Abstract

Filters serve as core equipment to ensure the normal operation of micro-irrigation systems, with head loss and filtration efficiency serving as the two key indicators for evaluating performance. In this study, we used a pre-pump filter-pontoon mesh rotary filter as the research object and conducted physical model tests under the flow rate (798–1050 L1 h−1), sand content (0.5–2.5 g1 L−1), and aperture of the filter screen (0.125–0.180 mm). We then adopted range analysis, variance analysis (ANOVA), dimensional analysis, and the multiple linear regression (MLR) method to analyze the results. The results showed that the order of factors affecting the head loss of the assessment indices, from large to small, was as follows: flow rate, sand content, and aperture of the filter screen. The order of factors affecting the filtration efficiency of the assessment indices from large to small was as follows: sand content, flow rate, and aperture of the filter screen. Predictive models for head loss and filtration efficiency were developed, with coefficients of determination R2 of 0.969 and 0.954, and root mean square error (RMSE) values of 0.1041 and 0.0183. The model exhibited high accuracy and could be used to predict the head loss and filtration efficiency of the pontoon mesh rotary filter. In the test range, the optimal working condition of this filter was a flow rate of 930 L1 h−1, sand content of 2.0 g1 L−1, and 0.150 mm aperture of the filter screen. In addition, the head loss under this condition was 0.281 m, and the filtration efficiency was 84.01%. These results could serve as a reference for the further optimization and application of the pontoon mesh rotary filter, while also enriching the hydraulic performance and filtration performance of the pre-pump filter.

Similar content being viewed by others

Introduction

With the increase in population worldwide, global water scarcity is expected to increase significantly in the coming decades, especially in regions with scarce and uneven precipitation1. The agricultural sector has the highest historical and predicted global freshwater consumption rate between 1900 and 21002, with global irrigated farmland accounting for 20% of total farmland3. The use of filters in farmland irrigation systems consumes significant amounts of energy, resulting in carbon emissions and environmental pollution. In 2020, China’s carbon dioxide emissions reached 102.4 billion tons, accounting for approximately 31.8% of global carbon dioxide emissions4. Therefore, the further development of new water-saving technologies, improving water resource utilization, and the construction of water-saving and green agriculture, have become inevitable development trends5,6.

Filters serve as key equipment of the first pivot in micro-irrigation systems, filtering and purifying the irrigation water source and improving irrigation water efficiency. Currently, filters for irrigation can be divided into two forms, namely, post-pumps and pre-pumps, with post-pump filters mainly consisting of screen, sand, disc, and combined filters7,8. However, the post-pump filter performs filtration and flushing work under strong pressure conditions, resulting in issues such as large head loss and high energy consumption, producing large amounts of carbon emissions. With the development of irrigation technology, experts have focused on low energy consumption, low pollution, low emission, and high efficiency as the goals of irrigation technology to improve the efficiency of irrigation utilization9,10. Therefore, pre-pump micro-pressure filters have been proposed, which differ from post-pump filters in that the filter is installed before the pump, with the boundary conditions changing from strong pressure to micro-pressure, thus reducing the head loss and the energy consumption of the micro-irrigation system pump. This provides energy savings and makes the system more environmentally friendly. Pre-pump micro-pressure filters can be subdivided into two forms according to the filtration method. The first involves using the head at the end of the sedimentation tank to complete filtration and flushing under natural conditions. For example, Tao et al.11 proposed a pre-pump distributor mesh filter, Li et al.12 proposed a rotating cone bucket mesh filter, and Tao et al.13 designed a micro-pressure filtration rinse tank. The second filter type floats above the surface of the water, using its own pressure and nozzles inside the device for filtration and rinsing, and is collectively known as a pontoon mesh rotary filter. This filter has a different filtration method compared to the above-mentioned filters. The main reason for the clogging of filters for micro-irrigation involves the presence of suspended solids in irrigation water, mainly due to the presence of silt, algae, and other substances14,15. In actual irrigation projects, the previous filter filtration mechanism involves filtering the pre-filter water in a pressurized or self-pressurized manner into the inner cavity of the filter, from the interior through the filter mesh filter. Although the filter can be rinsed in a timely manner, filter clogging caused by silt and algae cannot be avoided16,17. The pontoon mesh rotary filter works in the opposite way, the filtered water is filtered from the outside to the inside by self-flow, with the mesh blocking the impurities outside. Simultaneously, it rinses the external mesh. This operational method can greatly reduce the probability of filter clogging, improve filtration efficiency, reduce pump energy consumption, reduce carbon emissions and reduce environmental pollution. Specifically, Xi et al.18 presented pre-pump-suspended hydrodynamic self-cleaning filters, while Ma et al.19 invented a floating submersible pump microfiltration all-in-one machine, and Wang et al.20 applied a pre-pump low-pressure microfilter to the drip irrigation system of the 102 Corps in Xinjiang, China. This system filtered impurities such as plankton, melon flesh, and moss in the water body to meet the water quality requirements of the water-saving irrigation system, presenting good results.

