Abstract

The long ring pommel Dao (a kind of single-edged blade), a significant indigenous Chinese weaponry innovation of the Western Han Dynasty, is researched this study. Employing a comparative research methodology, we conduct a scientific analysis of samples excavated from the tombs of marquisates across various regions of China, spanning from the northern to the southern extremities. This analysis encompasses metallographic examination, inclusion composition analysis, and scanning electron microscopy (SEM), complemented by the application of a metallurgical kinetic model to reconstruct key smelting operations. The semifinished materials of the long ring pommel Dao are sourced from two primary origins: bloomery carburized steel and cast iron-puddling joint decarburization steel (cast iron-Chaogang steel). Both pathways exhibit a predominance of FeOx·SiO2y oxide inclusions. Our investigation particularly emphasizes the Fe2SiO4 inclusions, which have a melting point of 1178℃. By leveraging the length/width ratio of Fe2SiO4 inclusions, we can ascertain whether the smelting process involved an all-liquid phase. Notably, the length/width ratio of Fe2SiO4 inclusions in the cast iron-puddling joint process exceeded 5. Additionally, our findings reveal that during the cast iron-puddling joint decarburization process, when the forging temperature falls below 880℃, the mesh-like Fe2SiO4 inclusions undergo fragmentation. This phenomenon provides crucial insights into the forging system of the Han Dynasty, facilitating a more detailed reconstruction of its metallurgical practices.

Similar content being viewed by others

Introduction

Grand funerals were popular during the Chinese Western Han Dynasty (202 BCE-8 CE), contributing a substantial number of exquisite funerary objects. These artifacts act as a rich source for the study of the political, economic, artisanal, and cultural conditions of the Han dynasty. The Han political structure was a hybrid of the county system and principality system, marquis obey emperor’s order while they also take significant autonomy in their principality. The marquis’ tombs exhibit not only have the hallmarks of royal burials—such as relative uniformity, substantial scale, and abundant grave goods—but also distinct regional cultural attributes. The iron and steel weapons, including Daos (single-edged blades) and Jians (long two-edged blades), unearthed from these tombs were personal possessions of the deceased during their lifetime. The Han Dynasty’s “Wu Le Gong Ming” system, a quality traceability mechanism incorporating all participants from state authorities to workshop workers, ensured that each weapon in the marquis’ tomb was top class quality, reflecting the pinnacle of Han iron and steelmaking technology. During the Han period, iron and steelmaking technologies flourished, characterized by two primary processes: bloomery smelting and cast iron production1,2,3. The bloomery process operated at lower temperatures and did not undergo a complete liquid phase, whereas the cast iron process involved higher temperatures and a complete liquid phase. Semifinished billets were produced through various processes, tailored to the final application of the tools.

The ring-pommel Dao is distinguished by its ring pommel, an element that originated in the pre-Qin period and solidified its basic structural form during the Han Dynasty. During the Warring States period, the size of ring-pommel Dao was relatively small, typically less than 20 cm (approximately one Chinese foot, also known as the one-foot Dao), and was worn vertically at the waist as a utility tool. It could serve as an officer’s eraser for correcting errors on bamboo slips, or a Rong Dao, as a razor for personal grooming. During the Han-Xiongnu conflict, the primary fighting force transitioned to cavalry. In cavalry combat, chopping with swords could cause the wrist or thenar eminence to loosen due to the impact force, potentially resulting in falling the weapons. The extended length ring-pommel Dao began to emerge as a weapon, as soldiers could wrap a short rope or silk cloth around the ring head and tie the other end to their wrist, thereby reducing the risk of weapon loss and maintaining combat effectiveness. The longer ring-pommel Dao, measuring over 60 cm, conferred greater power in pursuing enemies, thus commanding high value. The thick back of the ring head, thin blade, trapezoidal cross-section, and straight or slightly inward-arched body shape were all conducive to chopping and exhibited significant lethality, making it an indisputable battlefield weapon. Long ring-pommel Daos have been discovered in numerous Central Plains tombs, and this study selects one sample from the Mancheng No. 1 Han Tomb4,5, two samples from the Shizishan Han Tomb in Xuzhou6, one sample from the Haihun Principality in Nanchang7, and one sample from the Nanyue Principality in Guangzhou during the reign of Emperor Wu of the Western Han Dynasty8. Due to the geographical isolation of the Nanyue Principality and the complex political relations with the Han Dynasty in the Central Plains, the steel Jian buried with Zhao Mo was also included in our research. Because iron/steel can be corroded after being buried underearth 2000 years, few long-ring pommel Dao can still retain the complete shape and can be sampled. Hence these few samples are very valuable. Metallographic analysis and inclusion studies were conducted on the aforementioned samples, complemented by thermodynamic and kinetic studies of the inclusion growth process, to identify key details of the smelting process of the long ring-pommel Dao.

