Abstract

Cellulose nanocrystals (CNC), which possessing unique cholesteric liquid crystal properties, can self-assemble and then stack into layered structures to produce structural colouration. By controlling the periodicity of these layered structures, the films with various colors can be fabricated, which could be used as a new generation of environmentally friendly pigments. In this study bamboo-based CNC were utilized as the raw material for constructing vibrantly colored CNC film via layer-by-layer self-assembly process by adding hydroxypropyl cellulose (HPC) to regulate the pitch. By controlling CNC/HPC ratios at 100/0, 92/8, 87/13 and 82/18, the color of the film was in blue, green, yellow and red, respectively. Furthermore, by extending the equilibrium time and adjusting the solvent composition being typically required to allow for the self-assembly, the directional arrangement of the crystalline aggregates was facilitated, resulting in CNC films with more uniform colors and optimized optical and mechanical properties of the films.

Similar content being viewed by others

Introduction

Effect pigments are widely used in industries such as cosmetics, beverages, paints, anti-counterfeiting, automotive coatings, and packaging1. The basic principle of effect pigments is to use mica with a low refractive index as substrate, and to coat the surface with metal oxides to produce optical color effects with interference2,3. However, the main substrates are natural and synthetic mica, which involve the extensive destruction of non-renewable natural resources and high-energy consumption in synthetic processes, and the waste of the products can easily lead to secondary environmental pollution. Therefore, scientists are actively looking for green, low-cost, sustainable, and recyclable materials to produce two-dimensional flaky materials with optical effects and special functions to replace existing natural and synthetic materials. Against the background of low carbon and sustainable development, cellulose nanocrystals (CNC)-based structural color films have attracted much attention due to their simple preparation process, low energy consumption, and minimal environmental pollution4,5,6.

Cellulose has the advantages of being widely sourced, having a high output, being sustainably produced, non-toxic, highly renewable, having a short production cycle, low cost, and being biodegradable7,8. CNCs consist of β (1–4) linked D-glucose units ordered in a highly crystalline structure, with a dimension of approximately 5–30 nm in width and 100–500 nm in length9. CNC rods extraction using acid hydrolysis have sulphate ester groups and a high aspect ratio10. The colloidal stability is crucial for self-assembly of the CNCs in aqueous solutions, from the isotropic liquid crystal state to the cholesteric liquid crystal (CLC) as the concentration of CNC increases on drying. When the concentration of the CNC suspension is above the critical concentration, under the influence of electrostatic forces, it can self-assemble to form crystalline-like tactoids, which further stack into a layered structure. At the single crystal level, to reduce these electrostatic interactions, the internal structure and external morphology of CNC will experience distortion, giving CNC a certain degree of chirality and forming a left-handed helical arrangement of planar cholesteric liquid crystals11,12,13. After the CNC suspension is completely dried, the layered structure can be retained in the film, forming bright structural colors visible to the naked eye14. By precisely tuning the periodic spacing within the layered structure of CNC films, it is possible to create films that display a variety of colors. This tunability holds significant potential for CNC to serve as an alternative to traditional pigments.

The brittleness of CNC films is a factor that limits their extensive application. Self-assembled CNC films are influenced by factors such as thickness, crystallinity and rigidity. Therefore, the addition of flexible materials is crucial for the preparation of flexible CNC films. Poly(vinyl alcohol)15, poly(ethylene glycol) (PEG)16,17,18, polyurethane19 have been incorporated to increase film flexibility and mechanical strength. Xu et al.20 used glycerol as a plasticizer to successfully prepare CNC composite films with high flexibility. However, such additives (like glycerol, glucose, polyols, polyethylene glycol), while improving the mechanical properties of the film, also have strong hygroscopicity, which increases the film’s ability to absorb moisture, thereby affecting the film’s adhesion to the substrate and peelability17,21. To avoid this issue, Huang et al.22 co-assembled CNC with polyethylene glycol diacrylate (PEGDA) precursor and then formed a three-dimensional cross-linked network through UV curing, which improved the brittleness of the film and prepared a highly flexible and stable CNC/PEGDA composite film. Liu et al.23 added the ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl) as a plasticizer. Due to the strong ionic interactions between CNC and AmimCl, the ionic liquid permeates the CNC film evenly, preparing a flexible and color-adjustable CNC film. These methods not only improve the flexibility of CNC films but also reduce the adhesion between the film and the substrate, which is beneficial for the separation of the film from the substrate. However, compared with additives like glycerol, additives such as PEGDA and AmimCl are not environmentally friendly and cannot be directly applied to industries such as food and cosmetics24. Furthermore, the addition of polymers can also adjust the film color by changing the pitch size. By varying the concentration of polymer, iridescent colors from red to blue can be achieved25.

