Abstract

The present study discusses the effects of an applied magnetic field on the tensile characteristics and formability behavior of a dual-phase steel sheet. The work also reports the novel design of electromagnetic tool for uniaxial tensile test and Erichsen cupping experiments with their performance analysis. The electromagnetic tool is developed as an external attachment to a conventional uniaxial tensile test specimen while testing in a universal testing machine. For the simulations, the electromagnetic tool is modelled with different magnetic flux density values. The electromagnetic tool is designed and fabricated based on the predicted results of magnetic flux density distribution in the specimen obtained from simulations. Furthermore, the experimental results obtained from tensile tests show a significant improvement in the tensile strength and normal anisotropy due to the magnetic field. The microstructural investigations are carried out on samples taken from the specimens tested to 20% of plastic strain with and without the magnetic field by electron backscattered diffraction and correlated with the changes in the tensile properties. The effect of magnetic field shows that the material’s texture becomes stronger, the grain dislocation density decreases, and the material’s twin boundary increases. The magnetic force microscopy frequency analysis is also performed to evaluate the evidences of magnetic field on the tensile tested specimens. A significant increase in the values of strengths and anisotropy but a slight decrease in ductility and strain hardening exponent are observed in the specimens tested with the magnetic field. A modified electromagnetic tool is designed as an attachment to the sheet samples to be tested in the Erichsen cupping machine to study the influence of a magnetic field on the forming behavior. The results of Erichsen cupping experiments are obtained with and without a magnetic field. It is observed that the magnetic field increases the values of the Erichsen Index, suggesting an enhanced formability, which may be attributed to the increase in normal anisotropy of the sheet.

Similar content being viewed by others

Introduction

The deformation behaviour of a dual-phase (DP) steel is primarily governed by its microstructure, which consists of martensite and ferrite phases. This complex microstructure is a result of chemical composition and controlled thermo-mechanical processing parameters, influencing key mechanical properties such as strength, ductility and formability. The magneto-mechanical response of DP steel is significantly influenced by its ferromagnetic nature. Ferromagnetic materials, including DP steels, possess magnetic domains1,2 whose behaviour under an external magnetic field (MF) plays a crucial role in their magneto-mechanical properties3,4,5,6. The magnetization behaviour of the atoms causes ferromagnetic materials to develop multiple small magnetic domains within their crystal structure7,8. The variation in microstructural features, such as distribution and morphology of the martensite and ferrite phases, further affect the domain structure, thereby influencing the materials response to an applied MF9,10. Under the effect of a MF, individual atomic magnetic moments naturally tend to align in the same direction, leading to a domain realignment11,12. This reorientation of magnetic domain can affect dislocation motion and texture evaluation during deformation, establishing a direct relationship between the magnetic field, microstructure, and mechanical properties of material.

A few researchers have attempted to characterize the effect of MF (in the transverse direction) on mechanical, microstructural, and physical properties in steels and other ferromagnetic materials13,14,15,16,17,18,19. The MF applied in the transverse direction lowers the fatigue life of a mild steel specimen due to dislocation’s mobility13. The pulsating AC MF of 0.094 T magnitude was seen to influence the softening behavior of AISI4340 steel at room temperature resulting in the reduction of hardness due to the vibrations assisting the movement of dislocations14. The MF gradient influences the pearlitic transformation and enhances the hardness of a high carbon steel at elevated temperatures containing Mn and Cr, which is otherwise dependent on the compositions of a steel15. The effects of magnetic and electric fields of higher magnitude were also studied in terms of recrystallization, grain growth, and texture, and it was suggested that MF can be employed for microstructural control in various alloys and compounds16. The tension test performed with pulsed MF in the range of 1.0 T to 2.5 T affects the hardness, residual stress and dislocation density after deformation17. It was noticed that with a magnitude of pulsed MF upto 1.3 T, the values of hardness and residual stress were observed to decrease but these properties again enhanced at magnitudes of more than 1.3 T. MF affects the tensile properties of Eurofer-97 steel in uniaxial tension and results in an increment of almost 1% in the tensile and yield strengths18. The MF influences the mechanical properties and microstructure in steel specimens and it was observed that the applied MF decreases the ductility but increases the grain size and hardness19.

