Abstract

As a prerequisite and foundation for production and manufacturing, the design of product manufacturing process plays a crucial role in improving production efficiency, controlling resource consumption, shortening production cycles, and reducing processing costs. With the rapid development of advanced manufacturing technologies, product manufacturing process design is increasingly characterized by ambiguity, multi-solution possibilities, and cross-disciplinary integration, posing higher demands on enterprises’ capabilities in process design and innovation. To identify and innovatively address these issues within complex product manufacturing process, this study proposes a problem-driven innovation design strategy model for product manufacturing process. In the problem identification phase, opportunities are identified and categorized based on the product context and manufacturing process, followed by problem identification and the construction of problem elements using problem analysis methods. After identifying the problems, the type of innovation required is determined, and corresponding methods are applied to generate a set of solutions with innovation potential. These solutions are then evaluated and validated to determine the optimal innovation design for the product manufacturing process. If a solution fails validation, the problem is re-identified or re-solved, and the above steps are repeated until a validated final solution is achieved. Finally, the feasibility of the proposed strategy is demonstrated through a case study on the innovation design of the wax pattern manufacturing process for gas turbine blades.

Similar content being viewed by others

Introduction

As a result of the highly competitive market environment nowadays, the quality and performance of products have become the key to the establishment and development of an enterprise1. As the bridge connecting product design and manufacturing2, the product manufacturing process plays a vital role. Proper process decisions and reasonable process planning can provide scientific guidance for manufacturing, significantly improving product quality, controlling resource consumption, shortening development cycles, and reducing processing costs3. The manufacturing process refers to the series of methods and procedures by which a producer, utilizing production tools, transforms raw materials and semi-finished products into final products. Manufacturing process design generally refers to the process by which design personnel, based on their experience, expertise, and insight, analyze the characteristics of the product, processing requirements, and manufacturing environment. They then adopt appropriate processing methods based on current manufacturing conditions to systematically complete the processing flow design to achieve the goals set by the product design4. Manufacturing process design is the core content of manufacturing industry, every successful product is backed by meticulously designed and optimized manufacturing processes5. Due to the current product presents a short cycle, more varieties, batch changes and other new characteristics of the product manufacturing process design puts forward new requirements, the existing manufacturing process design is mainly manifested as excessive reliance on the experience of the process designers, low degree of innovation in manufacturing process design, the existence of more repetitive design and so on, there is an urgent need to carry out the innovation design of the product manufacturing process design in order to enhance the level of the process.

The key feature of the manufacturing process innovation design is innovation, which was defined by Joseph Alois Schumpeter as “the process of establishing a new production function by integrating new factors and conditions of production into the existing production system”6. He proposed five basic types of innovations in 19127, the second of which is “innovation by means of new methods of production technology”, which has been defined by the academic community as “manufacturing process innovation”. The second of these is “innovation by means of new production techniques”, which has been defined by academics as “manufacturing process innovation”. Design is the act of steering an existing state in a better direction, a process of continually identifying and solving problems8. Product manufacturing process design is also so, through the identification of product manufacturing process problems, and put forward a variety of possibilities to solve the problem, and constantly improve and optimize the product manufacturing process design to achieve the goals. Problem discovery is the starting point for problem-solving, an essential part of the creative process, and the foundation of product manufacturing process innovation9. In the fields of education and scientific research, there are mainly two research directions. One is based on specific methods, such as analogical thinking methods10; the other is based on a specific theme, such as setting new problem situations and proposing questions around the theme. In fields such as art and architecture, there is a greater emphasis on methodological tools such as brainstorming and behavioral mapping methods11. In the field of product manufacturing process design, Duflou et al. proposed a model of opportunity identification and technology conflict resolution for the casting process and its integration into the TRIZ innovation methodology12. Ferrer et al. argued that the solution to the manufacturing process design problem should take into account the technological conflict between the process and the environment, and constructed a computer-aided design model for green innovation based on hierarchical development13. Although different methods have been proposed to identify problems in various fields, they are isolated from each other and lack effective integration. In practice, the product manufacturing process usually involves multiple links, covering technology, process, materials, equipment and other aspects, which makes problem identification particularly complex. A single problem identification method may be difficult to comprehensively and accurately identify problems in complex product manufacturing process scenarios. Therefore, a systematic strategy model is urgently needed to organically integrate different methods in order to identify various problems in the product manufacturing process more efficiently and accurately.

Problem identification is followed by problem solving. Innovation methods serve as theoretical guidance for innovation-driven development and are largely applied in the problem-solving process of product innovation design. A relatively complete theoretical framework has been established for product innovation design, including traditional methods such as TRIZ14, axiomatic design (AD)15, creative template method (CT)16,and function-behavior-structure (FBS)17. Additionally, some scholars have further developed methods and theories for product innovation by integrating these traditional approaches with current advanced technologies18,19. Yun et al. summarized the application of machine learning techniques in object recognition for product manufacturing, which can, to some extent, assist in product process design20. Product manufacturing process Design is a creative process of solving process problems, the designer needs to stimulate innovation thinking and generate problem solutions with the support of innovation methods and knowledge. In the process of product manufacturing process design, problem solving after problem discovery often depends mainly on the experience and knowledge of manufacturing process personnel, and lacks systematic guidance for analyzing and solving process-related problems. In the process of manufacturing process problem solving process is characterized by ambiguity, experience and uncertainty, which brings serious blindness to the innovation design of the manufacturing process. Therefore, how to help manufacturing process designers rationally select and effectively apply appropriate innovation methods in the innovation design process of product manufacturing process has become a key issue that needs to be solved urgently.

To address the challenges of problem identification and problem-solving in the design of product manufacturing process, this study proposes a problem-driven product manufacturing process innovation strategy model. First, the product manufacturing process is integrated into the problem identification phase to uncover innovation opportunities in product manufacturing process design and construct problem elements based on problem analysis methods. Next, a problem-solving approach based on innovation strategies is proposed to provide strategic guidance to process personnel in generating process innovation solutions. Finally, evaluation methods are employed to select the optimal solution from the set of proposed solutions.

Related works

Problem identification

The book “The creative vision: A longitudinal study of artistic problem finding” by psychologists Getzels and Csikszentmihalyi laid the foundation for academic research on problem discovery21. Since then, research on problem discovery has gradually attracted scholarly attention and developed. The development and progress of any discipline starts with discovering and posing problems, and scholars have defined problem discovery from multiple perspectives, as shown in (Table 1).

Similarly, scholars have proposed various methods for problem identification. Meister et al. argued that the problem detection, the analysis of the problem and its causes (most frequently mentioned) and the evaluation of taken measures are activities that are directly supported by MA (manufacturing analytics)28. The logic tree analysis method is commonly considered to have been proposed and promoted by McKinsey & Company, and is also known as problem tree, deduction tree, or decomposition tree. This method requires users to have specialized knowledge and identifies the causal relationships of system events through a top-down deductive approach. Miranda et al. used the problem tree method to identify issues29. Waghen proposed an interpretable logic tree analysis (ILTA) method, which characterizes and quantifies causal relationships occurring over time in engineering systems with minimal human expert involvement30. In the field of product design, there are also several problem discovery methods, including fishbone diagram analysis, causal chain analysis, brainstorming, and the 5 WHYs method. Bernard used the fishbone diagram analysis method to analyze ergonomic risks associated with land-based oil drilling platforms and assessed risk factors based on machines, methods, materials, measurements, personnel, and environment31. Mei et al. identified the problem of the liquefied natural gas ship loading arm’s inability to connect quickly and accurately through causal chain analysis32.

