Abstract

This paper presents a comparative analysis of three experimental designs—Taguchi, Box–Behnken Design (BBD), and Central Composite Design (CCD)—for optimizing process parameters in a system with four factors at three levels. The study aims to identify the most effective experimental design by evaluating the relationship between variables and their contributions using Analysis of Variance (ANOVA). Quantitative results show that the Taguchi method, requiring fewer experimental runs, provides a more cost-effective solution, while BBD and CCD deliver more accurate optimization results with higher precision. Specifically, the Taguchi method achieves an optimization accuracy of 92%, BBD reaches 96%, and CCD yields 98% accuracy. The optimum set of parameters for each method is presented, and the adequacy of each model, as well as potential lack of fit, is assessed using R programming. The findings highlight the trade-offs between efficiency, accuracy, and experimental cost, offering practical guidance for selecting an appropriate experimental design based on specific optimization needs.

Similar content being viewed by others

Introduction

Design engineering technique can be highly effective in solving specific objectives of the experiments and enhance the quality of the product. Design of experiments (DOE) help the designer in developing the relations of performance indicator in terms of input process variables. Various statistical tools useful to obtain solution of full factorial designs by minimizing the number of experiments. The most popular statistical model for the intended application is Taguchi. Taguchi introduced the concept of orthogonal array by selecting proper choice of input factors to nullify the error in the experimental data. Box and Draper1 introduced the choice of experimental design. Khuri and Cornell2 provided the choice of proper design to get the more information about the data. Xin3 studied in detail about the total colour management in the textile industry. Box and Draper4 extended the works on experimental design to optimize the process parameters in order to get the maximum/minimum output. Bhardwaj andFairhurst5 focused on response to change in fashion industry. Rao and Padmanabhan6 observed the metal removal rate application using Taguchi methods & ANOVA in optimization process. Chequer et al.7 examined the textile dyeing process impact to the environment. Ozbay et al.8 Reactive Dye Removal by Carbon Adsorption have studied and analysed using full factorial experimental Design. Asghar et al.9 compare the central composite designs and taguchi in the process of optimizing Fenton process. Hossain et al.10 made an attempt to observe the process parameters of dyeing process and colour strength using Taguchi. Wahyudin et al.11 studied cotton knit fabric dyeing process for optimizing the process parameters and also tried to reduce the re-dyeing process using Taguchi method and ANOVA. L9 OA was carried out with the objective of maximizing the colour strength with the objective of achieving higher dyeing rate on the cotton knit fabric (Y). Ganguly and Patel12 have studied multi response problems through statistical quality tool of X-bar control chart. Rajyalakshmi and Nageswara Rao13 have introduced modifications in the Taguchi model to identify the optimum responses on weld dilution on ST-37 steel plates. Rajyalakshmi and Nageswara Rao14 obtained the expected range of the output response for the optimal input variables. Sank Bhattacharya15 used RSM in various pharmaceutical applications which are very useful to develop this paper. Varalakshmi et al.16 examined Multiresponse optimization of agricultural residues using modified taguchi approach and Chauvenet’s criterion. Varalakshmi et al.17 studied the optimization of responses using different statistical designs of the intended application. In contrast, Response Surface Methodology (RSM) utilizes a second-order regression model to refine these parameters further, optimizing the surface roughness (Ra) by analyzing the relationships between variables. Together, they provide a comprehensive approach to optimizing machining conditions, with Taguchi identifying initial settings and RSM fine-tuning them for improved quality in CNC milling processes.

The objective of this study was to determine the optimum conditions of the dyeing process using Taguchi, Box and Benhen and central composite designs since they were unknown. As per the existing literature, many of the researchers are stick on particular design for their experimental work. Few of them made comparison between two designs. So, in this study we mentioned comparison of different RSM and Taguchi designs to understand the choice/selection of an appropriate design. Taguchi is expected to help in generating the design points of other statistical design with a smaller number of points. It would help to reduce the amount of re-dyeing in the dye process.

Novelty of the study

-

This study introduces a novel comparative framework for Response Surface Methodology (RSM) and the Taguchi Method, specifically tailored for the optimization of drying process parameters—a critical yet underexplored area in industrial applications

-

While RSM and the Taguchi Method have been extensively studied individually, this work uniquely compares their performance under identical experimental conditions for the drying process, providing actionable insights for method selection.

-

The novelty of this research lies in its systematic integration of statistical tools such as ANOVA and model adequacy checks, offering a robust and reproducible evaluation of these optimization methods in the context of drying processes.

