Abstract

The impact of light radiation, a predominant energy release mechanism in nuclear explosions, on material properties is of critical importance. This investigation employed an artificial light source to replicate the effects of nuclear explosion radiation and utilized a physical information neural network (PINN) to examine the temperature evolution and corresponding changes in the mechanical properties of carbon fiber/epoxy composites (CFEC). A light source simulating nuclear explosion’s light radiation was built to irradiate the CFEC, then measure the reflection spectrum and temperature of samples. A heat conduction model was developed, and the temperature dynamics were obtained through the integration of PINN with experimental data. Post-irradiation testing indicated significant modifications to the sample properties, with the thermal and photochemical effects of the simulated radiation leading to a decrease in reflectance across multiple wavelengths. This resulted in different reductions in tensile strength (1.64%), compressive strength (17.35%), interlamellar shear strength (ILSS) (0.51%), and post-impact compressive strength (2.77%). The insights gained from this comprehensive analysis are essential for the rapid prediction of temperature changes and the formulation of robust light radiation protection strategies for equipment exposed to nuclear explosion environments.

Similar content being viewed by others

Introduction

The nuclear explosion’s immediate release of energy within a limited volume is a force of immense destruction, mediated by five primary factors: shock waves, light radiation, instantaneous nuclear radiation, residual nuclear radiation, and nuclear electromagnetic pulses1,2,3. Light radiation is a predominant channel for energy release, representing 30–40% of the explosion’s energy, spanning ultraviolet, visible, and infrared spectra4,5,6,7,8. Given their numerous advantageous properties, carbon fiber/epoxy composites (CFEC) find widespread application in industries requiring durability and performance. In the context of military and aerospace engineering, these materials must endure substantial light radiation from weapon explosions and solar exposure. The impact of photothermal interactions on the properties of CEFC is thus a well-researched area. Nevertheless, the constraints of conducting experiments with nuclear weapons necessitate the use of simulated light sources for studying the material’s response to nuclear light radiation9,10,11,12,13.

The thermal interaction with light radiation unfolds in three stages for CFEC. Initially, the heating stage involves rapid heat absorption by the material’s surface, causing the surface resin to approach thermal decomposition temperatures. This is followed by the thermal decomposition stage, wherein rising temperatures induce the breakdown of chemical bonds within the carbon fibers, yielding decomposition products such as gases and coke. The final stage is ignition, where the material’s surface conditions facilitate combustion. Numerous studies have investigated the effects of light radiation on these composites14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29. The thermal degradation of CFEC in air typically progresses through three stages. Initially, during the early pyrolysis of the epoxy resin, the decomposition of less stable segments occurs within a temperature range of 573 K to 673 K. Subsequently, the decomposition of numerous chain segments and the release of gases from the epoxy resin take place between 673 K and 823 K. Finally, the pyrolysis of the carbon fiber commences after the substantial decomposition of the epoxy resin, typically at temperatures exceeding 823 K to 973 K or higher30,31. When composites are heated to temperatures within the glass transition range, thermo-mechanical effects such as softening and/or polymer decomposition may ensue. Degradation is notably more pronounced in an oxidizing environment compared to a vacuum or inert atmosphere32,33. Research indicates that degradation is characterized by mass loss from various surfaces at differing rates34,35. For instance, Wang et al. observed that compressive properties of CFEC laminates initially increase but decline with temperature variation17. Zhu et al. explored the influence of processing temperature on the composite’s micro and macro interface characteristics18. Zhang et al. utilized COMSOL software to simulate thermal stress in multilayered composites exposed to high-power lasers24. Fang et al. studied mechanical properties after high temperature exposure, and provided functions for tensile property degradation and transverse failure prediction after high temperature25. Askari et al. studied the impact properties of carbon fiber epoxy resin composites and the effects of thermal aging. Fiber fracture and delamination are the essential reasons for the decrease in impact strength26. Min et al. studied the thermal conductivity and sound insulation properties of CFEC27. Li et al. studied the influencing factors on the tensile properties of carbon fiber composite materials from the perspective of matrix resin and fiber volume content28. Sun et al., studied mechanical properties under varying high and low temperatures (ranging from − 50 °C to 200 °C), finding a decreasing trend with increasing temperature within this range29. Despite extensive research, most studies rely on traditional numerical methods like finite difference or finite element techniques.

