Abstract

The use of clay soils in road construction showed various limitations including swelling potential, which adversely affect the stability and durability of road structures. It is thus fitting that this study intended to use a mixture of clay and recycled concrete debris as a sustainable alternative for road construction. Various characterization tests were carried out, including Proctor compaction tests, CBR bearing capacity and odometer tests, as well as X-ray diffraction and infrared spectroscopy analyses to study the mineralogical composition of the samples. The results showed that the addition of 25% of recycled concrete debris improves the density, compaction capacity and strength of the treated soils. The CBR bearing capacity increased from 4.5 to 40% after saturation, while odometer tests revealed potent stability and low deformation under load. The incorporation of concrete debris also reduced swelling indices, resulting in better soil performance. This study demonstrates the effectiveness of recycling concrete debris to reinforce soils used in road construction, offering a sustainable and environmentally friendly solution for road construction.

Similar content being viewed by others

Introduction

This work aims at the valorization of new local natural and industrial materials, specifically clay and concrete waste, which are abundant in Morocco, within the construction industry, contributing to the conservation of natural resources in addition to reducing the carbon footprint1. Our modern concerns require us to maintain and develop our communication routes while preserving natural resources2. Road infrastructure projects are often hampered by a lack of suitable materials3. This problem is exacerbated when it comes to large embankments, due to the enormous quantities of materials required and the associated pathologies (slope failure, differential settlement, foundation failure, longitudinal crack formation, etc.)4. Furthermore, locally available materials in large quantities may not be suitable for reuse in their natural state (swelling, plasticity, low strength, changing behavior)5. Several materials, such as concrete debris (due to the interesting characteristics of this type of material: amorphous structure, large amount of available silicon, etc.)6, have been recycled and used as materials in public works. The construction of civil infrastructure will always result in the production of inevitable waste, largely due to poor management and excessive ordering of construction materials by unskilled workers1. This work is being carried out to meet national needs for road materials and explore new sources of aggregates to ensure project supply7. Clay soils are known to be sensitive to water variation during seasonal cycles, causing major issues for buildings worldwide8. This shrink-swell phenomenon only applies to clay soils, but its extent depends on the mineralogical, chemical, and mechanical nature of the clay soil components9. So far, few reliable solutions have been proposed, despite the need to treat this waste and preferably recover and reuse it in other construction sectors, such as civil engineering, particularly public works10,11. The use of fine soils, especially clay, in road embankments is often subject to issues related to their evolving nature and clay structure12. In fact, these clays are usually deposited due to their unfavorable characteristics for reuse in road construction13. Traditionally, these soils can be recycled by treating them with concrete debris to compensate for their poor mechanical characteristics and workability14,15. Our modern concerns oblige us to maintain and develop our communication routes while preserving natural resources. Road infrastructure projects are often hampered by a lack of suitable materials16. Therefore, there is a strong demand for the management of waste generated in the form of “construction and demolition” (C&D) waste by local municipal councils due to the growing construction sector in developing countries1. This problem is exacerbated in large embankments because of the large quantities of materials required and the pathologies associated with these earthworks (slope failure, differential settlement, foundation failure, longitudinal crack formation, etc.). On the other hand, in order to dispose of certain materials considered as concrete waste, environmental and economic factors must be taken into account. To valorize these materials (clay and concrete waste) in road construction, this study proposes mixing clay with various proportions of concrete (0%, 15%, 20%, and 30%). After identifying the selected materials, the mixtures (clay + concrete waste) are subjected to the main mechanical road tests, such as Proctor compaction tests, bearing capacity tests before and after immersion using the CBR press, various road tests, and oedometer tests. The results obtained on the different samples are then compared to the requirements of current standards. Through this work, we aim to study the mechanical behavior of clay-concrete waste mixtures to highlight the potential of this stabilization technique. This translation keeps the scientific tone and content intact, ready for use in academic or professional contexts.

Benefits of the work carried out

The aim of this study is to explore the use of a mixture of clay and concrete debris for road construction. The study focuses on assessing the mechanical properties, durability and performance of these mixtures. The results obtained could open up new prospects for wider use of these materials in road construction. This could make a significant contribution to the sustainability of road construction projects, while helping to preserve the environment by potentially reducing the amount of concrete debris sent to landfill and by using local resources such as clay.

