Abstract

Extensive research has been conducted to mitigate the hazards of coal mine dust. Dust suppressants are crucial for enhancing the dust and fall efficiency of water media. Currently, environmentally-friendly, functional, polymeric, and microbial dust suppressant, which represent new types of suppressants, are primarily in the experimental and exploratory stages. Commercial models are not yet mature, and further validation through field tests and over time is required to assess the continuous effectiveness, environmental friendliness, safety, economic feasibility, and simplicity of the process of new dust suppressant. Consequently, this study utilized response surface methodology to optimize the conditions for microbial fermentation to synthesize the biobased dust suppressant γ-PGA. The fermentation extracts of Bacillus licheniformis were analyzed by thermogravimetric analysis. Infrared spectroscopy was employed to explore the functional group structure of the synthesized products; the wettability of γ-PGA was tested using an optical method for measuring contact angle/surface tension and transmission electron microscopy. The results indicated that screening, optimizing, and culturing Bacillus licheniformis could produce γ-PGA fermentation fluid with a maximum yield of 23.76 g/L. Infrared spectroscopy analysis showed that the purified product contained typical functional groups of γ-PGA. Changes in the contact angle of γ-PGA solution with coal dust over time demonstrated that brown coal was wetted extremely quickly, with the largest change in contact angle; within 5 min of dropping the fermentation liquid, the contact angle sharply decreased from 69° to 0°, completely wetting the brown coal. Transmission electron microscopy revealed that the coal pores became looser when wetted by water, and when the γ-PGA wetted the surface of the coal dust, the solution penetrated into the pores, forming a liquid film that enveloped the medium within the coal pores and suppressed the native dust. Due to the abundance of free carboxyl groups (a-COOH), amino groups (NH–), and carbonyl groups (CO) on the molecular chains of γ-PGA, along with numerous hydrogen bonds between the γ-PGA chains, γ-PGA has a strong ability to absorb and retain water, making its capacity to wet solids significantly stronger than that of plain water. This research is expected to lay the experimental foundation for the development of green and efficient dust suppression materials for mining applications. In mining applications, γ-PGA solutions demonstrate versatile dust suppression capabilities. For operational face dust control, γ-PGA can be applied through high-pressure spray systems directly onto coal mining surfaces. Its rapid wetting properties enable immediate capture of airborne particulates. In material transportation systems, γ-PGA combined with foaming agents generates dust-suppressive foam that adheres to conveyor belts or coal loads in mining vehicles. Pre-wetting treatments using γ-PGA solutions prior to coal crushing operations leverage the polymer’s exceptional water absorption and retention capacities. This pretreatment reduces coal brittleness, thereby minimizing the generation of new particulates during mechanical fragmentation processes. The technology exhibits potential for cross-industry adaptation. In construction demolition scenarios, γ-PGA formulations could integrate with dust suppression cannons to mitigate transient particulate emissions. Road dust management represents another promising application, where γ-PGA solutions may enhance the longevity of surface moisture retention when deployed via standard road sprinkler systems, thereby reducing maintenance frequency.

Similar content being viewed by others

Introduction

The mining sector is one of the main drivers for global economic growth, supplying energy for various industries, construction, and manufacturing. However, mining processes create dust, one of the most dangerous threats to the environment that now also greatly affects human health. Since mechanized mining technologies in underground coal mines have developed rapidly in recent decades, the volume of coal dust production has dramatically increased and caused more complex problems affected with coal dust pollution1. The challenges of managing coal dust are exacerbated by its suspensibility and hydrophobic nature, which not only makes it prone to spontaneous combustion and explosions but also reduces the lifespan of precision equipment and triggers the onset of pneumoconiosis, resulting in substantial casualties and economic losses2,3. Consequently, finding more effective methods to control coal dust has become a daunting and urgent task for researchers4,5. Among the various solutions, the application of dust suppressant is considered one of the effective methods to address this issue6,7,8.

In history, research on dust suppressant for coal mine has long focused on chemical dust suppressant, which play a certain role in dust suppression in mines9,10. However, many chemical dust suppressant have low surfactant activity, are high in toxicity, are irritating, corrosive, and have a low degree of degradability and the suppressant are not environmentally friendly, which greatly limit the wide application of chemical dust suppressant in coal mines11,12. At the same time, biodegradable green dust suppressant, with inherent biodegradability and high surface activity, have no secondary pollution problems. Achieve no secondary pollution, no toxicity and harm to humans and animals. Therefore, biodegradable and green-eco-friendly dust suppressant are the development direction of future generations of dust suppressant13,14.

Researchers have developed eco-friendly coal dust suppressant using biopolymers and biodegradable materials, which are characterized by their green, environmentally friendly nature and lack of secondary pollution. Additionally, the suppressant pose no threat to personnel, the environment, or equipment15,16. Cao Shuijing et al. developed a foam-type dust suppressant using corn starch and stearyl alcohol to graft copolymer surfactants, aimed at reducing coal dust concentrations underground. The surfactant raw materials were cost-effective, and the process was straightforward. The composite foam dust suppressant effectively encapsulated and moisturized coal dust, enhancing dust reduction efficiency17. The study lacks a comparative analysis of the effectiveness of their suppressant against other common dust control agents. Additionally, the research primarily focuses on reducing coal dust concentrations underground, leaving a gap in understanding its applicability to surface coal mining. Furthermore, the long-term environmental impact of the suppressant remains unclear, necessitating further investigation into its biodegradability and ecological safety. A comprehensive assessment of these factors would help in better understanding and optimizing the suppressant’s overall effectiveness17.

Wang Hetang et al. developed a bio-dust suppressant (BDS) synthesized through the fermentation of Bacillus subtilis. They analyzed the optimal fermentation conditions for high-yield production of the strain using response surface methodology and Design Expert software. The BDS is a cyclic lipopeptide with a long alkyl chain, featuring peptide bonds –NH–CO–. It exhibits excellent surface activity and demonstrates significant advantages in terms of wetting performance and economic efficiency while also showing good environmental tolerance. However, the study only investigated the wetting effect of BDS on specific coal dust and did not analyze the differences in its efficacy on various types of coal dust. Therefore, further research is needed to explore the universality of BDS on coal dusts with different degrees of metamorphism18.