Physics-Informed Neural Networks (PINN) represents an innovative deep learning algorithm designed specifically for solving both forward and inverse problems associated with partial differential equations (PDE)36,37,38,39,40,41,42,43,44. PINN incorporates physical prior knowledge enabling profound integration between data and physical mechanisms resulting proxy models adhering strictly physical constraints and needing minimal training data sets. Mishra et al. have successfully applied PINN to solve the radiation transfer partial differential equation, a problem of paramount importance in astrophysics, nuclear engineering, and medicine41. Similarly, Brett et al. have developed model of laser interact with biological tissue resolved via PINN42. Additionally, PINN has been utilized to predict unsteady temperature fields and unknown heat sources in two and three dimensions43. However, no reported study analyzing CFEC subjected nuclear explosion simulated light source with PINN.

Here, we utilized a nuclear simulation light source to investigate the optical radiation effects on CFEC. We constructed a simulated nuclear light source to irradiate the composites, and analyzed the reflectivity pre- and post-irradiation. Notably, the reflectivity of test samples across various wavelengths decreased post-irradiation. Utilizing temperature data measured by sensors, we conducted network training with PINN to derive the temperature evolution of the heat conduction model during the irradiation process. Furthermore, we evaluated the tensile strength, compressive strength, interlamellar shear strength (ILSS), and post-impact compressive strength of the samples. We calculated the average values, standard deviations, and dispersion coefficients of the mechanical properties before and after irradiation. Our research provides valuable insights into the performance impact of CFEC under optical radiation, offering guidance for the development of optical radiation protection strategies for related equipment.

Experiment setup

The experimental design incorporated a solar simulator to replicate the light radiation effects of a nuclear explosion. The simulator, which included a high-energy xenon lamp, reflector, optical integrator, fast gate, filter, and collimating lens, was calibrated to deliver a radiation flux of one solar constant, corresponding to approximately 1353 W/m2. Notably, the light source provided high stability, superior collimation, and a uniform irradiation profile. In the experimental arrangement, a concave mirror with a diameter of 450 mm was used to focus the simulated nuclear light radiation. Temperature measurements were taken using a sensor (model EX1048A) with a measurement accuracy of 0.5 °C. Furthermore, a fiber optic spectrometer (model QE65Pro), capable of measuring with 1 nm and 10 nm resolutions over a 400–1000 nm wavelength range, was employed to record the reflection spectra of the samples. Figure 1 presents the diagram of the nuclear explosion simulation irradiation test. The test begins with stable light radiation emission from the simulator directed at the concave mirror. By adjusting the mirror’s angle through an aperture for intensity and spot size regulation, the optimized beam is then directed onto CFEC material sample’s front surface.

The step-by-step experimental procedure is as follows: initially, the power density at the sample stage was measured using a power meter, and the distance between the concave mirror and the stage was fine-tuned to achieve the specified light intensity. The reflection spectrum within the 400–1000 nm range was subsequently measured, and the absorption spectrum of the sample was documented. The sample was then placed on stage, and its initial temperature was recorded. The temperatures on sample’s front and rear surfaces after irradiation for 9 s were measured. The maximum temperature on the rear surface and its corresponding time were also recorded. The specific temperature measurement procedure is as follows. Initial temperature measurements are recorded on the sample prior to irradiation. Post-irradiation, temperature measurements are taken at both the front and back of the irradiation site. Initially, the EX1048A temperature sensor is connected to the measurement equipment to ensure a stable and reliable connection. Subsequently, the thermocouple within the EX1048A is securely contacted with the sample, with careful verification of contact stability to prevent loosening or detachment during the measurement process. Upon confirming stable contact, the temperature value is read from the measuring device and saved for subsequent data analysis and processing. The temperature value is derived from an array of thermocouples, demonstrating consistent readings across the sample. After irradiation, the reflection spectrum of the sample was re-evaluated. To assess the effects of the simulated radiation on mechanical properties, a comprehensive set of mechanical tests was conducted. These tests included tensile, compression, interlamellar shear, and post-impact compression evaluations. The sample’s performance pre- and post-irradiation were compared and analyzed.

