Abstract

Currently, bamboo fibers (BFs) are commonly processed through alkali boiling softening pretreatment, which generates wastewater that poses environmental pollution risks. This process is also complex and requires significant human and material resources. In contrast, the saturated steam softening pretreatment method studied in this study is environmentally friendly and significantly simplifies the post-processing of bamboo fiber preparation. Additionally, it provides methods and parameters for the hygrothermal-mechanical extraction of bamboo fibers. In this study, three-year-old bitter bamboo (Pleioblastus amarus) growing in Zhongtai town, Yuhang district, Hangzhou city, China was selected as the raw material. Firstly, bamboo fibers were prepared by crushing and mechanical extraction after softening through alkaline boiling and saturated steam pretreatment, respectively. The yield, mechanical properties, and other indicators of the fibers were then tested and compared. Subsequently, Scanning electron microscopy (SEM) was employed to observe and comparatively analyze the microstructural morphology of the two types of fibers. Infrared spectroscopy (IR) was performed on the functional groups of bamboo after alkali boiling and saturated steam softening to investigate changes in cellulose, hemicellulose, and lignin. Finally, the mechanism of mechanical extraction of bitter bamboo (Pleioblastus amarus) fibers by saturated steam pretreatment was further analyzed.

Similar content being viewed by others

Introduction

In the field of natural fiber research and development, bamboo fiber has recently emerged as an innovative material with considerable promise1. Bamboo, renowned for its abundant reserves, swift growth cycles, exceptional mechanical properties marked by high tensile strength and rigidity, favorable processability, and ubiquitous availability across diverse geographical locations, is a pivotal sustainable and renewable non-wood forest resource within China’s forestry industry2,3,4. The primary constituents of bamboo biomass comprise cellulose (ranging from 45 to 55%), hemicellulose (15–25%), lignin (15–30%), pectin (0.5–1.5%), and other organic and inorganic compounds5,6,7,8. Bamboo fibers (BFs) exist within the bamboo structure as bundles, which are bonded to each other longitudinally and laterally by multiple roots arranged both vertically and horizontally and enclosed by parenchyma tissue9.

To harness the superior attributes of BFs, a separation and extraction process is essential to eliminate the parenchyma tissue from bamboo and procure bamboo fiber. Direct acquisition of bamboo fiber from the bamboo stem is infeasible, necessitating several treatments. Preparation of BFs can be achieved through physical methods10, chemical methods11,12, biological methods13, and combined technologies14. The quality and tensile strength of the fibers are directly influenced by the separation method employed. The physical method, though simple, yields coarse and rigid fibers. Chemical methods are highly efficient but incur high costs and generate pollution. Biological methods impose stringent requirements on the process environment and are typically utilized for refining coarse BFs15. Combined technology integrates two or three preparation processes to produce BFs. The application of multiple treatment methods at various stages of BF extraction is advantageous for maximizing benefits. Given bamboo’s complex structure and high lignin content, timely fiber extraction using a single technology is challenging. Therefore, combined technology is more prevalent and accelerates fiber production. For instance, a combined treatment involving pretreatment or post-treatment of bamboo strips using chemicals or enzymes and steam explosion (SE) is one such method that yields fibers16. Pretreatment is a crucial and preliminary step, also representing the most significant and costly operational unit. Pretreatment options encompass physical, chemical, physicochemical, and biological pretreatments17,18. Among them, the chemical method is commonly used as a pretreatment for BFs preparation. Enzymes such as hemicellulase, cellulase, pectinase, and xylanase have been reported to effectively degrade the bamboo structure and dissolve the binding materials (including lignin and pectin) of the fibers19. Enzyme treatment reduces the energy consumption and environmental pollution associated with the fiber separation process20. Salt pretreatment removes portions of lignin and hemicellulose from bamboo. Alkali pretreatment efficiently delignifies cellulose, chemically expands cellulose, facilitates enzymatic saccharification of bamboo, and disrupts the chemical linkage between hemicellulose and lignin, thereby removing most of the lignin and hemicellulose21,22,23,24,25. This improves the interfacial adhesion between bamboo fiber and matrix materials for composite preparations.

