Abstract

With respect to high-speed trains, a significant proportion of interior noise is caused by high-frequency vibrations, which are generated at the wheel-rail contact and transmitted through the secondary suspension system in the bogie, to the carbody. Among suspension components, the effect of the traction rod is always underestimated. To research this structure-borne sound transmission, a structure-borne sound model of the traction rod was established, and introduced into a 3D train/track coupled dynamic model. This is suitable to research dynamic behavior at high frequencies, since it considers the inertial effect of heavy and suspension components. The simulated results of these models show that the traction rod force within 26 Hz significantly increases during variable-speed operation, due to the large vertical and pitch movements of the carbody, caused by acceleration and deceleration. In the 26–1000 Hz range, the structural eigenmodes of the traction rod are excited, causing many maxima to occur in the traction force curves. The power contribution rate of the traction rod to the carbody in the 32–259 Hz range varies significantly, from less than 20%, to more than 40%, at different running stages. The influence of the traction rod on structure-borne sound cannot be neglected.

Similar content being viewed by others

Introduction

In railway trains, short-wave track irregularities and higher-order wheel wear polygon irregularities excite high-frequency vibrations from the wheel/rail contact surface1,2. These vibrations are transmitted to the carbody through the suspension components of the bogie. This is known as structure-borne sound transmission3. Measurements4,5 show that structure-borne bogie noise is an important factor in interior noise. It mainly differs due to different bogie designs. As a secondary suspension component that only provides a connection between the bogie and the carbody for longitudinal traction and braking forces, the effect of the traction rod6 on structure-borne sound transmission is always neglected.

The traction rod, consisting of simple bars with rubber joints, is thought to transfer less vertical and lateral force to the carbody at low frequencies, due to the pitch and yaw motion of the bar and variable stiffness of the rubber joints, especially when the train is running at a constant speed. Structure-borne sound is transmitted in the form of high-frequency vibrations, where the inertial effect cannot be ignored. Internal resonances in the traction rod may cause significant vibration transmission at the corresponding natural frequencies, which may fall within the structure-borne sound frequency range. Compared to low-frequency vibrations, less force is required to excite high-frequency vibrations of the same amplitude. This means that although the force transmitted by the traction rod is small, the high-frequency vibration can be significant. Huang et al.7 point out that while the train is running at high speeds, the vibration of the bogie can be transmitted to the carbody through the traction rods. However, the influence of the traction rod in high-frequency vibration transmission, as well as its contribution to vertical vibration transmission, is not clear.

In recent years, vehicle-track coupled dynamics established by Zhai8 have developed rapidly and have been widely used to study the roles of structures such as traction motor9,10,11, gearboxes12, and brake system13 in train traction and braking. However, in these models, traction rods are typically modeled as massless equivalent stiffness elements14,15. Huang et al.7 established a dynamic model of the rigid-flexible coupling system of the carbody, and studied the influence of the traction rod on the elastic vibration of the carbody. The results show that the longitudinal stiffness affects the elastic vibration of the carbody, and a traction rod with variable stiffness can significantly reduce the vertical and longitudinal vibrations of the carbody, without affecting its lateral vibrations. Ma and Song16 introduced an effective stiffness model of the traction rod into a subway vehicle model, and analyzed its influence on the vehicle’s vertical dynamic behaviour. Their study concluded that the vertical effective stiffness of the traction rod will increase the stiffness of the secondary suspension, which can increase the vibration of the carbody. Bokaeian et al.17,18 studied the influence of the traction rod on the dynamic behavior of the carbody, and investigated the possibility of improving ride comfort by optimizing the stiffness of the traction rod. In that study, the traction rod was modeled as a nonlinear element. Dumitriu et al.19 analyzed the influence of the traction rod on the vertical vibration characteristics of the rail vehicle body, considering the damping of the traction rod, and tested a proportional model in the laboratory, to verify the accuracy of their model. The longitudinal vibration characteristics were evaluated in three cases: without a traction rod, with a damped traction rod, and with an undamped traction rod. The established model in the above research is a low-frequency model, which ignores the inertial effect of the traction rod. With respect to the effect of the traction rod on high-frequency vibration transmission, only a few studies have been found. Liu et al.20 established a finite element model based on beam elements, to research the structure-borne sound transmission to the carbody. The model is a linear model, and the research assumes that the train is running at constant speed, ignoring the nonlinear influence of the rubber joint at the end of the traction rod.

In summary, the role of the traction rod in the process of high-frequency vibration transmission is not clear. The purpose of this paper is to investigate the effect of the traction rod on high frequency vibration transmission. The traction rod of a Chinese high-speed train is taken as an example, and the structure-borne sound contribution of the traction rod at both constant and variable speeds is discussed.

