Abstract

To characterize the dynamic mechanical response and vibration-damping characteristics of a layered rubber core (LRC) in a stand-off damping structure, a series of experiments were carried out and a continuous power-law variable fractional-order Kelvin–Voigt constitutive model (VFKV) is proposed in this study. The nonlinear elastic behaviors of LRC under wide strain rate are fitted by the hyperelastic and the viscoelastic constitutive model, respectively. Firstly, based on the assumption of continuum mechanics, the fitting abilities of six hyperelastic constitutive models, i.e., the modified Mooney-Rivlin model including M-R(2), M-R(3) and M-R(5), Yeoh model, Ogden(2) and Ogden(4) model are compared. Additionally, various integer-order viscoelastic constitutive models, including Maxwell, Kelvin–Voigt (K–V), Poynting–Thomson (P–T), Zener, and Burgers, and constant and variable fractional order viscoelastic constitutive models, were employed to fit and describe the constitutive characteristics of the LRC. Finally, the VFKV model was employed to assess the loss ability for LRC and single-layer rubber, which was validated through the energy method. This confirms the universal applicability of the model. It is concluded that the VFKV model have the highest and relatively stable fitting correlation values for all three LRCs and single-layer rubber, with a fitting deviation below 1%. Thus, this method provides assistance and guidance for the selection of constitutive model to characterize the mechanical behavior of rubber-like materials under wide strain rates. In addition, it can save engineering calculation time by eliminating the establishment of complex structural dynamics equations and interlayer motion transfer equations.

Similar content being viewed by others

Introduction

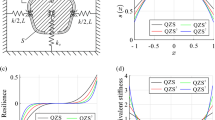

Constrained layer damping (CLD) structures are widely used for vibration isolation in aerospace, bridges, vehicles, and other practical engineering applications, in which the middle core layer (MCL) is often made of one or more different types of rubber-like materials. In this case, the choice of a suitable MCL material is crucial, rubber with a high relative elasticity modulus is always selected as the stand-off layer1, and the damping layer is made by a low relative elasticity modulus rubber2; the above two layers are then bonded together using an epoxy resin bonding-gum to form an LRC, which is a two-layered form of MCL. At this time, a kind of stand-off damping structure will be formed3,4 (see Fig. 1), and it has gained a lot of attention due to its better vibration-reducing properties. To further improve vibration-damping performance of rubber-based structures, the accurate characterization and prediction of rubber’s complex mechanical response under various strain rate applications are necessary, and its accuracy is closely related to the constitutive model used. However, these rubber-like materials are sensitive to strain-rate5,6,7,8. Therefore, the suitable constitutive modelling for layered rubber cores under various strain rates needs to be established, and its mechanical loss properties are still in the initial exploratory stage.

Currently, there are two constitutive models to describe and predict the stress–strain characteristics of rubber-like materials under various strain rate: hyperelastic constitutive models (such as Mooney-Rivlin9,10, Ogden11,12 and Yeoh13) and viscoelastic constitutive models14,15,16. Hyperelastic constitutive models are based on experimental data obtained from quasi-static tests9,11, in which strain energy density functions are used to fit and solve the corresponding model parameters. These parameters are then used to characterize the stress–strain behavior of the materials. Such models are strain-rate independent and thus have limitations when applied to rubbery soft material that exhibit both hyperelastic and viscoelastic characteristics17. Later on, the higher-order models for the nonlinear large-deformation behavior of rubber-like materials were further explored. For example, Li et al.18 improved the Mooney-Rivlin constitutive model and found that the engineering stress and elastic modulus fitted by this model were linearly positively correlated with the strain rate at high strain rates and that the stress–strain response significantly exceeded that under quasi-static conditions. Similarly, Peng et al.19 proposed an anisotropic hyperelastic constitutive model for cord-rubber composites that considered the interaction between the rubber and cord under quasi-static conditions. In addition, İsmail20 developed a strain energy density function with two material parameters based on strain tensor invariants to describe the hyperelastic behavior of rubber-like materials under uniaxial tension, equibiaxial tension, and shear deformation. A literature review revealed that most studies used hyperelastic constitutive models to characterize the quasi-static behavior of rubber-like materials.

The second type of constitutive models is viscoelastic constitutive models, which include both integer-order and fractional derivative constitutive models21,22,23. In low strain rate quasi-static tests, integer-order models describe the material’s linear elastic behavior under minor strains and phenomena like strain softening, strain hardening24,25 under large-deformations, and strain hysteresis26 under cyclic loading. However, they are unable to accurately represent the viscoelastic characteristics of the material in the time domain under high strain rate loading. To address this issue, fractional calculus theory is introduced, and a series of fractional derivative constitutive models have been proposed to describe the hyperelastic deformation, viscoelastic creep, and relaxation behaviors of materials24,25,27. It has been found that variable fractional constitutive models can explain the dynamic mechanical response of materials as the strain rate changes. For example, Yu et al.28 used a linear variable order to describe the relationship between parameters such as the elastic modulus of rubber polymers and strain rate. Wei et al.29 proposed a rate-dependent variable fractional constitutive model applicable over a wide strain rate range using a power function variable order to describe the nonlinear stress–strain response of materials with changing strain rates. Liu et al.24 proposed a viscoelastic constitutive model that accurately predicted the stress relaxation and stress-softening responses of EPDM. The previous literature shows that rubber-like materials exhibit nonlinear large deformation characteristics, with previous research primarily focusing on quasi-static mechanical property analysis. To gain a deeper understanding of the nonlinear responses of rubber, it is essential to expand the strain rate range and investigate its nonlinear stress–strain behavior across a wide spectrum of strain rates. At present, the research in this area is still in its infancy and requires further exploration.

In this study, the LRC as a middle core material used in stand-off damping structures is composed of silicone and fluoro rubber. Three types of LRCs were prepared and tested under varying strain rates with a universal material testing machine and Split Hopkinson Pressure Bar (SHPB). A variable fractional-order constitutive equation was constructed based on the Kelvin model, which is suitable for describing and predicting the mechanical behavior of LRC over a wide range of strain rates. Subsequently, the loss factor of the LRC was derived based on the VFKV constitutive model, providing a rapid and accurate method for estimating the energy dissipation characteristics and stress–strain responses of multi-layer damping structures. The results could provide help for improving vibration-reducing performance of various damping structures. The innovation of this work lies in the development of the continuous power-law variable fractional-order Kelvin–Voigt constitutive model, which universally predicts the mechanical properties of layered and single-layer rubber materials with less than 1% error. The loss factor calculated by the VFKV model also closely aligns with values obtained using the energy method, offering a comprehensive and efficient approach to characterize the dynamic mechanical behavior and energy dissipation of LRC-based damping structures under varying strain rates.