Researchers worldwide have carried out considerable research on the head loss and filtration efficiency of post-pump filters for micro-irrigation. Puig-Bargués et al.21,22, Duran-Ros et al.23,24,25, Wu et al.26, Zong et al.27,28, and Elbana et al.29 adopted a method that combines the results of physical tests and dimensional analysis to establish the relational equations between the head loss of different types of filters and various factors. All these methods have been verified to have a good predictive effect. Liu et al.30 derived head loss values of 2.8 and 3.8 m for 80 and 120 mesh, respectively, in self-cleaning screen filters at a flow rate of 220 m3 h−1, and31 derived a head loss of 1.5 m for 120 mesh Y-screen filters at 5.65 m3 h−1 under clear water conditions. Alipujiang et al.32 studied the head loss of torpedo screen filters with 120 and 80 mesh, and compared the relationship between the aperture and wire diameter of 80-mesh and 120-mesh screens. Because the wire diameter of 80-mesh screens was smaller than that of 120-mesh, and the aperture of 80-mesh screens was much larger than that of 120-mesh, the head loss produced by the 80-mesh screens was less than the head loss produced by 120-mesh screens. Shi et al.33 carried out an experimental study on the relationship between head loss, flow rate, and sand content for a new type of flap screen filter. The results showed that the inlet flow rate served as an important factor affecting the head loss, and a mathematical model was established between the head loss and flow rate, and the error of the mathematical model was within 10%. Liu et al.34 elucidated the relationship between head loss, discharge time, flow rate, sand content, aperture of filter screen, and particle gradation, and established and verified the mathematical expressions of head loss and discharge time through theoretical analyses. In the range of test conditions, the maximum head loss was 15.81 m and the minimum loss was 8.97 m. Hasani et al.35 assessed stacked filters, conventional mesh filters, and self-cleaning mesh filters at different pressures and found that the stacked filters exhibited the best performance among self-cleaning mesh filters. Deus et al.36 proposed a hydraulic characterization method for the backwashing process of sand filters for micro-irrigation to evaluate the effects of sand particle size, the height of the filter layer, and the design of the sand filters on the backwashing process. Researchers have also carried out relevant studies on the hydraulic performance and filtration performance of pre-pump filters for micro-irrigation. Tao et al.37 established a prediction model for the filtration efficiency of a self-cleaning drum-shaped mesh continuous filter using dimensional analysis to take into account the rotational speed of the device. Tao et al.38 established a prediction model for the head loss of pre-pump micro-pressure filters and used the magnitude analysis method to establish a filter. The predictive models of head loss, sand interception quality, and filtration efficiency of the filter were established. Li et al.39 and Tao et al.40 determined the optimal working conditions of the pre-pump micro-pressure filters using PPR and NSGA-II and indicated that both timed rinsing and continuous rinsing were applicable to the pre-pump micro-pressure filters. Xi Wei et al.41 studied the change in the head loss and filtration efficiency of the floating mesh rotary filter by changing the sand content and flow rate and determined the optimal working condition under the test conditions.

The technology of pre-pump micro-pressure filters has become increasingly mature; however, few studies have assessed floating mesh rotary filters. Therefore, this research focused on carrying out physical tests on a model of head loss and filtration efficiency for a floating mesh rotary filter in the laboratory, and it used variance analysis, range analysis, and dimension analysis to build a prediction model of key factors and assessment indicators. The factors affecting the head loss and filtration efficiency of the floating mesh rotary filter and the optimal working conditions were determined. The experimental results support the good hydraulic performance of the micro-pressure dynamic boundary and the theoretical filtration results, while also providing a basis for the structural optimization and application of a floating mesh rotary filter, thereby serving as a reference for the development of sustainable and green irrigation.

Materials and methods

Test device

The pontoon mesh rotary filter circulation system was constructed in the Agricultural Hydraulic Engineering Laboratory of Xinjiang Agricultural University, and the physical picture and circulation diagram are shown in Figs. 1 and 2.

Schematic diagram of the pontoon mesh rotary filter circulation system. Note: 1. Muddy pool; 2. pressure gauge; 3. flow meter; 4. outlet pipe; 5. pump and inverter; 6. drive nozzle; 7. outlet valve; 8. return pipe; 9. pontoon; 10. filter screen; 11. float box; 12. blades; 13. flushing nozzle; 14. internal bearings.

According to the figure, the specific structure of the float rotary filter consisted of 10 filter mesh, 12 blades, 6 drive nozzles, 13 rinse nozzles, 11 float box, 9 pontoon, and 14 internal bearings, where the diameter and length of the cylinder body were 0.25 and 0.29 m. The outside of the cylinder body was uniformly arranged with 6 rectangular blades, with a length and height of 0.29 and 0.025 m. For the pontoon mesh rotary filter test, the circulatory system consisted of 1 muddy pool, 2 pressure gauges, 3 flow meters, 4 water outlet pipes, 5 pumps and inverters, 7 outlet valves, 8 return pipes, and 1 pontoon mesh rotary filter. The length, width, and height of the muddy pool were 0.655, 0.51, and 0.25 m, respectively.

The principle of operation was as follows. For the filtration process, the pontoon mesh rotary filter floated above the surface of the irrigation water, through pressure caused by its own mass, and its own rotation of the water caused by the shear force promoted the irrigation water through the screen from the outside to the inside, undergoing tangential penetration into the filter cavity. In addition, the filtered water in the inner chamber was pumped out into the pipework. This test cycle device carried a portion of the clean water through the pump back to the drive nozzle, and the drive nozzle impacted the outside of the filter blade, resulting in drum rotation. Due to the rotation of the drum, the dirt attached to the surface of the filter screen was removed, which improved the cleanliness of the surface of the filter screen and was more conducive to the filtration of external water. During the filtration process, dirt greater than the aperture of the filter screen was isolated by the filter screen and stagnated on the outside of the filter screen, waiting to be rinsed.

For the flushing process, the rotation of the device caused the filter screen and water flow to undergo shear force. As a result, the impurities outside the filter screen and the water flow experienced a collision, and some of the dirt bounced off the surface of the filter screen. The filtered clean water was partially returned to the rinsing nozzle to rinse the filter screen from the interior to the outside, and the high-pressure water flow removed the impurities on the surface of the filter screen. Rinsing while filtering maintained the filter in an unclogged state and allowed for long-term filtration.

Test equipment and materials

Table 1 shows the models and specifications of the instrumentation used in the test. The test equipment mainly consisted of water pumps, electronic turbine flow meters, and pressure gauges. The test sediment selection of Urumqi City, with natural loss from the West Mountains, was used to simulate the actual irrigation water sediment project. However, to shorten the test time and observe the obvious test phenomenon, an additional proportion of 2.13% (particle size 0.25–0.5 mm) and 0.04% (particle size 0.5–1 mm) of sediment was added. Due to the smaller proportion, it was regarded as close to the scene. The particle size distribution of the test sediment samples is shown in Table 2.

The specific test steps were as follows. A certain proportion of sand was added before the start of the test, the frequency converter was adjusted to control the speed of the pump and achieve the designed flow rate, with the flow rate stable for about 3 min before the start of the test. The real-time sediment concentration was measured using the displacement method41,43, and the calculation formula of sand content was calculated with an Excel table utilizing Microsoft Office software. The sand content could be immediately obtained by only utilizing the total mass of the conical bottle and muddy water, weight of sediment. The displacement method could complete the sample collection and measurement within 50 s. The total sand content of the circulation system remained constant throughout the test. The sediment concentration monitoring interval was 360 s. The device speed was measured using a rotational speed gauge. After each set of turbid water tests, the entire test system was cleaned and the next set of tests was carried out.