According to earlier research, MF affects phase transitions, dislocation mobility, recrystallization, and grain development, all of which influence mechanical property changes. Although, extensive research has been conducted on the characterization of mechanical properties of various DP steels, the influence of an applied magnetic field (MF) on their deformation behaviour and formability remains largely unexplored. To bridge this gap, the objective of the current study is to design and develop a novel electromagnetic tool that will generate uniform MF in the specimen used for tensile testing and Erichsen cupping. This tool enables a systematic investigation of the effect of MF on tensile properties and formability behaviour of DP590 steel sheet. The tensile specimens are prepared with an orientation of 0°, 45°, and 90° w.r.t. the rolling direction (RD) of the sheet and the experiments for both tensile and anisotropy are performed to analyse the effect of MF20,21. In order to design the electromagnetic uniaxial tensile test (EMUTT) tool, a magnetostatics finite element analysis (FEA) of a tensile specimen is performed and the values of magnetic flux density are obtained over the gauge length. Furthermore, after analyzing the EMUTT tool performance on a 50 kN UTM, a modified electromagnetic tool is developed for the samples to be tested in Erichsen cupping machine to evaluate MF effects on sheet formability. A predetermined magnitude of magnetic flux density is applied in Erichsen cupping experiments, and results obtained with and without MF indicate that MF enhances the Erichsen Index (IE), suggesting an improved formability. The effect of MF is confirmed by electron backscattered diffraction (EBSD) analysis performed on samples tested with and without MF. The microstructural characterization shows a decrease in grain dislocation density, an increase in twin boundaries, and a stronger texture in the samples tested with MF. This demonstrates a potential of MF-assisted forming by harnessing the dislocation movement and microstructural evolution. The results provide important information for creating cutting-edge material design strategies for sectors such as magneto-assisted manufacturing and automobile crash-resistant structures.

Magnetostatics simulation and experimental setup

A DP590 steel sheet with a thickness of 1.6 mm is selected for the experimental work. The chemical composition of the sheet is given in Table 1.

Magnetostatics simulation

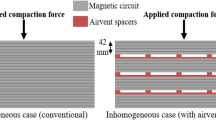

A novel EMUTT tool is designed and developed as an external attachment to the tensile specimen for a conventional universal testing machine (UTM). The proposed electromagnetic tool generates a uniform MF in the tensile specimen during the uniaxial tension test when attached to the specimen. The Maxwell Ansoft V13 software simulates the variation of different electromagnetic fields in the tensile specimen. The magnetic flux density is set up along the specimen’s gauge length in the magnetostatics simulation analysis. A standard tensile specimen CAD model simulates the magnetic performance of the EMUTT tool. The study is focused on the gauge length where a uniform MF is applied, and the specimen behaves as an electromagnet core inside the EMUTT tool. A B-M characteristic plot for DP590 steel sheet in powder form is plotted using a vibrating sample magnetometer (VSM), and a value of bulk conductivity of 2000000 siemens/meter is assigned to the FEA model for magnetostatics analysis as shown in Fig. 1a. The B-M curve, also known as a magnetization curve, is the graph plotted between magnetic flux density (B) and magnetizing force (M). A bulk conductivity of 58000000 siemens/meter and a relative permeability of 0.99 are assigned to the copper wire used in the EMUTT tool model. The simulation is based on the numerical solution of Maxwell’s equations over a finite region22, with assigned material properties, source inputs, and boundary conditions. The distribution of magnetic flux density is obtained from the simulations using the EMUTT tool along the gauge length, as shown in Fig. 1b. After fabricating the tool based on the simulation results, the magnetic flux density at the tensile specimen surface was measured using a digital Gauss meter and found to be 0.22 to 0.25 T. The results of the simulation of distribution of magnetic flux density are in sync with the results obtained by experimental measurements.

EMUTT tool simulations and experimental tool setup. (a), B-M curve of DP590 steel sheet, (b) contour plot along the parallel length, (c) magnetic flux distribution contour plot of sheet, (d) comparison of experimental and simulation results of the magnetic flux density distribution along the width and length of the sheet, and (e) experimental setup showing EMUTT tool attached to the specimen on a UTM (created using PTC Creo 5.0.6.0) and Erichsen cupping machine setup with electromagnetic tool.

A modified electromagnetic tool is also designed for the Erichsen cupping test samples based on MF distribution results. An FEA model is developed and simulated for the sheet sample (300 mm of length × 75 mm of Width × 1.6 mm of thickness) using the same set of parameters obtained for the FEA model of the tensile samples. However, different values of these parameter such as coil current, number of coil turns and coil positioning are systematically varied and iterated. This optimization process ensured the desired MF distribution for the sheet sample while maintaining consistency with the FEA model. The simulation results of the contour plot of magnetic flux density on the sheet sample with two electromagnetic tools of the same dimensions placed at the two extreme ends of the sample to achieve nearly 0.29 T at the focus area of the sheet are shown in Fig. 1c. The distribution of the magnetic flux density plot in the functional area of the length and width of the sheet is shown in Fig. 1d. The results of the simulation of magnetic flux density are in sync with the results obtained by experimental measurements on the Erichsen cupping samples.