-

Explore the use of a mixture of clay and concrete debris to improve the durability and efficiency of road construction projects.

-

Assessing the mechanical properties, durability and performance of these mixtures to open up new prospects for their use in road construction.

-

To help protect the environment by reducing the amount of concrete debris sent to landfill and by using local resources such as clay.

-

Stimulate economic and social development, particularly in developing countries, by encouraging the recycling industry and creating new jobs.

-

Propose innovative, economical and environmentally-friendly solutions to strengthen the public works sector by recovering concrete waste.Ces objectifs visent à promouvoir une approche durable et efficace dans la construction routière en exploitant les ressources locales et en réduisant l’impact environnemental des projets de construction.

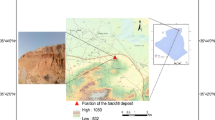

Presentation of materials

The materials used in this study (clay and concrete waste) are local materials that are widely available in the Ouazzane region. However, it should be pointed out that their exploitation and reuse in the road sector are not yet fully mastered in our country (Fig. 1).

Natural material (clay)

This figure shows the particle size distribution of natural clay, indicating the proportions of different particle sizes. The particle size curve reveals the size and proportion of fine, medium, and coarse particles. This information is crucial for assessing the mechanical and geotechnical properties of natural clay, such as its plasticity, permeability, and water retention capacity. The granulometric analysis reveals that the soil is less clayey than that of other soils. These results can be confirmed by the classification of fine soils. Based on the curve, the sample exhibits a finer granulometry. We can preliminarily deduce that the soils of Ouazzane will be more compressible.

Industrial material (concrete debris)

The intact samples taken from the clay layer at the site were subjected to physical and chemical identification tests at the Control Laboratory Tests and studies of building and public works, TEST-BUILDING, Kenitra, Morocco. Local materials are widely available for building and public works. However, should be noted that the use and reuse of these materials in road construction is not yet fully mastered in our country. To optimize their use, concrete scrap (Fig. 2) is a mixture of different types of clay and concrete waste used in road construction. Concrete waste from companies containing toxic elements that present a real danger to health and the environment, Recycled concrete scrap reused. They are then crushed and sieved in the laboratory.

Materials and methods

The physicochemical and mechanical identification tests were carried out at the TEST-BUILDING building and public works testing and design laboratory in Kenitra, Morocco, on the soils used in this geotechnical study of RP 4527 from KP 8 + 300 to KP 19 + 000 in OUEZZANE Province (Morocco). Before moving on to the mechanical tests, we began the experimental part with a series of tests to identify and characterize the materials used.

Experimental protocol

The clayey soil studied represents the main type of clay soil in the province of Ouazzane. The samples are collected as blocks at a depth of 1 m. These blocks of clayey soil are carefully crushed and sieved in the laboratory to avoid altering their mineralogical structure17. After identification, the samples are reconstituted in the laboratory according to the granular class (0/20) and subjected to various road mechanical tests, namely: the modified Proctor test, the CBR test after immersion, and the oedometer test. The samples subjected to mechanical tests are prepared as mixtures, according to the following proportions of natural clay and concrete waste:

-

Sample 1: Mixture (clay + 0% concrete debris),

-

Sample 2: Mixture (clay + 15% concrete debris),

-

Sample 3: Mixture (clay + 20% concrete debris),

-

Sample 4: Mixture (clay + 25% concrete debris).

Tests conducted

The prepared samples are subjected to mechanical tests in the laboratory (Modified Proctor compaction tests and CBR bearing tests after immersion (California Bearing Ratio) and odometric tests, Los Angeles and Micro-Deval).

-

Modified Proctor compaction tests (NM 13.1.023 (2019)), are used to study the suitability of mixes for compaction and to determine their optimum mechanical characteristics (\(\:{W}_{OPM}\)et\(\:{\:\rho\:d}_{OPM}\))18.

-

Immediate and post-immersion bearing capacity tests (NM 13.1.128 (2019)), are used respectively to assess the load-bearing capacity of mixes under machine traffic during project construction (Immediate Load-Bearing Index: ILBI) and under the worst hygrometric conditions and traffic (CBR Index after immersion: CBRimm)19,20.

-

The oedometer compressibility test, or fundamental test, is a direct application of consolidation theory. It used to assess the amplitude of settlement and its evolution21,22.

