was derived by integrating the 2D CSAMT data. A full 3D geophysical survey yields more accurate findings than 3D geophysical data generated by merging 2D geophysical data. The accuracy of 2D/3D RQD is directly related to the precision of 2D/3D CSAMT data. Hence, the current 3D RQD is less accurate than the 3D RQD that would have been obtained from a full 3D CSAMT survey. The accuracy of the present 3D RQD models is higher in the vicinity of the profiles, whereas the inaccuracy rises as the distance from the profiles increases. Nonetheless, the 2D inverted model may introduce ambiguity in the deeper strata if the subsurface resistivity exhibits considerable variation in directions orthogonal to the observed lines. By doing a complete 3D resistivity survey with data inverted, this ambiguity brought on by 3D structures can be eliminated.

Additionally, geophysical approaches do have their limits. All geophysical methods rely on identifying variations in the characteristics of geological materials. If such differences are absent, geophysical approaches will be ineffective. The disparities encompass acoustic velocities and variations in the electrical characteristics of materials. Electrical techniques rely on variations in electrical resistivity. To get reliable results, geophysical methods must be supplemented with known geological information derived from drill data. The 2D/3D resistivity techniques represent a pragmatic and economical balance between minimal survey expenses and satisfactory accuracy of results. Nonetheless, the uncertainties might impact the precision of resistivity model findings throughout the acquisition, processing, and interpretation phases. Various environmental and geological contexts yield a wide range of data sets. Nonetheless, the inversion method can lower the inverted model uncertainty and produce findings that are more in line with the known geology by varying the inversion parameters. When measuring resistivity along a line, the subsurface is considered to be 2D. For this hypothesis to work, resistivity surveys must be conducted across the lengths of the extended structures. Even with dependable inversion methods, high-quality data, and dense data coverage, the 2D resistivity survey will yield unclear results if the 2D geology assumption is incorrect. How deeply a current can go into the earth determines the accuracy of resistivity surveys. As a result of current being trapped in the top layer due to extremely low or high resistivity, sufficient current may not flow into the subsurface, leading to misleading results from the lower layers. Drilling data integration is essential for the proposed technique to work. Nevertheless, it can minimize the number of boreholes needed to acquire geotechnical information throughout the entire site. CSAMT is commonly employed to probe subsurface structures and mitigate the effects of weak natural signals to a modest degree. However, a variety of elements, such as metal barriers, electrical cables, and transmission devices, can have a substantial impact on the quality of resistivity measurements, producing ambiguous findings and interpretations. However, this work shows that appropriate CSAMT survey design can reduce these impacts and provide reliable data quality. High-quality data was gathered at the project site because there was no electrical or human disturbance. RQD can be affected by sudden changes at different layered interfaces since it depends on connecting the small core lengths. An RQD value of 100%, which corresponds to a resistivity of 3000 Ωm, indicates the rock mass’s highest stability. By reducing variability in the predicted geotechnical model, the geophysical RQD provides a more accurate and thorough evaluation of the rock units’ reliability compared to the drilling RQD. Therefore, the validity of geotechnical model for existing buildings is critically questioned due to insufficient boring tests. However, the geophysical method bridges the gaps between accurate geomechanical models and inadequate boreholes.

Conclusions

Our study creates new opportunities for the precise determination of the integrity of rock units using non-invasive methods in rock mechanics and geotechnical engineering. Indirect RQD assessment may assess the rock mass’s strength over a large region without drilling data, according to CSAMT research. Boreholes are the most often used technique for monitoring technical characteristics. However, drilling methods come with a slew of negative aspects and can be quite costly. This study offers a more thorough and precise evaluation of the rock mass’s condition than conventional geotechnical testing while decreasing the number of boreholes needed. The flexible equations that predict RQD were derived by analyzing CSAMT-drilling data from several places. This allowed us to evaluate the firmness of rock formations in varied settings. The RQD was calculated using the standard equations, allowing for a thorough examination of the rock unit strength across the whole study region. Resistivity less than 350 Ωm and RQD less than 25% were utilized to characterize very low grade sandstone in a five-layer geomechanical model. RQD between 25 and 50% for resistivity increasing from 350 to 700 Ωm was used to identify the low grade hornstone. RQD 50–75% and resistivity 700–1000 Ωm were used to evaluate the medium-quality granite that was moderately worn or fractured. High-quality granite that was inadequately weathered or fractured was assessed using RQD between 75 and 90% for resistivity 1000–1500 Ωm. The unweathered granite of exceptionally good grade was evaluated using RQD 90–100% and resistivity greater than 1500 Ωm. Moreover, four faults, identified as F1, F2, F3, and F4, were identified. These faults were 200–400 m thick, reached depths of 1300 m, and were primarily northwest to southeast orientated.

