Abstract

Due to the great increase in the non-thermal plasma (NTP) bio-applications, especially thanks to its antimicrobial properties, many types of NTP generating devices have been developed recently. However, a comparison of these devices is difficult due to the differences in the setup of studies testing them, e.g., in species of microorganisms used and sample preparations. In this study, we optimized a robust and reproducible standard protocol using Bacillus subtilis spores and applied it to compare seven different NTP generating devices in terms of technical parameters and sporicidal properties. Inhibition zones determined using the Aurora software and the complete inhibition of bacteria growth induced by the NTP treatment were analyzed to determine both local and overall effects, respectively. The highest sporicidal efficacy of the tested devices was achieved by the volume dielectric barrier discharge from Wroclaw, which inhibited 99.9% of colony forming units after 30 min of exposure. To our knowledge, a comparative study of this extent has not been published to date. The presented protocol is based on an established bacterial method and can therefore serve as a general standard for an effective comparison of NTP sources across laboratories worldwide.

Similar content being viewed by others

Introduction

The antimicrobial properties of non-thermal plasma (NTP) are of great interest and the focus of many scientific groups, research articles and reviews1,2,3. Indeed, it has been demonstrated that NTP, thanks to its antimicrobial properties, has a great potential for applications, e.g., in the food industry, medicine, or agriculture. However, the published results cannot be readily compared with each other due to the large variation in study setups, e.g., type of NTP devices, species of microorganisms, sample preparations, or treatment conditions. Therefore, a unifying method for comparing NTP sources is needed to exploit the full potential of this novel antimicrobial agent.

NTP is an ionized gas usually generated by various types of discharges. It contains reactive oxygen and nitrogen species (RONS), the main agent responsible for its antimicrobial properties. The most common discharge types used in NTP generating devices are dielectric barrier discharge (DBD) and corona discharge. While DBD is formed between two planar electrodes separated by a dielectric layer, the corona discharge burns between one sharp pin electrode and a second conductive electrode of various shapes and materials. These discharges form the basis of many different NTP generating devices, tailored for various suitable applications. The most common devices are various types of plasma jets or pens with additional built-in gas flow and surface or volume DBD devices with a large NTP-treated area. Due to their different build-up, plasma jets produce a plasma plume with a rather local effect, while DBD devices can treat larger surface areas. A few publications focused on a comparison of different devices 4,5, but all the studies were limited to only testing two or a few devices. To draw conclusions about general trends among NTP generating devices concerning their properties, a larger test sample needs to be analyzed.

Approaches addressing the standardization of comparison of NTP generating devices published to date are very diverse. Mann et al. 6 introduced a comparison of antimicrobial properties of NTP generating devices by normalizing published efficacy data to the treated surface area. While this method is simple and readily applicable, it does not sufficiently capture the complex features of different plasma devices. Alves et al.7 opened a discussion on standards and best practices to improve communication, reproducibility and transparency within the NTP and related fields. They addressed the challenges associated with NTP standards for measurements, diagnostics, computations, reporting related to NTP sources and highlighted the importance of sufficient data management and proper documentation of procedures to meet relevant regulatory standards. Although these general principles are helpful, a specific solution in the form of reference protocol is lacking. Studies on the topic of unification of NTP device comparison are very diverse, and none of the suggestions have been widely implemented in the field.

The only regulating standard is the DIN SPEC (Deutsche Institut für Normung specification) 91315 which was introduced to standardize and unify requirements for NTP medical devices8, listing basic criteria for physical and biological characterization regarding international and national standards. The goal was to ensure user safety and accelerate technology transfer. Although these standards were applied in some studies5,9, and they are useful for commercial devices, they are not widely accepted probably due to their complexity and troublesome implementation. Moreover the microbiological part still needs to be improved since it includes detection of the inhibition zones on agar plates (for five pathogens) and suspension treatment. This specification is a German national standard and in the future it is highly likely to become a European standard and possibly even an ISO standard, which would ensure that sufficient testing quality is maintained in most countries worldwide. To our knowledge, there is no normative standard regulating plasma devices in medicine in other countries.

To solve this problem, a promising solution for comparing NTP generating devices has been proposed by Shaw et al.10, presenting a robust and reproducible reference protocol. It compared NTP generating devices in terms of sporicidal efficacy using a well defined biological sample. Preparation and evaluation of the microbial sample, using spores of the Gram-positive bacterium Bacillus subtilis applied on a porous polycarbonate membrane is described in detail in the protocol. This sample is non-pathogenic, resistant to the increase in temperature during the NTP treatment, and the spore suspension can be stored for a long time without any changes. Moreover, spores of B. subtilis are used as a test organism for the sterilization processes11,12. The NTP sporicidal efficacy is evaluated as a total number of surviving bacteria washed from the sample after the treatment, analyzed by colony forming units (CFU) counting. Despite many advantages, the protocol also has some weaknesses, such as the direct comparison of plasma jets with only local effect and other more broadly acting devices or the laborious preparation of the stock suspension. Based on these weaknesses, Khun et al.13 suggested minor modifications of the protocol, especially in the evaluation part and used it to compare the efficacy of four devices with different discharge types. While Shaw et al. evaluated the CFU inhibition of the washed and agar-inoculated sample, Khun et al. additionally analyzed inhibition zones directly on the membranes. This modification provides additional information about the NTP device properties and allows for a better comparison between plasma jets and DBDs, as the differences in treated areas are taken into account. Although the modifications of the protocol have led to improvements in results evaluation, it has not led to its implementation by other scientific groups.