The above-mentioned film materials are mostly sourced from wood. However, wood is a precious resource that takes a long time to grow (typically 20 to 60 years). As a result, with the enforcement of wood conservation and logging restriction policies, its large-scale applications are significantly constrained26. Regarding to this issue, Peng et al. prepared the sisal cellulose nanocrystals‑assembled film by evaporation-induced self-assembly method27. Furthermore, bamboo has a similar chemical composition and microstructure to wood and sisal, yet it surpasses them in terms of strength and toughness, bamboo grows rapidly, its growth cycle is generally 3–5 years28. Therefore, compared to wood and sisal, bamboo has better environmental and economic advantages. Although bamboo cellulose films or composite films prepared using bamboo CNCs have been widely reported29,30. Unfortunately, there has little report so far on the preparation of structural color films using bamboo-based CNCs.

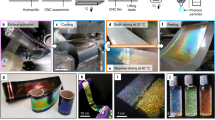

China leads the worlds in bamboo production, thus, in this work, bamboo was selected as the raw material for the preparation of CNCs by pretreatment, alkali treatment, and acid hydrolysis treatment. The CNC film was prepared by the evaporation-induced self-assembly method. Hydroxypropyl cellulose (HPC) is used to regulate the pitch size formed in CNC suspensions during self-assembly process of CNC, achieving changes in film color and effectively addressing the issue of film cracking caused by the high rigidity of CNC. Moreover, the effect of the presence of Ca2+ on the thickness and color was investigated. This study takes full advantage of the high crystallinity of bamboo fiber and the high aspect ratio of CNC to provide a new option to improve the versatility of bamboo fiber applications and create more high value-added products.

Experimental

All the chemical reagents were of analytical grade and used without further purification. Potassium hydroxide (KOH), acetic acid, toluene, sodium hypochlorite (NaClO) and sulfuric acid (H2SO4) were used to extract CNC from bamboo fiber. The above chemicals are all purchased from Shanghai Sinopharm Chemical Reagent Co., Ltd, Shanghai, China. Hydroxypropyl cellulose (HPC) was purchased from Shanghai Macklin Biochemical Co., Ltd, China. Ethanol absolute (EtOH) and calcium chloride (CaCl2) was purchased from Sinopharm Chemical Reagent Co., Ltd, China.

Preparation of CNCs

Bamboo fragments were used as raw materials sourced from Yongtai, Fujian. Bamboo fragments were shredded into small pieces and then a crusher was used to pulverize it into powder. Finally, the bamboo powders were sieved with a 200-mesh to collect the powders for subsequent use. The CNCs were extracted by the following pretreatment, alkali treatment, and acid hydrolysis treatment.

Pretreatment: The bamboo powders were packed and placed into Soxhlet extractor with a 2:1 volume ratio of toluene and ethanol solution being boiled under the conditions of 90 °C for 8 h, followed by ethanol washing, and drying.

Sodium hypochlorite and alkali treatment: The obtained powders were treated by sodium hypochlorite method to remove lignin31. The powders were placed into a conical flask with sodium hypochlorite and acetic acid ratio of 1.2:1 and heated by water bath at 75 °C. The same dose of sodium hypochlorite and acetic acid were added every 1 h, and repeat 5 times until the sample turns white. The samples were cooled to room temperature, and washed with deionized water until pH = 6. Finally, the samples were dried in an oven at 55 °C to obtain the total cellulose. Then the total cellulose was soaked in 5% KOH solution for 24 h and then was heated at 80 °C for 3 h under stirring, washed with deionized water, and dried. Finally, white microcrystalline cellulose was obtained.

Preparation of CNC suspensions: 10 g of white microcrystalline cellulose powder was placed into a flask with 150 mL of 60% H2SO4 and slowly stirred at a constant temperature of 45 °C. The acid hydrolysis reaction was carried out at different times (60, 90 and 120 min). When the reaction was stopped, distilled water was slowly added to the beaker to dilute the acid solution. Then, the supernatant was poured off and the white suspension was centrifuged at the speed of 10,000 r/min for 10 min under the temperature of 10 °C for three times, and the precipitate obtained by centrifugation was put into a dialysis membrane and dialyzed to about pH = 6. Finally, the well-dispersed CNCs suspension was obtained by concentration and sonication.

