Abstract

Several mechanisms were postulated to reduce drilling problems, improve hole cleaning characteristics, and keep the bit in good condition for the second usage. This study was conducted on Majnoon Field in southeastern Iraq to optimize the bit and drilling parameters. The results indicated that the 16” SFD75D bit proved the preferred bit for both vertical and deviated wells due to its directional capabilities. MMD and MME were the best bit types for 12.25” and 8.5” sections and proved more successful than the FX and EQ types. The maximum weight on bit (WOB), Round per Minute (RPM), mud weight, and flow rate must be 25.45–73 klbs, 50-179.22, 10.5–10.8 ppg, and 662–940 gpm respectively, according to the drilling section. The wells with the J-shape showed a better penetration rate (increased 50–100%) and steadier torque than those with the S-shape for all drilling sections, with some deviations in the Shiranish, Sadi, and Tanuma Formations. The wells in the south have a sliding percentage of drilling hours more than in the north of the Field, and the inclination of the wells in the south was generally more stable and had lower hydraulics requirements than in the north of the Field.

Similar content being viewed by others

Introduction

The invention and adaptation of diamond compacts made from a polycrystalline thin layer material has been a significant milestone in the drill bit design development1,2. The self-sharpening diamond blanks are carefully mounted onto a tungsten carbide slug, a durable material known for its hardness and wear resistance. This assembly is then press-fitted into precisely machined, pre-prepared slots within the bit body, ensuring a secure and stable fit that optimizes the performance and longevity of the bit. PDC (polycrystalline diamond compact) bits do not use moving parts like bearings and cones, which makes them most reliable3. They cut rocks in a shear action, similar to a lathe operation4, requiring less energy, and therefore, lower weight on bit (WOB) is necessary for a longer service life for the rig and drill string5 (Fig. 1). PDC plates are prone to detachment of the diamond layer from the tungsten carbide substructure in the case of mechanical shocks6. Modernization processes are underway to increase mechanical resistance of the diamond layer. One of the new technologies involves an additional layer that forms a compact blade PDC7. The third layer is designed to absorb mechanical shocks and is positioned between the polycrystalline and the tungsten carbide layers8. PDC cutting structures cannot withstand temperatures above 800 °C9. Therefore, it is crucial to ensure efficient operation by appropriately cleaning the hole. The bit profile plays a crucial role in drilling as it helps to clean and control the drilling direction10.

The two most commonly used profiles are double cones and shallow cones11. The first type is better for maintaining the hole diameter and directional control, while the second type allows for higher ROP. Bits with deeper cones offer better operational stability12. Additionally, the length of the tool affects steerability, meaning the shorter the tool, the easier it is to change the direction of action13. The application of PDC is associated with certain limitations and risks. These tools are sensitive to lost junk in the borehole and require proper hole cleaning14. Moreover, fractured and fragile geological formations threaten bit sustainability15. Avoiding excessive reaming is significant for the bit life16. The discovery that vibrations are a significant factor in premature PDC bit failure has led to major changes in the design and development of these bits17. A link between these vibrations and inefficiencies in PDC bits was found, especially when drilling through rigid formations18.

Various types of vibrations (axial, torsional, lateral, and whirl) and the effects on the initiation, spread, and intensification of vibrations were identified19. Implementing stabilization techniques helps to improve drilling efficiency, enhance wear characteristics, extend the life of the bit, and allow PDC bits to be used in much harder formations20. Because of their rock dislocation mechanism, PDC bits drill faster than the other bit types under the same load21. If PDC bits could effectively drill through rigid formations while maintaining their speed advantage, operators could achieve significant cost savings22. The industry requires technologies that can elevate PDC bit performance to new levels23. PDC cutters typically underperform in difficult formations because of inconsistent dynamic forces and ineffective rock fragmentation. These factors are the main contributors to the early failure of PDC cutters and bits24. The dual-cutter design helps lower the Mechanical Specific Energy (MSE) compared to a single-cutter setup. The vertical displacement of the rear cutter has a minimal impact on the MSE, whereas the horizontal displacement plays a significant role in influencing the MSE20. In the M-type rock column, the bottom hole created by the central-grooved PDC bit experiences tensile stress in the radial, circumferential, and axial directions. As you move away from this area, the stress gradually transitions from tensile to compressive23. Kianoush et al., 2023 studies the effect of hole size, bottom hole temperature, and composition on the stability of the well24. A safe mud weight window helps forecast, avoid, and mitigate wellbore instability, lowering drilling costs and minimizing safety risks25,26.

Design of PDC bit with crown profile

The crown profile design is based on three basic profiles: single, shallow, and double cone profile27. A PDC bit with a single cone profile is appropriate for soft to medium-soft formations. It is typically equipped with larger cutters in the middle to distribute density and can assist hydraulic power in acquiring a high penetration rate in soft formations28. A PDC bit with a shallow cone profile is appropriate for soft to medium-hard formations29. It is usually fixed with cutters in low to high distributing density, resulting in a longer lifespan due to the reinforced resistance ability of the cutters30. A PDC bit with a double cone profile featuring a sharp nose and a deep inner cone is appropriate for medium-hard to rigid formations31. It is typically fixed with cutters in the middle to high distributing density. The light cone profile is also commonly used in Thermally Stable Polycrystalline (TSP) and natural diamond bit designs32. A newly developed cutter layout is enhancing the performance of PDC bits by utilizing different-sized PDC cutting elements in a unique arrangement, which improves stability, ROP, and durability33.