To improve protocol applicability, we employed easily transportable samples (dried, thin membranes with spores of non-pathogenic bacterium) and aimed at preparing and evaluating samples in a single laboratory (shipping of the membranes). This strategy enables a uniform procedure, ensuring results consistency across NTP devices from any laboratory worldwide. Furthermore, we simplified sample preparation and made it more robust by minor modifications of the protocol, such as replacing sample preparation in the laboratory with purchasing a commercial stock spore suspension. Another modification introduced controls within the same tested membrane, by using one half of the membrane for NTP treatment, while the other half served as control. This approach rules out the impact of any differences between individual samples. The last modification we tested was the automation of the inhibition zones evaluation by introducing the Aurora software using machine learning. To test the improved protocol, we compared sporicidal effects of seven different NTP generating devices developed in various locations throughout Europe. In addition, we analyzed basic technical parameters, such as the type of excitation signal, deposited power, excitation voltage as well as thermograms of the membranes after NTP exposure. The obtained results indeed revealed several general trends regarding the parameters influencing the resulting sporicidal effect. In conclusion, we believe the modified protocol provides a good characterization and comparison of any type of NTP generating devices for biological applications.

Results

Technical characterization of compared NTP generating devices

The technical characterizations of used NTP generating devices are summarized in Table 1 and described in more detail in Materials and methods. The following parameters were compared: peak-to-peak voltage measured at the NTP generating device (supply voltage pp), power measured at the NTP generating device and working gas. Furthermore, the type of excitation signal and the setting of other tunable parameters are listed. The compared devices were driven either by radiofrequency waves (RF), micropulses, microwave source, or direct current (DC). In most cases, the frequency of the pulses and the repetition frequency (or duty cycle) were tunable. For all the plasma jet devices the gas flow was also tunable and its value is mentioned in the column “working gas”.

All parameters were fine-tuned to balance thermal damage to the membrane and sporicidal efficacy. Roman numerals represent multiple testing of the same device at different parameters (working gas, repetition frequency/duty cycle). Designed to be easy to use, “plug-and-play”, the indirect RF source (1) does not allow for tuning of any parameters, all are hardware encoded. The PCC (2) device allows for tuning of the repetition frequency and the peak voltage. The RF Ar/He jet (3), designed to be a widely flexible device, can be tuned in both the RF frequency and the duty cycle frequency; optimal values selected for use with He and Ar are depicted in Table 1. Both the volume DBD (vDBD (4)) and the Ar jet (5) have a fixed supply frequency and their powers are tuned by setting the pulse duration, i.e., the duty cycle in %, as depicted in Table 1. The corona discharge (CD (6)) device had the current and voltage set during manufacture to make it user-friendly and easy to handle. The MiniJet (7) is a commercial device equipped with a front panel where the power and the gas flow can be set directly in watts and L/min, respectively.

The power of the devices differs substantially, ranging between 0.41 and 24 W. The RF Ar/He jet (3) and an indirect RF source (1) have the lowest power (between 1 and 2 W) which is comparable to the CD (6) device (around 1 W). The PCC (2) device (4 W) and MiniJet (7) (5 W) are a bit more powerful. The vDBD (4) and the Ar jet (5) devices both offer quite a large range of power 5.4–24.2 W and 4.6–12.2 W, respectively.

CFU reduction after exposure to compared NTP generating devices

To determine the sporicidal effect of the studied NTP generating devices, the membranes were covered with a layer of B. subtilis spores, following the modified standard protocol as described in Materials and methods.

To ensure that the transport of the prepared samples did not affect the quality of the results, a preliminary study of membrane aging was performed (for 5 samples for each case), which showed that the membranes remained unchanged for a few days, with a 30% decrease in CFU after a week and a decrease of less than 40% after half a year (data not shown). Considering the fact that half of each membrane is a control sample and the other half is an NTP exposed sample, the aging factor of the membranes should not significantly affect the results.

After NTP exposure, the number of surviving bacteria in each sample was determined by CFU counting, as summarized in Table 2. Ultraviolet (UV) radiation exposure, a conventional disinfection method, was used as positive control and yielded more than a 4-log reduction, with just a few CFU remaining. The strongest sporicidal effect was observed for the vDBD (4) device with only around 10 CFU detected after the treatment and about a 4-log reduction, comparable to the one observed for the positive control. MiniJet (7) was the most effective plasma jet device with approximately 2.5-log reduction. The other devices have shown only mild reduction of around 1-log and less. For tunable devices, there was almost no correlation between CFU reduction and the set power. The RF Ar jet (3.I and 3.II) using Ar as a working gas was more effective (around 1-log reduction) than RF He jet (3.III and 3.IV) using He (around 0.5–log reduction).

Inhibition zones after exposure to compared NTP generating devices

Another way of determining the sporicidal effect of the studied NTP generating devices is the examination of the percentage of inhibition (colony-free) zones (Fig. 1). Samples were prepared as described above, except for the cutting in halves, and the whole membrane was exposed to NTP. Afterwards, membranes were placed on agar plates directly and cultivated. The images were analyzed by the Aurora software, normalized to untreated control and inhibition zones were determined and depicted in percent (Table 2). The positive control (UV radiation) yielded about 95% inhibition zone. The strongest spore reduction was observed for vDBD (4), with just a few colonies remaining within the membrane surface area after the cultivation. This translated into 86 to 97.5% inhibition zones (at different powers), which corresponds to the results of CFU reduction and compares to the positive control or is even stronger. MiniJet (7) was less efficient, with about 15% inhibition zone. The inhibition zones inflicted by PCC (2), indirect RF source (1), RF Ar/He jet (3), and Ar jet (5) ranged between about 2 and 13%. Similarly to the CFU reduction, the Ar gas flow seemed to be a bit more effective than the He one, with almost no dependency on power (for individual devices). After the treatment by the CD (6) device, the membrane surface area was completely covered with bacteria colonies, which was only slightly thinner than in the corresponding control.