The model of the traction rod

The finite element model

As a critical transmission component connecting the traction system and the vehicle body, the traction rod plays an essential role in transmitting traction force, and in providing vibration damping and buffering. Figure 1 shows the structure of the traction rod used in Chinese high-speed trains. As shown in Fig. 1, the traction rod consists of a main body and two metal pins. Rubber joints are installed at both ends of the traction rod to connect the main body with the pins, providing vibration damping, and a certain level of torsional and deflection stiffness. There are C-shaped slots within the rubber joints, employed to achieve variable stiffness in the traction rod. The metal pins at both ends are twisted by 90 degrees around the longitudinal direction, ensuring equal stiffness in both the lateral and vertical directions, thereby maintaining the balance of lateral and vertical forces on the traction rod.

Based on its structure, a finite element model of the traction rod is established. In the finite element model, the main body, rubber joints, and metal pins are modeled using solid elements. The damping characteristics of the rubber in the finite element model are represented by a constant damping loss factor. The model does not consider the nonlinear characteristics of the rubber material, such as frequency nonlinearity or amplitude nonlinearity. Since measurements of the rubber joint in the axle box under preload conditions shows that the rubber joint demonstrates a nearly linear dynamic behavior21. Specifically, the effect of static preload on the dynamic response is minimal, indicating that the amplitude nonlinearity is weak in the relevant operating conditions. Regarding the temperature effect on rubber, in this paper, we have not included temperature-dependent effects in the model. This is because, due to the presence of the train’s air flow during operation, the temperature variations in the traction rod are not significant.

Measurement

To analyze the transmission characteristic, the Frequency Response Function (FRF) values of the traction rod are determined based on measurements. During measurements, the traction rod is suspended by ropes, to approximate the boundary conditions of a free body. An electromagnetic exciter attached at one of the metal pins to produce white noise signals, a force sensor is used between the exciter and the mental pin, and an accelerometer is used to measure the longitudinal motions of the other metal pin, as shown in Fig. 2a. The accelerometer has a sensitivity of 100 mV/g, a measurement range of ± 50 g, and a frequency response from 1 Hz to 10 kHz, ensuring high accuracy over a wide frequency range. Under the excitation of white noise, both the force and acceleration are measured. The FRF is obtained by dividing the Fourier transform components of the acceleration by those of the force.

In the finite element model, the damping property of the rubber is represented by a constant damping loss factor. The rubber vibration isolation material achieves vibration isolation and attenuation by absorbing vibrational energy, and its damping value represents the energy dissipation capability of the rubber material. The damping loss factor is expressed as the ratio of the energy dissipated in one vibration cycle to the energy stored during that cycle, which can be simplified as the ratio of the loss modulus to the storage modulus. For the finite element model, we adopted a linear assumption, which allows us to use the damping loss factor to simulate the damping characteristics of the rubber layer. This simplification assumes that the material behaves linearly within the given range of applied forces and frequencies, which is a common assumption in modeling for computational efficiency. The non-linear characteristics, such as frequency-dependent and amplitude-dependent characteristics, are not taken into account. As shown in Fig. 2b, by adjusting the parameters of rubber material in the finite element model, a good agreement between calculated and measured FRF can be achieved. The finite element model of the traction rod can effectively simulate the rod’s dynamic characteristics.

From Fig. 2b, it can be seen that the FRF has a local maximum value at around 200 Hz. In order to explain the cause of the maximum value of the FRF, a modal analysis of the traction rod is carried out, using the established finite element model. Figure 3 shows the structural eigenmodes of the traction rod. There are 13 structural eigenmodes between 0 and 1000 Hz. These structural eigenmodes can be divided into two types: (1) the rigid movement or rotation of the pin, where eigenfrequencies occur in the frequency range between 0 and 295 Hz, as shown in Fig. 3a; and (2) the elastic deformation of the traction rod body, where eigenfrequencies occur in the frequency range between 343 and 1000 Hz, as shown in Fig. 3b. Based on the traction rod vibration modes shown in Fig. 3a, the peak near 200 Hz in the FRF is primarily attributed to the translational motion of the metal pin. Additionally, since the excitation and response points are not symmetric, the rotation of the metal pin also contributes to this peak to a certain extent.

The influence of longitudinal force

In Section "The finite element model", the traction rod was excited by a small force, to approximate the boundary conditions of the vehicle running at a constant speed. Due to the presence of C-shaped slots in the rubber joints of the traction rod, the stiffness of the traction rod varies with the longitudinal force. When the vehicle is running at a constant speed, the longitudinal force is small, and regions A and B of the rubber joints in Fig. 1 are not in contact. When the vehicle accelerates or brakes, the longitudinal force is large, and the rubber parts in regions A and B come into contact, increasing the stiffness. Figure 4 shows the variation of longitudinal force with longitudinal displacement of the rubber joints, simulated by the finite element model. In the figure, the longitudinal direction corresponds to X-axis, lateral direction corresponds to Y-axis, and vertical direction corresponds to Z-axis. In the simulation, fixed constraints were applied to the outer metal ring, and displacement constraints were applied to the metal pins, with the reaction force on the metal pins being calculated. As shown in Fig. 4, with the increase in displacement, the reaction force increases. The slope of the curve represents the stiffness of the rubber joints. The stiffness increases gradually with the increase in displacement. Comparing the stiffness in three directions, the vertical stiffness is the highest, followed by the longitudinal stiffness. The lateral stiffness is the lowest. This is because of the presence of the C-shaped slots distributed in the longitudinal direction of the traction rod.