Selection and analysis of steel sword samples

The selection and analysis of different long ring pommel Daos and long Jians samples as below Figs. 1, 2, 3, 4 and 5. Our group summarized analyzed results are shown in Table 1.

Location of sampled Han tomb8 (The Historical Atlas of China,1996 2nd, https://www.doc88.com/p-0354694199477.html?s=like&id=3).

Long ring-pommel Daos of Shizishan Chu Principality Han tomb in Xuzhou, Jiangsu6.

Ring-pommel Daos and long jians of Nanyue Principality Han tomb in Guangzhou, Guangdong8.

Long ring-pommel Dao of the Haihun Principality Han tomb in Nanchang, Jiangxi7.

In Table 1, metallographic observation can easily determine the carbon content in the sample and make a preliminary judgment of the high carbon iron or low carbon steel sample material organization. The inclusions in the above samples were also analyzed, results are shown in Fig. 6 below.

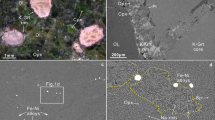

The composition of the inclusions was all FeO · SiO2. There are large-sized inclusions in the core of the Shizishan long ring pommel Dao, which extends in one direction; The Mancheng No.1 Han Tomb long ring pommel Dao also has a large size inclusion in the middle of the blade, with 2.5 mm in length, 0.5 mm in width. The smelting temperature of bloomery ironmaking process is low, and the ferrous oxide-silicate inclusions are mostly large-size spherical. In the sword samples of the Nanyue Principality and the Haihun Principality, the deformation of the inclusions was greater comparing with bloomery products in Fig. 6(a) and(b), and there are also some small spherical inclusions less than 10 μm also appeared. In cast ironmaking process, although the smelting temperature is high it could be uneven in the whole furnace, thus creating both small granular and long mesh inclusions.

Discussion

Carbon content differentiation

The furnace temperature of bloomery ironmaking was about 800–1000 °C (the temperature may reach higher), and the bloomery products was solid bloomery iron with low carbon content. This ironmaking technology is using charcoal combustion to generate CO, and using reductivity of CO to reduce iron trioxide in iron ore to metallic iron, the carbon content of bloomery ironmaking was low, generally less than 0.05% in the liquid state (the carbon content of pure iron/wrought iron can be as low as 0.02%). The product is soft and malleable, thus is not suitable for making Dao/sword materials; hence blacksmiths always forged and repeatedly heated its solid surface to increase carbon after contact with charcoal fire directly, to form the bloomery carburizing steel. The metallographic microstructure of the carburized layer on the surface is mainly ferrite and pearlite, with carbon content raised to about 0.50-0.80%.

Cast iron process was operated at a higher temperature than bloomery ironmaking, which completely melted the iron and produced liquid pig iron. In the Han Dynasty, the main fuel was charcoal, and the corresponding reducing atmosphere was CO. when the temperature in the furnace was above 1200 °C, ore were reduced because of the reaction CO + FexOy=Fe + CO2, and there was also a carburizing process in molten iron. With the increase of carbon content in molten iron, the melting temperature of iron gradually decreased originally 1538 °C, then 1380 °C when the carbon content reached 2.00%, further dropped to about 1200 °C when the carbon content reached 4.00%. Since the liquid cast iron itself has a high carbon content about 2.11-4.0%. If combined with decarbonization methods such as puddling process, the carbon content of the final cast iron product would drop to 0.5–1.2%. For the 0.5–0.8% carbon content of sampled materials, the processing technology needs further research.

