Abstract

There are some drawbacks such as the propagation and spread of bacteria and viruses during the use of normal paper. Therefore, this work designed a starch styrene-acrylic antibacterial emulsion for improving the paper properties. The modified antimicrobial monomer was prepared by the subject-object recognition of β-cyclodextrin with hydrophobic modified titanium dioxide. The antibacterial performance of prepared emulsion was tested by Escherichia coli, Staphylococcus aureus. And the mechanical properties of the modified paper were measured according to the national standards. The results showed that the antibacterial emulsion has excellent comprehensive performance with the viscosity of 1750 mPa·s, the inhibition ring diameter of 11.82 mm, the good chemical stability and storage stability. Therefore, the proposed cationic starch styrene-acrylic antibacterial emulsion has promising applications in paper surface modification.

Similar content being viewed by others

Introduction

The environment in which people lived was often infected by microorganisms such as bacteria, molds, yeasts and viruses1,2,3. The paper which we use so widely is no exception, which raises safety concerns about physical health. Therefore, the antibacterial properties of paper are crucial. Usually, modifying paper with antibacterial emulsion can obtain satisfactory paper performance.

Many studies have utilized antimicrobial emulsions to prepare paper coatings. Chen et al.4 prepared a novel kind of antibacterial fluorinated acrylic emulsion by emulsion polymerization. The results showed that functional monomers were bonded into the polymer chain, and enabled the emulsion had good weatherability and antibacterial activity. Leclercq et al.5 studied antimicrobial Pickering emulsions expressed good antimicrobial activity. Zhou et al.6 synthesized styrene-acrylic antibacterial emulsions with different MEMT content by emulsion copolymerization, which showed strong and durable antibacterial activity against Escherichia coli and Staphylococcus aureus. Styrene-acrylic emulsions, which have excellent water resistance, alkali resistance, scrub resistance, and adhesive force, have been used as the main emulsion to enhance paper properties7. Making styrene-acrylic emulsions antimicrobial is the focus of this paper.

The surface of the paper was modified by adding antimicrobial agent to emulsion, which resulted in improved paper properties and antimicrobial properties of the paper surface. Titanium dioxide (TiO2) was one of the most common antimicrobial agents8, which had been extensively studied for its wide range of applications in catalysis, photocatalysis, antimicrobial agents and in the civilian field as self-cleaning nano-coating affecting the quality of people’s lives9,10,11,12. Its unique physicochemical properties were dependent on the crystalline phases, the size and shape of the particles13. However, TiO2 was easily agglomerated which was not conducive to its function, so TiO2 was organically modified or doped metal to improve its dispersibility14,15.

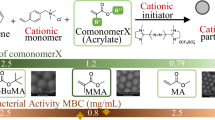

Styrene-acrylic emulsion mixed with starch had high-cost performance and a wide range of applications. In this study, anatase TiO2 was introduced into cationic starch (CS) linked styrene-acrylic emulsion12. In the experiment, TiO2 was organically modified by KH570 silane coupling agent, and hydroxyl group of TiO2 reacted with silane coupling agent to result in a large amount of silicon encapsulated on the surface of TiO2, which effectively improved the dispersion of TiO2. This Silane coupling modified KH-TiO2 was further hydrophobically modified by adamantane carbonyl chloride to introduce hydrophobic Ada, and obtain the object about Ada-KH-TiO2 with good hydrophobicity. Then, the modified TiO2 antimicrobial monomer TiO2-CD-HAM was prepared by the subject-object recognition, in which the Ada group of the object Ada-KH-TiO2 was encapsulated by the hydrophobic cavity of the subject alkenyl cyclodextrin β-CD-HAM. Followed, the CS styrene-acrylic antimicrobial emulsions were prepared by copolymerization and blend of antimicrobial monomer with styrene, acrylic acid and CS. It was expected to be used as a novel antimicrobial modifier on the paper surface to achieve antimicrobial properties to paper, and broaden the antimicrobial applications of TiO2.The main reactions of this study were shown in Fig. 1.