To analyze the impact of longitudinal force on the vertical and lateral vibration transmission under different conditions, the finite element model was used to simulate the vibration transmission. Figure 5 shows the variations of lateral and vertical stiffness under different longitudinal loads.

From Fig. 5, it can be seen that the variation in longitudinal force has a minimal impact on the lateral and vertical stiffness of the rubber joints. Therefore, the subsequent analysis will not consider the influence of longitudinal preload on the lateral and vertical stiffness.

To obtain the nonlinear relationship between the force and displacement of the rubber joints, a cubic polynomial was used to fit the longitudinal, lateral, and vertical curves.

where, F is the force, the unit is the N or N⋅m, and ∆x is the relative displacement, in units of m or rad. It is important to note that the stiffness nonlinearity considered in this study is induced by the structure. In fact, rubber materials can have significant nonlinearities, such as creep and temperature variations. When considering the nonlinearity of rubber materials, the changes in the material may lead to increased stiffness, which is not accounted for in this study.

The structure-borne sound model

To maintain vehicle stability during traction and braking, China Railway High-speed (CRH) vehicles utilize a Z-shaped traction rod structure.

Each bogie contains two traction rods, which are fixed to the body bolster through a center pin. The center pin consists of a spindle, a rubber layer, and an outer metal layer. Like the rubber joint of the traction rod, the rubber layer of the center pin has a nonlinear stiffness. Referring to the model of the rubber joint at the end of the traction rod, a cubic polynomial was used to fit the Force–displacement curves of the longitudinal, lateral, vertical and yaw directions, which are shown in Fig. 6. Table 1 shows the parameters of the rubber joint model and the rubber layer model.

Figure 7 shows the structure and equivalent model of the traction rod-center pin. Table 2 shows the degrees of freedom for the traction rod model. In this model, the spindle is considered to be fixed to the vehicle body. The outer metal layer is considered to be fixed to the metal pin of the traction rod, which is considered as a rigid body in longitudinal, lateral, vertical, and yaw directions. The rubber layer and rubber joints are considered to have nonlinear stiffnesses, which are shown in Table 1.

The rigid-flexible coupling dynamic model is used to describe the dynamic behavior of the traction rod body. The floating frame of reference formulation (FFRF) is used to describe the kinematics of the flexible body, and integrated into a multibody model. By applying a modal synthesis as a condensed description, the deformation field w(x,t) is described in the following way:

where, Φk(x) are the shape functions, which can be calculated by the finite element model, and scalar variables \(q_{k} (r)\) are the modal coordinates, which are the degrees of freedom for the deformational motion.

The current absolute position \(P_{{{\text{abs}}}}\) of the particle is obtained by applying the rotation matrix \(R_{B}\) and the absolute position vector \(P_{B,ref}\), which describes the current position of the body’s reference point.

As shown in Eq. (3), the FFRF uses a superposition of the motions of the undeformed body and the deformational motions. The motions of the undeformed body, also called “rigid-body motions”, are described as the motion of the reference coordinate system, also called “reference frame”, wherein the vector \(P_{B,ref}\) describes the current position of the reference coordinate system’s origin, and the matrix \(R_{B}\) describes the current spatial orientation of the reference coordinate system.

The characteristic of the traction rod in vehicle

A train-track coupled dynamic model is established in this section, to research the characteristic of the traction rod. The model consists of two subsystems, one describing the train, and the other one describing the track.

Train-track coupled dynamic model

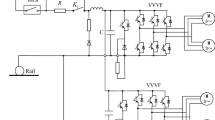

Figure 8 shows the train/track coupled dynamic model. As shown in Fig. 8a, the train subsystem consists of 4 vehicles, arranged in the formation of “M-T-T-M”, where the M means power vehicle, and T means trailing vehicle.

Vehicle models of Chinese high-speed trains have been established using multibody dynamics, shown in Fig. 8b. Each power vehicle or each trailing vehicle is modeled as a rigid body, which includes 7 rigid components: a carbody, two bogies, and four wheelsets. Each rigid body has 6 degrees of freedom. The components of primary suspensions are modeled as massless force elements. The air springs are modeled as equivalent stiffness elements in longitudinal, lateral, and vertical directions. The dampers are modeled as equivalent damping elements in the corresponding directions. The anti-roll bar is modeled as an equivalent stiffness element in the roll direction. The traction rod is modeled in the same way as the structure-borne model mentioned in Section "The model of the traction rod".

To sum up, all of the components of the vehicle, except for the traction rod, are modeled as rigid bodies or massless force elements. This approach aims to eliminate the interference of the structural eigenmode of other components, so as to analyze the impact of the traction rod in the high-frequency region.