Fabrication of CNC/HPC composite films

CNC films were prepared by the following procedure via self-assembly. Mixing a 5% CNC solution (in deionized water) with 5% HPC solution at different ratios to form CNC/HPC composite films, where the ratio of CNC to HPC is represented as a/b, with a and b representing the respective proportions of CNC and HPC. Four ratios were selected for study, namely 100/0, 92/8, 87/13, 82/18. Each mixed solution was thoroughly stirred for 3 h. Subsequently, 1 g of the suspension was poured into 35 mm polystyrene petri dishes that had been plasma treated. To slow down the evaporation of the solution, the petri dishes were sealed with film to slow down the evaporation rate to near zero. The dishes were then placed in a constant temperature and humidity chamber (25 °C, 30% RH) to stand. Selected equilibrium times of 0, 2, 4, and 6 days were used, and at the end of the respective times, the sealing film and lids were removed, and the dishes were placed in a vacuum drying oven at 50 °C for 90 min to obtain the films.

Fabrication of CNC/HPC/CaCl2 composite films

CaCl2 powder was dissolved in a solution with water/ethanol ratio of 1:4 to prepare a 0.05% CaCl2 solution. Then, a CNC suspension is mixed with the CaCl2/EtOH solution in a mass ratio of 5:1 and being thoroughly stirred to prepare a 5% CNC/CaCl2/EtOH suspension. Next, 5wt% CaCl2/EtOH/CNC suspension was mixed with a 5wt% HPC suspension in different ratios (100/0, 92/8, 87/13, 82/18) by thoroughly stirring, and then placed in a sealed dish. After standing for 2 days, the suspension is placed in an oven at 50 °C to remove the solvent, thus CNC/HPC/CaCl2 composite films were fabricated.

Characterisation

The crystal structures were carried out using powder X-ray diffraction (XRD) on a BRUKER D8 ADVANCE diffractometer (40 kV and40 mA) with Cu-Ka radiation at room temperature. The morphologies of as-prepared samples were studied by Nova Nano SEM 230 scanning electron microscope (SEM) with 3.00 kV scanning voltages. The UV-Vis diffuse reflectance spectra (DRS) of the samples with BaSO4 as a reference were recorded on a Shimadzu UV-2600 UV-vis spectrophotometer. The ImageJ software was used to measure the pitch size in each cross-sectional image. Zeta potential and particle size of the original CNC were measured by Zeta potential analyzer (Zeta-sizer Nano ZS90). The texture of the CNC films was observed by placing the CNC films under mutually perpendicular polarizers in the refection mode of the DM2700P microscope (Leica, Germany). Photographs were taken with a mobile phone. The samples were cut into rectangular lengths of 20 × 10 mm and tested for mechanical strength at room temperature using a WDW-1 electronic universal testing machine (China). The loading rate was 0.5 mm/s, and each sample was tested at least 3 times.

Results and discussion

Chacterisation of CNC

The morphology and property of CNC were depended on the preparation conditions. The effect of hydrolysis time on the stability of CNC suspensions was investigated. The photographs of CNC suspensions with a concentration of 5% being hydrolyzed for 60 min, 90 min and 120 min are shown in Fig. 1. As the hydrolysis time increases, the color of the suspension gradually darkens, shifting from an initial milky white to a pale blue, and eventually to a brownish-yellow. After keeping static for 30 days, it was found that the suspension of CNC-60 min underwent severe sedimentation. This is due to some of the hydroxyl groups on the surface of the cellulose are replaced by negatively charged sulfate groups during acid hydrolysis, which impart stability to the suspension through electrostatic interactions32. The CNC-90 min and CNC-120 min suspensions showed no sedimentation, it is because that the increase in hydrolysis time led to an increase in sulfate ester groups on the CNC, thereby enhancing the surface charge density of the suspension. Thus, high surface charge density is key to maintaining the uniformity and stability of the suspension and preventing sedimentation.

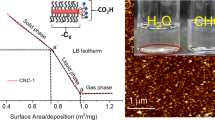

Zeta potential with a typical threshold of an absolute value greater than 30mV indicating good stability of the CNC suspension33. Zeta potentials of CNC-60 min, CNC-90 min, and CNC-120 min were − 25.1mV, -32.8mV, and − 41.9mV, respectively. The absolute values of Zeta potentials of the CNC suspensions increased with the extension of hydrolysis time, indicating that the esterification reaction between sulfuric acid and CNC hydroxyl groups increased the content of negatively charged sulfate ester groups27, thereby enhancing the overall stability of the suspension, which is the same to the results observed in Fig. 1.

