Abstract

This study investigated the use of cotton linter pulp with the blending of cellulose nanofibers (CNFs) to produce paper with improved functional attributes. The CNFs were added to cotton linter pulp in varying proportions (0, 20, 40, 60, 80, and 100% on a dry weight basis). The paper handsheets of 60 ± 1 g/m2 were prepared and evaluated for surface morphology, crystallinity, mechanical, barrier, and optical properties. Surface morphology revealed the high compactness of paper incorporated with CNFs. No significant changes in the surface roughness of the paper were observed upon the addition of CNFs. Mechanical properties substantially improved with CNF loading, leading to a notable increase in tensile strength (3.6–9.4 fold), tearing resistance (1.6–2.1 fold), bursting strength (1.1–4.2 fold) and folding endurance (6–184 fold) compared with control paper. The CNFs blending caused a marked reduction in Cobb value (up to 63.3%) and increased air resistance (up to 34.3%), demonstrating the high barrier properties of paper. The optical properties showed a decrease in brightness (up to 31.8%) and variable opacity trends with the addition of CNFs. The findings suggested cotton linters are suitable for producing high-quality specialty paper. The research ascertained the potential of CNFs as a sustainable green material to enhance the mechanical and barrier performance of paper products.

Similar content being viewed by others

Introduction

The accelerated economic growth and concerns about the environment have caused increased demands for eco-friendly paper and products made from paper, especially in the packaging industry. Paper, a material that can degrade naturally, holds as great promise for replacing plastic in the making of packages and bags. However, the paper manufacturing sector consistently faces challenges regarding mechanical, physical, and printing improvements to cater to the increasing demand for high-quality paper products1. A significant option is to incorporate additives or fillers into the manufacturing process with the goal of enhancing the quality of the paper. Transitioning from conventional petroleum-derived supplements, researchers are looking for renewable, environmentally friendly nanoadditives for performance enhancement and the functionalization of paper. Recent developments involve using “green” nanoadditives to produce paper with specific improved characteristics such as strength, luster, writing, and recyclability2.

Nanocellulose (NC) is emerging as a promising green reinforcement for improving paper and paper-based products’ strength and preventative properties34,. NC has attracted increased interest from both researchers and industries on account of its biodegradability, renewability, sustainability, high surface area, high aspect ratio, exceptional optical characteristics, lightweight, stiffness, and high strength. The tunable surface properties and compatibility of NC with pulp make it a smart and eco-friendly alternative to several issues faced by the papermaking sector5. NC can be extracted from any cellulosic biomass such as wood, lint, cotton stalks, and coconut fibers and other natural fibers, sugarcane bagasse, algae, etc. Cotton linters are the comparatively short fibers attached to the cottonseeds after removing longer fibers during the ginning process. Cotton linters, a by-product of the textile industry, are mechanically extracted from seed surfaces and are primarily utilized in cellulose production6. India produces about 0.4–0.5 million metric tons of cotton linters annually. Being the purest form of cellulose, with over 90% cellulose content, cotton linters serve as an excellent source for producing NC. Furthermore, the extraction of NC from cotton linters is simpler compared to woody biomass, which requires an additional purification process to remove lignin and hemicelluloses7.

Many successful results have been reported for the applications of NC in paper manufacturing2,8,9,10,11. Among the different uses, NC as a dry strength enhancer and coating material are major applications in papermaking12,13. Extensive research has been conducted on the use of cellulose nanofibers (CNFs) to enhance the wet and dry strength characteristics of bleached chemical pulps. CNFs as an additive offer several advantages over traditional mechanical beating and refining used to enhance the strength of pulp. Adding NC to the pulping mixture can significantly improve the tensile strength and rigidity of the final paper, make it less porous and denser, and thus improve its air resistance8,14. Moreover, adding CNFs does not harm the overall structure of pulp fibers, thus extending their lifetime, which is beneficial for the recycling of paper15. Shi et al. (2024) corroborated the enhancement (20% increase) in the strain at break of polylactic acid (PLA) with the incorporation of 1 wt% cellulose nanocrystals (CNC) resulted in increased ductility16. Zhu et al. (2015) utilized the cellulose fibers for paper making and reported that reduction in the mean diameter of the constituent fiber (from 27 μm to 11 nm) improved the mechanical properties viz. strength (from 6.7 to 275.2 MPa), toughness (from 0.13 to 11.68 MJ/m3) and fracture toughness (from 143.3 to 1481.4 J/m2) of the developed paper17. This incremental rise in the toughness of paper was attributed to the enhanced interface area and formation of strong hydrogen bonds among cellulose chains.

