Abstract

Microbial lipases could be used to hydrolyze or recombine fats and oils, and had great applications in food processing, bioenergy and chemical industry. Mucor circinelloides was an important gamma-linolenic acid producing strain, and its genome was predicted to contain a large number of genes encoding lipases, the key enzymes in lipid metabolism. In the present study, a potential lipase WJ_23 from Mucor circinelloides WJ11 was cloned for the first time and heterologously expressed and purified to homogeneity in Pichia pastoris. By SDS-PAGE analysis, the molecular weight of the recombinant lipase was estimated to be ~ 34 kDa. The optimal temperature and pH of the recombinant lipase were 50 °C and 9.0, respectively. The recombinant lipase had good thermal stability at 50 °C with a broad pH stability from 6.0 to 11.0. After incubation at 37 °C for 24 h, the activity of the recombinant lipase remained over 95% between pH 7.0 and 9.0. The recombinant lipase possessed a preference for the long chain substrates. Using p-NPP as substrate, the measured kinetic parameters Vmax and Km were 94.34 U/mg and 6.37 mmoL/L, respectively. In addition, the activity of the recombinant lipase was not affected obviously by various metal ions, and it exhibited certain stability and tolerance towards several kinds of organic solvents. This research might provide a basis for the further industrial application of recombinant M. circinelloides lipase.

Similar content being viewed by others

Introduction

Lipase, also known as triacylglycerol acylhyrolase (EC3.1.1.3), can not only catalyze ester hydrolysis and transesterification, but also catalyze ester synthesis, acid hydrolysis and alcoholysis1,2. As a multifunctional hydrolase, lipase has been widely applied in food processing, bioenergy and and chemical industry1,3. Lipases are commonly found in animals, plants and microorganisms, and there are many kinds of lipases derived from microorganisms1,3,4. Although the information about the genes and proteins of microbial lipases has been relatively abundant, the types of lipases with strong vitality, good stability and wide action conditions used in food processing, oil industry and other fields are still limited.

The oleaginous fungus Mucor circinelloides was the first strain to commercially produce lipids rich in gamma-linolenic acid (GLA), an ω-6 polyunsaturated fatty acid with a variety of bioactive functions5,6. Meanwhile, M. circinelloides could grow well on the medium containing triglycerides, suggesting that the fungus might be a potential lipase producer7. Previously, a few studies focused on whole-cell catalysis of ester synthesis, catalysis and transesterification using immobilized M. circinelloides, which indicated that a certain amount of lipase could be synthesized effectively in M. circinelloides cells, but only one lipase had been reported in M. circinelloide (orginally named as Mucor javanicus)8,9,10. Recently, our comparative analysis of genomes found that M. circinelloides contained a large number of genes encoding lipases, including potential secretory lipase genes11. And we have proved that the lipases Lip 10 and Lip 6 from M. circinelloides poessesed dual-function of lipase and acyltransferase activities12,13. However, the exact biological roles of most of M. circinelloides lipases during lipid metabolism and their potential application remain unclear.

In the present study, the lipase WJ_23 from M. circinelloides WJ11 has been selected for study because it was found to be a secreted protein with high transcriptional level11. The typical yeast expression system Pichia pastoris, widely used in enzyme industry to produce recombinant proteins, has been the first choice for expressing heterologous proteins because of its high yield and high secretion efficiency. This paper reported the cloning of the cDNA sequence of the lipase WJ_23 gene from M. circinelloides WJ11 and its expression as a secreted protein in P. pastoris. Additional, the recombinant lipase was purified to homogeneity and the biochemical charaterization was also performed in detail. This research provides a theoretical basis for the further application of lipase in M. circinelloides.

Materials and methods

Strains, plasmid and chemicals

The strain M. circinelloides WJ11 (CTCC No. M2014424) with established lipase activity was previously stored in our lab. The plasmid pPIC9K and P. pastoris GS115 obtained from Invitrogen were used for heterologous expression in P. pastoris. p-Nitrophenyl butyrate (p-NPB) and p-Nitrophenyl palmitate (p-NPP) was obtained from Seebio Biotech. Inc. (Shanghai, China).