Discussion

Comparison of hyperelastic constitutive models

To identify a constitutive model that can accurately characterize the mechanical properties of LRCs across a wide strain rate, this section compares and analyzes the applicability of different hyperelastic constitutive models in fitting the stress–strain curves of LRCs at both high and low strain rates. Based on the assumption of continuum mechanics, six phenomenological hyperelastic constitutive models were selected to fit the mechanical response of LRCs under quasi-static conditions. Meanwhile, the fitting coefficient R2 is selected as the criterion for evaluating the applicability of the constitutive model. The characteristics, strain energy density function relationship, and stress–strain formula of each constitutive model are shown in Table 4. Among these models, the M-R model was initially proposed by Mooney, with Rivlin9 improving its general form. Subsequently, improved versions such as M-R(2), M-R(3), and M-R(5) were proposed based on the original M-R model. The expression for the M-R model is as follows:

where Cij is a constant and satisfies C00 = 0.

where I1 and I2 represent the first and second principal invariants of the material, respectively.

In this study, the nonlinear curve fitting tool in origin software was used to fit and analyze the stress–strain data obtained from the experiment by using the corresponding constitutive model.

Quasistatic compression

Figures 2, 3 and 4 show the fitting of stress–strain curves of LRCs under various compressive displacements using different constitutive models, it can be observed that the applicability of the constitutive model to the mechanical response curve of LRC varies under different compressive displacements. For these models, the order of prediction accuracy of constitutive models is as follows: Ogden(4) ≈ M-R(5) > Yeoh > Ogden(2) > M-R(3) > M-R(2) (See Figs. 2d, 3d, and 4e). Among them, Ogden(4) and M-R(5) showed the best-fitting effects, and the changes in their correlation coefficients were consistent. When predicting the stress–strain curves of the three types of LRC at the maximum compression displacement, the correlation coefficient value of M-R(5) differs by only 0.01% from that of Ogden(4). This indicates that these two models can accurately fit and predict the static mechanical responses of the three LRCs at low strain rates.

The Yeoh model exhibited high correlation coefficients exceeding 0.97 for three LRCs under different compression displacements, providing an approximately accurate prediction of the static mechanical properties of LRCs. The Ogden(2) model closely follows, with correlation coefficients above 0.95 for all fitted curves, offering an approximate prediction of the stress–strain curves of the three LRCs. The fitting correlation coefficients of M-R(3) changed with compression deformation. At small compression deformations, the fitting effect was similar to that of the Ogden(2) model. However, when the compression deformation increased to 2.4 mm (see Figs. 2c and 3c) or 3.5mm (see Fig. 4d), the model exhibited significant jumping in both the elastic and softening stages, causing a deviation in the trend direction of the latter part of the fitted curve. Furthermore, these jumps and deviations increased with strain, affecting the prediction results and introducing errors.

In addition, It can be observed that the M-R(2) model has the worst fitting and predictive performance, particularly under large compression deformations. As shown in Figs. 2c, 3c and 4d, when the compression displacement far exceeds half of its total thickness, a nonlinear large deformation occurred in LRCs, and there is a significant deviation between the fitting curve of the M-R(2) constitutive model and the original curve. Moreover, the error of the correlation coefficient was positively correlated with compression deformation. As the compression deformation increased, the error in the correlation coefficient and deviation from the original test data also increased. Consequently, this model was unsuitable for LRC prediction.

Concretely, Fig. 2 shows the fitting of the 2F1S stress–strain curve for different constitutive models under different compressive displacements. In the experiment, the compression displacement.

variables of 0.8mm, 1.6mm, and 2.4mm were sequentially changed. In the initial small-strain range, the stress increases linearly with strain, showing an elastic stage, which is most pronounced at a 0.8 mm compression displacement (see Fig. 2a)) Further increasing the strain causes movement of internal chain segments within the LRC, leading to an increase in temperature and a softening phenomenon with stress lagging behind strain. This stage was known as the strain-softening phase, which is particularly evident at a 2.4 mm compression displacement (see Fig. 2c). Following the conclusion of the strain-softening stage, with increasing strain, the stress increases significantly, and its slope was notably greater than that observed during the softening stage. This stage was designated as the strain-hardening phase (see Fig. 2b and c). Subsequently, as the stress gradually increases, the molecular chains begin to misalign or break, resulting in material failure.

And, as shown in Figs. 2b,c, 3b,c, 4b,c and d, when the compression displacement variable exceeded half of the total thickness of LRC, different LRCs experienced four mechanical deformations. Furthermore, as the compression displacement increment increased, the response of the stress–strain curve at each stage also increased accordingly. The stress–strain curves under quasi-static compression tests for 1F2S and 2F2S are also the same (see Figs. 3 and 4) .

From Figs. 2d, 3d, 4e, a correlation can be observed between the order of the hyperelastic constitutive model and its fitting correlation; the higher the order and number of parameters, the better the fitting correlation. This observation was based on the parameter characteristics of the hyperelastic constitutive models in Table 1 considering all discussions and analyses. For instance, the M-R(5) and Ogden(4) models can accurately describe and predict the quasi-static mechanical response of the LRC.

SHPB tests

Figures 5, 6 and 7 illustrate the dynamic response of the three LRCs under different high-strain-rate impacts (1600 s−1, 2600 s−1, 3600 s−1). It can be observed that, under dynamic impact, the fitting situation of each hyperelastic constitutive model is entirely different from that during quasi-static compression. Except for the M-R(5) model, which maintains an approximately accurate fitting prediction effect, the other models show significant variations with no regularity. In particular, the contrast gap in the fitting effects between the Ogden(4) and Ogden(2) models under the two working conditions was noticeable.

Overall, the M-R(5) model demonstrated the best dynamic fitting effect, accurately approximating and predicting the dynamic variation characteristics of the three LRCs. In contrast, the Ogden(2) model exhibited the poorest fitting effect, with the largest coefficient of determination error. Additionally, it shows a linear fit for all three types of LRC, deviating entirely from the experimental stress–strain curve.