Experiment section

Materials

β-CD (a water-soluble macrocyclic oligosaccharide was composed of seven D-glucopyranose by α-(1,4) bonding) was purchased from Shanghai Shanpu Chemical Co., Ltd. Adamantane formic acid was purchased from Aladdin Reagent Co., Ltd. (Shanghai, China). TiO2, styrene, acrylic acid, methyl methacrylate, methyl acrylate, N-hydroxymethyl acrylamide, hydrochloric acid, 3-Methacryloxypropyltrimethoxysilane (silane coupling agent KH570), ammonium persulfate solution, 4-dimethylaminopyridine, toluene, and anhydrous ethanol were all purchased from Energy Reagent (Shanghai, China). E. coli, S. aureus was sourced from China-Malaysia National Joint Laboratory, Biomedical Research Center. All reagents were of analytical grade.

TiO2 of Silane coupling modification and hydrophobic modification (KH-TiO2 and Ada-KH-TiO2)

TiO2 of 2.0 g was added into 125.0 mL HCl of 2.0 mol/L, and mechanically stirred at room temperature for 4.0 h, ultrasonically dispersed for 30.0 min, washed with distilled water to neutral, then drip washed with anhydrous ethanol, and vacuum dried at 50 ± 0.5 ℃ to obtain the pretreated TiO2. Then, pretreated TiO2 of 2.0 g was added into the reaction system with toluene as solvent, and a certain amount of silane coupling agent about KH570 was then added under stirring and ultrasonic dispersion at 40 ± 0.5 ℃ for 40.0 min, the reaction system was reacted under reflux at 80 ± 0.5 ℃ for 24.0 h. After filtration, toluene, anhydrous ethanol and distilled water were added separately to remove unreacted silane coupling agent, dried in vacuum at 50 ± 0.5 °C, the KH-TiO2 was prepared16,17.

Adamantane carboxylic acid of 5.0 g was added into sulfoxide chloride of 100.0 mL, and a small amount of dimethylformamide (DMF) was added into the reaction system. The temperature was increased to 80 ± 0.5 ℃ for 4.0 h, the excess sulfoxide chloride was removed by spin distillation and dried at room temperature to obtain adamantane carbonyl chloride. The 4-dimethylaminopyridine (DMAP) were dissolved in trichloromethane of 15.0 mL. A certain amount of KH-TiO2 and adamantane carbonyl chloride were added, stirred well, dehydrating agent with dicyclohexylcarbodiimide (DCC) of 0.5 g was added, the reaction was carried out at 60 ± 0.5 ℃ for several hours, and the sample of the reaction was washed with trichloromethane solution, 1.0 mol/L HCl, anhydrous ethanol, and distilled water, respectively; filtered, dried at 50 ± 0.5 ℃ under vacuum, the Ada-KH-TiO2 was prepared.

Preparation of alkenyl cyclodextrin β-CD-HAM

β-CD of 5.0 g was added into DMF of 15.0 mL, followed by the addition of DCC of 1.0 g and triethylamine of 5.0 mL were added, stirred well, the HAM of 5.0 g was added and reacted at 15 ± 0.5 °C for 5.0 h, filtered, the filtrate was precipitated with 30.0 mL of acetone to obtain the crude product. The filtrate was purified by the addition of dilute acetic acid, potassium carbonate solution, acetone and methanol. Then, the white solid powder of β-CD-HAM was obtained by filtration and drying.

Preparation of antimicrobial inclusion monomer TiO2-CD-HAM

The antimicrobial inclusion monomer was prepared by ultrasonication and freeze-drying with Ada-KH-TiO2 as the object and β-CD-HAM as the subject to investigate the effects of different inclusion methods and different dosage ratios of the subject to the object on the inclusion monomer.

Ultrasonication method: Ada-KH-TiO2 of 0.5 g was added into 50.0% ethanol solution of 30.0 mL, ultrasonically dispersed for 30.0 min, β-CD-HAM of 0.5 g was added to the reaction system and dispersed by sonication at 40 ± 0.5 °C for 30.0 min. The reaction was heated at 40 ± 0.5 °C for 6.0 h, filtered, washed and dried in vacuum at 50 ± 0.5 °C. The antimicrobial of the TiO2-CD-HAM inclusion complex of subject-object recognition was obtained.

Freeze-drying method: β-CD-HAM of 2.0 g was added into distilled water of 20.0 mL, Ada-KH-TiO2 of 0.25 g was added into anhydrous ethanol of 5.0 mL. Ada-KH-TiO2 anhydrous ethanol solution was slowly dropped into β-CD-HAM aqueous solution under magnetic stirring, the reaction was carried out at 25 ± 0.5 ℃ for 1.0 h, and the product was put into a freeze-drying box for drying. Finally, the TiO2-CD-HAM was obtained18.