Energy deposition (thermograms) after exposure to compared NTP generating devices

The energy deposition was tracked by generating infrared pictures (thermograms) of the sample after NTP treatment. Table 3 shows thermograms of the membranes and the peak temperature after 30 min of NTP treatment. The first evaluated characteristic was the distribution of deposited energy on the surface of the membrane. For the PCC (2) and indirect RF source (1), the area of peak temperature was observed at the center of the sample with a sharp drop towards the edge. The opposite is true for the vDBD (4) where temperature is homogeneous across the whole membrane. In the case of the RF Ar/He jet (3) the working gas seems to influence the temperature distribution, with Ar associated with overall lower temperature dropping towards the edge, and He associated with higher and more homogenous temperature. A similar temperature pattern (higher and homogenous) was observed for the CD (6) device. The peak temperature seems to be dependent on the power in individual devices. The MiniJet (7) showed the overall highest peak temperature of around 60 ̊C.

Discussion

To standardize NTP applications in the medical field and food industry, NTP generating devices and the NTP treatment need to be tested uniformly. This raises a need for a tool for an effective comparison of antimicrobial properties of different NTP generating devices. Although some studies addressed the standardization of testing and comparison of NTP generating devices4,5,6,7,8,9, no protocol has become widely used to date. To address the persisting need for a robust and widely applicable protocol, we built upon a standard protocol described by Shaw et al.10, modified by Khun et al.13, and implemented changes for further standardization, simplification and user-friendliness. We applied the newly designed protocol on seven NTP generating devices from laboratories across Europe, and provided a comprehensive comparison of their efficacy.

The modified protocol is described above to provide potential users with details on each step, ensuring good reproducibility of the results. In our approach, we envision that while exposure to NTP using different devices takes place in laboratories worldwide, the biological samples are prepared and evaluated in a single central laboratory. This allows for extending the protocol applicability while ensuring reproducibility of the results. Unlike the previous version of the protocol, we used a single membrane sample cut in halves for both NTP treatment and control, respectively. In this way, the impact of any differences between individual samples is avoided. Our preliminary data on aging of membranes containing B. subtilis spores (simulating possible changes during transport of samples to the central laboratory) show that the viability of spores decreases by 30% after one week and by less than 40% after half a year of storage. The splitting of the membranes, using half as control and half for exposure to NTP and subsequent evaluation of its sporicidal effect, eliminates the possible influence of transport (approximately 2–3 days in this study) on the inaccuracy of the results. In addition, spores are resistant to mild temperature changes and drought, which may be the only stress factors during transport.

Comparison study and general trends

The performed comparison of NTP generating devices using the modified protocol is unique in many aspects. To the best of our knowledge, this is the first study of this extent: comparing the sporicidal efficacy of seven different NTP generating devices, from five different European laboratories. For this reason, it is difficult to evaluate our data in comparison with previously published reports, as studies of comparable extent are not available or they employ completely different methods of evaluation.

This comparison study revealed some interesting general trends linking the technical parameters of the devices with their effectiveness against B. subtilis spores. Based on the obtained results, vDBD (4) has the strongest sporicidal efficacy followed by the Ar plasma jets (Ar jet (5) and RF Ar jet (3.I and 3.II)). Both vDBD (4) and Ar jets (Ar jet (5) and RF Ar jet (3.I and 3.II)) use direct exposure when charged particles and short-lived species are directly in contact with bacteria. This corresponds to the results of previous studies14,15 showing that the direct exposure to NTP leads to inactivation much faster than the indirect one. However, direct NTP treatment exposes the sample to a higher flux of charged particles, short-lived highly-reactive species and a strong electric field. Therefore, cautious fine-tuning of parameters is required to avoid damages to sensitive materials (e.g., thermosensitive biomolecules, electronics, or delicate materials). In the current study, we controlled for heat stress by regulating the highest temperature of the sample. While the used spores should remain unaffected up to 110 ̊C, we observe initial thermal damage of the membrane around 70 ̊C, and so kept the temperature below 65 ̊C in all experiments. This proved challenging for the Ar jets (Ar jet (5) and RF Ar jet (3.I and 3.II)), where streamers were formed, producing tightly focused spots of high energy deposition and hence parameters had to be carefully fine-tuned to prevent membrane damage in these spots.

Our data show that the Ar plasma jets seem to be more effective than the He ones, which corresponds to previous studies16,17. The overall interaction of the RF Ar/He jet (3) with the sample while using He and Ar was different. The RF Ar jet (3.I and 3.II)) provided direct treatment of the sample (the NTP plume was touching the membrane) while the RF He jet (3.III and 3.IV) delivered the charged particles to the sample indirectly, via the afterglow. The energy deposition differed as well: when using Ar, the temperature was overall lower and focused into the sample center; when using He, the temperature increased almost uniformly across the whole membrane.

Overall, it seems that the sporicidal effect does not depend on power, neither when comparing data for a single tunable device nor across different devices. This is somewhat surprising as power increase was reported to enhance the production of reactive species in NTP, and thus the resulting antimicrobial effect18,19. If we consider in more detail the results obtained in our study for devices with the similar power or thermogram, it appears that their sporicidal efficacy differs. For example, devices with power around 5 W, i.e., vDBD (4.III) (5.4 W, 99.9%), Ar jet (5.III) (4.6 W, 88%) and MiniJet (7) (5 W, 99.3%) vary in their sporicidal effect by approximately one order of magnitude. Their inhibition zones are also different, which is given by the nature of jets and DBDs. On the other hand, if we compare devices and configurations of a very low power (between 0.4 and 2 W) (indirect RF source (1), RF Ar/He jet (3) and CD (6)) we get a very similar and mild sporicidal effect (all six possibilities within one order of magnitude). In both cases there is a slight correlation of a sporicidal effect and power, even though for higher powers this correlation disappears. There are also studies reporting no significant influence of power on the antibacterial effect of NTP available as well20,21. Then it seems that a direct correlation of power and sporicidal effect does not exist and it also depends on other parameters of the device. Regarding the thermograms, they do not seem to be dependent on the power of the device, neither reflect their sporicidal properties. For example the devices having similar thermograms are Ar jet (5.II) (7.7 W) and RF Ar jet (3.II) (1.5 W) having similar sporicidal properties about 90% or CD (7) (1.1 W) and vDBD (4.III) (5.4 W) with more than 2.5 orders of magnitude difference in the spore inhibition. However, it is complicated to compare devices with similar characteristics because the aim of this study was to select very different ones.

