Abstract

The particle-matrix interfacial interaction is studied through the viscoelastic properties in magnetorheological elastomers, comprising 25 wt% of electrolyte iron particles with (MRE25G) and without (MRE25) grease as an additive. The cross-link density (CLD) and electron microscopy images of the MRE25G sample show a decrease in particle-matrix interface interaction compared to MRE25. However, the magnetisation curve remains identical for both MRE25 and MRE25G. The storage (G’) and loss modulus (G’’) in MRE25 exhibit higher values than that of pure elastomer (MRE0) and MRE25G. The decrement in G’’ value in MRE25G suggests decreased interfacial interaction between particle-matrix and the change in the LVE regime in MRE25G. The increased critical strain amplitude by 2 to 2.5 times upon adding grease indicates a higher re-agglomeration rate than de-agglomeration. In zero magnetic field, the cohesive energy increases nearly five times for MRE25G compared to MRE25, demonstrating increased structure stability with strain. The increase in particle-particle interaction due to the reduction in particle-matrix friction has also enhanced the magnetic field-induced effect, the MR effect, by 30% at the highest magnetic field in MRE25G. The creep-recovery results suggest that the elastic stress (EM) remains identical to the magnetic field for MRE25 and MRE25G. At the same time, the Maxwell viscosity for MRE25G is higher than MRE25. Thus, the interface interaction exhibits a higher impact in zero fields and nearly contributes the same to the field.

Similar content being viewed by others

Introduction

Magnetorheological elastomer (MRE)- a particle-filled polymer-based composite with tunable visco-elastic properties when exposed to the external magnetic field (B)- is a subject of interest because of its vast application potential1,2,3,4,5,6,7,8,9,10. Numerous review articles and papers were published on this innovative material11,12,13,14,15. However, the industrialisation of these materials is yet to be realised. The limitation is that each application requires different viscoelastic properties. For example, the primary requirement in a seismic application is to possess a high storage modulus even at high shear strain amplitude. In contrast, a damper should have a high storage modulus at a small strain amplitude. Thus, a good MRE must possess high storage and low loss modulus with a high tunable magnetic field-induced range.

In MRE, magnetic particles and polymer matrix are the core components; hence, (i) interfacial interaction, i.e. particle-matrix, (ii) magnetic properties of dispersed particles, and (c) particle concentration are vital factors that influence the end properties of MRE. For example, the interfacial interaction defines the mechanical properties of the MRE, such as the shear stress (complex modulus). The magneto-induced modulus depends on the magnetic properties of dispersed particles in a matrix and the particle volume fraction, while maximum particle loading depends on the morphology of particles. These permutation combinations make the synthesis of MRE for a given application a challenging task. Many research approaches addressed these issues11,12,13,14,15.

In earlier studies16,17,18,19,20,21,22,23, it was reported that altering the shape of the dispersed magnetic particles (non-spherical shaped) improves the interfacial interaction between the particles and matrix. This improved interaction can enhance the storage modulus (elastic properties) values at a lower loading of particles. The other way to enhance the particle-matrix interaction is to surface coat the particles to improve the cross-link density and, thus, storage modulus24. In contrast, when it comes to an irregularly shaped particle dispersion in a polymer matrix, the additional factor influences the interface between the particle and matrix and between the particles (which increases the friction between the particles). The improved particle-matrix interaction (due to the large surface area available) inhabits the rotation of particles under the influence of the magnetic field; thus, magnetic field-induced enhancement (defined as MR-effect) in storage modulus decreases compared to spherical particles (point contact) dispersion in elastomers (at same volume fraction and magnetic field). The above two competitive processes must be optimised to retain the MRE properties for given applications. The magneto-field-induced effects are crucial for MR elastomers to function as smart elastomers.