In sequence, Fig. 5 illustrates the dynamic impact response of 2F1S. With an increase in strain rate, the range of stress and strain variations also increased. And, the mechanical response intervals at each stage expanded and became more pronounced. For 2F1S, the fitting curves of Ogden(2), Yeoh, M-R(3), and M-R(2) deviated significantly from the original dynamic response curve. As the loading and strain rates increase, the fitting error increases significantly. The Ogden(2) model exhibited the poorest fitting effect, with the largest coefficient error and a linear fitting state that was entirely at odds with the experimental stress–strain curve. Although the Yeoh model can approximate the original data in quasi-static compression, it exhibits opposite fitting effects at high strain rates, accompanied by increased fitting errors, particularly in the context of small strain ranges, where it becomes entirely detached from the test data.

At the same time, the fitting effect of the M-R(2) model and the Yeoh model is approximately the same when the strain range is 0–0.05 (Fig. 5a), and the strain range is 0–0.06 (Fig. 5b and c). As the strain increases, the fitting curves of both models begin to diverge in opposite directions. The mechanical response is in Figs. 5b,c, 6b,c, 7b and c (at strain rates of 2600 s−1 and 3600 s−1), it was found that under large deformations, the M-R(2) model predicted a trend that deviated from the original curve direction and lagged in the mechanical response stage of the original curve. It is worth noting that in these figures, damage failure has already occurred in the original curve, whereas the M-R(2) fitting curve has begun to enter the strain-hardening stage. In contrast, the M-R(3) model has a slightly better correlation than the previous three models; when fitting the dynamic stress–strain curves at different strain rates, the correlation coefficient can reach up to 95%. However, this method could not fully describe the dynamic mechanical responses of composite rubber materials.

By comparing the mean fitting correlation coefficients of the three hyperelastic constitutive models under high strain rates for 1F2S (see Fig. 6), it can be inferred that the fitting correlation order is M-R(5) > Yeoh > M-R(3) > M-R(2) > Ogden(4) > Ogden(2). Similarly, the analysis in Fig. 16 reveals that the fitting correlation order of each model for 1F1S is M-R(5) > M-R(3) > M-R(2) > Yeoh > Ogden(4) > Ogden(2).

Further, A comparison of the fitting correlation coefficients of each hyperelastic constitutive model for the different LRC revealed that the errors in the fitting correlation coefficients of 2F1S and 1F1S were significantly larger than those of 1F2S. The error in the fitting correlation coefficients of each hyperelastic model for 2F1S was the largest, followed by that of 1F1S, the smallest was that of 1F2S. Moreover, the values of the fitting correlation coefficients of all constitutive models were greater than 90% (see Fig. 6). These phenomena are due to the leverage amplification effect of the stand-off layer, which can increase the energy dissipation characteristics of the damping layer. Furthermore, within a specific range, as the thickness ratio between the stand-off and damping layers increased, the shear energy dissipation effect became more significant. When the thickness of the stand-off layer is greater than that of the damping layer (i.e., the elastic modulus of the stand-off layer should be greater than that of the damping layer)31, it enhances the dynamic energy dissipation capability beyond its deformation range for the damping layer. Consequently, the overall mechanical response curve of LRC increased rapidly, resulting in a significant dynamic response.

Therefore, when designing stand-off vibration damping structures, it is essential to study the thickness ratio and material properties of the stand-off and damping layers to control their amplification factors and ensure that the damping layer is in a state of maximum energy dissipation. For example, the thickness of the SR damping layer in 1F2S is twice that of the FKM stand-off layer, which results in a smooth dynamic response with minimal oscillations in the stress–strain variations.

Model selection

Following a comprehensive evaluation of various hyperelastic constitutive models for fitting and predicting the behaviour of LRCs under quasi-static compression and dynamic impact conditions, it was determined that the M-R(5) model exhibited the greatest stability and was capable of approximately describing the stress–strain characteristics of the LRC. Nevertheless, under dynamic impact, the fitting correlation coefficient values have not yet reached the target requirement (> 96%), particularly in the small strain range (transition from the elastic stage to the softening stage), where the fitting curve tends to deviate from the original data as the strain rate increases. Furthermore, hyperelastic constitutive models cannot account for the variation in material parameters at different stages of stress–strain in layered rubber or their physical significance. Consequently, this study seeks to identify suitable models by employing viscoelastic constitutive models to describe the mechanical responses (static and dynamic) of LRCs across a wide range of strain rates.

Comparison of viscoelastic constitutive models

Quasistatic compression

To accelerate research progress, a 2F2S LRC with a stand-off layer-to-damping layer thickness ratio of 1:1 was selected as the experimental group for testing the mechanical properties under quasi-static conditions. Various integer-order viscoelastic constitutive models, including Maxwell, Kelvin–Voigt (K–V), Poynting–Thomson (P–T), Zener, and Burgers, were employed to fit and describe the constitutive characteristics of the LRC. The schematic diagrams and mechanical constitutive equations for each model are presented in Table 2.

From Fig. 8, it is evident that the Burgers model demonstrates superior fitting performance compared to the other models at various compression displacements. It accurately captures the creep and relaxation characteristics of 2F2S. In contrast, both the Zener and P–T models with three parameters exhibited linear fitting, deviating significantly from the original test data curves. For the two classical viscoelastic models under different compression displacements, the K-V model exhibited a linear increasing trend in stress across the entire strain range. However, the fitting curve of the Maxwell model closely resembles the experimental stress–strain curve, particularly at a compressive displacement of 3.5 mm, where the fitting curve coincides with that of the Burgers model. This suggests that the Maxwell model can effectively describe the stress relaxation phenomenon of materials under constant strain loading in the time domain, which is consistent with Baz’s conclusion35.

Therefore, further exploration of the fitting correlation of the Burgers model and other integer-order models under dynamic impact is warranted. The applicability of the Burgers model in high strain rate situations will be observed, and its suitability for describing the dynamic response of other LRC will be investigated after meeting the 2F2S dynamic mechanical properties.

SHPB tests

Figure 9 shows the fitting of various integer-order viscoelastic models to the stress–strain characteristics of 1F1S under the dynamic SHPB impact tests. At different strain rates, only the Burgers model demonstrated the most accurate fit, describing and predicting the dynamic response of 1F1S accurately. In particular, the Burgers model can predict the linear and softening stage characteristics of 1F1S accurately in the initial small-strain deformation region. The Zener model coincided with the trend of the Burgers model only at a strain rate of 1600 s−1. In contrast, the other integer-order models deviated from the original curve, and this deviation became more pronounced as the strain rate increased. At strain rates of 2600 s−1 and 3600 s−1, these models exhibit linear fitting. A comparison of these integer-order models with their fitting under quasistatic compression revealed that Maxwell’s model exhibited the most significant discrepancy in fitting the correlation coefficient, indicating that it is not well-suited for describing material constitutive relationships under dynamic strain loading rates. Considering the universality of the models, further investigation is required to examine the fitting and predictive correlations of integer-order viscoelastic constitutive models, with a particular focus on the Burgers’ model in 2F1S and 1F2S situations.