-

The purpose of the oedometer compressibility test (standard NM 13.1.003) is to study the consolidation of a sample of intact or reworked soil subjected to vertical loads, drained in this direction and held laterally by a rigid wall23,24.

Essais de résistance aux chocs et à l’usure

Micro-Deval and Los Angeles trials (NM EN1097-1 (2018)25,26 and NM EN 1097-2 (2018))27,28 permettent respectivement d’évaluer la résistance des matériaux étudiés à l’usure en présence d’eau et aux chocs.

Los Angeles test drive

The Los Angeles test measures the number of elements smaller than 1.6 mm produced by subjecting the material to standardized ball impacts in the LOS ANGELES machine.

If M: is the mass of the material tested, m: is the mass of elements smaller than 1.6 mm produced during the test, the resistance to fragmentation by impact is expressed by the quantity.

By definition, this dimensionless quantity is called the material’s angle coefficient (LA).

The purpose of the test is to measure the resistance to fragmentation by impact of the elements of an aggregate sample.

Results and discussions

The samples prepared in the laboratory were subjected to several tests (identification tests and mechanical tests). The results obtained are presented below.

Essai Micro-deval

This method consists of measuring the wear resistance of a sample of aggregates. This Moroccan standard applies to natural and artificial aggregates used in construction and public works.

The test determines the microdeval coefficient which is the percentage of the original sample reduced to a dimension smaller than 1.6 mm by rotation in a cylinder.

The test consists of measuring the wear produced under defined conditions by the reciprocal friction of aggregates in a rotating cylinder with an abrasive load.

Expressing results

With: MDE: Micro Deval in the presence of water. M: Refusal at 1.6 mm sieve.

Material identification

The physicochemical identification of the clay yielded the characteristics summarised in Table 1.

From these results, we can conclude that the plasticity index is IP > 40, according to the applicable standards, classifying the material studied in the very high plasticity, medium-hard category. It is also a very clayey material (VBS > 8). Based on the obtained results, we observe that it is a highly plastic clay material, classified as class At according to the LCPC classification and class A3 according to the GMTR classification. These results suggest that this type of clay has a very large interlayer spacing, allowing water to infiltrate and ensuring the plastic behavior typical of this material.

Impact and wear resistance test results

Materials are subjected to various stresses such as friction and impact, which can lead to wear or crushing of the grains. This can potentially cause problems in the pavement. The results of the Los Angeles (LA) and micro-Deval (MDE) tests, presented in Table 2, indicate that the clay materials and mixtures studied meet the requirements of the NM EN 1097-2 (2018) and NM EN 1097-1 (2018) standards for aggregates intended for pavement structures. They are classified in categories D and C respectively, which means that they can be widely reused in pavement layers, starting with subgrades. In other words, the test results show that the materials studied comply with the standards in force for their use in pavement construction, and they can be used successfully in the various layers of the pavement, starting with the subgrades.

All these results lead us to believe that the soil is swelling clay. Suspecting that soil may be swelling as early as the preliminary reconnaissance campaign allows us to anticipate the confirmation reconnaissance campaigns by adapting them to the nature of the site.

X-ray diffraction

X-ray diffractometry (XRD) is a method generally suited to the study of ordered compounds on an atomic scale, and particularly to the identification of the mineralogical composition of clay assemblages, for which it allows the crystalline phases to be identified. The method involves applying radiation at a wavelength in the X-ray range (between 0.1 and 10 nm) to a sample in Fig. 3. Analysis of the crystalline phases is made possible by the periodicity of the atomic arrangement of the crystals34,35.

The method based on the experimental application of Bragg’s law:

Where n: The order of the diffraction, λ: The wavelength of the emitting source, d: The spacing between two successive parallel planes of the crystal lattice, θ: The diffraction angle.

The Fig. 3 presents an X-ray diffraction (XRD) spectrum comparing natural clay and hardened concrete waste. The results show notable differences between the two samples in terms of mineralogical composition. Natural clay is characterized by typical minerals such as montmorillonite and kaolinite, known for their plastic properties and chemical reactivity. In contrast, concrete waste reveals the presence of quartz, portlandite (Ca(OH)2), and hydrated calcium silicate phases (C-S-H), which are indicative of Portland cement hydration reactions.