Recently, our group reported25,26 viscoelastic properties of electrolyte iron particles–based MRE having non-spherical-shaped particles. The choice of EIP over carbonyl particles (CIP-spherical shaped) was based on the higher value of the reinforcing factor of EIP to CIP, which signifies adequate polymer–filler interaction27. The later interaction leads to a higher storage modulus at the small magnetic field because of the low demagnetising factor. It was demonstrated that by varying the filler concentration, the non-spherical particles-based MRE exhibits a higher storage modulus than spherical particles-based MRE28,29. The increased storage modulus value was attributed to the higher particle-matrix interaction and friction between the particles. The experimental results were compared with the theoretical models developed to explain strain sweep results30. The MR-effect observed in EIP-based MRE was higher (at the same volume fraction level) than CIP-based MRE at a smaller magnetic field, but it saturates faster. The limitation of loading higher than a certain volume fraction (due to particle shape) restricts the MR-effect enhancement with concentration.

The novel contribution of the present work is to improve the MR-effect or field-induced magnetic response in EIP-based MRE by reducing the particle-matrix interface interaction without compromising the elastic limit operation under strain deformation (i.e., linear viscoelastic regime- LVE) at a given magnetic particle volume fraction. One must avoid particle-particle friction interference to understand the particle-matrix interface’s role in the MR effect. For this, the volume fraction of the particle was reduced, with an anticipation that the increased particle-particle distance would reduce the particle-particle friction; thus, only particle-matrix interfacial interaction contribution can be studied.

To achieve the goal, we prepared the polymer-magnetic particle composite in the present work and investigated the contribution of particle-matrix interfacial interaction on viscoelastic properties using magnetorheometry techniques. The magnetic particle composite (MRE) was synthesised with and without an interface modifier, and the magneto-rheometry results were compared to understand the influence of particle-matrix interaction on viscoelastic properties. The relevant models were explored and modified to explain the observed viscoelastic properties.

Experimental

MRE preparation

The electrolyte iron particles (EIP) were procured from Industrial Metal Powder Pune, India, having an average size of d50, 7–8 μm, and the amount of α-iron is 97%. A liquid silicon rubber RTV-1010 was procured (Aditya Silicone, Delhi), along with a curing agent. A predefined weight of electrolyte iron particles (25% by weight) and liquid rubber were homogenised and kept at 300 rpm for four hours to disperse the particles and degas under the vacuum. Later, the curing agent was added, stirred for another 5 min, poured into the mould, degassed for 3 minutes, and cured without a magnetic field. Thus, an isotropic sample of MRE25 was obtained of 20 mm diameter and 1.01 ± 0.02 mm thick. The density of MRE is 1520 kg/m3. Similarly, Silicon grease (interface modifier) was added (~ 2% by weight- the choice is based on the best results of storage modulus obtained, and it is particle concentration-dependent) in Si-oil and stirred for a few hours till the grease was mixed in the oil. In this modified carrier, 25% by weight EIP particles were added, and using an earlier procedure, MRE was obtained and designated as MRE25G. The density of MRE25G is 1490 kg/m3. A pure Si-rubber (MRE0) was also prepared for study. The detailed composition and properties of MRE25 and MRE25G are given in Table 1.

Measurements

To obtain the cross-link density (CLD) in MRE, the swelling measurement technique31,32, and to calculate the CLD values, the Flory-Rehner32 equation was used. The CLD values were obtained by taking the average of three sets. The X-ray diffraction (XRD) patterns were recorded using Bruker powder diffractometer D2-Phaser system equipped with LYNXEYE detector. The Cu-Kα radiation was used as an X-ray source. The XRD pattern was recorded in the range of 2θ of 10–700. Particle morphology was investigated using scanning electron microscopy images recorded by the Jeol SEM 6021LA model. The quasi-static magnetic properties were measured for MRE using a vibrating sample magnetometer (VSM) (Lakeshore Model 7404, USA). The instrument was calibrated using NIST-approved Ni-standard. All the data were recorded at 300 K, and the magnetic field was varied from − 1 T to 1T.