Given the research gaps identified, there exists an urgent requirement to investigate innovative and ecologically sound methods for mitigating dust in mining activities. The utilization of biological agents for dust suppression emerges as a propitious option owing to their capacity for decomposition, minimal harmful effects, and efficacy in dust management as indicated by Mulugeta et al.19. Notably, among these bio-based solutions, γ-polyglutamic acid (γ-PGA) distinguishes itself as a versatile and environmentally benign polymer with a wide range of applications spanning agriculture, food industry, and biomedical sectors, as highlighted by Liu et al. 20.

Despite the potential it holds, the utilization of γ-PGA as a dust suppressant in the mining sector has not been extensively investigated. The production of γ-PGA via microbial fermentation presents a viable and cost-efficient method for generating this biopolymer on a large scale21. Furthermore, the distinct characteristics of γ-PGA, including its significant water solubility, biocompatibility, and capacity to form films, render it a compelling option for mitigating dust in mining activities22.

Previous studies have predominantly focused on the applications of γ-PGA in biomedical fields such as drug carriers, as well as agricultural domains including water-retaining agents and controlled-release fertilizers, with its functional design primarily centered on biocompatibility and biodegradability. This study has conducted in-depth investigations into the methodological limitations of prior research and proposed targeted solutions, thereby advancing the field through systematic problem identification and resolution. By harnessing the capabilities of microbial fermentation and biopolymer synthesis, this research aims to develop an environmentally effective solution to reduce dust emissions in the mining environment. The industrial application of γ-PGA in coal mine dust suppression, emphasizing its wettability, permeability, and dust fixation capabilities was systematically explored in this study. The findings provide new possibilities for the practical implementation of γ-PGA in industrial environmental protection sectors, demonstrating significant practical value.

Materials and methods

Experimental chemicals and instruments

Experimental drugs and instruments are shown in Table 1. Experimental instruments are shown in Table 2.

Strain source

Samples were collected from the improved soil around coal gangue piles. The improved soil creates a suitable environment through pH adjustment, organic matter supplement and heavy metal passivation, and combines the resistance of Bacillus licheniformis, metabolic diversity and artificial restoration intervention to make the area rich in Bacillus licheniformis. Twenty colonies were isolated and cultured from the samples. On account of γ-PGA-producing bacteria colonies exhibit highly viscous properties, a moist surface, and string-forming characteristics, these traits facilitate the preliminary selection of γ-PGA-producing bacterial strains. These traits were likely assessed visually and manually after one day of cultivation on solid medium. Visually identified as colonies with a glossy or wet appearance. Observed when colonies were touched with a sterile loop, highly viscous colonies would stretch or form “strings” when the loop was pulled away. After one day of cultivation on solid medium, three colonies with high viscosity and string-forming properties were isolated from larger colonies for inoculation into LB liquid medium and slant medium (LB) for preservation and further selection. The strains from preliminary screening underwent PCR amplification of their 16S rDNA using Pfu high-fidelity DNA polymerase from Trans Gen Biotech. Based on the fluorescence quantification results, samples were mixed in respective proportions. Gel-extracted PCR products were analyzed by SDS-PAGE. The selected strains were preliminarily identified through PCR and sequence homology analysis. Sequencing results were searched for similarity in the NCBI database using the Blast program, and strains with high homology were used to construct a phylogenetic tree using the Neighbor-joining method.

Synthesis experiment of biopolymer dust suppressant γ-PGA

The synthesis experiment for the biopolymer dust suppressant γ-PGA begins with the activation and cultivation of γ-PGA-producing bacterial strains to obtain fermentation broth. The target product, γ-PGA, is then purified from the fermentation broth using ethanol precipitation, as outlined in Fig. 1. Sterile distilled water is mixed with isolated bacterial materials and homogenized. The mixture is then boiled at 100 °C for 10 min to kill non-spore-forming bacteria. After cooling, the supernatant is diluted in a gradient and cultured in a constant temperature incubator. Once specific colonies grow on NA plates, they are inoculated onto LB medium and expanded in a water bath shaker. The LB seed culture is diluted in sterile sodium chloride-proteose peptone buffer at a predetermined ratio and evenly spread on blood agar plates for incubation in a constant temperature incubator. The cultured strains are transferred to LB medium for further expansion in a water bath shaker. The solution from the LB medium is inoculated into Non-MSG fermentation medium and cultured in a water bath shaker for fermentation. After fermentation, γ-PGA in the fermentation liquid is separated and extracted using ethanol precipitation. The pH of the fermentation liquid is adjusted to below 3 using HCl, followed by centrifugation at 8000 rpm for 30 min. A specific volume of the supernatant is taken, adjusted back to its original pH, and anhydrous ethanol is added. The mixture is left to precipitate for 72 h and then centrifuged. The precipitate is resolubilized in an appropriate amount of ultrapure water, freeze-dried at − 85 °C, and weighed. The γ-PGA standard and the freeze-dried extract are separately mixed with dry KBr powder. The mixture was ground into a fine powder, and packed into a pellet mold to form a transparent thin discs. These are then characterized using infrared spectroscopy and nuclear magnetic resonance spectroscopy.

Optimization of conditions for synthesizing γ-PGA by Bacillus licheniformis

Optimizing the fermentation conditions to enhance the yield of γ-PGA from Bacillus licheniformis necessitates the adjustment of both the components of the fermentation medium and the culture conditions. Different strains require specific environments and components for growth, which directly influences the yield of γ-PGA. A Box-Behnken design and Response Surface Methodology (RSM) were employed to optimize fermentation conditions by constructing regression equations and response surface plots. RSM is an experimental technique that thoroughly considers the interactions among factors affecting the target, which is widely used in multifactorial and multilevel experiments. This approach has many advantages, such as elimination of extreme combinations, reduction of experimental burden and quantification of interaction effects.