The components of the inter-vehicle suspensions are used to transfer the inter-vehicle force, especially when the train is accelerating or braking. Among these components, couplers, inter-vehicle dampers, and tight-lock vestibule diaphragms have a significant influence on the dynamic behavior. In the present model, the nonlinear couplers and inter-vehicle dampers are modeled as nonlinear spring-damper elements, and are retractable only along the axial direction. The tight-lock vestibule diaphragm is simplified as a linear 3D spring element, which can restrain the adjacent vehicles in the longitudinal, lateral, vertical, rolling, pitching, and yawing directions. The detailed inter-vehicle suspension model can be found in research22.

When the train starts, the traction motors in the power vehicle provide the longitudinal traction force, transmitted to the motor bogie—motor traction rod—motor carbody—inter-car suspension—trailer carbody—trailer traction rod—trailer bogie, ultimately causing the train’s acceleration. When the train employs electric braking, the traction motor generates longitudinal braking force in a similar way. This longitudinal braking force is transmitted along the same path to the trailer, causing the train’s deceleration.

To simulate the train’s traction and braking, equivalent traction and braking forces are applied to the wheelset in the motor bogie, as shown in Fig. 8b. The traction and braking forces of the motor car are as shown in Fig. 8c.

The track subsystem consists of rail, fasteners, track slab, and cement asphalt mortar(CAM) layer. The rail is modeled as a Timoshenko beam, which can describe the bending deformations in the vertical and lateral direction, as well as torsional deformations. The fasteners are modeled based on the Kelvin-Voigt model, positioned between the rail and the track slab. The track slabs are modeled as a finite-element model. The CAM layer is regarded as a continuous elastic and damping layer. More detailed information about the ballastless track model can be found in research23.

A wheel-rail contact model is used to link the coupling vehicle subsystem and the track subsystem. Hertz’s nonlinear elastic contact theory is used to solve the contact mechanics problem, and the normal contact force is obtained from its solution. Shen-Hedrick-Elkins creep theory24 is used to calculate the creep forces.

The traction rod force

To analyze the effect of the traction rod on the high-frequency transmission forces of the train, the simulation was conducted with the train running at varying speed on a straight track, to approximate the longitudinal load through the traction rod. At the start of the simulation, i.e. at t = 0 s, the train runs at a constant speed of 300 km/h. At t = 5 s, braking forces are applied to the wheelsets in the motor vehicles, causing the train’s speed to decrease from 300 km/h to 200 km/h. Once the speed reaches 200 km/h, the braking forces are set to zero and the train then runs at a constant speed of 200 km/h until t = 63 s, when traction forces are applied to the wheelsets in the motor vehicles, causing the train’s speed to increase from 200 km/h to 300 km/h. Once the speed reaches 300 km/h, the traction force is set to zero. The train then runs at a constant speed of 300 km/h. Traction or braking force is applied to the wheelset in the motor bogie, and the variation of the force with speed is shown in Fig. 8c.

Figure 9 presents the time–frequency diagram of the traction rod forces transmitted to the carbody in the power vehicle. To generate this diagram, the traction rod force signal, recorded in the time domain during vehicle operation simulation, was first segmented into overlapping or non-overlapping windows, with each window representing a short time period over which the signal can be assumed to be stationary. For each segment, a Fast Fourier Transform (FFT) was applied to convert the time-domain signal into the frequency domain, revealing the frequency components within that specific time window. The FFT results for all segments were then arranged sequentially, creating a time–frequency representation, where the y-axis corresponds to time, the x-axis represents frequency, and the intensity of the color reflects the magnitude of the frequency components at each time point. This method enables a clear visualization of how the frequency content of the traction rod forces changes over time, providing valuable insights into the dynamic characteristics of the forces transmitted to the carbody during operation. The above train’s operation is divided into four stages, which are shown in Fig. 9a. From Fig. 9a, the following results can be seen:

-

1.

During vehicle operation, the peak frequencies of the longitudinal force are 128 Hz and 194 Hz, the peak frequencies of the lateral force are 60 Hz, 128 Hz, 194 Hz, 343 Hz, 482 Hz, and 990 Hz; and the peak frequencies of the vertical force are 60 Hz, 134 Hz, and 198 Hz. According to the structural eigenmodes of the traction rod shown in Fig. 2, 60 Hz, 128 Hz, and 194 Hz are the eigenfrequencies of the rigid movement or rotation of the pin, while 343 Hz, 482 Hz, 712 Hz, and 990 Hz are the eigenfrequencies of the flexible deformation of the traction rod body. The 134 Hz frequency corresponds to the frequency of the train passing over a sleeper.

-

2.