Engineered rock mass appears to be more stable as the RQD parameter values rise, according to the results. The premise behind construction designs was that the optimum rock mass would consist of fresh or entire granite, whereas inferior rock units including sandstone, hornstone, and granite that was badly or moderately weathered should be avoided. The site construction was completed in the centre region down to a depth of 700 m based on our anticipated 2D/3D RQD models. There is a strong correlation between the RQD models and the local geology. Based on our research, this technology has the potential to be a more economical alternative to costly drills for producing more accurate geotechnical modeling maps, as compared to conventional geotechnical methods. When geotechnical engineers lack sufficient drilling data but have access to good geomechanical models, geophysical approaches can help bridge the gap by quickly and thoroughly evaluating the rock unit’s state. The geotechnical parameters may be better explained in future research if the empirical equations are improved by applying the concepts of rock mechanics. This method would increase the understanding of the connection between geophysical and geomechanical characteristics, making it more applicable to geoengineering applications.

Data availability

Data available on request from the corresponding author.

References

Duan, S. W. & Xu, X. E. Discussion of problems in calculation and application of rock mass integrity coefficient. J. Eng. Geol. 21, 548–553 (2013).

Hasan, M., Shang, Y. & Meng, Q. Evaluation of rock mass units using a non-invasive geophysical approach. Scientific Reports. 13(1), 14493 (2023). (2023).

Nourani, M. H., Moghadder, M. T. & Safari, M. Classification and Assessment of Rock Mass parameters in Choghart Iron Mine using P-wave velocity. J. Rock Mech. Geotech. Eng. 9, 318–328 (2017).

Akingboye, A. S. & Bery, A. A. Rock mass quality evaluation via statistically optimized geophysical datasets. Bull. Eng. Geol. Environ. 82, 376 (2023).

Olayanju, G. M., Mogaji, K. A., Lim, H. S. & Ojo, T. S. Foundation integrity assessment using integrated geophysical and geotechnical techniques: case study in crystalline basement complex, southwestern Nigeria. J. Geophys. Eng. 14 (3), 675–690 (2017).

Di, Q. et al. An application of CSAMT for detecting weak geological structures near the deeply buried long tunnel of the Shijiazhuang-Taiyuan passenger railway line in the Taihang Mountains. Eng. Geol. 268, 105517 (2020).

Butchibabu, B., Sandeep, N., Sivaram, Y. V., Jha, P. C. & Khan, P. K. Bridge pier foundation evaluation using cross-hole seismic tomographic imaging. J. Appl. Geophys. 144, 104–114 (2017).

Jianliang, W. et al. Integrated geophysical survey in defining subsidence features of Glauber’s salt mine, Gansu Province in China. Geotech. Geol. Eng. 40, 325–334 (2022).

Aizebeokhai, A. P., Olayinka, A. I. & Singh, V. S. Application of 2D and 3D geoelectrical resistivity imaging for engineering site investigation in a crystalline basement terrain, southwestern Nigeria. Environ. Earth Sci. 61 (7), 1481–1492 (2010).

An, Z., Di, Q., Wu, F., Wang, G. & Wang, R. Geophysical exploration for a long deep tunnel to divert water from the Yangtze to the Yellow River, China. Bull. Eng. Geol. Environ. 71, 195–200 (2012).

Aqazddammou, A. et al. Experimental and Numerical Study on the influence of Cut Design, deviation factor, and Rock Mass Quality on the blast pull performance. Geotech. Geol. Eng. 42, 6601–6623 (2024).