Preparation of CS

3-chloro-2-hydroxy propyl trimethylammonium chloride of 3.8 mL, solid powder of NaOH of 1.0 g and water of 1.0 mL were mixed in a beaker. Then, potato starch of 10.0 g was added to the reaction system, stirred well. The system was reacted in a microwave oven at low heat for 70 s, soaked in anhydrous ethanol for 60.0 min and then pumped and filtered, washed with 80.0% ethanol solution and dried at 60 ± 0.5 °C to obtain CS.

Preparation of CS styrene-acrylic Antibacterial Emulsion

Distilled water of 75.0 mL was added to a four-mouth flask with CS of 5.0 g and 20.0% initiator ammonium persulfate solution (APS) under stirring. The reaction system was heated at 90 ± 0.5 ℃ for 30.0 min, the pH value was adjusted to 5.0—6.0 by acetic acid. 20.0% mixed monomers (styrene of 11.0 mL, butyl acrylate of 13.0 mL, methyl methacrylate of 4.5 mL, dimethyl aminoethyl methacrylate of 2.0 mL, and acrylic acid of 1.0 mL), 20.0% APS and β-CD-HAM of 4.13 g, Ada-KH-TiO2 of 0.56 g (blending) and TiO2-CD-HAM of 1.0 g (copolymerization) were separately added. The reaction system was stirred for 10.0 min, and the remaining mixed monomers and initiators were added continuously dropwise within 90.0 min. The temperature was reduced to 86 ± 0.5 ~ 88 ± 0.5 ℃, and reacted for 3.0 h. The temperature was reduced to room temperature, and the CS styrene-acrylic antimicrobial emulsion was obtained19.

Characterization

FTIR(Nicolet 380, Thermo Electron, America); Thermogravimetric analysis (TG209 F3, NETZSCH, Germany); SEM (JSM 6330 F, Shimadzu, Japan); and XRD diffractometer (Panalytical X′Pert PRO, PANalytical B.V.). Rotational viscometer of NDJ-79 (Shanghai Sendi Scientific Instruments and Equipment Co., Ltd., China).

Testing of emulsions and their paper properties

Viscosity, nonvolatile content, storage stability, and chemical stability of the emulsions were tested according to the national standards20.

Paper performance includes paper breaking resistance, folding resistance, creasing stiffness, smoothness, etc. The Paper Breakage Resistance was determined according to GB/T 454–2002. The Folding Resistance of Paper and Board was determined according to GB/T 457–2008. The Creasing stiffness of Paper and Board was determined according to 22,364–2008. The Smoothness of Paper and Board (Buick Method) was determined according to GB/T 456–2002. These tests were carried out in accordance with the prescribed methods.

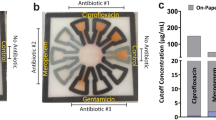

Antimicrobial performance test

The inhibition circle method was adopted to test the antimicrobial performance of paper. The bacteria were activated overnight in advance. Then, the appropriate bacteria were removed into the agar block in the culture dish and uniformly punched on the surface. Subsequently, the right amount of emulsion was taken into the hole. These were sealed and refrigerated for 4.0 h, then incubated in an incubator for 24.0 h, removed for observation, and the size of the inhibition circle was tested and recorded.

Theoretical calculation

The interactions between the subject and object molecules were theoretically investigated through theoretical calculation, the most probable configurations of the inclusion complexes were identified, and the experimental results were verified. The DMol3 module of MS Software (Materials Studio 8.0, America) was used to calculate the subject-object recognition inclusion of Ada molecules with β-CD, the subject-object recognition inclusion of adamantane carbonyl chloride molecules with β-CD, and the interaction of the inclusion complexes with TiO2, respectively. The effect of the error value on the inclusion structure was explored through structure optimization to get a stable inclusion structure, which was then interacted with TiO2 to obtain the optimized β-CD-Ada-TiO2 inclusion. The value of the ΔE was calculated based on the inclusion structure and the minimum energy value, as in Eq. (1). The structure was more stable while the smaller value of ΔE.