Surge-swab pressure in the wellbore

Different rheological properties of drilling fluid can affect the surge-swab pressure in the wellbore34. The Herschel–Bulkley method is a two-term non-linear approach to mud and debris rheology35. This method involves raising the strain to a user-selected power, which can be greater or less than 1. In contrast to the Bingham method, which raises the strain to the power of 1, the Herschel–Bulkley method can expand strain to non-integer powers greater than 1, as O’Brien uses a quadratic formula (raising strain to the powers of 1 and 2)36 (Fig. 2). The Herschel–Bulkley equation is:

where \(\:\tau\:\) = Shear stress, K = Consistency, \(\:{\tau}_{y}\)= Yield stress, n = Flow index, and \(\:\left(\frac{{dv}_{x}}{dz}\right)\) = Shear rate

The challenges encountered during drilling in the southern Iraq formations are outlined in Fig. 3, based on a prior study that addressed this issue37. They will be incorporated into the current research. Losses are anticipated at the base of the Dammam, Hartha, Mishrif, and Zubair Formations. A significant washout was observed in the Tanuma Formation. The variability in the Mishrif reservoir’s architecture and rock types may cause irregular sweep efficiency and potential water breakthroughs. Sloughing formations are present in the Tanuma, Nahr Umr, and Upper Shale formations. The potential for stuck pipes is high in the Mishrif, Nahr Umr, and Zubair Formations. Drilling through entire anhydrite layers in the Lower Fars and Rus Formations caused drilling bit damage and abrasion, though this issue had a lesser impact on the drilling operations. The Dammam Formation was the most problematic, accounting for 56.4% of drilling issues (both caving and mud loss) among all wells drilled. At the same time, no significant problems were encountered in the Dibdibba, Khasib, Rumaila, Ahmedi, Mauddud, and Shuaiba Formations38.

Drilling problems analysis for each Formation in Rumaila Field37.

The main objective of this work is to optimize PDC bit selection and drilling parameters for improved drilling efficiency in the Majnoon Field. The novelty lies in the comparative analysis of different bit types and their performance across various formations, which has not been extensively documented in the existing literature.

Geological setting

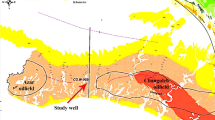

The Majnoon oilfield is a massive oil field situated 60 km (37 mi) from Basra, in the southern Iraq’s Basra Governorate37. It is known to be one of the most abundant oilfields globally, with an estimated 38 billion barrels of oil reserves38. The name ‘Majnoon’ comes from Arabic and means ‘crazy,’ referring to the excessive amount of oil present in a dense area39 (Fig. 4).

The shape of Majnoon Field is like a banana and has a north-south orientation40. It is believed to be a folded structure caused by pressure, likely stemming from salt deposits beneath the Jurassic layer. Within the field are four significant reservoirs and seven smaller ones ranging in age from the Lower Cretaceous to the Paleocene41. These reservoirs cover a vertical distance of approximately 3000 m42. The main reservoirs in descending order are Hartha, Mishrif-Ahmadi, Nahr-Umr, Zubair, and Yamama formations, with Yamama being the deepest and holding the majority of hydrocarbons at Majnoon43. Yamama and Mishrif formations comprise half of the total major reservoir volume. Minor reservoirs within the field include Khasib, Sadi, Tanuma, Ghar, Shiranish, and Shuaiba Formations that may also hold hydrocarbons44. Drilling high-angle Zubair wells can be challenging because of the long tangent section. S-shaped wells are more stable compared to J-shaped wells. The stability of Mishrif wells with an S-shape configuration is generally worse than that of J-shaped and horizontal wells. The average maximum horizontal stress direction is 55 +/− 20 and 235 +/− 20 degrees, which is better than 142 +/− 35 or 322 +/− 35 degrees45,46,47.

Methodology

Wells design and objects

Wells MJ-X1, X2, X3, X6, and MJ-X7 are S-Shape producer wells and were drilled in 36”, 24”, 16”, 12 ¼”, and 8 ½” hole sections. The target was to reach Nahr Umr, Zubair, Ahmadi, and Khasib Formations respectively. Wells MJ-X4 and MJ-X5 are J-Shape producer wells and were drilled in 36”, 24”, 16”, 12 ¼”, and 8 ½” hole sections also. The target was to reach Zubair Formation (Table 1; Fig. 5). The wells were selected to represent different locations in the Field. The wells MJ-X2, X3, and X4 are located in the north of the Field, while the others are in the south (Fig. 4-C).