Results

The reflection spectra of CEFC samples, pre- and post-irradiation, are detailed in Fig. 2. To enhance the quality of spectral data and improve the accuracy of subsequent analyses, we applied denoising techniques to the reflectance spectra of tensile, compressive, interlaminar shear, and post-impact compressive samples. The red curve signifies the reflectance spectrum prior to irradiation, the blue curve represents the denoising spectrum prior to irradiation, the green curve represents the spectrum subsequent to irradiation and the black curve represents the denoising spectrum subsequent to irradiation. The data indicate that the spectral reflectance is higher pre-irradiation. However, the difference in reflectance varies among the different samples. The presence of noise in the spectrum can be attributed to several factors. The performance of the fiber optic spectrometer, particularly its electronic and detector noise, is a primary source of noise45. Additionally, the physical properties of the CFEC samples can influence the measurement results. For instance, surface roughness and internal structural non-uniformity may increase the amount of scattered light, thereby introducing measurement noise46. Environmental factors also contribute to noise, with temperature variations being a notable source. Temperature changes can affect reflectance measurements by causing thermal expansion or contraction of the materials, thereby altering the measurement outcomes47. Figure 2(a) presents the reflection spectrum of the tensile sample, exhibiting a growth slope of 0.0096/nm for the reflectance spectrum from 500 to 950 nm before irradiation. Subsequent to irradiation, this slope decreases to 0.0063/nm from 500 to 950 nm. The R2 values of both fitting are 0.998. The reflectance spectrum of the compressive sample is shown in Fig. 2(b). The linear fitting slope of the reflectance before irradiation, within the wavelength range of 400–950 nm, is 0.0028/nm, which increases to 0.0031/nm after irradiation from 721.7 to 950 nm. The R2 values of both fitting is 0.987 and 0.995, respectively. Figure 2(c) depicts the reflection spectrum for the interlamellar shear samples. The fitting functions are R=-0.0000129λ2 + 0.0289λ + 7.92 and R=-0.0000125λ2 + 0.0289λ + 7.64, respectively. It can be seen that the interlaminar shear samples have nearly the exact same reflectance curve before and after irradiation, which may due to the arrangement of fibers and interlayer bonding setting in interlaminar shear samples. The R2 values of both fitting is 0.995 and 0.994, respectively. Figure 2(d) illustrates the reflection spectrum of the post-impact compressive samples. A growth slope of 0.0042/nm is observed before irradiation within the wavelength range of 647–950 nm, marginally increasing to 0.00494/nm after irradiation within the wavelength range of 647–950 nm. The R2 values of both fitting are 0.995.

In order to understand the thermal dynamics of CEFC subjected to simulated nuclear light radiation, we conducted a rigorous analysis of temperature evolution across various mechanical stress conditions, including tensile, compressive, interlaminar shear, and post-impact compressive scenarios. The numerical simulation incorporated key material properties: a density of 1.5 × 10− 3 g/mm³, a heat capacity of 0.712 J/(g·K), and a thermal conductivity of 0.7 W/(m·K). The simulation also integrated the Stefan-Boltzmann constant of 5.67 × 10− 8 W/(m²·K⁴), with the energy flux density from the simulated nuclear light ranging between 800 and 1000 W/mm². The samples were fabricated with thicknesses of 2 mm for tensile, 3 mm for compressive, and 6 mm for both interlaminar shear and post-impact compressive tests, with an irradiation duration of 9 s. Based on the comprehensive data set in Table 1, we computed average temperatures prior to irradiation, as well as the final surface temperatures at the front and rear, and the consequential temperature change at the rear surface. These metrics proved pivotal calibrating our heat transfer model, elucidating intricate patterns of composite’s evolving thermal states under specified conditions.