The optimization experiment for fermentation conditions utilized five factors at three levels as shown in Table 3, with each factor having three values: high (+ 1), low (− 1), and a default middle value (0). Different fermentation conditions were set in the experiment, including fermentation broth temperature (°C), pH, inoculum volume 100 ml solution (g/L), and the amounts of sodium glutamate (g/L) and sodium citrate (mL) added. The total fermentation duration was set at 96 h. For a five-factor three-level BBD configuration, the total number of experimental conditions is derived from the formula (1):

where:

k is number of factors;

Cp is the number of central point replicates, typically are 6–10 replicates to estimate experimental error.

Substituting the values:

Thus, the 46 experimental conditions comprise 40 factorial design points which generated from pairwise high-low combinations of factors and 6 central point replicates. This structured approach ensures robust exploration of the design space while minimizing resource expenditure, making BBD a gold standard for multifactorial bioprocess optimization. The Design Expert software (12.0, https://design-expert.net/) for encoding was used to generate a code table.

Identification of fermentation extracts

The fermentation products were extracted by ethanol precipitation method. Initially, the pH of the fermentation broth was adjusted to approximately 2 using hydrochloric acid, followed by centrifugation for 15 min in a GTR10-1 high-speed refrigerated centrifuge. A certain volume of the supernatant was then taken and neutralized to the original pH value using NaOH. Three times the volume of anhydrous ethanol was added to the supernatant, and the mixture was allowed to stand until a significant amount of precipitate formed at the bottom. The precipitate was redissolved in an adequate volume of pure water and then frozen in a refrigerator for 8 h for pretreatment. Finally, the samples were placed in a − 60 °C vacuum freeze-dryer for approximately 5 days to obtain the dried extract. The obtained crystalline particles were thoroughly ground and then mixed with dry KBr in a 1:100 ratio for further grinding. The fine powder was placed into an infrared spectrometric steel ring, ensuring the powder covered the bottom of the ring, to form a transparent thin film. The steel ring was then compressed and placed into a Fourier-transform infrared spectrometer for scanning, obtaining an infrared spectrum ranging from 4000 to 400 cm−1. The infrared spectrum of the resulting product was compared with the standard spectrum of γ-PGA to determine whether the strain had produced γ-PGA.

Characterization of novel bio-based dust suppressant γ-PGA

Thermogravimetric analysis of the extract

The thermogravimetric analyzer was turned on to preheat for 3 h before commencing the measurement. The baseline was select and the temperature was set to 450 °C with a heating rate of 10 °C/min. The option was chosen to correct + sample, and two crucibles were put in the device. After the balance stabilizes, a zeroing calibration was performed. Once zeroing is complete, one crucible was removed, the γ-PGA sample was added to it, and the crucible was returned to the instrument. Once the sample mass stabilizes, the run button was pressed to begin the testing phase. Repeat the above steps with a standard sample of polyglutamic acid. all the data obtained during the tests were record.

Analysis of wetting performance of γ-PGA

Appropriate amounts of brown coal, bituminous coal, non-stick coal, coking coal, and fatty coal dust were ground to 100 mesh. The coal dust was then compressed into cylindrical specimens with a polished flat surface using a compactor, and the formed pellets were placed on microscope slides. The computer and the optical contact angle measurement instrument were turned on, and then, the associated software is clicked on, the camera was turned on and adjusted the brightness accordingly. The microscope slide with the coal dust pellet were placed on the lifting platform. The instrument’s knob was adjusted to set the test platform to an appropriate height and distance until a clear image of the hydrophobic coating surface of the sample is visible on the software. A syringe was used to draw an adequate amount of the Bacillus licheniformis fermentation product and rinse the sample 3–5 times. After rinsing, an appropriate amount of the fermentation fluid was drew, the needle position was adjusted so that the lower end of the needle can be displayed in the image, and the the droplet and the surface of the coal dust pellet was clearly showed. The Bacillus licheniformis fermentation fluid was dropped onto the coal dust pellet and the photographs were taken to record the process. Photographs of the contact angle are taken every 5 min, totaling 4 images. After recording, the syringe was cleaned with water, the fermentation fluid with pure water was replaced, and the above steps were repeated to photograph and record the contact angles of pure water on the coal dust as a blank control. The coal dust samples were contacted with both ultrapure water and γ-PGA solution for 48 h. The changes in the surface morphology of the coal dust was observed using a transmission electron microscope.

Analysis of infrared spectral changes in coal dust

Appropriate amounts of brown coal, bituminous coal, non-stick coal, coking coal, and fatty coal dust were ground to 200 mesh. Pulverized coal sample stored in sealed bags for later use. Approximately 10 mg of each of the five prepared types of coal dust were moistened thoroughly using lichen fermentation broth, then placed in a drying oven until completely dry, and subsequently stored in sealed bags. A suitable amount of the two types of coal dust was mixed with KBr in a 1:100 ratio, thoroughly ground in a mortar to form a uniform fine powder, and then the mixture sample was compressed into a translucent thin flake using a pellet press. The flake was scanned 32 times in a Fourier Transform Infrared Spectrometer (FTIR) to obtain an infrared spectrum ranging from 4000 to 400 cm−1, which served as the control group. The dried coal dust was then mixed with KBr in a 1:100 ratio, re-ground, and pelletized to form another uniform translucent disk. This disk was scanned another 32 times in the FTIR to obtain an infrared spectrum within the same wavelength range. By comparing the infrared spectra of the coal dust before and after treatment with the dust suppressant, significant changes in absorption peaks were noted, allowing for the analysis and summarization of the dust suppression effectiveness of the biobased suppressant γ-PGA.