The rotational rheometer, Physica MCR 301 (Anton Paar, Graz, Austria), was used to measure the viscoelastic properties of MREs. A parallel plate measuring system (PP20) with a diameter of 20 mm was used. The rheometer is attached with a magneto-cell (Physica MRD 180/1T) to perform magnetorheological measurements. As defined earlier33 for magnetorheological fluid, the reference value of magnetic flux density differs from the weighted average flux density by roughly 13%. The magnetic flux density changed by varying the current (I) in the coil from 0 A to 4 A (corresponds to zero to 0.64 T). The current control is much easier; therefore, the current varies, and the corresponding magnetic field intensity was calculated.

The dynamic moduli (storage and loss moduli) measurements were performed in the dynamic mode with a fixed normal force and varying the torque according to harmonic law. The disked shape sample, with a diameter of 20 mm and thickness of 1.02 mm, was secured between the stationary bottom plate and the moving upper plate connected to the rotor. A 5 N normal force was applied (waited for 120 seconds before the measurement) to avoid any slippage between the measuring walls and the sample surface. The strain amplitude was varied from 0.01 to 10% to avoid wall slip at a larger strain amplitude. The normal force (5 N) applied will produce multi-axial loading on the sample. Therefore, one cannot get an absolute value of the storage modulus. Nevertheless, the interest here is to understand the influence of interfacial interaction on the magnetic field-induced effect. Therefore, the dependency of storage modulus G’, loss modulus G” on the oscillation frequency, strain amplitude, and magnetic field were studied for MRE25 and MRE25G. All rheology measurements were carried out at 300K.

Results and discussion

Characterisation of elastomers

Figure 1a shows the XRD patterns for the MRE25 sample. Two intense peaks at 44.72° and 65.67° corresponded to (110) and (200) planes of a body-centred cubic Fe. The lattice parameter obtained is 0. 2865 nm. The same results were obtained for MRE25G (figure not shown for brevity).

In elastomer, fillers are either reinforcing or non-reinforcing types. The classifications are based on the interaction of fillers with binders. A strong interaction (reinforcing type fillers, for example, surface-active carbon blacks) with binder modifies the elastic properties of materials (rupture strength increases). In contrast, in non-reinforcing type fillers (where the fillers are much larger than molecular spacing), the interaction between the particle and binder is weak, for example, glass beads, magnetic and nonmagnetic particles and various salts. Both fillers influence the elastomer’s cross-link density (i.e., cross-link contents per unit volume), thus visco-elastic properties.

Figure 1b shows the cross-link density of MRE filled with 25 wt% non-spherical shaped electrolyte iron particles in a silicon matrix with and without grease. The CLD decreased 3.6 times for the MRE25G sample compared to MRE25. In MRE, the rubbers bind the particles by physical or chemical bonds via molecular chain segments of the rubber and hydroxyl groups distributed on the surface of the particles. Thus, the particle bonding (in the case of non-reinforcing particles) can be considered secondary cross-link points of the rubber matrix. The interactions between the particle and the matrix depend on the number of cross-link points available. The non-spherical particles will have a higher surface area and more cross-link points, thus creating a high cross-link density. In MRE25, the particle-matrix interaction is higher than spherical particles, resulting in high cross-link density. The addition of an interface modifier, grease, coats the surface of the particles. Thus, the number of secondary cross-link points decreases, which results in a decrease in particle-matrix interface interaction. Thus, there is a decrease in CLD value for MRE25G.

The modified interface influence can also be manifested in the SEM images, amplitude sweep, and creep recovery with magnetic fields.

In MRE, it was reported earlier that the interaction of magnetic particles with the matrix leads to the concept of bound and free rubber. The bound rubber is on the particle-matrix interface, and its elastic properties differ from free rubber. Therefore, when microscopic images were recorded, they exhibited a white layer around the surface. The thickness of this layer defines the degree of interface interaction of the particle with the matrix. A similar effect was observed earlier by Fan et al.34 when SEM images were recorded. Figure 2 shows the SEM images for MRE25 and MRE25G samples. In both cases, the particles are well distributed, and minimum clustering or aggregation of the particles was observed.