Research on FeO·SiO 2 series inclusions

Formation mechanism of FeO·SiO2 series inclusions in ancient Chinese ironmaking & steelmaking process

FeO·SiO2 inclusions are a common and large proportion of inclusions in all Western Han ring-pommel Daos’ samples, regardless of bloomery carburized process or cast iron + puddle process. FeO·SiO2 inclusions were formed from semifinished billet oxidation and following folding forging process. When semifinished billet was exposed in the air during forging process, the oxidation reaction occurs under the 800–1400 °C high temperature, as a result both Fe oxides and Si oxides can exist because the Ellingham standard free energies values of these generated oxidations are all less than 0. and these oxides formation are in order from easy to difficult: SiO2, FeO, Fe3O4, Fe2O3. All phase diagrams in this manuscript were drawn by FactSage 8.0 thermodynamics software and show in Fig. 7. The FactPS, FToxid and FSstel modules in the FactSage 8.0 were used.

In the Fe-O phase diagram of Fig. 7, when the temperature is 800–1200 °C, the oxides that can stably exist with the increase of oxygen content are FeO, Fe3O4 and Fe2O3, and the actual oxidation structure is FeO, Fe3O4 and Fe2O3 from the inside to the outside.

The oxides system is FeO, Fe3O4, Fe2O3, SiO2 and Fe2SiO4 when the steel contains Si elements as shown in Fig. 8. Under the same diffusion driving force, the mass transfer rate of Fe ions in the oxides from high to low is: FeO, Fe3O4 and Fe2O3 as show in Table 2, resulting in the thickest FeO layer and the thinnest Fe2O3 layer in the three-layer structure of iron oxide scale9,10,11. The O diffusion coefficient in the Fe2O3 layer is significantly higher than that of Fe, as this reason the thickening of the Fe2O3 layer mainly depends on O diffusion. the O diffusion coefficient in SiO2 is much smaller than that in Fe oxide, resulting in the slow growth of SiO2. SiO2 could be generated when the semifinished billet is exposed to air but the SiO2 layer would not grow thick. Fe2SiO4 is formed by the depolymerization of FeO and SiO2, according to the order of O content from low to high, the phases that appear in the phase diagram are SiO2, FeO + Fe2SiO4, Fe3O4, and Fe2O3. The actual oxidation structure from the inside to the outside is SiO2, FeO + Fe2SiO4, Fe3O4, Fe2O3.

The bonding energy of the interface is higher than the absolute value of the energy/binding energy released by the free surface bonding, stronger than the bonding capacity between the free surfaces. The ideal binding energy formula is as follows:

E1 and E2 represent the energy of the matrix and oxide layer when they exist alone, E12 represents the total energy of the matrix and the oxide layer after the interface is formed, and A represents the area of the interface between the matrix and the oxide.

We compared the binding energy of Fe/FeO and Fe/FeOi-Si(FeO) interfaces, and the interface energy is significantly enhanced after Si segregation, from − 5.452 J/m2 to -7.848 J/m2.The oxidation activation energy represents the degree of difficulty of the oxidation process of iron and steel products, and in general, the activation energy is calculated from the oxidation weight gain rate constant, and the expression is as follows9:

Q is the oxidation activation energy of iron and steel products, T is the oxidation temperature, R is the gas constant, and A is the model constant.

We applied Yuan‘s method and did dynamic experiment of FeO·SiO2 series inclusion growth at initial stage10, the Oxidative weight of Si-Fe alloy gain rate constants at different temperatures was shown in Table 3. When the temperature was lower than 1150 °C, the oxidation weight gain at the same time was 0.35 > 0.75 > 1.5 > 2.2, and increasing the Si content at this temperature can improve the oxidation resistance of steel products. When the temperature was higher than 1150 °C, the oxidation rate of 2.2Si was the highest, while the melting point of Fe2SiO4 was 1173 °C, which means the mass transfer capacity of melted Fe2SiO4 is greater than that of the solid state, and the liquid Fe2SiO4 is also easier to deform.