However, the utilization of chemicals during the alkaline treatment process has been found to adversely impact the chemical composition of bamboo, ultimately leading to a deterioration in fiber performance. There are numerous methods for extracting fibers, including compression milling, roller milling, fiber separators, steam explosions, the use of chemicals, and a blend of chemicals and pressure26. These various extraction techniques had differing impacts on the properties of bamboo fiber. The extraction processes could either enhance or degrade the performance of the fibers, affecting their mechanical, physical, and structural characteristics. Chemical methods, in particular, alter the chemical composition of the fibers, thereby influencing and potentially damaging their structure. The most prevalent mechanical fiber extraction technique employed in industrial settings is roller pressing, which has been known to cause fiber crushing or breaking, uneven fiber separation, and consequently, poor fiber quality, with critical indicators such as uniformity, length, and fineness failing to meet the rigorous specifications demanded by textile fibers.

In response to the challenges posed by high pollution levels, complex processing steps, and inconsistent fiber uniformity associated with conventional alkaline pretreatment and mechanical roller pressing methods, this study introduces a novel approach involving the hydrothermal modification of bamboo. This method aims to investigate the softening and fiber extraction of bamboo by altering the application of load. While steam softening of bamboo for flattening purposes has already been incorporated into industrial practices27,28,29,30,31,32,33, there remains a notable lack of experimental research focusing on bamboo fiber extraction. Thus, building upon the existing body of knowledge, this paper delves into the preparation of bamboo fibers and the methodologies for load application through mechanical fiber extraction utilizing saturated steam-softened bamboo.

The study employs an environmentally benign, time-efficient, and labor-saving hydrothermal process for the extraction of bamboo fibers. This process significantly simplifies the overall production workflow and minimizes wastewater and waste liquid emissions, thereby aligning with the overarching objectives of “dual carbon” reduction targets. This green and eco-friendly approach not only offers a fresh perspective for the industrial application of bamboo fibers but also contributes to the advancement of sustainable practices within the textile industry. Furthermore, research endeavors aimed at selecting suitable industrialized bamboo species, particularly focusing on bitter bamboo, and investigating hydrothermal-mechanical fiber extraction techniques for bamboo hold the potential to not only propel the development and utilization of bitter bamboo but also exert a profound impact on enhancing bamboo fiber preparation technology.

Materials and methods

Experimental materials

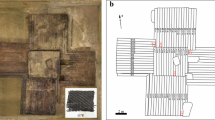

Bitter bamboo (three-year-old) growing in Zhongtai town, Yuhang district, Hangzhou city, China, with an initial moisture content of 12%34. Air-dried bitter bamboo specimens were divided into 2 groups (6 in each group) which were shown in Fig. 1. One group was softened by saturated steam pretreatment and the other by alkali boiling pretreatment. After softening, the bamboo fiber extraction test began immediately.

Softening agent: Sodium hydroxide (NaOH), chemically pure.

Experimental equipment and instruments

High-temperature saturated steam autoclave: Shandong Dingxing Machinery Co., Ltd.;

Cutting machine: Wuyi Ruite Tools;

Bamboo slicing machine: laboratory-made;

Bamboo crushing and fiber separation machine: laboratory-made;

Electronic balance: BSM model, Shanghai Zhuojing Co., Ltd.;

Fourier Transform Infrared Spectrometer: Nicolet 6700, Thermo Fisher Scientific;

Blast drying oven: 101-00BS model, Shangcheng Instrument Manufacturing Co., Ltd.;

Multi-function electronic strength tester: YG028PC, Wenzhou Bain Instrument Co., Ltd.;

Electronic microscope: YG002 model, Wenzhou Bain Instrument Co., Ltd.;

COXEM desktop scanning electron microscope: EM-30PLUS, COXEM Co., Ltd. (Korea);

Induction cooker: NLG350, Zhongshan Hanlin Electric Appliance Co., Ltd.

Experimental methods

Alkali boiling softening pretreatment method

The three-year-old Zhongtai bitter bamboo culms are first processed into bamboo strips using a bamboo slicing machine, with the bamboo nodes removed. These bamboo strips are then placed into a steaming and softening pot for the softening experiment. The concentration of the sodium hydroxide (NaOH) solution used is 4%, and the steaming temperature is set at 80 °C. During the experiment, it is ensured that the solution covers the bamboo strips completely to prevent them from floating on the water surface, which could affect the softening effect. The steaming and softening process lasts for 6 h. Afterward, the alkali-boiled bamboo strips are removed and their masses are measured individually. For measurement, the bamboo strips are taken out of the steaming and softening pot, drained of any surface liquid, weighed, and the results are recorded. Each experimental condition is subjected to 5 boiling and softening experiments, and the final results are averaged.