The PINN training research was conducted using tensile sample test data to obtain network parameters, enabling the rapid calculation of the temperature evolution process. The PINN training protocol entailed constructing the heat conduction equation and defining computational parameters in alignment with the physical model. We utilized the finite difference method to discretize the initial and boundary conditions, which were then interpolated to configure the PINN’s initial and boundary settings. The neural network architecture featured an input layer with 2 neurons, 4 hidden layers each comprising 20 neurons, and an output layer with 1 neuron. The network employed a tanh activation function, initialized weights via Glorot normal distribution, and implemented a learning rate of 10− 3. Both Adam and L-BFGS optimizers were harnessed to refine the loss function. The culmination of this process was the validation of the final PINN model against stringent evaluation criteria. Figure 3 illustrates predicted temperature evolutions generated by PINN models. Figure 3(a) illustrates the temporal progression of temperature in the irradiated tensile sample. Figure 3(b) shows the convergence of training and testing error curves for the PINN solution, with both errors converging to approximately 10− 5, underscoring the PINN’s precision and reliability. Figure 3(c) and 3(d) respectively display varying positional time interval dependent thermal profiles, providing deep insights into behavior under irradiation conditions and offering innovative approach predicting CFEC responses in extreme environments.

The thickness and temperature of the front and rear surfaces on compressive and interlaminar shear samples are almost identical to those of the tensile sample, indicating that the temperature evolution process trained by PINN is also consistent with that of the tensile sample. Here, the temperature evolution process corresponding to post-impact compressive samples are shown in Fig. 4. Figure 4(a) shows the temperature evolution process of post-impact compressive samples with a thickness of 3 mm, and Fig. 4(b) shows the temperature evolution process of post-impact compressive samples with a thickness of 6 mm. It can be seen that temperature conducts from the front surface to the rear surface along the thickness direction, and there is a decrease in temperature at thicker areas relative to their thickness.

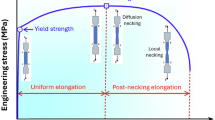

The mechanical properties of CFEC materials are pivotal for their performance across various industrial applications. Figure 5 depicts a comparative evaluation of the tensile strength, compression strength, interlaminar shear strength (ILSS), and post-impact compressive strength of these composites pre- and post-irradiation. It can be seen that the average tensile strength of the sample before the light radiation test was 1833 MPa, while after the light radiation test, the average tensile strength of the sample decreased to 1803 MPa. The radiation from the simulated light source has slight effect on the tensile strength of CEFC. Figure 5(b) shows a comparison of compression strengths pre- and post-irradiation. It can be observed that prior to exposure, average compressive capabilities measured at approximately 893.2 MPa, whereas following treatment this figure dropped significantly reaching 738.2 MPa, indicating substantial influence exerted by simulated radiations upon CFEC’s compressional characteristics. Figure 5(c) shows a comparison of the interlaminar shear strength (ILSS) of the sample before and after light radiation. It can be seen that the average ILSS of the sample before the light radiation test was 97.8 MPa, while the average ILSS of the sample after the light radiation test was 97.3 MPa. This is because the chemical bonds on the surface of the sample were broken after being irradiated with light radiation, causing local debonding of the sample interface and resulting in a slight decrease in ILSS. Figure 5(d) shows the comparison of the post-impact compressive strength before and after irradiation. It can be seen that the average post-impact compressive strength of the sample before the irradiation test was 274.4 MPa, while the average post-impact compressive strength of the sample after the irradiation test was 226.8 MPa. The simulated irradiation test has a certain degree of impact on the post-impact compressive performance of CFEC.

