Abstract

In order to enhance the passability and motion flexibility of a mobile robot operating on unstructured terrain, a centipede style multi-drive module articulated mobile robot has been developed. This robot combines passive deformation wheels with flexible articulation devices, enabling it to passively adapt to complex and variable obstacle terrains. Additionally, the passive deformation wheels have been optimized. Based on the study of the passive deformation mechanism of the wheels, a mechanical model of the robot’s obstacle-crossing capability has been established, and the robot’s passability across different terrains has been analyzed. Experimental results under various terrains demonstrate that the robot features a rational structural design, excellent obstacle-crossing performance, and high motion flexibility, allowing it to passively adapt to complex and variable obstacle terrains.

Similar content being viewed by others

Introduction

In the development of mobile robots so far, there have been many innovative and groundbreaking advancements in mobile mechanisms. From traditional mobile robots with a single movement mode, to composite mobile robots that combine various movement modes, significant progress has been made. The most typical examples of composite mobile robots are the wheel-track composite type and the wheel-leg composite type1,2,3,4,5.

For the structural design of wheel-track composite mobile robots, two design approaches are commonly used: the wheel-track mechanism superposition type and the wheel-track mechanism fusion type6,7. Wheel-track superimposed composite mobile robots typically involve a simple combination of independent wheel and track mechanisms. These robots generally have two independent drive systems, allowing for switching between movement modes based on terrain. While this design offers good reliability, it also results in a complex structure. The inclusion of two sets of mobile mechanisms increases the overall weight of the robot, thereby reducing its load capacity8,9. On the other hand, wheel-track fusion composite mobile robots integrate wheels and tracks into a single system with only one set of drive mechanisms. This design enables the selection of the most effective motion mode according to different terrains. However, it requires the introduction of a deformation mechanism for mode switching, which tends to be slow, making real-time performance difficult to guarantee. Additionally, complex obstacle environments and frequent switching of motion modes can complicate the control system and reduce the lifespan of the actuators10,11,12.

In terms of the structural design of wheel-leg composite mobile robots, four main design methods are commonly used: multi-motion mode, rotating leg structure, active deformation wheel, and passive deformation wheel13,14,15,16. The multi-motion mode mobile robot is similar in design concept to the stacked composite mobile robot, featuring two independent drive systems. However, the robot’s control system is complicated by the active switching device required to convert between the two motion modes17,18. The rotating leg mobile robot has a simple control system, an easy-to-design structure, and high mobility. However, during motion, the robot’s center of mass oscillates frequently and with large amplitude, resulting in poor dynamic stability and potential damage to the robot’s hardware equipment19,20,21. Active deformation wheeled robots can move quickly and efficiently on flat surfaces using wheeled motion. When encountering obstructed terrain, they can switch to legged motion through an onboard deformation mechanism, providing high obstacle-crossing capability. However, this design requires additional drive and energy to maintain the deformation, which not only increases the system’s weight but also complicates the control system22,23,24. Passive deformation wheeled robots combine the advantages of wheeled motion with the ability to passively adapt to terrain. By deforming in response to external forces from the terrain, these robots can achieve passive obstacle-crossing without the need for additional driving force. This simplifies the overall structure of the robot, reduces its size and weight, and makes the control system less complex25. However, research on this passive deformation mechanism is still limited.

In summary, although the existing mobile robots have already possessed strong obstacle-crossing performance, they still generally suffer from the problems of insufficient stability, high energy consumption and poor motion flexibility. Therefore, this paper designs an articulated mobile robot based on passive deformation wheels from the structural aspect by drawing on the mechanism of centipede body structure. In the obstacle-crossing process, the robot wheels can passively realize the transformation from wheel-type to wheel-leg type, which not only reduces the power consumption but also eases the control difficulty. The change of the robot’s motion pattern only occurs during the obstacle-crossing process, which ensures the stability of the robot’s motion. Moreover, the flexible articulation device of the robot ensures the flexibility of the robot’s movement, which can be adapted to complex environments such as factories and fields.

The main contents of this paper are as follows: Chap. 1 introduces the overall configuration of the robot, including the design of its passive deformation wheels and flexible articulation device, and optimizes the four-bar mechanism within the passive deformation wheels. Chapter 2 focuses on the mechanism of passive deformation of the wheels under external forces. Combined with an analysis of the overall forces acting on the robot in the coupled state of multiple drive modules, a mechanical model for the robot’s obstacle-crossing is established, and its passing performance is analyzed. Chapter 3 describes the construction of a robot prototype and presents a series of comprehensive experiments to evaluate the robot’s obstacle-crossing performance, motion flexibility, and passability. Finally, the paper concludes with a summary.

Robot optimization design and analysis

Robot structural design

Robot general configuration analysis

The locomotor system of a centipede mainly consists of three parts: muscle fibers, bony plates, and footsteps. The most distinctive feature of the centipede’s carapace is its chitinous exoskeleton, which covers the entire carapace. The back of each body segment is covered by a dorsal plate, while the abdomen is covered by a ventral plate. The dorsal and ventral plates are connected by membranous plates on both sides. Footsteps are located on both sides of the body, and under the innervation of nerve fibers, they can perform various complex movements26.