Most problem identification methods are used to construct problem elements. Agre argues that the problem element consists of awareness, undesirability, difficulty, and solvability33. Modern information processing psychology indicates that the components of any problem include givens, goals, and obstacles. Overall, the above studies mainly focus on definitions, methods, and construction of problem elements in fields such as psychology, education, and product design. Research from the perspective of product manufacturing process design is relatively scarce. Moreover, the product manufacturing process design process design multiple disciplines and fields, which is more complex in problem identification. Therefore, for the identification of complex problems in the design of product manufacturing process, there is an urgent need for an integrated problem identification method to systematically identify and analyze the multi-dimensional problem factors involved in the product manufacturing process, and to lay the foundation for the subsequent innovation design of the product manufacturing process to solve the problem.

Problem solving methods with innovation potential

Problem identification is followed by problem solving. Many fields and organizations have adopted design as a means and method to address problems. Paton et al. proposed a framework innovation method in 201134, which uses “framework intervention” to design and solve reasoning, in order to expand problem contexts, innovate categories, and enhance design and solving capabilities. In the field of product design, since conceptual design is a key stage for innovation in the product development process, problem solving with innovation potential is mostly concentrated in the conceptual design stage35.

Existing research on conceptual problem solving with innovation potential can be divided into five directions: thinking-oriented, method-oriented, process-oriented, knowledge-oriented, and tool-oriented. Thinking-oriented research aims to clarify the behaviors and thinking patterns exhibited by designers during the design process, guiding them to shift their thinking modes, break out of fixed thinking patterns, and thereby effectively achieve product innovation with creativity. For example, the Six Thinking Hats method36. Method-oriented research uses extensive design practice to gradually make researchers aware that the process of product innovation design follows certain rules. By systematically and comprehensively summarizing the innovation environment, process, steps, goals, and content, it proposes formalized and structured methods with innovation potential. This type of research is represented by TRIZ, providing designers with methods such as conflict analysis, substance-field analysis, and technical evolution analysis37. Process-oriented research is based on understanding the nature of the product conceptual design process, expressing and formulating corresponding conceptual design process models to guide designers in systematically and orderly executing product concept creation. For example, Suh proposed the axiomatic design model describing the mapping of user, functional, physical, and process domains38. Similarly, there are models like FBS and FEBS. Knowledge-oriented research mainly utilizes existing scientific and technological knowledge to inspire designers to generate concepts with innovation potential for problem-solving. It focuses on the acquisition, representation, organization, and inferential application of design knowledge. For example, Cheong extracted functional knowledge in the SVO (subject-verb-object) form from natural texts using syntactic analysis and concept classification techniques39. Tool-oriented research focuses on developing computer-aided tools to support designers in completing product innovation, tools such as B-Link40, TechNet41, etc.

In the process of problem solving with innovation potential, due to the complexity and diversity of problems, the application of a single innovation method often relies too heavily on the designer’s experience or is only suitable for certain types of problems. Therefore, some researchers have studied the integrated application of multiple innovation methods. Zhao et al. proposed a design methodology for home entrance disinfection devices based on AHP-FAST-FBS, and could effectively improve the scientific rigor and effectiveness of the home entrance disinfection device design42. Lee et al. proposed a systematically integrated innovation design method that combines text mining, QFD, and TRIZ, and validated its feasibility through the design of smart glasses43. Rong et al. proposed a product innovation design process composed of three theoretical methods: Kano, axiomatic design (AD), and theory of the solution of inventive problems (TRIZ), and demonstrated the effectiveness of this method through the design practice of a portable two-wheeled self-balancing vehicle44.

Similarly, there are also many problems faced in the process of product manufacturing process design. In terms of processing technology, Xue et al. proposed an intelligent design methodology for the debugging process of complex electronic products, and developed a system tool to support the intelligent design of debugging processes for complex electronic products, which was validated through a case study on the design of a debugging process scheme for communication navigation and identification products45. In terms of generating assembly sequence plans and disassembling sequence plans46. Bedeoui et al. proposed the generation of assembly sequences plans (ASPs) based on three algorithms47. Zhang et al. developed a novel MOPSO-based approach for PODs with multiple non-ideal surfaces as well as local deformations. The effectiveness of the proposed approach was validated through case studies involving assemblies of plane-to-plane and plane-to-cylindrical surfaces, as well as the prediction of coaxial accuracy for a fuel pump48. In complex mechanical products, the disassembly of vulnerable parts is a major requirement for ensuring efficient design. Bedeoui et al. have proposed a new disassembly tool based on the concept of vulnerable part priority49. In order to meet environmental and economic goals, the authors have proposed a new method for parallel disassembly of products based on the collaborative parallel assembly and disassembly technology of humans and robots50. To solve the practical problem of disassembling retired power batteries, a new cost-aware model of multi-manned disassembly line balancing problem with different work modes (MWM-DLBP) is proposed51.

From the above research on problem solving methods, it can be found that in the product-oriented design stage, especially in the conceptual design stage, designers can effectively solve the problems in the design process by using innovation methods. Problem solving in the product manufacturing process design stage usually relies heavily on the experience of the designer and the application of advanced technology. However, in the process of product manufacturing design, it usually involves multiple links such as technology, process, and equipment. With the increase of innovation and efficiency requirements in the manufacturing industry, the method of relying solely on individual experience and discrete technology is gradually showing its limitations. Therefore, it has become an urgent need in the field of process design to construct a systematic innovation strategy model to guide designers to break through the traditional thinking stereotypes and realize efficient and reusable innovation paths.

Problem-driven product manufacturing process innovation strategy model

This research is a problem-oriented study that utilizes an innovation strategy model to help enterprises address the challenges they face in the product manufacturing process design. Process innovation design is closely related to innovation methods. However, there are many innovation methods currently available, and enterprises face issues such as difficulty in problem identification, low problem-solving efficiency, and the limited application of innovation methods. Therefore, assisting process personnel in effectively identifying problems and obtaining problem-solving with innovation potential for different issues has become crucial.

Specifically, the use of single methods in the process of product manufacturing process innovation design is insufficient. To enhance the support of innovation methods for the product manufacturing process, it is necessary to organically integrate these methods and provide strategic guidance to manufacturing process personnel during the stages of problem identification, problem-solving, and solution determination in the product manufacturing process plan to meet product design objectives. Therefore, this study integrates multiple innovation methods to construct a problem-driven product manufacturing process innovation strategy model. The model can provide systematic strategic guidance to process personnel, generate solutions with innovation potential, and improve the efficiency of solving problems in product manufacturing process solutions.

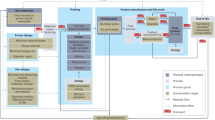

The problem-driven product manufacturing process innovation strategy model mainly consists of three layers: the problem identification layer, the problem-solving layer, and the solution determination layer, as shown in (Fig. 1).

-

(1)

Problem identification layer: The main purpose of this layer is to construct a set of product problem elements. Firstly, based on the current product background and processing technology, opportunity identification is carried out to further determine the type of opportunity. Corresponding problem analysis methods are selected for different opportunity types, and product process innovation problems are determined through problem analysis methods. Finally, a set of problem elements is formed. The specific steps are described in Sect. 4.1.

-

(2)

Problem solving layer: The main purpose of this layer is to obtain a collection of solutions. Firstly, the specific problems in the set of problem elements are analyzed to determine the types of innovation problems. The types of innovation problems are mainly divided into four categories: improvement-type problems, substitution-type problems, integration-type problems, and thinking-type problems. Different innovation solution strategies are summarized for different types of innovation problems. Then, the set of solutions with innovation potential is obtained through the corresponding strategy. The specific steps are shown in Sect. 4.2.