Most research has focused on reinforcing pulp with up to 10% NC. However, higher proportions of NC are rarely reported in the literature, primarily due to the high manufacturing costs and energy consumption involved in its production. The key challenge is reducing the manufacturing cost of NC production to align with the cost-effective nature of high-volume paper products. Chemo-mechanical synthesis of CNFs is the latest technological development that can be employed to reduce energy consumption and, thus, production costs5. Recently, the researchers at ICAR-Central Institute for Research on Cotton Technology, Mumbai optimized a process protocol for energy efficient synthesis of NC at pilot scale using the combination of enzymatic treatment and temperature-regulated refining18. This has opened up avenues for the widespread use of NC in various value-added applications.

Previously, the development of paper from a blend of cotton linter pulp and cellulose nanofibers (CNFs) extracted from cotton linters had not been attempted. Adding an appropriate amount of CNFs is crucial for achieving a reinforcing effect. Therefore, blending higher proportions of CNFs into the pulp may have positive or negative impacts on the final paper quality. Further research is required to examine how incorporating the higher amount of CNFs into cotton linter pulp affects the mechanical and barrier properties of the resulting paper.

In this research work, CNFs were blended with cotton linter pulp with the objective of producing paper with higher mechanical and barrier properties, reduced porosity, better air resistance, durability, non-tearability, etc. The resulting paper, possessing these properties, may have the potential as a specialty paper for various applications. The CNFs were extracted from cotton linters using enzymatic hydrolysis with subsequent controlled-temperature refining. Paper handsheets containing varying proportions of cotton linter pulp and CNFs were prepared to evaluate the effect of CNF integration on surface morphology, crystallinity, mechanical properties (including tensile strength, bursting strength, tearing resistance, and fold endurance), barrier properties (air resistance and water absorptivity), as well as optical properties (brightness and opacity).

Material and methods

Materials

Cotton linters (6 to 12 mm long), which are considered first cut, were obtained from the Ginning Training Centre (GTC), ICAR-CIRCOT, Nagpur, India. These linters were utilized for the extraction of CNFs. Other reagents viz. cellulase enzyme (Biopol), hydrogen peroxide, sodium silicate and sodium hydroxide were procured from Thermo Fischer Scientific, India Pvt. Ltd., Mumbai.

Extraction of CNFs

CNFs were extracted from cotton linters using previously reported energy-efficient process involving the pretreatment using specific enzymes followed by refining at a controlled temperature18. The bleached cotton linters, dispersed uniformly in water (material to liquor ratio (MLR) = 1:20) with the addition of 1% (v/w) cellulase enzyme (Biopol) (filter paper activity: 12.42 FPU/mL), were kept for reaction at 45 °C for 1 h, maintaining a pH of 4.5 using 0.2 M acetate buffer. Thereafter, cellulase was deactivated by heating at ≥ 70 °C and washed off from the fibers with water. This was followed by the beating of enzyme-treated fibers for 1 h using a pilot scale beater (Parasons Machinery, India) powered with an induction motor (10 HP/7.5 kW, 1455 rpm). The beaten pulp was then conveyed to a tri-disc refiner (Parasons Machinery, India) having 32 cm disc diameter and 4 refining surfaces. The refining was performed at 23 ± 5 °C for 30 min for 15 passes. Cold water was circulated through the refining system to maintain the process temperature. The CNFs obtained from the refiner were collected for further analysis.

Preparation of pulp

The pulp was prepared from cotton linters using a standard pulping process. About 500 g of cotton linters were digested in a laboratory rotary digester (Premier International, India) using 4% NaOH at 160 °C for 90 min, while keeping the MLR as 1:5. The digested material was then washed thoroughly and beaten in a laboratory beater (Parasons Machinery, India) for 60 min. The beaten pulp was bleached using hydrogen peroxide (3 g/l), sodium silicate (2 g/L) and sodium hydroxide (1 g/L) at 70 °C for 60 min using 1:20 MLR in a laboratory rotary digester. The bleached pulp was then washed thoroughly.

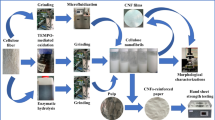

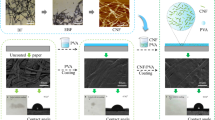

Preparation of CNFs-incorporated paper handsheets

The bleached cotton linter (BCL) pulp was used for preparing paper handsheets. CNFs in different concentrations (0, 20, 40, 60, 80 and 100% on a dry weight basis) were added to the pulp, and the paper handsheets produced were coded as PN0, PN20, PN40, PN60, PN80, and PN100, respectively. The BCL pulp without CNFs (PN0) was treated as a control sample. The uniform dispersion of pulp and CNFs was achieved by mixing (1350 rpm for 15 min) in a pulp disintegrator (Universal Engineering Corporation, India). Cationic starch 5% (w/w) was added to the pulp to assist in retention. The paper handsheets of 60 ± 1 g/m2were prepared as per TAPPI T-220 sp-16 (2016) standard19 using a lab handsheet former and dried in the natural environment (Fig. 1). Several sheets of each composition were produced for evaluation and testing (Fig. 2).