Discussion

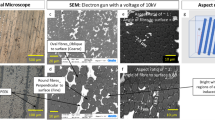

The experimental results show that the relevant properties of each sample slightly decrease after irradiation. The compressive strength of tensile, compressive, interlaminar shear, and post-impact compressive samples decreased by 1.64%, 17.35%, 0.51%, and 2.77% respectively. During the irradiation process, matrix fragments gradually increase and cross-section becomes rougher, resulting in decreased performance. The thermal expansion coefficient of the matrix resin is greater than that of carbon fiber. At lower temperatures, resin compresses, enhancing bonds and forming robust interfaces, improving compatibility and interlaminar shear capabilities. Conversely, elevated temperature cause matrix resin softened, diminishing adhesive forces, leading reductions in mechanical characteristics. The temperature data presented in Table 1 were derived from experimental observations. Utilizing the PINN method, we trained the data from Table 1 to elucidate the temperature evolution process, as depicted in Figs. 3 and 4. CFEC undergo thermal decomposition when subjected to light radiation. The epoxy resin commences cracking and carbonization at approximately 573 K. As the temperature escalates, a substantial number of chain segments within the epoxy resin decompose, accompanied by the release of gas. At 784 K, the thermal residue stands at 28.39%, decreasing to 2.881% at 1123 K. When the temperature within the irradiation zone reaches the carbon vaporization point of 3589 K, vaporization ablation ensues45,46,47. However, in our experiment, the highest surface temperature recorded was 512.0 K, which did not reach the pyrolysis threshold. Consequently, we did not observe any material fragments during the experiment and did not account for the influence of material fragments in the PINN simulations. Optical microscopy was employed for observation, revealing no morphological changes pre- and post-irradiation.

To comprehensively assess the mechanical properties and changes in various CFEC samples pre- and post-irradiation, we incorporated several analytical indicators: the coefficient of variation, Pearson correlation coefficient, and student’s t-test. Table 2 shows the performances of various samples pre- and post-irradiation. According to Table 2, the coefficients of variation for irradiated tensile, compression, interlaminar shear, and post-impact compression samples are 17.547, 6.9009, 78.595, and 18.468, respectively. For non-irradiated samples, these coefficients are 49.522, 7.1816, 117.96, and 22.073, respectively. The data dispersion degree is smallest for compression samples both pre- and post-irradiation. The student’s t-test results for each sample are 0.5534, 0.0675, 0.4251, and 0.5284, respectively. The student’s t-test indicates that the compression sample has the smallest P-value, suggesting that the compression sample is most significantly affected by light irradiation. The correlation coefficients for tensile, compression, interlaminar shear, and post-impact compression samples are 0.0553, 0.3062, 0.9507, and − 0.3276, respectively. The interlaminar shear sample exhibits the highest absolute value of correlation coefficient, indicating that the impact of light irradiation on interlaminar shear performance is the least pronounced.

In the experiment, irradiation resulted in a decrease in reflectivity across different test samples, with the exception of interlaminar shear samples. The degree of reflectivity decreases varied among samples. Mechanical properties such as tension, compression, Interlaminar shear, and post-impact compression all exhibited a certain degree of decline. In our simulations, PINN were employed to predict the temperature evolution of each sample in the thickness direction, avoiding the need for repetitive solving of traditional methods. PINN requires training only once for the same parameter problem and can be reused, offering a computational time advantage of approximately 10 times over traditional methods. This approach provides a novel method for rapid calculation of material heat transfer evolution.

Conclusion

The effects of nuclear explosion simulation light source irradiation on the mechanical properties of CFEC under tension, compression, interlaminar shear, and post-impact compression were investigated, with PINN utilized to simulate the temperature evolution process in the test samples. Experimental results indicated that irradiation led to a decreasing trend in the reflectivity, with the exception of interlaminar shear samples. In terms of mechanical properties, irradiation caused a certain degree of decrease in tensile, compressive, interlaminar shear, and post-impact compression properties. A heat transfer model for CFEC under simulated light source irradiation was constructed, with the PINN trained using this model in conjunction with experimental data to obtain the temperature evolution process of different test samples under irradiation. By integrating PINN with material heat transfer characteristics, new approaches for rapid calculation of material heat transfer evolution were provided, laying a solid foundation for constructing a large model capable of simulating material temperature evolution under extreme environment. Quantitative calculations of the relevant indicators for various mechanical properties pre- and post-irradiation provided important reference for evaluating material properties in nuclear explosion environments.