-

(3)

Solution determination layer: The main purpose of this layer is to determine the final plan. Based on the solution set obtained through the above process, the optimal solution is determined from the solution set through evaluation methods. The evaluation method mainly includes steps such as dentification of evaluation indicators, construct judgment matrix, determine indicator weights, construct weight matrix, find positive and negative ideal solutions, calculate ideal solution distance and program determination. If the solution does not pass verification, it returns to the problem identification layer or problem-solving layer for iterative solving until the final process innovation plan is verified and determined.

Methodology

Constructing problem elements

Nowadays, innovation-driven development has become a new focus of international progress, and practice has proven that “design innovation” is a crucial pathway for innovation-driven development. Essentially, design is an activity that guides the current state towards a better direction, continuously discovering and solving problems throughout the manufacturing process to ultimately achieve innovation goals. However, problem discovery is the starting point for problem-solving and forms the foundation of innovation. Products continuously evolve through the iterative process of discovering and solving problems. The process is crucial for product innovation, as it encompasses the methods, technologies, and procedures involved in product manufacturing, directly affecting the product’s quality, cost, and market competitiveness. Therefore, how to discover issues in the product manufacturing process and clarify the problems that need to be addressed is crucial.

In the fields of education and psychology, Antonijević pointed out that problems are cognitive barriers that prevent the realization of goals52. It refers to aspects of the current state that are less than ideal and unresolved, or unexpected developments. In the context of product manufacturing process issues, it often refers to cases where the product produced by the current manufacturing process does not meet the design requirements. Problems comprise many elements; currently, psychologists categorize these elements into three parts: given, goals, and obstacles. The given describes the known conditions of the problem at its initial state; goals summarize the conclusions at the problem’s target state; and obstacles are the main reasons that prevent achieving the target state, requiring specific thinking methods to find accurate answers. Building on these three parts, some scholars propose that the elements of a problem include the overall goal, initial conditions, methods of changing states, and obstacles.

Problems arise due to dissatisfaction of manufacturing process personnel with the products manufactured using the current manufacturing process scheme. Based on the research by the aforementioned scholars on the elements of a problem, the elements of a problem in the product manufacturing process include PT (Product Targets), KC (Known Conditions), OT (Opportunity Types), and Ob (Obstacles), as shown in Eq. (1):

PE represents problem elements, PT stands for product targets, which refers to the desired state of a specific function in the product. KC denotes Known Conditions, referring to the current situation related to the product manufacturing process. OT signifies opportunity types, indicating the type of opportunity associated with the current problem, which is relevant for subsequent problem-solving. Different opportunity types correspond to different problem-solving strategies. Ob refers to Obstacles, which are the main reasons that affect the product’s ability to achieve the target during the manufacturing process.

The process of determining problem elements is essentially the process of problem discovery. In this study, problems are identified through the construction of a problem guide set, leading to the development of problem elements. The main process is illustrated in (Fig. 2). Specifically, opportunity identification is guided by analyzing the problem background, which includes two main aspects: the product-related background and the product manufacturing process. Since the product manufacturing process directly affects the product’s design, quality, cost, and market competitiveness, the root causes of many issues often lie within the product manufacturing process. Therefore, this study focuses primarily on the product manufacturing process for determining problem elements, with supplementary analysis of the product-related background to identify product innovation opportunities. Opportunity types are further determined, and different problem analysis methods are employed for each opportunity type to identify the final problem elements.

Based on the group’s previous related research53,54, this study categorizes the types of opportunities into personnel-based opportunities, technology-based opportunities, all-new-based opportunities, and recognition-based opportunities. Personnel-based opportunities arise from requests for improvements made by process personnel regarding existing issues in the product manufacturing process. These opportunities are explicit and fundamental, and are generally obtained through methods such as causal chain analysis and surveys. Technology-based opportunities occur when process personnel are dissatisfied with existing product processes but do not know how to improve them. These opportunities are implicit and challenging to analyze, requiring personnel to improve processes from a principle-based perspective, relying on technological advancements or technology transfer from other fields. Methods such as QFD and first principles are commonly used. All-new-based opportunities involve innovative or disruptive process innovations driven by technological development. Essentially, these are new demands that often arise from technological advancements or trends. These opportunities are usually implicit, deep, and broad, and can typically be identified through methods such as brainstorming and trend analysis. Recognition-based opportunities involve process requirements related to the appearance and significance of the product. These opportunities are explicit, vague, and personalized, and such needs are often difficult to fulfill. They can typically be identified through methods such as observational analysis and ethnography.

Through the above problem discovery steps and methods, a problem elements set \(\:{S}_{PE}\) can be formed. Subsequently, problem-solving strategies are guided based on the issues in the element set.

\(\:{PE}_{i}\) represents the i-th problem element in the product elements set.

Problem solving based on innovation strategies

After identifying the problem elements in the product manufacturing process, the next step is to address the specific problem elements within the problem element set. Due to the abundance of innovation methods available, it is challenging for process engineers in enterprises to select the appropriate methods. Furthermore, with the continuous evolution and increasing demands of the manufacturing industry, low innovation efficiency has become a prominent issue in the manufacturing process innovation design. The main challenge now is to apply different innovation methods to various problems and effectively enhance problem-solving efficiency. Therefore, this section proposes a problem-solving method based on innovation strategies to assist process engineers in solving current issues in product manufacturing process.

Analysis of commonly used innovation methods

Innovation methods are strategies and tools developed based on innovation practices to assist in creative thinking. They are systematic descriptions and norms of the innovation environment, content, goals, processes, and steps, representing a structured summary and formalization of effective and mature creative thinking. Innovation methods can guide process personnel in innovation. Developed countries such as those in Europe and America place significant emphasis on these methods, while domestic research started relatively late compared to abroad, with studies gradually beginning in the 1960s. According to statistics, researchers have developed over 300 innovation methods to support product innovation design, with dozens being commonly used55. This study analyzes commonly used innovation methods from four aspects: supporting technologies, supporting information, supporting processes, and method types.

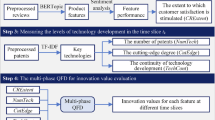

Study have shown that commonly used innovation methods are primarily based on seven supporting technologies: Adaptation/Induction/Organization (1), Randomness (2), Aggregation (3), Systematic Approach (4), Directionality (5), Directed Evolution (6), and Innovation Knowledge Base (7)56. The support of innovation methods for information is mainly reflected in their ability to provide stimulating information to process personnel during the process of innovation design. Based on the source and mode of information generation, it can be categorized into four types: External Guidance, Internal Guidance, Internal Random, and External Random57, as shown in (Fig. 3a). The innovation process is generally divided into three stages: identifying the problem, generating innovation ideas, and determining the solution with innovation potential. This process is further detailed into six steps: Problem Analysis (I), Problem Identification (II), Concept Solving (III), Domain Solving (IV), Solution Evaluation (V), and Combinatorial Optimization (VI)58,59, as shown in (Fig. 3b).

Research on commonly used innovation methods currently focuses on three aspects: Thinking flow type (X), thinking operation type (Y), and thinking procedure type (Z). In the application of specific innovation methods, they function in three areas: Innovation Analysis (①), Innovation Thinking (②), and Innovation Motivation (③)60. Innovation Analysis primarily assists personnel process in defining innovation problems and identifying innovation opportunities and resources. Innovation Thinking helps process personnel explore the solution space to obtain suitable solutions with innovation potential. Innovation Motivation involves providing stimulating information to process personnel, thereby inspiring innovation ideas.