Saturated steam softening pretreatment method

The three-year-old Zhongtai bitter bamboo culms are sliced into bamboo strips using a bamboo slicing machine, with the bamboo nodes removed. The prepared bamboo strips are then grouped and placed into a high-temperature saturated steam autoclave, as shown in Fig. 2. The steam temperature is set at 170 °C, and the holding time is 20 min, with an initial moisture content of 12%34. After the steam softening process, the bamboo strips are removed, and their masses are measured individually. The bamboo strips are drained of any surface liquid before being weighed and the results are recorded.

Testing the physical parameters

Determining the fiber yield of bitter bamboo

In assessing the influence of various factors on the softening efficacy of bamboo materials, this research employed the fiber yield of bamboo as a key performance indicator. Subsequent to performing a fiber separation test on the softened bamboo specimens, the fiber yield was quantitatively evaluated utilizing the formula outlined below:

Where X represents the fiber yield (%); m1 is the mass of bamboo fibers after drying at 100 ~ 105℃ to constant weight (g); and m2 is the mass of the bamboo strips after drying at 100 ~ 105℃ to constant weight before softening (g).

Testing the fiber fineness of bitter bamboo

The fineness of fibers, a measure of their thickness or thinness, is commonly quantified by their diameter or cross-sectional area. For the purpose of this study, a width-based measurement approach was chosen to assess the fineness of bitter bamboo fibers. Given the comparable characteristics and extraction methodologies shared by bamboo and bast fibers, a rapid assessment method specified in NY/T 1538—200735 for ramie fiber fineness was adapted to measure the diameter of bitter bamboo fibers.

Testing the mechanical properties of bitter bamboo fibers

The mechanical properties of bitter bamboo fibers were evaluated in accordance with the non-textile fiber breaking strength standard outlined in “NY/T 2635 − 2014“36 and referenced in “GB/T 41553 − 2022“37. The testing parameters of the multi-functional electronic tensile tester were configured as: an initial pre-tension of 0.01 N, a standardized gauge length of 10 mm between the upper and lower jaws, and a constant ascending speed of 300 mm/min. Randomly sampled bitter bamboo fiber specimens underwent testing on multi-function electronic strength tester.

Fourier transform infrared spectroscopy study of bitter bamboo

Using Fourier Transform Infrared Spectroscopy (FTIR), the chemical structural changes of bitter bamboo under different modification pretreatments were studied. The pretreated bitter bamboo samples were first crushed and ground into powder that passed through a 100-mesh (147 μm) sieve. The FTIR scanning parameters were set as follows: KBr pellet method, 32 scans, a resolution of 4 cm⁻¹, and a scanning range of 0 to 4500 cm⁻¹ in the mid-infrared region.

Results

After performing fiber opening treatments on the bamboo materials processed by the two softening pretreatment methods, the extracted fiber strength and fiber yield were compared. Based on a comprehensive consideration, the most suitable softening and fiber extraction method was determined.

The bamboo pretreated by the alkali boiling softening method and the saturated steam softening method were subjected to fiber extraction pretreatments using a laboratory-prepared bamboo fiber extraction machine, as shown in Fig. 3. Figure 3a shows the fiber extraction of bitter bamboo after alkali boiling softening, and Fig. 3b shows the fiber extraction of bitter bamboo after saturated steam softening.

As can be seen from Fig. 3, after being subjected to alkali boiling softening and saturated steam softening pretreatments followed by mechanical rolling, the surface color of the bitter bamboo has changed. Specifically, the surface color of the bamboo pretreated with alkali boiling softening has deepened, and after rolling, the bamboo materials separate completely; if not separated in time, they may become sticky. The separated fibers are shown in Fig. 4a. For the bamboo treated with saturated steam softening, its surface color also darkens, and fibers can be separated after rolling without causing adhesion. The separated fibers are shown in Fig. 4b.