In the early stage of high-temperature oxidation of iron and steel products, the partial pressure of oxygen in the atmosphere is greater than that of SiO2 and FexO, so the two oxides nucleate and grow on the surface of steel products simultaneously. As can be seen from the above, FexO is FeO at this time. Since the Fe content in the matrix is much higher than the Si content, FeO grows rapidly, gradually becomes layered, and SiO2 is encapsulated in an iron oxide layer. With the gradual thickening of the FeO layer and the continuous occurrence of the [Si][O] reaction under thermodynamic conditions, the original interface is in an oxygen-poor environment, which forces the FeO at this position to exist stably and decompose [O]. Because the diffusion coefficient of [Si] is smaller than that of [O], [O] diffuses into the matrix, resulting in SiO2 being more inclined to grow longitudinally into the body11. Because the [Si] content in ancient iron and steel products is very low, it is difficult for SiO2 to continue to grow. Due to the abundant supply of Fe, as the oxidation continues, FeO continues to grow, and oxygen is transferred to the original interface, which promotes the oxidation reaction, which is the process of formation of iron oxide scale inclusions in steel.

Division of bloomery ironmaking/ cast iron by FeO · SiO2 series inclusions

After describing the formation mechanism of Fe2SiO4, Fe2SiO4 appeared in the unearthed ring pommel Daos and long Jians, showing different two morphological characteristics, which are large single granular and long mesh. When the smelting temperature is lower than 1150 °C, Fe2SiO4 is in solid state which is not easy to deform under forging, as a result the morphological characteristic is more inclined to single granular. When the smelting temperature is higher than 1150 °C, Fe2SiO4 is in liquid state which can be deformed easily, finally the morphological characteristic is long mesh. The smelting temperature of bloomery is low, and the ferrous oxide-silicate inclusions are mostly large-size spherical, as shown in Fig. 6(a)(b), and the known SEM images of bloomery ironmaking are also used as references, Fig. 10 is the sample of the bloomery carburized steel inclusion area in Mogou Temple, Lintan, Gansu Province12. Figure 11 is the inclusion area of the bloomery carburized steel long Jian in Haihun Principality8. Figure 12 is the short iron sword of Datangcheng in Guiping13 and the Yongchu Dao inclusion area of Cangshan Han Tomb in Fig. 1314. Inclusions in bloomery carburized steels found in a wide area in China also conform to the conclusion that morphological characteristic is more inclined to large single spherical. As the smelting temperature is high yet uneven in the cast furnace, the morphological characteristic of cast iron products is both small granular and mesh, as shown in Figs. 6c and d, 14 and 15. To further describe the morphology of inclusions scientifically, granular and long mesh are distinguished by the length/width ratio. If length/width ratio is greater than 5, inclusions tend to appear in full-liquid deformation phase during the forging process, thus the whole smelting path would be analysed as cast iron process. By comparing the length/width ratio of Fe2SiO4 inclusions, it can distinguish between bloomery iron and cast iron products.

Carburizing steel inclusions in Mogou Temple, Lintan, Gansu Province12.

Morphology of granular ferrous oxide-silicate inclusions of bloomery carburized Jian in the Haihun Principality8.

Morphology of granular ferrous oxide-silicate inclusions in bloomery carburized short steel Jian of Datangcheng in Guiping13.

Morphology of iron-smelting granular ferrous oxide-silicate inclusions in Yongchu bloomery carburized steel Jian of Cangshan Han Tomb14.

Morphology of strips ferrous oxide-silicate inclusions in Lintong Xinfeng pudding steel15.

Morphology of long strip reticulated ferrous oxide-silicate inclusions of long steel Jian in Datang City, Guiping13.

In view of the SEM-EDS observation of the large single ferrous oxide-silicate inclusions, the ferrous oxide-silicate inclusions may be homogeneous “single phase” or staggered “complex phase”. These two situations were caused by the same oxidation under different durations, sharing the same inclusion composition16,17,18.