Experimental design

The sandy water test of the pontoon mesh rotary filter was conducted under full experimental design with a total of 75 groups, and the factors and levels are shown in Table 3. Because the sediment in the irrigation water source could easily cause clogging of the irrigator, and to meet the requirements of the irrigation water source, the aperture of the filter screen was generally taken as 1/10–1/7 of the minimum runner size of the irrigator in this micro-irrigation system40. Thus, the commonly used apertures of the filter screen were selected as 0.125, 0.150, and 0.180 mm. Most of the irrigation water sources in Xinjiang region consist of surface water and are characterized by high sand content and large particle size, with sand content varying significantly between seasons. To simulate the change in sand content in the actual project and to shorten the test time, the range of sand content in this study was set to 0.5–2.5 g1 L−141. The range of the filter flow rate was 768–1068 L1 h−1, as obtained by the pre-experiment, thus, 798, 858, 930, 1008, and 1050 L1 h−1 were selected in the range. Therefore, the influence on filter head loss and filtration efficiency was examined. The experiment was repeated three times, and the obtained results were averaged.

The theoretical calculation of filter head loss is shown in Fig. 3, with the 1–1 cross-section and 2–2 cross-section serving as the reference sections, and 0–0 the reference plane. The energy equations for 1–1 cross-section and 2–2 cross-section could be obtained:

where Z1 (m) is the distance from cross section 1–1 to the reference surface 0–0; Z2 (m) is the distance from the midpoint of cross section 2–2 to the reference surface 0–0; P1 and P2 (Pa) are the pressures of reference sections 1–1 and 2–2, respectively, where P1 denotes the atmospheric pressure and P2 the pressure obtained from the pressure gauge; v1 and v2 (m1 s−1) signify the average flow rates of reference sections 1–1 and 2–2, respectively (v1 could be ignored and recorded as 0, and v2 could be obtained from the flow rate and the cross-sectional area of the outlet pipe); ρ (kg1 m−3) denotes the density of the liquid; g (m1 s−2) is the acceleration of gravity; α1 and α2 denote the momentum correction coefficients, which are taken to be 1.0; and hw (m) signifies the head loss of the water flow between sections 1–1 and 2–2. This was derived from Eq. (1):

In summary, Eq. (2) presents the expression for calculating the local head loss of the test filter.

Measurements of real-time sand content are primarily obtained using replacement methods40,42, the specific equation is as follows:

where ρ is the density of clear water (kg1 m−3), ρs is the density of sediment (kg1 m−3), ρm is the density of muddy water (kg1 m−3), S is the sand content (kg1 m−3), m muddy water is the mass of muddy water in the conical flask (kg), m conical flask+muddy water is the total mass of the conical flask and the muddy water (kg), m conical flask is the mass of the conical flask (kg), and V conical flask is the volume of the conical flask (m3).

The equation for the filtration efficiency η is given by Eq. (4):

where η is the filtration efficiency (%), S0 is the design sand content (g1 L−1), and S1 is the effluent sand content (g1 L−1).

Research methods

In this study, range and variance analyses were used to process the test results, with Ki and Ei corresponding to the sum of the head loss and filtration efficiency at each level of each factor, and ki and ei corresponding to the mean values of the head loss and filtration efficiency at each level of each factor. The magnitude of range R was determined by calculating the difference between the maximum and minimum values of the mean values of the test indices at different factor levels. The primary and secondary importance of each factor was judged by the size of the range R, with a larger R value indicating a higher influence of the corresponding factor on the indicator. After the homogeneity of the variance and normality test, the data met the basic assumptions and could be analyzed based on the variance. The significance of a factor on the head loss or filtration efficiency was determined according to the magnitude of the P value, when P > 0.05 it indicated no significance, while P < 0.05 indicated significance, as marked by *, with P < 0.01 marked by ** and P < 0.001 marked by ***. A smaller P-value meant greater significance of the corresponding factor. Multiple comparisons of the main effects were used to determine the optimal working conditions for the pontoon mesh rotary filter.

In this study, the least squares method was used to estimate the parameters in the regression equation to determine the relationship between the experimental indices and several factors. The factors affecting the head loss and filtration efficiency of the pontoon mesh rotary filter were processed by using the method of magnitude analysis, and the values of the relevant dimensionless terms were calculated. Next, 60 groups of experimental data were selected according to the spatial factor distribution map, and the relevant parameters were obtained by multiple regression analysis using SPSS 25.0 software, to obtain a prediction model for the head loss and efficiency of the overrate of the pontoon mesh rotary filter. Finally, the remaining 15 groups of data were used to validate the model.

Results and discussion

Range analysis of head loss and filtration efficiency

Table 4 represents the head loss and filtration efficiency results of the filters under muddy water conditions, along with the range analysis. According to Table 4, the sand content, flow rate, and aperture of the filter screen all affected the head loss and filtration efficiency of the filter. The head loss was the lowest when the flow rate was 798 L1 h−1, the sand content was 0.5 g1 L−1, and the aperture of the filter screen was 0.180 mm. The filtration efficiency was highest when the sand content was 2.5 g1 L−1, the flow rate was 1050 L1 h−1, and the aperture of the filter screen was 0.125 mm.

Figure 4 shows the trend of the mean head loss under various factor levels. As shown in the diagram, the head loss increased with an increase in the flow rate, which was consistent with the changes in other types of filters33,40. When the filter structure was unchanged, its resistance coefficient also remained largely unchanged. This was in accordance with the relationship between head loss and flow velocity (flow rate): the greater the flow rate, the greater the head loss. When the sand content increased, the head loss also increased. The primary reason for this was that as the sand content increased, more sediment was intercepted by the filter mesh per unit time, resulting in exacerbated clogging of the filter mesh and a consequent increase in head loss. When the aperture of the filter screen increased, the head loss decreased. The change in the aperture of the filter screen also affected the change in wire diameter that constituted the screen, and the external sandy water exhibited different resistance between the wire diameter and the aperture31. Notably, the aperture of the filter screen increased, the resistance between the external water flow and the screen decreased, and the head loss decreased. Among these, the flow rate was the main factor that affected the head loss of muddy water in the filter, followed by the sand content, and the aperture of the filter screen.