-

(1)

Research on innovation methods primarily focused on thinking flow is mainly represented by studies from some developed countries in Europe and America. This approach emphasizes the free flow of thought and views invention and creativity as inevitable results of imaginative, associative, insightful, and intuitive thinking activities. Methods proposed include brainstorming, checklists, morphological analysis, and biomimicry.

-

(2)

Research on innovation methods focused on thinking operation is primarily represented by studies from Japan. This approach leans towards the practical operation of thought and views invention and creativity as inevitable results of the organic interaction between logical and non-logical thinking, achieving breakthroughs in thinking. Methods proposed include the KJ method, Six Thinking Hats, and mind mapping.

-

(3)

Research on innovation methods focused on thinking procedure is primarily represented by studies from the former Soviet Union. This approach views invention and creativity as inevitable results of organized thinking activities based on objective laws of cognition, achieved through specific procedures rather than by chance. Methods proposed include TRIZ theory, systematic innovation thinking techniques, creative templates, and the FBS method.

Based on preliminary laboratory research, various commonly used innovation methods are listed as shown in (Appendix Table 1)61. A comparative analysis of the application characteristics of these methods from the aspects is conducted to lay the methodological foundation for subsequent application of strategy methods.

Problem solving methods

In order to avoid as much as possible the blindness that may occur when designers are looking for solutions to design problems, this paper develops the corresponding problem types for the types of opportunities on the basis of the group’s previous related research53,54. To address issues of different types of opportunity, this study first defines corresponding problem types, namely improvement-type problems, substitution-type problems, integration-type problems, and inspiration-type problems. Furthermore, different problem-solving methods corresponding to these problem types are proposed. These methods, supported by problem-solving strategies and relevant knowledge services, aim to stimulate creative thinking in process personnel, leading to strategic problem solving and generating solutions. The specific strategic problem-solving model is shown in (Fig. 4).

As shown in Fig. 4, four problem-solving methods are proposed: Improved innovation methods, Substitute innovation methods, integrated innovation methods, and Heuristic innovation methods to support problem-solving.

Improved innovation methods are suitable for improvement-type problems, primarily addressing conflicts in existing technical systems. They originate from specific improvement needs proposed by process personnel for existing manufacturing process schemes and often use TRIZ theory and creative templates for problem-solving. Process personnel can choose method based on specific improvement-type problems to design.

Substitute innovation methods are suitable for substitution-type problems, mainly when the improvement of the existing technical system has reached its limit. These strategies originate from the dissatisfaction of process personnel with existing manufacturing process schemes without knowing how to improve them. They often use FBS and first principles for problem-solving. For example, when using FBS for innovation design, the behavior and structure corresponding to the product function can be mapped to assist process personnel in innovating the behavior or structure in the manufacturing process scheme.

Integrated innovation methods are suitable for integration-type problems, mainly targeting new or disruptive process schemes characterized by the combination of multiple technologies. These strategies arise from new demands, technological advancements, or development trends in the process. Combination innovation starts with the design goals, analyzes the existing system parameters and manufacturing process scheme components, and uses analogical thinking to apply manufacturing process schemes from other fields to the current manufacturing process. By comparing and combining the corresponding manufacturing process schemes, product innovation schemes are generated.

Heuristic innovation methods are suitable for thinking-type problems, mainly for manufacturing process scheme problems without specific goals. These are characterized by non-logical thinking innovation, achieved by stimulating the thinking of process personnel. This strategy often uses brainstorming and mind mapping for problem-solving. When facing such design problems, the strategy pushes a large amount of information related or unrelated to the manufacturing process design problem to the process personnel, forcing them to make associations and generate ideas.

This process mainly involves the strategic problem-solving of product manufacturing process problem elements to obtain manufacturing process innovation schemes. Subsequently, the manufacturing process innovation scheme set is evaluated and validated to determine the final product manufacturing process scheme.

Defining solutions with innovation potential

After problem-solving, multiple product manufacturing process design solutions are obtained. The optimal solution among them is usually determined through a solution evaluation method. Solution evaluation is a method where process personnel analyze, compare, and assess the set of solutions, helping them to select the optimal solution from the many available, ensuring that the chosen solution can address the current issues in the process engineering. The chosen solution is then subjected to validation; if the validation is successful, the final solution is determined. If other issues are found during the validation phase or if the problem-solving is incomplete, the process iterates back to problem-solving. This cycle is repeated until the solution passes validation and the final solution is determined. The solution determination process is shown in (Fig. 5).

In this paper, a solution evaluation method based on AHP and TOPSIS is used. The Analytic Hierarchy Process (AHP) was first proposed by American scholar Saaty in 1971 and is a decision-making method that combines qualitative and quantitative analysis. This method has a scientific decision-making structure and systematic nature, which can effectively assist process personnel in making decisions. The Technique for order of preference by similarity to ideal solution (TOPSIS) is often used in multi-objective decision-making manufacturing processes, allowing for the comparison of the advantages and disadvantages of various solutions to obtain the optimal solution. The TOPSIS analysis method is a multi-attribute decision-making technique. The basic concept of this method is that the selected alternative should have the shortest distance to the positive ideal solution and the farthest distance from the negative ideal solution62. In the TOPSIS analysis method, the schemes of the evaluation objects are converted into a matrix of attribute values, with each row representing an evaluation object and each column representing an attribute. By calculating the distance between each scheme and the positive and negative ideal solutions, the degree of superiority of each scheme is evaluated, and the optimal scheme is selected. Due to its strong objectivity and operability, this method is widely used in the analysis of corporate competitiveness. However, because the TOPSIS analysis method cannot determine the weights of each evaluation index, weights need to be assigned before evaluation. Therefore, in this paper, the two methods are combined by introducing the AHP method before the TOPSIS analysis method to determine the weights of each evaluation index, making the evaluation more scientific and effective. The process of the solution evaluation method based on AHP and TOPSIS is shown in (Fig. 6).

In this study, the AHP method is first used to determine weights. A decision expert group \(\:G=\left\{{G}_{1},{G}_{2},\dots\:,{G}_{n}\right\}\) composed of \(\:N\) experts evaluate each evaluation index. According to Table 2, the experts compare the \(\:n\) evaluation indexes pairwise to establish a judgment matrix. By applying the judgment matrix, the weight vector is obtained, and the weight of each evaluation index is calculated.

To ensure data validity, the weight calculation results need to pass consistency testing, which is calculated using Formula (4).

In the formula, \({C_I}\) represents the consistency index, \({R_I}\) represents the random consistency index, with values shown in (Table 3); \({C_R}\)represents the consistency ratio. When \({C_R}\) = 0, it indicates perfect consistency; when \({C_R}\) is close to 0, it indicates satisfactory consistency; as increases, the level of inconsistency becomes more severe. When \({C_R}\) ≤ 0.1, the judgment matrix is considered to have passed the consistency check, and the weights of the evaluation indicators are deemed to be acceptable.

Next, the TOPSIS analysis method is used for scheme evaluation. Let there be M evaluation schemes, forming the scheme set \(\:P=\{{P}_{1},{P}_{2},\dots\:,{P}_{m}\}\); and N evaluation criteria, forming the criteria set \(\:I=\{{I}_{1},{I}_{2},\dots\:,{I}_{n}\}\). The evaluation criteria feature matrix is63

Where, in Formula (5), \({a_{ij}}\) represents the score of the j-th evaluation index in the i-th alternative. Then, after standardizing the evaluation criteria feature matrix \(\:\varvec{A}\), the standardized matrix \(\:{\varvec{B}}_{ij}\) is obtained.