The most notable feature is the reduction in the bound rubber in MRE25G (Fig. 2b) than MRE25 (Fig. 2a). The thickness of the bound rubber is lower in the case of MRE25G, which supports the reduction in interface interaction between particle and matrix due to the addition of grease during the curing process. The percentage of the surface modifier is very small, 2% by weight, but its influence is visible in SEM images. The magnetic filler concentration is constant (i.e. 25% by weight). Thus, the magnetic properties must remain the same. However, there may be a slight change in the value of initial magnetic susceptibility.

Figure 3 shows the room temperature (300 K) magnetisation curve for MRE25. The magnetisation curve remains identical for both MRE25 and MRE25-G. The saturation magnetisation (Ms) and initial susceptibility (χi) values obtained fitting (red line in Fig. 3) the Frohlich –Kennelly (FK) law35 to experimental results (Points) are Ms = 85 kA/m and χi = 0.55. The initial susceptibility for MRE25G is 0.53. Thus, the variation is within the experimental error. Considering the particle saturation magnetisation of the 1604 kA/m, the magnetic volume fraction for MREs is 5.3%.

Amplitude sweep measurements

In these experiments, strain amplitude tests with and without a magnetic field were performed at 1 Hz. Figure 4a–c shows the variation of storage and loss modulus with strain amplitude without magnetic field for MRE0, MRE25, and MRE25G, respectively.

Both moduli, storage and loss, exhibit constant values of \(\:{G}_{0}^{{\prime\:}}\) and \(\:{G}_{0}^{{\prime\:}{\prime\:}}\), with \(\:{G}_{0}^{{\prime\:}}\) > \(\:{G}_{0}^{{\prime\:}{\prime\:}}\), till critical strain value \(\:{\gamma\:}_{LVE}\) is reached. The constant modulus region with increasing strain amplitude is linear viscoelastic. The strain amplitude range, where the \(\:{G}^{{\prime\:}}\) value decreases by 5% of \(\:{G}_{0}^{{\prime\:}}\), is considered a linear visco-elastic (LVE) regime. Above the LVE, the \(\:{G}^{{\prime\:}}\) decreases with strain amplitude, while \(\:{G}^{{\prime\:}{\prime\:}}\) shows an increase. These phenomena above the LVE region are the same for MRE0, MRE25 and MRE25G samples.

First, let us consider the linear visco-elastic regime, where both moduli remain constant. The values of \(\:{G}_{0}^{{\prime\:}}\) and \(\:{G}_{0}^{{\prime\:}{\prime\:}}\) in MREs differ, and MRE25 exhibits higher values than MRE0 and MRE25G. The decrease in the storage modulus value is around 19.5% in MRE0, while in MRE25G is 17%, while the loss modulus shows 39% and 31%, respectively, in MRE0 and MRE25G. On the contrary, the critical strain value where the LVE region ends is 0.02, 0.002 and 0.006 for MRE0, MRE25 and MRE25G, respectively (Fig. 4). The observed higher percentage of decrement in \(\:{G}^{{\prime\:}{\prime\:}}\)value in MRE25G compared to MRE25 suggests the decrease in the particle-matrix friction. Thus, the observed behaviour of an increase in the LVE regime and a reduction in loss modulus in MRE25G compared to MRE25 can be explained as follows.

In the present case, the weight fraction of the particle is 25%, corresponding to 5.1% by volume. Thus, the matrix will make major contributions to the moduli. However, the particle shape (a flake shape) creates more cross-link points for cross-link density (CLD). The higher CLD in MRE25 reduces the LVE (Linear visco-elastic) region but increases the storage and loss modulus because of higher particle-matrix friction. In the case of MRE25G, the CLD has been reduced nearly three times. Thus, the particle-matrix friction also reduces, which is reflected in a decrease in loss modulus. In addition, the SEM image shows that bound rubber contribution is more in MRE25, while it is less in MRE25G. The bound rubber elastic strength is lower than free rubber; therefore, in MRE25, the LVE regime is less, but the stiffness creates higher \(\:{G}^{{\prime\:}}\) and \(\:{G}^{{\prime\:}{\prime\:}}\) values. On the contrary, in MRE25G, the reduction in particle-matrix friction, as evident from the lesser bound rubber contribution, improves the elastic regime of the matrix, thus higher LVE. A small change in the storage modulus value between MRE0 and MRE25G also evidences this. Thus, the percentage reduction in loss modulus and increase in the LVE regime validate the reduction in particle-matrix interfacial interaction in MRE25G.