Figure 5 presents the pattern of average filtration efficiency across different factor levels. As can be seen, the filtration efficiency increases in tandem with a rise in flow rate. This is because an increased flow rate accelerates of the rotational speed of the float. Subsequently, the augmented shear force between the screen surface and external sediment renders it more difficult for the sediment to infiltrate the float’s inner cavity, culminating in an increase in filtration efficiency, akin to the research on self-cleaning drum mesh continuous filters by Tao et al.37. The filtration efficiency also increases with a growth in sand content. The explanation lies in the fact that as the sediment load in the water flow amplifies, the quantity of sediment instantaneously trapped by the screen mesh swells, leading to an elevation in filtration efficiency. Nevertheless, as the sand content steadily mounts, the rate of increase in filtration efficiency tapers off. This is due to the propensity of a higher sand content to clog the screen mesh. However, thanks to the self-cleaning capacity of the pontoon mesh rotary filter, the clogging issue does not become overtly prominent. This attests to the sterling filtration, self-cleaning, and anti-clogging capabilities of the rotary filter with float mesh. Furthermore, the filtration efficiency wanes with an expansion in the aperture of the filter mesh. The reason is that as the screen aperture broadens, the size of the sand particles retained by the screen enlarges, permitting more sand particles to access the float’s inner cavity. Consequently, the sand content in the filtered water augments, and filtration efficiency diminishes.

Variance analysis of head loss and filtration efficiency

Table 5 shows the ANOVA of muddy water head loss, with the results showing that under a significance level of 0.05, the flow rate had a significant effect on the head loss of the filter, followed by the sand content, and finally the screen aperture, with the same results as the range analysis.

Table 6 shows the ANOVA results of muddy water filtration efficiency, indicating that at a significance level of 0.05, the sand content had a significant effect on the filtration efficiency of the filter, followed by the flow rate, and finally the aperture of the filter screen, which was the same as the range analysis results.

Multiple comparison of main effect analysis

The significance of the F-value could indicate whether variations in the test results occurred from differences in the different treatments, possibly implying a significant difference between different treatments. However, it was not possible to determine which treatments significantly differed from each other, thus, multiple comparisons were needed to determine the significance of these differences, with the multiple comparison results shown in Table 7.

For the head loss, when the flow rate Q was taken as Q1, the differences with Q2, Q3, Q4, and Q5 were significant. Thus, the differences with other groups were significant when Q was taken at different levels, where the larger the flow rate, the larger the head loss. Sand content S had a significant effect on the head loss, with a clear difference between S taken as S5 and other levels, and no significant difference on the head loss when S was taken at other levels. In general, the head loss increased with increasing sand content. Under the assessment index of filtration efficiency, when the flow rate Q was taken as Q1, the difference was significant with Q4 and Q5, and when Q was taken as Q2, the difference was significant with Q1 and Q5. When Q was taken as Q3, the difference was significant with Q1 and Q2, where the higher the flow rate, the higher the filtration efficiency. Sand content had a significant effect on filtration efficiency, and when S was taken as S1, its difference with S2, S3, S4, and S5 was significant, and when S was taken as S2, its difference with S1, S4, and S5 was significant. The remaining differences between the levels were not significant, where the higher the sand content, the higher the filtration efficiency.

The flow rate was the primary factor influencing the head loss of muddy water, with the head loss being smallest when Q1 was taken. The flow rate was the second most influential factor on the filtration efficiency, and the filtration efficiency was largest when Q5 was taken. Therefore, Q should be taken as Q1 or Q5, but the head loss was the largest when Q5 was taken, and to balance the relationship between the head loss and filtration efficiency, the final Q was taken as Q3. Similarly, we verified that the sand content of S could be taken as S1 or S5. However, the filtration efficiency of the working condition when S was taken as S1 was the smallest. The corresponding conditions for head loss were greater when S5 was taken, and when S was S3, it demonstrated both good filtration efficiency and small head loss, with the final S taken as S3. The aperture of the filter screen for the impact of head loss and filtration efficiency ranked third, taking into account the head loss and filtration efficiency of the relationship between the aperture of filter screen selection d2.

In summary, the optimal working condition of the pontoon mesh rotary filter was the flow rate Q, which was taken as Q3 (930 L1 h−1), the sand content S was taken as S3 (1.5 g1 L−1), and the aperture of the filter screen was taken as d2 (0.150 mm). The head loss under this condition was 0.271 m, and the filtration efficiency was 80.69%. Post-pump filter self-cleaning screen filters had flow rates of 160, 180, 200, and 220 m3 h−1, and the mesh aperture was 0.1 mm, corresponding to maximum head loss values of 8.97, 11, 12.95, and 15.81 m, respectively33. The head loss of the Y-mesh filter at a flow rate of 5.65 m3 h−1 and mesh size of 120 mesh was 1.5 m30, with different specific test conditions. However, the head loss obtained during the scope of this test was much lower than the post-pump filter.

Prediction model of muddy water head loss and filtration efficiency based on dimensional analysis

Figure 6 shows the spatial point distribution aperture of the filter screen, sand content, and flow rate at different levels for each working condition. Sixty groups of data (spatial point locations shown as blue balls in the illustration) were selected through the spatial factor distribution map to establish the model, and 15 groups of data (spatial point locations shown as red balls in the illustration) were used to validate the model, which maximally ensured the scientific validity and homogeneity of the model for validation.

Table 8 shows the parameters affecting the head loss and filtration efficiency of the filter muddy water and the corresponding dimensionless terms. To investigate the relationship between the filter head loss (hw), filtration efficiency (η), flow rate (Q), aperture of filter screen d, sand content (S), and other factors, the experimental data were first processed to calculate the values of the relevant dimensionless terms. Then, SPSS 25.0 software was used to obtain the relevant parameters through multiple linear regression analysis; finally, the prediction model of the filter head loss and filtration efficiency was obtained.