SEM micrographs of CNC particles hydrolyzed for different times is shown in Fig. 2. It can be observed that the obtained CNC particles exhibit a rod shape, furthermore, as the hydrolysis time increases, the length of the particles gradually decreases and becomes more uniform. The average size of CNC-60 min, CNC-90 min, and CNC-120 min are 210.7 nm, 149.1 nm, and 103.6 nm, respectively. Their polydispersity indices (PDI) are 0.622, 0.521 and 0.353, respectively, indicating that the particle size distribution becomes more uniform as the hydrolysis time increased. This phenomenon can be attributed to the reaction between sulfuric acid and the hydroxyl groups (-OH) in the cellulose molecules, where the amorphous regions of the cellulose are gradually removed, and the crystalline regions, due to their more compact structure, are retained but gradually break and form smaller CNC particles27.

Characterisation of CNC/HPC film

To address the issue of difficulty in peeling off thin films from hydrophilic substrates and the shrinkage problem caused by insufficient adhesion of hydrophilic CNC dispersions on hydrophobic substrates, plasma technology was employed to treat the Petri dish substrates. The water contact angle of the petri dish before and after treatment are 79.2° and 20.8°, respectively, which indicating that the hydrophilicity of the substrate surface was enhanced, thereby promoting the improvement of compatibility between the CNC suspension and the polystyrene substrate. By this treatment, it could allow the CNC suspension to form a more uniform and continuous film on Petri dish substrate.

The presence of HPC significantly influenced the coloration of the composite film. Four films with varying CNC/HPC were fabricated and a noticeable color shift was observed as the HPC content increased. This indicates that the addition of HPC did not interfere with the self-assembly capability of CNC. As illustrated in Fig. 3, when the HPC content increased from 0 to 18%, the film color transitioned progressively: from initial blue-purple (0% HPC) to green (8%), yellow (13%), and finally red (18%).

The initial blue-purple hue originated from the intrinsic aspect ratio of CNC, which governs its self-assembled chiral nematic structure. Due to the smaller dimensions of CNC used in this study, the self-assembled structure exhibited a shorter pitch, corresponding to shorter-wavelength reflectance (blue-purple). Upon incremental HPC incorporation, the abundant hydroxyl (-OH) groups on HPC formed hydrogen bonds with CNC surface hydroxyls. This interaction, combined with steric hindrance effects, enlarged the chiral nematic pitch, thereby shifting the reflected wavelength toward longer values (green to red)34,35. Furthermore, in CNC/HPC suspensions with identical ratios, films cast without equilibrium treatment displayed uneven color distribution, exhibiting mixed hues. In contrast, prolonged equilibrium time not only enhanced color uniformity but also intensified the chromaticity.

Polarized optical microscopy (POM) analysis reveals distinct morphological differences between unbalanced and equilibrated cellulose nanocrystal (CNC) films. As depicted in Fig. 4, unbalanced films exhibit spherical microdomains with reduced structural order, forming a freely oriented multi-domain architecture. This disordered morphology is attributed to the kinetic limitations encountered during crystalline aggregate growth. The resulting grain boundaries and localized defects between domains negatively impact mechanical integrity and optical uniformity, as documented in prior studies36.

Notably, the varying sizes and orientations of crystalline-like aggregates result in stacked lamellar structures of different sizes, causing pitch differences, which generating pitch discrepancies that manifest as uneven coloration in both 2-day equilibrated and non-equilibrated films. As the equilibrated time increases, it is observed that the spindle-shaped structures in films equilibrated for 2 days begin to gradually merge under POM, forming larger domain sizes. After 4 days, the boundaries between different domains start to disappear, forming larger domain areas. By the time of 6 days, the multi-domain structure almost vanishes, and the film forms long-range ordered domain areas. This temporal evolution confirms that prolonged suspension equilibration promotes domain fusion and orientation alignment, ultimately reducing structural defects and enhancing color homogeneity. After 6 days, the macroscopic morphology reveals that the CNC film has a uniform color, but some discoloration still exists under POM. This is due to the anisotropic cholesteric liquid crystal (CLC) helical architecture, consistent with established optical phenomena37,38.