Huang, H. et al. Rock mass quality prediction on tunnel faces with incomplete multi-source dataset via tree-augmented naive bayesian network. Int. J. Min. Sci. Technol. 34 (3), 323–337 (2024).

Khamehchiyan, M., Rahimi Dizadji, M. & Esmaeili, M. Application of rock mass index (RMi) to the rock mass excavatability assessment in open face excavations. Geomech. Geoeng. 9 (1), 63–71 (2013).

Siavash, S. & Hossein, J. An exact algorithmic method based on trigonometrical relations to predict the rock quality designation. Int. J. Min. Sci. Technol. 23 (3), 429–434 (2013).

Wang, M., Liu, W., Liu, H. & Xu, W. Development of empirical equations between uniaxial compressive strength and point load index: a case study for sandy dolomite. Sci. Rep. 14, 26399 (2024).

Warren, S. N., Kallu, R. R. & Barnard, C. K. Correlation of the Rock Mass Rating (RMR) System with the unified soil classification system (USCS): introduction of the weak Rock Mass Rating System (W-RMR). Rock Mech. Rock Eng. 49, 4507–4518 (2016).

Barnard, C., Kallu, R. R., Warren, S. & Thareja, R. Inflatable rock bolt bond strength versus rock mass rating (RMR): a comparative analysis of pull-out testing data from underground mines in Nevada. Int. J. Min. Sci. Technol. 26 (1), 19–22 (2016).

Ma, J. et al. A probability prediction method for the classification of surrounding rock quality of tunnels with incomplete data using bayesian networks. Sci. Rep. 12, 19846 (2022).

Zhang, T., Liu, S. & Cai, G. Correlations between electrical resistivity and basic engineering property parameters for marine clays in Jiangsu, China. J. Appl. Geophys. 159, 640–648 (2018).

Salaamah, A. F., Fathani, T. F. & Wilopo, W. Correlation of P-wave velocity with Rock Quality Designation (RQD) in volcanic rocks. J. Appl. Geol. 3 (2), 62–72 (2018).

Azad, M. A. et al. Development of correlations between various engineering rockmass classification systems using railway tunnel data in Garhwal Himalaya, India. Sci. Rep. 14, 10716 (2024).

Wu, P. K. K., Chan, C. T. H. & Tsui, R. W. S. A review of the Q-System and the GSI based on recent tunnel and Cavern Projects in Hong Kong. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-04158-0 (2024).

Ho, G. R. et al. Surface traces and related deformation structures of the southern Sanyi Fault, Taiwan, as deduced from field mapping, electrical-resistivity tomography, and shallow drilling. Eng. Geol. 273, 105690 (2020).

Hasan, M., Shang, Y., Meng, H., Shao, P. & Yi, X. Application of electrical resistivity tomography (ERT) for rock mass quality evaluation. Sci. Rep. 11, 23683 (2021).

Zhang, L. Determination and applications of rock quality designation (RQD). J. Rock Mech. Geotech. Eng. 8, 389–397 (2016).

Shang, Y. J. et al. Application of Integrated Geophysical Methods for Site Suitability of Research Infrastructures (RIs) in China. Appl. Sci. 11, 8666 (2021).

Bery, A. A. & Saad, R. Correlation of Seismic P-Wave velocities with Engineering parameters (N Value and Rock Quality) for Tropical Environmental Study. Int. J. Geosci. 3, 749–757 (2012).

Parks, E. M. et al. Comparing electromagnetic and seismic geophysical methods: estimating the depth to water in geologically simple and complex arid environments. Eng. Geol. 117 (1–2), 62–77 (2011).

Hu, X. Y. et al. Mineral exploration using CSAMT data: application to Longmen region metallogenic belt, Guangdong Province, China. Geophysics 78, B111–B119 (2013).

Coulibaly, Y., Belem, T. & Cheng, L. Numerical analysis and geophysical monitoring for stability assessment of the Northwest tailings dam at Westwood Mine. Int. J. Min. Sci. Technol. 27 (4), 701–710 (2017).

Lin, C. H. et al. Application of geophysical methods in a dam project: life cycle perspective and Taiwan experience. J. Appl. Geophys. 158, 82–92 (2018).