Scanning electron microscopy (SEM) of CNFs

To determine the surface morphology and size, the CNF suspension was diluted using deionized water (HPLC grade) with a 50 dilution factor. A droplet of the diluted sample was placed on the sample holder for air-drying which was then coated with gold/ palladium using a vacuum sputter in order to improve their conductivity. The sample was then observed under the microscope (Philips XL30 SEM, Netherlands) at 12 kV accelerating voltage and 8000 × magnification. The fiber diameter was measured using ImageJ software (IJ1.46r). The SEM image was opened in ImageJ, and the scale was set using the Set Scale option. A binary image was created via Adjust > Threshold. The straight-line tool was used to draw perpendicular lines across the fibers, and the diameter was measured using Analyze > Measure. The recorded values were then exported to Excel for mean size analysis (Table S1).

Characterization of CNFs- incorporated paper

Surface morphology

SEM of paper samples was done to study their surface morphology and compactness. A small section of paper samples was mounted, coated, and scanned at 200 × magnification using the same procedure as described in Sect. “Scanning electron microscopy (SEM) of CNFs”.

X-ray diffractometry (XRD)

X-ray diffractometer (PANalytical X’Pert PRO, Netherlands) with nickel-filtered Cu Kα (α = 1.54 A°) radiation was used for the diffraction analysis. The scanning was done at 40 kV and 30 mA with 2θ varying from 10° to 40°, at a speed of 10º/min. The crystallinity index (CI) was determined using the following formula20:

where I200 is the total intensity of the 200 peak at 2θ = 22.8º and Iam is the minimum observed intensity between the 110 and the 200 peaks.

Atomic Force Microscopy (AFM)

Atomic Force Microscopy (AFM) analysis was carried out using a diInnova AFM (Veeco, USA) with the objective of quantifying the roughness of the CNFs-incorporated paper. A small uniform section of paper was cut and placed on a freshly cleaved mica surface and dried under an infrared lamp. The images were taken using a silicon nitride cantilever in tapping mode at room temperature. The scan rate of 1.0 Hz and 512 lines per 5 μm were set to get optimum contrast without filtration.

Mechanical properties

Tensile index (TI), tearing resistance (TR), bursting strength (BS) and fold endurance (FE) of handsheets were measured according to standard methods- TAPPI T 494 OM-13 (2013), TAPPI T 403 OM-15 (2015), TAPPI T 414 OM-12 (2012) and TAPPI T 511 OM-02 (2002), respectively21,22,23,24. The readings are the average of ten tested samples.

Water absorbency (Cobb test)

The water absorbency of paper handsheets was measured using the Cobb apparatus following the TAPPI method T441 (2013)25. The results were expressed as Cobb value (g/m2).

where,

W1 = Initial paper weight and W2 = Final paper weight after test.

Air resistance

Air resistance refers to the amount of air passed through the paper samples and was measured by smoothness and porosity tester (Universal Engineering Corporation, India). The results were presented as the time required to pass 100 mL of air through the paper handsheet26.

Optical properties

The optical properties of paper handsheets were determined using Universal 710 Opacity and Brightness Tester (UMS, India) according to TAPPI standards- T 452 (2018) and T 425 (2016), respectively27,28.

Statistical analysis

Analysis of variance (ANOVA) was obtained by performing the univariate analysis in the general linear model at 5% level of significance. The least significant differences among the observations were calculated by Duncan’s Multiple Range Test (DMRT) at 95% confidence level using SPSS 16.0 package. The values of each response were expressed as average ± standard deviation.

Results and discussion

SEM of CNFs

The CNFs suspension prepared by enzymatic hydrolysis and subsequent controlled-temperature refining had a 4% solid content. SEM analysis of the CNFs showed their size on a nanometer scale. Chemo-mechanical processing of cotton linters drastically reduced the size from 20.5 ± 2.3 μm (Fig. 3a) to 126 ± 42 nm (Fig. 3b), depicting about a 99% reduction in size. As reported in earlier work, the hydrolysis of cotton fibers by cellulase enzyme eased the fibrillation process and produced nanofibers in comparatively less refining time18.

Surface morphology

The effect of CNFs addition on the inter-fibril gap and the compactness of the paper was accessed by studying the surface morphology of handsheets using SEM. It can be seen from SEM micrographs that the inter-fiber gap is reduced upon increasing the CNFs concentration (Fig. 4). When the inter-fibril space is reduced, the adhesion property of fiber increases. This is possibly due to better bonding of fibrils in the paper, which in turn improved its mechanical properties29. The CNFs are believed to facilitate higher hydrogen bonding due to their high specific area. In addition, the aspect ratio (L/D) is very high in CNFs, allowing them to form a dense, uniform network with less porosity30. Similar inter-fibril bonding and reduced pore size were reported in recycled paper reinforced with CNFs31. Incorporation of cellulosic nanofibers into paper newspapers were observed to enhanced the link ability, and filled voids between pulp fibers, consequently reducing the porosity9.