Electromagnetic tool setup and experimentation

An experimental setup comprising of an EMUTT tool is designed for a UTM to carry out a set of uniaxial tensile tests, as shown in Fig. 1e. The tensile specimen is prepared as per ASTM-E8M standard and it is mounted inside the electromagnet tool. The machine’s upper and lower jaws are used to secure the specimens. The machine’s upper jaw is movable and connected to a load cell, and the bottom jaw is stationary. The predicted flow of magnetic flux lines inside the tensile specimen due to the EMUTT tool is also shown in schematic diagram. A DC-regulated power supply is used to connect the electromagnet tool to produce the MF in the tensile specimens, and the magnitude is measured with the help of a digital gaussmeter. To study the effect of MF on the tensile properties of the sheet in different directions, the tensile specimens are prepared by laser cutting with an orientation of 0°, 45° and 90° w.r.t. the RD of the sheet and all the specimens are tested at a cross-head speed of 5 mm/min. A set of three tensile samples prepared in three different directions are tested to capture the reproducibility of the results. The tensile experiments are carried out with and without the use of the EMUTT tool to observe the changes in the tensile properties of the sheet. The experiments are performed to validate the results obtained from simulations of the EMUTT tool with 13 Voltage and 5 Ampere current supplied by the DC-regulated power supply. After the characterization of the tensile properties of the selected sheet material without the MF, the tensile experiments are also performed with the EMUTT tool fitted to the specimens. To measure the anisotropy of the sheet in line with the ASTM-E517 standard, all specimens are subjected to 20% plastic strain, both with and without the MF. The electron backscattered diffraction (EBSD) technique is used to study the deformation behaviour of the tested specimens for microstructural characterization.

Results

Effect of magnetic field on tensile properties

The tensile properties of the specimens oriented at 0°, 45°, and 90° to the RD obtained with the use of EMUTT tool are obtained by experiments. It is observed that the yield strength (YS) and ultimate tensile strength (UTS) increases with the effect of the MF. The increase in YS and UTS may be attributed to the alignment of the spin direction under the effect of MF, which is applied parallel to the loading direction along the length of the specimen. In the case of the results obtained without MF, the orientation of the spins w.r.t. the loading direction is at random. It is assumed that the spins are completely aligned and form a good spin-to-spin coupling due to MF. The MF results in spin-to-spin coupling (bond interaction of spins) with electron clouds, resulting in the molecular bonds becoming stronger23,24.

The results of true stress-true strain obtained by testing of specimens with an orientation of 0°, 45° and 90° to the RD with and without the MF are shown in Fig. 2a,c. Due to the MF, the tensile strength in the specimens tested with an orientation of 0°, 45°, and 90° is observed to increase by 3.5, 3.0, and 4.0%, respectively. This improvement can be attributed to the hindrance offered to the movement of dislocations by spin to spin coupling, which is further enhanced by increased formation of twin boundaries due to MF. Additionally, grain elongated along the loading direction contributed to strain hardening, thereby enhancing the tensile strength. The instantaneous n-values (strain hardening exponent) as a function of true strain are also determined for the specimens tested with an orientation of 0°, 45°, and 90° to RD as shown in Fig. 2a–c. It is observed that the values of n are slightly decreased with MF near the necking zone in all the cases. It is also depicted that for the specimens oriented at 0°, and 90° to RD, the effect of MF on n values are more pronounced than that of the specimen at 45° to RD. This behaviour may be attributed to the magnetic field having a least influence at 45° to RD, leading to a smaller change in n value. The magnetic field is observed to be significant along the principal material directions (0°, and 90° to RD) causing a noticeable change in the work hardening exponent in the specimens. This instantaneous n-values plays a significant role in predicting sheet metal deformation behaviour during a forming operation, influencing both product quality and process efficiency.

Tensile properties and XRD pattern of steel with and without MF. (a–c), True stress-true strain plots and true instantaneous n-values as a function of true strain are examined with and without MF for specimens oriented at 0°, 45°, and 90° to RD, and (d) XRD patterns of 0°, 45°, and 90° to RD are investigated with and without MF.