Portlandite, observed in the recycled concrete, is an indicator of the alkaline nature of the material, promoting reactions such as carbonation. The presence of quartz in both samples reflects a common component used in aggregates. These phases play a crucial role in the mechanical and chemical resistance of concrete. Recycled concrete waste, rich in active phases, offers opportunities to develop sustainable concrete formulations as a partial replacement for natural aggregates, thereby contributing to the reduction of ecological footprints.

In the future, studies should focus on the impact of the mineralogical properties of waste materials on the durability and mechanical performance of new concrete mixes. The optimization of recycling techniques, such as chemical or thermal treatments, could improve the quality of recycled aggregates. Furthermore, analyzing the chemical interactions between these materials and other additives, such as fly ash or slag, could pave the way for high-performance, eco-friendly concrete. Lastly, the combined use of natural clays and concrete waste in geotechnical applications warrants exploration to maximize their valorization.

Infrared (IR)

Infrared spectroscopy is a diagnostic method for determining the nature of chemical bonds present in a molecule. Experience shows that certain vibration frequencies, known as ‘group frequencies’, are characteristic of the presence of a chemical group in the molecule under study. The mechanical theory of vibrations makes it possible to predict the existence of group frequencies on the basis of the orders of magnitude of the different types of force constant36.

The results presented in the study show the infrared (IR) absorption spectra of different samples, including clay alone, concrete waste and mixtures of clay with different concentrations of concrete waste. These IR spectra are used to identify the functional groups present in the samples and to understand the chemical interactions that occur when they are combined. Infrared spectroscopy the spectra obtained are shown in Fig. 4.

It seems that you have provided a series of spectral data obtained from different combinations of materials, including clay and concrete waste, using infrared spectroscopy. These data appear to represent the frequencies (expressed in cm−1) through which various chemical bonds and molecular vibrations are observed in the samples studied. The frequency bands indicate the types of bonds and functional groups present in the samples in Table 3.

It seems that you would like to analyze these spectral data. Here is one possible interpretation of these results:

Figure 4 illustrates the infrared spectra of clay mixtures combined with different proportions of concrete waste (0%, 15%, 20%, 25%), allowing for the identification of functional groups present and the evaluation of chemical interactions. The bands located in the region 3620–3627 cm−1 are associated with the stretching vibrations of hydroxyl (OH) groups in kaolinite. Their stability demonstrates that the clay structure remains unchanged despite the progressive addition of concrete waste. Furthermore, the bands appearing between 1736 and 1749 cm−1 reflect the vibrations of carbonyl (C = O) bonds, which could originate from organic compounds or carbonation products formed during the chemical reaction with the alkaline components of concrete waste.

A notable intensification is observed in the bands between 1426 and 1410 cm−1, characteristic of carbonate (CO32−) vibrations, particularly calcium carbonate (CaCO3). This reflects an increasing contribution of carbonated phases with the rising proportion of concrete waste, likely from residual cement fines. The bands between 988 and 1002 cm−1, representing the vibrations of Si-O bonds, show a gradual modification of the silicate structures, indicating a chemical interaction between the silicate phases of the clay and those of the waste material.

The results indicate that the addition of concrete waste to clay matrices alters the chemical properties of the mixture, notably through the formation of carbonated phases and the modification of silicate networks. These changes could enhance the durability and mechanical properties of the materials, suggesting potential applications in fields such as construction and road techniques.

For future studies, it would be relevant to optimize the proportions of waste to maximize performance, use complementary analytical techniques to precisely identify the secondary phases formed, and assess the chemical and mechanical durability of the materials under real-use conditions. Such research would also contribute to promoting a sustainable approach to concrete waste recycling.

The mechanical tests

The study of the mechanical behavior of the materials studied focused on compaction tests using the modified Proctor method, CBR bearing capacity tests after immersion and oedometer compressibility tests. These tests give an idea of the mechanical response of the different materials under different types of stress, which are generally encountered on a real scale, under road traffic.

Modified proctor compaction tests

The modified Proctor compaction tests presented in Fig. 5 show that the addition of concrete waste increasingly reduces the sensitivity of the mixes to water. The latter presents less rounded Proctor curves (less sensitive to water) relative to natural clays alone. This is particularly apparent in the case of mixes of clay and concrete waste between 15 and 25%, due to the fact that concrete waste (insensitive to water) occupies a large proportion of the mixes (Table 4).