The bamboo strips after each softening pretreatment were removed from the softening equipment, their surfaces were wiped to remove any excess liquid, and they were then passed through a bamboo fiber extraction machine to prepare the bitter bamboo fibers through rolling. The extracted bitter bamboo fibers were oven dried and weighed for recording. The fiber yield of bitter bamboo fibers after different softening processes is shown in Table 1.

As can be seen from Table 1, the fiber yield after alkali boiling softening is 32%, while the fiber yield after saturated steam softening is 60.47%, which is 28.47% higher than that after alkali boiling softening.

Random samples were taken from the fibers after softening and extraction processing, and their fineness was tested. The fineness is shown in Table 2.

Figure 5 shows the fineness test diagram of bitter bamboo fibers. According to Table 2, the maximum diameter of the bitter bamboo fibers obtained after alkali boiling softening is 278.08 μm, the minimum diameter is 112.18 μm, and the average diameter is 200.11 μm. After saturated steam softening, the maximum diameter of the bitter bamboo fibers is 265.83 μm, the minimum diameter is 113.53 μm, and the average diameter is 192.27 μm. Among them, the average diameter of the fibers after saturated steam softening is smaller than that obtained by alkali boiling softening, with a difference of 7.84 μm in the average value. The difference between the thickest and thinnest fibers obtained after alkali boiling softening is 59.65%, while the difference between the thickest and thinnest fibers obtained after saturated steam softening is 57.29%.

The excellent mechanical properties of fibers can directly impact the performance of products processed and prepared subsequently. Therefore, fibers pretreated with alkali boiling softening and saturated steam softening were randomly sampled and placed in a multi-functional electronic tensile tester for tensile experiments. Tables 3, 4 show the results of the mechanical tensile property tests of bitter bamboo fibers after alkali boiling softening and saturated steam softening, respectively. Figure 6 shows the tensile properties of bamboo fibers extracted after deferent softening pretreatments.

From Table 3, it can be seen that after alkali boiling softening, the maximum breaking force of bitter bamboo fibers is 1625.47cN, the minimum breaking force is 387.57cN, the fiber breaking elongation is 1.96%, and the elastic modulus is 117.09cN/dtex. According to Table 4, after saturated steam softening, the maximum breaking force of bitter bamboo fibers is 1694.59cN, the minimum breaking force is 481.13cN, the fiber breaking elongation is 2.14%, and the elastic modulus is 126.24cN/dtex. The fibers obtained after saturated steam softening exhibit superior performance in breaking strength, breaking tenacity, breaking elongation, and elastic modulus compared to those obtained through alkali boiling softening.

Discussion

Morphological analysis of bitter bamboo fibers

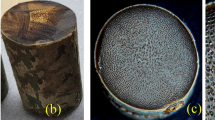

Using the COXEM benchtop scanning electron microscope (SEM), the morphology of softened and defibrillated bitter bamboo fibers was observed. As shown in Fig. 7, the SEM images are magnified 200 times. The left image shows the fiber morphology which was extracted after alkali boiling softening method. It can be observed that there is a small amount of residual parenchyma cells on the surface of the bitter bamboo fibers after alkali boiling softening, with most individual fibers exposed. The right image depicts the fiber morphology which was extracted after saturated steam softening pretreatment. It can be seen that there are more residual parenchyma cells on the surface of the bitter bamboo fiber bundles after saturated steam pretreatment, with most individual fibers encapsulated by parenchyma cells and only a small portion exposed. As shown in Fig. 7 gaps exist between individual fibers, indicating that bamboo fibers are formed by parenchyma cells, gums, and other components adhering to each other along the fiber direction to form fiber bundles, with individual bamboo fibers arranged parallel to each other. This morphology resembles capillaries, giving bamboo fibers the ability to quickly absorb and evaporate moisture, earning them the nickname “breathable fibers”38. This unique structure of bamboo fibers imparts properties such as strong moisture absorption, good breathability, and antibacterial characteristics. Precisely because of these features, bamboo fibers have gained widespread popularity in the textile industry39.