Results and analysis

Identification of γ-PGA producing bacteria

Identification of γ-PGA producing bacteria is typically achieved through methods encompassing colony morphology, Gram staining, physiological and biochemical tests, and genetic characteristics. Physiological and biochemical experiments are conducted to determine the strains that produce γ-PGA. Selected strains are inoculated onto solid media and cultured for 24 h at a temperature of 37 °C, followed by the observation of colony morphology and characteristics. Bacillus licheniformis, a common spore-producing bacterium, is identified by its round colonies, typically gray–white or pale yellow, with uneven surfaces and wrinkled, rough edges, as depicted in Fig. 2.

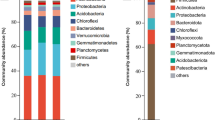

Sequences are assembled and submitted to the NCBI database for comparison using the BLAST website against nucleotide sequences in the GenBank database. By analyzing nucleotide sequence homology, strain CMI3 is identified as belonging to the genus Bacillus. A phylogenetic tree of the strain CMI3 is constructed. This tree, as shown in Fig. 3, reveals that CMI3 is most closely related to Bacillus licheniformis strain SCDB 14, with a homology of 92%. Therefore, CMI3 is confirmed as Bacillus licheniformis, a Gram-positive thermophilic bacterium.

Optimization and mechanism of fermentation conditions

Samples under various conditions were fermented in Landy medium for 96 h. The code table contains 46 sets of codes were generated to explore the relationship between BDS yield and fermentation conditions under the influence of multiple factors. The yield of γ-PGA for each set of fermentation conditions was obtained and is presented in Table 4.

Taking the fermentation broth temperature (A, in °C), pH value of the fermentation broth (B), inoculation volume of 100 mL solution(C, in mL), sodium glutamate addition (D, in g/L), and sodium citrate addition (E, in g/L) as independent variables, and product yield as the dependent variable, a quadratic regression model was established based on the results in Table 4. The regression equation is shown as Eq. (2):

From Eq. (2), the maximum predicted yield of γ-PGA is 23.556 g/L under the conditions of temperature A = 37 °C, pH B = 7.708, inoculation volume C = 2.985 mL, sodium glutamate addition D = 8.056 mL, and sodium citrate addition E = 2.385 mL. Repeating the experiment under these conditions resulted in a product yield of 23.64 g/L, indicating a prediction error of 3.57%.

The validation of quadratic polynomial RSM model reliability (Fig. 4) indicates that the prediction error of the model constructed is small. To further test the accuracy of the predictive model, the standardized external residual’s normal distribution and the distribution of standardized external residuals were examined, as shown in Fig. 5.

The straight line in Fig. 5a represents the cumulative normal distribution of the standardized external residuals predicted by the model, while the scatter points depict the positions of the actual yield’s standardized external residuals in the cumulative normal distribution. As shown in Fig. 5a, the scatter points are close to the normal distribution line; The distribution of standardized external residuals between actual and predicted yields, as shown in Fig. 5b, exhibits a random pattern centered around the "zero line." This observation provides evidence for the close alignment between the predictive model and the actual outcomes, thereby further validating its accuracy.

According to Table 3 and Eq. (2), it is evident that different fermentation conditions significantly impact the yield of the target product. In fact, the significance of the effects of variables such as fermentation temperature pH, Inoculum size, amount of sodium glutamate added, amount of sodium citrate addition on the target product yield varies, and these factors also interact with each other. Therefore, the above variables were combined in pairs and designed by Response Surface Methodology (RSM), the 2D contour plots and 3D response surfaces generated help determine the extent of interaction between the fermentation factors and their significant impact on the target product yield. Among them, the effects of amount of sodium glutamate addition and sodium citrate addition are most significant, as illustrated in Fig. 6.

The addition of sodium glutamate and sodium citrate significantly influences the microbial production of γ-PGA, with an observed interaction between the two. Citric acid, a crucial intermediate in the tricarboxylic acid cycle, is indispensable for the synthesis of γ-PGA and plays a vital role in its production. While some citric acid is synthesized during the microbial metabolic process, the amount is insufficient to meet the synthesis requirements of the target product.

According to Figs. 4 and 6, all quadratic term coefficients are negative, indicating that the response surface is concave and possesses a unique global maximum. The response surface exhibits a single concave structure without saddle points or local extrema, with the extremum point corresponding to the global maximum. The coefficient of the DE interaction term is − 1.07, and its negative value demonstrates that a synergistic increase in D and E significantly inhibits production. The interaction between D and E markedly suppresses yield through mechanisms such as resource competition or metabolic inhibition. However, optimization can be achieved through some strategies. Controlling the value of E to leverage its positive interactions with B and C (BE and CE), thereby offsetting the negative impact of DE; Or, increasing the value of D to amplify its linear term advantage and positive interaction with temperature (AD). In addition, it’s important to balancing quadratic term constraints to avoid parabolic effects caused by excessive individual increases in D or E. Ultimately, the negative DE interaction is effectively mitigated through coordinated optimization of global variables, enabling the attainment of maximum production yield.

From Eq. (1) and the 3D response surfaces of sodium glutamate addition and sodium citrate addition, the linear term coefficient of sodium glutamate was found to be positive, indicating that increasing the amount of sodium glutamate enhances yield when interaction and quadratic effects are excluded. The negative quadratic term coefficient suggests a concave parabolic relationship between the amount of sodium glutamate and yield, with a distinct maximum point. Interaction analyses revealed three significant pairwise effects involving sodium glutamate: AD, demonstrating that elevated temperature amplifies the positive effect of sodium glutamate; BD, implying that higher pH attenuates the yield-enhancing role of sodium glutamate; DE, where increased sodium citrate suppresses D’s yield improvement. The optimized D value was determined as 8.06 g/L through model integration. The negative linear term coefficient of sodium citrate suggests that increasing the amount of sodium citrate alone may reduce yield. Its quadratic term coefficient further indicates a concave downward parabolic relationship, with a distinct yield maximum. Interaction analyses revealed three key effects, The BE interaction demonstrates that higher pH partially offsets sodium citrate’s negative effects; the CE interaction shows enhanced yield benefits from sodium citrate at elevated inoculation levels; conversely, the DE interaction exhibits significant suppression, where concurrent increases in D and E synergistically reduce yield. The optimal E value was determined as 2.39 g/L.