Crystallinity

XRD analysis of CNFs and all paper samples was conducted to identify any changes in the crystallinity index (CI) due to different CNFs loading. The XRD diffractogram of all samples (Fig. 5) displayed characteristic peaks of cellulose at 1–10 (14.7º 2θ), 110 (16.5° 2θ), 200 (22.5° 2θ), and 004 (34.5° 2θ) crystallographic planes. The CNFs showed a CI of 88.5%. The CI of paper samples PN0, PN20, PN40, PN60 and PN80 was found to be 92.7%, 86.3%, 88.8%, 88.4% and 85.2%, respectively. Results indicated that the blending of pulp with CNFs led to a substantial decrease in CI values. A significant difference in the CI of kraft pulp and CNFs made from Eucalyptussp. was reported earlier30. The low CI of CNFs can be attributed to the hornification of CNFs during the high-speed grinding process, which disrupts the cellulose crystal structure and leads to degradation in this area32.

Atomic Force Microscopy (AFM)

The roughness of CNFs and CNFs-incorporated paper handsheets was determined using AFM analysis (Fig. 6). The ‘Ra’ (average roughness) value of the CNFs was 0.1858 μm. Whereas, the ‘Ra’ values were found to be 0.2473, 0.2223, 0.0873, 0.1059, and 0.0665 μm for the paper samples PN0, PN20, PN40, PN60, and PN80, respectively. No particular trend was observed in the roughness of paper upon reinforcing with CNFs. Hence, it was concluded that the addition of CNFs does not significantly alter the surface roughness of the paper. The CNFs within the paper are to be interlaced and arranged randomly, imparting random surface orientation to the paper33. This randomization may be the reason for the difficulty in obtaining a particular trend in the roughness value.

Mechanical properties

The mechanical properties of CNFs-incorporated paper handsheets are outlined in Table 1. The incorporation of CNFs led to a notable enhancement in the mechanical strength of paper.

Tensile strength (TS)

TS of paper signifies the bonding that occurs during paper formation and is dependent on the inter-fibril adhesion properties of the paper26. It is required to withstand a load. In applications such as paper bags, the TS conveys the maximum weight of goods the bag can carry. The TS of the paper, expressed in terms of Tensile Index (TI), increased from 5.50 to 51.96 Nm/g with an increase in the addition of CNFs with the addition of CNFs (Table 1). The typical TI value for Grade III kraft paper is 29.5 Nm/g34. The inclusion of 40% CNFs brought about 3.6 times rise in the TI (31.7 Nm/g), which meets the BIS standards.

Previous work reported 32.4% increase in TS of bamboo sheets with addition of 10% NC35. Similarly, about 98% improvement in TS was recorded earlier for recycled paper reinforced with 5 wt % CNFs derived from empty fruit bunches36. The high strength of CNFs-incorporated papers is due to the enhancement in specific surface area that boosts fiber–fiber hydrogen bonding and increases sheet density15,35. A similar trend was observed in this study showing the 9.4-fold increase in the TS of paper incorporated with 80% CNFs. The results are in line with the SEM analysis, which revealed a reduction in the inter-fibril gap and improvement in inter-fibrillar force with increasing incorporation of CNFs into the paper. The significantly high enhancement in TS of CNFs-added paper in this study could be attributed to the source of CNFs, the preparation method, and the level of reinforcement15.

Tearing resistance (TR)

Tearing strength was measured as internal TR rather than the edge-tear strength of paper. TR refers to the paper’s capacity to resist tearing forces. It is experiential that higher tear strength correlates with better quality and extended shelf life of the paper. It can be employed to characterize paper behavior across various applications, ensure newsprint quality, and assess the durability of packaging paper, particularly in applications requiring shock absorption capabilities. The typical TR value for paper was 50 mN as per BIS standards37. TR values for PN0, PN20, PN40, PN60, and PN80 were observed as 160, 250, 260, 260, and 340 mN, respectively (Table 1). The addition of 20% to 80% CNFs resulted in a 1.56 to 2.13 fold increase in TR. A similar TR increase in NC-blended paper was reported earlier2. TR depends on the length of fibers and the bonding between them. CNFs when reinforced in pulp, achieve good interfiber bonding. Greater fiber–fiber links, increased hydrogen bonding, and comparatively longer fibers with small diameters (high aspect ratio) distribute stress within the elastic region, thereby improving the TR of paper82,.