Properties and strengths of each device

The current comparison reveals the properties and strengths of each device and hence what application it could be best suitable for. The vDBD (4) shows the strongest sporicidal properties, homogenous across the sample and does not cause thermal damage. Nevertheless, its disadvantages include the limitation in sample thickness due to the distance between electrodes and a higher chance of damage to sensitive materials (e.g., electronics or delicate materials). In summary, these properties make vDBD (4) devices ideal for decontamination of thin, resistant objects possibly of larger areas (e.g., plant seeds, dressings or certain medical instruments).

The second strongest sporicidal effect was observed with the Ar plasma jets (Ar jet (5) and RF Ar jet (3.I and 3.II)). Their sporicidal effect is only local, but the affected area is quite large considering the plasma plume dimensions. Moreover, these plasma jets appear to be gentle to the treated material increasing the sample temperature to only around 30 ̊C even after 30 min of exposure. Together, these properties make the Ar plasma jets promising for application where precisely focused and harmless treatments of small areas are required, for example in medicine (e.g., wound treatment, blood coagulation, dentistry, and ophthalmology).

A unique set of parameters was observed for the CD (6) device with homogeneous and harmless treatment (highest sample temperature only up to 36 ̊C). Unlike the other tested devices, it is portable, easy to use (has a single turn-on/turn-off button) and safe (no need for a high-voltage (HV) power supply). Its disadvantage is a rather milder sporicidal effect, however, it works in a closed atmosphere cumulating the reactive species which can interact longer with the sample. Overall, it is well suited for applications requiring gentle treatment of larger areas (e.g., skin treatment and support wound healing), providing an alternative to disinfection and offering simple operation also suitable for long-term self-care.

Future plans

The obtained results showed that the improved standard protocol is suitable for a defined and comprehensive evaluation of NTP generating devices from different laboratories (in our case across Europe) and allows their direct comparison. Further improvements are being considered, including the automatization of sample preparation and extension of aging study, necessary for shipping over longer distances for central laboratory testing. Expanding the testing to more devices with different properties will provide more details and reveal additional trends, which may eventually help direct future development plans in NTP generating device design. All of the above may contribute to the wider implementation of the standard protocol that would support the development of NTP bioapplications and provide a tool to investigate and to increase the understanding of critical parameters of NTP generating devices.

Materials and methods

Sporicidal activity determination using the modified standard protocol

The current improved standard protocol (experiment workflow depicted in Fig. 2) is based on a previously published protocol10 later modified by Khun et al.13. We made several following optimizations to the previous protocols to standardize the comparison of NTP devices. We simplified sample preparation by purchasing a commercial stock spore suspension. The samples were prepared and also evaluated in the same laboratory and only shipped to the respective laboratories for exposure by individual devices. We also introduced controls within the same tested membrane, and automated the analysis of inhibition zones using Aurora software.

Sample Preparation

Spores of the Gram-positive bacterium Bacillus subtilis (ATCC 6633) were deposited to a membrane (Whatman Nuclepore Track-Etched Polycarbonate Membrane Filter, hydrophilic, 25 mm in diameter, circle, 0.1 μm pore size) in a homogeneous monolayer. This bacterium was selected as a suitable non-pathogenic bacterial representative used to determine the sterilizing ability of various agents. A stock suspension of B. subtilis spores (Excelsior scientific, Cell Line 6633, 108 CFU per 0.1 mL) was diluted 1:1000 in sterile Ringer’s solution (8.6 g/L NaCl, 0.3 g/L KCl and 0.33 g/L CaCl2 in Water for Injections). The membrane was inserted into a holder (Whatman Swin-Lok Syringe-Type Reusable Membrane Filter Holders, for 2.5 cm filter, polypropylene holder) and sterilized in an autoclave. The spores were deposited via filtration using a vacuum flask closed with a rubber plug and connected to a vacuum pump and a pressure gauge. The sterilized holder with the membrane was connected to the tube passing through the plug and a 10 mL syringe with the working spore suspension was attached to the top of the filter holder (Fig. 2). The suspension was filtered through the membrane using the vacuum flask at approximately 80 kPa for 10–15 min, and the empty syringe was removed afterwards. To form a homogeneous layer of spores, sterile air was blown through the membrane for another 5 min. The membrane was removed from the holder under sterile conditions and placed in an open Petri dish to dry for about 1 h.

NTP exposure

Samples (dried membranes with deposited spores) were cut in half, one half was treated with NTP and the other one served as control. All NTP treatments performed by different devices had a fixed duration of 30 min and were performed at a distance of 1 cm between the electrode and the sample, except for the indirect RF source (1), where the distance was smaller due to its setup, as explained below. For each device, the most efficient configurations determined in preliminary experiments were used for the NTP treatments. Afterwards, surviving spores were detected on both the treated and control samples in parallel. In case NTP exposure and sample evaluation took place in different laboratories, each membrane half was placed in a separate sterile Petri dish and sealed with parafilm, and only the half to be treated was shipped.