The optical uniformity of CNC/HPC composite films is intrinsically governed by the structural periodicity of their cholesteric pitch. To quantitatively assess this relationship, cross-sectional SEM analysis was systematically conducted on both non-equilibrated and 6-day equilibrated films (Fig. 5). Cross-sectional SEM analysis elucidates the critical role of equilibration time and hydroxypropyl cellulose (HPC) content in structural organization. Increasing HPC concentration systematically expands the cholesteric pitch while maintaining helical integrity, indicating effective intercalation of HPC within CNC lamellae. Moreover, both non-equilibrated and 6-day equilibrated films can form the helical structure of cholesteric liquid crystals, indicating that HPC is compatible with CNC, and the addition of HPC did not destroy the structural characteristics of CNC self-assembly. Further observation reveals that the different equilibrated times significantly affect the orderliness of the film structure. Non-equilibrated films display disordered lamellar stacking attributed to insufficient CNC-HPC interaction time, whereas 6-day equilibrated counterparts exhibit periodic long-range order. This indicates that as the equilibrated time extends, the interaction between CNC and HPC is strengthened, and the crystalline-like aggregates better orient and stack, forming a more uniform and ordered lamellar structure39.

After complete drying, cholesteric liquid crystals can maintain their helical structure and fix the size of the pitch, which reflecting light with a wavelength corresponding to their own pitch. As the content of HPC increases, the wavelength of the CNC/HPC composite film shifts from 405 nm to near 655 nm (as shown in Fig. 6), which corresponds to the color changes observed by naked eye, proving that HPC can effectively regulate the color of the film. The impact of different equilibrated times on the optical performance of CNC films with the same ratio shows that films prepared by extending the equilibrated time show narrower peaks, and the color of the film is more uniform. This indicates that CNC has more opportunities for self-assembly during a longer equilibrium process, thereby achieving a more orderly and compact arrangement of crystalline-like aggregates. The enhanced orderliness makes the stacking of the lamellar structure more compact, with a slight reduction in the interlayer distance, which is the reason for the slight blue shift in the reflected wavelength of the film. Since the interference effect of light is more pronounced in ordered structures, the reflection peak of the structural color in the visible wavelength becomes narrower, making the structural color film show a more vivid and uniform color10, which is observed in Fig. 3.

The mechanical reinforcement mechanism of CNC/HPC composite films was quantitatively investigated through tensile testing at room temperature. As systematically documented in Fig. 7, HPC incorporation induces remarkable mechanical enhancement on strength and ductility. For non-equilibrated films, the tensile strengths of the films with varying ratios of CNC to HPC (100:0, 92:8, 87:13, 82:18) are 21.7 MPa, 32.2 MPa, 50.3 MPa, and 61.1 MPa, respectively. Tensile strength escalates from 21.7 MPa (neat CNC) to 61.1 MPa (82:18 CNC: HPC ), representing a 181% enhancement. The elongation at break increases from 0.247 to 0.531%. For 6-day equilibrated films: the tensile strengths of the films increase to 26.4 MPa, 42.3 MPa, 58.2 MPa, and 70.3 MPa, respectively, demonstrating 266% total strength gain versus pure CNC. The elongation at break increases to 0.581%, achieving 135% ductility improvement. This enhancement stems from HPC-mediated hydrogen bonding that reinforces the CNC network and repairs interfacial defects30. This network enhances intermolecular connections and allows HPC to fill and repair defects between CNCs, dissipating external forces more effectively and thus improving the tensile strength and elongation at break of the films. Furthermore, equilibrated time significantly affects the orderliness of the film structure. Non-equilibrated films exhibit disordered lamellar structure, which may be due to insufficient interaction time between CNC and HPC, leading to incomplete orientation and stacking of crystalline-like aggregates. In contrast, 6-day equilibrated films achieve periodic stacking and monodisperse interlamellar spacing structure. This indicates that extending the equilibrated time allows for better interaction between CNC and HPC, leading to a more uniform and ordered lamellar structure and more consistent pitch size, thereby enhancing the overall optical performance of the film20,40.