In which: ΔE was for the minimum energy mode, kcal/mol; E0 was for the minimum energy of an inclusion, kcal/mol; E1 was for the minimum energy of the subject, kcal/mol; E2 was for the minimum energy of the object, kcal/mol.

Results and discussion

X-ray diffraction characterization

The X-ray diffraction patterns of TiO2-CD-HAM and pre-inclusion subject and object were shown in Fig. 2. As could be seen from Fig. 2a, the diffraction peaks of Ada-KH-TiO2 were weakened at 25.3° and 47.8° compared to KH-TiO2, and a new diffraction peak was appeared at 15.4°, which indicated that the crystal structure of Ada-KH-TiO2 was changed greatly. As could be seen from Fig. 2b, the diffraction peaks of β-CD-HAM were obviously enhanced at 17.5°, 19.9° and 21.5° compared to β-CD, indicated that the structural crystalline shape of the modified β-CD was more changed. The diffraction peaks of the inclusion complexes were weakened compared with those of β-CD-HAM and Ada-KH-TiO2 at 25.1° and 17.5°, and disappeared at 47.9° and 39.2°, indicated that adamantane was encapsulated in the cyclodextrin cavity, which led to the structural crystal shape of the inclusion complex was more variable21.

Fourier transform-infrared spectroscopy characterization

The FT-IR spectra of TiO2, KH-TiO2 and Ada-KH-TiO2 were shown in Fig. 3A. Curve a showed the stretching vibration of hydroxyl groups and adsorbed water on the TiO2 surface at 3426 cm-1 and 1630 cm-1. It could be seen from the spectral curve b that 1187 cm-1 were the stretching vibration absorption peak of Si–O bond and the peak at near 1054 cm-1 was the characteristic absorption peak of Ti–O-Si bond22,23. Curve b had a significantly stronger peak at 1630 cm-1 than curve a, due to the superposition of olefin peak in KH570 after coupling. It indicated that KH570 were successfully grafted on the surface of TiO2, and the stretching vibration absorption peak of C = O bond from KH570 was appeared at 1720 cm-1, so KH570 was selected as silane coupling agent to modify TiO224. Curve c was the spectrum of Ada-KH-TiO2 at the optimal mass ratio 1:1 of adamantane carbonyl chloride to KH-TiO2. It could be seen from curve c that 900 cm-1was the vibrational peak of the Ada skeleton, 1040 cm-1 to 1500 cm-1 were the characteristic peaks of Ada and 1630 cm-1 was the stretching vibration peak of C = O bond, which showed that Ada had been successfully grafted onto the surface of the KH-TiO225,26. The FT-IR spectra of β-CD, β-CD-HAM, Ada-KH-TiO2, mixture and inclusion complex were shown in Fig. 3B. It could be seen from the curve b in Fig. 3B that showed 1633 cm-1 was the stretching vibration absorption peak of C = C bond about β-CD-HAM, 1672 cm-1 and 1245 cm-1 were the stretching vibration absorption peak of the C = O and C-N bond in the amide moiety, which showed that C = C bond of the HAM had been successfully attached to β-CD, the alkenyl cyclodextrin monomer β-CD-HAM was obtained. Curve d was a mixture of β-CD-HAM and Ada-KH-TiO2 with a mass ratio of 1:1 by Ultrasonication method. Curve e was the inclusion complex of β-CD-HAM and Ada-KH-TiO2 with a molar ratio of 1:1 by Freeze-drying method. Compared with the spectrum of curve c, the disappearance or weakening of the characteristic peak of Ada could be seen from curves e, while the characteristic peak of Ada in curve d had not disappeared. It could be concluded that hydrophobic Ada had been successfully encapsulated in the hydrophobic cavity of β-CD-HAM by subject-object recognition27. Besides, in Fig. 3A, B,and C, 2927 cm-1 was the stretching vibration absorption peak of C-H bond, but the stretching vibration of the C-H bond in Ada was more intense. From Figs. B and C, the peak of curve e at 2927 cm-1 was weaker in comparison to the others, which could also indicate that Ada was successfully encapsulated. The FT-IR spectra of TiO2-CD-HAM inclusion complex were shown in Fig. 3C. These curves in the spectra were different molar ratios of Ada-KH-TiO2 to β-CD-HAM. It could be seen from the spectrum of Fig. 3C that the characteristic peaks of Ada had not disappeared between 1039 cm-1 to 1573 cm-1 in curves a, b, and c, which indicated the poor effect of the encapsulation by the ultrasonic method. The characteristic peaks of Ada were weakened between 1039 cm-1 to 1573 cm-1 when the encapsulation of freeze-drying method was used. It could be seen from the curve e that the characteristic peaks of Ada were almost completely disappeared when the molar ratio of Ada-KH-TiO2 to β-CD-HAM was 1:1, which indicated the conclusion that the encapsulation effect was best when freeze-drying method was used, and the molar ratio of Ada-KH-TiO2 to β-CD-HAM was 1:1.