XRD analysis

To analyze the effect of MF at atomic level, the results obtained by XRD are shown in Fig. 2d which depicts three different peaks for ferrite and martensite occurring at planes of (110), (200) and (211) corresponding to the orientation of specimens w.r.t. RD tested to 20% of plastic strain with and without MF. It is interesting to see that all three peaks’ intensity differ w.r.t. the RD and intensity of the peak at the plane (110) are affected the most due to MF. It is also observed that due to MF, the highest intensity of peaks is seen in samples oriented at 45° to RD, which also corresponds to the highest UTS and a lower ductility, followed by the samples oriented at 90° and 0° to RD. Due to MF, the values of interplanar spacing (d-spacing) are observed to marginally increase, and the values of 2θ are decreased in the same plane of peaks corresponding to the orientation of specimens tested w.r.t. RD in three different directions. As evident in the XRD pattern, the tensile stress in the specimen leads to an increase in d-spacing, which causes the value of 2θ to shift towards a lower value in the peak25. The increase in the interplanar spacing for a given plane indicates the higher degree of interaction of the dislocations with the spin orientations26,27. The plastic deformation is governed by the collective motion and interaction of dislocations on a slip plane which is affected by the interplanar spacing28.

Effect of magnetic field on anisotropy

The change in the anisotropy of the sheet metal is determined in terms of plastic strain ratio (R) when tested to 20% of plastic strain with MF as shown in Fig. 3a. The values of R are found to increase due to MF, however, the significant changes in the R are observed in the 0° and 90° to the RD as compared to the specimen at 45° to RD. The normal anisotropy (\(\overline{R }\)) of the sheet is observed to increase by 22.6% due to MF, which may enhance the formability of the steel sheet. The coefficients of variation of the specimens tested with 20 % plastic strain 0°, 45°, and 90° to the rolling direction, with and without the magnetic field for the repeatability and reproducibility of the test. It is noticed that the values of coefficient of variation lie within the acceptable range, as per ASTM E517-19. The MF enhances the grains elongation in the loading direction and increase the formation of twin boundaries. The twin boundaries act as obstacles to the movement of dislocations, improving the strain hardening. Together, these changes enable the material to deform evenly in the thickness direction under the influence of MF, resulting in an increase in normal anisotropy values as compared to the case without MF.

Anisotropy and dome height with and without MF. (a) Variations of plastic strain ratio (R) with and without MF, (b) a change in percentage thickness (%t) w.r.t. the radius of the dome (Rd), at the transverse-section view of the dome profile, (c) relation between the dome height and the radius of the dome have been determined at transverse-section view, and (d) punch force vs. punch displacement plot demonstrates the effect of MF.

Effect of magnetic field on formability

The formability of the steel sheet is evaluated by the Erichsen Index (IE) number in the cupping experiments. The variation in percentage thickness (%t) with radius of dome (Rd) is shown in Fig. 3b. It is observed that the percentage thinning is higher with MF than that of results obtained without MF. The values of IE for deformed sheets tested with and without MF are displayed in a transverse section as shown in Fig. 3c. Due to MF, the sample is stretched considerably with delayed necking, exhibiting a higher height of the cup, and the value of IE is found to increase by approximately 1.5 mm. The formability of the sheet increased in biaxial stress due to the value of anisotropy greater than one if the quadratic yield function was used29. The increase in the value of IE may be attributed to the higher normal anisotropy of the sheet due to MF. The punch force with relative displacement graph confirmed that the height of the cup is increased by 13% due to MF, as shown in Fig. 3d. Due to MF, the punch force required to deform the sheet is also observed to increase from 41.9 to 47.8 kN.

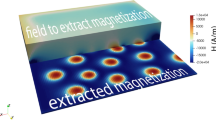

Magnetic force microscopy (MFM) analysis

The magnetic force microscopy (MFM) technique is adopted to characterize the magnetic properties of the samples taken from the specimens tested with and without the MF. Results of the MFM frequency contrast of sample taken from the tested specimen without MF are shown in Fig. 4a. It is observed that the magnetic signals are very feeble in a scanned area of the tested samples which indicates the absence of MF. Further, a small area is zoomed-in to present a contour map indicating the frequency of less than 25 Hz. On the contrary, a sample taken from a tested tensile specimen with MF is also analysed in MFM frequency contrast modulation as shown in Fig. 4b. It is interesting to notice the evidences of magnetic signals in a scanned area which appeared in the form of tiny bubbles, confirming the effect of MF during plastic deformation. It is also seen that some of the nanoparticles are not emitting any MFM frequency contrast, suggesting that these nanoparticles are either nonmagnetic or intermetallic compounds which get less magnetized due to their martensitic nature. The zoomed-in image of the contour map frequency peak (Fig. 4b) illustrates that the frequency is increased to a maximum of 90 Hz.