Prediction model of muddy water head loss based on dimensional analysis

The relationship between head loss of the filter and various physical parameters under muddy water conditions could be expressed as

According to the π theorem, the underlying physical quantities were used to derive nine dimensionless quantities to describe the head loss of the filter, with ρ, d, v, and πi representing the dimensionless, underlying physical quantities

Substituting dimensionless quantities into Eq. (5) yielded Eq. (16):

where a is an empirical coefficient, and k1, k2, k3, k4, k5, k6, k7, k8, and k9 denote empirical indices.

The data were verified to meet the normality and homogeneity of variance, and Fig. 7 shows a normal P-P plot of the regression standardized residuals.

Table 9 presents the regression coefficients of the head loss regression equation, indicating that the coefficient of determination of the model, R2, was 0.969, demonstrating high accuracy for model prediction. For a filter of a particular configuration, certain geometric variables were excluded from the model due to their dimensionless π terms obtained as constants or missing correlations. The multiple linear regression model only retained parameters with significance levels of less than 0.05, and for variable π10, the significance did not reach the pre-determined level but was still included in the model to examine the effect on head loss.

Table 10 shows the ANOVA results of the muddy water head loss prediction model, from which we observed that the significance level of the model was less than 0.005, indicating that the model was extremely significant.

After substituting the parameters of the regression model obtained by multiple regression analysis into Eq. (17), the following formula for the head loss under muddy water conditions was obtained:

where v is the flow rate of the connected pipe, which could be expressed as v = 4Q/πd2; Eq. (17) can be converted to Eq. (18) by simplification:

Based on the exponents of the variables in Eq. (18), it is evident that the head loss exhibits direct proportionality to the flow rate Q, and sand content S. Conversely, the head loss is inversely proportional to screen aperture d, and rotational speed n. Notably, screen aperture has the greatest influence on head loss, with flow rate being the second most influential factor.

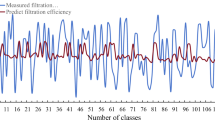

The predicted values obtained from the prediction of Eq. (18) were compared with the measured values, as shown in Fig. 8. The results showed that the predicted values of the model were in good agreement with the measured values, indicating that the model could more accurately predict the head loss of the filter under muddy water conditions.

Prediction model of muddy water filtration efficiency based on dimensional analysis

The relationship between the filtration efficiency of the filter and various physical parameters under muddy water conditions could be expressed by:

Similar to the steps for dealing with head loss, by using the π theorem, the underlying physical quantities could be used to derive nine dimensionless quantities to describe the filtration efficiency of the filter, with the underlying physical quantities of ρ, d, v, and πi representing the dimensionless quantities:

Substituting dimensionless quantities into Eq. (19) yielded Eq. (30):

As shown in Eq. (30), K was an empirical coefficient, with k1, k2, k3, k4, k5, k6, k7, k8, and k9 signifying empirical indices.

The data were verified to meet the normality and homogeneity of variance. Figure 9 shows a normal P-P plot of the regression standardized residuals.

Table 11 presents the regression coefficients of the filtration efficiency regression equation, indicating that the coefficient of determination of the model, R2, was 0.969, with high accuracy of the model prediction. For a filter with a particular configuration, certain geometric variables were excluded from the model due to their dimensionless π terms obtained as constants or missing correlations. The multiple linear regression model only retained parameters with significance levels less than 0.05, and for variable π10, the significance did not reach the pre-determined level but was still included in the model to examine the effect on filtration efficiency.

Table 12 shows the ANOVA results of the predictive model for muddy water filtration efficiency, which demonstrated that the significance level of the model was less than 0.005, indicating that the model was extremely significant.

After substituting the parameters of the regression model obtained by multiple regression analysis into Eq. (30), the following formula for the filtration efficiency under muddy water conditions was obtained:

where v is the flow rate of the connected pipe, which could be expressed as v = 4Q/πd2; Eq. (31) can be converted to Eq. (32) by simplification:

From the exponents of the variables in Eq. (32), it is observable that the filtration efficiency is direct proportion to the sand content S, the rotational speed n, and the flow rate Q. Conversely, it is inverse proportion to the aperture diameter of the screen d. Moreover, it is worth noting that the sand content has the most prominent impact on the filtration efficiency.

The predicted values obtained from the prediction of Eq. (31) were compared with the measured values, as shown in Fig. 10. The results demonstrated that the predicted values of the model were in good agreement with the measured values, and the model could more accurately predict the filtration efficiency of the filter under muddy water conditions.