Detailed drilling data, such as bit types, drilling parameters (e.g., weight on bit, rotational speed), and performance indicators (rate of penetration, bit life, etc.), were gathered from the operational records of seven wells in the Majnoon field (Figs. 2C and 4). To ensure the accuracy of the data, it was verified by cross-referencing with geological surveys, maintenance logs, and historical performance reports.

The hydraulic parameters for 12.25 and 8.5” section were estimated by the following equations:

where TFA = total flow area (in2), jet = nozzle diameter in 32nd of the inch, Vj = nozzle velocity (ft/sec), PO = pump output (gpm), PDb= bit pressure drop (psi), MW = mud weight (ppg), HPb= bit hydraulic horsepower, Ab= Area of the bit (in2), PP = pump pressure, Q = flow rate (gpm).

The Herschel–Bulkley model was utilized to simulate the rheological properties of the actual drilling fluid. The study primarily examined the effects of drilling fluid flow under various rheological conditions by a transient flow model. Moreover, the run speed based on Herschel–Bulkley fluid was developed to predict bottom-hole transient surge-swab pressure during tripping operation and to confirm the best parameters.

Limitations

-

I.

Geological variability within the Majnoon Field may affect the generalizability of findings.

-

II.

The analysis is based on a limited number of wells, which may not fully represent diverse conditions.

-

III.

The dynamic nature of drilling operations means optimized parameters may require further adjustment based on real-time conditions.

Innovations

-

I.

The study provides a comparative analysis of various PDC bit types across different formations, which is relatively novel.

-

II.

Integrating geological context into the optimization process acknowledges the impact of lithology on drilling efficiency.

-

III.

Using hydraulic sensitivity analysis to optimize drilling parameters is a noteworthy methodological advancement.

Results and discussion

Bit selection and rate of penetration

Three types of PDC bit were selected according to the field observation of the previous wells that were drilled in this field. These types were SF76H for the 16” section, MMD75H for the 12.25” section, and MMD74H bit for the 8.5” section. The specifications and features of these kings of bits are shown in Table 2.

24” bit size

This section was drilled successfully using the 24” XT1GRC. However, recently, the 24” EBXT1GRC was used in MJ-X5. The bit was drilled at a higher ROP at 21 m/hr compared to 10–14 m/hr in previous wells. Most bits had 1–1 dull at the first run and 2–2 at the second run.

16” bit size

There is a need to design a bit that can drill similarly to the SF76H and is easier to steer. The choice of the SFD75D bit was based on the explicit problems from the previous wells (especially J- shape wells) drilled by the SF76H bit. The drill bit performance for the 16” section includes using the 16” SFD75D in directional wells (S- shape). The 16” SFD75D proved the preferred bit due to its directional capabilities in this section. In addition, that was achieved in well MJ-X6 by the same bit with improved results (drilled 1822 m cumulatively) in the wells MJ-X5 and MJ-X6. Moreover, the 16” SF76H drilled the 16” Section vertically in well MJ-X4 (Fig. 6). The performance of this bit exceeded expectations, achieving an average ROP of 27 m/hr, which is 35% higher than previous benchmarks. The cutting structure of this bit is (7 blades with 19 mm). According to the depth-based data, the average WOB is 25.45klbs (28.1klbs excluding sliding intervals) with a maximum value of 56klbs. The average rotational speed at the surface is 42.69 RPM with a total average value of 154.51 RPM applied on the bit - excluding the sliding intervals. The other optimized parameters are summarized in the Table 3.

12.25” bit size

For the first time in the history of the north area of Majnoon field, the proposed 12.25” MMD75H drilled the section in the north of the Field with one bit on the well MX-X3. The 12.25” MMD75H drilled a total of 1106 m at an avg. ROP of 12.9 m/hr and came out in excellent condition. The well MJ-X3 has 1.71 drilling days less than the well MJ-X2 in this section. The better performance continues in the well MJ-X4 with an ROP of 14.8 m/hr. The most critical formation to drill was Umm Er Radhuma: this interval falls after Dammam. It consists of hard dolomite interbedded with anhydrite and dolomite. The transition of drilling from a relatively soft formation to a rigid one (Umm Er Radhuma) risks damaging the bit face due to the sudden impact with high rock strength. Another hazard is drilling deeper from Umm Er Radhuma to the relatively softer Aaliji. In this case, the damage occurs at the bit external cutting structure (at bit shoulder and gage) (Fig. 6). The other optimized drilling parameters are summarized in the Table 4. The 12.25” MMD75H drilled a total of 700 m at an avg. ROP of 16.5 m/hr in the well MJ-X6 at the south of the Field and came out in excellent condition.

8.5” bit size

The well MJ-X3 has a higher ROP and fewer trips performed, and the 8 ½” MMD65R was used successfully on a motor assembly to achieve an ROP at 16.7 m/hr. The drilling bit was the Pull Out of the Hole (POOH) to change the drive system to the RSS and use the 8 ½” MME74H to complete the section where the achieved ROP was 16 m/hr. The 8.5” MMD and MME bit type proved more successful than the FX type, so it was used in the wells Mj-X4 and later. The bit has reached the target depth with excellent performance of the MME74H bit in the well MJ-X4 to the other types (EQH12R and FXD65) in the previous wells. The other optimized drilling parameters are summarized in the Table 5.