Cardarelli, E., Cercato, M. & De Donno, G. Surface and borehole geophysics for the rehabilitation of a concrete dam (penne, Central Italy). Eng. Geol. 241, 1–10 (2018).

Diallo, M. C., Cheng, L. Z., Rosa, E., Gunther, C. & Chouteau, M. Integrated GPR and ERT data interpretation for bedrock identification at Clericy, Quebec, Canada. Eng. Geol. 248, 230–241 (2019).

Shadrin, A. & Diyuk, Y. Geophysical criterion of pre-outburst coal outsqueezing from the face space into the working. Int. J. Min. Sci. Technol. 29 (3), 499–506 (2019).

Lu, K. et al. Using electrical resistivity tomography and surface nuclear magnetic resonance to investigate cultural relic preservation in Leitai. China Eng. Geol. 285, 106042 (2021).

Hung, Y. C., Chou, H. S. & Lin, C. P. Appraisal of the spatial resolution of 2D Electrical Resistivity Tomography for Geotechnical Investigation. Appl. Sci. 10, 4394 (2020).

Asch, T. H. & Sweetkind, D. S. Audio-magnetotelluric characterization of range-front faults, Snake Range. Nev. Geophys. 76 (1), B1–B7 (2011).

Streich, R. Controlled-source electromagnetic approaches for hydrocarbon exploration and monitoring on land. Surv. Geophys. 37, 47–80 (2016).

Wynn, J., Mosbrucker, A., Pierce, H. & Spicer, K. Where is the hot rock and where is the ground water-using CSAMT to map beneath and around Mount St. Helens. J. Environ. Eng. Geophys. 21, 79–87 (2016).

Lei, D. et al. Anti-interference test for the new SEP instrument: CSAMT study at Dongguashan Copper Mine, China. J. Environ. Eng. Geophys. 22 (4), 339–352 (2017).

Yu, C., Chang, S., Han, Y., Liu, J. & Li, E. Characterization of geological structures under Thick Quaternary formations with CSAMT Method in Taiyuan City, Northern China. J. Environ. Eng. Geophys. 24 (4), 621 (2019).

Hasancebi, N. & Ulusay, R. Empirical correlations between shear wave velocity and penetration resistance for ground shaking assessments. Bull. Eng. Geol. Environ. 66, 203–213 (2007).

Sharma, P. K. & Singh, T. N. A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bull. Eng. Geol. Environ. 67 (1), 17–22 (2008).

Diamantis, K., Bellas, S., Migrios, G. & Gartzos, E. Correlating wave velocities with physical, mechanical properties and petrographic characteristics of peridotites from the central Greece. Geotech. Geol. Eng. 29, 1049–1062 (2011).

Akin, M. K., Kramer, S. L. & Topal, T. Empirical correlations of shear wave velocity (vs) and penetration resistance (SPT-N) for different soils in an earthquake-prone area (Erbaa-Turkey). Eng. Geol. 119, 1–17 (2011).

Khandelwal, M. Correlating P-wave velocity with the Physico-Mechanical properties of different rocks. Pure. appl. Geophys. 170, 507–514 (2012).

Yang, J., Zhang, H. & Cui, Z. Stability Analysis and countermeasures of Rock Block in Underground Cavern. GUANGDONG WATER Resour. HYDROPOWER. 5, 23–27 (2021). (In Chinese).

Qin, X. Application of Unwedge program to geological stability analysis of deep buried deposits. Comprehensive 8, 270–273 (2017). (In Chinese).

Wang, R., Yin, C., Wang, M. & Di, Q. Laterally constrained inversion for CSAMT data interpretation. J. Appl. Geophys. 121, 63–70 (2015).

Zhamaletdinov, A. A. A method for quantifying Static Shift distortions using a magnetic field of controlled source (CSAMT). Seismic Instruments. 56, 555–563 (2020).

Simpson, F. & Bahr, K. Practical Magnetotelluricsp.254 (Cambridge University Press, 2005).

Zhang, M., Farquharson, C. G. & Li, C. Improved controlled source audio-frequency magnetotelluric method apparent resistivity pseudo-sections based on the frequency and frequency–spatial gradients of electromagnetic fields. Geophys. Prospect. 69, 474–490 (2021).