Medium and culture conditions

The K&R culture medium for M. circinelloides WJ11 consisted of glucose 30 g/L, yeast extract 1.5 g/L, ammonium tartrate 3.3 g/L, Na2HPO4 2.0 g/L, KH2PO4 7.0 g/L, MgSO4·7H2O 1.5 g/L, FeCl3·6H2O 0.008 g/L, CaCl2·2H2O 0.1 g/L, CuSO4·5H2O 0.0001 g/L, MnSO4·5H2O 0.0001 g/L, ZnSO4·7H2O 0.001 g/L, Co(NO3)2·6H2O 0.0001 g/L. The spore suspension (approx. 107 spores/mL) from the wild strain M. circinelloides WJ11 was cultured in 150 mL of K&R medium in a 1 L flask and shaken at 150 rpm at 30 °C for 24 h, and then the mycelium was collected for lipase cDNA gene extraction.

Pichia pastoris harboring recombinant plasmid was inoculated into 50 mL of BMGY medium (yeast nitrogen base 13.4 g/L, glycerol 10 g/L, yeast extract 10 g/L, peptone 20 g/L, biotin 4 × 10–4 g/L, potassium phosphate buffer solution 0.1 mol/L, pH 6.0) in a 250 mL flask at 200 rpm and 28 °C for 24 h. Then, BMGY solution was centrifuged at 5000 r/min at 4 °C for 5 min, and all the precipitated thallus were collected. The thallus was re-suspended with 25 mL BMMY medium (yeast nitrogen base 13.4 g/L, peptone 20 g/L, yeast extract 10 g/L, biotin 4 × 10–4 g/L, potassium phosphate buffer solution 0.1 mol/L, methanol 50 mL/L, pH 6.0) and placed in 250 mL triangular bottles for culture at 28 °C and 200 r/min for 120 h. During the induction of expression, 0.5% sterile methanol was added to the medium every 24 h.

Gene cloning of M. circinelloides lipase

The partial cDNA sequence of the lipase WJ_23 (evm.model.scaffold00001.31) from M. circinelloides WJ11 excluding its signal peptide and propeptide fragment was cloned by RT-PCR. The total RNA of M. circinelloides WJ11 was extracted with Trizol (Invitrogen) and then reverse-transcribed using Prime Script™ RT reagent Kit (TaKaRa). RT-PCR was performed using the forward primer (5′–3′: GAATTCGCTCCAGCTTCTTCTTCTCA) and the reverse primer (5′–3′: GCGGCCGCTTAGTGGTGGTGATGGTGATGCAGACACAA ACC) with restriction sites EcoR I and Not I at the 5′- and 3′- ends, respectively. The PCR process was performed by 30 continuous cycles as follows: denaturation at 94 °C for 30 s, gradient annealing for 30 s at an interval of 1 °C from 63 °C to 55 °C and extension at 72 °C for 60 s. The PCR product was purified and digested with EcoR I and Not I, and then ligated into pPIC9K. The constructed plasmid was verified by enzymatic restriction and sequencing analysis.

Expression of lipase in P. pastoris

The correct recombinant plasmid was linearized by Sac I, and then electrotransformed into P. pastoris GS115. The voltage was 1.5 kV and the shock time was 4–10 ms. The transformants were screened on MD agar plates (yeast nitrogen base 13.4 g/L, glucose 20 g/L, biotin 4 × 10–4 g/L, agar 20 g/L) at 30 °C for 2–4 days. The MD medium is characterized by a lack of certain essential nutrients, such as adenine and histidine, and therefore can only support the growth of inverters that are capable of synthesizing these amino acids themselves. The screening of recombinant P. pastoris can be performed by using histidine deficient medium. Because the host P. pastoris is histidine-deficient (his−), it cannot grow on basic medium. When the recombinant vector pPIC9K-lipase is integrated into the chromosome, the his4 gene on the vector is also integrated into the chromosome, so that P. pastoris can grow on the basic medium14. Using yeast genomic DNA as template, the lipase gene in the transformants was confirmed by PCR. For gene expression, the colonies were cultured in YPD medium (yeast extract 10 g/L, glucose 20 g/L, peptone 20 g/L) at 30 °C for 24 h, and then inoculated into BMGY medium with shaking (200 rpm) at 30 °C until OD600 reached 5–6. The cells were centrifuged and then resuspended in BMMY. The methanol with a final concentration of 1.0% (v/v) was replenished every 24 h during the induction stage.