There are three main potential complications that may arise at elevated concentrations of sodium glutamate and sodium citrate. High sodium glutamate may elevate osmotic pressure, inhibiting microbial growth or inducing cellular dehydration. Excess sodium glutamate could also accumulate intermediate metabolites such as ammonium ions, leading to pH fluctuations or toxicity. Excessive sodium citrate may be preferentially metabolized for energy rather than γ-PGA synthesis, reducing product yield. Citrate ions may buffer medium pH but could inhibit key metabolic enzymes at elevated concentrations.

Figure 7 illustrates that γ-PGA is formed through the polymerization of l-glutamate and d-glutamate. d-glutamate cannot be directly absorbed by cells; it is only synthesized from l-glutamate via two pathways. The first pathway involves the conversion of l-glutamate to d-glutamate by glutamate racemase. The second pathway begins with the conversion of l-alanine to d-alanine, followed by the transformation of d-alanine to d-glutamate by d-alanine aminotransferase. The addition of l-glutamate to the culture medium significantly enhances the production of γ-PGA without generating by-products. To address the dual requirements of γ-PGA high-yield production dependent on the logarithmic growth phase of bacterial cells and the need to circumvent potential inhibitory effects of sodium glutamate, a staged supplementation strategy can be implemented. This approach may involve initial addition of 6 g/L sodium glutamate followed by incremental supplementation to reach 8.6 g/L during the mid-phase cultivation period.

As revealed by response surface methodology (Fig. 6), the higher γ-PGA yield under specific conditions essentially stems from RSM’s ability to quantify multivariate interactions and identify optimal condition combinations that drive the microbial metabolic network into a “state of optimal balance”. This equilibrium maximizes the activity of microbial key enzymes, while also suppresses competing metabolic pathways, and avoids environmental stress on the microbial system. Such systematic optimization, which integrates multifactorial synergies and antagonisms, cannot be achieved through single-factor experiments.

Fourier transform infrared spectroscopy analysis of the extract

From the comparison illustrated in Fig. 8, it is observed that the absorption peaks of the product obtained from Bacillus licheniformis fermentation closely resemble those of pure polyglutamic acid. The region from 4000 to 1350 cm−1 represents absorption bands produced by stretching vibrations, while the region from 1350 to 650 cm−1 corresponds to the fingerprint region.At 3415.87 cm−1, an absorption peak appears, which is attributed to the symmetric stretching vibrations of N–H bonds. At 1606.71 cm−1, the stretching vibration band of the carbonyl group (C=O) in the amide group is observed. The symmetric vibration band of COOH forms an absorption peak at 1426.53 cm−1, and the bending vibration of the aromatic C–H is noted at 922.52 cm−1. These characteristics are roughly similar to those of the absorption peaks of pure polyglutamic acid, confirming that the fermentation product of Bacillus licheniformis is γ-PGA.

A broad, strong absorption peak formed between 3500 and 3000 cm−1 results from the combined effects of multiple N–H and O–H bond stretching vibrations. The peak at 1593.95 cm−1 is due to the asymmetric stretching of COO–, and the peak at 1137 cm−1 corresponds to the asymmetric stretching of the ester COC, indicating that in addition to γ-PGA, the Bacillus licheniformis product also contains lipopeptides.

Comparative results and analysis of extracts with γ-PGA using TG-DSC

According to the heat absorption and exothermic peaks of DSC (differential scanning calorimetry), it is possible to determine whether chemical and physical changes have occurred in the measured substance.

Figure 9 indicates that both the extracted product and the pure polyglutamic acid exhibit a process of initial endothermic followed by exothermic reactions. As the temperature increases from 0 to 100 °C, the evaporation of water occurs in the pure polyglutamic acid. Between 100 and 150 °C, the polyglutamic acid begins to decompose thermally, displaying minor weight loss before stabilizing. Combustive weight loss begins at approximately 270 °C, reaching an equilibrium around 350 °C. For the γ-PGA product, water evaporation occurs up to 200 °C, with the thermogravimetric (TG) curves of both substances showing minimal differences within this temperature range. The thermal decomposition of the extracted product initiates at approximately 200 °C, and by approximately 350 °C, it begins to undergo combustive weight loss, retaining about 55% of its mass at 450 °C. Comparing the TG-DSC curves of the extracted product and pure polyglutamic acid leads to the following conclusions: The dust suppression agent, developed from the fermentation of lichens and Bacillus subtilis, begins its thermal decomposition around 200 °C, while the pure polyglutamic acid starts this process between 100 and 150 °C. At 450 °C, the γ-PGA product retains 55% of its mass. However, the extracted product 's curve does not exhibit significant stability, possibly due to impurities in the extract. Nevertheless, the γ-PGA product’s ability to function as a dust suppressant, as evidenced by fermentation, suggests its feasibility and research value. γ-PGA is noted for its excellent film-forming properties, adhesive characteristics, and biocompatibility, making it suitable for dust suppression applications. This chapter investigates the thermal stability of γ-PGA and examines its effects on the surface potential, contact angle, and functional groups of coal dust, thereby providing experimental evidence for the use of γ-polyglutamic acid as a biologically-based dust suppressant in mining applications.

Analysis of the wetting properties of γ-PGA

This section examines the wetting behavior of γ-PGA, focusing on its ability to enhance moisture retention and distribution when applied to various substrates. The wetting properties are critical for its effectiveness as a dust suppressant, impacting how well γ-PGA binds to coal dust particles and surfaces. The evaluation involves measuring the contact angle when γ-PGA solutions are applied to different coal surfaces. A lower contact angle indicates better wetting capability, essential for forming a cohesive film over coal dust particles, thereby reducing airborne particulates.