The graph presents the dry density (g/cm³) as a function of the optimal moisture content (%) for several clay and concrete debris mixtures. In general, the dry density increases with moisture up to a certain point, after which it decreases. This phenomenon is characteristic of granular materials and reflects the impact of moisture on compaction. The clay-only mixture (0% concrete debris) reaches the maximum density between 12% and 14% moisture content. The addition of 15%, 20%, and then 25% concrete debris progressively decreases the maximum density. This is due to the presence of inert materials, such as concrete debris, which hinder compaction. The optimal moisture content remains relatively stable for mixtures with up to 20% debris but shifts slightly for the mixture with 25% debris.

These results suggest that mixtures with a higher proportion of concrete debris are less effective in terms of compaction, which could influence their use in applications requiring high density, such as embankments or roadbases. Thus, to maximize density, it is recommended to limit the proportion of concrete debris to 15%, while considering the potential benefits of debris in terms of durability and cost.

CBR after immersion tests

The reconstituted clay samples are wetted to their optimum water content for compaction, reproducing their actual state when demixed, and are then subjected to CBR tests before and after immersion in accordance with standard (NM 13.1.128) allowing us to study their immediate bearing capacity (IPI) and their bearing capacity after immersion (CBRimm) respectively. The punching resistance of the samples before and after immersion presented in Table 5 shows that the CBR indices after immersion are significantly higher than the CBR indices before immersion. The natural material studied may develop a certain amount of cementing of the particles in contact with the water, which significantly improves its bearing capacity in the wet state. This characteristic is undoubtedly important for a road material.

After immersion, the specimens were punched on a motorised CBR press with a maximum punching force of 50 kN. The results obtained are shown in Fig. 6.

The load-bearing capacity of the mixes improved significantly and became very interesting for glass contents of between 0 and 25%.

The results of the CBR index obtained for different dosages after 24 h, 3 days, and 8 days of curing are presented in Fig. 7. These results show a proportional improvement in the bearing capacity of the soil with the different dosages and different curing times compared with the value of the CBR index of the natural soil, which is considered very low (4.5)37,38.

The results show that after only 24 h of curing, there was a considerable increase in the bearing capacity of the soil, a rapid improvement that was due to the immediate action of the concrete debris. The bearing capacity index reached a value of 40 with 25% concrete debris. This means that the incorporation of concrete debris improves the strength and stability of the mixes, offering superior performance to clay mixes alone, especially at higher proportions of concrete debris. The submerged CBR values obtained after treatment comply with the recommendations of the GTR French earthmoving guide. This is why we opted for this dosage for the odometer test, in order to maintain the economic aspect of the treatment.

The graph analyzes the effect of adding concrete debris on the dry density and CBR indices after immersion for different clay mixtures. In general, it is observed that dry density increases with CBR indices, reflecting better resistance to penetration and better compaction of the samples. For the clay mixture with 0% debris (Mix (clay + 0% concrete waste)), the growth of density and CBR indices is moderate. The addition of 15% concrete debris (Mix (clay + 15% concrete waste)) significantly improves penetration resistance and compaction, with a faster increase in CBR indices. Increasing the concrete debris content to 20% (Mix (clay + 20% concrete waste)) continues to improve performance, but at a slower rate. At 25% concrete debris (Mix (clay + 25% concrete waste)), the highest density and CBR indices are observed, suggesting optimal compaction. The increase in concrete debris seems to improve the structure and compaction, likely due to their less porous nature.

After immersion, the density and CBR index increase, indicating that water promotes cohesion and enhances the performance of the mixtures. The results suggest that mixtures containing concrete debris can be used in applications where high strength is required, such as embankments or roadbases. By optimizing the proportion of concrete debris, particularly up to 25%, the durability and strength of the mixtures can be improved.

This figure shows a comparison of the forces as a function of the indentations during the immediate bearing capacity tests and after immersion. The differences observed in the forces indicate the loss of soil strength due to water absorption. Mixtures containing concrete debris performed better than clay alone, suggesting that the addition of concrete debris improves the strength and stability of the treated soil. This improvement could be attributed to the ability of the concrete debris to reinforce the soil structure, thereby reducing the adverse effects of moisture on its mechanical properties. These results highlight the potential usefulness of concrete debris in improving soil performance, particularly in environments where moisture is a critical factor to consider.