SDS-PAGE and western blot analysis

Polyacrylamide gel electrophoresis gel was prepared by Beyotime SDS-PAGE gel rapid preparation kit. The concentration of separation glue is 6%, and the concentration of concentration glue is 5%. 20 µL lipase sample and 5 µL loading buffer were placed in boiling water bath for 5 min before loading. The electrophoresis condition was 200 V and 45 min. After the electrophoresis completed, the glue concentrate is removed and placed in the electric transfer solution for transfer printing. The electric transfer instrument was set as 30 V and 30 min. The transfer film was rinsed with 1 × PBST buffer for 3 times and 5 min, then closed at room temperature for 2 h. Then, the antibody was added for incubation for 1 h, and finally rinsed with 1 × PBST buffer for 3 times, left for 2 min and then photographed.

Purification of recombinant lipase

The culture supernatant of recombinant P. pastoris strain was obtained by centrifugation and then concentrated by ultrafiltration. The lipase was sedimented with 70% (v/v) ethanol and gathered by centrifugation (10,000×g, 20 min). The lipase activity was not affected by ethanol during the purification process because of the short precipitation time. The precipitate was dissolved in 100 mL buffer A (20 mM sodium acetate, 20 mM imidazole and 500 mM NaCl, pH 7.4), and dialyzed by 2 L of buffer A at 4 °C for 12 h and used to a nickel affinity column. The samples were filtered (0.22 μm) and loaded to bind Ni–NTA column pre-balanced with buffer A. The linear gradient with 0–500 mM imidazole in buffer A was used at a flow rate of 1.0 mL/min for 1 h. The fractions containing ρ-NPP hydrolase activity were pooled and dialyzed with 1 L of buffer B (20 mM Tris–HCl, pH 8.0) at 4 °C overnight. Finally, the purified enzyme was concentrated by ultrafiltration and stored at -80 °C.

Determination of yeast biomass

The optical density at 600 nm (OD600) representing the yeast biomass, was measured by a spectrophotometer during the cultivation.

Lipase activity assay

Lipase activity was determined by using p-Nitrophenyl butyrate (p-NPB) or p-Nitrophenyl palmitate (p-NPP) as substrates15. 50 μL fermentation supernatant and 100 μL 10 mmol/L p-NPB or p-NPP were added into 3.85 mL Tris–HCl buffer system (50 mmol/L, pH 8.0) at 40 °C for enzymatic reaction, and the absorption value of p-nitrophenol at 410 nm was determined. The enzyme activity unit (U) was defined as the amount of enzyme required for hydrolysis to produce 1 μmoL p-nitrophenol within 1 min at pH 8.0 and 40 °C, which is a unit of lipase activity. Each value represents the mean of three independent measurements.

The lipase activity towards triolein, tributyrin or olive oil was measured as follows. The triolein, tributyrin or olive oil emulsions were prepared by emulsifying triolein/tributyrin/olive oil with 4% polyvinyl alcohol solution in a ratio of 3:1, respectively. The reaction solution including 5 nM purified enzyme, 2 mL of emulsion and 2.5 mL of 50 mM Tris–HCl buffer (pH 8.0), was incubated for 15 min and then 7.5 mL of ethanol was added to finish the reaction. The released fatty acids were measured by titration with 50 mM NaOH. One unit of lipase activity was defined as the amount of enzyme that released 1 µmol of fatty acid per min at 40 °C and pH 8.0. Each experiment and its blank control were repeated in triplicate.