Inclination

Figure 7 shows the inclination in the 12.25” sections on the wells MJ-X1 and MJ-X2 against the formation drilled. In the well MJ-X2, the directional objective was to maintain a tangent of 32.9° inclination. In MJ-X1 and MJ-X2, there is a tendency to build inclination in the Dammam and UER formation. On MJ-X2, the inclination was held through; the Aaliji to Hartha and dropped through the Sadi and Tanuma formations.

Drilling parameters

The optimizing drilling parameters program was applied in all the wells. The results of drilling parameters for the wells MJ-X1 and MJ-X3, which are located respectively in the south and the north of the field (Fig. 8), show that the ROP in the Dammam Formation must be controlled by reducing RPM not WOB, reduced and optimized drilling parameters are highly interbedded in the Umm Er Radhuma Formation for both wells. The RPM must be lower at 20 m before the top of Aaliji. After the transition, the drilling parameters increased. Reduced and optimized drilling parameters are highly interbedded - Complete losses may expected in the Hartha Formation.

Figure 7 shows that applying the same WOB and RPM at the north and south wells of the field will affect the flow rate. It will be better in the north than in the south, which leads to a change in the drilling plan in the south for the later wells (MJ-X7; for example) for WOB and RPM to be as in Fig. 9 and the flow rate reaches 750 GPM.

The most inclination in the wells located at the north of the Field happened in the UER Formation then the inclination reduced gradually in the Aaliji and Shiranish Formations to be semi-stable in the Hartha and later Formations.

The inclination in the wells located at the south was generally semi-stable except for some deviations in the Shiranish, Sadi, and Tanuma Formations.

Torque on bit (TOB)

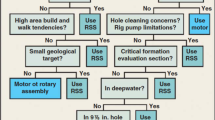

Figure 10 shows different parts of the bit (gauge pad, cutters, blades, etc.) have different walk tendencies as a whole the bit has relatively neutral walk tendency (arrow in the Red). In addition, the reactive torque because of drilling with the input parameters. The MME74H for the 12.25” and 8.5” sections is showing steady torque in general in both wells (Fig. 11).

Figure 12 shows the reactive torque due to drilling with the input parameters. The MMD75H bit size 8.5” is showing a steady torque “not fluctuating a lot when going cutter to another cutter”.

Optimizing the hydraulics for 12.25 and 8.5 section

Hydraulic sensitivity for 12.25 and 8.5” section of the wells MJ-X4 and MJ-X7, (represent the north and the south parts of the Field respectively) can be summarized in Fig. 12. Based on the hydraulic calculations for the wells MJ-X4 and X7 (Table 6), it is recommended to fit the 12.25” MMD75H with 7 × 13/32nd (Total Flow Area (TFA): 0.9072 in2), which will lead to Hydraulic power per Square Inch (HSI) of 1.5 hp/in2 for both the wells at 650 for MJ-X4 and 600 gpm for MJ-X7. On the 8.5” Motor BHA for the wells MJ-X4 and X7, it is recommended to utilize 7 × 13/32nd (TFA: 0.9072 in2), which will lead to an HSI of 2.63 hp/in2 for the well MJ-X4 at 600 gpm and 1.53 hp/in2 for the well MJ-X6 and MJ-X7 at 500 gpm (Fig. 13).

Optimizing the surge–swab pressure in the 8.5” section

The results of the surge–swab hydraulics (bit depth at 3394 m, mud density of 10.20 ppg, fracture gradient of 11.00 ppg, and pore pressure of 9.80 ppg) and (N = 0.66, K = 0.46, and Tau = 8.35 for Herschel–Bulkley) indicate that the Maximum run speed for the bit must be 60 m/min (Fig. 14).

Discussion

Drilling challenges

Bit balling may be an issue for the 16” section in the Lower Faris Formation and Sect. 12.25” in the Shiranish Formation. That did not happen with the well Mj-X1 and later. Slowing Bit rotation on the bottom of the Formation and reducing flow rate were utilized to break up the clay ball on the bit. The Mud system is to be pre-treated with a surfactant if the rate of penetration drops in these formations to prevent bit balling. Cellar jets have a history of washing out, so the BHA design for RSS was reviewed to consider overcoming the washout in the Zubair and Nahr Umr Shale without changing the bit jet systems as in the well MJ-X2. This procedure succeeded in the well MJ-X3 and later. Baroids require reservoir PSD (pore size distribution) to optimize the Particle Size Distribution of bridging material and lost circulation materials formulation.

Well type

The wells with the J-shape showed a better penetration rate than those with the S-shape for all drilling sections until the target depth. The MME bit family for the 12.25 and 8.5” sections showed steadier torque in the J-shape wells than those with the S-shape. The torque on the bit was stable in both types for the bit size 12.25”, while for the 8.5” bit, it was worse in the J-shape wells than those of the S-shape.