Comparing Stage 2 and Stage 1, the traction rod force within 26 Hz significantly increases during variable-speed operation. This is due to the vertical and pitch movements of the carbody, caused by acceleration and deceleration, which increase the low-frequency traction rod force. In the 26–300 Hz range, the amplitude of the traction rod force significantly increases, but the peak frequency remains essentially unchanged, mainly because the mode of the traction rod’s metal pin is excited. Above 300 Hz, although the amplitude is very small, it generally increases due to acceleration and deceleration, which cause the rubber joints and layers to be in a compressed state, increasing stiffness, and reducing the force attenuation with frequency. Additionally, during acceleration, the longitudinal force significantly increases at 300 Hz, because the increase in longitudinal force leads to greater stiffness in the rubber joints and layers, raising the original peak frequency from 200 to 300 Hz. This frequency change also appears during deceleration, but it is less noticeable, since the deceleration force is much smaller than the traction force.

-

3.

Comparing Stage 1 and Stage 4, the force amplitude at Stage 4 is larger than at Stage 1 for the same speed. The reason for this is that the vertical and pitch movements of the carbody remain significant, affecting the traction rod force. The force amplitude takes a long time to become reduced. Compared to Stage 1, Stage 4 more accurately reflects the actual operating conditions of trains, as constant speed operation does not exist in reality. During steady-speed travel, the train experiences resistance, causing a cycle of acceleration and idling. These results in the train body exhibiting pitching and heaving motions, which in turn cause the drawbar to transmit significant forces. This implies that the influence of the traction rod in the vertical vehicle model is underestimated, which assumes the vehicle is running at a constant speed.

The force transmission

In order to quantify the transmission characteristic of the traction rod, the transmissibility is defined as the quotient of the frequency components of the force between the carbody and traction rod, divided by the frequency components of the force between the bogie and traction rod for the same frequencies. The force time-domain signals were then divided into four stages, as indicated in Fig. 9a.

For each stage, a Fast Fourier Transform (FFT) was applied to convert the time-domain force data into frequency-domain spectra. This resulted in four separate frequency spectra, each representing the force distribution across frequencies for a particular stage. The transmissibility for each stage was calculated by taking the ratio of the frequency components of the carbody and traction rod forces to those of the bogie and traction rod forces at corresponding frequencies. These results are presented in Fig. 10, providing a clear comparison of the traction rod’s transmission characteristics across different stages.

From Fig. 10, it can be seen that in the range of 0–200 Hz, the transmissibilities of longitudinal, lateral, and vertical forces in the traction rod show peaks. The vertical force transmissibility also shows peaks in the high-frequency region above 300 Hz, indicating sensitive frequency bands for high-frequency vibration transmission. Therefore, it is necessary to consider the characteristics of the traction rod when studying the impact of bogie structure-borne noise.

The longitudinal force transmissibility of the traction rod in Stage 1 and Stage 3 differs significantly from other stages, and the lateral and vertical force transmissibilities in Stage 1 also differ markedly from those in other stages. This indicates that the transmission characteristics of the traction rod are not constant. It should be noted that the definition of transmission remains constant for linear systems. The huge change between different stages means the nonlinear characteristics of the traction rod cannot be ignored.

The high-frequency characteristic

The train-track coupled dynamic model in Section "The characteristic of the traction rod in vehicle" cannot be used to discuss the effect of the traction rod on high-frequency vibration transmission, or its contribution to structure-borne noise. In this section, the MBS vehicle model in the train/track coupled model is replaced with a high-frequency model, to investigate the high-frequency characteristics of the traction rod.

Rigid-flexible coupling vehicle model

High-frequency vehicle models of Chinese high-speed train have been established, as shown in Fig. 11 Each power vehicle or trailing vehicle is modeled as a rigid-flexible coupling dynamic model, which includes 15 heavy components: a carbody, two bogies, eight axle boxes, and four wheelsets. The carbody is modeled as a rigid body. The floating frame of reference formulation (FFRF) is used to describe the kinematics of a flexible body in the rigid-flexible coupling dynamic model25,26,27. Table 3 shows the degrees of freedom of the models of these heavy components.

Structural eigenmodes of the wheelset, the axle box, and the bogie frame, in the frequency range between 0 and 1500 Hz, are imported into the vehicle model, to ensure that the modeled high-frequency vibration can be transmitted to the traction rod.

The bogies in Chinese high-speed trains generally use a two-stage suspension system. The primary suspension system consists of roller bearings, rubber bushing, coil spring pair, and vertical damper. The secondary suspension system consists of an air spring, anti-roll bar, traction rod, lateral damper, and yaw damper. Figure 11 shows the high-frequency model of these suspension systems. The traction rod model is the same as the model established in section "The model of the traction rod".