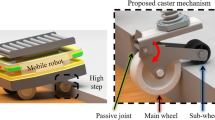

Based on the body structure of the centipede and its motion system generation mechanism, the configuration generation mechanism of the articulated mobile robot is obtained, as shown in Fig. 1. The robot consists of three main parts: the body, the joints, and the feet. The body primarily includes the robot shell as well as internal components such as controllers, motors, and power supplies. The joints are flexible articulating devices that provide flexible connections and terrain adaptation when the robot turns or crosses obstacles. The feet are one of the most important components for robot movement, and the design concept of passive switching of movement modes through a deformed wheel configuration is adopted. This allows the robot to use wheeled motion when walking on flat or slightly uneven ground, while the wheels can passively switch to a wheel-legged form when encountering vertical obstacles such as steps, enabling the robot to adapt to the terrain and change to a wheel-legged movement mode.

By analyzing the generation mechanism of the robot’s overall configuration, the articulated mobile robot’s overall structure is designed as shown in Fig. 2. The structure is symmetrical and divided into three sections, with each section’s drive module connected by a flexible articulation device. Each section module is symmetrically equipped with two passive deformation wheels, and each wheel is individually driven by a stepping geared motor to enable the robot’s functions, such as walking, steering, and obstacle crossing. The robot can flexibly configure the number of drive modules and flexible articulation devices according to different obstacles in various scenarios. Additionally, each drive module is equipped with a control signal wire connector, which allows for the mutual transmission of control signals between modules while maintaining mechanical connections. This design satisfies the robot’s operational requirements in different scenarios and under various obstacle conditions.

Passive deformation wheel structure design

Existing deformation wheels can be categorized into three types based on their structural principles: articulated, pin-groove, and crank-slider types. Each type has its own advantages and disadvantages27. The articulated deformation wheel has a simple configuration, flexible deformation, low frictional resistance between components, and high switching efficiency. However, it requires the design of a limiting mechanism to address potential interference between wheel legs, and its deformation ratio generally does not exceed 1.5. The pin-groove deformation wheel features a simple structural configuration, a small number of components, and compact external dimensions, with a deformation ratio of about 2. However, it suffers from high frictional resistance between components and the presence of dead spot positions. The crank-slider deformation wheel offers greater design freedom for wheel leg configuration, with a deformation ratio typically less than 2. However, it requires higher motor drive torque and is not suitable for mobile robots carrying larger loads.

In order to address the shortcomings of the deformation efficiency of existing deformation wheels, based on the above analysis of the structural configuration principles of deformation wheels and combined with the requirements of current robot application scenarios, this paper integrates the advantages of the articulated deformation wheel’s structural principles and proposes a passive deformation wheel based on a four-bar mechanism. The key deformation device of the wheel is primarily designed based on the concept of the four-bar mechanism. As shown in Fig. 3, which illustrates the deformation principle of the wheel, the left side of the figure depicts the wheel’s four-bar mechanism. In this mechanism, the OC rod is fixed, the OA rod is the driving member, the AB rod is the connecting rod, and the BCD rod is the follower. When the OA rod rotates, as shown in Fig. 3, it drives the BCD rod to swing, with the CD rod acting as the swing leg.

Fig. 4 shows the structure of the passive deformation wheel, which is mainly divided into two parts, inner and outer. The central spindle in the middle of the wheel is fixed with the rotating rod inside the wheel hub and the Three-pronged connecting rod outside, the rotating rod inside the wheel is connected to the wheel hub by a reset spring, which is a The rotating rod inside the wheel hub is connected to the wheel hub by a reset spring, which is a compression spring, and the three-pronged connecting rod outside the wheel hub is connected to the swing leg hinged on the wheel hub by a tension spring. When an external torque is applied to the rotating rod, the rotating rod will rotate relative to the wheel hub, and at the same time, the reset spring inside the wheel is compressed, and the external three-pronged connecting rod will drive the swing leg to swing, when the external torque on the rotating rod is cancelled, the reset spring will be reset, and the swing leg will return to its original position.

There are six limit screws mounted evenly on the wheel hub, divided into first limit screws and second limit screws. The first limit screws are used to limit excessive swing leg spread, the second limit screw is used to limit the reverse rotation of the three-pronged connecting rod and to preload the reset spring. The swing leg and wheel hub are fitted with a permanent magnet in the corresponding position to prevent the swing leg from opening when the wheel is travelling on level ground or on ground with a slight slope.

The wheels are deformed by the friction they create with the ground, which in turn changes the robot’s movement pattern. When the robot walks on the flat ground, due to the relatively small rolling friction, the relative rotation angle between the three-pronged connecting rod and the wheel hub is small, at this time, the torque generated by the tension spring is smaller than the permanent magnet magnetic torque, the swing leg on the wheel will not be open, the robot is wheeled motion mode. When the robot encounters an obstacle and sliding friction occurs, the sliding friction force is larger than the rolling friction force, the three-pronged connecting rod and wheel hub rotate at a larger angle relative to each other, and the torque generated by the tension spring is larger than the permanent magnet magnetic torque, and the wheel swing leg opens up. The motion of the robot changes to wheel-leg motion mode.

Design and analysis of flexible articulating device

Structural designs

The flexible articulating device is one of the key components ensuring the robot’s smooth motion and adaptability to different terrains. Currently, most designs use hinges or soft-body connections to link each module, enabling flexible adaptive motion for the robot28,29. Among these, hinges are widely used due to their ease of installation. However, they have a shorter lifespan, are less resistant to impact, and are prone to wear and tear over time. On the other hand, soft-body connections can better adapt to external environments and offer strong impact resistance. However, their molds are more expensive to produce, and the control system is more complex.

Based on the centipede body joint structure, a flexible articulating device was designed by combining the advantages of hinge connection and flexible body connection. As shown in Fig. 5, the device is mainly divided into three parts:

-

1.

Flexible articulated part: including Articulated spring, Spring retaining plate and Spring cover.

-

2.