Effect of phosphorus content of molten steel on the formation of Fe2SiO4 inclusions

Moreover, [P] content in molten steel will also have an influence on decreasing the melting temperature on Fe2SiO4 inclusions. FeO is precipitated first at the beginning of the cooling process, and the amount of primary crystalline FeO increased during the cooling process of molten steel. when the temperature decreased to the binary eutectic point of FeO and Fe2SiO4, Fe2SiO4 began to precipitate. [P] could react with [O] and form P2O5 if molten steel content included [P], and the liquid phase composition moves to the ternary eutectic point at the same time, finally, P2O5 would react with Fe2SiO4 to form Fe3(PO4)2. When the temperature of actual molten steel reduced the FeO-SiO2-P2O5 ternary eutectic point, Fe3(PO4)2 can be precipitated as shown in Fig. 16. The presence of P2O5 will reduce the FeO/Fe2SiO4 inclusions melting temperature, and the melting temperature of FeO/Fe2SiO4 in 1%Si-0.1%P steel would drop from 1178 °C to about 1000 °C. Therefore, FeO/Fe2SiO4 inclusion presents liquid elongated state or mesh situation in cast iron process product. Yang19 and Zhang21 researched Cahogang process, which was a refining process belonging to cast iron process. Chaogang process was after blast furnace, the whole process goes from liquid to solid. and Chaogang process could reduce carbon content in liquid iron to form low carbon steel19,20,21.

Effect of forging temperature on the morphology of Fe2SiO4 inclusions

When the reaction temperature reaches 950 °C, Fe2SiO4 could be found in steel product. In the forging stage, the temperature of semifinished steel billet decreasing consistently, the Fe2SiO4 has a plastic range temperature above 880 °C, this means Fe2SiO4 inclusions can be deformed on the steel billet surface without breaking. while the forging temperature is below 880 °C, the Fe2SiO4 plasticity decreases, and it cannot be well deformed with the steel. Mesh or long strip Fe2SiO4 would be broken in to some small or short pieces16,17,18. We can use this character to further determine the actual forging temperature. The fragmented Fe2SiO4 inclusions are shown in Fig. 17.

Fragmented Fe2SiO4 inclusions8.

Therefore, according to deep research in the morphology types of Fe2SiO4 inclusions, the ironmaking and steelmaking process of long ring pommel Dao and long jian was further distinguished. (1) When a long mesh Fe2SiO4 inclusion with a length/width ratio greater than 5 is found, it means the smelting temperature is higher than 1150 °C, and it is more inclined to cast iron decarburization steel, which is more likely to be the path of cast iron-puddling joint steel. If the mesh or long strip Fe2SiO4 inclusion is broken, there may be a duration that the temperature is lower than 880 °C during the forging process. (2) If there are multiple large-size spherical Fe2SiO4 inclusions, or obvious unreduced iron ore inclusions, then it is a bloomery carburizing steel process.

Research on the development of the ring Pommel Dao in the Han dynasty

During the Warring States period, the primary combat form involved chariots cooperating with infantry, thus they were equipped with Jians for slashing and stabbing. In the Western Han Dynasty, as cavalry combat with the Xiongnu intensified, the long ring pommel Dao began to flourish as they proved to be more effective than Jian in chopping and splitting due to the thicker back of the ring head knife. The Dao did not require sharpening on both edges, making its production cost cheaper than that of the Jian. Given the complexity of ancient swordsmanship, the Dao was easier to learn, which was crucial for reducing soldier training time. For these reasons, the battlefield application of the Dao gradually surpassed the Jian. The late Western Han Dynasty Yinwan Han Tomb unearthed a record titled “wuku yongshi 4th nian bing che qi ji bu (weapons and vehicles collection in arsenal of Yongshi fourth years),” which documented the number of weapons in the arsenal of Donghai County at that time, including 156,135 Daos and 99,901 Jians. Additionally, the number of shields recorded in the instrument collection book matched that of the Jians, suggesting that shield and Jian infantry may have remained standard in the Western Han Dynasty. In the Eastern Han Dynasty, the number of Jians gradually decreased, culminating in the Three Kingdoms period at the end of the Eastern Han Dynasty, when Sun Quan Huangwu five years (226 CE) recorded “made ten Jians, ten thousand Daos,” indicating that the Dao had become the most important battlefield short weapon. Over the 400 years from the Warring States Period to the end of the Eastern Han Dynasty, there was a high probability that there were fewer long Jians and more ring-pommel Daos on the battlefield.