Comparison between the north and south part of the field

The MME74H bit size 8.5” showed a better performance in the north part of the Field than in the south (Figs. 8 and 9). The results in Figs. 11 and 12 indicate that the torque on the bit (TOB) for the entire bit and bit destination and for drilling time was generally steady and similar for the wells in the north and south of the field for the bit dc-31510 size 12.25”. while the (TOB) for the MME74H bit size 8.5” for bit drilling time was steady generally for the wells in the south of the field for the bit size 8.5”. The torque on the bit in the wells in the south is more than that in the north. According to hydraulic sensitivity analysis (Fig. 13), the well MJ-X4 at the north of the Field requires HSI and JIF at a flow rate of 650 gpm more than the well MJ-X7 at a flow rate of 600 gpm. That is indicating that the drilling process at the south has fewer requirements than the north, which needs to adjust the hydraulic power and bit jet force to achieve the economic benefits.

On MJ-X2, the 12.25” MMD75H drill bit showed similar or higher rates of penetration (ROP) in all formations compared to the more aggressive 12.25” MME65DM used on MJ-X1. The ROP per formation increased from 12.29 m/hr to 15.91 m/hr on MJ-X2, from the Dammam formation to the Sadi formation. However, the average ROP in the Tanuma formation dropped significantly to 6.87 m/hr. This decrease in ROP can be attributed to the increased presence of shale lithology in this Formation (Fig. 15). The ROP in the Tanuma formation is similar on both MJ-X1 and MJ-X2. The main factor affecting the well MJ-X1 is the sliding percentage of the drilling hours. On the well MJ-X1, 30.46% of the total drilling hours were spent on sliding, whereas on MJ-X2, the reduction was 10% of the drilling hours were spent on sliding (Fig. 16).

The wells (MJ-X2 at the north and Mj-X6 at the south) were experimented with for confirmed results for 16 and 12.25” sections. Most of the drilling parameters comply with the recommended parameters, especially since the lithology of the north part of the Field revealed more transition zones than projected and an unexpected abundance of Marl. Generally, the drilling performance of the bit in the north was better than in the south part of the Field (Fig. 17).

Conclusions

Previous field trials in southern Iraq have shown inconvenient bit performance results according to the economic issues and the drilling time. The recent wells depended on the lessons learned from the previous wells and experimented with new techniques for bit and drilling parameters.

-

1.

The 16” SFD75D bit proved the preferred bit due to its directional capabilities in this section for the vertical and deviated wells, while 12.25” MMD75H and MME74H were the best bits, and for the 8.5” section, the 8.5” MMD and MME bit proved more successful than the FX and EQ types.

-

2.

According to the drilling parameters, the maximum WOB, RPM, mud weight, and flow rate for Sect. 16” should be 25.45 klbs, 154.51, 10.5 ppg, and 927 gpm respectively.

-

3.

The drilling parameters for the north and south parts of the Field varied in the 12.25” section, in which the maximum WOB should be 43 and 38 klbs, RPM 179.22 and 167.73, mud weight 10.7 and 10.66 ppg, and flow rate 940 and 744 gpm at the north and the south of the Field respectively.

-

4.

The maximum drilling parameters for the 8.5” section for WOB should be 73 and 47 klbs, RPM 50 and 62, mud weight 10.85 and 10.8 ppg, and flow rate 761 and 662 gpm at the north and the south of the Field respectively.

-

5.

In the southern wells, 30.46% of total drilling hours were spent on sliding, whereas on the north of the Field, the reduction was 10% of the drilling hours spent on sliding.

-

6.

The wells with the J-shape showed a better penetration rate (increased 50–100%) and steadier torque than those with the S-shape for all drilling sections. The torque on the bit for the 8.5” bit was worse in the J-shape wells than those in the S-shape.

-

7.

The inclination of the wells in the south was generally more stable providing specific inclination angles and ranges than in the north of the field, except for some deviations in the Shiranish, Sadi, and Tanuma Formations.

-

8.

The drilling process in the south has hydraulic requirements, such as hydraulic power and bit jet force lower than in the north. This adjustment aims to achieve economic benefits. To meet these hydraulic requirements, the bit’s maximum running speed must be 60 m/min for depths below 3,400 m.

Data availability

Data is provided within the manuscript.