Magnetic force microscopy (MFM) frequency analysis. (a) Frequency contour map and frequency distribution plot of samples tested without MF, (b) Frequency contour map and frequency distribution plot of samples tested with MF, (c) 3D frequency resonant images for tensile specimen tested without MF and (d) 3D frequency resonant images for tensile specimen tested with MF.

Fig. 4c,d show frequency resonant images obtained from the scan of the samples taken from the tensile specimens tested without and with the MF, respectively. A number of peaks and valleys of MFM frequency are observed in a sample taken from the tested specimen with the MF and compared with the results of frequency contrast images of sample taken from the tested specimen without MF. A maximum value of MFM frequency (100.9 Hz) is observed due to MF. The frequency peaks confirmed that the magnetic domains aligned with the MFM magnetized tip are still present in the tested specimen with MF.

Discussion

The microstructural features are discussed in the samples taken from the specimens tested to 20% of plastic strain at the 0°, 45°, and 90° w.r.t the RD with and without MF. The inverse pole figure (IPF) maps for tested specimens without MF oriented at 0°, 45°, and 90° to the RD shows the average grain size of ~ 6.7, 6.3 and 7.2 μm, respectively as shown in Fig. 5a,d,g, respectively. The colour distribution in IPF maps illustrates a higher percentage orientation of grains in plane (111) within the microstructure, followed by (001) and (101) in both the samples of 0° and 45° to the RD. In the sample of 90° to the RD, the IPF shows the same trend in orientation of grains in plane (111) but the distribution is followed by (101) and (001). It is also observed that, the low angle grain boundaries (LAGB) are much higher than high angle grain boundaries (HAGB) in samples with 0° and 90° to the RD, followed by the case of 45° to the RD (Fig. 5b,e,h).

EBSD images of tested specimens without MF. (a) IPF map for 0° to the RD, (b) grain boundary map at 0° to the RD, (c) KAM map at 0° to the RD, (d) IPF map for 45° to the RD, (e) grain boundary map at 45° to the RD, (f) KAM map at 45° to the RD, (g) IPF map for 90° to the RD, (h) grain boundary map at 90° to the RD, (i) KAM map at 90⁰ to the RD, and (j–l) Misorientation angles for 0°, 45° and 90° to the RD, respectively.

In the samples of 0°, and 90° to the RD, the kernel average misorientation (KAM) maps confirmed that the local strain distribution and dislocation density are maximum in majority of grains, as the bigger grains are nucleated and grown to smaller sub-grains due to plastic deformation, but in the case of samples of 45° to the RD, the conversion of bigger grains in smaller sub-grains is the least as shown in Fig. 5c,f,i. It is also noticed that the distribution of blue colour patch within the grains represent a lesser change in the dislocation density in that region.

The distribution of the misorientation angles for tested specimens without MF for the samples of 0°, 45°, and 90° to the RD as shown in Fig. 5j,k,l, shows a higher value of the average misorientation angle in the samples of 45° to the RD followed by the samples of 0° and 90° to the RD. A lower average value of misorientation angle in the tested specimens corresponds to a higher dislocation density20.

The microstructures of the specimen tested with MF are shown in Fig. 6. The IPF images with colour distribution triangle of the samples taken from specimens tested with MF oriented at 0°, 45°, and 90° to the RD are shown in Fig. 6a,d,g, respectively. In the case of 0° and 45° to the RD, it is observed that MF affects the orientation of planes within the grains as compared to the results obtained without MF for the same orientation. MF reduced the percentage distribution of plane (111), but increased the distribution of the plane (001) and least affecting the plane (110). In the case of sample for 90° to RD (Fig. 6g compared to Fig. 5g), MF increases the distribution for planes (001) and (111) but lowers the distribution of plane (110). These results could be attributed to the interaction of dislocation density with the spins at respective orientation axis due to combined effect of deformation and MF. The X-Ray diffraction results also supports that MF affects the intensity of peaks and marginally increases the d-spacing of the interplanar distance. Due to MF, the percentage increase in the intensity of peaks is much higher for the samples of 0° and 90° to RD and it is the lowest for 45° which may be attributed to the orientation of planes within the grains. In the case of BCC metals, owing to the complex nature of the slip phenomenon, slip occurs on (110) plane in the closed packed direction <111> during plastic deformation30. This behaviour may have resulted in the formation of elongated grains due to MF, and it is also observed that the grain size is increased by about 46, 24, and 43% of the grain size obtained for the samples without MF for orientations of 0°, 45°, and 90° to the RD, respectively.