(A) FT-IR spectra of TiO2, KH-TiO2 and Ada-KH-TiO2. a: TiO2; b: KH-TiO2; c: Ada-KH-TiO2. (B) a: β-CD; b: β-CD-HAM; c: Ada-KH-TiO2; d: mixture; e: inclusion complex. (C) FT-IR spectra of TiO2-CD-HAM inclusion complex. a: ultrasonic method (1:2); b: ultrasonic method (1:1); c: ultrasonic method (2:1); d: Freeze-drying method (1:2); e: Freeze-drying method (1:1).

Scanning electron microscopy characterization

The SEM images of TiO2, modified TiO2, β-CD before and after modification and TiO2-CD-HAM were shown in Fig. 4. As could be seen from a and b in Fig. 4, TiO2 raw material was flocculent and irregular agglomeration phenomenon. The acid-treated TiO2 still had the same morphological characteristics as TiO2, but it had a looser structure and better dispersion than TiO2. As could be seen from picture c in Fig. 4, the characteristic structure of TiO2 after silane coupling modified KH-TiO2 was complete structure with fluffy interstructural dispersion and preferable dispersion. Figure 4d displayed the SEM image of Ada-KH-TiO2, the adamantane carbonyl group was adhered to the surface of TiO2, and the interstructural gap between the TiO2 molecules was increased, further indicated that the dispersion of TiO2 was improved after the introduction of hydrophobic adamantane. At the same time, the hydrophobic adamantane can be embraced in the hydrophobic cavity of cyclodextrin by subject-object recognition, resulting in antimicrobial inclusion monomer TiO2-CD-HAM. As could be seen from e and f in Fig. 4, the β-CD surfaces were continuous crystals, and the lamellar crystals of β-CD-HAM were irregularly stacked. Figure 4g showed that TiO2 in TiO2-CD-HAM was attached to the surface of CD crystals with large gaps and good dispersion performance, which proved that Ada molecules were successfully encapsulated with β-CD-HAM28.

Thermogravimetric analysis characterization

The TGA traces of Ada-KH-TiO2, β-CD-HAM, mixture, TiO2-CD-HAM were shown in Fig. 5. As could be seen from Fig. 5, the temperature of the main initial weight loss of the inclusion prepared by freeze-drying method was 265.1 °C, and the residual mass was 21.7%. The temperature of the main initial weight loss of the mixture prepared by ultrasonication method was 224.8 °C, and the residual mass was 36.27%. The temperature of the main initial weight loss of β-CD-HAM was 296.6 °C, and the residual mass was 19.3%. The temperature of the main initial weight loss of Ada-KH-TiO2 was 235.3 °C, and the residual mass was 45.92%. The ultrasonication method didn’t change the respective thermal properties of the subject and object, and the residual mass of the resulting inclusion was the average of the residual masses of the subject and object. In contrast, the thermal decomposition temperature of the inclusion complex prepared by freeze-drying method was slightly lower than that of the main subject β-CD-HAM, but the residual mass was the same as the subject residual mass, indicated that the object molecule Ada-KH-TiO2 was fully encapsulated in the subject.

Emulsion Properties

In the experiment, the total mass of mixed monomers and the proportion of each monomer were kept constant, and the effects of the mass of water, APS, CS and adding way of antimicrobial agent on the performance of the emulsion were investigated. The results were shown in Table 1, Table 2, Table 3.

As could be seen from Table 1, the nonvolatile content and the viscosity value was varied with CS, water and initiator mass. The requirements of the chemical stability of the emulsions were meted, but the storage stability was unstable except for the sample of No. 12.