Abbreviations

- BHA:

-

Borehole Assembly

- DLS:

-

Dogleg Severity

- ECD:

-

Equivalent circulating density

- Gpm:

-

Gallon per Minute

- Hp:

-

Horse Power

- HSI:

-

Hydraulic power per Square Inch

- JIF:

-

Jet Impact force

- MD:

-

Measured Depth

- MW:

-

Mud Weight

- POOH:

-

Pull Out of the Hole

- PPG:

-

Pound per Gallon

- ROP:

-

Rate of Penetration

- RPM:

-

Round per Minute

- RSS:

-

Rotary Steerable System

- SPP:

-

Stand Pipe Pressure

- TFA:

-

Total Flow Area

- TOB:

-

Torque on Bit

- TVD:

-

True Vertical Depth

- TVXT:

-

Traditional Vertical Christmas tree

- UBD:

-

Underbalanced Drilling

- UER:

-

Umm Er Radhuma Formation

- UMV:

-

Upper Master Valve

- USV:

-

Underwater Safety Valve

- VBR:

-

Variable Bore Ram

- VR:

-

Valve Removal

- WBM:

-

Water-Based Mud

- WCCP:

-

Well Control Contingency Plan

- WCE:

-

Well Control Equipment

- WCP:

-

Well Control Package

- WD:

-

Water Depth

- WFS:

-

Wells Functional Specification

- WOB:

-

Weight on Bit

- WOC:

-

Wait on Cement

- WP:

-

Working Pressure

- WPSI:

-

Wells Process Safety Incident

References

Boussahaba, H. et al. New and advanced PDC bit design with innovative backup layout cutters helps extend bit life without sacrificing rate of penetration during a heterogeneous application, Northwest Kuwait. In International Petroleum Technology Conference D012S118R001. IPTC. https://doi.org/10.2523/IPTC-20030-MS (2020).

Roberts, S. L., Bailey, M. J., Babaie Aghdam, A., Suleiman, A. & Fathy, A. Novel drill bit analysis to delay and mitigate fixed cutter thermal damage. In SPE Asia Pacific Oil and Gas Conference and Exhibition D021S017R002. SPE. https://doi.org/10.2118/205578-MS (2021).

Ratov, B. et al. Calculations on enhancement of polycrystalline diamond bits through addition of superhard diamond-reinforced elements. Machines 11 (4), 453. https://doi.org/10.3390/machines11040453 (2023).

Chen, P. et al. Review of PDC cutter–rock interaction: Methods and physics. Geoenergy Sci. Eng. 211995. https://doi.org/10.1016/j.geoen.2023.211995 (2023).

Ma, S., Wu, M., Chen, L. & Lu, C. A robust integrated control design for weight-on-bit fluctuation suppression in drilling process subject to fractured formations. ISA Trans. 136, 223–234. https://doi.org/10.1016/j.isatra.2022.10.029 (2023).

Sotoodeh, K. Equipment and Components in the Oil and Gas Industry Volume 1: Equipment (CRC, 2024).

Boryczko, P. Drill bit selection and optimization in exploration well 6507/6-4A in the Nordland Ridge Area (Master’s thesis, University of Stavanger, Norway) (2012). http://hdl.handle.net/11250/183432

Xiao, Z. et al. Structural design and analysis of large-diameter D30 conical polycrystal diamond compact (PDC) teeth under engineering. Rotary Min. Cond. Mater. 17 (2), 477. https://doi.org/10.3390/ma17020477 (2024).

Gao, K., Xu, X., Jiao, S. & Li, Z. Modeling and experimental research on temperature field of full-sized PDC bits in rock drilling and coring. Energy Rep. 8, 8928–8938. https://doi.org/10.1016/j.egyr.2022.07.016 (2022).

Pessier, R., Wallace, S. & Oueslati, H. Drilling performance is a function of power at the bit and drilling efficiency. In SPE/IADC Drilling Conference and Exhibition SPE-151389. SPE. https://doi.org/10.2118/151389-MS (2012).

Mazen, A. Z., Mujtaba, I. M., Hassanpour, A. & Rahmanian, N. Mathematical modelling of performance and wear prediction of PDC drill bits: Impact of bit profile, bit hydraulic, and rock strength. J. Petrol. Sci. Eng. 188, 106849. https://doi.org/10.1016/j.petrol.2019.106849 (2020).

Pessier, R. & Damschen, M. Hybrid bits offer distinct advantages in selected roller-cone and PDC-bit applications. SPE Drill. Complet.. 26 (01), 96–103. https://doi.org/10.2118/128741-PA (2011).

Chen, T., Liu, G., He, X., Li, J. & Wang, W. Calculation method of the build-up rate of the internal push point-the-bit rotary steering tool. Geoenergy Sci. Eng. 230, 212177. https://doi.org/10.1016/j.geoen.2023.212177 (2023).

Belozerov, D. Drill bits optimization in the Eldfisk overburden (Master’s thesis, University of Stavanger, Norway) (2015). http://hdl.handle.net/11250/301097.

Zhang, J. Borehole stability analysis accounting for anisotropies in drilling to weak bedding planes. Int. J. Rock Mech. Min. Sci. 60, 160–170. https://doi.org/10.1016/j.ijrmms.2012.12.025 (2013).

Fernandes, M. & Cook, C. Drilling of carbon composites using a one shot drill bit. Part I: Five stage representation of drilling and factors affecting maximum force and torque. Int. J. Mach. Tools Manuf. 46 (1), 70–75. https://doi.org/10.1016/j.ijmachtools.2005.03.015 (2006).

Pastusek, P. E., Barajas, P. E., Payette, G. & Sowers, S. PDC bit selection guidelines based on physics and lessons learned. In SPE Annual Technical Conference and Exhibition? D021S025R004. SPE. https://doi.org/10.2118/214139-MS (2023).