Rigid-flexible switching part: including Recessed bushing, Taper bar, Telescopic shaft and Plain bearing.

-

3.

Mode locking part: including Photoelectric switch, Electromagnetic actuator, Limit latch and Restrictor bar.

Based on the three-part mechanical connection described above, the robot can switch between a rigid connection and a three-degree-of-freedom flexible connection for each drive module, adapting to fluctuating terrain or obstacles.

In Fig. 5a, when the robot passes through steps, slopes, variable curvature terrain, and small fluctuating localized protruding depression obstacles, the limit latch mounted on the electromagnetic actuator cooperates with the cone in the limit rod away from the end of the telescopic shaft to realize the limit of the limit rod, so that the convex sleeve outer taper cannot cooperate with the inner taper of the concave sleeve. At this time, the drive modules are flexibly connected, and the articulation spring in the flexible articulation device can be regarded as a three-degree-of-freedom hinge equipped with a torsion spring, which can realize the three-degree-of-freedom rotation between the drive modules to ensure the robot’s terrain adaptability and motion flexibility.

In Fig. 5b, when the robot encounters a trench or a depression with a large depth of terrain, the electromagnetic actuator is energized to contract, at which point the limit latch no longer cooperates with the cone in the restrictor bar away from the end of the telescopic shaft. Afterwards, the distance between the front and rear drive modules is shortened, so that the outer tapered surface of the taper bar gradually cooperates with the inner tapered surface of the recessed bushing, and the limit latch gradually cooperates with the cone in the restrictor bar near the end of the telescopic shaft. finally the restrictor bar is limited, the taper bar is pushed into the recessed bushing to realize the rigid connection between the drive modules. In the process of changing the drive module from flexible to rigid connection, the baffle assembled on the electromagnetic actuator transmits limit signals for the photoelectric switch to ensure the accuracy of the rigid changeover between the drive modules.

Angle range of articulation

When the flexible articulation device is in the flexible connection state, the tapered outer edge of the recessed bushing limits the oscillation of the taper bar, thereby affecting the robot’s turning radius to some extent. Therefore, it is necessary to analyze the swing range of the flexible articulating device. Fig. 6 illustrates the maximum rotation angle of the device in its radial plane when the robot is operating at its minimum turning radius.

In Fig. 6, P is the contact point, a is the length of the articulated spring, \({d_1}\) and \({d_2}\) are the diameters of the outer rings of the spring cover and taper bar, respectively. Assuming that the center of rotation of the articulated joint is the center point O of the articulated spring, the maximum rotation angle \({\theta _{\hbox{max} }}\) can be derived from the geometric relationship as follows:

In summary, the analysis demonstrates that the flexible articulating device has a range of rotation within its radial plane \(\left[ { - {\theta _{\hbox{max} }},{\theta _{\hbox{max} }}} \right]\).

Optimization analysis of passively deformed wheel

Optimization of four-bar mechanism for wheel

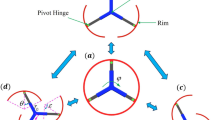

Fig. 7 shows a sketch of the four-bar mechanism before and after deformation. The rod OA is three-pronged connecting rod with length \({l_{{\text{OA}}}}\), the rod AB is extension spring, the rod BC is swing leg connector with length \({l_{{\text{BC}}}}\), OC is the wheel hub parameter and its value is set to 69 mm, \(\alpha\) and \(\zeta\) are the initial angles of the three-pronged connecting rod and swing leg connector respectively, \({\beta _2}\)and \({\beta _1}\) are the angles of rotation of the three-pronged connecting rod and swing leg connector when bars AB and BC are co-linear, respectively.

In the following, the values of the four parameters \({l_{{\text{BC}}}}\), \({l_{{\text{OA}}}}\), \(\alpha\), and \(\zeta\) will be determined so that the swing angle \({\beta _2}\) of the swing leg connector is larger when the three-pronged connecting rod angle \({\beta _1}\) is smaller. The initial values and the range of variation of the design parameters of the known four-bar mechanism are shown in Table 1.

(a) Relationship between the initial length \({l_{{\text{BC}}}}\) and the two rotation angles \({\beta _1}\), \({\beta _2}\), (b) Relationship between the initial length \({l_{{\text{OA}}}}\) and the two rotation angles \({\beta _1}\), \({\beta _2}\), (c) Relationship between the initial angle \(\alpha\) and the two rotation angles \({\beta _1}\), \({\beta _2}\), (d) Relationship between the initial angle \(\zeta\) and the two rotation angles \({\beta _1}\), \({\beta _2}\).

Fig. 8 shows a plot of the \({\beta _1}\) and \({\beta _2}\) turning angle relationship with the variation of the remaining one parameter when the three parameters are constant values. Given four parameters \({l_{{\text{BC}}}}\), \({l_{{\text{OA}}}}\), \(\alpha\), and \(\zeta\) of 12 mm, 40 mm, 30°, and 20° respectively. In Fig. 8a, as the length \({l_{{\text{BC}}}}\) increases, the turning angle \({\beta _2}\) gradually increases, and the corresponding pendulum angle \({\beta _1}\) increases and then decreases, the \({l_{{\text{BC}}}}\) corresponding to the maximum of \({\beta _1}\) is selected as the optimal initial length, i.e., \(l_{{{\text{BC}}}}^{{{\text{Opt}}}}\)= 12.5 mm. In Fig. 8b, as the length \({l_{{\text{OA}}}}\) increases, the turning angle \({\beta _2}\) decreases exponentially corresponding to the gradual increase of the pendulum angle \({\beta _1}\). Considering that the pressure angle on the four-bar mechanism becomes larger while \({l_{{\text{OA}}}}\) increases, \(l_{{{\text{OA}}}}^{{{\text{Opt}}}}\)= 55 mm is selected as the optimal initial length. In Fig. 8c, with the increase of the angle \(\zeta\), the decrease of the turning angle \({\beta _2}\) is smaller, and the corresponding decrease of the pendulum angle \({\beta _1}\) is larger than \({\beta _2}\). Considering the mounting structure of the wheel, \({\zeta ^{{\text{Opt}}}}\)= 12° is selected as the optimal initial angle. In Fig. 8d, as the angle \(\alpha\) increases, the turning angle \({\beta _2}\) decreases less, and the corresponding pendulum angle \({\beta _1}\) increases and then decreases, the \(\alpha\) corresponding to the maximum of \({\beta _1}\) is selected as the optimal initial angle, i.e., \({\alpha ^{{\text{Opt}}}}\)= 31°.