As could be seen from Table 2, all products had good storage stability. The nonvolatile content and viscosity were lower at the larger water content. The viscosity value of emulsion was greater when the mass of APS was greater than 1.4 g and the mass of CS was greater than 11.0 g. However, the viscosity value was too great to make the experimental stirring difficult, the construction difficult later on. So, the optimum process conditions of the experiment were the mass of APS of 1.4 g, the mass of CS of 10.0 g, and the mass of H2O of 150.0 mL.

Table 3 showed the effect of adding method of antibacterial agent on the properties of emulsions. It could be seen from the Table 3 that the chemical stability of emulsions was qualified and storage stability was better by the copolymerization or blending methods. The maximum viscosity value was only 190 mPa·s at the adding mass of β-CD-HAM of 8.07 g and Ada-KH-TiO2 of 1.076 g in the blending method. However, the viscosity of the emulsion was raised to 1,750 mPa·s when the adding mass of inclusion was only 1 g in the copolymerization method, but the non-volatile content of the compounds did not increase. So, it was concluded that the cross-linking polymerization between monomers was effectively promoted by the copolymerization method.

Paper properties

Figure 6 showed the properties of modified paper by CS styrene-acrylic antimicrobial emulsion. Samples 1 ~ 8 in Fig. 6a, b, c and d correspond to antimicrobial emulsions 1 ~ 8 in Table 3, respectively, and No. 9 was white paper. As could be seen from Fig. 6, the two adding methods of antibacterial agent by copolymerization or by blending with CS styrene-acrylic emulsion had different changes in their breakage resistance, folding resistance, smoothness and crease stiffness. The maximum breakage resistance was up to 279 kPa, the maximum folding resistance was up to 53 times, the maximum smoothness was up to 41.06%, and the maximum crease stiffness was up to 0.8mN·m under optimal conditions.

Antimicrobial properties of antimicrobial emulsions

The antimicrobial performance of the antimicrobial emulsion was tested against E. coli and S. aureus as shown by specimens No. 1 ~ 8. The antimicrobial activity of each emulsion was shown in Fig. 7a and b.

The antimicrobial properties of CS styrene-acrylic antimicrobial emulsions against E. coli were tested and the results were shown in Table 4.

Figure 7a showed the antibacterial effect of antimicrobial emulsion on E. coli and Fig. 7b showed the antibacterial effect of antimicrobial emulsion on S. aureus. Table 4 showed the antimicrobial test results of CS styrene-acrylic antimicrobial emulsions against E. coli. These specimens No. 1 ~ 8 correspond to the antimicrobial effect of the corresponding emulsions No. 1 ~ 8 in Fig. 7a and Fig. 7b, respectively. As could be seen from Fig. 7a, Fig. 7b and Table 4, the antimicrobial emulsions showed significant antimicrobial effects against the gram-negative bacterium E. coli, with the inhibition zone of 11.82 mm for Emulsion No. 3 and 11.02 mm for Emulsion No. 7, both of which reached the degree of medium sensitivity. It was shown that antibacterial inclusion monomer TiO2-CD-HAM formed by CD-based subject-object recognition not only effectively improved the performance of CS styrene-acrylic emulsions, but also conferred better antimicrobial properties to CS styrene-acrylic emulsions.

Theoretical calculation of CD-Ada subject-object recognition

The optimized geometric docking results were shown in Fig. 8a, b and c. Table 5 showed the data for E subject, E object and E inclusion. According to Eq. (1), when the subject and object were encapsulated in the stoichiometric ratio of 1:1, the ΔE values of the β-CD-adamantane inclusions (ΔE1) and the β-CD-adamantane carbonyl chloride inclusion(ΔE2) were -0.02 kcal/mol and 0.01 kcal/mol, respectively. The lower interaction energy values of the β-CD-Ada inclusion complexes indicated that the β-CD-Ada inclusion complexes were more stable than the β-CD-adamantane carbonyl chloride inclusion complexes.