Temperature optimum and thermostability

The optimal temperature was measured at temperatures of 20–80 °C in the buffer containing 50 mM sodium taurodeoxycholate,10 mM NaCl and 20 mM Tris–HCl at pH 8.0 using ρ-NPP as substrate. The thermostability was determined by incubating 5 nM purified enzyme at 50–80 °C in 50 mM Tris–HCl buffer (pH 8.0). The residual activity of samples was measured at different intervals using p-NPP as the substrate. Each experiment was repeated in triplicate.

pH optimum and stability

The optimal pH was measured with a pH range of 6.0–11.0 using potassium phospate buffer (pH 6.0–7.0), Tris–HCl buffer (pH 7.0–9.0) and glycine–NaOH buffer (pH 9.0–11.0), respectively. The pH stability was determined in a variety of buffers with different pH and 5 nM purified enzymes at 37 °C for 24 h, and then residual activity was assayed with p-NPP as substrate. Each experiment was repeated in triplicate.

Determination of kinetic parameters

The kinetics of lipase was determined using ρ-NPP as substrate under optimal reaction conditions. The Michaelis–Menten parameters, Vmax and Km, were calculated according to the double reciprocal plots of the reaction curve with the substrate concentrations in the range of 0.1–2.0 mM. The reaction was terminated by ice bath immediately after 5 min at pH 8.0 and 40 °C.

Effect of metal ions on lipase activity

The effects of different metal ions (Mn2+, Cu2+, Zn2+, Mg2+, Co2+, Ca2+, Ba2+, Fe3+ and Ni2+) on lipase activity were performed as follows: 5 nM purified lipase was pre-incubated in Tris–HCl buffer (50 mM, pH 8.0) with each metal ion at a concentration of 1 mM at 37 °C for 1 h, and then the residual activity was measured against p-NPP. The enzyme activity without metal ion was defined as 100%. Each experiment was repeated in triplicate.

Stability in organic solvent

The stabilities of lipase in various organic solvents (propanol, methanol, n-butanol, ethanol, iso-octane, glycerol and dichloromethane) were measured in Tris–HCl buffer (50 mM, pH 9) containing of 5 nM purified enzyme and 50% or 75% (v/v) of each solvent. After incubation at 20 °C for 18 h, the aliquots were removed to analyze the residual activity against p-NPP. The enzyme activity without organic solvents was defined as 100%. Each experiment was repeated in triplicate.

Effect of surfactants on lipase activity

The effects of various surfactants including Tween 60, Triton X-100, SDS and sodium taurodeoxycholate (TDOC) at concentrations of 1 mM and 10 mM on the recombinant lipase were measured. 5 nM purified lipase was added into Tris–HCl buffer (50 mM, pH 9) with each surfactant. After incubation at 37 °C for 30 min, the residual activity towards p-NPP was then assayed. The enzyme activity without surfactants was defined as 100%. Each experiment was repeated in triplicate.

Statistical analysis

The software of SPSS Statistics 22 was employed for this statistical analysis. All data are expressed as mean ± standard deviation and the standard error of the mean is calculated from three independent experiments. The difference between the test means was adopted by Student’s t-test and p < 0.05 was considered statistically significant.

Results

Cloning and expression of M. circinelloides lipase in P. pastoris

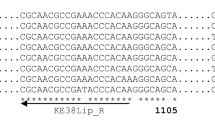

The nucleotide and the corresponding amino acid sequences of M. circinelloides lipase were shown in “Supplemental Data”. By analysis of the protein sequence of M. circinelloides lipase, it was found that the total protein sequence was 457 amino acids, which was divided into three parts: signaling peptide, pre-peptide and mature peptide. Signaling peptide and propeptide were responsible for guiding the localization and transport of protein, and were subsequently cut off. Mature peptide, a total of 298 amino acids, is the final form of protein molecule with a complete biological function. The cDNA sequence of the lipase gene (evm.model.scaffold00001.31) excluding the signal peptide and propeptide was reverse transcribed from the total RNA of M. circinelloides WJ11 and cloned into P. pastoris expression vector pPIC9K. Nucleotide sequence analysis indicated that the gene length was 894 bp and encoded a mature protein containing 298 amino acids. The cloned lipase gene was inserted into the expression vector pPIC9K, and the recombinants were screened on MD/YPD plates and verified by PCR. The P. pastoris GS115 transformed with the vector pPIC9K was used as a control. After methanol induction for 120 h, the ρ-NPP hydrolase activity in the culture supernatant of recombinant P. pastoris achieved 1.24 U/mL, which increased 3.26-fold than that of native extracellular lipases extracted from M. circinelloides. The increase of lipase production might be related to the high expression and efficient secretion of the enzyme in P. pastoris. The protein concentration in the culture supernatant was 530 μg/mL. SDS-PAGE and Western Blot analysis revealed that a major protein band of approximately 34 kDa was secreted into the culture medium (Figs. 1, 2). Under the same culture conditions, no ρ-NPP hydrolase activity was detected in the culture supernatant of the control strain.