The above analysis yields the optimal initial values of the four parameters, which in turn yields the turning angle \({\beta _2}\)= 22.71° and the pendulum angle \({\beta _1}\)= 128.57°, at which point the rod AB and rod BC are co-linear in Fig. 7.

Analysis of wheel deformation ratio

The deformation ratio of the wheel is defined as the ratio of the wheel’s radius when the swing leg is fully opened to its radius when the swing leg is closed. The deformation ratio not only reflects the deformation capacity of the deformation mechanism but also indirectly indicates its obstacle-crossing ability. The initial state of the wheel is defined as when the swing leg is closed, and a coordinate system \(\left\{ {{x_w},{y_w}} \right\}\) is established, as shown in Fig. 9.

In Fig. 9, the center of the deformed wheel \({O_w}\) is the coordinate origin, r is the wheel radius, \(\lambda\) is the angle between the line \({O_w}{\text{A}}\) and the line \({\text{A}}{{\text{B}}_i}\left( {i=1,2} \right)\), which changes with the swing of the pendulum leg. \({O_w}{{\text{B}}_1}\) and \({O_w}{{\text{B}}_2}\) are the radii of the deformed wheel in the closed and expanded states, respectively. Based on the geometric relationship, the following results can be derived:

\(\left| {{O_w}{B_2}} \right|\)in Eq. (2) is obtained through derivation on \(\lambda\):

Considering the practical situation, when the wheel swing leg is closed, there is a minimum of \(\lambda\) as \({\lambda _{\hbox{min} }}\)= 30°, and from Eq. (3), the maximum of \(\lambda\) is \({\lambda _{\hbox{max} }}\)= 180°. Considering the optimization of the wheel, the installation position of the first limit screw and the actual barrier-crossing stability and other factors, \({\lambda _{\hbox{max} }}\)= 122° is taken, so there is an actual deformation ratio k is:

From Eq. (4), it can be observed that the passive deformation wheel has a large deformation ratio and exhibits strong obstacle-crossing capability.

Analysis of robot obstacle crossing and performance

Analysis of robot obstacle-crossing

Deformation process of wheel crossing

Fig. 10 shows a schematic diagram of the forces at various stages of deformation of a deformed wheel when encountering an obstacle. Here, \({l_i}\left( {i=1,2, \cdots ,7} \right)\) represents the length of each rod or spring; \({\alpha _1}\) is the angle between the line connecting the articulated center of the swing leg and the center of the wheel hub and the axis of the permanent magnet; \({\alpha _2}\), \({\alpha _3}\), and \({\alpha _4}\) are the initial position angles of the rotating rod, three-pronged connecting rod, and swing leg relative to the wheel hub, respectively; \({f_m}\) is the magnetic force of the magnet; \({f_{e{\text{1}}}}\) and \({f_{e{\text{2}}}}\) are the forces of the reset spring and tension spring, respectively; \({f_{s{\text{1}}}}\)and \({f_{s{\text{2}}}}\) are the sliding friction forces at the two points of contact between the wheel and the obstacle, respectively; r is the wheel radius.

When the robot moves on a flat surface at a constant speed, the deformation wheel is primarily subjected to rolling friction, and its friction torque is equal to the effective combined torque generated by the two reset springs inside the wheel. It is assumed that the maximum value of the driving torque M is greater than both the effective combined torque generated by the two reset springs in the wheel and the torque generated by the maximum static friction applied to the wheel. As shown in Fig. 10b, the relationship between the friction force \({f_{si}}\left( {i=1,2} \right)\) and the rotation angle of the rotating rod relative to the wheel hub \({\alpha _t}\) is as follows:

In Eq. (5), \({k_{e1}}\) is the stiffness of the reset spring, \({l_{e1}}\) is the original length of the reset spring.

ince the rotation angle of the rotating rod is the same as that of the three-pronged connecting rod, the relationship between the rotation angle \({\alpha _t}\) of the three-pronged connecting rod and the swing angle \({\alpha _s}\) of the swing leg can be derived from Fig. 10c:

In Eq. (6), x and y are intermediate variables and do not need to be solved.

Taking the articulation center of the swing leg with the wheel hub as the reference point, the magnetic torque \({T_m}\) can be derived from Fig. 10a as follows:

According to Fig. 10c and Eq. (6), the torque \({T_{e2}}\) generated by the tension spring is as follows:

In Eq. (8), \({k_{e2}}\) is the stiffness of the tension spring, \({l_{e2}}\) is the original length of the tension spring.

The above analysis shows that the torque \({T_{e2}}\) generated by the tension spring must be greater than the magnetic torque \({T_m}\) of the permanent magnet for the swing leg to open, assuming the swing leg’s own gravity is not taken into account.