Figure 10 shows the dynamic mechanical responses of 2F1S at different strain rates. It can be observed that in comparison with other integer-order models. However, the Burgers model has a superior fitting effect, it can accurately describe the dynamic stress–strain characteristics of 2F1S. In particular, during the fitting stage of strain hardening and subsequent mechanical changes, the correlation between the data and the model is significantly reduced, exhibiting a linear increasing trend. One contributing factor is the substantial dynamic stiffness and elastic modulus of the 2F1S LRC, which results in pronounced oscillations during the SHPB impact tests. Consequently, the Burgers model cannot track variable orders.

Furthermore, in comparison with the dynamic fitting of the 1F1S LRC, both the Zener and Burgers models demonstrated consistent trends in variation. Meanwhile, the P–T model exhibited a trend comparable to that of the experimental curve at strain rates of 1600 s−1 and 2600 s−1.

From Fig. 11, it can be observed that, compared with other viscoelastic models, the Zener and Burgers models demonstrated relatively better fitting performance for 1F2S, with consistent fitting curves between the two models.

Comparison of constitutive models

The results of Figs. 9, 10 and 11 indicate that the Zener three-parameter and Burgers four-parameter models of the integer-order viscoelastic model can approximately and stably fit the dynamic response of each compound rubber. However, compared to the original test data, the fitting correlation is low, and the error is significant, indicating that further improvement is necessary. Furthermore, it can be seen from Table 2 that the constitutive equations of both models are based on variants of the integer-order K-V model. Consequently, in the next stage of research, the K-V-based fractional order derivative viscoelastic model will be employed to identify a constitutive model that can accurately describe and predict the dynamic and static mechanical responses of 2F1S LRC, which is the most active in terms of dynamic performance.

As shown in Fig. 12, the spring-dashpot unit is now commonly used to describe the complex nonlinear behaviour of stress and strain instead of the spring and dashpot units33. The constitutive relationship of this unit not only simplifies the number of parameters of the model but is also more applicable. Its fractional-order derivative constitutive relationship is:

where E is the elastic modulus of the material, τ is the relaxation time, t is the loading time, ε(t) denotes the strain, σ(t) denotes the stress, α represents the order of the fractional-order derivative model for viscoelastic unit, which is able to describe the evolution trend of the curve of the complex mechanical properties of the rubber in the process of deformation in time, and it is valued in the range of 0–1. When α = 0, the viscoelastic unit transforms into a linear spring unit, and when α = 1, then it corresponds to a dashpot unit.

According to the Boltzmann superposition principle, the stress response of Eq. (3) can be transformed into:

where Dα represents fractional derivative operator and Γ(•) denotes gamma function.

Because the viscoelastic response parameters of the spring-dashpot unit are time- and strain-rate-dependent, the transformation Eq. (4) can be obtained:

Equation (3) represents the constitutive model referred to as the fractional-order Boltzmann model (FB)14.

Figure 12b shows the physical form of the FKV constitutive model, which is represented by the spring gluing pot element in parallel with the spring. The integer-order constant term dashpot c shown in the figure is converted into a viscoelastic function model containing (E,τ,α). Combining Eq. (5), the FKV model can be obtained as follows:

The mechanical response curves of the 2F1S LRC fitted with the fractional-order FB, FKV model and integer-order Burgers model at a strain rate of 1600 s−1 are shown in Fig. 13a. It can be observed that, in the initial small strain range (i.e., the transition zone between linear and nonlinear stages), the fitting effect of the FB model is superior to the FKV model. Overall, both FB and FKV models exhibited better fitting effects than the Burgers model and were closer to the experimental data. However, some gaps still exist that require further improvement in the fitting correlation. Considering that the fractional order α is related to both time t and strain ε(t), it can be further transformed into α(ε). Based on this consideration, the expression of the fractional variational model is shown in Eq. (7).

where coefficients A, index B, and parameter Z are constants.

As shown in Fig. 13b, the variable-order VFB model of the fractional power law performed better than the constant-order FB model in terms of the fitting effect. In particular, the small strain range can describe entirely the stress–strain response of the LRC. Therefore, the power-law strain variable order can be used to explore the stress–strain relationship of the LRC further, that is, to transform the FKV model into VFKV by modifying Eq. (6).

In addition, the relaxation time τ in the fractional constitutive model decreases with increasing strain rate36,37,38. Therefore, the material’s relaxation time response mechanism can be altered by adjusting the strain rate. Assuming that \(m = \tau \dot{\varepsilon }\), where m is a constant, and considered the influence of strain rate and relaxation time on the elastic modulus based on the VFB model, this approach is referred to as the VFB-1 model in literature29. To more accurately characterise the stress–strain behaviour related to strain rate in LRCs, this study compares the dynamic stress–strain characteristics of 2F1S using the VFB-1 model with those of the VFB and VFKV models. As shown in Fig. 13c, the predicted curves of both VFB-1 and VFB models perfectly coincide with the original data within an applied strain range of 0–0.025, but there is some deviation in subsequent deformation intervals, whereas the VFKV model can accurately predict mechanical properties of 2F1S throughout the entire deformation range. Consequently, it is essential further to extend fractional viscoelastic constitutive models to other strain rates and observe whether they can maintain consistency at levels similar to those in the 1600 s−1.

Model selection

To highlight the fitting and prediction of the fractional-order model (see Fig. 14), this study selected the integer-order Burgers model as the control group and the VFB, VFB-1, and VFKV fractional-order constitutive models as the experimental groups. These four models were then used sequentially to fit the mechanical response of 2F1S at 2600 s−1 and 3600 s−1. The results showed that the fitting correlation of the VFKV model was more significant than those of the other three models, and it could accurately describe the dynamic mechanical properties of 2F1S.

Observing the dynamic response fitting and prediction of the VFB and VFKV models to 1F2S and 1F1S in Figs. 15 and 16, it is evident that, overall, the correlation between the fitting and prediction under various strain rates is higher for the VFKV model than for the VFB model. The VFKV model could accurately fit the original stress–strain curves of both types of LRCs. However, the dynamic response of the LRC is relatively stable, the fitting and prediction performances of the VFB model aligned with those of the VFKV model (see Figs. 15b and 16b). Nevertheless, when a high-strain-rate impact leads to a strain failure stage in the laminated rubber, the VFB model fails to track and fit as effectively as the VFKV model (see Fig. 16c).