During the softening process of bitter bamboo fibers, significant differences in the extracted fibers arise due to the distinct methods of alkali boiling pretreatment and saturated steam pretreatment. Alkali boiling pretreatment leverages the solubility of lignin in sodium hydroxide solution to disrupt the lignin structure in bamboo materials40,41. This weakens the binding force between cellulose and hemicellulose, allowing external mechanical pressing to separate the parenchyma cells, gums, and other components from the fiber exterior. In contrast, saturated steam pretreatment softens bamboo by reducing the glass transition temperature of lignin and hemicellulose under the combined effects of high temperature, high pressure, and water vapor. Steam under high pressure forcibly fills the intercellular spaces within bamboo slices, and upon pressure release, the overheated liquid in the cells rapidly vaporizes, causing the weak structures within the bamboo to break down and reduce its modulus. External mechanical pressing then facilitates the separation of parenchyma cells, gums, and other components from the fiber exterior.

Functional group analysis of softened bitter bamboo fibers

The reasons for the above phenomena were analyzed. The analysis revealed that saturated steam is a state of steam in which the vapor pressure is equal to the ambient pressure, caused by the thermal motion of gas molecules. When the bamboo strips were placed in a high-temperature saturated steam autoclave, the intercellular spaces within the strips filled with saturated steam, causing the internal temperature of the strips to increase. During pressure release, the saturated steam vaporized the overheated liquid inside the bamboo material and exerted an outward force, causing the cells to rupture and the interior to become rough42.

Bamboo fibers primarily consist of three components: lignin, cellulose, and hemicellulose, with trace amounts of ash, pectin, and other substances5,6,7,8,43. Cellulose is the primary constituent of bamboo fibers and a crucial factor in determining their suitability as textile bamboo fibers. The cellulose content in bamboo can vary depending on the bamboo’s age, species, and growth region, typically ranging around 45%. Hemicellulose accounts for 14–25% of the fiber content and serves as an encapsulating agent. Lignin, an aromatic compound, determines the color of bamboo fibers44. Together with pectin and other components, lignin acts as a “binder” between cellulose and other microfibers within the cell wall. The Fourier Transform Infrared Spectroscopy (FTIR) spectra of untreated, alkali-boiled, and saturated steam-softened bamboo are shown in Fig. 8.

The C-O-C stretching vibration peak at 1045 cm− 1, which originates from lignin and cellulose in bamboo, undergoes a change in intensity after alkali boiling and saturated steam softening, indicating partial degradation of lignin in the bamboo. The intensity change is more pronounced in alkali-boiled samples (28.88% transmittance) compared to saturated steam-softened samples (39.27% transmittance), suggesting greater lignin degradation in the former. The absorption peak at 1400 cm-1, attributed to alkyl C-H bending vibrations and in-plane bending vibrations of hydroxyl OH, indicates further degradation of lignin and amorphous cellulose within the bamboo45. Changes in peak intensities at 1620 and 1664 cm− 1, corresponding to aromatic ring skeletal vibrations and stretching vibrations of carbonyl C = O conjugated with aromatic rings, respectively, suggest degradation of hemicellulose46. The C-O stretching vibration at 1738 cm− 1, originating from lignin and hemicellulose, shows decreased intensity in both treatments, indicating degradation of some hemicellulose and cellulose, with more pronounced degradation in alkali-boiled samples (32.32% transmittance) compared to saturated steam-softened samples (40.62%)47.

The O-H stretching vibration absorption peak is observed at 3427 cm-1. Compared to untreated bamboo, the hydroxyl stretching vibration is weaker in alkali-boiled and saturated steam-softened bamboo due to the catalytic enhancement of water, alkali concentration, pressure, and steam temperature on the amorphous region of cellulose during the softening processes. These external forces weaken the bonding forces between cellulose molecules, leading to cellulose degradation and oxidation of hydroxyl groups in the amorphous region of cellulose, extracted in the formation of aldehyde and carboxyl groups48. Consequently, the hydroxyl stretching vibration peak intensities of alkali-boiled and saturated steam-softened bamboo are weaker than those of natural bamboo, with more significant degradation in the former (15.59% transmittance) compared to the latter (24.38% transmittance).

Alkali boiling degrades lignin, cellulose, and hemicellulose more extensively, whereas saturated steam softening, achieved through the combined effects of high temperature and pressure, leads to a lower Tg (glass transition temperature) and less thermal degradation of lignin, cellulose, and hemicellulose, preserving the inherent structural characteristics of bamboo49. This contributes to the superior mechanical properties of fibers obtained through saturated steam softening compared to those obtained through alkali boiling.