Methods

In order to describe the temperature dynamics within CFEC subjected to simulated nuclear light radiation, a thermal conduction model was established here, which can be given as followed15,16,

Where, T, K, \(\rho\)c are the temperature, thermal conductivity, density, and heat capacity of CFEC, respectively. The model incorporates boundary conditions identified through experimental observations, distinguishing between the front and rear surface boundaries. The boundary conditions corresponding to the irradiated material are given by:

where, n is the magnitude of the unit normal vector, A is the absorption coefficient of the material, I is the intensity of the light energy flux, h is the coefficient for natural convection heat transfer, \(\varepsilon\)is the surface emissivity of the material, \(\sigma\) is the Stefan Boltzmann constant. Numerical resolution of these equations reveals the temperature evolution process.

The PINN was used in conjunction with the thermal conduction model to derive the numerical solutions. PINN is a synthesis of perceptron, deep neural networks, and automatic differentiation, enriched with physical insights from the heat transfer model. This approach computes partial derivatives that embed physical information, initial conditions, and boundary conditions, thus constructing a loss function for the partial differential equation. By refining the network’s parameters to minimize the loss function’s mean squared error, we obtained the numerical solution of the model. Our methodology was benchmarked against the traditional finite difference method for numerical solution of similar models. Boundary data from this conventional method were interpolated and integrated into PINN’s boundary loss function. As Eq. (1) describes a one-dimensional transient heat conduction problem with the temperature field \(T(x,t)\) as a function of position (x) and time (t), the PINN-based solution approach, illustrated in Fig. 6, takes (x) and (t) as inputs and yields the temperature (T) as the output. The PINN loss function, which encapsulates physical constraints, initial conditions, and boundary conditions, is defined as follows:

where, \({N_f}\) is the number of internal points, \(los{s_f}\) is the physical constraint residual term, used to constrain the neural network to satisfy the heat conduction equation. \({N_b}\) is the cumulative number of boundary points for initial and boundary conditions. \(los{s_b}\) is the constraint residual term. \({w_1}\)、\({w_2}\) are the dynamically adjusted weight variables corresponding to \(los{s_f}\) and \(los{s_b}\). The loss function (\(Loss\)) is minimized to yield an approximate solution \(T(x,t)\) for Eq. (1). The approximate solution is primarily represented by a feedforward neural network, capable of determining the physical field values at any location within the domain. The trained network model efficiently predicts these values through matrix multiplications, establishing a direct mapping between point coordinates and physical fields. This enhances the analysis of temperature evolution dynamics in the composite materials under nuclear light irradiation. Notably, the grid independence of the PINN methodology significantly improves the efficiency and accuracy of the numerical analysis by eliminating computational dependencies on grids.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Hu, S. C.Liu, Military Applications of Nuclear technology -nuclear weapons[M] (Shanghai Jiao Tong University, 2016).

Wang, J. & Li, L. Effects of and Protection against Nuclear weapons[M] (Beijing Institute of Technology, 1993).

Du, X. Nuclear Physics and Nuclear arms Control research[M] (Science Publishing House, 2017).

Martin, S. B. Setting by Nuclear explosion: a revisit and use in nonnuclear applications. J. Fire. Prot. Eng. 14 (4), 283–297 (2004).

Jung, H. & Shim, W. Calculation of Thermal Fluence from extremely high-energy Emission in Air. IEEE Trans. Nucl. Sci. 62 (3), 1395–1398 (2015).

Wang, J. et al. Handbook of Parameters for High Altitude Nuclear Explosion Effects[M] (Atomic Energy, 2010).

Wu, J. Study on Theory and Experimental of the Characteristics and Detection Technology of Nuclear Explosion Radiation[D] (Huazhong University of Science and Technology, 2000).

Marrs, R., Moss, W. & Whitlock, B. Thermal Radiation from Nuclear Detonations in Urban Environments, Tech. Rep (Lawrence Livermore National Lab.(LLNL), 2007). (United States).

Zheng, Y. Introduction to Nuclear Explosion Monitoring Technology[M] (National Defense Industry, 2019).