Based on the results above, CNC/HPC film could be fabricated under the condition of being equilibrated for 6 days, which it takes long time. To address the kinetic limitation of prolonged 6-day equilibration in pure CNC/HPC systems, an accelerated assembly strategy through solvent-cationic modulation was developed. As demonstrated in Fig. 8, introducing CaCl2/EtOH into the CNC/HPC suspension (82:18 ratio) enabled fabrication of structurally ordered films within 2 days - a 67% reduction in processing time. This indicates that the addition of EtOH and CaCl2 did not interfere with the self-assembly process of CNC but rather enhance in color saturation. Under POM observation, the elimination of spherical domains and reduction in domain boundary density for the CNC/HPC/CaCl2 film, indicating a good mutual fusion effect between crystalline-like aggregates. The addition of ethanol improved the dispersibility of CNC in the suspension, which is beneficial for reducing particle aggregation. Meanwhile, ethanol can reduce the surface tension of the suspension, allowing CNC particles to deposit and arrange uniformly on the substrate, thereby increasing the orderliness of the CNC film. Furthermore, Ca2+ can form chelation with hydroxyl groups on CNC or HPC, accelerating the “locking” of CNC positions and thus increasing the rate of CNC self-assembly41,42. This promotes the close arrangement and orderly stacking of crystalline-like aggregates, thereby shortening the time and making the film formation process more efficient.

Cross-sectional SEM (Fig. 9) quantifies that additive-modified system achieves high pitch uniformity. This is consistent with the uniform color of the CNC/HPC/CaCl2 film shown in Fig. 8. The film color due to the selective reflection of visible light and the maximum refection wavelength λmax is related to the helical pitch P of the phase structure, the average refractive index nave, which follows the Bragg Eq. 28:

The refractive index of HPC is generally 1.53, the refractive index of CNC is 1.5, and the addition of CaCl2 can be ignored for the overall refractive index, thus an average refractive index of 1.51 was taken, and θ value was taken as 90° (i.e., the incident light is perpendicular to the film plane) for calculation. The average values of the pitch for four films were found to be 279 nm, 347 nm, 381 nm and 452 nm, respectively. Based on these parameters, the theoretical reflection wavelengths calculated were 421 nm, 523 nm, 575 nm, and 682 nm, respectively, which is matched with experimental values obtained from UV-visible reflection spectra (Fig. 9e) (432 nm, 522 nm, 581 nm, and 680 nm, respectively). In addition, it was also observed that CNC/HPC/CaCl2 film having a narrower peak shape, indicating that the addition of ethanol and calcium chloride accelerated the rate of oriented arrangement of CNC crystalline-like aggregates, giving ordered lamellar structure.

The mechanical reinforcement parallels optical improvements (as shown in Fig. 10), the tensile strengths of the CNC/HPC/CaCl2 films are 28.3 MPa, 37.4 MPa, 59.3 MPa, and 74.5 MPa, respectively. Tensile strength gains 22% increase compare to pure system. This demonstrates further strength gains is attributable to that ethanol improves CNC dispersion and reduces surface tension, while Ca²⁺ chelation with hydroxyl groups accelerates positional locking of crystalline aggregates42,43,44.

Conclusions

The film with uniform color was fabricated using CNC particles via self-assembly process. The effect of HPC, equilibrium time and the CaCl2 on the properties of CNC films was fully investigated. The increase in HPC content changed the film color from blue-purple to red and simultaneously improved the film’s tensile strength. Extending the equilibrium time to 6 days resulted in an increase in the tensile strength of the films with the same ratio. The equilibration achieves long-range cholesteric order, reducing optical defects. Adding ethanol and a low concentration of CaCl2, uniformly and controllable thickness films were successfully prepared via accelerating the fusion rate of crystalline-like aggregates. These findings advance the rational design of CNC-based functional materials, providing critical insights for bamboo fiber valorization and high-value biopolymer applications.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Maile, F. J., Pfaff, G. & Reynders, P. Effect pigments-past, present and future. Prog Org. Coat. 54(3), 150–163 (2005).

Cavalcante, P. M. T., Dondi, M., Guarini, G., Barros, F. M. & Benvindo, A. Ceramic application of mica Titania pearlescent pigments. Dyes Pigm. 74(1), 1–8 (2007).

Zhao, Y. et al. Preparation of green carbon quantum Dots coated core-shell type Pearl pigment Kieselguhr@TiO2@TiO2 – x. Mater. Chem. Phys. 242, 12258 (2020).

Saraiva, D. V., Remiëns, S. N., Jull, E. I. L., Vermaire, I. R. & Tran, L. Flexible, photonic films of surfactant-functionalized cellulose nanocrystals for pressure and humidity sensing. Small Struct. 5(7), 2400104 (2024).

Bai, C. et al. Regulation of the optical properties of cellulose nanocrystal films by sealed deposition treatment. Sci. Techn. Food Indus. 45(4), 1–9 (2024).

Benjamin, E. et al. Large-scale fabrication of structurally coloured cellulose nanocrystal films and effect pigments. Nat. Mater. 22, 352–358 (2022).