To fully demonstrate the applicability of the proposed VFKV model in representing a comprehensive and wide range of strain-rate-related mechanical responses, a detailed verification process is shown in Fig. 17.

Determination of variational fractional order constitutive model

Strain rate characteristics

In this study, the most accurate constitutive model is chosen to fit and predict the dynamic stress–strain response of three LRCs under high strain rates. Firstly, the fitting correlation coefficients of the best fitting hyperelastic constitutive model (M-R(5)) in Section “Materials and manufacturing”, the integer order viscoelastic constitutive model (Burgers) in Sect. 3.2.1, and the fractional order viscoelastic constitutive model (VFKV) in Sect. 3.2.2 were compared. Then, the constitutive model with the best fitting correlation coefficient for different LRCs was selected (see Table 3).

As shown in Fig. 18 and Table 3, the M-R(5) model was selected from the hyperelastic constitutive models, the Burgers model was chosen from the integer-order viscoelastic constitutive models, and the VFKV model was selected from the fractional-order viscoelastic constitutive models. Comparison of fitting correlations coefficient R2 of the three models at the three strain rates, the VFKV model has the highest and relatively stable fitting correlation values for all three LRCs, which is significantly better than the other two models. The error value of the fitting correlation coefficient can be controlled within 1%, allowing for accurate fitting the dynamic mechanical changes in LRC.

However, there are differences in the applicability of the Burgers and M-R(5) models for different layered rubbers. For the 2F1S, the fitting correlation coefficient of the Burgers model was higher than that of the M-R(5) model at strain rates of 2600 s−1 and 3600 s−1. Nevertheless, at a strain rate of 1600 s−1, the fitting correlation coefficient was lower than that of the M-R(5) model by approximately 0.3%. For the 1F2S, all three models had fitting correlation coefficients above 98%, with the VFKV model performing the best, with R2 exceeding 99.6% at all three strain rates. The Burgers and M-R(5) models were only approximately equal to the VFKV model at a strain rate of 1600 s−1, with a difference below 0.3% at strain rates of both 2600 s−1 and 3600 s−1. For the 1F1S LRC, the fitting correlation coefficients for the Burgers model were more significant than those for the M-R(5) model at all three strain rates, with a maximum difference of up to 2% at a strain rate of 2600 s−1. In summary, when comparing the effective average fitting correlation coefficients for each LRC under high strain impact among the three models, their predictive accuracy ranks as follows: VFKV > Burgers > M-R(5).

Figure 19 shows the stress–strain properties of 1F1S predicted by the VFKV model during quasi-static compression. It can be observed that the prediction curve of the VFKV model perfectly matches the original test data, accurately reproducing the mechanical response of 1F1S at the large-deformation compression stages. Compared to the impact at high strain rates, the prediction performance of the VFKV model was even better under quasi-static conditions. This further demonstrates the broad applicability of the VFKV model, not only for predicting the dynamic characteristics of layered rubber at high strain rates but also for extending the quasi-static compression deformation response at low strain rates.

Variational VFKV model

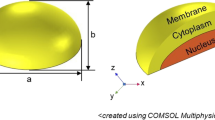

To further validate the broad applicability and generalisation of the VFKV model, it was applied to predict the quasi-static tensile mechanical properties of single rubbers at low strain rates. The quasi-static tensile properties of the FKM and SR were predicted using the VFKV model according to the standards for determining the tensile stress–strain properties of vulcanised or thermoplastic rubbers in ISO 37:2005 and GB/T 528–2009. Three quasi-static tensile strain rates of 0.0017s−1, 0.017s−1 and 0.17s−1 were set, and the correlation between the VFKV model prediction curves and the experimental data was compared.

As shown in Fig. 20, the VFKV model accurately predicted the mechanical properties of the two single-layer rubbers at different quasi-static tensile rates, with a fitting correlation coefficient of 100%. This indicates that the VFKV model has high predictive applicability for composite and single rubber materials. Compared with the prediction effect under a high strain loading rate, the VFKV model exhibits higher stability and accuracy under a low strain rate. This is because the internal molecular structure of the material under high strain rate impacts is in a continuous coupling cycle of freeze–thaw unchaining and reorganisation and is highly influenced by external factors such as temperature and frequency. In conclusion, the VFKV model can approximate, accurately describe and predict the mechanical properties of LRCs over a wide range of strain rates.

Furthermore, the applicability of those hyperelastic and viscoelastic constitutive models mentioned above was analysed, and it was concluded that the M-R(5) fit coefficient was optimal within the hyperelastic constitutive model. In particular, the hyperelastic constitutive model is effective in predicting the strain-softening, strain-hardening, and strain-failure stages. In contrast, the viscoelastic constitutive model has the best fitting effect in a small strain-deformation range, covering both the linear stage and strain-softening transition zone. In addition, the mechanical properties within a small strain range determine the initial trend of the entire curve. Therefore, based on experimental observations and trial-and-error methods, the M-R(5) model was combined with the VFKV model into a piecewise function as follows:

Figure 21 shows the fitting effect of the composite piecewise function. Observing the overall trend of this model, it was found that the function could approximately and accurately predict the nonlinear stress–strain relationship of LRC under various strain rates. However, at the junction point of 0.06, there may be some discontinuities and jumps owing to the mismatched trends of the two piecewise functions.

Prediction of the stress–strain relationship of three LRCs at three strain rates using Eq. (14).

This model is a phenomenological constitutive equation that can be conveniently used as a rapid prediction method in engineering applications. Nevertheless, if one aims to explore the energy-dissipation characteristics of layered damping structures, this model has specific directionality and limitations. This is because it cannot elucidate the relationship between the relaxation time, elastic modulus, damping coefficient, and fractional order concerning the strain rate within a wide range of strain loading rates, thus failing to reveal the dynamic behavioural characteristics of the LRC. Consequently, it is not applicable, and VFKV models should still be chosen for research purposes.

Energy consumption characteristics of layered rubber core

To obtain the vibration reduction characteristic of three types of LRCs, the energy method and the VFKV model were used. Table 4 lists the loss factor of each LRC and single-layer rubber FKM and SR at 0.5 Hz. The loss factor derived from the VFKV model is given as follows:

where E″ represents the energy dissipation modulus, E′ represents the energy storage modulus, α represents the order, and w is the angular frequency.