He, R. et al. Advances in nuclear detection and readout techniques. Nucl. Sci. Tech. 34 (12), 205 (2023).

Mei, X. & Diqing, F. Fuzzy comprehensive evaluation method for nuclear/non-nuclear explosions using multi-layer neural networks, in Proceedings of the 7th National Academic Annual Conference on Nuclear Electronics and Nuclear Detection Technology, (1994).

Li, J. Research on Nuclear Explosion Detection systems[D] (Xi an:Xi an Institute of Optics and Precision Mechanics of CAS, 2001).

Li, X. Research on Recognition Method of Atmospheric Nuclear Explosion Optical Radiation under Optical Interference Conditions[D] (Academy of Military Sciences (AMS), 2022).

Wang, Y. et al. Experimental techniques for investigating thermal transport in nuclear materials. J. Nucl. Sci. Technol., 1–21 (2024).

Chen, M. J., Bo, W., Hong & Shuxin, B. Ablative mechanism of carbon-fiber/epoxy composite irradiated by repetition frequency laser. High. Power Laser Part. Beams. 20, 6 (2008).

Jingyang, B. S. & Fubiao, Y. Mechanical damage mechanisms of carbon-fiber/epoxy composites irradiated by repetition frequency laser Fiber Reinforced Plastics/Composites 3, 12–15 (2010).

Wang, H., Li, J., Jegan, L. & Nandhitha, N. Temperature Effects on the Compression Property of Carbon Fiber Epoxy Laminated Composite, Shandong Textile Science Technology 054,54 Intelligent Automation & Soft Computing 36(1),1215–1226 (2022). (2013).

Zhu, M. et al. Effect of processing temperature on the micro- and macro-interfacial properties of carbon fiber/epoxy composites. Compos. Interfaces. 21, 443 (2014).

Han, Y., Juan, B. & Chen, G. Numerical Simulation on Thermal stress of Anti-reflection Film produced by multiple pulse laser irradiation. J. Changchun Univ. Sci. Tech., 5 (2015).

Cheng, H. & Sun, B. Effects of temperature on Interfacial properties of Carbon Fiber/Epoxy composites. J. Donghua Univ. (Natural Science). 42 (03), 318–322 (2016).

He, M. et al. Research on Pyrolysis of Carbon-Fiber Reinforced Epoxy Resin Composite irradiated by CW Laser. Mod. Appl. Phys. 7 (001), 46–50 (2016).

Zhang, F., Yin, Y. & Xia, Y. Research on the performance of CCF700-12K Carbon Fiber and their composites. Aerosp. Mater. Technol. 49 (6), 3 (2019).

Sun, G. et al. On the effects of temperature on tensile behavior of carbon fiber reinforced epoxy laminates. Thin-Walled Struct. 164, 107769 (2021).

Zhang, X. et al. Study on numerical analysis of temperature field and stress field of carbon fiber reinforced polymers irradiated by high power laser. Laser Technol., (2021).

Fang, Y., Fang, Z., Huang, D., Jiang, Z. & Zhou, X. Experimental investigation on mechanical performance of Carbon Fiber Reinforced Polymer Wire after exposure to elevated temperature. Compos. Struct. 274 (1), 114388 (2021).

Askari, M., Javadi, M., Eslami-Farsani, R. & Geranmayeh, A. Impact properties of carbon fibers-epoxy composite/aluminum laminates: effect of cryogenic and thermal aging. Iran. Polym. J. 32, 187 (2022).

Min, J. Study on Thermal Conductivity and Sound Insulation Performance of Carbon Fiber/Epoxy Composites[D] (Harbin Engineering University, 2022).

Li, B. et al. Experimental research on influencing factors of Tensile properties of CFRP plates. Industrial Constr. 53 (10), 164–168 (2023).

Sun, S. et al. Effects of High and Low Temperature on Mechanical properties of Carbon Fiber Reinforced Plastics. Fiber Glass. 3, 7–13 (2023).

Piao, Y. H., Wang, Z. & Wen, F. Study on pyrolysis kinetics of typical carbon fiber/epoxy composites. New. Chem. Mater. 52 (6), 139–143 (2024).