Validation of head loss and filtration efficiency prediction models

To verify the reliability of the predicted results of the filter head loss and filtration efficiency prediction model, 15 groups of points selected by the spatial factor distribution map were verified. The validation results are shown in Table 13, indicating that the maximum relative error between the predicted and measured values of head loss was 9.59%, the minimum relative error was 0.52%, and the average relative error was 0.185%. As shown in Eq. (17), the head loss of the filter as related to the aperture of the filter screen d, gravitational acceleration g, density of water ρ, sand content S, rotational speed n, the velocity of the connecting pipe v, and dynamic viscosity μ, in which the velocity of connecting pipe v was calculated by the ratio of flow rate Q and diameter of the connecting pipe D. Therefore, when the diameter of connecting pipe was certain, the velocity of the connecting pipe v was dependent on the magnitude of the flow rate Q. Therefore, when the diameter of connecting pipe was certain, the velocity of the connecting pipe v depended on the size of the flow rate Q, so the head loss of muddy water was also related to the flow rate. The aperture of filter screen d served as a constant value, and the variation range of water density ρ and dynamic viscosity μ with temperature was small. Thus, we assumed that the prediction model was primarily related to the inlet flow rate, sand content, and filter area. Puig–Bargués et al.21, and Duran-Ros et al.23 used dimensional analysis to derive equations for calculating the head loss of micro-irrigation filters as \(\frac{\mu }{{\Delta H^{1/4} Q^{1/2} C^{3/4} }} = k\left( {\frac{{\Delta H^{3/4} V}}{{C^{3/4} Q^{3/2} }}} \right)^{a} \left( {\frac{{\Delta H^{1/2} A}}{{C^{1/2} Q}}} \right)^{b} \left( {\frac{{\Delta H^{1/4} \varphi_{f} }}{{C^{1/2} Q^{1/2} }}} \right)^{c} \left( {\frac{\rho }{C}} \right)^{e}\) and \(\frac{{V_{f} C^{1/2} }}{{\Delta H^{1/2} }} = b\left( {\frac{\rho }{C}} \right)^{{e_{1} }} \left( {\frac{\mu }{{\Delta H^{1/2} C^{1/2} D_{P} }}} \right)^{{e_{2} }}\), respectively, where the corresponding coefficients of determination, R2, were 0.882 and 0.984, respectively, with the former smaller than the coefficient of determination of the model established in this experiment, 0.969, and the latter higher than the coefficient of determination of the model established in this study. In addition, the root-mean-square errors were 0.061 and 0.040, respectively, which were lower than the present head loss model, 0.1041. Due to the different test conditions of the respective models, the test flow rate used by Duran–Ros was 7.20–9.36 m3 h−1, the water source used consisted of wastewater, and the considered parameters were more those in the present test. Puig-Bargués used wastewater mainly considering organic clogging, and the test flow was in the range of 0.32–5.51 m3 h−1. This test considered sandy water, and the parameters of the model were slightly different, though overall showed that it was feasible to establish the head loss model of pontoon mesh rotary filter by using magnitude analysis. This approach could accurately predict the head loss of a pontoon mesh rotary filter. Zong et al.27 and Tao et al.38 established head loss prediction models through the application of dimensional analysis, which also included the aperture of filter screen d and flow rate Q. The coefficient of determination R2 difference was very small, however, the flow rate range was higher than the scope of this test, and the follow-up could increase the flow rate of this study.

The maximum relative error between the predicted and measured values of filtration efficiency was 9.62%, the minimum relative error was 0.84%, and the average relative error was 0.833%. The prediction accuracy of the prediction model was high, with a better prediction of the filtration efficiency. According to Eq. (30), the filtration efficiency was related to the filter water density ρ, the aperture of the filter screen d, gravitational acceleration g, sand content S, rotational speed n, and the flow velocity v. The flow rate was calculated from the velocity of the connecting pipe v, indicating a direct relationship between the filtration efficiency and the flow rate. Compared to Tao et al.37, who built a self-cleaning drum-shaped mesh continuous filter filtration efficiency prediction model using magnitude analysis, \(\eta = 88.06S^{ - 0.084} Q^{ - 0.007} n^{0.012}\), the model parameters all included the sand content S, rotational speed n, and coefficient of determination R2, which did not significantly differ.

Conclusions

The results obtained in this study were only applicable to the pontoon mesh rotary filter under the following conditions: a flow rate of 768–1068 L1 h−1, apertures of filter screen of 0.180, 0.150, and 0.125 mm, and sand content of 0.5–2.5 g1 L−1. Other working conditions will require further study.

This study assessed the hydraulic performance and filtration performance of a pre-pump filter—pontoon mesh rotary filter, and we obtained the following conclusions.

-

(1)

The flow rate had a significant effect on the head loss of the pontoon mesh rotary filter, followed by the sand content, and the effect of the filter screen aperture was not significant, indicating that the head loss increased with the flow rate and sand content. The sand content had a significant effect on the filtration efficiency of the pontoon mesh rotary filter, followed by the flow rate, and finally by the aperture of the filter screen.

-

(2)

The optimal working condition of the pontoon mesh rotary filter was determined by polar analysis and analysis of variance (ANOVA) with filtration efficiency and head loss as the comprehensive indexes, i.e., the flow rate was 930 L1 h−1, the sand content was 1.5 g1 L−1, and the mesh aperture diameter was 0.150 mm. At this time the head loss and filtration efficiency were 0.271 m and 80.69%, respectively.

-

(3)

Predictive models for head loss and filtration efficiency of pontoon mesh rotary filters under muddy water conditions were developed based on dimensional analysis combined with multiple linear regression for \(\frac{{h_{w} }}{d} = 4.823\left( {\frac{gd}{{v^{2} }}} \right)^{ - 0.892} \left( {\frac{S}{\rho }} \right)^{0.021} \left( \frac{nd}{v} \right)^{ - 0.263} \left( {\frac{\mu }{\rho vd}} \right)^{0.025}\) and \(\eta = 2.056\left( {\frac{S}{\rho }} \right)^{0.15} \left( {\frac{gd}{{v^{2} }}} \right)^{ - 0.01} \left( \frac{nd}{v} \right)^{0.001}.\) The coefficients of determination of the model exponents, R2, were 0.969 and 0.954, respectively, which could well predict the head loss and filtration efficiency of the filter under muddy water conditions.

Data availability

All data generated or analysed during this study are included in this published article.

Abbreviations

- h w :

-

Head loss (m)

- η :

-

Filtration efficiency (%)

- P :

-

Significant difference indicator (–)

- Ki :

-

Sum of head loss at each level of each factor (–)

- kii :

-

Mean value of head loss at each level of each factor (–)

- Ei :

-

Sum of filtration efficiency at each level of each factor (–)

- eii :

-

Mean value of filtration efficiency at each level of each factor (–)

- R :

-

Range (–)

- Z :

-

Position head (m)

- \(\frac{P}{\rho g}\) :

-

Pressure head (m)

- \(\frac{{\alpha v^{2} }}{2g}\) :

-

Velocity head (m)

- F :

-

Inter-group difference index (–)

- Q :

-

Flow rate (L1 h−1)

- S :

-

Sand content (g1 L−1)

- d :

-

Filter screen aperture (mm)

- v :

-

Flow rate of connecting pipe (m1 s−1)

- ρ :

-

Density of water (kg1 m−3)

- V f :

-

Average flow rate of filter mesh (m1 s−1)

- μ :

-

Dynamic viscosity (pa1 s−1)

- L :

-

Filter length (m)

- g :

-

Gravitational acceleration (m1 s−2)

- n :

-

Rotation speed

- D :

-

Connecting pipe diameter

- a/K :

-

Experience index

- π i :

-

Dimensionless parameter (–)

- R2 :

-

Coefficient of determination (–)

- RMSE:

-

Root mean square error (–)

References

He, C. Y. et al. Future global urban water scarcity and potential solutions. J. Nat. Commun. 124, 667–4676. https://doi.org/10.1038/S41467-021-25026-3 (2021).