After weighting, the weighted normalized matrix \(\:{\varvec{Z}}_{ij}\) is obtained:

Next, determine the positive and negative ideal solutions by letting:

The positive ideal solution is obtained as:

The negative ideal solution is obtained as:

Then, the distances of each solution from the positive and negative ideal solutions are calculated using formulas (12) and (13)64, respectively:

Finally, the evaluation score for each solution is calculated using formula (14):

Solutions are ranked based on their evaluation scores \(\:{S}_{i}\). A higher score indicates that the solution better meets the needs of the process personnel, whereas a lower score indicates less satisfaction. The solution with the highest evaluation score is selected as the final solution. After selecting the highest-scoring solution through the evaluation method, further experimental validation is conducted. Experimental simulations are used to analyze the results and determine the feasibility of the solution. If the experimental validation shows that the solution does not meet the product manufacturing requirements, the solution is iteratively redesigned, and the problem is redefined or re-solved. After obtaining the revised solution, it is validated again through experiments to determine its feasibility. If experimental validation meets the requirements, the solution is confirmed as the final one.

Case study

The problem-driven product manufacturing process innovation strategy model proposed in this study will be used to address relevant issues in the manufacturing process of gas turbine blades. It will guide process personnel to innovate the manufacturing equipment and manufacturing process content involved in the blade production manufacturing process, thereby achieving manufacturing process innovation, improving the manufacturing efficiency of gas turbine blades, and reducing casting costs.

Gas turbine blade machining process problem identification

Background analysis and identification of types of opportunities

The gas turbine is a thermal engine widely used in aviation, power generation, marine, and petrochemical fields. It has features such as high-power density, relatively low carbon emissions, quick startup, and the ability to burn environmentally friendly fuels. The operational efficiency of a gas turbine depends on the manufacturing quality of the turbine blades, which are key components of the gas turbine. They operate in harsh environments, enduring high temperatures, high pressure, and enormous centrifugal forces due to high-speed rotation. They are complex in structure, featuring thin walls and cavities, and are typically produced using investment casting. Investment casting is a special precision casting technology for near-net-shape metal forming with minimal (or no) subsequent machining. Its main processes can be divided into wax pattern preparation, shell preparation, casting pouring, and post-treatment stages65. These can be further subdivided into wax pattern pressing, assembly and storage, slurry dipping and sand coating, shell drying, dewaxing and firing, alloy melting and pouring, hot isostatic pressing of castings, and heat treatment processes, as shown in (Fig. 7).

As the investment casting process progresses, dimensional deviations in multiple production steps continue to accumulate and propagate, leading to continuous changes in component dimensions. This results in a significant difference between the final casting dimensions and the initial design dimensions. The changes in dimensions during the investment casting process are shown in (Fig. 8)66. The preparation of wax patterns, as the starting point of the investment casting process, directly determines the dimensional shape of the shell. Therefore, the quality of the wax pattern has a major impact on the dimensional accuracy of the casting. Obtaining high-precision wax patterns is a prerequisite for producing high-quality investment castings.

Dimensions in the investment casting process66.

Through the analysis of the investment casting process for gas turbine blades, opportunity identification by process personnel reveals that the most critical component affecting gas turbines is the turbine blade. The key to the turbine blade lies in the wax pattern forming stage in the investment casting process, indicating that controlling wax pattern deformation of the turbine blade is crucial. Further analysis of the wax pattern deformation problem in turbine blades shows that due to the complex shape of the turbine blades, during the pressing and cooling process, the wax pattern undergoes deformation due to non-uniform shrinkage. This directly affects the forming accuracy of the blade wax pattern, resulting in dimensional deviations and scrap. Through background analysis, industry status surveys, and analysis of the turbine blade manufacturing process, process personnel understand the current problems and propose improvements to related manufacturing equipment by reducing the non-uniform shrinkage of turbine blades to control wax pattern deformation. This is classified as a personnel-based opportunity.

Element construction of wax mold deformation problem for turbine blades

Through the above process, the classification of opportunity types can be achieved, and then the problem can be analyzed using the corresponding problem analysis methods for each opportunity type, constructing problem elements. In this case, the opportunity type is a personnel-based opportunity. Based on the method of constructing problem elements in Sect. 4.1, personnel-based opportunities are mainly analyzed using the causal chain analysis method. A causal chain is a series of logically cause-and-effect linked problems and reasons, serving as an analytical tool for comprehensively identifying the shortcomings of an engineering system. Through multiple searches for reasons, other elements acting behind the identified reasons may be discovered until the limits of fields such as physics, chemistry, biology, or geometry are reached. Through causal chain analysis, the root cause of the problem can be identified, ultimately recognizing the key defects of the engineering system being analyzed.

From the analysis in the previous section, the initial problem is identified as the deformation of the turbine blade wax mold. The steps to establish the causal chain are as follows:

-

(1)

The direct causes of the initial problem mainly include three factors: poor properties of the turbine blade wax mold raw materials, wax mold tooling, and unreasonable wax injection process parameters.

-

(2)

The direct causes of poor wax material properties include a high thermal expansion coefficient, poor stability, and low or high viscoelasticity of the wax material.

-

(3)

The causes of unreasonable wax mold tooling are high structural complexity and poor surface roughness of the mold.

-

(4)

The wax mold manufacturing process parameters are mainly related to wax injection temperature, wax injection pressure, wax injection speed, and holding time.

-

(5)

The thermal expansion coefficient and viscoelasticity are simultaneously affected by the chemical composition and temperature of the wax mold raw materials.

-

(6)

The reason for high structural complexity is the unreasonable mold design, leading to uneven stress during cooling and different shrinkage rates at various parts, causing wax mold deformation.

-

(7)

Surface roughness is due to uneven coating of the mold surface structure, affecting the quality of wax mold formation.

The final causal chain analysis diagram is shown in (Fig. 9).

Through causal chain analysis, the problem elements in the turbine blade wax mold deformation process are constructed, as shown in (Table 4).

Based on the content in Table 4, a problem set \(\:{S}_{deformation}=\{{PE}_{1},{PE}_{2},{PE}_{3}\}\) can be formed for turbine blade wax mold deformation, where \(\:{PE}_{1}\) refers to Problem 1, \(\:{PE}_{2}\) refers to Problem 2, and \(\:{PE}_{3}\) refers to Problem 3.

Turbine blade problem element set oriented problem solving

The problem elements related to the deformation of the turbine blade wax mold have been identified through the problem discovery process. Next, solutions will be generated based on the strategic problem-solving model developed in this study. In this study, the innovation strategy for problem-solving is determined through the mapping relationship between the opportunity types in the problem elements and the problem types in the problem-solving strategies. From the above problem discovery analysis, it is determined that the turbine blade issue in gas turbines is a personnel-based opportunity, with the corresponding problem type being an improvement problem. Thus, the problem-solving strategy is determined to be improvement innovation strategies, primarily using TRIZ and creative template methods. In the previous section, the problem discovery process identified a set of problems related to the deformation of turbine blade wax molds, including three specific issues. Since \(\:{PE}_{1}\) and \(\:{PE}_{3}\) are inclined towards material and manufacturing process design, \(\:{PE}_{2}\) is used as an example for problem-solving in this study to more directly reflect structural design, resulting in a set of solutions.