Based on the data in Table 4, the loss factors obtained by the two methods were approximately equal, thereby proving the effectiveness of the VFKV model. Moreover, it is worth noting that compared to single-layer rubber, LRC not only reduces thickness, but also significantly increases its loss factor. It demonstrates the ability of the stand-off layer to enhance the shear energy dissipation in the damping layer. Furthermore, the thickness of 1F1S is half of FKM and SR, but its loss factor is approximately 3.3 times that of FKM and 2.5 times that of SR. And, the thickness of 2F1S is 0.8 times that of FKM and SR, while the loss factor of 2F1S is approximately 3.7 times that of FKM and 2.8 times that of SR. The thickness value of 1F2S is also 0.8 times that of FKM and SR, and its loss factor value is 3.16 times that of FKM and approximately 2.36 times that of SR. Therefore, using LRC as the MCL can not only reduce the size and weight of the structure, but also improve its vibration reduction and energy dissipation performance. In addition, from Table 7, it can be seen that the ranking of LRC loss factor values is: 2F1S > 1F1S > 1F2S, that is, the loss factors of 2F1S, 1F1S and 1F2S are 0.4714, 0.4276 and 0.3983, respectively. This is because the thickness ratio of the stand-off layer to the damping layer affects the storage modulus and dissipation modulus of LRC.

Method

Materials and manufacturing

The rubber specimens and their cross-sections are shown in Fig. 22. Here, fluoro rubber (FKM) and silicone rubber (SR) used in this work were purchased from Hebei Lanhui Rubber Science and Technology Co., Ltd. The thicknesses of these rubber materials are divided into two sizes: 2 mm and 1 mm, with an error of less than 0.05 mm. Rubber specimens with diameters of 8 mm were cut using a cylindrical cutter and hammer. These specimens were obtained from various precut and moulded rubber sheets.

Preparation of layered rubber core

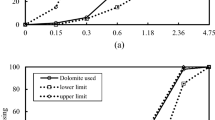

Figure 23 provides the stress–strain characteristics of two rubbers under quasi-static tensile loading, from which the elastic modulus, coefficient of viscoelasticity, and other mechanical parameters of the rubbers are obtained, as shown in Table 5. Owing to the friction between the specimen and plate, the rubber shows apparent tubular shrinkage during the quasi-static compression test3,30,31,32, which is determined to be approximately incompressible, and the Poisson’s ratio of each rubber is 0.499. Similarly, Young’s modulus of FKM is larger than that of SR.

To perform the characteristics of the LRCs used in the stand-off damping structure4, the SR, Bonding gum (B-G), and FKM are sequentially stacked and combined to form an LRC in which the B-G is bonded using a unique adhesive for fluororubbers (the composition of which includes an epoxy resin, a natural rubber liquid, a coupling agent, and a curing agent) by means of cold vulcanisation. This study ignored the influence of adhesive.

The fabrication process of the FKM-SR is illustrated in Fig. 24. During the preparation, the surfaces of each rubber layer were polished and examined for smoothness and roughness. Subsequently, the bottom layer of FKM was placed in a unique mould and coated with an adhesive, followed by rapid stacking of SR. The alignment of the two rubber layers was then checked to ensure a complete overlap. Upon adjustment, cold vulcanisation was initiated, accompanied by applying a constant pressing force. After a five-minute interval, the adhesion state at the bonding surface was observed to confirm the stability of the bonding layer. The compression pressure was subsequently increased and maintained for three hours. During this period, the adhesion and shape were inspected, after which sanding and shaping were performed to prepare for the subsequent impact testing phase.

Figure 25 shows a schematic of different LRCs, along with the front and top views of the specimens. At the same time, Table 6 lists the names of the three LRCs designed in this study, the thickness ratio between the stand-off and damping layers, the weight share (percentage) of the material in each layer, and the total thickness.

Experimental procedures

Quasi-static and cyclic loading compression tests

In this study, quasi-static uniaxial compression and cyclic loading compression tests of the three different LRCs were performed using an double-column electronic tensile compression universal material testing machine, as shown in Fig. 26. The upper and lower loading heads of the tester were equipped with 500N pressure transducers with a measurement accuracy of 1/1000N. The geometry and shape of the specimens, as well as the test procedure for the uniaxial compression tests, were performed in accordance with relevant international standards, namely ISO 23,529:2004 and ISO 37:2005. In this experiment, the thickness of the LRC was varied at a constant loading rate, using material thickness as the compression variable to observe the stress–strain characteristic. Because 1F1S had a total thickness value of 2.1 mm, its compression value had a limited range of variation. Therefore, to perform quasi-static compression tests, 1F1S was scaled up by a factor of 2, resulting in the use of 2F2S. Details regarding the compression-displacement loading of each LRC are provided in Table 7.

In addition, cyclic loading compression tests were conducted on different layered rubber cores according to the loading steps specified in GB/T 7757-2009/ISO 7743:2007 at a loading rate of 10 mm/min. Both quasi-static tests were performed at room temperature (23℃), with each set of test designs including three samples, the average value was taken as the final result.

Figure 27 shows the stress–strain hysteresis curves of the 2F2S subjected to cyclic loading. From Fig. 27 a hysteresis effect was observed between the strain and stress. One of the important dynamic mechanical response characteristics for the evaluation of the LRC is the energy-dissipation properties. Here, WL and WU represent the values of the energy changes during the loading and unloading of the LRC, respectively. The energy-dissipation equation is given as follows:

where E’ represents the energy storage modulus of the material; η is the loss factor, which is used to evaluate the viscoelastic vibration reduction characteristics of the material. \(\Delta W = W_{L} - W_{U}\) represents the energy lost by the material doing work in the period, and \(W_{st} = W_{U}\) represents the material storing energy in the period.

SHPB tests

Given the strain-rate effect on rubber-like materials10, it is evident that their mechanical response varies with the strain rate. Therefore, it can be inferred that the dynamic mechanical properties also change at different strain rates. Consequently, to accurately assess the mechanical response of LRC, it is essential to focus on the stress–strain behaviour of the material at both low and high strain rates.

As shown in Fig. 28, high-speed impact tests were conducted using a Hopkinson Shock Compression Bench. In Fig. 28b, the components of the test system are illustrated, including the air pump, air gun, launch controller, velocity sensor, striker bar, incident bar, transmission bar, strain gauges, and data acquisition device. The transmission, incident, and reflector rods in the system were constructed from a low-impedance aluminium alloy with a diameter of 14.5 mm. This material possesses a modulus of elasticity of 75 GPa, yield strength of 200 MPa, density of 2.8 × 103kg/m3, Poisson’s ratio of 0.3, and longitudinal wave speed of 4982 m/s33,34.