Chen, B. et al. Mechanical damage mechanisms of carbon-fiber/epoxy composites irradiated by repetition frequency laser. Fiber Reinforced Plastics/Composites. 4 (3), 12–15 (2010).

Tsotsis, T. K. Thermo-oxidative aging of composite materials. J. Compos. Mater. 29 (3), 410–422 (1995).

Fang, J., Hu, X. & Yue, C. Y. Thermal degradation study of interpenetrating polymer network based on modified bismaleimide resin and cyanate ester. Polym. Int. 52, 15–22 (2003).

Hancox, N. L. Thermal effects on polymer matrix composites: part 2. Thermal degradation. Mater. Des. 19, 93–97 (1998).

Wolfrum, J., Eibl, S. & Lietch, L. Rapid evaluation of long-term thermal degradation of carbon fibre epoxy composites. Compos. Sci. Technol. 69, 523–530 (2009).

He, W. B., Ma, Y. G., Pang, L. G., Song, H. C. & Zhou, K. High-energy nuclear physics meets machine learning. Nucl. Sci. Tech. 34, 88 (2023).

Lu, L. et al. DeepXDE: a deep learning library for solving differential equations. SIAM Rev. 63 (1), 208–228 (2021).

Yu, J. et al. Gradient-enhanced physics-informed neural networks for forward and inverse PDE problems. Comput. Methods Appl. Mech. Eng. 393, 114823 (2022).

Yang, Q. H. et al. Physics-constrained neural network for solving discontinuous interface K-eigenvalue problem with application to reactor physics. Nucl. Sci. Tech. 34, 161 (2023).

Liu, H. R. et al. Anti-noise performance of the pulse coupled neural network applied in discrimination of neutron and gamma-ray. Nucl. Sci. Tech. 33, 75 (2022).

Mishra, S. & Molinaro, R. Physics informed neural networks for simulating radiative transfer. J. Quant. Spectrosc. Radiative Transf. 270, 107705 (2021).

Bowman, B. et al. Physics-informed neural networks for the heat equation with source term under various boundary conditions. Algorithms 16 (9), 428 (2023).

Yu, B., Gan, Z., Zhang, S., Gu, Y. & Yao, W. Predication of 2D/3D unsteady-state temperature fields and heat sources upon the physics informed neural networks. Eng. Mech. 41, 1 (2023).

Baker, N. et al. Workshop Report on Basic Research Needs for Scientific Machine Learning: Core Technologies for Artificial Intelligence (Tech. Rep. (USDOE Office of Science (SC),, 2019). Washington, DC (United States).

İplikçi, H. et al. Effects of nanosecond laser ablation parameters on surface modification of carbon fiber reinforced polymer composites. J. Compos. Mater. 57 (18), 2843–2855 (2023).

Wang, Z. et al. Development of laser processing carbon-fiber-reinforced plastic. Sensors 23 (7), 3659 (2023).

Li, X. et al. Influence of surface treatment with infrared nanosecond laser on adhesion performance of adhesion-bonded carbon fiber/epoxy composite. J. Adhes. Sci. Technol. 34 (13), 1399–1425 (2020).

Acknowledgements

This work was supported by National Natural Science Foundation of China (U2330109, 61805212); Foundation of National Key Laboratory of Plasma Physics (6142A04230302); Natural Science Foundation of Shaanxi Province (2022JQ-660, 2020JQ-830); The Youth Innovation Team of Shaanxi Universities.

Author information

Authors and Affiliations

Contributions

Lin Yuan, Jun Li, Boyu Wang, Xin Zhang and Weijie Zhu proposed the system, performed the experiments and wrote the main manuscript text. Yang Liu, Haiyang Zhang, Xiaoxiang Han prepared the figures and supervised the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yuan, L., Li, J., Wang, B. et al. Temperature dynamics and mechanical properties analysis of carbon fiber epoxy composites radiated by nuclear explosion simulated light source. Sci Rep 15, 1799 (2025). https://doi.org/10.1038/s41598-025-85959-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-85959-3