Bursting strength (BS)

High BS signifies more inter-fibrillar bonding and, thus, high compactness in the paper. High BS is of utmost importance in paper packaging applications. The BS value of the control paper (PN0) was found to be 883 N, which was significantly lower than the typical BS value for kraft paper as per BIS standards (2160 N)37. Results showed that blending the cotton linter pulp with CNFs showed a marked increase in the BS of paper samples, values ranging from 981 to 3727 N. The addition of 40% CNFs led to a 2.5 times increase in the BS of the developed paper, achieving the required standard. About 15% enhancement in BS when incorporating up to 3% NC was observed earlier36. Similarly, 14% increase in the burst index of 10% NC-reinforced blended paper was obtained2. This suggests that fine NC fibers act as bridges between long fibers in kraft paper via different mechanisms such as linking, wrapping, and interlacing, therefore improving the inter-fiber bonding and mechanical strength properties2,36.

Folding endurance (FE)

FE refers to the maximum number of times a paper can be folded with load without breaking the paper. It is an essential property for printing grades (books, maps, or pamphlets), bond paper, currency grade paper, and packaging paper that undergoes multiple folding. The FE for paper handsheets PN0, PN20, PN40, PN60, and PN80 was found as 1, 6, 17, 115, and 184, respectively. It was observed that the maximum incorporation of CNFs in the PN80 paper showed 184 times higher FE value compared to the control paper (PN0).

A similar trend was noticed in NC-blended paper2. The authors achieved a 271% enhancement in FE by adding 10% NC. About 87% and 248% FE improvement in microfibrillated and nanofibrillated reinforced pulp sheets respectively was reported earlier3. The high foldability of CNFs-incorporated paper could be attributed to long and flexible fibers, mechanical entanglement, and strong hydrogen bonding. The increased folding endurance with the addition of CNFs could be ascribed to enhanced fiber–fiber bonding due to higher specific surface area and increased paper density2,38.

Water absorptivity/Cobb value

Water absorptivity refers to the amount of water absorbed by a piece of paper (1m2) within a specified time. Since paper consists of randomly interlocked layers of fibers, its structure exhibits varying levels of porosity. Therefore, the permeability of fluid (liquid and gaseous) through the paper structure becomes a crucial property for its practical applications. Cobb values measure the paper’s resistance to the penetration of aqueous solutions or water, reflecting its degree of hydrophilicity. The typical Cobb value for kraft paper is 24–30 g/m2 as per BIS standards.

Table 2 shows that the Cobb value decreased as CNFs were increasingly incorporated. The highest Cobb value (381.60 g/m2) was found in PN0 paper without CNFs, while the lowest Cobb value (140.20 g/m2) was found in PN80. The results indicated a 39.8% to 63.3% decrease in water absorptivity of CNFs-incorporated paper handsheets. Kumar et al. (2020) noted a comparable trend in a paper reinforced with CNFs38. This could be related to the binding ability of CNFs to pack more fibers together in a paper. Afra et al. (2016) observed a similar decrease in water absorption in paper coated with CNF, attributed to the formation of a continuous layer with fewer pores compared to the base paper (control sample), resulting in decreased water penetration39. Likewise, the low water absorptivity observed in this study may be linked to the increased compactness and reduced inter-fibril gaps in the CNF-incorporated paper, as corroborated by the SEM results.

Air resistance (AR)

The AR of the paper is an indirect measure that describes the pore structure of the paper. Paper with high AR is less porous and less permeable to the air. AR is a significant factor in deciding the applications of the paper. The results revealed a marked increase in the AR of paper samples upon CNFs incorporation. The AR for the control paper was 20.92 s/100 mL, while the CNFs-based paper exhibited values ranging from 21.45 to 28.09 s/100 mL. The PN80 paper sample, with the highest CNFs incorporation, demonstrated a notable 34.3% increase in AR. CNFs are thought to have fine structure, filling the voids within a fiber network alongside larger fibers. The outcome likely lowered the permeability of air through the paper structure, as the compressed CNFs created an extended pathway for the diffusion of air molecules40. About a 50% decrease in air permeance with the inclusion of nano crystalline cellulose (NCC) at levels up to 10% was documented8. This characteristic makes CNFs a promising material for application in the papermaking industry, particularly in the realm of food packaging on account of their significant barrier performance.

The high AR of CNF-incorporated paper samples is linked to the closure of pores41. The reduced porosity is crucial for enhancing mechanical strength. Paper having low porosity exhibits heightened mechanical strength which was attributed to high hydrogen bonding facilitated by the high specific area of CNFs2.

Optical properties

Brightness is the percentage of blue light (specifically at 457 nm wavelength) that a paper reflects. Opacity, on the other hand, is the amount of light prevented from passing through a sheet42. Factors influencing paper opacity include its thickness, the quantity and type of filler, the extent of bleaching, and the presence of coatings. As per the ISO 11,475 standards, the typical brightness value for kraft paper is 78–80, while the diffuse opacity value is 85.