As shown in Fig. 11b, the roller bearings mainly consist of an inner ring, an outer ring, and rollers. The contact stiffness within the roller bearing is very high in the longitudinal, lateral, and vertical directions. In the present vehicle model, the roller bearing is modeled as a nonlinear force element. In the bearing model, the outer ring of the bearing is considered fixed to the axle box, while the inner ring is considered fixed to the wheel axle. By considering the geometric characteristics of the relative kinematics between the rollers, inner ring, and outer ring, the contact deformation of a single roller δn, can be calculated28,29. The total contact force can be obtained as follows:

where, N represents the total number of rollers in one row, with a bearing typically containing two rows of rollers, fx, fy, and fz represent the total longitudinal, lateral, and vertical forces transmitted by the bearing, respectively, Qn is the total contact force of the one roller, and Kδ is the equivalent contact parameter. When δn < 0, it means that the roller is out of contact with the inner and outer rings, and the contact force at this time is 0. \(\alpha_{e}\) denotes the inclination of the symmetry axes of the rollers against the symmetry axis of the entire roller bearing, which is constant. \(\theta_{n}\) denotes the circumferential angle of the roller.

In order to describe the dynamic behavior at high frequency, the rubber bushing, the coil springs, and the anti-roller bar are modeled as finite element models. The modal synthesis, which uses the eigenmodes of these components calculated by finite element models as shape functions, is applied to integrate these models into the full vehicle model. The rubber pad is modeled as a spring-damper element. Structural eigenmodes of the wheelset, the axle box, and the bogie frame in the frequency range between 0 and 1500 Hz, are imported into the vehicle model, to ensure that the modeled high-frequency vibration can be transmitted to the traction rod.

The dampers, being the vertical damper, lateral damper, and yaw damper, are modeled as the structure-borne model found in reference30. The model focuses on the force between the piston rod and the damper body, by considering compressible fluid behavior and accurate flow rate-pressure relationships. The pins at the end of the damper, piston rod and damper body are modeled as lumped masses, while the rubber joints are modeled as linear spring-damper elements. The air spring is modeled as a spring element in the longitudinal, lateral and vertical directions. Table 4 shows the degrees of freedom of the models of each suspension component. A high contact stiffness, which is far higher than the structural stiffness of the original component, was added between different component models, to ensure the equivalent stiffness of the combination is nearly equal to the structural stiffness of the component. The influence of the contact stiffness is very small, and the vibration reduction of the contact stiffness model is negligible.

Contribution of traction rod based on vibration power

A bogie is a complex structure, with multiple suspension elements and multiple coupled motion directions. The motion direction of a particular suspension component can be referred to as a path, and the magnitude of the structure-borne noise transmitted through this path represents the contribution of this path to the response point. According to the Transfer Path Analysis (TPA) method, the contribution of a path to the response point is the product of the excitation force and the admittance. Therefore, the amplitude of the suspension force does not entirely reflect the amount of structure-borne noise transmitted by the suspension element, as the contribution is also related to the admittance from the structural excitation point to the response point. When the admittance is small, even if the transmitted force is large, its contribution may be small.

Therefore, to facilitate comparison of the contribution of various suspension elements to structure-borne noise, this paper uses the concept of power flow to evaluate the contribution of each suspension element to structure-borne noise. Power represents the ability of an external force to perform work, or the ability of a structure to consume energy per unit time. Traditional vibration noise control research methods measure the transmission of vibrations in structures, using single physical quantities, such as velocity or displacement. The vibration power flow method studies structural vibration problems from the perspective of energy, combining these physical quantities. It includes the magnitudes of force and velocity, and considers the phase relationship between them. The formula for mechanical power in frequency domain is:

where, Pi is the power transmitted through path i, Fi is the force at the contact point of path i, vi is the vibration velocity at the contact point of path i, and \(\theta_{i}\) is the phase difference between force and velocity.

From the formula, it can be seen that the main advantage of the power flow method is that it considers both the force and velocity transmitted to the structure, thereby also considering the structure’s admittance. Power is a scalar and can thus be compared, to reflect the contribution of different paths. Compared to traditional analysis methods, the power flow analysis method is particularly suitable for evaluating the vibration isolation effectiveness of complex flexible systems. It can uniformly evaluate various vibration noise control methods, using the concept of transmitted power flow, either by reducing the input power to the structure, or by controlling the energy transmission paths. In cases of multiple coupled connections, comparing the magnitude of power flow can evaluate the vibration isolation effectiveness of each suspension element.

The method for calculating the power contribution ratio is as follows:

where, ci is the contribution ratio of path i, Pi is the power transmitted through path i, and ∑Pi is the sum of the powers transmitted through all paths.

To obtain the power contribution ratio, the total power of the force and velocity signals at each frequency is first calculated by applying the Fast Fourier Transform (FFT) to the time-domain signals of the traction rod forces between the carbody and traction rod and the velocity at the link point of the carbody. The power at each frequency is determined by Eq. (8). Then a 1/12 octave band spectrum is obtained by dividing the frequency range into bands, and then calculating the power within each band. Finally, the power contribution ratio is calculated by Eq. (9). Figure 12a shows the representation of the power contribution ratio. The ordinate in the figure is the percentage of contribution. The total height of all columns is 100%, and the height of the color column represents the percentage of the contribution at this frequency.