EBSD images of specimens tested with MF. (a) IPF map for 0° to the RD, (b) grain boundary map at 0° to the RD, (c) KAM map at 0° to the RD, (d) IPF map for 45° to the RD, (e) grain boundary map at 45° to the RD, (f) KAM map at 45° to the RD, (g) IPF map for 90° to the RD, (h) grain boundary map at 90° to the RD, (i) KAM map at 90⁰ to the RD, and (j–l) Misorientation angles for 0°, 45° and 90° to the RD, respectively.

The grain boundary map depicts a distribution of grains with LAGB and HAGB. It is seen that a fraction value of LAGB for specimens tested with MF (Fig. 6b,e,h)) is lower than the fraction values of LAGB for specimens tested without MF (Fig. 5b,e,h). On the other hand, due to MF, fraction values of HAGB are observed to be higher in all the cases of the specimens oriented at 0°, 45° and 90° to the RD. It may be concluded that the specimens tested with MF exhibit higher strength and increased normal anisotropy with only a slight reduction in ductility, attributed to a lower number of favourable slip systems. Thus, at first glance, it appears that the MF orients the spin in the direction of applied load along the length of the specimen and interacts with the slip directions and planes which results in a higher strength31.

The KAM maps of the samples taken from tested specimens oriented at 0°, 45° and 90° to the RD with MF is shown in Fig. 6c,f,i. It is noticed that some of larger grains are not deformed uniformly as compared with the samples tested without MF (Fig. 5c,f,i) for the same orientation. This could be attributed to the alignment of direction of the electron spin along the magnetic domains parallel to the direction of MF which further results in the hindrance to the movement of dislocations within the grains. The distribution of the misorientation angles for tested specimens with MF for 0°, 45°, and 90° to the RD are shown Fig. 6j,k,l. The average values of the misorientation angle due to MF are decreased in all the specimens. It is concluded that due to MF, the LAGB is decreased with the decrease in the local strain distribution within the grains.

In order to analyze the texture, the pole figures of the samples tested with and without MF are compared in terms of pole figures for the planes {001}, {110} and {111} as shown in Fig. 7. In both the cases, the pole figures of tested specimens for three different orientations to the RD fall in the category of weak texture in terms of multiples of random distribution (MRD). The value of MRD intensity increases from 2.090 to 3.514 for 0°, 2.370 to 2.937 for 45°, and 2.618 to 4.324 for 90° to the RD due to MF. An increase in the value of MRD indicates an improvement in the texture32. It is also reported in the literature that plastic deformation may improve the texture with a slight grain growth33.

For the purpose of determining the percentage of dislocation density within the microstructure of the tested specimens with and without MF, the geometrically necessary dislocations (GND) maps with colour distribution and bar graph are analyzed as shown in Fig. 8. The average values of GND density obtained with MF in the tested specimens oriented at 0°, 45° and 90° to the RD, is seen to decrease by about 7.4, 4.9, and 7.4%, respectively which is also demonstrated by KAM maps. A lower value in the dislocation density for sample oriented at 45° to the RD could be due to a smaller magnetic domain size than the values found in the other two orientations34. It also seen that the dislocations due to MF are distributed in a non-uniform manner within a grain and in some of the larger grains the dislocations are completely missing (as represented by blue shade in Fig 8). The twin boundary maps for BCC are also obtained for most favourable slip system of (112) <111> in the microstructure of the samples taken from the tested specimens with and without MF as shown in Fig. 9. The impediment to dislocation movement results in the formation of twin boundaries, which further glide and cross-slip35. It is noticed that the values of fraction of twin boundaries in a plane of (112) is found to be 0.272, 0.252 and 0.309 in the samples taken from the specimens tested without MF at an orientation of 0°, 45° and 90° to RD, respectively. It is observed that the value of fraction of twin boundaries (112) plane is 0.319, 0.274 and 0.355 of the samples taken from the tested specimens With MF for 0°, 45° and 90° to RD, respectively. So, that the value of twin boundaries due to MF, are increased by 17.2, 8.4 and 14.8% in the samples taken from the tested specimens w.r.t. 0°, 45° and 90° to the RD, respectively. The increased in the values of the twin boundaries and decreased of the GND due to MF are predominated to the grain growth, increased tensile strength and normal anisotropy of the DP steel sheet.