Purification of the recombinant lipase

The recombinant lipase was purified to homogeneity by ultrafiltration, ethanol fraction and Ni–NTA chromatography (Table 1). The purified lipase was homogeneous by SDS-PAGE (Fig. 3), and it showed a specific activity of 3.9 U/mg and a recovery of 35.4.

SDS-PAGE analysis of the recombinant lipase purification process. Lane M, protein marker; lane 1, culture supernatant sample of the recombinant P. pastoris; lane 2, effluent sample of the recombinant P. pastoris; lane 3: cleaning fluid sample of the recombinant P. pastoris; lane 4: eluent sample of the recombinant strain P. pastoris.

Temperature and pH properties

Temperature has a significant effect on enzyme activity. The effects of temperature on the lipase activity were investigated from 20 to 80 °C. The optimal temperature curve of the lipase showed that the activity improved with increasing temperature from 20 to 50 °C and decreased from 50 to 80 °C and it retained nearly 60% residual activity at 70 °C (Fig. 4A). Thus, the optimum temperature of this recombinant lipase was at 50 °C, which was higher than that of most lipases from fungi or bacteria (40–45 °C). The thermal stability showed that the lipase remained 80% of activity retained after 24 h at 50 °C or 10 h at 60 °C, but was rapidly inactivated above 70 °C (Fig. 4B).

Effects of pH and temperature on activity and stability of the recombinant lipase. (A) Temperature optimum. The samples were determined in Tris–HCl (pH 9.0). The activity of lipase at 30 °C as 100%. (B) Thermostability. The stability of the enzymes were performed in Tris–HCl (pH 9.0) at 50 °C (solid black square), 60 °C (solid black circle) and 70 °C (solid black triangle). The activity of lipase without heat treated was defined as 100%. (C) pH optimum. The samples were determined in the following buffer: potassium phospate (pH 6.0–7.0), Tris–HCl (7.0–9.0) and glycine–NaOH (pH 9.0–11.0). The activity of lipase at pH 9.0 was defined as 100%. (D) pH stability. The enzyme activity was determined after incubation 24 h at 37 °C in the above buffers. The activity of lipase at pH 9.0 was defined as 100%. All activity were performed in triplicate. Error bars correspond to the standard deviation of three independent determinations.

The optimal pH and stability of lipase were determined at pH ranging from 6.0 to 11.0. It was worth noting that the lipase exhibited comparatively high activity with alkaline conditions, and the optimal pH is 9.0 (Fig. 4C). The lipase was considerably stable (> 80% of maximum) with a broad pH range of 6.0–11.0, and maintained more than 95% of the initial activity between pH 7.0 and 9.0 after incubation at 37 °C for 24 h (Fig. 4D).

Substrate specificity

Different lipases have different substrate specificity for soluble ester and insoluble triglycerides. The specificity of the recombinant lipase towards the chain length of esters was determined with p-nitrophenyl-fatty acyl esters and triglycerides (Table 2). The lipase activity towards the C16 p-nitrophenyl-fatty acid ester p-NPP was improved by 1.24-fold compared with that of C4 ester p-NPB. Meanwhile, when comparing with that of the C4 triglyceride tributyrin, the activity towards the C18 ester triolein was increased by 1.25-fold. Therefore, the preference specificity of this lipase for long chain length substrates was obvious, which was consist with our previous findings on the lipases from Candida antarctica and Pseudozyma hubeiensis16.