Mechanical analysis of robot obstacle crossing

The robot crosses the obstacle in three main phases, corresponding to the first, second, and third drive modules all crossing the obstacle. Each phase involves two scenarios: the first scenario occurs when one drive module crosses the obstacle while the other two drive modules remain in contact with the ground; the second scenario occurs when, as the drive module moves, one of its neighboring drive modules loses contact with the ground. Both scenarios need to be analyzed separately. The minimum output torque of the robot is determined by analyzing the robot’s obstacle-crossing mechanics. The parameters used in the analysis process and their meanings are detailed in Table 2.

The obstacle-crossing process of the first drive module is analyzed as shown in Fig. 11. In Fig. 11a, since only the first drive module lifts up, the articulation center between the first and second drive modules is taken as the reference point. From this, the torque balance equation for the first scenario in the first drive module’s obstacle-crossing process can be expressed as follows:

In Fig. 11b, both the first and second drive modules are lifted up. Taking the articulation center between the second and third drive modules as the reference point, the torque balance equation for the second scenario in the obstacle-crossing process of the first drive module can be expressed as follows:

Fig. 12 shows the obstacle-crossing process of the second drive module, which is similar to the process analyzed above. The torque balance equations for the first and second scenarios in the obstacle-crossing process of the second drive module are as follows:

Fig. 13 shows the obstacle-crossing process of the third drive module, which is similar to the process analyzed above. The torque balance equations for the first and second scenarios in the obstacle-crossing process of the third drive module are as follows:

In summary, the minimum output torque \({M_{\hbox{min} }}\) of the motor can be determined as follows:

In Eq. (15), i = 1,2,3; j = 1,2.

Robot passability analysis

Robot passability generally refers to the ability of a robot to navigate complex obstacle terrains, such as grass, steps, and trenches30. This capability depends on both the physical properties of the terrain and the structural performance parameters of the robot.

Slope passability

Fig. 14 shows the longitudinal motion of the robot parallel to the slope. When the robot is moving at a constant speed or at rest on the slope, the driving force \({f_Q}\) of the robot must be less than or equal to the maximum static friction \({f_{s\hbox{max} }}\) between the slope and the contact point. Otherwise, the robot will slide down the slope. At this point,

In Eq. (16), \(\mu\) is the coefficient of sliding friction. When the angle of the slope is greater than the inverse tangent value of the coefficient of sliding friction, the robot slides down the slope.

Step passability

Steps are one of the most common obstacles encountered in daily life, making it necessary to analyze them. Fig. 15 shows a schematic diagram of the robot’s maximum height span when the swing leg of the passive deformation wheel is fully extended to its maximum angle. Each parameter in the figure corresponds to the parameters defined in Table 2.

As shown in Fig. 15, the following relationships can be derived through geometric analysis:

From Eq. (17), the maximum height \({h_{\hbox{max} }}\) of the step that the robot can cross is as follows:

Trench passability

The ability of a robot to cross a trench is related to parameters such as wheelbase. When the robot crosses the trench, the articulation needs to transition from a flexible connection to a rigid connection. As a result, the wheel spacing between the two drive modules decreases, and the maximum span that the robot can cross is determined by the reduced axle spacing at this stage. Fig. 16 shows a schematic diagram of the robot crossing a trench. From this diagram, the maximum trench width \({l_{t\hbox{max} }}\) that the robot can cross can be derived as follows:

In Eq. (19), \(\Delta s\) is the moving distance of the two drive modules when the articulation changes from a flexible connection to a rigid connection.

Performance experiments on different terrains

The designed articulated mobile robot experimental prototype is shown in Fig. 17. This prototype is developed to meet the requirements of high passability and motion flexibility in complex and variable obstacle terrains. Each section of the robot’s drive module is connected through a flexible articulating device. Key control system components, such as the power supply, stepper motors, gearboxes, drivers, and controllers, are installed inside the drive module, while passive deformation wheels are mounted on both sides of each drive module section.

In order to ensure the comprehensive performance of the robot, it is necessary to determine the mounting position of the wheels on the drive module. First, the space utilization inside the drive module of the robot should be as high as possible. Second, to ensure the robot’s passing performance, the robot chassis should have the highest possible ground clearance. Moreover, the wheels should preferentially come into contact with obstacles. In summary, the optimal mounting position for the wheels is near the chassis in the forward direction of the drive module.

After the construction of the robot experimental prototype and system is completed, it is necessary to verify the robot’s performance through experiments, including walking, climbing, trench crossing, and step crossing. The pose of each drive module of the robot is acquired in real time using sensors.

Robot performance experiment on flat terrain

Level ground walking is the foundation for proper robot operation. The first drive module in the forward direction of the robot is designated as the first drive module, and a right-angle coordinate system is established for each drive module of the robot accordingly. As shown in Fig. 17, the rotation angle about the Z-axis is defined as the yaw angle of the drive module, the rotation angle about the Y-axis is defined as the pitch angle of the drive module, and the rotation angle about the X-axis is defined as the side tilt angle of the drive module. (This definition is used for all subsequent experiments and serves as the benchmark for experimental testing of the robot.)