In this study, problem-solving is primarily based on the TRIZ method within the improvement innovation strategies. TRIZ is a systematic innovation method, standing for “theory of inventive problem solving,” and it originated in the Soviet Union. It mainly includes the Ideal final result (IFR), substance-field analysis, conflict matrix, and inventive principles. The most classic and commonly used is the contradiction conflict resolution theory, where a technical conflict is defined as the contradiction between achieving two or more goals when solving a problem. Therefore, after extensive research, Altshuller summarized 39 universal technical parameters and 40 inventive principles, establishing corresponding relationships between them. Conflicts in the system can be mapped to the conflict matrix, and the inventive principles can then guide engineers in problem-solving.

After analyzing Problem 2, it was found that the main obstacle is the complexity of the wax mold structure, meaning that the shape of the mold causes uneven stress on the wax mold during the cooling process. Different shrinkage coefficients at different positions lead to wax mold deformation. Additionally, changes in the shape of the wax mold affect the overall system stability, thus this process is categorized as a technical conflict. The problem is concretized based on the technical conflict resolution process, and the detailed analysis of this problem is shown in the block diagram in (Fig. 10).

The problem discovery steps have been completed in the previous sections. Next, we define the technical conflict by converting \(\:{PE}_{2}\) into the TRIZ problem model—technical conflict. In this case, the technical conflict arises from improving the shape of the mold, which may lead to a reduction in system stability. Therefore, this conflict situation is summarized into two parameters from the 39 standard technical parameters: the parameter to be improved is shape; the parameter that deteriorates is stability. Then, we consult the conflict matrix to find the recommended inventive principles. The conflict matrix is shown in (Table 5).

By consulting the conflict matrix, it is recommended by TRIZ theory to use inventive principles 33, 1, 18, and 4. Table 6 provides a detailed introduction to these inventive principles.

The process personnel then use the inventive principles recommended by TRIZ theory for creative brainstorming, leading to the development of initial solutions. These solutions focus on refining specific processes within the original manufacturing plan to achieve innovation in the manufacturing process design, as shown in (Table 7).

Solution determination and validation

Solution definition

As shown in Table 7, the process engineers proposed four initial solutions based on TRIZ inventive principles. To evaluate these four solutions comprehensively, a scheme evaluation using AHP and TOPSIS methods will be conducted. Based on research on scheme evaluation indicators67,68,69,and considering the specific application of this case, this study includes six evaluation criteria: design efficiency, manufacturability, cost, production efficiency, reliability and stability, and safety. The specific meanings of each criterion are shown in (Table 8).

First, the AHP method was used to determine the weights of each evaluation indicator. In this study, five relevant manufacturing process experts were selected to perform pairwise comparisons of the evaluation indicators using the scales provided in (Table 2). The scores obtained were used to calculate the weight of each indicator, as shown in (Table 9), using the relevant formula (3). Consistent with the consistency checking method described, the weights of each evaluation indicator were tested. According to formula (4), CR = 0.0437 < 0.1, indicating that the weights of the evaluation indicators meet the requirements.

Based on the weights of each evaluation indicator, a weighted matrix was constructed. In this study, to more accurately evaluate the solutions, ten experienced manufacturing process experts were selected to score each indicator for the four proposed solutions. The scoring range was from 1 to 10, as detailed in (Table 10).

After scoring, the arithmetic mean is taken as the final value of each evaluation indicator, as shown in (Table 11).

According to formula (6), the scores are normalized to obtain the standardized matrix as shown in (Table 12).

Using formula (7) and the weights of the evaluation criteria, the weighted standardized matrix is obtained as shown in (Table 13).

Finally, using Eq. (14), the distances from each alternative to the positive and negative ideal solutions and the evaluation scores are calculated. The results are shown in (Table 14).

The larger the evaluation score Si, the closer the alternative is to the positive ideal solution, indicating a better alternative. As shown in Table 14, the evaluation score of Alternative 2 is significantly higher than that of the other alternatives, thus Alternative 2 is selected.

Solution validation

This section focuses on conducting relevant experiments to verify whether the results of the selected plan meet the requirements. Construct a model of gas turbine blade wax mold, as shown in (Fig. 11), and obtain the blade wax mold through wax mold preparation process.

Before optimization, the deformation of the turbine blade wax pattern is shown in (Fig. 12). Due to aerodynamic design requirements, there is a significant difference in wall thickness of heavy-duty gas turbine blades. The relatively thick sections at the root and mid-span of the blade cause uneven cooling of the wax pattern, resulting in substantial shrinkage differences across various parts of the blade. Figure 12 shows that the deformation parameters are larger in the middle section.

Turbine blade wax mold design is carried out based on Solution 2, and a cold wax core is added inside the wax mold. The schematic diagram illustrating the positions of the gas turbine blade wax pattern and the cold wax core model is shown in (Fig. 13a), with the cold wax core location highlighted in the red box. The physical representations of the blade wax pattern and the cold wax core are presented in (Fig. 13b), where the left side depicts the wax pattern of the gas turbine blade, and the right side displays the cold wax core.

Experimental verification of Solution 2 is carried out, and the dimensional inspection results of the turbine blade after the addition of the cold wax core are shown in (Fig. 14).

Figure 14 shows that, compared to the results without using a cold wax core, the deformation at the leaf back and leaf bowl positions has significantly reduced, effectively minimizing the deformation in the thicker parts of the blade and demonstrating better resistance to deformation. However, deformation of the wax pattern during the shrinkage process is still inevitable, so controlling deformation during the cooling stage after wax pattern pressing is also crucial.

After analysis, it is necessary to redefine the problem and then proceed with problem solving and solution determination. As some steps in the iterative design process are similar to previous steps, they are not detailed here. Problem analysis of deformation during the cooling process after wax pattern pressing reveals that there is limited research on controlling wax pattern deformation during cooling. Therefore, it is identified as a novel opportunity. For novel opportunities, the problem elements are determined through methods such as brainstorming and trend analysis by process personnel, resulting in the problem \(\:PE=\{PT,KC,OT,Ob\}\)= {small deformation during the cooling process of the turbine blade wax pattern, none, novel opportunity, as the wax material itself undergoes shrinkage and deformation during cooling}.

Next, the problem will be solved based on the strategic problem-solving model proposed in this study. For novel opportunities, which correspond to integration problems, the solution involves using combinatorial innovation strategies. The combinatorial innovation strategies include analogy and combination methods. Since there were no prior solutions to the problem, most solutions need to be transferred from other fields or innovatively combined with existing methods to obtain a final solution. Using combinatorial innovation strategies, the following initial solutions are obtained, as shown in (Table 15).

Next, based on the evaluation method proposed in this study, the schemes are assessed. Since the steps are like those described above, detailed explanation is omitted here. The evaluation method indicates that solution 3 has a higher score, so solution 3 is selected for experimental verification.

Solution 3 primarily involves adding a shaping fixture to the original manufacturing process. This fixture, also known as a molding tool, is designed according to the shape of the turbine blade wax mold. It provides uniform support and fixation to ensure the stability of the wax mold’s shape and dimensions. First, design a shaping frame to completely enclose the key areas of the wax mold. The inner surface of the frame should closely match the shape of the wax mold. Second, add support ribs within the shaping frame to provide additional rigidity and support, especially for thicker sections. Finally, design fixing fixtures (such as clamps or bolts) to secure the wax mold within the shaping frame.