Walczak, A. The use of world water resources in the irrigation of field cultivations. J. Ecol. Eng. 22, 186–206. https://doi.org/10.12911/22998993/134078 (2021).

Kuang, W. N., Gao, X. P., Tenuta, M. & Zeng, F. J. A global meta-analysis of nitrous oxide emission from drip-irrigated cropping system. Global Change Biol. 27, 3244–3256. https://doi.org/10.1111/GCB.15636 (2021).

Khan, S. A. R., Sharif, A., Golpîra, H. & Kumar, A. A green ideology in Asian emerging economies: From environmental policy and sustainable development. Sustain. Dev. 27, 1063–1075. https://doi.org/10.1002/sd.1958 (2019).

Li, Y. Y., Li, Y. L. & He, J. Strategic countermeasures for China’s water resources security in the new development stage. J. Hydraul. Eng. 52, 1340–1346. https://doi.org/10.13243/j.cnki.slxb.20210704 (2021).

Rashid, K., Jasur, M., Jilili, A. & Bakhtiyor, K. Challenges for the sustainable use of water and land resources under a changing climate and increasing salinization in the Jizzakh irrigation zone of Uzbekistan. J. Arid Land 12(01), 90–103. https://doi.org/10.1007/s40333-020-0092-8 (2020).

Adin, A. Clogging in irrigation systems reusing pond effluents and its prevention. Water Sci. Technol. https://doi.org/10.2166/wst.1987.0163 (1987).

Wang, J., Liu, H. F., Cheng, Y. B., Li, X. L. Overview of the research and development status of domestic filters for micro-irrigation. Water Sav. Irrig. 34–35 (2003).

Tarjuelo, J. M. et al. Efficient water and energy use in irrigation modernization: Lessons from Spanish case studies. J. Agric. Water Manag. 162, 67–77. https://doi.org/10.1016/j.agwat.2015.08.009 (2015).

Li, Y. K. et al. Analysis of the current situation of the construction and research of low-carbon and environmentally friendly drip irrigation technology system. J. Trans. Chin. Soc. Agric. Mach. 47, 83–92. https://doi.org/10.6041/j.issn.1000-1298.2016.06.011 (2016).

Tao, H. F. et al. Micro pressure flter in front of pump: China, 202020260675.0[P]. 2020-11-03.

Li, Q. et al. Rotating cone bucket mesh filter: China, 202220601131.5.[P]. 2022-03-19.

Tao, H. F. et al. A micro-pressure filtration rinse tank: China, 201610063409.70.[P]. 2017-06-16.

Adin, A. & Alon, G. Mechanisms and process parameters of filters screens. J. Irrig. Drain. Eng. (ASCE) 112, 293–304. https://doi.org/10.1061/(ASCE)0733-9437(1986)112:4(293) (1986).

Gilbert, R. G., Ford, H. W., Bucks, D. A., French, O. F. & Adamson, K. C. Trickle irrigation: Emitter clogging and other flow problems. J. Agric. Water Manag. 3, 159–178. https://doi.org/10.1016/0378-3774(81)90001-9 (1981).

Li, Q. Q., Zong, Q. L., Liu, Z. J. & Lan, J. Horizontal self-cleaning screen filter discharge time test and calculation. J. Drain. Irrig. Mach. Eng. 32, 1098–1104. https://doi.org/10.3969/j.issn.1674-8530.14.0020 (2014).

Mohamed, A. Y. A. et al. Effects of wastewater pre-treatment on clogging of an intermittent sand filter. Sci. Total Environ. 876, 162605–162605. https://doi.org/10.1016/J.SCITOTENV.2023.162605 (2023).

Xi, W., Ma, L. J., Wu, Y. X., Ma, L. A kind of pre-pump suspended hydraulic drive self-cleaning filter: China, 202220388768.0[P]. 2022-02-24.

Ma, X. et al. Floating submersible pump microfiltration integrated machine: China, 202121722628.4[P]. 2021-12-14.

Wang, D. H., Ding, Y. J. & Huang, Y. Development and use of pre-pump low-pressure microfilter in drip irrigation system of 102nd regiment. Xinjiang Farm Res. Sci. Technol. 40, 45–46 (2017).

Puig-Bargués, J., Barragán, J. & De Cartagena, F. R. Development of equations for calculating the head loss inefuent fltration in microirrigation systems using dimensional analysis. Biosyst. Eng. 92, 383–390. https://doi.org/10.1016/j.biosystemseng.2005.07.009 (2005).

Puig-Bargués, J., Barragán, J. & De Cartagena, F. R. Filtration of effluents for microirrigation systems. Trans. ASAE 48, 969–978. https://doi.org/10.13031/2013.18509 (2005).

Duran-Ros, M., Arbat, G., Barragán, J. & De Cartagena, F. R. Assessment of head loss equations developed with dimensional analysis for microirrigation filters using effluents. Biosyst. Eng. 106, 521–526. https://doi.org/10.1016/j.biosystemseng.2010.06.001 (2010).

Duran-Ros, M., Puig-Bargués, J., Arbat, G., Barragán, J. & De Cartagena, F. R. Effect of filter, emitter and location on clogging when using effluents. Agric. Water Manag. 96, 67–79. https://doi.org/10.1016/j.agwat.2008.06.005 (2008).

Duran-Ros, M., Puig-Bargués, J., Arbat, G., Barragán, J. & De Cartagena, F. R. Performance and backwashing efficiency of disc and screen filters in microirrigation systems. Biosyst. Eng. 103, 35–42. https://doi.org/10.1016/j.biosystemseng.2009.01.017 (2009).

Wu, W. Y., Chen, W., Liu, H. L., Yin, S. Y. & Niu, Y. A new model for head loss assessment of screen filters developed with dimensional analysis in drip irrigation systems. J. Irrig. Drain. 63, 523–531. https://doi.org/10.1002/ird.1846 (2014).