The brightness of CNFs-incorporated paper handsheets significantly decreased with increasing proportion of CNFs. The brightness of the control paper (PN0) was 82.43%. For the PN80 sample, the brightness was only 56.20%; depicting about a 31.8% reduction at the highest CNFs incorporation. This decrease in brightness might be due to the compact network enabled by CNFs, as evidenced by SEM micrographs, reduces the inter-fiber gap limiting the scattering of light as also reported43. The reduction in coefficient of light scattering by 2% was earlier reported in CNFs-blended paper44.

Nevertheless, the opacity trend differed from that of brightness. The opacity of paper samples showed an increasing trend up to 40% CNFs incorporation, followed by a gradual decrease as CNFs incorporation continued to rise. The PN40 paper sample presented the highest opacity at 96.35%, while the PN80 paper sample showed the lowest opacity at 80.40%. In contrast, it was found that incorporating 8% CNFs enhanced the brightness and reduced the opacity of newspaper made from chemo-mechanical pulp by approximately 3.5% and 0.8%, respectively9. The reverse trend was maybe because of the lower level of CNFs addition (less than 10%). A slight decrease in brightness and the opacity of CNFs-blended paper samples was noted due to an increment in transparency38. The CNFs addition produced a densely packed structure that avoids light scattering, producing more transparent and less opaque paper.

The difference in the trend reported by various researchers can be explained by the fact that the brightness and opacity are related to the nature of the pulp utilized for NC and paper production. A decrease in the brightness of the paper reinforced with NC produced from sisal pulp was earlier observed2, which was mainly related to the higher residual lignin compared to pine and eucalyptus pulps.

Overall, when comparing the CNFs/cotton linter pulp paper with papers produced from other biomass such as eucalyptus, bamboo, or recycled fibers, the CNFs from cotton linters exhibited significant enhancements in mechanical performance, with tensile strength reaching 77.90 N (a 9.4-fold increase) and bursting strength up to 3727 N (a 4.2-fold increase). Although similar studies on papers derived from eucalyptus or bamboo pulps have reported notable improvements, the magnitude of enhancement is higher here due to the greater CNF incorporation, which can be partly attributed to the high purity and favorable surface characteristics of cotton linter CNFs that promote extensive hydrogen bonding and efficient interfiber adhesion. Moreover, the extent of porosity reduction and barrier improvement underscores the effectiveness of cotton linters as a reinforcement source, even though variations in intrinsic fiber structure and processing methods across different biomass may lead to differences in barrier performance. It is also noteworthy that the high CNF loadings in this study resulted in reduced brightness and non-linear changes in opacity, likely because a denser fiber network limits light scattering, whereas biomass sources with higher residual lignin may inherently exhibit lower brightness but different opacity trends. This suggests that while cotton linter-based papers excel in mechanical reinforcement, there might be trade-offs in optical performance depending on the intended application. Additionally, the extraction of CNFs from cotton linters offers a simpler, more sustainable, and cost-effective route compared to woody biomass, which typically requires additional purification steps to remove lignin and hemicelluloses, thereby contributing to waste valorization in the textile industry.

Conclusions

This research explored the application of cotton linters, a by-product of the textile industry, in papermaking. The paper was made from cotton linter pulp blended with CNFs with a focus on improving its mechanical and functional properties. The study demonstrated that the addition of CNFs to cotton pulp substantially enhanced the tensile strength, bursting strength, tearing resistance, and fold endurance of the produced paper. The surface morphology of CNF-incorporated paper handsheets revealed a less porous, more compact paper structure due to improved inter-fibrillar force. The XRD analysis showed that the CNFs retained their inherent crystalline structure even after the refining process. CNFs primarily enhanced internal bonding, leading to improved barrier performance, decreased water absorbency, and greater air resistance. Additionally, CNFs altered the optical characteristics of the paper. Overall, blending higher proportions of CNFs with cotton linter pulp resulted in paper with excellent mechanical properties, making it suitable for specialty paper applications like printing paper, packaging paper, release liner, decor paper, label paper, etc. CNFs also altered the optical characteristics of paper. CNFs primarily enhanced internal bonding, leading to improved barrier performance, including low water absorbency and high air resistance. Additionally, CNFs altered the optical characteristics of the paper. Overall, blending higher proportions of CNFs with cotton linter pulp resulted in paper with excellent mechanical properties, making it suitable for specialty paper applications. The findings underscore the benefits of using cotton waste to produce pulp and CNFs, highlighting its potential as a sustainable and eco-friendly material for the paper industry. However, the commercial viability and scalability of CNFs-incorporated cotton linter paper need further exploration. Further research and development are required to substantiate the improvements or advantages gained with fully cotton waste-based paper, which can compensate for the increased cost.

Data availability

All data generated or analysed during this study are included in this published article.

References

Balea, A. et al. Industrial application of nanocelluloses in papermaking: A review of challenges, technical solutions, and market perspectives. Molecules 25(3), 526. https://doi.org/10.3390/molecules25030526 (2020).