In Fig. 18, the robot’s level ground walking is divided into three phases: straight-line walking, turning, and straight-line walking. Fig. 19 shows the changes in the attitude angles of each drive module of the robot when walking on flat ground at a speed of 0.2 m/s. The yaw angle of the robot before and after the turn is 100°, and the yaw angles of the three drive modules change almost synchronously, with smooth transition curves. From the pitch angle change curves of the three drive modules, it can be observed that, due to inertia, the pitch angle of the robot increases during the starting and stopping processes. As the robot moves, the pitch angles of the three drive modules change accordingly, ranging from − 1.187° to 0.939°. These pitch angle changes can be reduced or mitigated by implementing smooth acceleration and deceleration intervals in the control system. Additionally, due to ground unevenness and the grooves of the wheel swing legs, the roll angles of the three drive modules fluctuate with high frequency, ranging from − 0.020° to 0.017°. The above analysis demonstrates that the robot exhibits excellent motion stability and flexibility.

Robot performance experiment on sloping terrain

Slopes are one of the most common obstacles in unstructured environments. Experiments were conducted using simple slopes with adjustable angles, and the coefficient of friction between the wheels and the slopes was measured to be approximately 0.5.

Fig. 20 shows the robot slope spanning experiments, where the robot spans slopes of 16.7° and 21.8° with a speed of 0.2 m/s, respectively. As can be seen in Fig. 20, the robot climbs the slope without tilting, overturning, slipping and the wheel swing legs do not open. The variation of the pitch angle of each drive module when the robot is going uphill is shown in Fig. 21. Due to inertia and poor wheel speed coordination between the modules, the pitch angle of the robot will have a small variation during the startup and uphill process, and the pitch angle of each drive module will be corrected at the 9th second after the robot finishes going uphill. The above analysis shows that the robot has strong climbing ability and good passability.

Robot performance experiment on trench terrain

A simple trench with adjustable width was constructed, as shown in Fig. 22, the robot crossed the trenches with widths of 174.5 mm, 224.5 mm, 274.5 mm, 294.5 mm, and 324.5 mm, respectively, at a speed of 0.2 m/s. The values of L1, L2, and Δs in the prototype are 239.5 mm, 100 mm, and 44 mm, respectively (refer to Table 2 and Eq. 19 for the definitions of L1, L2, and Δs). The maximum width of the trench that the robot can cross is 295.5 mm.

Since each drive module is rigidly connected when the robot crosses the trench, only the overall robot pitch angle needs to be measured. The pitch angle change curve of the robot when crossing the trench at each width is shown in Fig. 23. t is the trench width, and the robot pitch angle hardly changes when t = 174.5 mm. When t = 224.5 mm and t = 274.5 mm, the change of robot pitch angle is small, and there will be some fluctuation when passing through the trench, but it can be crossed smoothly. When t = 294.5 mm, although the robot was able to cross successfully, its pitch angle varied greatly, with the maximum angle reaching − 10.09°, which might incur the risk of the tail end of the robot falling into the trench. When t = 324.5 mm, the tail end of the robot falls into the trench and cannot cross the trench.

A simple trench with adjustable width was constructed, as shown in Fig. 22. The robot crossed trenches with widths of 174.5 mm, 224.5 mm, 274.5 mm, 294.5 mm, and 324.5 mm at a speed of 0.2 m/s. Since each drive module is rigidly connected when the robot crosses the trench, only the overall robot pitch angle needs to be measured. The pitch angle change curves of the robot when crossing trenches of different widths are shown in Fig. 23. Here, t represents the trench width. When t = 174.5 mm, the robot’s pitch angle remains almost unchanged. For t = 224.5 mm and t = 274.5 mm, the robot’s pitch angle changes slightly, with some fluctuations observed while crossing the trench, but the robot can still pass smoothly. When t = 294.5 mm, although the robot successfully crosses the trench, its pitch angle varies significantly, reaching a maximum angle of -10.09°, which may pose a risk of the robot’s tail end falling into the trench. At t = 324.5 mm, the robot’s tail end falls into the trench, and it fails to cross.

Through the above analysis, it can be concluded that the maximum width of the trench obstacle the robot can successfully cross is 274.5 mm, which is 21 mm smaller than the theoretical maximum value. The ratio of this width to the robot’s own length is 0.35. Compared to traditional 4-wheeled mobile robots, this robot demonstrates a certain level of trench-crossing capability.

Step crossing experiment for robot

Steps are among the most common vertical obstacles in daily environments. The robot successfully traversed a 160-mm-high step at a speed of 0.1 m/s. As illustrated in Fig. 24, the robot demonstrated smooth obstacle negotiation, with passive wheel deformation completing in 1.2 s. Fig. 25 presents the pitch angle variations of each drive module. The data reveal that the front drive module exerts a traction effect on the rear module, thereby enhancing the robot’s obstacle-crossing capability. Notably, pitch angle fluctuations remained minimal during wheel deformation, indicating high stability of the deformation mechanism. The actual step height the robot can cross is 79.73 mm smaller than the theoretical maximum value (in the prototype, the values of r and L4 are 75 mm and 181 mm, respectively. Referring to Eq. (18), the maximum step height the robot can cross is 239.73 mm). The ratio of the obstacle-crossing height to the robot’s own height is 1.07, indicating strong passability.

The overall technical parameters of the articulated mobile robot experimental prototype (Fig. 16) obtained through the above tests are shown in Table 3. The robot features a compact size, lightweight construction, and significant wheel deformation capability, endowing it with strong obstacle-crossing ability, excellent stability, and superior motion flexibility.