Conclusion

Through the comparative analysis of the long ring pommel Daos and Jians excavated from the Western Han Dynasty marquis ' tombs, it is evident that the semifinished materials for top-class long ring pommel Daos originate from two primary sources: bloomery carburized steel and cast iron-puddling joint decarburization steel. The microstructural uniformity of bloomery carburized steel tends to be relatively poor, resulting in shorter final products. However, the overall organizational uniformity improves when cast iron-puddling joint steel is combined with bloomery carburized steel through folding and forging.

-

(1)

Comparative analysis reveals that the overall carbon content of ring pommel Daos made from bloomery carburizing steel is low, with poor internal structural uniformity. The inclusions are predominantly silicate, and their size is relatively large. In contrast, ring pommel Daos produced with cast iron-puddling joint decarburization steel technology exhibit higher carbon content, superior internal structural uniformity, and smaller Fe2SiO4 inclusions compared to those from bloomery carburizing steel.

-

(2)

To scientifically describe inclusion morphology, granular and mesh-like inclusions can be distinguished by Fe2SiO4 inclusions length/width ratio. If the length/width ratio exceeds 5, the inclusions are likely undergoing full-liquid deformation during forging, suggesting a cast iron smelting process. If the length/width ratio is less than 5, it is possible bloomery iron product.

-

(3)

Judging from the number of iron weapons unearthed, the Western Han Dynasty had mastered the technology of cast iron-puddling joint steel, with its proportion of unearthed objects being larger than that of bloomery carburized steel. Geographically, the long ring pommel Dao in the Central Plains exhibits nearly identical shapes. However, due to the remote location of Guangzhou, despite the kingdom’s proficiency in using cast iron-puddling joint steel to forge long Jians. The unearthed ring-pommel Dao remains in the form of 30-centimeter style of the Warring States period.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Li, Z. The development of iron and steel technology in ancient China (中国封建社会前期钢铁冶炼技术发展的探讨). Acta Archaeol. Sin. (考古学报) 2, 1–22 (1975).

Han, R. A metallographic study on early iron objects of China (中国早期铁器(公元前5世纪以前)的金相学研究). Cult. Relics (文物) 2, 87–96 (1998).

Chen, J. & Zhang, Z. The criteria of ancient Chinese puddling steel technology (基于炉渣分析的古代炒钢技术判定问题). Cult. Relics South. China (南方文物) 01, 115–121 (2016).

Beijing University of Iron and Steel Technology. Metallographic study of the Metal Objects Unearthed from the Han Tomb of Mancheng, in: Institute of Archaeology, Chinese Academy of Social Sciences and Hebei Provincial Institute of Culture Relics (Eds.), Excavation of Han Tomb at Mancheng. Culture Relics. Publishing House, 369e376. 北京钢铁学院金相实验室. 满城汉墓 部分金属器的金相分析报告[M]. 中国社会科学院考古研究所, 河北省文物管理处. 满城汉墓发掘报告. 北京: 文物出版社, 1980: 369e376. (1980).

Institute of Archaeology, Chinese Academy of Social Sciences and Hebei Provincial Institute of Culture Relics. Excavation of Han Tomb at Mancheng. Culture Relics Publishing House (in Chinese). 中国社会科学院考古研究所, 河北省文物管理处. 满城汉墓发掘报告. 北京: 文物出版社, 1980: 369e376. (1980).

Institute of Historical Metallurgy and Materials, University of Science and Technology Beijing. The museum of the Terra-Cotta warriors and horses of Han dynasty, Xuzhou, 1999. Study on iron and steel artefacts unearthed from the Prince’s tomb of the Chu state in Shizishan. Cult. Relics. 7 (7), 84e91 (1999).

Jiang, J. 2022.Scientific Analysis and Research of iron Weapons Unearthed from the Tomb of Liu He, Marquis of Haihun in the Western Han Dynasty. Master Degree. 西汉海昏侯刘贺墓出土铁兵器科学分析研究.

Chen, J. The iron and Steel Technology of Central Plain and North of China during Han and Jin Periods(汉晋中原及北方地区钢铁技术研究) (Peking University Press (北京大学出版社), 2007).