CFU reduction

The reduction of CFU after the NTP treatment of spores was analyzed by bacterial cell recovery from the membrane. The membrane half (treated or control) was transferred with sterile tweezers into a sterile 50 mL Falcon test tube containing 10 mL of sterile Ringer’s solution and 5 sterile glass beads. Spores were washed into suspension by vigorous mixing for 60 s using a vortex mixer. To determine the number of viable bacteria, the suspension was decimally diluted, inoculated on Luria–Bertani (LB) agar plates (Miller, Belgium), cultivated for 24 h at 37 °C, and colonies were counted and normalized to corresponding untreated control. All experiments were performed in triplicates (three biological repetitions of one technical replicate), averaged, and depicted in percent +/- standard deviation.

Analysis of the Inhibition zones—Aurora

To analyze the local sporicidal effect of NTP treatment, the size of the inhibition zone (i.e., area without bacterial growth) on the sample was examined as described previously13. Samples were prepared as described above and the complete (uncut) membrane was treated with NTP as described above. Afterwards, treated membranes were placed directly on the LB agar plates (Miller, Belgium) and cultivated for 24 h at 37 °C. After the cultivation, images of the plates with membranes were taken and the area of inhibition zones was analyzed using Aurora software, in collaboration with HexTech s.r.o., Czech Republic. This tool was already used for the same purpose22,23 and is described more in detail by Hrudka24. It uses artificial intelligence (AI) and machine learning for the classification of pixels in the input image according to the intensity values of the RGB channels. This approach enables the software to accurately differentiate between bacteria-free areas (inhibition zones) and microbial cultures and define a percentage of the sample area occupied by the microbial culture with over 98% accuracy. The results were normalized to corresponding untreated controls. All experiments were performed in triplicates, averaged, and depicted in percent +/– standard deviation.

NTP generating devices

Seven different NTP generating devices from five laboratories across Europe were studied, namely indirect RF source (1), PCC (2), RF Ar/He jet (3), vDBD (4), Ar jet (5), CD (6) and MiniJet (7). All of them operate at atmospheric pressure, making them suitable for biological applications. In preliminary experiments, the parameters of individual devices were fine-tuned for the highest sporicidal efficacy while avoiding damage to the sample. These preliminary tests were conducted for a wider range of the parameter combinations (for devices allowing it) in the same way as described above for the main experiments. Configurations that destroyed the membrane due to high or very focused energy deposition were excluded. We selected several configurations that seemed to match the above and used them for comparison study. The configurations are listed in the table of technical parameters (Table 1) together with details on the type of excitation signal, power (measured at the NTP generating device), supply voltage peak to peak (also measured at the NTP generating device) and working gas (flow rate, if there is any). The discharge power of non-DC supplies was determined using Lissajous figures, which depict the charge transferred between the electrodes as a function of the voltage supplying the device. The Lissajous figures were generated by measuring the HV supplying the NTP generating device and the voltage on the measurement capacitor connected in series. The charge generated during the discharge in the NTP generating device (microdischarges) was determined and its dependence on the supply voltage was plotted, enabling discharge power calculation25. Treatment with UV light (254 nm) using a laminar flow box lamp was included as a conventional sterilization method and served as positive control.

Indirect radiofrequency (RF) source (1)

The indirect RF source (1) (Fig. 3) is a special type of plasma jet device developed at Consorzio RFX in Padova, Italy. Compared to traditional plasma jet devices this one does not work with direct contact of NTP with the treated sample26. Its base is made of a copper tube, 12.0 ± 0.5 mm in diameter, closed on one side with a grounded grid electrode made of brass. The second grid electrode is placed 1.0 ± 0.1 mm above the grounded one, inside the tube, and it is excited with a RF voltage of 5.0 ± 0.2 MHz frequency and 1.0 ± 0.1 kV peak-to-peak amplitude. When He flows inside the tube, at a rate of 3.0 ± 0.1 L/min, NTP is formed between the two grids. The total power transferred to the NTP was measured previously, using a Hall current probe27, to be approximately 0.41 ± 0.05 W. To fully exploit the chemical species produced by the NTP which enrich the afterglow, the source shall be placed as close as possible to the sample. Several studies have already been carried out on this device; showing inactivation efficacy on different bacterial species28,29.

Plasma coagulation controller (PCC) (2)

The Plasma Coagulation Controller (PCC (2)) (Fig. 4) is a He plasma jet device developed at Consorzio RFX in Padova, Italy. Although originally developed for enhancing blood coagulation, its antibacterial efficacy has been reported as well20. A central tungsten electrode, powered by voltage micropulses, is covered with a glass capillary (outer diameter of 1.0 ± 0.1 mm) and surrounded by a glass nozzle (inner diameter of 3.5 ± 0.2 mm); and a grounded ring electrode is placed just outside the nozzle. NTP is generated in the gap between the capillary and the nozzle, where He flows at a rate of 2.0 ± 0.1 L/min, and a plasma plume develops behind the nozzle. The two following parameters can be tuned: the frequency and the amplitude of the pulses. In the present study, pulses of 6.1 ± 0.1 kV repeated at 5.00 ± 0.01 kHz frequency were selected for testing. Since the micro-pulsed waveform slightly bounces on the negative side after the initial positive pulse, the peak-to-peak voltage is higher than the peak voltage control parameter. Exact power measurement for this source has not become available to date; however, an upper limit of the power was determined by measuring voltage and current on the low voltage side. This value includes transformer dissipation and therefore cannot precisely determine the power transferred to NTP, but estimates it is below 4 W. More technical details were published previously30.