Conclusion

Facing the requirements of high passability and motion flexibility performance of mobile robots in non-structural environments, this paper draws on the body structure of centipede, integrates passive deformation wheels and flexible articulation device, designs a wheel-and-leg articulated mobile robot capable of passively adapting to complex and variable obstacle terrains. By optimizing the four-bar structure in the passively deformed wheel, the analysis results in a wheel deformation ratio of 2.416, which has a strong barrier-crossing performance. Based on the study of wheel passive deformation mechanism, a mechanical model of robot obstacle-crossing is established, and the robot’s passability on slopes, trenches and steps is analyzed. Finally, a robot prototype was constructed, and a series of comprehensive experiments were carried out on the robot’s obstacle-crossing performance, motion flexibility, and stability. The experimental results show that the robot structure is reasonably designed, the theoretical analysis is correct, and it has strong obstacle-crossing performance, motion flexibility, and can passively adapt to the complex and variable obstacle terrain.

Future studys will focus on the following aspects: First, regarding the optimization of the dimensional parameters of the four-bar mechanism, although the current study achieved some optimization results by analyzing the variables individually, there may be limitations when considering the simultaneous effects of multiple parameters. Therefore, we plan to introduce iterative optimization methods in future work to further optimize the overall mechanical structure of the robot and improve its structural performance. Second, due to uncertainties such as ground friction, wheel deformation, and articulation deformation, we did not include typical complex terrains (e.g., multi-step and variable curvature terrains) in the experiments. In future work, we plan to incorporate motion and obstacle-crossing control strategies to enable the robot to adapt to more complex environments. Moreover, to enable the robot’s localization, navigation, and other functions, additional sensors such as radar, cameras need to be integrated. However, these additional loads may affect the robot’s motion performance. After finalizing the control strategy, we will conduct comprehensive tests on various terrains, taking into account parameters such as the size and distribution of the robot’s loads.

Data availability

The data supporting the results of this study are presented in the main text. Raw data and codes are available from the corresponding author upon reasonable request.

References

Xu, K. et al. Whole-body stability control with high contact redundancy for wheel-legged hexapod robot driving over rough terrain. Mech. Mach. Theory. 181, 105199. https://doi.org/10.1016/j.mechmachtheory.2022.105199 (2023).

Xu, K. et al. Adaptive impedance control with variable target stiffness for wheel-legged robot on complex unknown terrain. Mechatronics 69, 102388. https://doi.org/10.1016/j.mechatronics.2020.102388 (2020).

Kim, Y. G. et al. Autonomous terrain adaptation and user-friendly teleoperation of wheel-track hybrid mobile robot. Int. J. Precis. Eng. Manuf. 13, 1781–1788. https://doi.org/10.1007/s12541-012-0234-9 (2012).

Bruzzone, L., Baggetta, M., Nodehi, S. E., Bilancia, P. & Fanghella, P. Functional design of a hybrid Leg-wheel-track ground mobile robot. Machines 9, 10. https://doi.org/10.3390/machines9010010 (2021).

Bai, D. P., Ji, Q. H., Zhang, B., Hong, H. C. & YangH, Y. Development and experimental study of multi-motion model robot with wheel-track compound structure. International Conference on Mechanical, Control and Computer Engineering Harbin, China: 392–399. https://doi.org/10.1109/ICMCCE51767.2020.00093 ( IEEE, 2020).

Gong, Z., Xie, F. G., Liu, X. J. & Shentu, S. Z. Obstacle-crossing strategy and formation parameters optimization of a multi-tracked-mobile-robot system with a parallel manipulator. 152 103919. https://doi.org/10.1016/j.mechmachtheory.2020.103919 (2020).

Luo, Z. R., Shang, J. Z., Wei, G. W. & Ren, L. A reconfigurable hybrid Wheel-track mobile robot based on Watt II Six-Bar linkage. Mech. Mach. Theory. 128, 16–32. https://doi.org/10.1016/j.mechmachtheory.2018.04.020 (2018).

Li, Z. Q., Ma, S. G., Li, B., Wang, M. H. & Wang, Y. C. Analysis of the constraint relation between ground and self-adaptive mobile mechanism of a transformable wheel-track robot. Sci. China Technological Sci. 54, 610–624. https://doi.org/10.1007/s11431-010-4228-5 (2011).

Zhu, Y. H., Fei, Y. Q. & Xu, H. W. Stability analysis of a wheel-track-leg hybrid mobile robot. J. Intell. Robotic Syst. 91, 515–528. https://doi.org/10.1007/s10846-017-0724-1 (2018).

Zhu, Y. & Kan, J. M. Prediction of the lateral stability of a forestry chassis with an articulated body and fitted with luffing wheel-legs. Biosyst. Eng. 224, 143–160. https://doi.org/10.1016/j.biosystemseng.2022.10.007 (2022).

Wang, B. et al. Design and analysis of a wheel-leg compound variable curvature ship hull cleaning robot. Ocean Eng. 266 (2), 112755. https://doi.org/10.1016/j.oceaneng.2022.112755 (2022).

García, J. M., Martínez, J. L., Mandow, A. & Garcia-Cerezo, A. Caster-leg aided maneuver for negotiating surface discontinuities with a wheeled skid-steer mobile robot. Robot. Auton. Syst. 91, 25–37. https://doi.org/10.1016/j.robot.2016.12.007 (2017).

Raza, F., Zhu, W. & Hayashibe, M. Balance stability augmentation for wheel-legged biped robot through arm acceleration control. IEEE Access. 9, 54022–54031. https://doi.org/10.1109/ACCESS.2021.3071055 (2021).

Priyaranjan Biswal, Prases, K. & Mohanty Development of quadruped walking robots: A review. Ain Shams Eng. J. 2 (12), 2017–2031. https://doi.org/10.1016/j.asej.2020.11.005 (2021).