Fusheng, G. et al. Structural setting of the Zoujiashan-Julong’an region, Xiangshan volcanic basin, China, interpreted from modern CSAMT data. Ore Geol. Rev. 150, 105180 (2022).

Phoenix Geophysics CMTPro. The Canadian Phoenix CMT Pro Version Software for CSAMT data Processing (Toronto, 2020).

Phoenix Geophysics, C. S. A. M. T. S. W. The Canadian Phoenix CSAMT-SW Version Software for CSAMT data Inversion (Toronto, 2020).

Junaid, M., Abdullah, R. A., Sa’ari, R., Shah, K. S. & Ullah, R. A comparative study of the infuence of volumetric joint counts (jv) and resistivity on rock quality designation (RQD) using multiple linear regression. Pure. appl. Geophys. 180, 2351–2368 (2023).

Alemdag, S., Sari, M. & Seren, A. Determination of rock quality designation (RQD) in metamorphic rocks: a case study (Bayburt-Kırklartepe dam). Bull. Eng. Geol. Environ. 81, 214 (2022).

Sánchez, L. K., Emery, X. & Séguret, S. A. Geostatistical modeling of Rock Quality Designation (RQD) and geotechnical zoning accounting for directional dependence and scale effect. Eng. Geol. 293, 106338 (2021).

Deer, D. U., Hendron, A. J., Patton, F. D. & Cording, E. J. Design of surface and nearsurface construction in rock. In: (ed Fairhurst, C.) Failure and Breakage of rock. Society of Mining Engineers of AIME. New York.237–302 (1967).

Deere, D. U. & Deere, D. W. The rock quality designation (RQD) index in practice. In: (ed Kirkaldie, L.) Rock Classification Systems for Engineering Purposes, ASTM STP 984. American Society for Testing and Materials, Philadelphia. 91–101 (1988).

Mira Geoscience Ltd. GOCAD Mining Suite 3D Geological Modeling Software (Nancy University, Lorraine, 1999).

Webring, M. W. M. I. N. C. A Gridding Program Based on Minimum Curvature: U.S. Geological Survey Open File Report. 81–1224, p. 41p (1981).

Zhang, W., Ren, J., Li, C., Wang, W. & Zhu, F. Complexity Feedback of Individual Indexes and Composition Analysis of Specific Energy Index for Measurement-while-drilling technology of roof bolter. IEEE Trans. Instrum. Meas. 73, 1–8 (2024).

Zhang, W., Yu, J., Ren, J., Li, C. & Ma, J. Experimental study on the Butterfly shape of the Plastic Zone around a hole near Rock Failure. Fractal Fract. 8 (4), 215 (2024).

Acknowledgements

The authors wish to acknowledge the institutions that facilitated the research for this study: The National Natural Science Foundation of China; The State Key Laboratory of Mountain Hazards and Engineering Resilience, Institute of Mountain Hazards and Environment, Chinese Academy of Sciences; China-Pakistan Joint Research Center on Earth Sciences, CAS-HEC, Islamabad, Pakistan; The International Science and Technology Cooperation Program of Shanghai Cooperation Organization, Science and Technology Department, Xinjiang, China; and The State Key Laboratory of Lithospheric and Environmental Coevolution, Institute of Geology and Geophysics, Chinese Academy of Sciences.

Funding

The National Natural Science Foundation of China’s Research Fund for International Young Scientists (RFIS-I) (Grant No. 42350410442), and International Science and Technology Cooperation Program of Shanghai Cooperation Organization, Science and Technology Department, Xinjiang, China (Grant No. E202301005) provided financial support for this study.

Author information

Authors and Affiliations

Contributions

M.H., L.S. and P.C conceived and designed the experiments. M.H., L.S. and Y.S. performed the experiments. M.H., L.S. and P.C. analyzed and composed the data. M.H. and L.S. wrote the paper. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hasan, M., Su, L., Cui, P. et al. Development of deep-underground engineering structures via 2D and 3D RQD prediction using non-invasive CSAMT. Sci Rep 15, 1403 (2025). https://doi.org/10.1038/s41598-025-85626-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-85626-7