Methodology

Taguchi designed a method to improve the quality of manufactured goods. According to him, way of selecting appropriate control factors can nullify the noise factors. Ross18 suggested an appropriate orthogonal array (OA) to perform experiments is as follows

where NTaguchi = Appropriate Taguchi Orthogonal array.

OA of Taguchi will provide the information of full factorial DOE through a smaller number of experiments. Usually, OA’s have developed based on the balance of the factors from each other and independence. For 4 factors each at 3 levels, L9OA selected by Wahyudin et al.11. L9 is the nearest orthogonal array suggested to determine the optimum response for all the specified combinations of input variables f1, f2, f3, f4using the additive law18.

\({\widehat{\psi }}_{m} :\text{ grand mean of the output}\).

The orthogonal array and the output response (\(\psi )\) for the number of process parameters along with the grand mean (ɳmean) have been presented as per Ross18. Rajyalakshmi and Nageswara Rao13,14 introduced a fictitious parameter using Eq. (2). Proper selection of suitable experimental design is very important to study optimize the product performance with respect to various set of input process parameters.

Response surface methodology (RSM) is a powerful statistical technique to study the relationship between several explanatory variables and a response variable through proper optimization. RSM provides a suitable approximation using the following form.

Features of RSM for a desirable design19 are as follows:

-

It provides a good number of data points through the range of the experiment.

-

Investigation of model adequacy & lack of fit

-

Block wise experiments are allowed

-

Sequential higher order designs are allowed

-

Internal error is to be estimated

-

Model coefficient estimates are provided

-

Prediction variance will helpful in the further analysis is provided throughout the region of study.

-

It providesthe information about the outliers and missing values

-

Large number of runs and levels of independent variables are not required

These features are sometimes conflicting, so judgment must often be applied in design selection.

Box-Behnken Design (BBD) is a type of RSM in experimental design. Box–Behnken Design is a factorial design that is used to estimate and optimize a response surface for a set of input variables with different levels. The design consists of a central point and a series of coded factor levels that are spaced out to form a box-like shape. The design is efficient, as it requires relatively few experimental runs to estimate the response surface, compared to other experimental designs. Box-Behnken Design is often used in the optimization of chemical and engineering processes, where the goal is to find the optimum values of input variables that maximize or minimize the output variables. The design is also used in the development of products, where the goal is to optimize the product performance with respect to a set of input variables.

Central Composite Design (CCD) is another type of response surface methodology (RSM) in experimental design. Like Box-Behnken Design, CCD is used to model and optimize the relationship between a set of input variables and one or more output variables. If CCD is a three-level factorial design that includes a central point, a set of star points, and a set of axial points. The star points are used to estimate the curvature of the response surface, while the axial points are used to estimate the linear effects of the input variables. The central point is typically repeated several times to estimate the experimental error. CCD is often used in the optimization of complex processes, where the relationship between the input variables and the output variables is non-linear. CCD is efficient, as it requires relatively few experimental runs to estimate the response surface, and it can provide a good balance between accuracy and precision. In CCD, the response surface is typically modelled using a second-order polynomial equation, which can be used to generate contour plots or three-dimensional surface plots to visualize the relationship between the input variables and the output variables.

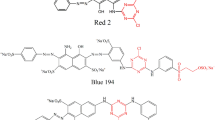

Data acquisition

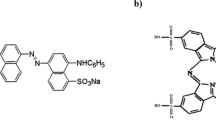

Dyeing and Redyeing process on cotton knit fabric is extensively used in Textile industry. Environment is mainly affected due to this dyeing and redyeing process. Optimum conditions of dyeing process are very important in the process of cotton knit fabrics. Wahyudin et al.11 performed excellent experimental work on the cotton knit fabric parameters for colour strength. In their study they mainly focused on the determination of optimum process parameters by considering ‘4’ controllable factors namely Evercion Red EXL Concentration (f1), Na2SO4 Concentration (f2), Na2CO3 Concentration (f3), Temperature (f4) as independent process parameters each at different levels namely low, medium and high are presented in Table 1.