Bjelonic, M., Sankar, P. K., Bellicoso, C. D., Vallery, H. & Hutter, M. Rolling in the deep–hybrid locomotion for wheeled-legged robots using online trajectory optimization. IEEE Rob. Autom. Lett. 5 (02), 3626–3633. https://doi.org/10.1109/LRA.2020.2979661 (2020).

Orozco-Magdaleno, E. C., Cafolla, D., Castillo-Castaneda, E. & Carbone, G. Static balancing of wheeled-legged hexapod robots. Robotics 9 (02), 23. https://doi.org/10.3390/robotics9020023 (2020).

Chen, H. Y. et al. Development of a novel leg-wheel module with fast transformation and leaping capability. Mech. Mach. Theory. 163, 104348. https://doi.org/10.1016/j.mechmachtheory.2021.104348 (2021).

Bjelonic, M. et al. Keep Rollin’—Whole-body motion control and planning for wheeled quadrupedal robots. IEEE Rob. Autom. Lett. 4 (02), 2116–2123. https://doi.org/10.1109/LRA.2019.2899750 (2019).

Zhang, S. et al. Design and motion analysis of reconfigurable wheel-legged mobile robot. Def. Technol. 18 (06), 1023–1040. https://doi.org/10.1016/j.dt.2021.04.013 (2022).

Zhang, C., Li, X. L., Zhu, X. Q. & Li, Y. A step-climbing strategy of hexapod robot with eccentric wheel legs. 2018 IEEE 7th Data Driven Control and Learning Systems Conference (DDCLS). Enshi, China, 426–430. https://doi.org/10.1109/DDCLS.2018.8516027 (IEEE, 2018).

Okasa, N. M., Alzo’ubi, A. K., Mughieda, O., Kewalramani, M. & Almasri, A. H. A near-optimum multi-objective optimization approach for structural design. Ain Shams Eng. J. 15 (2), 102388. https://doi.org/10.1016/j.asej.2023.102388 (2024).

Lee, D. Y., Kim, S. R., Kim, J. S., Park, J. J. & Choo, K. J. Origami wheel transformer: A variable-diameter wheel drive robot using an Origami structure. Soft Rob. 4 (02), 163–180. https://doi.org/10.1089/soro.2016.0038 (2017).

Sun, T., Xiang, X., Su, W. H., Wu, H. & Song, Y. M. A transformable wheel-legged mobile robot: design, analysis and experiment. Robot. Auton. Syst. 98, 30–41. https://doi.org/10.1016/j.robot.2017.09.008 (2017).

Bai, L., Guan, J., Chen, X. H., Hou, J. Z. & Duan, W. B. An optional passive/active transformable wheel-legged mobility concept for search and rescue robots. Robot. Auton. Syst. 107, 145–155. https://doi.org/10.1016/j.robot.2018.06.005 (2018).

Kim, Y. S., Jung, G. P., Kim, H., Cho, K. J. & Chu, C. N. Wheel transformer: A wheel-leg hybrid robot with passive transformable wheels. IEEE Trans. Robot. 30 (06), 1487–1498. https://doi.org/10.1109/TRO.2014.2365651 (2014).

Esra, B. et al. In situ Chitin isolation from body parts of a centipede and lysozyme adsorption studies. Mater. Sci. Engineering: C. 70 (1), 552–563. https://doi.org/10.1016/j.msec.2016.08.048 (2017).

Jiang, H., Xu, G. Y., Zeng, W. & Gao, F. Design and kinematic modeling of a Passively-actively transformable mobile robot. Mech. Mach. Theory. 142, 103591. https://doi.org/10.1016/j.mechmachtheory.2019.103591 (2019).

Yamano, A., Kimoto, T., Inoue, Y. & Chiba, M. Optimal swimming locomotion of snake-like robot in viscous fluids. J. Fluids Struct. 123, 104007. https://doi.org/10.1016/j.jfluidstructs.2023.104007 (2023).

Zhang, L. W., Xu, Q. P. & Liu, J. Y. Dynamic modeling for continuous locomotion of bionic soft worm-like robot. Int. J. Non-Linear Mech. 162, 104702. https://doi.org/10.1016/j.ijnonlinmec.2024.104702 (2024).

Serdobintsev, Y. P., Ivanyuk, A. K. & Karlov, V. I. Experimental determination of the passability characteristics of mobile robotic complex with adaptive wheels. 2019 international conference on industrial engineering, applications and manufacturing (ICIEAM), Sochi, Russia, 1–6. https://doi.org/10.1109/icieam ( IEEE, 2019).

Acknowledgements

This work was supported by the Aerospace Science and Technology Group Applied Innovation Program (Grant No. G1_5056D582). Thanks to Prof. Chengjun Ding and Engineer Dong Wang for their guidance. Thanks to Tan Zhang, Tengfei Ma, Xinbao Li, Zijian Li, Jianing Zhang, and Xuehong Zhu for their assistance in the project.

Author information

Authors and Affiliations

Contributions

Tan Zhang wrote the main manuscript text and designed the prototype 3D model. Chengjun Ding provided the conceptual innovation of the study. Dong Wang and Xuehong Zhu were in charge of robot machining and assembly. Dong Wang was responsible for acquiring funding. Tengfei Ma built the drive system. Tan Zhang and Zijian Li handled system integration and debugging. Tan Zhang, Xinbao Li and Jianing Zhang captured experimental photographs and collected the experimental data. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, T., Ding, C., Wang, D. et al. A centipede-inspired robot with passive terrain adaptation: optimized design and performance analysis. Sci Rep 15, 16823 (2025). https://doi.org/10.1038/s41598-025-97457-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-97457-7