Radiofrequency (RF) plasma jet (3)

The radiofrequency plasma jet (RF Ar/He jet (3)) (Fig. 5) developed at the Università di Milano-Bicocca, Italy, is a device designed for operating with large parameter tunability and enables studies on NTP generation in RF electric fields31. A central tungsten electrode is covered with aluminum oxide, except for a 13 ± 1 mm at the end, which remains exposed. A grounded ring electrode is placed outside the nozzle made of a standard Pasteur pipette (internal diameter of 5.0 ± 0.2 mm, tapered at the end to 3.5 ± 0.5 mm), where the Ar or He gas flows at a rate of 3.0 ± 0.1 L/min and the plasma plume is formed. This configuration is designed to reduce the sensitivity of the device to the surrounding environment. A sinusoidal voltage generator in the MHz range delivers a HV waveform to the central tungsten electrode, amplified by a resonant circuit formed by an inductor and the device capacitance. The power supply is modulated with a 5% duty cycle on a kHz-based time scale. Two tunable parameters impact the operation of the source: i.e., the frequency of the generated voltage waveform, in the range of 1–15 MHz, and the frequency of the modulation, ranging between 0.1 and 10 kHz. The power of the source has been measured using a Rogowski coil, properly correcting for parasitic phase shift32. However, given the high noise typical for the RF range, the measurement is affected by a large error.

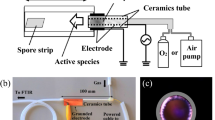

Volume DBD device (4)

The volume DBD (vDBD (4)) (Fig. 6) is an NTP generating device with a planar electrode configuration developed at Wroclaw University of Science and Technology, Poland. Its antibacterial and antifungal properties were reported previously33,34. The plane-parallel electrodes are made of aluminum with dimensions of 110 × 110 mm and the distance between them is 3 mm. The upper electrode is supplied with a HV AC pulse generator (Dora PS, Wroclaw, Poland), and the bottom one is grounded and covered with a 1 mm thick aluminum oxide dielectric layer. NTP is generated in the air gap between the upper electrode and the dielectric layer. At atmospheric pressure, this type of discharge acquires the form of many independent transient current filaments or microdischarges. Increasing supply voltage generates significantly more microdischarges35. The voltage amplitude was set to 6.2 ± 0.2 kV and the fundamental frequency of the sinusoidal signal forming a voltage pulse of variable period was 38 ± 2 kHz. The treated samples were placed on the dielectric layer and were hence in direct contact with NTP. NTP treatment was carried out at three different discharge powers ((24.2 ± 0.2) W, (14.8 ± 0.2) W, and (5.4 ± 0.2) W) determined from Lissajous curves as described previously36. The power dissipated in the device was regulated by setting the period of the voltage pulse. The power system showed some instability of operation leading to changes in the period of the pulse repetition during the measurements. To overcome this issue, we used the concept of duty cycle (i.e., ratio of pulse duration over pulse repetition time).

Ar plasma jet (5)

The Ar plasma jet device developed at Wroclaw University of Science and Technology, Poland is a cylindrical plasma jet with additional Ar gas flow (Ar jet (5)) (Fig. 7). Its main element is an aluminum oxide tube with inner and outer diameters of 1.6 and 5.5 mm, respectively. Two ring brass electrodes are placed on its outer surface, 5 mm apart, and supplied with a HV AC pulse generator (Dora PS, Wroclaw, Poland). Electric discharge develops inside the dielectric tube and the generated NTP is carried out with the Ar flow of 2.5 ± 0.2 L/min. This setup allows for direct treatment of sample surfaces with a plasma plume, the diameter of which decreases with distance from the outlet of the dielectric tube. The used supply voltage amplitude was 5.5 ± 0.2 kV and the fundamental frequency of the sinusoidal signal was 38 ± 2 kHz. NTP exposure was carried out at three different discharge powers (i.e., powers dissipated in the device to generate NTP), as determined using Lissajous curves and regulated by varying the period of the voltage pulse. Similarly to the vDBD (4) device, some instability in the operation of the power supply system (i.e., fluctuation of the pulse repetition time) was observed during the NTP exposure. Therefore, we used the duty cycle parameter to set the operating conditions of the device.

Corona discharge device (6)

The Corona discharge CD (6) device (Fig. 8) developed at the University of Chemistry and Technology, Prague, Czech Republic is a “plug and play” NTP generating device operating in the air37. It is based on a DC bipolar corona discharge with a point-to-ring electrode system. The point electrode is a syringe needle (Medoject 0.6 mm × 25 mm needle) and a brass conical ring electrode approximately 11 mm in diameter is 3.3 mm below. When connected to the HV DC power supply, a negative corona discharge is formed on the tip of the point electrode (connected to the negative terminal of a HV source) and a positive one burns at the edge of the ring electrode (connected to the positive terminal of a HV source), together forming the bipolar corona discharge. The current and voltage of the discharge are 150 ± 20 µA and 7 ± 0.1 kV, respectively, as had been set by precise positioning of the electrodes. The electric system is covered by a tubular 3D-printed PETG (polyethylene terephthalate glycol) core, which makes the device safe and easy to manipulate and operate. The overall arrangement and geometry lead to the creation of an ion wind by ions accelerated in the electric field between the electrodes. It carries the reactive species from the discharge towards the sample and then back to the electrode system through the holes around the ring electrode. Therefore, the atmosphere around the sample is closed (no access to fresh ambient air) and accumulates the reactive species inside the sample chamber. NTP treatment by the CD (6) device is indirect, i.e., there is no direct contact between NTP and the sample, the sample is only impacted by the afterglow (the reactive species generated in NTP).

MiniJet (7)

The MiniJet PM-10.R (MiniJet (7)) device (Fig. 9) is available commercially (Heuermann HF-Technik GmbH, Germany)38, and is operated at the Czech Technical University in Prague in the laboratory PlasmaLab@CTU39. This device is based on the microwave Ar plasma jet. To ignite NTP, a nozzle (6 mm in diameter) is placed inside the starter box, mounted at the side of the chassis, in such a way that the inner electrode gently touches the wire meshwork inserted within. After the power is switched on, the nozzle is slowly pulled out of the box, and the NTP plume forms. The generated NTP is very pure and has a high degree of ionization, as determined by the operating frequency. The MiniJet (7) generator produces a constant and reproducible microwave signal of about 2.45 GHz in the ISM frequency band (reserved for industrial, scientific, and medical use). The working gas is Ar, as guaranteed by the manufacturer. Both the power (ranging between 2 and 10 W) and the flow (up to 3 L/min) can be set at the front panel. NTP temperature and size of the plume are directly proportional to the microwave power and inversely proportional to the gas flow. The schematic of the device is not provided, as it is not available.