Strain sweep experiment under the influence of magnetic field

Figure 5a,c illustrates the storage and 5b,d loss modulus variation with strain amplitude and magnetic field for MRE25 and MRE25G samples. In a linear viscoelastic regime, both moduli values increase with increased magnetic field strength. The magneto-induced increase in storage modulus is defined as the MR effect (i.e. \(\:\frac{\left[{G}^{{\prime\:}}\left(B\right)-\:{G}^{{\prime\:}}\left(B=0\right)\right]}{{G}^{{\prime\:}}\left(B=0\right)}*100\:\%.\:\) The MR effect is caused by intense magnetic interactions between particles, forming a three-dimensional structure with a field. Above the LVE regime, the variation of \(\:{G}^{{\prime\:}}\)decreases with an increase in magnetic field while ′′ exhibits a shift in peak position towards higher strain amplitude and peak intensity increases.

The value of critical strain (γc′) is nearly double in the case of MRE25G compared to MRE25. However, with the magnetic field, the critical strain increases for MRE25, while in the case of MRE25G, it initially increases, and at 320mT onwards, it decreases with increasing magnetic field. In MRE25G, the particles can move under the magnetic field because of the decrease in particle-matrix friction. Thus, particle-particle interaction becomes stronger. This increases the critical strain value and, thus, LVE.

The value of \(\:{G}_{0}^{{\prime\:}}\:\)below critical strain (\(\:{\gamma\:}_{c}^{{\prime\:}}\)) can also be used to calculate the cohesive energy (Ec), which describes the work needed to break the structure. The variation of Ec with strain is expressed as;

Here, τ is the shear stress. In the LVE regime, one can consider \(\:\tau\:=\:{G}_{0}^{{\prime\:}}\:\gamma\:\). Thus the Eq. (1) is rewritten as;

Using the values of storage modulus and critical strain, the cohesive energy values were calculated for MRE25 and MRE25G for different magnetic fields. The variation of Ec with a magnetic field is shown in Fig. 6a.

It is apparent from Fig. 6a that the cohesive energy increases nearly five times for MRE25G compared to MRE25 in a zero magnetic field. The value of Ec for MRE0 is 4.15 kJ/m3. The increase in cohesive energy demonstrates how decreased interfacial interaction increases the structure’s stability with strain. Thus, in MRE25G, the LVE regime shifts to a higher strain value. The increases in particle-particle interaction due to a reduction in particle-matrix friction have also enhanced the magnetic field-induced effect, the MR effect, in MRE25G (Fig. 6b ) by 30% at the highest magnetic field. It is to be mentioned here that the particle-particle friction hurts the MR effect as it hinders particle orientation in the direction of the magnetic field. However, the low volume fraction considered here may make the later contribution very small.

The loss modulus value at zero magnetic field decreases in the LVE regime for MRE25G compared to MRE25. Again, the decrease in the loss modulus indicates the influence of the particle-matrix interaction, which aligns with the earlier observed results. However, in both samples, the values of loss moduli at low strain increase with an increase in magnetic field (Fig. 5b,d). The LVE regime’s increase in loss modulus values describes the influence of particle-particle interaction in a magnetic field. Nevertheless, the relative change in the value of loss modulus with the magnetic field at 640 mT is higher in the case of MRE25G. The increase in the LVE regime value for MRE25G supports the argument of the strain-softening effect.