The final straightening tooling for the wax mold of the turbine blade is shown in (Fig. 15a). By adopting the wax mold straightening tooling, appropriate force is applied to the deformed part of the wax mold to control its deformation, and the dimensional inspection results are shown in (Fig. 15b), which can be compared with Fig. 14 to see that the deformation of the wax mold of the turbine blade is reduced, and it can be concluded that the deformation of the wax mold of the turbine blade can be effectively controlled by adopting the straightening tooling and the dimensions of the wax mold can be improved.

When enterprise manufacturing process personnel encounter similar problems, they usually rely on their own experience and intuition to choose a certain method to solve the problem. Although this experience-based decision-making method can produce certain effects in some cases, it often lacks systematic and scientific nature, which can easily lead to inefficient problem solving. Especially in the face of complex and innovative product processing and manufacturing processes, experience-oriented solution methods may not be able to effectively adapt to the emergence of new problems, thus affecting the overall production efficiency and innovation process. The problem-driven innovation design strategy model for product manufacturing process proposed in this study is designed to address the limitations of traditional methods in dealing with emerging problems. Different from the traditional empiricist approach, the methodology of this study is based on a systematic process that emphasizes starting from the essence of the problem and helps machining process designers to identify and solve problems more efficiently through clear steps and logic. It not only improves the efficiency of problem solving, but also provides strong support for the implementation of innovation.

Conclusions

In this study, we proposed a problem-driven product manufacturing process innovation strategy model, which mainly consists of three parts: the first part is the problem discovery section, aimed at identifying problems in the product manufacturing process and constructing problem elements; the second part is the problem-solving section, which focuses on solving the identified problems to generate solutions with innovation potential; the third part is the solution determination section, which aims to identify the optimal solution from the solution set. In summary, the main contributions of this paper are as follows. Firstly, a process for constructing problem elements is proposed, which integrates the product manufacturing process into the innovation opportunity identification process. By using problem analysis methods, issues within different types of innovation opportunities are identified, and problem elements are constructed, laying the foundation for subsequent problem-solving. Secondly, an innovation strategy-based problem-solving method is proposed, which involves strategic guidance for specific problems, assisting process personnel in generating manufacturing process innovation solutions and achieving innovation in the product manufacturing process. Finally, a solution evaluation method based on AHP and TOPSIS is proposed. The AHP method is introduced before the TOPSIS analysis to determine the weights of evaluation criteria, ensuring a more scientific and effective evaluation.

This study also has some limitations and requires further research in the future. Firstly, the complexity and uniqueness of processes in different industries and special product types may challenge the applicability of the proposed model. Secondly, the model is partly dependent on the subjective judgment of the designers involved, and may be subject to some bias and instability. Therefore, future research could focus on the following areas: (1) further expanding the applicability of the model by customizing improvements for different industries and special product types, while comparing it to previously used methods to demonstrate the validity of the approach; (2) studying more objective data and indicators to reduce the impact of subjective factors on the model, while introducing relevant computational methods to improve efficiency.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Cai, Y. & Wu, G. The U-shaped impact of export quality on firms’ innovation output: empirical evidence from China. PLoS One 19, e0298358 (2024).

Wen, X. et al. The key technologies of machining process design: A review. Int. J. Adv. Manuf. Technol. 120, 2903–2921 (2022).

Fitoussi, J. et al. Investigation of manufacturing process effects on microstructure and fatigue prediction in composite automotive tailgate design. Int. J. Adv. Manuf. Technol. 130, 4295–4310 (2024).

Liang, J. et al. A knowledge graph-based approach to modeling & representation for machining process design intent. Adv. Eng. Inf. 62, 102645 (2024).

Hoefer, M. J. & Frank, M. C. Automated manufacturing process selection during conceptual design. J. Mech. Des. 140, 31701 (2018).

Tan, R. TRlZ and Applications: the Process and Methods of Technological Innovation (Higher Education Press, 2010).

Schumpeter, J. A. & Swedberg, R. The Theory of Economic Development (Routledge, 2021).

Avşar, A. Z. & Grogan, P. T. Identification of design strategies and their effects on performance outcomes in pair parameter design tasks. J. Mech. Des. 146, (2024).

Runco, M. A. & Okuda, S. M. Problem discovery, divergent thinking, and the creative process. J. Youth Adolesc. 17, 211–220 (1988).

Wu, Y. & Weng, K. Using an analogical thinking model as an instructional tool to improve student cognitive ability in architecture design learning process. Int. J. Technol. Des. Educ. 23, 1017–1035 (2013).

Wilson, C. Brainstorming and Beyond: A User-Centered Design Method (Newnes, 2013).

Duflou, J. R. & Hondt, D. Applying TRIZ for systematic manufacturing process innovation: the single point incremental forming case. Proc. Eng. 9, 528–537 (2011).

Ferrer, J. B., Negny, S., Robles, G. C. & Le Lann, J. M. Eco-innovative design method for process engineering. Comput. Chem. Eng. 45, 137–151 (2012).

Rantanen, K., Domb, E. & Simplified, T. New problem solving applications for engineers and manufacturing professionals. (Times Mirror, 2002).

Suh, N. P. Axiomatic design theory for systems. Res. Eng. Des. 10, 189–209 (1998).

Mazursky, D. Creativity in Product Innovation (Cambridge University Press, 2002).

Gero, J. S. & Kannengiesser, U. The situated function–behaviour–structure framework. Des. Stud. 25, 373–391 (2004).

Chen, L. et al. Towards controllable generative design: A conceptual design generation approach leveraging the FBS ontology and large Language models. J. Mech. Des. 1–40 (2024).

Jin, X., Dong, H., Evans, M. & Yao, A. Inspirational stimuli to support creative ideation for the design of AI-powered products. J. Mech. Des. 1–31 (2024).

Yun, H., Kim, E., Kim, D. M., Park, H. W. & Jun, M. B. Machine learning for object recognition in manufacturing applications. Int. J. Precis Eng. Manuf. 24, 683–712 (2023).

Ives, S. W. The Creative Vision: A Longitudinal Study of Problem Finding in Art (JSTOR, 1977).

Greeno, J. G. Natures of problem-solving abilities. (1978).

Jay, E. S. & Perkins, D. N. Problem finding: the search for mechanism. Creat. Res. Handb. 1, 257–293 (1997).

Hayes, J. R. The Complete Problem Solver (Routledge, 2013).

Holman, D. M. What Am I Supposed To Do? Problem Finding and its Impact on Problem Solving (University of California, 2018).

Abdulla, A. M., Paek, S. H., Cramond, B. & Runco, M. A. Problem finding and creativity: A meta-analytic review. Psychol. Aesthet. Creat. Arts 14, 3 (2020).

Görlich, Y. Development of creative process assessment scale (CPAS). J. Creat. 33, 100042 (2023).

Meister, M., Beßle, J., Cviko, A., Böing, T. & Metternich, J. Manufacturing analytics for problem-solving processes in production. Proc. CIRP 81, 1–6 (2019).

Miranda, E. & Aryuni, M. Mobile-based Telemedicine Application during COVID-19 Pandemic (case Study in Sawah Besar Community Health center) 7–12 (IEEE, 2021).

Waghen, K. & Ouali, M. Interpretable logic tree analysis: A data-driven fault tree methodology for causality analysis. Expert Syst. Appl. 136, 376–391 (2019).

Bernard, A. & Varaprasad, G. Fishbone Diagram Analysis for Assessing Ergonomic Risks in Onshore Oil Rig Operations 1363–1372 (Springer, 2021).