Energy deposition (thermograms)

An infrared image (thermogram) was taken for each sample after 30 min of NTP treatment for energy deposition analysis. The infrared camera FLIR E4 2.0 L (Teledyne FLIR), IR resolution of 80 × 60, and accuracy of ± 2 °C, was placed about 20 cm over the sample (facing perpendicular to the sample). The images were processed and the peak temperature was determined using FLIR Tools software (FLIR Systems). Area corresponding to the membrane was selected for the analysis. The temperature scales were adjusted to be identical for all the samples to ensure comparability of the results.

Conclusion

In conclusion, several modifications to the previously published standard protocol were implemented in this study to improve its predictive value and applicability. The presented findings showed the applicability of the modified protocol for a comparison of a wide range of NTP generating devices. The novel approach with centralized testing is possible thanks to the sample robustness and transportability and should open the option of device testing for wide applicability. This type of testing will be easy to implement for the laboratories developing the NTP generating devices as it is simple and not demanding in terms of resources. This extensive comparative study on seven devices provided a valuable overview of their strengths and applicability and also revealed some general trends regarding the sporicidal effect of NTP. It is showing an influence of the type of working gas, while the power and associated deposited energy did not seem to affect the treatment much. The presented protocol addresses the current need in the field for an unbiased comparison between NTP devices developed in different laboratories and its robustness, simplicity, and user-friendliness will open it for wide use in the scientific community.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Scholtz, V. et al. Non-thermal plasma treatment of ESKAPE pathogens: a review. Front. Microbiol. 12, 89 (2021).

Varilla, C., Marcone, M. & Annor, G. A. Potential of cold plasma technology in ensuring the safety of foods and agricultural produce: a review. Foods 9, 1435 (2020).

von Woedtke, T., Emmert, S., Metelmann, H. R., Rupf, S. & Weltmann, K. D. Perspectives on cold atmospheric plasma (CAP) applications in medicine. Phys. Plasmas 27, 070601 (2020).

Boekema, B. K. H. L. et al. A new flexible DBD device for treating infected wounds: in vitro and ex vivo evaluation and comparison with a RF argon plasma jet. J. Phys. D: Appl. Phys. 49, 044001 (2016).

Hahn, V., Brandenburg, R. & von Woedtke, T. Springer, DIN SPEC 91315: a first attempt to implement mandatory test protocols for the characterization of plasma medical devices. In Comprehensive Clinical Plasma Medicine (eds. Metelmann, H. R., von Woedtke, T., Weltmann, K. D.) (2018). https://doi.org/10.1007/978-3-319-67627-2_35.

Mann, M. S., Schnabel, U., Weihe, T. & Weltmann, K. D. & von Woedtke, T. A reference technique to compare the antimicrobial properties of atmospheric pressure plasma sources. Plasma Med. 5, 1 (2015).

Alves, L. L. et al. Foundations of plasma standards. Plasma Sources Sci. Technol. 32, 023001 (2023).

Mann, M. et al. Introduction to DIN-Specification 91315 based on the characterization of the plasma jet kINPen® MED. Clin. Plasma Med. 4, 789 (2016).

Jablonowski, H. et al. Characterization and comparability study of a series of miniaturized neon plasma jets. J. Phys. D: Appl. Phys. 57, 195202 (2024).

Shaw, A., Seri, P., Borghi, C. A., Shama, G. & Iza, F. A reference protocol for comparing the biocidal properties of gas plasma generating devices. J. Phys. D: Appl. Phys. 48, 484001 (2015).

Raguse, M. et al. Improvement of biological indicators by uniformly distributing Bacillus subtilis spores in monolayers to evaluate enhanced spore decontamination technologies. Appl. Environ. Microbiol. 82(7), 2031–2038 (2016).

Ulrich, N. et al. Experimental studies addressing the longevity of Bacillus subtilis spores—the first data from a 500-year experiment. PLOS ONE 13, 12 (2018).

Khun, J., Jirešová, J., Kujalová, L., Hozák, P. & Scholtz, V. Comparing the biocidal properties of non-thermal plasma sources by reference protocol. Eur. Phys. J. D 71, 263 (2017).

Fridman, G. et al. Comparison of direct and indirect effects of non-thermal atmospheric-pressure plasma on bacteria. Plasma Processes Polym. 4, 370–375 (2007).

Georgescu, N., Apostol, L. & Gherendi, F. Inactivation of Salmonella enterica serovar typhimurium on egg surface, by direct and indirect treatments with cold atmospheric plasma. Food Control 76, 52–61 (2017).

Martusevich, A. K. et al. Cold argon athmospheric plasma for biomedicine: biological effects, applications and possibilities. Antioxidants 11, 1262 (2022).

Lou, B-S. et al. Helium/argon-generated cold atmospheric plasma facilitates cutaneous wound healing. Front. Bioeng. Biotechnol. 8, 683 (2020).

Shimizu, T., Sakiyama, Y., Graves, D. B., Zimmermann, J. L. & Morfill, G. E. The dynamics of Ozone generation and mode transition in air surface micro-discharge plasma at atmospheric pressure. New. J. Phys. 14, 103028 (2012).

Lou, B-S. et al. Parameters affecting the antimicrobial properties of cold atmospheric plasma jet. J. Clin. Med. 8(11), 1930 (2019).