At the start of the test, the air pump was initiated, and the air gun was filled with an air supply. After that, the data acquisition interface of the upper computer was opened, and the data acquisition equipment was zeroed to ensure that the striker, incident and transmission bars were concentric. Furthermore, it was necessary to ascertain that the specimen was positioned in the centre between the incident and transmission bars and that the three were in close proximity to each other. Finally, the placement of the velocity sensor was verified.

Figure 29 illustrates the principle of the SHPB test, demonstrating the process of stress-pulse transmission in each bar and between the specimens. The desired strain-loading rate was achieved by adjusting the firing pressure of the air gun, which propelled the striker bar to attain the initial velocity. The high-speed shock wave is then transmitted from the striker bar to the incident bar, resulting in the generation of a first signal pulsed wave associated with the incident strain εI(t), as measured by resistive strain gage I. Due to an impedance mismatch between the bar and specimen material, the first pulse wave is directly reflected to the incident bar, generating reflected strain εR(t). Meanwhile, the remaining waves pass through the specimen; a portion enters the transmission bar after being reflected on the contact surfaces of the specimen and transmission bar (as shown by the second reflected pulse in Fig. 28, producing the transmitted strain εT(t) captured by the semiconductor strain gauge. The portion that entered the transmissive bar oscillated with time before disappearing, whereas the other part propagated back and forth inside the specimen until it ultimately failed owing to damage.

Figure 30 illustrates the waveform signals of the input and output pulses of different layered rubber cores at a strain rate of 1600 s−1, as well as the equivalent equilibrium relationship of the waveforms among the incident, reflected, and transmitted pulses. It can be observed that the superimposed waveforms of the incident and reflected pulses match well with the waveform of the transmitted pulse. This indicates that the different LRCs structure specimens in this study reached the stress equilibrium condition, which is consistent with the one-dimensional elastic wave theory and the assumed theory of stress uniformity. Therefore, the strain rate, strain, and stress of the specimens at different loading speeds were calculated as follows:

where C0 represents the one-dimensional elastic wave velocity of the compression bar,\(C_{0} = \sqrt {{{E_{0} } \mathord{\left/ {\vphantom {{E_{0} } {\rho_{0} }}} \right. \kern-0pt} {\rho_{0} }}}\); E0 and A0 represent the modulus of elasticity and cross-sectional area of the compression bar, respectively; As and Ls represent the instantaneous cross-sectional area and instantaneous length of the specimen, respectively.

Conclusion

To accurately characterize the mechanical properties of layered rubber cores (LRCs), this study focused on identifying constitutive models capable of precisely representing both their static and dynamic mechanical responses. This effort involved calibrating and comparing the fitting correlations of various hyperelastic and viscoelastic models under both quasi-static low-strain-rate and high-strain-rate dynamic impact conditions (1600 s−1, 2600 s−1, and 3600 s−1). The key findings of this research are summarized as follows:

-

(1)

At high strain rates, hyperelastic models with more parameters and higher polynomial orders, such as M-R(5), demonstrated superior stability and fitting performance. In contrast, integer-order and constant fractional-order viscoelastic models performed best within the small strain deformation range, covering both the linear phase and strain softening transition. The mechanical characteristics observed in this small strain range were found to play a crucial role in determining the initial trajectory of the entire stress–strain curve, thus influencing the overall dynamic response of the LRCs.

-

(2)

A continuous power-law fractional derivative model (VFKV) was proposed to address the complexities of LRCs’ mechanical behavior. This model offers both universality and generalization, effectively characterizing the nonlinear mechanical properties of layered rubber in small strain stages and tracking the strain–stress characteristics across large deformations under dynamic impact. Importantly, the fitting average errors for various LRC configurations and single-layer rubber remained consistently below 1%, ensuring a high level of accuracy in predicting their dynamic performance.

-

(3)

In terms of vibration reduction, parameters such as the loss factor, derived from the VFKV constitutive equation, showed excellent alignment with values obtained through energy-based methods. The loss factor for LRCs was significantly higher than that of single-layer rubber, owing to the stand-off layer, which enhances shear energy dissipation within the damping structure. Specifically, the loss factors for the 2F1S, 1F1S, and 1F2S configurations were found to be 0.4714, 0.4276, and 0.3983, respectively. These results underscore the superior damping performance of LRCs in comparison to single-layer rubber materials.

By addressing the limitations of traditional models and introducing a more refined fractional-order approach, this study contributes to the development of an advanced constitutive framework that can accurately capture the static and dynamic mechanical responses of LRCs. This work provides valuable insights for the optimization of damping structures in various high-performance engineering applications, where both steady-state and transient mechanical behaviors need to be considered.

Data availability

All data generated or analysed during this study are included in this published article.

Code availability

All the software used in this paper are open commercial software, such as ANSYS APDL, Origin, Matlab.

References

Kumar, S., Kumar, R. & Sehgal, R. Enhanced ACLD treatment using stand-off-layer: FEM based design and experimental vibration analysis. Appl. Acoust. 72(11), 856–872 (2011).

Yan, B. J. et al. Damping characteristic analysis and application of a tubular stand-off-layer sandwiched structure. Noise Control Eng. J. 65(6), 522–530 (2017).

Zhiying, R. et al. Research on mechanical properties of metal entangled structure-silicone rubber composite vibration damping materials. Polym. Compos. 44(3), 1967–1979 (2023).

Yellin, J. M. et al. An analytical and experimental analysis for a one-dimensional passive stand-off layer damping treatment. J. Vib. Acoust. 122(4), 440–447 (2000).

Mordvinkin, A. et al. Hierarchical sticker and sticky chain dynamics in self-healing butyl rubber ionomers. Macromolecules 52(11), 4169–4184 (2019).

Yoon, B. et al. Dynamic viscoelasticity of silica-filled styrene-butadiene rubber/polybutadiene rubber (SBR/BR) elastomer composites. Compos. Part B: Eng. 187, 107865 (2020).

Jiang, Y. et al. Compressive behavior of rubberized concrete under high strain rates//Structures. Elsevier 56, 104983 (2023).

Wang, Y. et al. Enhancing the thermal and electrical conductivities of silicone rubber composites by constructing a 1D–3D collaborative network. Polym. Compos. 43(8), 5640–5648 (2022).

Zhao, W. et al. Internal resonance characteristics of hyperelastic thin-walled cylindrical shells composed of Mooney-Rivlin materials. Thin-Walled Struct. 163, 107754 (2021).

Tang, H.-D. & Zhu, M.-L. A nonlinear breakage mechanics model: from extreme entire life model to breakage evolution of limestone based on separation of Helmholtz free energy under cyclic loading. Int. J. Geomech. 25(2), 04024336 (2025).