Wang, S., Ma, H., Ge, S., Rezakazemi, M. & Han, J. Advanced design strategies and multifunctional applications of Nanocellulose/MXene composites: A comprehensive review. Mater. Sci. Eng. R. 163, 100925 (2025).

Zhang, S. Y., Guo, J. R., He, J. H. & Ren, S. X. From cellulose in straw to transparent high-strength films. Acta Polym. Sinica 55(8), 1009–1020 (2024).

Habibi, Y., Lucia, L. A. & Rojas, O. J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 110(6), 3479–3500 (2010).

Zhao, G., Zhang, S., Zhai, S. & Pan, M. Fabrication and characterization of photonic cellulose nanocrystal films with structural colors covering full visible light. J. Mater. Sci. 55(20), 8756–8767 (2020).

Peng, Y., Wei, X., Liang, Y., Wang, X. & Chen, S. Niu, X. Advances in structural color composite films based on cellulose nanocrystals. Ind. Crops Prod. 221, 119294 (2024).

Yao, K., Meng, Q., Bulone, V. & Zhou, Q. Flexible and responsive chiral nematic cellulose nanocrystal/poly(ethylene glycol) composite films with uniform and tunable structural color. Adv. Mater. 29(28), 1701323 (2017).

Qin, Q. et al. Bottom-up and top-down strategies toward strong cellulose-based materials. Chem. Soc. Rev. 53, 9306–9343 (2024).

Chang, T. et al. Cellulose nanocrystal chiral photonic micro-flakes for multilevel anti-counterfeiting and identification. Chem. Eng. J. 446(1), 136630 (2022).

Wang, B. & Walther, A. Self-assembled iridescent, crustacean-mimetic nanocomposites with tailored periodicity and layered cuticular structure. ACS Nano. 9(11), 10637–10646 (2015).

Gu, M., Jiang, C., Liu, D., Prempeh, N. & Smalyukh, I. I. Cellulose nanocrystal/poly(ethylene glycol) composite as an iridescent coating on polymer substrates: Structure-color and interface adhesion. ACS Appl. Mater. Interfaces 8(47), 32565 (2016).

Bardet, R., Belgacem, N. & Bras, J. Flexibility and color monitoring of cellulose nanocrystal iridescent solid films using anionic or neutral polymers. ACS Appl. Mater. Interfaces 7(7), 4010–4018 (2015).

Walters, C. M., Boott, C. E., Nguyen, T. D., Hamad, W. Y. & Maclachlan, M. J. Iridescent cellulose nanocrystal films modified with hydroxypropyl cellulose. Biomacromolecules 21, 1295–1302 (2020).

Wan, H. et al. Rapidly responsive and flexible chiral nematic cellulose nanocrystal composites as multifunctional rewritable photonic papers with eco-friendly inks. ACS Appl. Mater. Interfaces 10(6), 5918 (2018).

Xu, M. C. et al. Multifunctional chiral nematic cellulose nanocrystals/glycerol structural colored nanocomposites for intelligent responsive films, photonic inks and iridescent coatings. J. Mater. Chem. C 6(20), 5391–5400 (2018).

He, Y. D. et al. Biomimetic optical cellulose nanocrystal films with controllable iridescent color and environmental stimuli-responsive chromism. ACS Appl. Mater. Interfaces 10(6), 5805–5811 (2018).

Huang, Y., Chen, G., Liang, Q., Yang, Z. & Shen, H. Multifunctional cellulose nanocrystal structural colored film with good flexibility and water-resistance. Inter J. Biolog. Macrom. 149, 819–825 (2020).

Liu, P., Guo, X., Nan, F. C., Duan, Y. X. & Zhang, J. M. Modifying mechanical, optical properties and thermal processability of iridescent cellulose nanocrystal films using ionic liquid. ACS Appl. Mater. Interfaces 9(3), 3085–3092 (2017).

Chen, C., Sun, W., Wang, J. & Gardner, D. J. Tunable biocomposite films fabricated using cellulose nanocrystals and additives for food packaging. Carbohydr. Polym. 321, 121315 (2023).

Gençer, A. & Schütz, C. Thielemans. W. Influence of the particle concentration and Marangoni flow on the formation of cellulose nanocrystal films. Langmuir 33(1), 228–234 (2017).

Li, Z. et al. A strong, tough, and scalable structural material from fast-growing bamboo. Adv. Mater. 32, 1906308 (2020).