Pego, M. F. F., Bianchi, M. L. & Yasumura, P. K. Nanocellulose reinforcement in paper produced from fiber blending. Wood Sci. Technol 54, 1587–1603. https://doi.org/10.1007/s00226-020-01226-w (2020).

Petroudy, S. R. et al. Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr. Polym. 99, 311–318. https://doi.org/10.1016/j.carbpol.2013.07.073 (2014).

Azeredo, H. M., Rosa, M. F. & Mattoso, L. H. Nanocellulose in bio-based food packaging applications. Ind. Crop. Prod. 97, 664–671. https://doi.org/10.1016/j.indcrop.2016.03.013 (2017).

Kumar R, Kumar G. Nanocellulose: Fascinating and sustainable nanomaterial for papermaking, in: Nanotechnology in Paper and Wood Engineering. Elsevier 389–407. https://doi.org/10.1016/B978-0-323-85835-9.00001-5 (2022).

Bharimalla, A. K. et al. Micro/nano-fibrillated cellulose from cotton linters as strength additive in unbleached kraft paper: Experimental, semi-empirical, and mechanistic studies. BioResources 12, 5682–5696. https://doi.org/10.15376/biores.12.3.5682-5696 (2017).

Patil, S. et al. Nanocellulose reinforced corn starch-based biocomposite films: Composite optimization, characterization and storage studies. Food Packag. Shelf Life 33, 100860. https://doi.org/10.1016/j.fpsl.2022.100860 (2022).

Adnan S, Azhar AH, Jasmani L, and et al. Properties of paper incorporated with nanocellulose extracted using microbial hydrolysis assisted shear process. In: IOP conference series: Materials Science and Engineering, 368 012–022. IOP Publishing. https://doi.org/10.1088/1757-899X/368/1/012022 (2018).

Kasmani, J. & Samariha, A. Effect of nano-cellulose on the improvement of the properties of paper newspaper produced from chemi-mechanical pulping. BioResources 14, 8935–8949. https://doi.org/10.15376/biores.14.4.8935-8949 (2019).

Samyn, P. et al. Nanoparticles and nanostructured materials in papermaking. J. Mater. Sci. 53, 146–184. https://doi.org/10.1007/s10853-017-1525-4 (2018).

Skocaj, M. Bacterial nanocellulose in papermaking. Cellulose 26, 6477–6488. https://doi.org/10.1007/s10570-019-02566-y (2019).

Brodin, F. W., Gregersen, O. W. & Syverud, K. Cellulose nanofibrils: Challenges and possibilities as a paper additive or coating material–A review. Nord. Pulp Pap. Res. J. 29(1), 156–166. https://doi.org/10.3183/npprj-2014-29-01-p156-166 (2014).

Balea, A. et al. Valorization of corn stalk by the production of cellulose nanofibers to improve recycled paper properties. BioResources 11(2), 3416–3431. https://doi.org/10.15376/biores.11.2.3416-3431 (2016).

Lengowski EC, Bonfatti Júnior EA, Kumode MM, et al. Nanocellulose in the paper making. In: Sustainable Polymer Composites and Nanocomposites. (Inamuddin, Sabu Thomas, Raghvendra Kumar Mishra, Abdullah M. Asiri eds) Springer Cham 1027–1066 https://doi.org/10.1007/978-3-030-05399-4_36 (2019).

Boufi, S. et al. Nanofibrillated cellulose as an additive in papermaking process: A review. Carbohydr. Polym. 154, 151–166. https://doi.org/10.1016/j.carbpol.2016.07.117 (2016).

Shi, S. C., Hsieh, C. F. & Rahmadiawan, D. Enhancing mechanical properties of polylactic acid through the incorporation of cellulose nanocrystals for engineering plastic applications. Teknomekanik 7, 20–28. https://doi.org/10.24036/teknomekanik.v7i1.30072 (2024).

Zhu, H. et al. Anomalous scaling law of strength and toughness of cellulose nanopaper. Proc. Natl. Acad. Sci. 112, 8971–8976. https://doi.org/10.1073/pnas.1502870112 (2015).

Bharimalla, A. K. et al. Development of energy efficient nanocellulose production process by enzymatic pretreatment and controlled temperature refining of cotton linters. Cellulose 30(2), 833–847. https://doi.org/10.1007/s10570-022-04959-y (2023).

TAPPI T 220 sp-16:2016. Physical testing of pulp handsheets.

Segal, L. G. et al. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 29(10), 786–794. https://doi.org/10.1177/004051755902901003 (1959).

TAPPI T494 OM-13:2013. Tensile breaking properties of paper and paperboard (Using constant rate of elongation apparatus).

TAPPI T 403 OM-15:2015. Bursting strength of paper.

TAPPI T T414 OM-12:2012. Internal tearing resistance of paper (Elmendorf-Type Method).

TAPPI T 511 OM-02:2002. Folding endurance of paper.