Kinetic studies

Under the optimal reaction conditions, the initial reaction velocity corresponding to different concentrations of p-NPP catalyzed by the recombinant lipase was determined according to the Lineweaver–Burk double reciprocal method17, as shown in Fig. S1 in the supplemental data. It could be inferred that the Km and Vmax of the recombinant lipase were 6.37 mM and 94.34 U/mg, respectively, which was similar to that of the native enzyme.

Metal requirement

The presence of metal ions has a certain impact on the enzyme. Some metal ions assist the catalysis of the enzyme as a cofactor in the reaction process of the enzyme to promote the reaction of the enzyme, while others might inhibit the enzyme18. In order to determine whether the recombinant lipase requires metal ions as cofactors, the hydrolysis activity of the recombinant lipase towards ρ-NPP was measured after adding metal ions for preservation. The metal requirement of lipase was measured using 1 mM metal ions (Mn2+, Cu2+, Zn2+, Mg2+, Co2+, Ca2+, Ba2+, Fe3+ and Ni2+). Among the tested metal ions in Table 3, Mn2+ and Fe3+ could slightly activate the enzyme activity to some extent, while Ni2+ showed a moderate inhibitory effect on the enzyme with remaining only 88% of activity, and other metals have no significant influence on the activity of lipase. Metal ions might affect enzyme activity by altering the structure of the enzyme or reacting with the substrate19. In the future, it is necessary to analyze the molecular structure of the interaction between the recombinant lipase and metal ions to elucidate the mechanism of the influence of metal ions on lipase activity.

Stability towards organic solvent and surfactants

Lipase can catalyze esterification and transesterification reactions, which has great potential in chemical industry19. Some applications of lipases often involve the use of organic phases, such as bio-manufacturing of biodiesel, which requires that the lipase involved in the production has a good tolerance to organic solvents. The effects of different concentrations of organic solvents (50% and 75%) on the stability of lipase were analyzed by incubating the enzyme solution at 20 °C for 18 h. From Table 4, there was not significant effect on the lipase activity in n-butanol, glycerol, isooctane and dichloromethane. The results demonstrated that the recombinant lipase had good stability in several kinds of organic solvents. Among of the tested organic solvents, the endurance of the lipase towards ethanol, methanol and propanol was restricted to a certain extent and the remaining activities with 75% of organic solvents were 45, 78 and 82%, respectively. It could be seen that ethanol inhibited the activity of lipase to some extent, since ethanol might cause protein denaturation, change the conformation and charge distribution of the enzyme, and affect the affinity and catalytic efficiency of the enzyme to the substrate20. In the future, it is necessary to analyze the molecular structure of the interaction between the recombinant lipase and organic solvents to elucidate the mechanism of the influence of organic solvents on lipase activity.

The influence of surfactants on enzyme activity becomes the key point in detergent industry. The activities of the recombinant lipase were tested in the presence of Tween 60, Triton X-100, SDS and TDOC (Table 5). The results demonstrated that the recombinant lipase had good stability in Triton X-100 and TDOC. In particular, TDOC can significantly increase the lipase activity. TDOC was an anionic surfactant with a large group, which bond to the hydrophobic amino acids of proteins to prevent protein aggregation and precipitation, thus increasing the stability of proteins15,21. The results showed that TDOC had an obvious stabilizing effect on lipase. However, the endurance of the lipase towards Tween 60 and SDS was restricted to a certain extent.

Discussion

As one of the important industrial enzymes, microbial lipase has great potential in many fields such as bioenergy, oil industry, food processing and so on1,3,22. Mucor circinelloides is an important producer of gamma-linolenic acid, and it is also rich in lipase, a key enzyme in lipid metabolism6,11. In our previous study, the genome information of M. circinelloides WJ11 was analyzed, and 47 potential lipase coding genes were found11. However, the structure, properties and functions of these lipases have not been systematically studied. The genetic analysis showed that the lipase WJ_23 in M. circinelloides WJ11 was a secreted protein with high transcriptional level, indicating that it might play an important role in the regulation of lipid metabolism. Therefore, in this study, the cDNA of the lipase WJ_23 was obtained by RT-PCR and expressed in P. pastoris GS115.