De Masi, G., Gareri, C. & Cordaro, L. Plasma coagulation controller: a low- power atmospheric plasma source for accelerated blood coagulation. Plasma Med. 8, 3 (2018).

Brun, P. et al. Antibacterial efficacy and mechanisms of action of low power atmospheric pressure cold plasma: membrane permeability, biofilm penetration and antimicrobial sensitization. J. Appl. Microbiol. 125, 2 (2018).

do Nascimento, F. et al. Plasma electrode dielectric barrier discharge: development, characterization and preliminary assessment for large surface decontamination. Plasma Chem. Plasma Process. 43, 1791–1817 (2023).

Trebulova, K. et al. Antimycotic effects of the plasma gun on the yeast Candida glabrata tested on various surfaces. Plasma Process. Polym. 21(9), 2400057 (2024).

Hrudka, J. et al. Automatic image analysis of the effects of non-thermal plasma on mold growth. In Proceedings of 25th International Symposium on Plasma Chemistry, Kyoto, Japan (2023).

KC, S. K., Sharma, S., Shrestha, R. & Subedi, D. P. Electrical characterization of an atmospheric pressure plasma jet. J. Nep Phys. Soc. 5, 85–90 (2019).

Martines, E. et al. A novel plasma source for sterilization of living tissues. New. J. Phys. 11, 115014 (2009).

Neretti, G. et al. Characterization of a plasma source for biomedical applications by electrical, optical, and chemical measurements. Plasma Process. Polym. 15, 1800105 (2018).

Brun, P. et al. Disinfection of ocular cells and tissues by atmospheric-pressure cold plasma. PLoS One 7(3), e33245 (2012).

Brun, P. et al. Antibacterial efficacy and mechanisms of action of low power atmospheric pressure cold plasma: membrane permeability, biofilm penetration and antimicrobial sensitization. J. Appl. Microbiol. 125(2), 398–408 (2018).

Cordaro, L. et al. On the electrical and optical features of the plasma coagulation controller low temperature atmospheric plasma jet. Plasma 2, 156–167 (2019).

Zampieri, L. & Martines, E. Design and optimization of a radio frequency plasma jet for biomedical applications. In 48th EPS Conference on Plasma Physics (2022). http://ocs.ciemat.es/EPS2022PAP/pdf/P1b.303.pdf.

Hofmann, S., van Gessel, A. F. H., Verreycken, T. & Bruggeman, P. Power dissipation, gas temperatures and electron densities of cold atmospheric pressure helium and argon RF plasma jets. Plasma Sources Sci. Technol. 20, 065010 (2011).

Czapka, T., Maliszewska, I. & Winkler, A. Decontamination of polymeric surgical sutures covered with bacterial biofilms using nonthermal plasma. Plasma Chem. Plasma Process. 41, 227–243 (2021).

Nowinski, D., Czapka, T. & Maliszewska, I. Effect of multiple nonthermal plasma treatments of filamentous fungi on cellular phenotypic changes and phytopathogenicity. Int. J. Food Microbiol. 2(408), 110428 (2024).

Kogelschatz, U. Dielectric-barrier discharges: their history, discharge physics, and industrial applications. Plasma Chem. Plasma Process. 23, 1–46 (2003).

Czapka, T., Maliszewska, I. & Olesiak-Bańska, J. Influence of atmospheric pressure non-thermal plasma on inactivation of biofilm cells. Plasma Chem. Plasma Process. 38, 1181–1197 (2018).

Klenivskyi, M. et al. Portable and affordable cold air plasma source with optimized bactericidal effect. Sci. Rep. 14, 15930 (2024).

MiniJet, Heuermann HF-Technik GmbH. https://hhft.de/10w-minijet (2024).

Brotankova, J., Mlynar, J., Pfeifer, M. & Svoboda, V. Plasmalab@ctu - new facilities in support of fusion education. In 20th Conference of Czech and Slovak Physicists Proceedings 186–187 (2020). https://www.plasmalab.cz.

Acknowledgements

The authors are grateful to Klára Obrová for valuable comments and suggestions during the manuscript revision.

Author information

Authors and Affiliations

Contributions

A.M. designed and conducted the experiments, analyzed and interpreted the acquired data and wrote the main manuscript text. L.Z. designed and constructed one of the NTP generating devices used in the study, contributed to the acquisition of data, drafted part of the manuscript and prepared Figs. 2, 3 and 4. T.C. designed and constructed two of the NTP generating devices used in the study, contributed to the acquisition of data, drafted part of the manuscript and prepared Figs. 5 and 6. J.H. created the Aurora software used in this study and partially analyzed the inhibition zones data. E.V. made substantial contributions to the conception and design of the study and later revised the manuscript. J.K. contributed to the design and constructed one of the NTP generating devices used in the study, contributed to the acquisition of data, drafted part of the manuscript and prepared Fig. 7. E.M. made substantial contributions to the design and construction of three of the NTP generating devices used in the study, contributed to the acquisition of data and drafted part of the manuscript.J.B. provided one of the NTP generating devices used in the work, drafted part of the manuscript and prepared Fig. 8. L.C. made substantial contributions to the design and construction of three of the NTP generating devices used in the study. G.DM. made substantial contributions to the design and construction of three of the NTP generating devices used in the study. V.S. made substantial contributions to the design of one of the NTP generating devices used in the study, helped with data interpretation, revised the manuscript and secured the founding.All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Machková, A., Zampieri, L., Czapka, T. et al. Modified protocol comparing sporicidal activity of different non-thermal plasma generating devices. Sci Rep 15, 7893 (2025). https://doi.org/10.1038/s41598-025-91279-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91279-3

Keywords

This article is cited by

-

Cold Atmospheric Plasma Applications in Viral Inactivation: Systematic Review and Metanalysis

Plasma Chemistry and Plasma Processing (2026)