Oedometer compressibility tests

The odometer tests shown in Figs. 8, 9 and 10 were carried out using equipment comprising a 75 mm diameter odometer cell. These tests are designed to assess the mechanical behaviour of the materials examined in terms of compressibility and swelling. Loading and unloading cycles are applied at a pressure of 3400 kPa. These tests provide essential information on the response of materials to applied and removed loads, enabling a better understanding of their characteristics in terms of deformation and behaviour under various stresses.

The compressibility indices decrease from 0.35 for pure clay to 0.19 for the mixture with 25% concrete debris. This reduction indicates an improvement in the mechanical strength of the treated mixture.

The compressibility index is a direct measure of the deformability of a soil under load. A decrease in this index means that the clay-concrete debris mixture is less prone to settlement under static and dynamic loads. This is explained by the granular structure of the concrete debris, which partially replaces the compressible clay particles and improves the density and stiffness of the material. This property is crucial for reducing differential settlements and ensuring the durability of road infrastructure.

The swelling indices progressively decrease with the addition of concrete debris in the clay mixture. The values decrease from 0.05 for pure clay to 0.025 for a mixture containing 25% recycled concrete debris. This shows a significant reduction in the soil’s ability to swell under the influence of moisture.

Pure clay is known for its high capacity to absorb water and expand, which can lead to excessive deformation in road structures. The addition of concrete debris, due to its granular properties and low reactivity to water, acts as a stabilizer by reducing the interactions between clay particles and moisture. This characteristic is essential for preventing heaving and deformation of expansive soils in road projects.

The preconsolidation stresses decrease significantly, from 0.50 MPa for pure clay to 0.12 MPa for a mixture with 25% concrete debris.

The preconsolidation stress reflects the initial resistance of the material to compression before it undergoes permanent deformation. The reduction of this stress might initially suggest a decrease in the initial stiffness of the treated soil. However, in this context, it indicates an improvement in the redistribution of stresses within the mixture. This means that the treated soil can better absorb and distribute applied loads without compromising its overall stability. This characteristic is particularly beneficial for road foundation layers, where the management of dynamic loads is crucial to prevent premature cracking.

The results from the figures demonstrate that incorporating recycled concrete debris into clayey soils significantly enhances their mechanical properties and stability. These improvements include:

-

Reduction in swelling indices, allowing for better resistance to moisture-drying cycles.

-

Decrease in preconsolidation stresses, promoting efficient load management without compromising structural stability.

-

Reduction in compressibility indices, ensuring more stable soils with less long-term settlement.

These results confirm the effectiveness of this approach for sustainable road construction, by valorizing construction waste and reducing environmental impact.

Conclusion

This study has proven that the integration of recycled concrete debris into clayey mixtures is an effective and sustainable alternative for road construction applications. The results obtained demonstrate that the addition of 25% concrete debris significantly improves the mechanical and physical properties of soils. Proctor compaction tests showed a higher dry density and better compaction capacity, indicating an improvement in the structural stability of the soils.

Moreover, California Bearing Ratio (CBR) tests revealed a significant increase after immersion, with values rising from 4.5% for pure clay to 40% with the addition of concrete debris. These results indicate enhanced resistance of the treated soils to water saturation, a crucial factor for the durability of road infrastructures.

Additionally, oedometer tests highlighted a reduction in compressibility and swelling indices, reflecting better soil stability and reduced deformation under load. This improves the soil’s ability to support heavy loads without excessive deformation, which is essential for roads subjected to intense traffic.

By incorporating recycled concrete debris, this approach offers a sustainable and environmentally friendly solution. It helps reduce construction waste while preserving natural resources, all while providing optimal technical performance. These results open promising prospects for the use of recycled materials in infrastructure projects, aligning innovation and sustainability to address current environmental challenges.

Data availability

All data generated or analysed during this study are included in this published article.

References

Shriram, M., Thushar, S., Shetty, B. M. & Mithun, A. Ranjith Strength and durability studies on air cured alkali activated pavement quality concrete mixes incorporating recycled aggregates. https://doi.org/10.1016/j.cscm.2021.e00732 (2021).

Talbi, A. The heritage process of historical buildings from the colonial era—Case of docks in Algeria. Doctoral dissertation, Université Mohamed Khider Biskra (2023).