Barnett, L., Al Dushaishi, M. F. & Khan, M. F. M. H. Experimental investigation of drillstring torsional vibration effect on rate of penetration with PDC bits in hard rock. Geothermics 103, 102410. https://doi.org/10.1016/j.geothermics.2022.102410 (2022).

D’Ambrosio, P., Prochaska, E., Bouska, R., Tinsley, D. & Hart, S. Cost effective ultra-large diameter PDC bit drilling in deepwater Gulf of Mexico. In SPE/IADC Drilling Conference and Exhibition SPE-163448. SPE. https://doi.org/10.2118/163448-MS (2013).

Liu, W., Li, Y. & Gao, D. New understandings of the applications of PDC cutters in oil and gas drilling. Int. J. Refract. Met. Hard Mater. 106724. https://doi.org/10.1016/j.ijrmhm.2024.106724 (2024).

Liu, W., Deng, H., Zhu, X. & Deng, K. The PDC cutter-rock interaction behavior in rock cutting: A review. Geoenergy Sci. Eng. 212168. https://doi.org/10.1016/j.geoen.2023.212168 (2023).

Wu, Z., Yuan, R., Zhang, W., Hu, S. & Jiang, W. Numerical simulation and field test of a PDC bit with mixed cutter arrangement to break non-homogeneous granite. Appl. Sci. 13 (16), 9133. https://doi.org/10.3390/app13169133 (2023).

Huang, J., Li, J., Xie, Q., He, Y. & Qian, L. Numerical investigations for rock-breaking process and cutter layout optimization of a PDC drill bit with dual-cutter. Buildings 14 (1), 129. https://doi.org/10.3390/buildings14010129 (2024).

Chen, X. et al. The stress field simulation of a novel M-type convex stepped bottomhole and the rate of penetration enhancement mechanism of a new type of central-grooved PDC bit for offshore deep & ultradeep well drilling. Ocean Eng. 293, 116706. https://doi.org/10.1016/j.oceaneng.2024.116706 (2024).

Kianoush, P. et al. Investigating the eff ect of hole size, bottom hole temperature, and composition on cement bonding quality of exploratory wells in Iran. Sci. Rep. 14, 29653. https://doi.org/10.1038/s41598-024-81269-2 (2024).

Jamshidi, E. et al. Scaling-up dynamic elastic logs to pseudo-static elastic moduli of rocks using a wellbore stability analysis approach in the Marun oilfield, SW Iran. Sci. Rep. 14, 19094. https://doi.org/10.1038/s41598-024-69758-w (2024).

Kianoush, P., Mohammadi, G., Hosseini, S. A., Keshavarz Faraj Khah, N. & Afzal, P. Determining the drilling mud window by integration of geostatistics, intelligent, and conditional programming models in an oilfi eld of SW Iran. J. Pet. Explor. Prod. Technol. 13 (6), 1391–1418. https://doi.org/10.1007/s13202-023-01613-6 (2023).

Ma, X., Cheng, W. & Zhu, L. Study and application of rock drilling resistance characteristics in the Jiyang depression formation. Processes 12 (5), 952. https://doi.org/10.3390/pr12050952 (2024).

Li, Y., Han, B., Li, M. & Liu, W. Forensic analysis of PDC bits at the Sinopec Shengli Oilfield. In Journal of Physics: Conference Series (Vol. 2566, No. 1, p. 012084). IOP Publishing. https://doi.org/10.1088/1742-6596/2566/1/012084 (2023).

Deng, L. C. et al. Evaluation on cutting performance of novel PDC cutter for pipe jacking machine. Undergr. Space. 14, 34–52. https://doi.org/10.1016/j.undsp.2023.06.003 (2024).

Xiaofeng, X. et al. PDC bit optimization scheme for tight oil reservoirs in the Jidong Oilfield based on rock anti-drilling characteristics. J. Pet. Explor. Prod. Technol. 12 (10), 2869–2881. https://doi.org/10.1007/s13202-022-01493-2 (2022).

Feenstra, R. Status of polycrystalline-diamond-compact bits: Part I development (includes associated papers 19032 and 19900). J. Petrol. Technol. 40 (06), 675–684. https://doi.org/10.2118/17919-PA (1988).

Mensa-Wilmot, G. & Krepp, T. Innovative cutting structure improves stability and penetration rate of PDC bits without sacrificing durability. In SPE/IADC Drilling Conference and Exhibition SPE-39310. SPE. https://doi.org/10.2118/39310-MS (1998).

Krishna, S. et al. Experimental evaluation of surge/swab pressure in varying annular eccentricities using non-newtonian fluid under Couette–Poiseuille flow for drilling applications. J. Petrol. Sci. Eng. 206, 108982. https://doi.org/10.1016/j.petrol.2021.108982 (2021).

Zheng, W. et al. Influence of elasticity of high-concentration paste on unsteady flow in pipeline transportation. Phys. Fluids. 36 (1). https://doi.org/10.1063/5.0176824 (2024).