Conclusions

This study compared the effects of alkali boiling and saturated steam softening on bitter bamboo (Pleioblastus amarus). By analyzing fiber yield, fineness, mechanical properties, fiber structural morphology via Scanning electron microscopy (SEM), and functional group changes using infrared spectroscopy (IR), the following conclusions were drawn:

After alkali boiling softening pretreatment, bamboo slices darken and fibers become yellow with adhesion. Saturated steam softening pretreatment also darkens slices but results in coffee-colored fibers without adhesion. Microstructural analysis showed less parenchyma tissue adhesion after alkali boiling, while some fibers detached after mechanical rolling. Functional group analysis revealed greater degradation of lignin, cellulose, and hemicellulose with alkali boiling compared to saturated steam pretreatment, which preserved structural characteristics due to decreased Tg (glass transition temperature), leading to less thermal degradation.

Specifically, fiber yield was 32% with alkali boiling and 60.47% with saturated steam softening method. Fiber fineness was 200.11 μm and 192.27 μm, respectively, while breaking force was 906.8 cN and 1204.66 cN, breaking elongation was 1.96% and 2.14%, and elastic modulus was 117.09 cN/dtex and 126.24 cN/dtex. Overall, fibers from saturated steam softening exhibited superior mechanical properties, fineness, and yield compared to those from alkali boiling. The application scope of bitter bamboo (Pleioblastus amarus) can be broadened further through the preparation of bitter bamboo fibers using the saturated steam softening pretreatment technique.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Lee, C. H., Yang, T. H., Cheng, Y. W. & Lee, C. J. Efects of thermal modifcation on the surface and chemical properties of moso bamboo. Constr. Build. Mater. 178, 59–71 (2018).

Zhang, Y., Yu, W. & Zhang, Y. Efect of steam heating on the color and chemical properties of neosinocalamus Afnis bamboo. J. Wood Chem. Technol. 33, 235–246 (2013).

Zhang, Y. M., Yu, Y. L. & Yu, W. J. Efect of thermal treatment on the physical and mechanical properties of phyllostachys pubescen bamboo. Eur. J. Wood Wood Product 71, 61–67 (2012).

Tan, T. et al. Mechanical properties of functionally graded hierarchical bamboo structures. Acta Biomater. 7, 3796–3803 (2011).

Liu, L. F., Wang, Q. L., Cheng, L. D., Qian, J. F. & Yu, J. Y. Modification of natural bamboo fibers for textile applications. Fiber. Polym. 12 (1), 95–103. https://doi.org/10.1007/s12221-011-0095-3 (2011).

Nayak, L. & Mishra, S. P. Prospect of bamboo as a renewable textile fiber, historical overview, labeling, controversies and regulation. Fash Text. 3 (1), 1–23. https://doi.org/10.1186/s40691-015-0054-5 (2016).

Tolessa, A., Woldeyes, B. & Feleke, S. Chemical composition of lowland bamboo (Oxytenanthera abyssinica) grown around Asossa Town, Ethiopia. World Sci. News 74, 141–151 (2017).

Rocky, B. P. & Thompson, A. J. Production of natural bamboo fibers – 3: SEM and EDX analyses of structures and properties. AATCC J. Res. 5 (6), 27–35. https://doi.org/10.14504/ajr.5.6.4 (2018b).

Ray, A. K., Mondal, S., Das, S. K. & Ramachandrarao, P. Bamboo—A functionally graded composite-correlation between microstructure and mechanical strength. J. Mater. Sci. 40 (19), 5249–5253. https://doi.org/10.1007/s10853-005-4419-9 (2005).

Okubo, K., Fujii, T. & Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A Appl. Sci. Manufac. 35 (3), 377–383. https://doi.org/10.1016/j.compositesa.2003.09.017 (2004).

Wang, C., Chen, Z., Li, Y., Siddique, Y. S. H. & Chen, Y. Lassified extraction and properties of bamboo fiber. J. Text. Res. 38 (11), 9–15. https://doi.org/10.13475/j.fzxb.20170201707 (2017).