Nicolle, S. & d’Hautefeuille, M. B. Anticipating the road: A case study in the east of French Guiana. VertigO Electron. J. Environ. Sci. 14(1) (2014).

Mieussens, C., Queyroi, D. & Vogien, M. Embankment built to failure—experimental site of cubzac-les-ponts. Bull liaison lab ponts chauss. http://worldcat.org/issn/04585860 (1974)

Hamza, B., Boumedjane, Z. & Remoum, K. E. Study of the mechanical behavior of marls in the eastern part of the municipality of Jijel (Kaous, Emir Abdelkader, Taher) for use in road construction (Jijel, Northeast Algeria). Doctoral dissertation, Univer-jijel (2022).

Sibille, L. Geotechnics for the technician IUT Civil Engineering and Sustainable Construction Module MXG5 (2018).

Boudlal, O., Khattaoui, M., Djemai, M. & Djebra, T. Study of the mechanical behavior of Marls from the Grande Kabylie (Algeria) for use in Road Construction (S25). In CFM 2015-22nd French Mechanics Congress. AFM, Maison de la Mécanique, 39/41 rue Louis Blanc-92400 Courbevoie (2015).

Khemissa, M., Mekki, L. & Mahamedi, A. Laboratory investigation of the behavior of an overconsolidated expansive clay in intact and compacted states. Transp. Geotech. 14, 157–168. https://doi.org/10.1016/j.trgeo.2017.12.003 (2018).

Bouazdia, S. numerical modeling of reinforcement by ballasted columns of an embankment resting on soft soil in the presence of a geosynthetic sheet by plaxis 2d and 3d code. Doctoral dissertation (2021).

Boudali, O. & Ouali, L. Valorization of a mix of marl and Plastic Waste in road Construction (National Days of Geotechnics and Engineering Geology, 2018).

Yahia, C. Study of the behavior of a mix of shale, plastic waste, and glass debris for use in the road sector. Doctoral dissertation, Université Mouloud Mammeri Tizi Ouzou (2019).

Boutiche, N. A. & Djeridi, S. Laboratory study of the compressibility and shear characteristics of a clay soil treated with lime. Doctoral dissertation, Faculty Of Applied Sciences Department Of Civil Engineering (2021).

Djama, Z. Mechanical and rheological behavior of concretes based on recycled aggregates. Doctoral dissertation, Université Mouloud Mammeri TiziOuzou (2015).

Belhaouci, S. Valorization of glass debris in road bodies (application to industrial glass). Doctoral dissertation, Université Mouloud Mammeri TiziOuzou (2015).

Saadani, S. & Houari, H. Behavior of concretes based on recycled aggregates. Doctoral dissertation, Université Frères Mentouri-Constantine 1 (2014).

Ramda, A., Boussouf, M., Sekhri, A. & Khelifi, R. E. Ecological architecture, towards a new type of collective housing in Algeria. Doctoral dissertation, University of Jijel (2019).

Kasinikota, P. & Tripura, D. D. Evaluation of compressed stabilized earth block properties using crushed brick waste. Constr. Build. Mater. 280, 122520 (2021).

Imanor, N. M. 13.1.023: Moroccan soil Standard, Recognition, and Testing. Determination of the compaction references of a material. Normal Proctor test Modified Proctor test. (2019).

Imanor, N. M. 13.1.128: Recognition and testing - CBR index after immersion. Immediate CBR index. Immediate Bearing Index - Measurement on sample compacted in the CBR mold (2019).

Tribak, H., Belkacem, A., E. Garouani, A. & Lahrach, A. Geotechnical study of compressible soils: Characterization, mechanism, and recommendation (case of the regions of Berrechid and Kenitra, Morocco). ESJ 16. https://doi.org/10.19044/esj.2020.v16n9p321 (2020).

Bensalah, J. Removal of the textile dyes by a resin adsorbent polymeric: Insight into optimization, kinetics and isotherms adsorption phenomenally. Inorg. Chem. Commun. 161, 111975. https://doi.org/10.1016/j.inoche.2023.111975 (2024).

Bensalah, J. et al. Cationic resin polymer A®IRC-50 as an effective adsorbent for the removal of Cr(III), Cu(II), and Ag(I) from aqueous solutions: A kinetic, mathematical, thermodynamic and modeling study. Inorg. Chem. Commun. 111272. https://doi.org/10.1016/j.inoche.2023.111272 (2023).