Conclusions

In order to determine the effect of magnetic field on deformation behaviour of a DP steel sheet, the researchers conceived and developed a novel electromagnetic uniaxial tensile test (EMUTT) tool as an external attachment to the specimens, then tested its performance. Based on the predicted results of magnetic flux density distribution obtained from simulations and experimental methods, the fabricated EMUTT tools apply a predetermined magnitude of MF in the loading direction of the tensile specimens. It is observed that tensile experiments with MF yielded considerable improvements in the tensile strength and normal anisotropy. This improvement can be attributed to the hindrance offered to the movement of dislocations by spin to spin coupling, which is further enhanced by increased formation of twin boundaries. After analyzing the EMUTT tools performance in tensile experiments, a modified electromagnetic tool is also designed and fabricated as an attachment with sheet samples for conducting cupping experiments to evaluate the effect of MF on forming behavior of the sheet. The Erichsen Index number (IE) data with and without MF suggested that the MF raises the IE values, implying an improved formability. The increase in the value of IE may be attributed to the higher normal anisotropy of the sheet due to MF. XRD data is collected to assess the impact of MF on interplanar spacings. A higher peak intensity with a lower value of 2θ is found to be associated with a marginally higher value of d-spacing. The evidence of MF present in the samples tested with and without MF is validated with a magnetic force microscopy (MFM) technique, which displays magnetic signals as nanoscopic bubbles. The microstructures analysis conducted through EBSD technique of the samples taken from different specimens tested to 20% of plastic strain with and without MF, correlated with the changes in the tensile properties. The IPF maps confirmed that the MF modifies grain orientation by increasing (001) plane distribution and adjusting (111) and (110) planes based on loading direction. Grain boundary analysis shows higher HAGB and lower LAGB fractions, indicating improved strength, enhanced normal anisotropy, and slightly reduced ductility. KAM maps highlight non-uniform deformation in larger grains due to electron spin alignment, leading to restricted dislocation movement and reduced local strain. Pole figure analysis confirms texture improvement with increased MRD intensity across all orientations. Microstructural analysis also confirms that MF has a substantial influence on the increased values of the twin boundaries but decreased values of the GND predominated to the grain growth, leading to an increased tensile strength and normal anisotropy of the DP steel sheet.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Langman, R. The effect of stress on the magnetization of mild steel at moderate field strengths. IEEE Trans. Magn. 21, 1314–1320 (1985).

Jiles, D. C. Theory of the magnetomechanical effect. J. Phys. D Appl. Phys. 28, 1537–1546 (1995).

Birss, R. R., Faunce, C. A. & Isaac, E. D. Magnetomechanical effects in iron and iron-carbon alloys. J. Phys. D Appl. Phys. 4, 322 (1971).

Atherton, D. & Szpunar, J. Effect of stress on magnetization and magnetostriction in pipeline steel. IEEE Trans. Magn. 22, 514–516 (1986).

Silva, E. et al. Detection of the magnetic easy direction in steels using induced magnetic fields. Metals (Basel) 6, 317 (2016).

Mian, G. & Yamaguchi, T. Stress effect on the magnetization process in Ni-Cu-Zn ferrite in a weak field. J. Magn. Magn. Mater. 68, 351–357 (1987).

Misra, A. Theoretical study of the fracture-induced magnetic effect in ferromagnetic materials. Phys. Lett. A 62, 234–236 (1977).

Permiakov, V., Dupré, L., Pulnikov, A. & Melkebeek, J. 2D magnetization of grain-oriented 3%-Si steel under uniaxial stress. J. Magn. Magn. Mater. 290–291, 1495–1498 (2005).

Li, J., Xu, M., Leng, J. & Xu, M. Modeling plastic deformation effect on magnetization in ferromagnetic materials. J. Appl. Phys. https://doi.org/10.1063/1.3695460 (2012).

Lihong, D., Binshi, X., Shiyun, D., Qunzhi, C. & Dan, W. Variation of stress-induced magnetic signals during tensile testing of ferromagnetic steels. NDT E Int. 41, 184–189 (2008).

Matsuo, T. Magnetization process analysis using a simplified domain structure model. J. Appl. Phys. https://doi.org/10.1063/13556923 (2011).

Ren, S. & Ren, X. Studies on laws of stress-magnetization based on magnetic memory testing technique. J. Magn. Magn. Mater. 449, 165–171 (2018).

Bhat, I., Muju, M. & Mazumdar, P. Possible effects of magnetic fields in fatigue. Int. J. Fatigue 15, 193–197 (1993).

Prasad, S. N., Singh, P. N. & Singh, V. Influence of pulsating magnetic field on softening behaviour of cold rolled AISI 4340 steel at room temperature. Scr. Mater. 34, 1857–1860 (1996).