TAPPI T441:2013. Water absorptiveness of sized (non-bibulous) paper, paperboard, and corrugated fiberboard (Cobb test).

Dhakane-Lad, J. et al. Influence of beeswax-chitosan biocoatings on physical and barrier properties of kraft paper. Cellulose 31, 8235–8248. https://doi.org/10.1007/s10570-024-06111-4 (2024).

TAPPI T 452 OM-18:2018. Brightness of pulp, paper, and paperboard (Directional Reflectance at 457 nm).

TAPPI T 425 om-16:2016. Opacity of paper (15/d Geometry, Illuminant A/2*, 89% Reflectance Backing and Paper Backing).

Das, A. K. et al. Nanocellulose: its applications, consequences and challenges in papermaking. J. Packag. Technol. Res. 4, 253–260. https://doi.org/10.1007/s41783-020-00097-7 (2020).

Campano, C. et al. Mechanical and chemical dispersion of nanocelluloses to improve their reinforcing effect on recycled paper. Cellulose 25, 269–280. https://doi.org/10.1007/s10570-017-1552-y (2018).

Viana, L. C. et al. Nanofibrillated cellulose as an additive for recycled paper. Cerne 24, 140–148. https://doi.org/10.1590/01047760201824022518 (2018).

Kalia, S. et al. Nanofibrillated cellulose: surface modification and potential applications. Colloid Polym. Sci. 292, 5–31. https://doi.org/10.1007/s00396-013-3112-9 (2014).

Li, A. et al. Overview of nanocellulose as additives in paper processing and paper products. Nanotechnol. Rev. 10, 264–281. https://doi.org/10.1515/ntrev-2021-0023 (2021).

Guan, M., An, X. & Liu, H. Cellulose nanofiber (CNF) as a versatile filler for the preparation of bamboo pulp based tissue paper handsheets. Cellulose 26, 2613–2624. https://doi.org/10.1007/s10570-018-2212-6 (2019).

Hipeni, A. R. H., Tan, J. W. & Shah, N. S. J. Effect of nanocellulose reinforced recycled paper towards tensile strength. J. Chem. Engg. Ind. Biotechnol. 10, 25–29 (2024).

Balea, A. et al. In situ production and application of cellulose nanofibers to improve recycled paper production. Molecules 24(9), 1800. https://doi.org/10.3390/molecules24091800 (2019).

IS 1397: 2020. Kraft Paper for Packing and Wrapping — Specification (third revision).

Kumar, V., Pathak, P. & Bhardwaj, N. K. Facile chemo-refining approach for production of micro-nanofibrillated cellulose from bleached mixed hardwood pulp to improve paper quality. Carbohydr. Polym. 238, 116186. https://doi.org/10.1016/j.carbpol.2020.116186 (2020).

Afra, E., Mohammadnejad, S. & Saraeyan, A. Cellulose nanofibils as coating material and its effects on paper properties. Prog. Org. Coat. 101, 455–460 (2016).

Nair, S. S. et al. High performance green barriers based on nanocellulose. Sustain. Chem. Process. 2, 1–7. https://doi.org/10.1186/s40508-014-0023-0 (2014).

Perdoch, W. et al. Influence of nanocellulose structure on paper reinforcement. Molecules 27, 4696. https://doi.org/10.3390/molecules27154696 (2022).

Engin, M., Sonmez, S. & Ozden, O. The effects of coating colours on base papers. Pigm. Resin Technol. 51(6), 553–563. https://doi.org/10.1108/PRT-06-2021-0064 (2022).

Altay, B. N. et al. Addition of fibers derived from paper mill sludge in paper coatings: impact on microstructure, surface, and optical properties. Sci. Rep. 13, 19350. https://doi.org/10.1038/s41598-023-46130-y (2023).

Jo, H. M. et al. Effect of nanofibrillated cellulose made from enzyme-pretreated bamboo pulp on paper strength. BioResources 16, 964–978. https://doi.org/10.15376/biores.16.1.964-978 (2021).

Acknowledgements

The authors express their gratitude to the ICAR-Central Institute for Research on Cotton Technology, Mumbai, India, for offering the necessary infrastructure to conduct the experiments.

Funding

The authors state that no financial assistance, grants, or other support was obtained during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

AKB: Conceptualization, Resources, Investigation, SP: Writing—Original draft, Writing—review & editing JDL: Data curation, Writing—review & editing MKM: Writing—review & editing, Resources VN: Project administration, Supervision SK: Validation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

None of the authors have any conflict of interest regarding the research, publication, or authorship of this manuscript. All authors have explicitly consented to submit this manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bharimalla, A.K., Patil, S., Dhakane-Lad, J. et al. Blending of cellulose nanofibers with cotton linter pulp to enhance the mechanical and barrier properties of paper. Sci Rep 15, 11788 (2025). https://doi.org/10.1038/s41598-025-96213-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96213-1