To understand more, the Fig. 5 results were normalised with their respective modulus at zero and replotted. Figure 7 shows the variation of normalised modulus versus strain for MRE25 and MRE25G. It is apparent from Fig. 7 that in the case of storage modulus, all the curves were superimposed on each other for both MREs. Nevertheless, the amplitude of loss modulus for MRE25G is less than MRE25 as overlap decreases at higher strain amplitude. This indirectly indicates the hardening of the matrix and a decrease in particle-matrix interaction. Thus, it correlates with the observed conclusion that interfacial interaction plays a dominant role in the viscoelastic properties of the MRE. An increase in loss modulus after LVE, a common feature observed in MRE, is related to breaking network structure under the strain or strain stiffening effect caused by the friction between particle-matrix26,36.

Creep-recovery measurements

The above studies demonstrate that adding a surface modifier (grease) in the MRE preparation has reduced the particle-matrix interfacial interaction. The reduction in interaction will improve the recovery strain in MRE when creep-recovery studies are carried out. Figure 8 shows the creep-recovery curves in zero magnetic fields for MRE25 and MRE25G at a given stress of 2 kPa. The sudden decrease in the instantaneous strain value in MRE25G and the decrease in recovery strain demonstrate the decreased interfacial interaction between the particles and matrix. The results were analysed using Burger’s (for creep)37 model given by Eq. (3) and Weibull’s (recovery)38 model Eq. (4), which are shown as solid (red) lines in Fig. 8.

EM and ηM define the Maxwell elastic stress and Maxwell viscosity, respectively. EK and ηK define the Kelvin-Voigt (KV) stress and KV viscosity, respectively. The parameter σ defines the applied shear stress value. In the above Eq. (1), the ratio of ηK/EK represents the relaxation time. The symbols K and M stand for Kelvin-Voigt and Maxwell, respectively.

Similarly, the Weibull distribution function explains the Creep-recovery curves of the experimental results. The time-dependent recovery strain (γRE) is represented as;

The parameter γr is delayed elastic strain, depending on ηr and β over recovery time t. The parameter t0 defines the recovery time.

The instantaneous strain, the ratio of applied stress, σ to Maxwell elastic stress, EM, decreases from 6.36 to 5.26 with the addition of grease. Similarly, the recovery strain (γr) decreases from 10.36 to 3.33. As discussed earlier, the influence of interfacial interaction will be more in recovery, which is also observed here. The percentage decrease in creep strain is 17.3%, while in recovery, it is 67.9%. Therefore, the particle-matrix interaction influences the recovery part more; this relates to the reduced secondary cross-link points due to the grease. Thus, with the addition of the surface modifier, the particles restructure under the given stress, and upon removal, they recover fast.

In all the analysis, it was observed that the Maxwell stress does not change much, but Kelvin-Voigt (KV) stress and KV viscosity increase by nearly 3.5 to 4. The increase in these values indicates that with the addition of grease, the viscoelasticity component has increased, justifying the claim that the interface interaction between matrix and particles has been modified. The influence of this reduced interface interaction may change the magnetic field-induced properties.

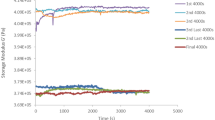

However, to understand the system’s behaviour under the magnetic field, creep-recovery measurements were also performed with varying magnetic field intensity, and results are shown in Fig. 9 for MRE25 and MRE25G. Figure 10 shows the variation of fit parameters obtained from Burger’s model with magnetic fields.

The elastic stress (EM) variation with the magnetic field (Fig. 10a) is identical for MRE25 and MRE25G, increasing with the magnetic field intensity. While the Maxwell viscosity for MRE25 and MRE25G (Fig. 10b) shows a similar variation with the magnetic field, the values of MRE25G are higher compared to MRE25. The variation of Kelvin stress and viscosity with magnetic fields also exhibit similar trends but differ in magnitude. Thus, the interface interaction in zero field exhibits higher impact, and with the field, it nearly contributes the same. The magnetic properties are not getting modified because of the reduced particle-matrix interaction. It only influences initially (0.0 to 160 mT) and exhibits saturation behaviour later.