As could be seen from the interaction of the β-CD-adamantane carbonyl chloride inclusion complex with TiO2 in Fig. 8c, the acyl chloride of β-CD-adamantane carbonyl chloride and the hydroxyl group of TiO2 were reacted by removing one molecule of HCl to form the ester. Table 5 showed the lowest energy of β-CD-adamantane carbonyl chloride-TiO2 was -11,714.3 kcal/mol, which was lower than the lowest energies of β-CD-adamantane carbonyl chloride of -5235.223 kcal/mol and TiO2 of -11,154.33 kcal/mol. Thus, β-CD-adamantane carbonyl chloride-TiO2 was more stable than β-CD-adamantane carbonyl chloride and TiO2. The feasibility of preparing β-CD-adamantane carbonyl chloride-TiO2 was theoretically demonstrated.

Conclusion

In this work, a novel kind of starch styrene-acrylic antimicrobial emulsion based on subject-object recognition was prepared by copolymerization of styrene, butyl acrylate, methyl methacrylate, dimethyl aminoethyl methacrylate, acrylic acid, TiO2-CD-HAM, and CS as an emulsifier. The viscosity of the emulsion was up to 1750 mPa·s, with good chemical stability and storage stability. When the surface of the paper was modified by this emulsion, the mechanical properties of the paper modified with breakage resistance of up to 279 kPa, folding resistance of up to 53 times, smoothness of up to 41.06%, crease stiffness of up to 0.8mN·m were improved, the antimicrobial property about the antimicrobial sensitivity of up to medium sensitivity was also achieved. In the meantime, the performance of CS styrene-acrylic emulsion was improved, the application of TiO2 was broadened.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Hanada, S., Pirzadeh, M., Carver, K. Y. & Deng, J. C. Respiratory viral infection-induced microbiome alterations and secondary bacterial pneumonia. Front. Immunol. 9, 2640 (2018).

Cox, J. et al. Associations of observed home dampness and mold with the fungal and bacterial dust microbiomes. Environ. Sci. Process. Impacts 23(3), 491–500 (2021).

Mizutani, T., Ishizaka, A., Koga, M., Tsutsumi, T. & Yotsuyanagi, H. Role of microbiota in viral infections and pathological progression. Viruses 14(5), 950 (2022).

Chen, Z., Wang, Q., Zhang, Z. & Lei, H. Preparation and properties of antibacterial fluorinated acrylic emulsion. Reactive Funct. Polym. 163, 104901 (2021).

Leclercq, L., Tessier, J., Nardello-Rataj, V. & Schmitzer, A. R. Highly active, entirely biobased antimicrobial Pickering emulsions. Chem. Med. Chem. 16(14), 2223–2230 (2021).

Zhou, X. et al. Preparation and properties of antibacterial styrene-acrylic emulsion containing thiazole structure and its application as coating. J. Coat. Technol. Res. 19(5), 1365–1379 (2022).

Stroganov, V., Amelchenko, M. & Kraus, E. Biodegradation of filled styrene-acrylic coatings in a laboratory kinetic plant. IOP Conference Series: Mater. Sci. Eng. 890(1), 012104 (2020).

Chen, M. C., Koh, P. W., Ponnusamy, V. K. & Lee, S. L. Titanium dioxide and other nanomaterials based antimicrobial additives in functional paints and coatings. Prog. Org. Coat. 163, 106660 (2022).

Jameel, N. Z. Synthesis of TiO2 nanoparticles by sol-gel method using laser ablation for nano paint application. PhD thes. (2015).

Bu, Y. et al. Bilayer composites consisting of gold nanorods and titanium dioxide as highly sensitive and self-cleaning SERS substrates. Microchimica Acta 184, 2805–2813 (2017).

Pazokifard, S., Esfandeh, M., Mirabedini, S. M., Mohseni, M. & Ranjbar, Z. Investigating the role of surface treated titanium dioxide nanoparticles on self-cleaning behavior of an acrylic facade coating. J. Coat. Technol. Res. 10, 175–187 (2013).

Haider, A. J., Jameel, Z. N. & Al-Hussaini, I. H. Review on: titanium dioxide applications. Energy Procedia 157, 17–29 (2019).

Wang, J. & Fan, Y. Lung injury induced by TiO2 nanoparticles depends on their structural features: size, shape, crystal phases, and surface coating. Int. J. Mol Sci. 15(12), 22258–22278 (2014).

Sztorch, B. et al. Improving the dispersibility of TiO2 in the colloidal system using trifunctional spherosilicates. Materials 16(4), 1442 (2023).