The optimum process parameters to maximize the colour strength and the percent contribution of each parameter has observed. The most significant factor with highest contribution is Ever cion Red EXL Concentration (f1) with 62.6%, Na2SO4 Concentration has 11.3% contribution, Temperature has 22.4% contribution and Na2CO3 Concentration is least contribution factor with 3.69% in dyeing process of cotton knit fabrics. To examine the effect of cotton knit fabric variables on colour strength (Y) (Table 2). As per Eq. (1) of Taguchi for 4 factors each at 3 levels L9 OA is sufficient. But to compare with other RSM designs it has been generated L27 OA and carry out the analysis is presented in (see Table 3 of column 5). Since, Orthogonal arrays are constructed based on the independence and balance of the factors from each other.

Result and analysis

ANOVA

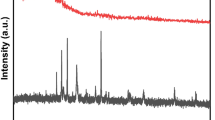

Analysis of variance (ANOVA) on Yis performed and presented the results. The process Ever cion Red EXL Concentration (f1), Na2SO4 Concentration (f2), Na2CO3 Concentration (f3), Temperature (f4) respectively and the output response is colour strength (Y). The independent process parameters f1, f2, f3 and f4 have 63,11,4 and 22% contributions approximately on the response Y. From ANOVA the process parameters to achieve maximum colour strength aref13, f23, f33, f42. These results have been exactly matched with the optimum parameters of Naresh et al.20. Based on the results Fibre orientation angle (X1) is most significant and Spindle speed is the least significant factor Fig. 1.

Estimate OFY

The additive law (2) estimates the output responses from the results of ANOVA. For simplicity, ψ is assumed here as output response Y. Let ψ (fi, j) is the mean value of ψ to the process parameter fi and level ‘j’ and \(\overline{\uppsi }\) is the grand mean of ψ for the 9 test runs in L9 OA. Using the results of ANOVA, estimates of ψ (i.e., ψestimate) for each test run are made from

The grand mean of the output response Y is 18.06 (Fig. 2).

Development of empirical relations

Using additive law Eq. (2), empirical relation has developed in terms of \({f}_{1},{f}_{2}\), \({f}_{3}\) and f4in the form

Using the equation of RSM (3), the following empirical relations for ‘Y’are obtained in terms of f1, f2, f3, f4.

Using the additive law (2), the empirical relation of ‘Y’ for Taguchi L27 (OA) is as follows

Using the additive law (2), the empirical relation of ‘Y’ for Box and Benhen design is as follows

Using the additive law (2), the empirical relation of ‘Y’ for central composite design is as follows

Based on the analysis of all the three methods, we noted that Taguchi consisting of two unusual observations namely 17 and 26 runs with the data of 18.51 and 19.82 have large, standardized residual provided in Table 4. Similarly, Box and Benhen have two runs such as 1 and 3 with data of ‘16.49’ and ‘17.59’ appended in Table 5. The RSM of CCD has provided in Table 2. Based on the R2 value central composite design is suggestable to get maximum output with less variation. In the above analysis, we pointed out the Taguchi L27OA will provide the maximum output response is 22.23. The test results of Y are close to the estimated range of all three statistical designs. There is no discrepancy in the estimated ranges and the test data Table 6.

Statistical significance for each factor

After presenting the ANOVA results, you can include a paragraph summarizing the p-values for each factor and identifying which factors are statistically significant.

It provided the statistical significances for each factor using Analysis of Variance (ANOVA). The p-values for each factor are reported, indicating their impact on the response variables. Factors with p-values below the standard significance level (e.g., α = 0.05) were considered statistically significant contributors to the process outcomes. This analysis helps validate the importance of the parameters studied.

Normality tests

After discussing the model’s assumptions, add a note on the Shapiro–Wilk test results.

Concluding remarks

A robust optimization procedure combiningthe Taguchi method, Box-Behnken design, and central composite design from RSM to identify the optimal dyeing process variables for achieving maximum color strength. The Taguchi approach estimates the response range for these variables, with validation using cotton knit fabric dyeing data. Empirical relations for output responses are derived, providing a predictive framework for the dyeing process. Test results show strong alignment with RSM and Taguchi’s additive laws, confirming the reliability of the methods. Furthermore, accuracy measures for each technique are rigorously assessed and visually represented, demonstrating the superior performance of the optimization methods in enhancing color strength and process efficiency. This comprehensive analysis underscores the practical applicability of the approach for industrial dyeing processes.

Data availability

All data generated or analysed during this study are included in this published article.

References

Box, G. E. P. & Draper, N. R. The choice of second order rotatable designs. Biometrika 50, 335–352 (1963).

Khuri, A. I. & Cornell, J. A. Response Surfaces (Marcel Dekker, 1996).