Tribak, H., Garouani, A. E. & P. E. S Geotechnical study of compressible soils: characterization, mechanism, and recommendation (case of the regions of Berrechid and Kenitra, Morocco). Eur. Sci. J. ESJ 16(9). https://doi.org/10.19044/esj.2020.v16n9p321 (2020).

Ouslimane, N., Barebita, H. & Belfaquir, M. Recycled concrete debris and valorization of crushed concrete and glass waste in road construction in Morocco. Innov. Infrastruct. Solut. 8(9), 239. https://doi.org/10.1007/s41062-023-01198-3 (2023).

Somé, S. C. et al. Evaluation of effects of short and long-term thermo-oxidative aging on chemo-rheological and mechanical properties of asphalt concretes. Road. Mater. Pavement Des. 1–30. https://doi.org/10.1080/14680629.2023.2172066 (2023).

Imanor, N. M. EN1097-1: Tests for Determining the Mechanical and Physical Properties of aggregates—Part 1: Determination of Resistance to wear (micro-DEVAL) (2018).

Imanor, N. M. EN 1097-2: Tests for determining the mechanical and physical properties of aggregates—Part 2: Methods for the determination of resistance to fragmentation (Los Angeles) (2018).

Strzałkowski, P. & Kaźmierczak, U. Wear and fragmentation resistance of mineral aggregates—a review of micro-deval and Los Angeles tests. Materials 14(18), 5456 (2021).

Imanor, N. M. ISO 17892-1: Determination of water content in soils by drying method (Oven-drying temperature) (2019).

Imanor, N. M. ISO 17892-12: Determination of the liquidity and plasticity limits (2019).

Imanor, N. M. 13.1.178: Determination of methylene blue value on soil (2018).

Imanor, N. M. ISO 17892-4: Determination of particle size distribution—Sieving method (2019).

G.M.T.R. Directorate of Roads and Road Traffic & Public Laboratory for Testing and Studies (Morocco): Moroccan guide for road earthworks (2002).

Boudaren, C. & Zater, M. Synthesis, characterization, and structural study by X-ray diffraction of mixed oxalates based on copper, titanium, and lead (2017).

Elmoueden, H. Study of the influence of alternative materials on the properties of foam mortars, with a view to their valuation (dredging sediments, chews, and fiberglass). Doctoral dissertation, National School of Mines-Telecom Lille Douai (2021).

Kalai, C. Study by complex impedance spectroscopy of the ionic transport phenomenon in transition metal doped diphosphate glasses. Doctoral dissertation, Universite Mouloud MAMMERI Tizi-Ouzou (2020).

Vindula, S. K., Chavali, R. V. P., Reddy, P. H. P. & Srinivas, T. Ground granulated blast furnace slag to control alkali-induced swell in kaolinitic soils. Int. J. Geotech. Eng. 13(4), 377–384. https://doi.org/10.1080/19386362.2017.1359901 (2019).

Cokca, E., Yazici, V. & Ozaydin, V. Stabilization of expansive clays using granulated blast furnace slag (GBFS) and GBFS-cement. Geotech. Geol. Eng. 27, 489–499. https://doi.org/10.1007/s10706-008-9250-z (2009).

Acknowledgements

The University Center for Analysis, Technology and Incubation Transfer Expertise (CUAE2TI), under the Ibn Tofaïl University of Kenitra. The National Center for Scientific and Technical Research CNRST of Morocco has made available the scientific equipment of the UATRS division. Control team, Building and public works tests and studies, TEST-BUILDING in collaboration with the Chemistry Department, Faculty of Science, Kenitra, Morocco. The authors extend their appreciation to the Researchers Supporting Project number (RSP2025R374) King Saud University, Riyadh, Saud Arabia.

Author information

Authors and Affiliations

Contributions

Conceptualization, original draft writing, reviewing, and editing: N.O., J.B., H.B. Formal analysis, investigations, funding acquisition, reviewing, and editing: M.E., Y.A.Y., M.K.O. Resources, data validation, data curation, and supervision: S.I., F.D., M.B.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ouslimane, N., Bensalah, J., Barebita, H. et al. Development and performance evaluation of alternative road construction material using clay and recycled concrete debris. Sci Rep 15, 9547 (2025). https://doi.org/10.1038/s41598-025-89708-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-89708-4