To analyze the influence of the traction rod on the high-frequency transmission forces of the train, the same running operation is simulated, based on the high-frequency model, in which measured track irregularities are used to excite the system at high frequency. Figure 12b, c, d and e compare the contribution rates of the secondary suspension components at different stages. The abscissa in the figure is 1 / 12 octave center frequency.

From these figures, it can be seen by comparing the power contribution to the carbody of the secondary suspension components at different stages, that the yaw damper has the most contribution to the whole frequency. The reason for this is that the longitudinal constraint of the vehicle is small, and the equivalent damping coefficient of the yaw damper is large. The lateral damper only has a significant contribution in the frequency range of 520–1030 Hz, related to the bogie’s high-frequency vibration. The traction rod and anti-roll bar have significant contributions in the frequency range of 32–259 Hz, which vary a lot at different stages. The contribution of the air spring can be neglected.

Figure 13 shows the variation in contribution rate of the traction rod at different stages. From Fig. 13, it can be seen that, excited by the short-wave irregularities, the power contribution rate of the traction rod in the 32–259 Hz range varies significantly between different stages. The contribution rate varies from less than 20%, to more than 40%, an increase of approximately 20%.

Conclusion

The effect of the traction rod on structure-borne sound transmission has been assessed by establishing a structure-borne sound model of the traction rod model, and incorporating it into the train-track coupled dynamic model. The main conclusions are as follows:

-

(1)

An finite element model of the traction rod was established. Laboratory measurement was carried out, to adjust the behavior of the corresponding models to the behavior of the real components. By simulation with the finite element model, and laboratory measurement, the flexible deformation characteristics of the traction rod, as well as the nonlinear characteristics of the rubber joints and rubber layers, were obtained. Based on these characteristics, a high-frequency model of the traction rod was established.

-

(2)

A 3D train-track coupled vibration transmission model was developed, which could be used to research dynamic behavior at high frequency. By modeling the wheelset, axle box and bogie frame as a rigid-flexible coupling model, and modeling the suspension components with a structure-borne sound model, the high-frequency vibration can transfer from wheel-rail contact surface, to the secondary suspension components. Also, the model can be used to research dynamic behavior when the train runs at different speeds.

-

(3)

During train operation, the structural eigenmodes of the traction rod are excited, leading to many maxima occurring, in the range of 0–1000 Hz, in the curve of the traction rod force transmitted to the carbody. The traction rod force under 26 Hz significantly increases during variable-speed operation, due to the vertical and pitch movements of the carbody caused by acceleration and deceleration, which increase the low-frequency traction rod force. In the 26–300 Hz range, the amplitude of the traction rod force significantly increases, but the peak frequency remains essentially unchanged, mainly because the mode of the traction rod’s metal pin is excited. Above 300 Hz, although the amplitude is very small, it generally increases due to acceleration and deceleration, which cause the rubber nodes to be in a compressed state, increasing stiffness, and reducing the trend of force attenuation with frequency.

-

(4)

It is necessary to consider the characteristics of the traction rod when studying the impact of structure-borne bogie noise. This is because the transmissibilities of longitudinal, lateral, and vertical forces in the traction rod exhibit peaks, indicating sensitive frequency bands for high-frequency vibration transmission. Also, the nonlinear characterization of the traction rod cannot be ignored.

-

(5)

Excited by the same track irregularities, the power contribution rate of the traction rod in the 32–259 Hz range changes significantly at different running speeds. The contribution rate increases from less than 20%, to more than 40%, an increase of approximately 20%.

Data availability

All data generated or analysed during this study are included in this published article.

References

Tao, G. et al. Polygonisation of railway wheels: a critical review. Rail Eng. Sci. 28, 317–345 (2020).

Wu, X. W. et al. An investigation of high-frequency vibration of bogie frame due to wheel/rail short-pitch irregularities and its control methodologies. Veh. Syst. Dyn. 62(12), 3297–3319 (2024).

Sievi A, Brick H, Rüst P (2021) Structure-borne noise contributions on interior noise in terms of car design and vehicle type. In 13th International Workshop on Railway Noise, Ghent, Belgium

Jin XS (2018) Key problems faced in high-speed train operation. China’s High-Speed Rail Technology: An International Perspective 27–45.

Li, M. X. et al. An investigation into high-speed train interior noise with operational transfer path analysis method. Railw. Eng. Sci. 29, 1–14 (2021).

Spiryagin M, Wu Q, Wolfs P, Spiryagin, V (2019) Design of powered rail vehicles and locomotives. In: Handbook of Railway Vehicle Dynamics, Second Edition, London, UK.

Huang, C. H. et al. Effect of longitudinal stiffness of traction rod on car body elastic vibration for high-speed passenger car. J. Traf. Trans. Eng. 10(3), 46–51 (2010).

Zhai, W. M. Vehicle–track coupled dynamics models (Springer, 2020).

Liu, Y. et al. Dynamic analysis of traction motor in a locomotive considering surface waviness on races of a motor bearing. Railw. Eng. Sci. 29, 379–393 (2021).