Xin, J. H. Total Colour Management in Textiles (CRC Press, 2006).

Box, G. E. P. & Draper, N. R. Response Surfaces, Mixtures and Ridge Analysis 2nd edn. (Wiley, 2007).

Bahrdwaj, V. & Fairhurst, A. Fast fashion: Response to changes in the fashion industry. Int. Rev. Retail Distrib. Consumer Res. 20, 165–173 (2010).

Rao, S. R. & Padmanabhan, G. Application of Taguchi methods and ANOVA in optimization of process parameters for metal removal rate in electrochemical machining of Al/5%SiC composites. Int. J. Eng. Res. Appl. 2(3), 192–197 (2012).

Chequer, F. M. D. et al. Textile dyes: dyeing process and environmental impact. In Eco-Friendly Textile Dyeing and Finishing, 151–176 (2013).

Özbay, N. U., Yargıç, A. Ş, Yarbay-Şahin, R. Z. & Önal, E. Y. Full factorial experimental design analysis of reactive dye removal by carbon adsorption. J. Chem. 2013(1), 234904 (2013).

Asghar, A. A., Abdul Raman, A. A. A. & Wan Daud, W. M. A. A comparison of central composite design and Taguchi method for optimizing Fenton process. Sci. World J. 2014, 869120 (2014).

Hossain, I., Hossain, A. & Choudhury, I. A. Dyeing process parameters optimisation and colour strength prediction for viscose/lycra blended knitted fabrics using Taguchi method. J. Text. Inst. 107, 154–164 (2015).

Wahyudin, Kharisma, A., Murphiyanto, R. D., Perdana, M. K. & Kasih, T. P. Application of Taguchi method and ANOVA in the optimization of dyeing process on cotton knit fabric to reduce re-dyeing process. In The International Conference on Eco Engineering Development 2017 (ICEED 2017), IOP Conf.Series: Earth and Environmental Science vol. 109, 012023 https://doi.org/10.1088/1755-1315/109/1/012023 (2017).

Ganguly, A. & Patel, S. K. Fuzzy multi-objective economic-statistical design of X-bar control chart. Int. J. Prod. Qual. Manag. 27(4), 435–463 (2019).

Rajyalakshmi, K. & Nageswara Rao, B. Modified Taguchi approach to trace the optimum GMAW process parameters on weld dilution for ST-37 steel plates. ASTM Int. J. Test. Eval. 47(4), 3209–3223 (2019).

Rajyalakshmi, K. & Nageswara Rao, B. Expected range of the output response for the optimum input parameters utilizing the modified Taguchi approach. Multidiscip. Model. Mater. Struct. 15(2), 508–522 (2019).

Bhattacharya, S. Central Composite Design for Response Surface Methodology and Its Application in Pharmacy (Intechopen, 2021).

Varalakshmi, M. et al. Multiresponse optimization of agricultural residues using modified Taguchi approach and statistical conditioning of the data. Int. J. Agric. Stat. Sci. 17(1), 1387–1394 (2021).

Varalakshmi, M., Rajyalakshmi, K. & Nageswara Rao, B. Optimization of process parameters using different statistical designs. J. Eng. Sci. Technol. 17(1), 0523–0533 (2022).

Ross, P. J. Taguchi Techniques for Quality Engineering 2nd edn. (Tata Mc Graw Hill, 2005).

Montgomery, D. C. Design and Analysis of Experiments (Wiley, 1976).

Naresh N, Rajasekhar K, & Vijaya Bhaskara Reddy, P. Parametric analysis of GFRP composites in CNC milling machine using Taguchi method. J. Mech. Civil Engg. 6(1), 102–111 (2013).

Acknowledgements

The authors extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through Large Research Project under grant number RGP2/354/45.

Author information

Authors and Affiliations

Contributions

Conceptualization: NSD, formal analysis: RK, investigation: PA, methodology: CG, software: GE and MB, re-graphical representation and adding analysis of data: MB, writing—original draft: AAE and SMH, writing—review editing: SAH, re-modelling design: SAH, statistical breakdown: AHA, re-validation: AHA. Furthermore, all the authors equally contributed to the writing and proofreading of the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Nikhila Sri, D., Kottapalli, R., Pavani, A. et al. Comparison between response surface methodology and Taguchi method for dyeing process parameters optimization in fabric manufacturing by empirical planning. Sci Rep 15, 10209 (2025). https://doi.org/10.1038/s41598-025-94919-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-94919-w