From Fig. 10a and b, it is observed that within 20 min of water dripping, there is no significant change in the contact angle of lignite, indicating that water does not easily wet lignite. The cultured lichen fermentation liquid exhibits hydrophilicity and wets coal dust more easily than pure water.

Figure 10a illustrates the variation of contact angle over time, showing that lignite wets very quickly. The maximum change in contact angle occurs within 5 min of dripping lichen Bacillus spores fermentation liquid, where the angle sharply decreases from 69° to 0°, resulting in complete wetting of the lignite. In the same time, the wettability of fermented products to gas coal, non-stick coal and fat coal is not as good as that of lignite. The change in contact angles for these coal types is relatively similar; anthracite changes by 24.9°, non-sticky coal by 24.7°, and fatty coal by 16.4°.

Transmission electron microscopy (TEM) was employed to compare the wetting of coal dust surfaces by clean water and γ-PGA solution. Figure 11a to d show the observed surface morphology of the coal samples.

Current research on microbial dust suppressants predominantly focuses on carbonate precipitates generated via urea hydrolysis by urease-producing bacteria. However, the cementation process releases ammonia gas during coal dust consolidation, posing environmental risks. Additionally, the high cost of urease utilization significantly hinders their large-scale application in industrial settings. Hu et al. used the response surface curve method to optimize the culture conditions for enrichment of urease-producing microorganisms from activated sludge. The surface of coal dust consolidated bodies treated with nutrient solution was covered with a layer of material, which is related to the colloidal properties of yeast extract, but this force is weak, which showed relatively weak resistance to wind erosion23. The coal pore morphology that treated by biological dust suppressant in this study shown in Fig. 11a to d reveals that the coal pores wetted by water are relatively loose. After the coal dust surfaces are wetted with purified product solution, the solution penetrates into the pores, forming a liquid film that envelops the media within the coal pores, thereby suppressing the native dust.

Due to the presence of numerous free carboxyl groups (–COOH), amino groups (–NH–), and carbonyl groups (–CO) on the molecular chains of γ-PGA, which are capable of hydration, and the extensive hydrogen bonding between γ-PGA chains, γ-PGA demonstrates a significantly enhanced ability to absorb and retain water. The hydroxyl group (–OH) of the carboxyl group (–COOH) acts as a hydrogen bond donor, forming bonds with oxygen atoms in water molecules, while the carbonyl group (C=O) functions as an acceptor by binding to hydrogen atoms of water. In the case of amino groups (–NH–), the N–H moiety within amide bonds serves as a hydrogen donor, interacting with oxygen atoms from water. Additionally, the highly polar carbonyl group (–CO–) engages water molecules through hydrogen bonding with their hydrogen atoms. Water molecules are adsorbed through hydrogen bonding by these functional groups, leading to the formation of multilayered hydration shells that substantially enhance water absorption capacity. Each polar group can coordinate multiple water molecules, creating extended hydration layers that facilitate bulk water retention.

It is hypothesized that interchain crosslinking in γ-PGA occurs primarily through two mechanisms, one is hydrogen bonding between the carboxyl group (–COOH) of one chain and the carbonyl group (C=O) of an adjacent chain, and the other is interactions between the N–H group of amide bonds and neighboring carbonyl groups (C=O). These interchain hydrogen bonds stabilize a three-dimensional network structure, which could structural reinforcement through mechanical stability enhancement, provision of nanoscale water reservoirs within interconnected cavities and restriction of water mobility. Consequently, when the solid surfaces are the same, γ-PGA’s capacity to wet solids is far superior to that of water. Consequently, when the solid surfaces are the same, γ-PGA’s capacity to wet solids is far superior to that of water.

The absorption peaks at 3600–3200 cm⁻1, as seen in Fig. 12, are primarily attributed to N–H and O–H stretching vibrations. After treatment with dust suppressant fermented by Bacillus licheniformis, the absorption peaks of both types of coal dust significantly broadened, indicating an increase in functional groups and an enhancement of intermolecular forces compared to raw coal. This also improved the hydrophilicity of the coal dust. The region between 1740 and 1650 cm−1 corresponds to the C=O stretching zone of carboxylic acids, and the absorption peak intensity increased after the coal dust was treated with thesuppressant. Meanwhile, the absorption peaks at 980–900 cm⁻1, primarily due to C–O–C stretching vibrations, showed a varying degree of reduction in both coal samples.

Conclusion and prospect

Conclusion

-

(1)

In this experiment, the yield of Bacillus licheniformis reached 23.64 g/L under optimized cultivation conditions. The fermentation medium contained the following components: 8 g/L sodium glutamate, 30 g/L glycerol, 2.4 g/L sodium citrate (C₆H₅Na₃O₇·3H₂O), 9 g/L ammonium sulfate ((NH₄)₂SO₄), 0.5 g/L magnesium sulfate (MgSO₄·7H₂O), 0.1 g/L manganese sulfate (MnSO₄·H₂O), 0.15 g/L calcium chloride (CaCl₂), and 0.5 g/L potassium dihydrogen phosphate (KH₂PO₄). The culture conditions were set at a temperature of 37 °C and a pH of 7.

-

(2)

According to the infrared spectra, the fermentation product of Bacillus licheniformis has characteristic absorption peaks similar to those of pure polyglutamic acid. An absorption peak is observed at 3415.87 cm⁻1, corresponding to the symmetric stretching vibration of N–H. The stretching vibration of the amide C=O is seen at 1606.71 cm⁻1. The symmetric vibration of the carboxyl group (COOH) forms an absorption peak at 1426.53 cm⁻1, while the bending vibration of the aromatic C-H ring has a corresponding effect at 922.52 cm⁻1. A broad and strong absorption peak between 3500 and 3000 cm⁻1 is caused by the combined stretching vibrations of multiple N–H and O–H bonds. The peak at 1593.95 cm⁻1 is due to asymmetric COO stretching, and the peak at 1137 cm⁻1 indicates asymmetric ester C–O–C stretching. These findings suggest that in addition to γ-PGA, the fermentation product of Bacillus licheniformis also contains lipopeptide compounds.