Mei, J., Feng, W. & Liang, Z. Improved design of LNG marine loading arm Docking method based on TRIZ theory. Appl. Sci. 13, 4525 (2023).

Agre, G. P. The concept of problem. Educ. Stud. 13, 121–142 (1982).

Paton, B. & Dorst, K. Briefing and reframing: A situated practice. Des. Stud. 32, 573–587 (2011).

Li, W., Li, Y., Wang, J. & Liu, X. The process model to aid innovation of products conceptual design. Expert Syst. Appl. 37, 3574–3587 (2010).

Göçmen, Ö. & Coşkun, H. The effects of the six thinking hats and speed on creativity in brainstorming. Think. Skills Creat. 31, 284–295 (2019).

Ilevbare, I. M., Probert, D. & Phaal, R. A review of Triz, and its benefits and challenges in practice. Technovation 33, 30–37 (2013).

Suh, N. P. The principles of design. (1990).

Cheong, H., Li, W., Cheung, A., Nogueira, A. & Iorio, F. Automated extraction of function knowledge from text. J. Mech. Des. 139, 111407 (2017).

Shi, F., Chen, L., Han, J. & Childs, P. A data-driven text mining and semantic network analysis for design information retrieval. J. Mech. Des. 139, 111402 (2017).

Sarica, S., Luo, J., Wood, K. L. & TechNet Technology semantic network based on patent data. Expert Syst. Appl. 142, 112995 (2020).

Zhao, Y., Wang, T., Zhang, C., Hamat, B. & Pang, L. L. L. Research on the application of AHP-FAST-FBS in the design of home entrance disinfection devices in the post-pandemic era. Sci. Rep. 14, 20550 (2024).

Lee, C., Tsang, Y. P., Chong, W. W., Au, Y. S. & Liang, J. Y. Achieving eco-innovative smart glass design with the integration of opinion mining, QFD and TRIZ. Sci. Rep. 14, 9822 (2024).

Rong, H., Liu, W., Li, J. & Zhou, Z. Product innovation design process combined Kano and TRIZ with AD: case study. PLoS One 19, e0296980 (2024).

Xue, H. et al. Research on intelligent design of debugging processes for complex electronic products based on knowledge graphs. J. Intell. Manuf. 1–20 (2025).

Chand, M. & Ravi, C. A State-of-the-art literature survey on artificial intelligence techniques for disassembly sequence planning. CIRP J. Manuf. Sci. Technol. 41, 292–310 (2023).

Bedeoui, A., Ben Hadj, R., Hammadi, M. & Aifaoui, N. Tool workspace consideration for assembly plan generation. Assem Autom. 41, 612–625 (2021).

Zhang, J. et al. A multi-objective search-based approach for position and orientation deviations in assemblies with multiple non-ideal surfaces. Adv. Eng. Softw. 199, 103820 (2025).

Belhadj, I., Khemili, I., Trigui, M. & Aifaoui, N. Time computing technique for wear parts dismantling. Int. J. Adv. Manuf. Technol. 103, 3513–3527 (2019).

Belhadj, I., Hammadi, M. & Aifaoui, N. Parallel disassembly approach with recycling rate calculation of industrial products. Int. J. Adv. Manuf. Technol. 113, 2969–2984 (2021).

Chu, M. & Chen, W. Multi-manned disassembly line balancing problems for retired power batteries based on hyper-heuristic reinforcement. Comput. Ind. Eng. 194, 110400 (2024).

Antonijević, R. Cognitive activities in solving mathematical tasks: the role of a cognitive obstacle. Eurasia J. Math. Sci. Technol. Educ. 12, 2503–2515 (2016).

Li, Y., Zhao, W. & Yan, Q. A process-based approach for computer aided product design. Comput. Integr. Manuf. Syst. 9, 0 (2003).

Chen, L. & Zhao, W. The product design of sanitation machinery based on innovative approaches. Mach. Des. Manuf. 253–255 (2010).

Li, Y. & Li, W. Method To Creative Design (Science, 2013).

Santos, V. M., Amaral, L., Mamede, H. S. & Gonçalves, R. Creativity in the Information Systems Planning Process 243–261 (IGI Global, 2016).

Howard, T. J., Culley, S. J. & Dekoninck, E. Information as an input into the creative process. (2006).

Pahl, G. & Beitz, W. Engineering Design: A Systematic Approach (Springer Science & Business Media, 2013).

Ulrich, K. T. & Eppinger, S. D. Product Design and Development (McGraw-hill, 2016).

Howard, T. J., Culley, S. & Dekoninck, E. A. Reuse of ideas and concepts for creative stimuli in engineering design. J. Eng. Des. 22, 565–581 (2011).

Wan, Y. Research on Process Programming and Method Application Based on Cognitive Mechanism for Product Conceptual Design (Sichuan University, 2014).

Triantaphyllou, E. & Triantaphyllou, E. Multi-Criteria Decision Making Methods (Springer, 2000).

De Montis, A., De Toro, P., Droste-Franke, B., Omann, I. & Stagl, S. Assessing the Quality of Different MCDA Methods115–149 (Routledge, 2004).

Malczewski, J. GIS and Multicriteria Decision Analysis (John Wiley & Sons, Inc, 1999).

Tamta, K. & Karunakar, D. B. Development of hybrid pattern material for investment casting process: an experimental investigation on improvement in pattern characteristics. Mater. Manuf. Process. 36, 744–751 (2021).

Cannell, N. & Sabau, A. S. Predicting Pattern Tooling and Casting Dimensions for Investment Casting, Phase II (Edison Materials Technology Center (EMTEC), 2005).

Liu, C., Ramirez-Serrano, A. & Yin, G. Customer-driven product design and evaluation method for collaborative design environments. J. Intell. Manuf. 22, 751–764 (2011).

Zhu, X., Niu, D., Wang, X., Wang, F. & Jia, M. Comprehensive energy saving evaluation of circulating cooling water system based on combination weighting method. Appl. Therm. Eng. 157, 113735 (2019).

Mohebbi, A., Achiche, S. & Baron, L. Multi-criteria fuzzy decision support for conceptual evaluation in design of mechatronic systems: A quadrotor design case study. Res. Eng. Des. 29, 329–349 (2018).

Acknowledgements

Thanks to all the researchers who provided advice and support during the writing process of this article. We would like to acknowledge the National Natural Science Foundation of China (52175241), Sichuan Science and Technology Program, China (2022ZDZX0037, 2021ZDZX0003 and 2021ZDZX0005) for funding this work. We also extend heartfelt thanks to the proof-readers, editors and reviewers who have helped us.

Author information

Authors and Affiliations

Contributions

Q.Z.: Conceptualization, Writing—original draft, Methodology. H.W.: Formal analysis. X.G.: Conceptualization, Writing—review & editing. Q.Z.: Investigation. H.Z.: Resources. X.L.: Supervision. K.Z.: Funding acquisition, Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics declarations

This study does not involve any clinical, animal, human tissue, or biological sample-related experimental research. This study does not involve discussions related to racial identities, personal religious beliefs, political views, financial information, sexual orientations, or any other personal privacy topics. All data and information were collected and recorded anonymously, without any actions that would infringe upon the privacy, dignity, health, or human rights of human participants. We confirm that all methods and procedures in this article were performed in accordance with the relevant guidelines and regulations, which comply with ethical regulatory requirements.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, Q., Wang, H., Guo, X. et al. Problem driven innovation design strategies research for product manufacturing process. Sci Rep 15, 14061 (2025). https://doi.org/10.1038/s41598-025-99097-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99097-3