After multiple rounds of plate screening, the initial p-NPP hydrolase activity in culture supernatant of the recombinant strain was 1.24 U/mL by 120 h of methanol induction in shaking flask, which was increased by 3.26-fold than that of wild strain. Although the activity of this recombinant lipase might be lower than that of the current commercial lipases or lipases from different organisms, the lipase activity could be improved through appropriate control strategies including the optimization of fermentation conditions and bioreactor scale-up production in our next work.

Lipase is one of the most important industrial enzymes, and its enzymatic properties are critical to its industrial application. In recent years, lipases have attracted increasing attention in the literature due to their catalytic versatility and wide industrial applicability. Recent studies highlight the role of these enzymes in sustainable processes, such as biodiesel production, oil and fat modification, and synthesis of bioactive compounds under environmentally friendly conditions23,24. Furthermore, their high substrate specificity, stability under extreme conditions, and possibility of immobilization in innovative matrices make lipases indispensable tools in the food, pharmaceutical, cosmetic, and biofuel industries, consolidating their impact on biotechnological advancement25,26. Comparative biochemical characterization of the recombinant lipase and the native lipase from M. circinelloides WJ11 showed that they had similar optimum temperature and pH. The recombinant lipase remained active over a wide pH range and was stable towards thermal denaturation, which was also consistent with the native one. In addition, the recombinant lipase preferentially utilized long chain length substrates and possessed good tolerance to various organic solvents. Obviously, these excellent properties of the recombinant lipase would be beneficial to its application in the changeable and complex industrial environments. In the future, we will further explore the influence of the molecular structure of the recombinant lipase on their properties or functions in specific industrial conditions such as biodiesel or food processing.

In summary, the lipase WJ_23 from M. circinelloides WJ11 was cloned, heterologously expressed and characterized in this study. Biochemical properties demonstrated that the recombinant lipase processed optimum activity at 50 °C and pH 9.0, and also had good thermostability at 50 °C and wide pH adaptability (retaining over 95% activity between pH 7.0 and 9.0 after incubation at 37 °C for 24 h). Meanwhile, the recombinant lipase was highly tolerant and stable to various organic solvents. Further improvement on the production of the recombinant lipase through fermentation technology is currently underway in our lab, and it will furnish a foundation for the industrial application of the recombinant M. circinelloides lipase.

Data availability

All data generated or analysed during this study are included in this published article.

References

Chandra, P., Enespa, Singh, R. & Arora, P. K. Microbial lipases and their industrial applications: A comprehensive review. Microb. Cell Fact. 19, 169 (2020).

Majumder, D. et al. Use of genomics & proteomics in studying lipase producing microorganisms & its application. Food Chem. 9, 100218 (2024).

Coelho, A. L. S. & Orlandelli, R. C. Immobilized microbial lipases in the food industry: A systematic literature review. Crit. Rev. Food Sci. Nutr. 61, 1689–1703 (2021).

Yao, W. et al. A valuable product of microbial cell factories: Microbial lipase. Front. Microbiol. 12, 743377 (2021).

Zhang, X. Y. et al. Production, biosynthesis, and commercial applications of fatty acids from oleaginous fungi. Front. Nutr. 9, 873657 (2022).

Fazili, A. B. A. et al. Mucor circinelloides: A model organism for oleaginous fungi and its potential applications in bioactive lipid production. Microb. Cell Fact. 21, 29 (2022).

Andrade, G. S. S., Freitas, L., Oliveira, P. C. & Castro, H. F. Screening, immobilization and utilization of whole cell biocatalysts to mediate the ethanolysis of babassu oil. J. Mol. Catal. B Enzym. 84, 183–188 (2012).

Garcia-Galan, C. et al. Biotechnological prospects of the lipase from Mucor javanicus. J. Mol. Catal. B Enzym. 93, 34–43 (2013).

Andrade, G. S. et al. Mucor circinelloides whole-cells as a biocatalyst for the production of ethyl esters based on babassu oil. Bioprocess Biosyst. Eng. 37, 2539–2548 (2014).

Efsa Panel on Food Contact Materials et al. Safety evaluation of the food enzyme triacylglycerol lipase from the non-genetically modified Mucor circinelloides strain AE-LMH. EFSA J. 21, e07755 (2023).