-

(3)

By comparing the infrared spectra of raw coal and coal dust treated with the dust suppressant, it is evident that the hydroxyl content of the treated coal dust increased significantly. The intermolecular forces between surface O–H groups of the coal dust were enhanced, improving the hydrophilicity of the coal dust and making it more easily wettable. This indicates that the dust suppressant primarily acts on the hydrophilic functional groups on the coal dust surface, achieving a certain level of dust suppression.

-

(4)

Through measuring the contact angle between coal dust and water, it was found that water had difficulty wetting the coal dust. However, after treatment with the dust suppressant, the contact angles of the four types of coal dust decreased to varying degrees, with even lignite being completely wettable. This indicates that thesuppressant exhibits excellent wetting effects on coal dust. Examination of coal pore morphology via transmission electron microscopy revealed that the pores wetted by water were relatively loose. After the surface of the coal dust was wetted by γ-PGA, the solution penetrated into the pores, forming a liquid film that enveloped the internal medium of the pores, thereby suppressing the original dust. Due to the abundant presence of three highly hydratable functional groups, namely, free carboxyl groups (a-COOH), amino groups (NH), and carbonyl groups (CO), on the molecular chains of γ-PGA, coupled with the presence of numerous hydrogen bonds between γ-PGA chains, it exhibits strong water absorption and retention capabilities. Therefore, when compared to water, γ-PGA has much greater wetting abilities on solid surfaces with the same characteristics.

-

(5)

After treatment with the dust suppressant produced by fermentation of Bacillus licheniformis, the absorption peaks of coal dust noticeably broaden, indicating an increase in functional groups relative to raw coal. This increase in functional groups enhances the intermolecular forces and improves the hydrophilicity of the coal dust. In summary, inoculating Bacillus licheniformis on optimized fermentation medium can synthesize γ-PGA, and the resulting product exhibits a certain level of dust suppression effectiveness.

Prospect

Compared with traditional surfactants, the carboxyl groups on the γ-PGA molecular chain can form hydrogen bonds and electrostatic adsorption with coal dust particles, enhancing the durability of adhesion. Moreover, it demonstrates compatibility with existing equipment. Critical components in field applications, such as high-pressure spray systems and foam generation devices, are standard dust suppression equipment in mining operations. The γ-PGA solution can directly replace traditional chemical dust suppressants without requiring large-scale infrastructure modifications. Therefore, γ-PGA dust suppressant has the potential for large-scale application.

Compared to traditional chemical dust suppressants, γ-PGA demonstrates significant environmental and economic benefits. γ-PGA is a natural biopolymer produced via microbial fermentation, which is fully biodegradable, degrading into harmless glutamic acid and water without long-term environmental residue or accumulation. In contrast, conventional chemical dust suppressants may contain recalcitrant organic compounds or heavy metal components, posing risks of soil and water contamination. Chemical inhibitors can also release volatile organic compounds or acidic constituents, which may disrupt soil microbial communities or impair vegetation growth over prolonged use.

γ-PGA effectively mitigates persistent pollution risks associated with conventional dust suppressants through its controlled biodegradability, while its lifecycle cost advantage derives from the utilization of renewable feedstocks. The degradation byproduct of γ-PGA, glutamic acid, serves as a bioavailable nitrogen source for plant uptake, demonstrating its phytoremediation potential in vegetation restoration. Furthermore, γ-PGA exhibits exceptional adaptability to complex field environments owing to its molecular tunability, including the formation of flexible film structures via interchain hydrogen-bonded networks and the enhancement of hydrophobicity through grafting hydrophobic segments.

Considering the variations in wettability among different types of coal, future studies should assess the effectiveness of the γ-PGA suppressant across a broader range of coal types. This could help in tailoring the suppressant formulations for specific coal properties to enhance dust control efficacy.

It is crucial to evaluate the environmental impact and safety of deploying γ-PGA-based dust suppressant, particularly in terms of biodegradability and toxicity. Long-term field studies could provide insights into the ecological footprint and potential health risks associated with the widespread use of such biotechnological solutions in mining and other dust-intensive industries.

These directions not only promise to enhance the understanding and application of biological dust suppressant but also contribute to the development of sustainable and effective solutions for managing coal dust in various industrial contexts.

Data availability

Sequence data that support the findings of this study have been deposited in the figshare with the primary accession code 27,922,662.

References

Fan, Y. J. et al. Material optimization of microbial dust suppressant nutrient solution based on response surface curve. Powder Technol. 385, 25–36. https://doi.org/10.1016/j.powtec.2021.02.061 (2021).

Song, W. J., Yang, Y. Y., Ran, J. P. & Pan, X. L. Suppression of coal dust by microbially induced carbonate precipitation using Staphylococcus succinus. Environ. Sci. Pollut. Res. Int. 26(35), 35968–35977. https://doi.org/10.1007/s11356-019-06488-x (2019).

Ameni, K., Aida, K., Mnif, I. & Sofiane, B. Enhancement of Aeribacillus pallidus strain VP3 lipase catalytic activity through optimization of medium composition using Box-Behnken design and its application in detergent formulations. Environ. Sci. Pollut. Res. 27(11), 12755–12766. https://doi.org/10.1007/s11356-020-07853-x (2020).

Dalfard, A. B., Parhamfar, M. & Karami, Z. Characterization of a Thermostable, acidic-Phytase from Bacillus tequilensis Dm018; Medium Optimization by Response Surface Methodology. Catal. Lett. 149(11), 2961–2972. https://doi.org/10.1007/s10562-019-02881-w (2019).