Liu, Y. Q., Chen, Z. G., Zhai, W. M. & Wang, K. Y. Dynamic investigation of traction motor bearing in a locomotive under excitation from track random geometry irregularity. Int. J. Rail. Transp. 10(1), 72–94 (2020).

Wu, G. S., Shen, L. J. & Yao, Y. Investigating the re-adhesion performance of locomotives with bogie frame suspension driving system. Int. J. Rail. Transp. 11(2), 267–288 (2022).

Wu, H. et al. Advancing high-speed train gearbox durability: enhanced bearing load and contact stress through transition from helical to herringbone gears. Railw. Eng. Sci. 32, 1–19 (2024).

Wang, Z. et al. A trailer car dynamics model considering brake rigging of a high-speed train and its application. Railw. Eng. Sci. 31, 269–280 (2023).

Eickhoff, B. M., Evans, J. R. & Minnis, A. J. A review of modelling methods for railway vehicle suspension components. Veh. Syst. Dyn. 24(6–7), 469–496 (1995).

Bruni, S., Vinolas, J., Berg, M., Polach, O. & Stichel, S. Modelling of suspension components in a rail vehicle dynamics context. Veh. Syst. Dyn. 49(7), 1021–1072 (2011).

Ma, W. H. & Song, R. R. Analyses of the additional stiffness function of the traction bar on the vertical dynamics performance of subway vehicle. Electr. Rev. 88, 39–43 (2012).

Bokaeian, V., Rezvani, M. A. & Arcos, R. Nonlinear impact of traction rod on the dynamics of a high-speed rail vehicle carbody. J Mech. Sci. Tech. 34, 4989–5003 (2020).

Bokaeian, V., Rezvani, M. A. & Arcos, R. A numerical and scaled experimental study on ride comfort enhancement of a high-speed rail vehicle through optimizing traction rod stiffness. J. Vib. Control 27(21–22), 2548–2563 (2021).

Dumitriu, M. & Apostol, I. I. The effect of the traction rod on the vertical vibration behavior of the railway vehicle carbody. Vehicles 5(4), 1482–1504 (2023).

Liu, X. et al. Measurements and modelling of dynamic stiffness of a railway vehicle primary suspension element and its use in a structure-borne noise transmission model. Appl. Acoust. 182, 108232 (2021).

Wang, Q. et al. Vehicle modelling for high-frequency vibration transmission through primary suspensions. Veh. Syst. Dyn. https://doi.org/10.1080/004231142444398 (2024).

Ling, L. et al. A 3D model for coupling dynamics analysis of high-speed train/track system. J. Zhejiang Univ. Sci. A 15(12), 964–983 (2014).

Xiao, X. B., Ling, L. & Jin, X. S. A study of the derailment mechanism of a high speed train due to an earthquake. Veh. Syst. Dyn. 50(3), 449–470 (2012).

Shen, Z., Hedrick, J. & Elkins, J. A comparison of alternative creep force models for rail vehicle dynamic analysis. Veh. Syst. Dyn. 12(1–3), 79–83 (1983).

Zhong, S. et al. Effect of wheelset flexibility on wheel-rail contact behavior and a specific coupling of wheel-rail contact to flexible wheelset. Acta Mech. Sin. 32(2), 252–264 (2016).

Claus, H. & Schiehlen, W. Symbolic-numeric analysis of flexible multibody systems. Mech. Struct. Mach. 30, 1–30 (2002).

Ling, L. et al. Integration of car-body flexibility into train–track coupling system dynamics analysis. Veh. Syst. Dyn. 56(4), 485–505 (2018).

Andréason, S. Load distribution in a taper roller bearing arrangement considering misalignment. Tribology 6(3), 84–92 (1973).

Wang, Z. W. et al. Effect of vehicle vibration environment of high-speed train on dynamic performance of axle box bearing. Veh. Syst. Dyn. 57(4), 543–563 (2019).

Benaziz, M., Nacivet, S. & Thouverez, F. A shock absorber model for structure-borne noise analyses. J. Sound Vib. 349, 177–194 (2015).

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (No. U1934203), National Key Research and Development Program (2021YFB3801803), and CRRC Technology Research and Development Program Project(2023CYA269).

Author information

Authors and Affiliations

Contributions

Qi Wang: Investigation (equal); Methodology (equal); Software (equal); Writing-original draft (equal). Xinbiao Xiao: Funding acquisition (equal); Methodology (equal); Software (equal); Writing-original draft (equal). Jian Han: Writing-original draft (equal); Supervision (equal). Yunhang Liu: Software (equal). Yanning Tang: Funding acquisition (equal); Xuesong Jin: Methodology (equal); Supervision (equal). All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

We, the authors of this paper, certify that we have no affiliation with, or involvement in, any organization or entity with any financial interest, or nonfinancial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Q., Xiao, X., Han, J. et al. High frequency traction rod model and its structure-borne sound transmission characteristic of high-speed trains. Sci Rep 15, 12940 (2025). https://doi.org/10.1038/s41598-025-96172-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96172-7