Zan, X. et al. Lipase genes in Mucor circinelloides: Identification, sub-cellular location, phylogenetic analysis and expression profiling during growth and lipid accumulation. J. Ind. Microbiol. Biotechnol. 43, 1467–1480 (2016).

Zan, X. et al. Novel dual-functional enzyme Lip10 catalyzes lipase and acyltransferase activities in the oleaginous fungus Mucor circinelloides. J. Agric. Food Chem. 67, 13176–13184 (2019).

Zan, X., Tang, X., Chu, L. & Song, Y. Dual functions of Lip6 and its regulation of lipid metabolism in the oleaginous fungus Mucor circinelloides. J. Agric. Food Chem. 66, 2796–2804 (2018).

Chen, D. L. et al. Heterologous expression and biochemical characterization of alpha-glucosidase from Aspergillus niger by Pichia pastroris. J. Agric. Food Chem. 58, 4819–4824 (2010).

Zhang, Y., Wang, L. & Song, Y. D. Heterologous expression and biochemical characterization of lipase from Burkholderia cepacia Lu10-1. Am. J. Biochem. Biotechnol. 13, 233–241 (2017).

Chen, M. et al. Discovery and characterization of a stable lipase with preference toward long-chain fatty acids. Biotechnol. Lett. 42, 171–180 (2020).

Tseng, S. J. & Hsu, J. P. A comparison of the parameter estimating procedures for the Michaelis–Menten model. J. Theor. Biol. 145, 457–464 (1990).

Riordan, J. F. The role of metals in enzyme activity. Ann. Clin. Lab. Sci. 7, 119–129 (1977).

Haryati, T., Widhiastuty, M. P., Warganegara, F. M. & Akhmaloka, A. Molecular characterization of transesterification activity of novel lipase family I.1. Biosci. Rep. 42, BSR20220654 (2022).

Shin, S., Wu, P. & Chen, C. H. Biochemical studies of the actions of ethanol on acetylcholinesterase activity: Ethanol–enzyme–solvent interaction. Int. J. Biochem. 23, 169–174 (1991).

Creveld, L. D., Meijberg, W., Berendsen, H. J. & Pepermans, H. A. DSC studies of Fusarium solani pisi cutinase: Consequences for stability in the presence of surfactants. Biophys. Chem. 92, 65–75 (2001).

El-Metwally, M. M. et al. Application of artificial neural networks for enhancing Aspergillus flavipes lipase synthesis for green biodiesel production. Heliyon 9, e20063 (2023).

Sales, M. B. et al. Sustainable feedstocks and challenges in biodiesel production: An advanced bibliometric analysis. Bioengineering 9, 539 (2022).

Jama, D. et al. Bioconversion of waste glycerol into viscosinamide by Pseudomonas fluorescens DR54 and its activity evaluation. Sci. Rep. 14, 1531 (2024).

Silva Almeida, C. et al. Enhancing lipase immobilization via physical adsorption: Advancements in stability, reusability, and industrial applications for sustainable biotechnological processes. ACS Omega 9, 46698–46732 (2024).

Dos Santos, K. M. et al. Enhanced biodiesel production with Eversa Transform 2.0 lipase on magnetic nanoparticles. Langmuir 40, 26835–26851 (2024).

Acknowledgements

This work was supported by National Natural Science Foundation of China (32101927), Shandong Key Laboratory of Food Resources and Healthy, Shandong Provincial Natural Science Foundation (ZR2020MC007) and School-City integration project in Zhangdian District (2021JSCG0016).

Author information

Authors and Affiliations

Contributions

Y.Z. was involved in the study conception, experimental design and execution, data analysis, figures and tables’ arrangement, result interpretation, manuscript writing and review of the final draft. Y.S., Z.L. and J.L. participated in the experimental research. Q.L. and Y.S. conceived the study and reviewed the original manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent to participate

All the authors agreed to participate in the scientific work.

Consent for publication

All the authors agreed to submit the manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Sun, Y., Liu, Z. et al. Heterologous expression and enzymatic properties of lipase from Mucor circinelloides. Sci Rep 15, 10871 (2025). https://doi.org/10.1038/s41598-025-93938-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-93938-x