Huang, H., Wang, X., He, L. & Wang, Y. The influence of ultrasonic-assisted extraction on bamboo fiber structure and mechanical properties. World Bamboo Rattan 17 (05), 21–26. https://doi.org/10.12168/sjzttx.2019.05.004 (2019).

Zhang, K. et al. Thermal and mechanical properties of bamboo fiber reinforced epoxy composites. Polymers 10 (6), 608. https://doi.org/10.3390/polym10060608 (2018).

Zou, Y., Zhang, W., Yuan, S., Zhang, J. & Chen, H. Effects of different pretreatments combined with steam explosion on the properties of bamboo fibers. Bio Resour. 18 (1), 855–868 (2023).

Zhao, H., Zhao, Z., Feng, F. & Chen, L. Effect of alkali-sulfite pretreatment on preparation of bamboo fiber. Furniture 42 (03), 14–18. https://doi.org/10.16610/j.cnki.jiaju.2021.03.004 (2021).

Fu, J. et al. Bio-processing of bamboo fibres for textile applications: a mini review. Biocatal. Biotransform. 30 (1), 141–153. https://doi.org/10.3109/10242422.2012.650450 (2012).

Chen, H. Z. & Liu, Z. H. Steam explosion and its combinatorial pretreatment refining technology of plant biomass to bio-based products. J. Bio Technol. 10 (6), 866–885. https://doi.org/10.1002/biot.201400705 (2015).

Hasan, M. & Islam, R. Advancements in chemical pretreatment techniques for enhancing bamboo fiber quality in textile applications: a critical review. J. Text. Eng. Fashion Technol. 10 (1), 55–63 (2024).

Rocky, B. P. & Thompson, A. J. Production of natural bamboo fibers – 1: experimental approaches to different processes and analyses. J. Text. I 109 (10), 1381–1391. https://doi.org/10.1080/00405000.2018.1482639 (2018a).

Wu, N., Xiao, R., Du, G. & Li, X. Influence of pectinase pretreatment on bamboo fiber-refining. For. Grassl. Mach. 26 (02), 34–38. https://doi.org/10.13594/j.cnki.mcjgjx.2015.02.010 (2015).

Yamashita, Y., Shono, M., Sasaki, C. & Nakamura, Y. Alkaline peroxide pretreatment for efficient enzymatic saccharification of bamboo. Carbohydr. Polym. 79 (4), 914–920. https://doi.org/10.1016/j.carbpol.2009.10.017 (2010).

Sun, S. L., Wen, J. L., Ma, M. G. & Sun, R. C. Enhanced enzymatic digestibility of bamboo by a combined system of multiple steam explosion and alkaline treatments. Appl. Energy 136, 519–526. https://doi.org/10.1016/j.apenergy.2014.09.068 (2014).

Kassaye, S., Pant, K. K. & Jain, S. Hydrolysis of cellulosic bamboo biomass into reducing sugars via a combined alkaline solution and ionic liquid pretreatment steps. Renew. Energy 104, 177–184. https://doi.org/10.1016/j.renene.2016.12.033 (2017).

Zhang, X. et al. Effect of steam pressure on chemical and structural properties of kenaf fibers during steam explosion process, BioResources 11 (3), 6590–6599.https://doi.org/10.15376/biores.11.3 (2016).

Phong, N. T., Fujii, T., Chuong, B. & Okubo, K. Study on how to effectively extract bamboo fibers from raw bamboo and wastewater treatment. J. Mater. Res. 1 (1), 144 (2012).

Singh, B. & Dessalegn, M. Y. Effect analysis of extraction processes of bamboo fiber. Nveo Nat. Volatiles Essent. Oils J. Nveo 4226–4246 (2021).

Kadivar, M. et al. Effect of bamboo species and pre-treatment method on physical and mechanical properties of bamboo processed by flattening-densification. Mater. Chem. Phys. 291, 126746 (2022).

Dixon, P. G. & Gibson, L. J. The structure and mechanics of Moso bamboo material. J. Royal Soc. Interface 11, 20140321. 2014 (2014).

Dauletbek, A. & Li, H. A review of basic mechanical behavior of laminated bamboo lumber. J. Renew. Mater. 10, 273–300 (2022).