Yuan, Q., Xu, G., Liang, W., He, B. & Zhou, M. Effects of oxygen content on the oxidation process of Si-containing steel during anisothermal heating. Int. J. Min. Metall. Mater. 25, 164–172 (2018).

Liu, X. J. et al. Effect of temperature on scale morphology of Fe1.5Si alloy. J. Iron Steel Res. Int. 20 (11), 73–78 (2013).

Wang, N. et al. Growth rate, microstructure and phase composition of oxide scales for three typical steels in simulated continuous casting process. J. Iron Steel Res. Int. 21 (12), 1065–1072 (2014).

Wen, J. Preliminary study on smelting technology of iron based on the analysis of the ironware unearthed from the Mogou site (2015).

Huang, Q. S. Iron artefacts unearthed from the ancient tombs in the Guangxi Region by metallographical analysis. Chin. Archaeol., 109–114 (2016).

Lu, X. Research on Chinese ring pommel Dao in Han Dynasty. Chin. Archaeol., 72–82 .(2013).

Liu, Y. et al. Scientific analyses of iron objects unearthed from burials of the Qin state in the late Warring-States period at Xinfeng town in Lintong district, Xi’an (陕西临潼新丰秦墓出土铁器的科学分析及相关问题). Archaeol. (考古) 07, 108–116 (2019).

Itoh, H., Hino, M. & Ban-ya, S. Thermodynamics on the formation of spinel nonmetallic inclusions in liquid steel. Metall. Mater. Trans. B. 28 (5), 953–956 (1997).

Yuan, Q., Xu, G., Liu, M., Hu, H. & Tian, J. Effects of rolling temperature on the microstructure and mechanical properties in an ultrafine-grained low-carbon steel. Steel Res. Int. https://doi.org/10.1002/srin.201800318

Nouri, A., Kheirandish, S. & Saghafian, H. A study of redistribution of silicon in dual phase silicon steels. Met. Sci. Heat Treat. 59 (9–10), 569–574 (2018).

Yang, J., Li, Y., Zhao, F. & Lou, P. Experimental studies on the iron objects unearthed from Mapaoquan site in Changping and a discussion of criteria for judging puddling steel (北京昌平马刨泉长城戍所遗址出土铁器的实验研究——兼论炒钢工艺的一种判据). Chin. J. History Sci. Technol. (中国科技史杂志) 2, 177–187 (2014).

Liu, H. F. et al. A view of iron and steel making technology in the Yan region during the warring States period and the Han dynasty: scientific study of iron objects excavated from Dongheishan site, Hebei Province, China. J. Archaeol. Sci. 47, 53–63 (2014).

Zhang, Z. Y. et al. Characteristics of various non-metallic inclusions in ancient cast iron and solid-state decarburized iron products from a government-run iron workshop during the Han dynasty in Dongpingling ruins, Shandong Province. J. Archaeol. Sci. Rep. 46, 103663 (2022).

Acknowledgements

This work was financially supported by National Natural Science Foundation Program of China (52374296). The pictures of ancient swords and ring-pommel were all taken from Institute of Historical Metallurgy and Materials, University of Science and Technology Beijing or Institute of Cultural Heritage and History of Science & Technology. The relevant reference permission has been obtained. This manuscript has not been previously published and is not currently in press, under review, or being considered for publication by another journal. All authors have read and approved the manuscript being submitted, and agree to its submittal to this journal.

Author information

Authors and Affiliations

Contributions

Shenyang Song Wrote this manuscript.Qian Wei supported this manuscript.Xintong Lu and Mokun Shan revised this manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Song, Sy., Qian, W., Lu, Xt. et al. Ironmaking and steelmaking process research on Chinese long ring pommel Dao in Han dynasty. Sci Rep 15, 8277 (2025). https://doi.org/10.1038/s41598-025-92785-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92785-0

Keywords

This article is cited by

-

The exchange of the iron process in the northwest of west han empire: a case study of the Xingfucheng cemetery site, Guyuan, Ningxia, Northwest China, ca. 202 BC-113 BC

Archaeological and Anthropological Sciences (2025)