Chambon, G., Freydier, P., Naaim, M. & Vila, J. P. Asymptotic expansion of the velocity field within the front of viscoplastic surges: Comparison with experiments. J. Fluid Mech. 884, A43. https://doi.org/10.1017/jfm.2019.943 (2020).

Al-Dujaili, S. H. A statistical survey for drilling problems at North Rumaila field, Southern Iraq. A review enhanced with well logs analyses. Jordan J. Earth Environ. Sci. (JJEES). in press. (2025).

Al-Dujaili, A. N. New advances in drilling operations in sandstone, shale, and carbonate formations: A case study of five giant fields in the Mesopotamia Basin, Iraq. Min. Sci. Technol. (Russia). 9 (4), 308–327. https://doi.org/10.17073/2500-0632-2023-08-146 (2024).

Le Vesconte, M. J., Tinkhof, R. & Hardman, P. The Majnoon field: A case study of drilling operations in a remote area of Iraq. In SPE/IADC Drilling Conference and Exhibition SPE-167949. SPE. https://doi.org/10.2118/167949-MS (2014).

Armenta, M., Tinkhof, R., Pointing, M., Cuthbert, A. & Ramsawak, S. Improving drilling performance at Majnoon Field. In SPE/IADC Middle East Drilling Technology Conference and Exhibition SPE-166685. SPE. https://doi.org/10.2118/166685-MS (2013).

Al-Jaberi, M. H., Sedkhan, M. T., Hussain, G. A. & Jasim, A. A. Assessment of heavy metals and ecological risk in the sediments of Thi Qar and Basrah governorates-Southern Iraq. In IOP Conference Series: Materials Science and Engineering (Vol. 928, No. 2, p. 022012). IOP Publishing. https://doi.org/10.1088/1757-899X/928/2/022012 (2020).

Mehenni, M., Guit, F., Majnoon Field, S. E. & Iraq A giant unique among other giants? In First EAGE Workshop on Iraq-Hydrocarbon Exploration and Field Development. EAGE Publications BV, cp-286-00002. https://doi.org/10.3997/2214-4609.20143558 (2012).

Al-Khafaji, A. J. et al. Source rock evaluation and petroleum generation of the lower cretaceous Yamama formation: Its ability to contribute to generating and expelling petroleum to cretaceous reservoirs of the Mesopotamian Basin, Iraq. J. Petrol. Sci. Eng. 217, 110919. https://doi.org/10.1016/j.petrol.2022.110919 (2022).

Christian, L. Cretaceous subsurface geology of the Middle East Region. GeoArabia 2 (3), 239–256. https://doi.org/10.2113/geoarabia0203239 (1997).

Al-Dujaili, A. N. Reservoir rock typing and storage capacity of Mishrif Carbonate Formation in West Qurna/1 Oil Field, Iraq. Carbonates Evaporites. 38 (4), 83. https://doi.org/10.1007/s13146-023-00908-3 (2023).

AL-Dujaili, A. N. Analysis of in-situ stress and well trajectory in carbonate and sandstone reservoirs. A case study of Mishrif and Zubair Formations in the West Qurna Oilfield, Southern Iraq. Iraqi J. Sci. (2024).

khudhur Abbas, L. & Mahdi, T. A. Reservoir units of Mishrif formation in Majnoon oil field, southern Iraq. Iraqi J. Sci. 2656–2663. https://doi.org/10.24996/ijs.2019.60.12.15 (2019).

Alsultan, H. A., Maziqa, F. H. & Al-Owaidi, M. R. A stratigraphic analysis of the Khasib, Tanuma and Sa’Di formations in the Majnoon oil field, southern Iraq. Bull. Geol. Soc. Malays. https://doi.org/10.7186/bgsm73202213 (2022).

Al-Ameri, T., Jafar, M. & Janet, P. Hydrocarbon generation modeling of the Basrah oil fields, Southern Iraq. In AAPG Annual Convention and Exhibition, Houston, Texas, Search and Discovery Article, Vol. 20116 (2011).

Al-Dujaili, A. N., Shabani, M. & Al-Jawad, M. S. The efficient and economical application of a cement slurry programme for sandstone and carbonate reservoirs. A case study of the Zubair, Mauddud, and Mishrif formations in a supergiant oilfield. South. Iraq Bull. Geophys. Oceanogr. (BGO). 65 (3). https://doi.org/10.4430/bgo00450 (2024).

Author information

Authors and Affiliations

Contributions

A. N: Conceptualization, Methodology, Writing - original draft preparation, ResultsM. A: Resources, Simulation, and Results.N. S.: Validation and corrections.N. T.: Checking, Optimization.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Al-Dujaili, A.N., Asad, M.S., Saeed, N. et al. Optimizing polycrystalline diamond compact bit selection and drilling parameters for deviated wells in the Majnoon Field, Iraq. Sci Rep 15, 3178 (2025). https://doi.org/10.1038/s41598-025-87484-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87484-9