Peng, Y., Zhang, Y., Li, Z., Xu, H. & Hou, X. Preparation and characterization of Sisal cellulose nanocrystals–assembled film. Fibers Polym. 24, 3027–3036 (2023).

Lu, H. et al. A novel method to prepare lignocellulose nanofibrils directly from bamboo chips. Cellulose 25, 7043–7051 (2018).

Liu, X. et al. Strong, tough, anisotropic, flexible, and transparent bamboo films. Industrial Crops Prod. 207, 117757 (2024).

Chen, Y., Zhang, Y., Long, J., Xu, K. & Zhong, T. Multiscale cellulose-based optical management films with tunable transparency and haze fabricated by different bamboo components and mechanical defibrillation approaches. Carbohydr. Polym. 348, 122811 (2025).

Kumar, R., Hubbell, C. A., Ragauskas, A. & Wyman, C. E. Comparison of laboratory delignification methods, their selectivity, and impacts on physiochemical characteristics of cellulosic biomass. Bioresour. Technol. 130, 372–381 (2013).

Guidetti, G., Atifi, S. & Vignolini, S. Flexible photonic cellulose nanocrystal films. Adv. Mater. 28(45), 10042–10047 (2016).

Hamid, A., Bee, S., Khadijah, Z. S. & Das, R. Synergic effect of tungstophosphoric acid and sonication for rapid synthesis of crystalline nanocellulose. Carbohydr. Polym. 138, 349–355 (2016).

Xue, R. et al. Self-healable, solvent response cellulose nanocrystal/waterborne polyurethane nanocomposites with encryption capability. ACS Nano 17(6), 5653–5662 (2023). (2023).

Sun, Z. et al. Self-healing, sensitive and antifreezing biomass nanocomposite hydrogels based on hydroxypropyl Guar gum and application in flexible sensors. Inter J. Biolog Macrom. 155, 1569–1577 (2020).

Wang, T., Wang, Y., Ji, C., Li, Y. & Yang, H. All-cellulose-based flexible photonic films. Adv. Funct. Mater. 2408464 (2024).

Prathapan, R., Tabor, R. F., Garnier, G. & Hu, J. Recent progress in cellulose nanocrystal alignment and its applications. ACS Appl. Bio Mater. 3(4), 1828–1844 (2020).

Rosa, R. R. et al. Cellulose nanocrystal aqueous colloidal suspensions: Evidence of density inversion at the isotropic-liquid crystal phase transition. Adv. Mater. 34(28), 2270211 (2022).

Yoshida, M., Iwase, H., Horikawa, Y. & Shikata, T. Evidence of a rod-like structure for hydroxypropyl cellulose samples in aqueous solution. Biomacromolecules 25(7), 4255–4266 (2024).

Xu, Y., Atrens, A. & Stokes, J. R. A review of nanocrystalline cellulose suspensions: Rheology, liquid crystal ordering and colloidal phase behaviour. Adv. Colloid Interface Sci. 275, 102076 (2020).

Xu, C. L. et al. Nonflammable superhydrophobic passive cooling cellulose-CaCO3 film. J. Colloid Interf Sci. 671, 529–542 (2024).

Qu, R. J., Wang, Y., Li, D. & Wang, L-J. Rheological behavior of nanocellulose gels at various calcium chloride concentrations. Carbohydr. Polym. 274, 118660 (2021).

Bruckner, J. R., Kuhnhold, A., Honorato-Rios, C., Schilling, T. & Lagerwall, J. P. F. Enhancing self-assembly in cellulose nanocrystal suspensions using high permittivity solvents. Langmuir 32(38), 9854 (2016).

Dahlström, C. et al. Stacking self-gluing cellulose II films: A facile strategy for the formation of novel all-cellulose laminates. Carbohydr. Polym. 344, 122523 (2024).

Acknowledgements

The authors thank the funding support by the Forestry Science and Technology Project of Fujian Province (No.2023FKJ27), Research Project of Fashu Foundation (MFK23007) and the Department of Science and Technology of Fujian Province (No. 2022H6021 and 2023J011394).

Author information

Authors and Affiliations

Contributions

Wang wrote the main manuscript text. Chen completed most of the experiments. Xiu finished drawing the figures. Xue and Gao finished processing part of the data. Lei revised the manuscript. Yuan and Liu and Xia are responsible for the design and supervision of experiments. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, L., Xiu, Y., Chen, X. et al. Spontaneously assembled cellulose nanocrystal structural color films with tunable properties. Sci Rep 15, 28840 (2025). https://doi.org/10.1038/s41598-025-98994-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-98994-x