Anssari-Benam, A. & Horgan, C. O. A three-parameter structurally motivated robust constitutive model for isotropic incompressible unfilled and filled rubber-like materials. Eur. J. Mech.-A/Solids 95, 104605 (2022).

Saidou, A. et al. High-order finite element model of bridge rubber bearings for the prediction of buckling and shear failure. Eng. Struct. 240, 112314 (2021).

Zoghi, S., Naderi, G. & Shokoohi, S. An investigation into hyper-elastic behavior of BR/epoxy-polyester hybrid/nanoclay nanocomposites. Polym. Compos. 39(S4), E2028–E2035 (2018).

Pan, Y. & Zhong, Z. A viscoelastic constitutive modeling of rubber-like materials with the Payne effect. Appl. Math. Model. 50, 621–632 (2017).

Meng, R., Yin, D. & Drapaca, C. S. A variable order fractional constitutive model of the viscoelastic behavior of polymers. Int. J. Non-Linear Mech. 113, 171–177 (2019).

Xu, B., Blok, R. & Teuffel, P. An investigation of the effect of relative humidity on viscoelastic properties of flax fiber reinforced polymer by fractional-order viscoelastic model. Compos. Commun. 37, 101406 (2023).

Luo, R. K. et al. An energy dissipation approach on complete loading-unloading and dynamic impact predictions with experimental verification for rubber anti-vibration component. Polym. Test. 63, 314–322 (2017).

Li, J. et al. Mechanical properties and constitutive model of aluminum powder/rubber matrix composites compressed at various strain rates. Int. J. Impact Eng. 121, 55–62 (2018).

Peng, X., Guo, G. & Zhao, N. An anisotropic hyperelastic constitutive model with shear interaction for cord–rubber composites. Compos. Sci. Technol. 78, 69–74 (2013).

Külcü, İD. A hyperelastic constitutive model for rubber-like materials. Arch. Appl. Mech. 90(3), 615–622 (2020).

Kuteneva, S. V. et al. Microstructure and properties of layered metal/rubber composites subjected to cyclic and impact loading. Compos. Struct. 285, 115078 (2022).

López-Campos, J. A. et al. Behavior characterization of visco-hyperelastic models for rubber-like materials using genetic algorithms. Appl. Math. Model. 66, 241–255 (2019).

Narayanan, P., Pramanik, R. & Arockiarajan, A. A hyperelastic viscoplastic damage model for large deformation mechanics of rate-dependent soft materials. Eur. J. Mech.-A/Solids 98, 104874 (2023).

Liu, X. et al. A visco-hyperelastic constitutive model to characterize the stress-softening behavior of ethylene propylene diene monomer rubber. Polymers 15(16), 3388 (2023).

De Angelis, F. et al. The influence of loading rates on hardening effects in elasto/viscoplastic strain-hardening materials. Mech. Time-Depend. Mater. 22, 533–551 (2018).

Cai, W. & Wang, P. Rate-dependent fractional constitutive model for nonlinear behaviors of rubber polymers. Eur. J. Mech.-A/Solids 103, 105186 (2024).

Oman, S. & Nagode, M. Observation of the relation between uniaxial creep and stress relaxation of filled rubber. Mater. Des. 60, 451–457 (2014).

Yu, P. et al. A macro-damaged viscoelastoplastic model for thermomechanical and rate-dependent behavior of glassy polymers. Macromol. Mater. Eng. 301(4), 469–485 (2016).

Bezazi, A. & Scarpa, F. Mechanical behaviour of conventional and negative Poisson’s ratio thermoplastic polyurethane foams under compressive cyclic loading. Int. J. Fatig. 29, 922–930 (2007).

Manconi, E. & Mace, B. R. Estimation of the loss factor of viscoelastic laminated panels from finite element analysis. J. Sound Vib. 329(19), 3928–3939 (2010).

Yan, B. et al. Dynamic characteristics analysis of tubular stand-off-layer sandwiched structure used in driving sprocket. Int. J. Heavy Veh. Syst. 29(2), 163–179 (2022).

Zhao, Z. et al. Optimization design of vibration reduction structure of driving sprocket based on niche adaptive genetic algorithm. Int. J. Acous. Vib. 27(2), 162–171 (2022).

Qin, Y. et al. Response of fractional Maxwell viscoelastic oscillator subjected to impact load. J. Chin. Inst. Eng. 43(8), 742–751 (2020).

Qin Yuan. Study on distributed order damping dissipation characteristics of viscoelastic buffer system under dynamic service conditions. Taiyuan University of science and technology, 2021.

Baz, A. M. Active and passive vibration damping (John Wiley & Sons, 2019).

Gao, Y., Yin, D. & Zhao, B. Fractional description for the rate-dependent viscoelastic response of tough hydrogels. Polym. Adv. Technol. 33(9), 2708–2719 (2022).

Tang, H.-D. & Zhu, M.-L. Energy evolution and nonlinear breakage constitutive model of granite influenced by non-uniformity of crystal combinations under cyclic loading. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-04307-5 (2025).

Wismans, M. et al. A macroscopic viscoelastic viscoplastic constitutive model for porous polymers under multiaxial loading conditions. J. Mech. Phys. Solids 183, 105499 (2024).

Acknowledgements

The work described in this paper was supported by Natural Science Foundation of China project (Grant No.52302475), Shanxi Province Graduate Innovation Project(Grant No.2022Y672) and Fundamental Research Program of Shanxi Province(Grant No.202203021212317).

Author information

Authors and Affiliations

Contributions

Z.Z.: Writing—review & editing, Writing—original draft, Software, Methodology, Investigation, Experiments, Conceptualization, Data curation, Validation. W.M.: Conceptualization, Methodology, Data curation, Writing—review and editing. B.Y.: Writing—review & editing, Writing—original draft, Project administration, Conceptualization, Methodology, Formal analysis.Guansen Qiao:Writing—original draft, Experiments, Resources, Investigation, Formal analysis, Data curation, Conceptualization. Y.Q.: Writing—review & editing, Funding acquisition, Experiments, Project administration, Investigation. Y.W.: Writing—review & editing, Experiments, Methodology, Investigation. Tao Yang:Writing—review & editing, Investigation, Methodology. H.R.: Writing—review & editing, Investigation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, Z., Meng, W., Yan, B. et al. Mechanical constitutive model of stand off damping composites layered rubber core under wide strain rates. Sci Rep 15, 10516 (2025). https://doi.org/10.1038/s41598-025-93910-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-93910-9