Okyay, T. O. & Rodrigues, D. F. Optimized carbonate micro-particle production by Sporosarcina pasteurii using response surface methodology. Ecol. Eng. 62, 168–174. https://doi.org/10.1016/j.ecoleng.2013.10.024 (2014).

Koniecznal, I. et al. Bacterial urease and its role in long-lasting human diseases. Curr. Protein Pept. Sci. 13(8), 789–806. https://doi.org/10.2174/138920312804871094 (2012).

Yu, Z. et al. Enhancement of ascomycin production via a combination of atmospheric and room temperature plasma mutagenesis in Streptomyces hygroscopicus and medium optimization. AMB Express 9(1), 25–31. https://doi.org/10.1186/s13568-019-0749-x (2019).

Iqbal, M. et al. Coal desulfurization using gamma and ultraviolet radiation. Energy Sources Part A Recovery Util. Environ. Eff. 39(12), 1–7. https://doi.org/10.1080/15567036.2017.1296906 (2017).

Guan, R. et al. Functionality of surfactants in waste-activated sludge treatment: A review. Sci. Total Environ. 609, 1433–1442. https://doi.org/10.1016/j.scitotenv.2017.07.189 (2017).

Pedro, J. P., Gea, T., Sanchez, A. & Font, X. Production of sophorolipids from winterization oil cake by solid-state fermentation: Optimization, monitoring and effect of mixing. Biochem. Eng. J. 115(1), 93–100. https://doi.org/10.1016/j.bej.2016.08.006 (2016).

Abbas, M. et al. Vibrio fischeri bioluminescence inhibition assay for ecotoxicity assessment: A review. Sci. Total Environ. 626, 1295–1309. https://doi.org/10.1016/j.scitotenv.2018.01.066 (2018).

Manickam, N., Bajaj, A., Saini, H. S. & Shanker, R. Surfactant mediated enhanced biodegradation of hexachlorocyclohexane (HCH) isomers by Sphingomonas sp. NM05. Biodegradation 23, 673–682. https://doi.org/10.1007/s10532-012-9543-z (2012).

Kaustuvmani, P., Rupshikha, P., Kalita, M. C. & Suresh, D. Characterization of biosurfactant produced during degradation of hydrocarbons using crude oil as sole source of carbon. Front. Microbiol. 8(3), 279. https://doi.org/10.3389/fmicb.2017.00279 (2017).

Vecino, X., Cruz, J. M., Moldes, A. B. & Rodrigues, L. R. Biosurfactants in cosmetic formulations: Trends and challenges. Crit. Rev. Biotechnol. 37, 911–923. https://doi.org/10.1080/07388551.2016.1269053 (2017).

Ma, Y., Zhou, G., Ding, J., Li, S. & Wang, G. Preparation and characterization of an agglomeration-cementingagent for dust suppression in open pit coal mining. Cellulose 25(1), 4011–4029. https://doi.org/10.1007/s10570-018-1826-z (2018).

Xia, W. J. et al. Synthesis, characterization, and oil recovery application of biosurfactant produced by indigenous Pseudomonas aeruginosa WJ-1 using waste vegetable oils. Appl. Biochem. Biotechnol. 166(5), 1148–1166. https://doi.org/10.1007/s12010-011-9501-y (2012).

Cao, S., Yang, Z., He, Y. & Cui, M. Preparation of underground coal dust foam dust suppressant Research on the performance of the system. Coal Eng. 49, 87–90. https://doi.org/10.11799/ce201703025 (2017).

Wang, H., He, S., Zhang, Q. & Zhao, X. Experimental study on synthesis of biological dust suppressant by microbial fermentation. J. China Coal Soc. 46(2), 12. https://doi.org/10.13225/j.cnki.jccs.XR20.1962 (2021).

Mulugeta, K., Kamaraj, M., Tafesse, M. & Aravind, J. A review on production, properties, and applications of microbial surfactants as a promising biomolecule for environmental applications. 1, 3–28 (2021). https://doi.org/10.1007/978-3-030-63575-6_1.

Liu, H., Yuan, P., Gao, X. & Du, Y. The study of a suppression agent for coal dust.2013. In International Conference on Materials for Renewable Energy and Environment 860–862 (IEEE, 2014). https://doi.org/10.1109/ICMREE.2013.6893808.

Luo, Z. et al. Microbial synthesis of poly-γ-glutamic acid: current progress, challenges, and future perspectives. Biotechnol. Biofuels 9(1), 134. https://doi.org/10.1186/s13068-016-0537-7 (2016).

Li, D. et al. Recent advances in microbial synthesis of poly-γ-glutamic acid: A review. Foods 11(5), 739. https://doi.org/10.3390/foods11050739 (2022).

Hu, X. et al. Medium optimization and dust suppression performance analysis of microbial-based dust suppressant compound by response surface curve method. Environ. Sci. Pollut. Res. 31(16), 24525–24535. https://doi.org/10.1007/s11356-024-32748-6 (2024).

Acknowledgements

This research was supported by the Natural Science Foundation of Shandong Province (Grant No. ZR2017PEE003), the Fundamental Research Project of doctor Funded by Binzhou university (Grant 2016Y31), the Seed Fundamental Research Funded by Binzhou university (Grant No. 16CX02010A), Civil Aviation University of China provincial and ministerial scientific research institutions open fund, College student innovation and entrepreneurship project(Grant 202410449025)

Author information

Authors and Affiliations

Contributions

M.C. and J.G. wrote the main manuscript text and S.Z. and W.L. prepared Figs. 1, 2, 3, 4 and 5 and G.Z. supervised the writing of the manuscript and T.S. and D.C. and C.W. prepared Figs. 6, 7, 8 and 9 and X.W and X.L. and Y.L. revised the manuscript format. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cheng, M., Zhang, S., Gao, J. et al. Optimized biosynthesis and performance enhancement of γ-PGA from Bacillus licheniformis: a study on wettability, microstructure, and environmental performance. Sci Rep 15, 24252 (2025). https://doi.org/10.1038/s41598-025-99084-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99084-8