Devi, K. S. et al. Investigation on the phase transformation and lattice parameters of Sn2+, Cu2+, La3+ and Ce4+ ions doped titania: characterization and solar light activity study. Optik 183, 496–507 (2019).

Wang, L. et al. Titanium dioxide grafted with silane coupling agents and its use in blue light curing ink. Coloration Technol. 136(1), 15–22 (2020).

Zhang, H., Yang, H. & Shentu, B. Effect of surface modification of titanium dioxide on the UV-C aging behavior of silicone rubber. J. Appl. Polymer Sci. 136(10), 47170 (2019).

Qiu, N. et al. Inclusion complex of emodin with hydroxypropyl-β-cyclodextrin: Preparation, physicochemical and biological properties. J. Mol. Liquids 289, 111151 (2019).

Sabzi, M., Mirabedini, S. M., Zohuriaan-Mehr, J. & Atai, M. Surface modification of TiO2 nano-particles with silane coupling agent and investigation of its effect on the properties of polyurethane composite coating. Prog. Org. Coat. 65(2), 222–228 (2009).

Su, Q. & Wang, Y. B. Performance testing of modified starch-synthetic resin polymer emulsions. J. Northwest Minzu University (Natl. Sci. Edit.). 04, 13–18 (2006).

Rezaei-Seresht, E., Rahmandoost, M. & Mahdavi, B. Green and selective iodination of diamondoid adamantane by β-cyclodextrin as a molecular reactor. J. Inclusion Phenomena Macrocyclic Chem. 95, 51–54 (2019).

Šijakova-Ivanova, T., Robeva-Čukovska, L., Jovanovski, F. & Kareski, S. Mineralogical characterization of riebeckite from Alinci. Rep. Macedonia. Geolog. Macedonica 32(1), 75–87 (2018).

Khataee, A., Sheydaei, M., Hassani, A., Taseidifar, M. & Karaca, S. Sonocatalytic removal of an organic dye using TiO2/Montmorillonite nanocomposite. Ultrasonics Sonochem. 22, 404–411 (2015).

Wang, C., Mao, H., Wang, C. & Fu, S. Dispersibility and hydrophobicity analysis of titanium dioxide nanoparticles grafted with silane coupling agent. Indust. Eng. Chem. Res. 50(21), 11930–11934 (2011).

Liao, Q. et al. An Efficient and practical method for the synthesis of saxagliptin intermediate 2-(3-Hydroxy-1-adamantane) -2-oxoacetic Acid and Its optimization. J. Chem. 2019(1), 5375670 (2019).

Jeon, J. W. et al. Carbonization of Carboxylate-Functionalized polymers of intrinsic microporosity for water treatment. Macromol. Chem. Phys. 221(5), 1900532 (2020).

Lee, H. J., Le, P. T., Kwon, H. J. & Park, K. D. Supramolecular assembly of tetronic–adamantane and poly (β-cyclodextrin) as injectable shear-thinning hydrogels. J. Mater. Chem. B 7(21), 3374–3382 (2019).

Lin, L. & Zou, C. Kinetic and thermodynamic study of magnetic separable β-cyclodextrin inclusion complex with organic phosphoric acid applied to removal of Hg2+. J. Chem. Eng. Data 62(2), 762–772 (2017).

Funding

This work was financially supported by the funds of National Natural Science Foundation of China (22165025, 21968032), Gansu Provincial Department of Education: Industrial Support Plan Project (2024CYZC-04), Key Project of Natural Science Foundation of Gansu Province (25JRRA037) , the Fundamental Research Funds for the Central Universities (31920240047, 31920240125–06), Chemistry Innovation Team of Northwest Minzu University (1001660139, 1001660141), Innovation and Entrepreneurship Education Reform Project of Gansu Provincial School of Higher Education (2021SJCXCYXM-01, 2021SJCXCYTD-01).

Author information

Authors and Affiliations

Contributions

Yanbin Wang conducted the research work and Qiong Su prepared all figures and carried out data analysis. Jinqin Zhao revised and edited the article. All authors contributed to writing—review & editing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Zhao, J., Ren, M. et al. Cationic starch styrene acrylic antibacterial emulsion based on subject object recognition of β-cyclodextrin for paper surface modification. Sci Rep 15, 9851 (2025). https://doi.org/10.1038/s41598-025-95026-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-95026-6