Zong, Q. L., Zheng, T. G., Liu, H. F. & Li, C. J. Development of head loss equations for self-cleaning screen filters in drip irrigation systems using dimensional analysis. Biosyst. Eng. 133, 116–127. https://doi.org/10.1016/j.biosystemseng.2015.03.001 (2015).

Zong, Q. L., Liu, F., Liu, H. F. & Zheng, T. G. Self-cleaning screen filter head loss test for drip irrigation in large fields. J. Trans. Chin. Soc. Agric. Eng. 28, 86–92. https://doi.org/10.3969/j.issn.1002-6819.2012.16.014 (2012).

Elbana, M., De Cartagena, F. R. & Puig-bargués, J. New mathematical model for computing head loss across sand media filter for microirrigation systems. J. Irrig. Sci. 31, 343–349. https://doi.org/10.1007/s00271-011-0310-4 (2013).

Liu, F., Liu, H. F., Zong, Q. L. & Gu, C. C. Study of head loss and discharge time of self-cleaning screen filters. Trans. Chin. Soc. Agric. Mach. 44, 127–134. https://doi.org/10.6041/j.issn.1000-1298.2013.05.023 (2013).

Liu, X. C., Tan, S. S., He, Q. P., Gong, W. W. & Wen, Y. H. Study of head loss in Y-screen filters. China Rural Water Hydropower 11, 24–26. https://doi.org/10.3969/j.issn.1007-2284.2015.11.006 (2015).

Abulimiti, A.,·Tumaerbai, H.,·Yusaiyin, M.,·Aikebaier, A. Experimental study of head loss in torpedo screen filters under clear water conditions. J. Irrig. Drain. 37, 64–71. https://doi.org/10.13522/j.cnki.ggps.2017.0188 (2018)

Shi, K., Liu, Z. J. & Li, M. experimental study on head loss of new flap screen filter. J. Drain. Irrig. Mach. Eng. 38, 427–432 (2020).

Liu, Z. J., Shi, K., Xie, Y. & Li, M. Hydraulic performance of self-priming mesh filter for micro-irrigation in Northwest China. Agric. Res. 11, 1–10. https://doi.org/10.1007/S40003-020-00531-X (2021).

Hasani, A. M., Nikmehr, S., Maroufpoor, E., Aminpour, Y. & PuigBargués, J. Performance of disc, conventional and automatic screen filters under rainbow trout fish farm effluent for drip irrigation system. Environ. Sci. Pollut. Res. Int. 29, 80624–80636. https://doi.org/10.1007/S11356-022-21465-7 (2022).

De Deus, F. P., Mesquita, M., Testezlaf, R., De Almeida, R. C. & De Oliveira, H. F. E. Methodology for hydraulic characterisation of the sand filter backwashing processes used in micro irrigation. J. MethodsX 7, 100962. https://doi.org/10.1016/j.mex.2020.100962 (2020).

Tao, H. F. et al. Filtration efficiency of self-cleaning drum-shaped mesh continuous filter. Desalin. Water Treat. 208, 227–238. https://doi.org/10.5004/dwt.2020.26459 (2020).

Tao, H. F. et al. Dimensional analysis-based head loss calculation for the micro-pressure filtering and washing tank. Water Supply 23, 1729–1742. https://doi.org/10.2166/ws.2023.083 (2023).

Li, Q. et al. Establishment of prediction models of trapped sediment mass and total filtration efficiency of pre-pump micro-pressure filter. J. Irrig. Sci. 40, 203–216. https://doi.org/10.1007/s00271-022-00770-6 (2022).

Tao, H. F. et al. Establishment of a projection-pursuit-regression-based prediction model for the filtration performance of a micro-pressure filtration and cleaning tank for micro-irrigation. J. Clean. Prod. 388, 135992. https://doi.org/10.1016/j.jclepro.2023.135992 (2023).

Xi, W., Jin, Z., Li, Q. & Tao, H. F. Effect of flow rate and sediment content on head loss and filtration efficiency of pontoon mesh rotary filter. Water Sav. Irrig. 05, 46–51. https://doi.org/10.12396/jsgg.2023508 (2024).

Wu, W. Y., Chen, W., Liu, H. L., Yin, S. Y. & Niu, Y. A new model for head loss assessment of screen filters developed with dimensional analysis in drip irrigation systems. Irrig. Drain. 63, 523–531. https://doi.org/10.1002/ird.1846 (2014).

Zhao, N. Sediment treatment measures in reservoirs of sediment-laden rivers in Xinjiang. Water Resour. Plan. Des. 5, 147–151. https://doi.org/10.3969/j.issn.1672-2469.2020.01.033 (2020).

Acknowledgements

We are grateful for support from the Major Science and Technology Project of Xinjiang Uygur Autonomous Region (2022A02003-4) and the Changji State “Two Regions” Science and Technology Development Programme-Demonstration Project on the Transformation of Scientific and Technological Achievements (2023LQG08). This research was also supported by the Natural Science Foundation of China (52369013), the Xinjiang Uygur Autonomous Region Special Project for the Construction of Innovative Environment (Talents, Bases)—“Tianshan Youth Plan” Project (2019Q075), the Xinjiang Uygur Autonomous Region Innovative Environment (Talents, Bases) Construction Special Project—Natural Science Foundation Project (2021D01B58), “Tianshan Talents” Cultivation Program for Cultivating “Three Agricultural”Key Talents, and the Xinjiang Key Laboratory of Hydraulic Engineering Safety and Water Disaster Prevention and Control (ZDSYS-JS-2022-15), and the group-supporting study abroad project was funded by the Xinjiang Uygur Autonomous Region People’s Government in 2019.

Author information

Authors and Affiliations

Contributions

Hongfei Tao made substantial contributions to the conception or design of the work.Zhen Jin and Lingwei Chen wrote the main manuscript text, Zhen Jin prepared Figs. 1–3, 6–10. Lingwei Chen prepared Figs. 4–5.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jin, Z., Chen, L., Li, Q. et al. Establishment of predictive models for head loss and filtration efficiency of pontoon mesh rotary filter based on dimension analysis. Sci Rep 15, 4219 (2025). https://doi.org/10.1038/s41598-025-87708-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87708-y