Shimotomai, M. Influence of magnetic-field gradients on the pearlitic transformation in steels. Mater. Trans. 44, 2524–2528 (2003).

Enomoto, M. enhanced phenomena in metals with electric and magnetic fields: II magnetic fields. Mater. Trans. 46, 1088–1092 (2005).

Hou, M. et al. Effects of pulsed magnetic fields of different intensities on dislocation density, residual stress, and hardness of Cr4Mo4V steel. Crystals (Basel) 10, 115 (2020).

Wang, Y. Q., Gorley, M., Kabra, S. & Surrey, E. Influence of a 1.5 T magnetic field on the tensile properties of Eurofer-97 steel. Fusion Eng. Design 141, 68–72 (2019).

Sidhom, A. A. E., Sayed, S. A. A. & Naga, S. A. R. The influence of magnetic field on the mechanical properties & microstructure of plain carbon steel. Mater. Sci. Eng. A 682, 636–639 (2017).

Yadav, R. D. & Gautam, V. Effect of magnetic field on deformation behavior of a steel sheet in uniaxial tension. J. Test Eval. 52, 20230284 (2024).

Datt Yadav, R. & Gautam, V. Effect of magnetic field on mechanical properties of an advanced high strength steel sheet. Mater. Lett. https://doi.org/10.1016/j.matlet.2024.136087 (2024).

Ida, N. Engineering Electromagnetics (Springer International Publishing Switzerland, 2015).

Levy, M. & Karki, D. Nonreciprocal transverse photonic spin and magnetization-induced electromagnetic spin-orbit coupling. Sci. Rep. 7, 39972 (2017).

Simpson, J. H. NMR Case Studies: Data Analysis of Complicated Molecules (Elsevier, 2017).

Ren, J. et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing. Nature 608, 62–68 (2022).

Zheng, X. Y. et al. Ultra-thin lithium aluminate spinel ferrite films with perpendicular magnetic anisotropy and low damping. Nat. Commun. 14, 4918 (2023).

Yan, J.-A., Wang, C.-Y. & Wang, S.-Y. Generalized-stacking-fault energy and dislocation properties in bcc Fe: A first-principles study. Phys. Rev. B 70, 174105 (2004).

Devincre, B., Hoc, T. & Kubin, L. P. Collinear interactions of dislocations and slip systems. Mater. Sci. Eng. A 400–401, 182–185 (2005).

Marciniak, Z., Duncan, J. L. & Hu, S. J. Mechanics of Sheet Metal Forming (Butterworth-Heinemann, 1992).

Ghandi, A., Shamanian, M., Rezaeian, A., Salmani, M. R. & Szpunar, J. A. Study of DP590 microstructure welded with resistance spot welding method by using EBSD technique. Metallogr. Microstruct. Anal. 10, 266–275 (2021).

Aravas, N. & Aifantis, E. C. On the geometry of slip and spin in finite plastic deformation. Int. J. Plast. 7, 141–160 (1991).

Immoor, J. et al. Weak cubic CaSiO3 perovskite in the Earth’s mantle. Nature 603, 276–279 (2022).

Suslova, A., El-Atwani, O., Sagapuram, D., Harilal, S. S. & Hassanein, A. Recrystallization and grain growth induced by ELMs-like transient heat loads in deformed tungsten samples. Sci. Rep. 4, 6845 (2014).

Srivastava, A. P. et al. Understanding the effect of irradiation temperature on microstructural evolution of 20MnMoNi55 steel. Sci. Rep. 12, 16366 (2022).

Zhang, Z. et al. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat. Commun. 8, 14390 (2017).

Acknowledgements

The authors would like to thank the staff of OIM and Texture lab at IIT Bombay for providing the testing of the electron backscattered diffraction (EBSD) technique and evaluation of the results. The authors would also like to thank the staff of the SPM (physics) IRCC central facility at IIT Bombay for providing the testing using the magnetic force microscopy (MFM) technique and evaluation of the results. The authors would like to thank the staff of the material testing laboratory of the Department of Metallurgy and Materials Engineering IIT Roorkee for providing the computer-controlled Erichsen cupping tester BECT-100.

Author information

Authors and Affiliations

Contributions

Ravi Datt Yadav came up with the idea for the study, developed the methodology, conducted the investigation, and wrote the main manuscript. Prof. Vijay Gautam supervised the project, review & Editing the manuscript and provided the resources.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yadav, R.D., Gautam, V. Magnetic field assisted uniaxial deformation and forming behaviour of an advanced high strength steel sheet. Sci Rep 15, 33732 (2025). https://doi.org/10.1038/s41598-025-94081-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94081-3