Wang, X. Z. et al. Effect of high-temperature saturated steam treatment on the physical, chemical, and mechanical properties of moso bamboo. J. Wood Sci. 66, 52–59 (2020).

Hadavinia, H. & Ghasemnejad, H. Effects of mode-I and mode-II interlaminar fracture toughness on the energy absorption of CFRP twill/weave composite box sections. Compos. Struct. 89, 303–314 (2009).

Song, W., Zhu, M. & Zhang, S. Comparison of the properties of fiberboard composites with bamboo green, wood, or their combination as the fibrous raw material. Bio Resour. 13, 3315–3334 (2018).

Bui, Q. B., Grillet, A. C. & Tran, H. D. A Bamboo treatment procedure: effects on the durability and mechanical performance. Sustainability 9, 1444 (2017).

Xu, X., Fan, X., Gong, Z. & Zhang, W. Experimental study on fiber extraction after saturated steam softening of Pleioblastus amarus. Forests 15, 1754. https://doi.org/10.3390/f15101754 (2024).

NY/T 1538–2007. Quick Test Method for Determination of Fineness of Ramie Fiber. Agricultural Industry Standard of the People’s Republic of China: Beijing, China, (2007).

NY/T 2635 – 2014. Test Method for Tensile Fracture Strength of Ramie Fibers. Agricultural Industry Standard of the People’s Republic of China: Beijing, China, (2014).

GB/T 41553 – 2022. Bamboo Fiber. National Standard of the People’s Republic of China: Beijing, China, (2022).

Wu, Y. F. et al. Effect of softening of bamboo specimen treated by steam. J. Zhejiang For. Sci. Technol. 36, 36–39 (2020).

Zhao, X., Peng, F., Cheng, K. & Liu, D. Enhancement of the enzymatic digestibility of sugarcane bagasse by alkali–peracetic acid pretreatment. Enzym. Microb. Technol. 44, 17–23 (2009).

Zhao, R. Y., Fu, D. J. & Sun, T. The effect of different softening treatment methods on quality of bamboo. J. Jiamusi Univ. (Nat. Sci. Ed.) 28, 637–640 (2009).

Chen, H. et al. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers. Cellulose 24, 333–347 (2017).

Asmare, F. W. et al. Physical and mechanical properties of coarse bamboo fibers extracted by different techniques. J. Fiber Bioeng. Inf. 15, 287–302 (2022).

Shao, Y. T. et al. Effect of high temperature saturated steam softening treatment on physical and mechanical properties of flattened bamboo. J. Bamboo Res. 9, 959–977 (2018).

Zhang, K. Thermal and mechanical properties of bamboo fber reinforced epoxy composites. Polymers 10, 608 (2018).

Gao, J. et al. Effects of combined acid-alkali and heat treatment on the physiochemical structure of moso bamboo. Sci. Rep. 10, 6760 (2020).

Huang, M. X. et al. Mechanical properties and structure characterization of bamboo softened by high temperature steam. J. Forest. Eng. 1, 64–68 (2016).

Fan, M., Dai, D. & Huang, B. Fourier transform infrared spectroscopy for natural fibres. Fourier Trans. Mater. Anal. 3, 45–68 (2012).

Cai, S. X. et al. Effects of high temperature hydrothermal treatment on chemical constituents of Pinus massoniana. J. Southwest For. Univ. 38, 217–220 (2018).

Huang, M. X., Zhang, W. B. & Zhang, X. C. Effects of high temperature hydrothermal treatment on chemical constituents of Pinus massoniana. J. Zhejiang Univ. 32, 897–902 (2015).

Acknowledgements

This paper was supported by Zhejiang Science and Technology Department public welfare project, grant number LNG21C160006.

Author information

Authors and Affiliations

Contributions

Conceptualization and experiment design, X. X., W. Y., Z. G and W.Z.; material preparation, characterization, and performances test, X.X., W. Y., X. F. and W.Z.; writing-original draft preparation, X. X, Z.G. and W. Y.; writing-review & editing, X.X. and W.Y.; data analysis and scientific discussion, all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xu, X., Yu, W., Fan, X. et al. Mechanism analysis of mechanical extraction of Pleioblastus amarus fibers by saturated steam pretreatment. Sci Rep 15, 4028 (2025). https://doi.org/10.1038/s41598-025-88059-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88059-4