Conclusion

The particle-matrix interfacial interaction was reduced with the addition of grease as an additive in synthesised MRE, and this reduction is attributed to decreases in secondary cross-link points available on the particle surface. The SEM images support the mechanism of reduction in interface interaction between particle and matrix. The weakening of interfacial interaction leads to decreased storage and loss of moduli values. Nevertheless, it enhances the magnetic-field-induced variation of MRE by 30%. Adding an additive (here, grease) modifies the interfacial surface interaction, resulting in an improved LVE region by nearly 3 times, correlating the improved re-agglomeration rate to the de-agglomeration rate. The influence of interfacial interaction improves cohesive energy by 5 times in MRE25G.

The elastic stress (EM) remains identical when creep recovery studies were performed for MRE25 and MRE25G, and it increases with increasing magnetic field. In contrast, the Maxwell viscosity for MRE25 reduces than that of MRE25G. The variation of Kelvin stress and viscosity with magnetic fields also exhibit similar trends but differ in magnitude. Thus, the interface interaction in zero field exhibits higher impact, and with the field, it nearly contributes the same. The magnetic properties are unaffected by the reduced particle-matrix interaction. It only influences initially (0.0 to 160 mT) and exhibits saturation behaviour later. The present study demonstrates that reducing particle-matrix interfacial interaction makes it possible to achieve a higher magnetic field-induced effect and enhanced linear viscoelastic region in MRE.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Deng, H. X. & Gong, X. L. Application of magnetorheological elastomer to vibration absorber. Commun. Nonlin Sci. Numer. Simul. 13 (9), 1938–1947. https://doi.org/10.1016/j.cnsns.2007.03.024 (2008).

Bose, H., Rabindranath, R. & Ehrlich, J. Soft magnetorheological elastomers as new actuators for valves. J. Intell. Mater. Syst. Struct. 23 (9), 989–994. https://doi.org/10.1177/1045389X11433498 (2012).

Liao, G. J., Gong, X., Xuan, S. H., Kang, C. J. & Zong, L. H. Development of a real-time tunable stiffness and damping vibration isolator based on magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 23 (1), 25–33. https://doi.org/10.1177/1045389X11429853 (2012).

Bastola, A. K. & Li, L. A new type of vibration isolator based on magnetorheological elastomer. Mater. Des. 157, 431–436. https://doi.org/10.1016/j.matdes.2018.08.009 (2018).

Liu, A. et al. A real-time controllable electromagnetic vibration isolator based on magnetorheological elastomer with quasi-zero stiffness characteristic. Smart Mater. Struct. 28 (8), 085037. https://doi.org/10.1088/1361-665X/ab2e44 (2019).

Bica, I. Magneto resistor sensor with magnetorheological elastomers. J. Ind. Eng. Chem. 17 (1), 83–89. https://doi.org/10.1016/j.jiec.2010.12.001 (2011).

Qi, S. et al. Magnetorheological elastomers enabled high-sensitive self-powered tribo-sensor for magnetic field detection. Nanoscale 10 (10), 4745–4752. https://doi.org/10.1039/c7nr09129j (2018).

Hu, T., Xuan, S., Ding, L. & Gong, X. Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater. Des. 156, 528–537. https://doi.org/10.1016/j.matdes.2018.07.024 (2018).

Ladipo, I. L., Fadly, J. D. & Faris, W. F. Characterization of magnetorheological elastomer (MRE) engine mounts. Mater. Today: Proc. 3 (2), 411–418. (2016).

Wu, C., Zhang, Q., Fan, X., Song, Y. & Zheng, Q. Smart magnetorheological elastomer peristaltic pump. J. Intell. Mater. Syst. Struct. 30 (7), 1084–1093. https://doi.org/10.1177/1045389X19828825 (2019).

Liu, T. & Xu, Y. Magnetorheological elastomers: Materials and applications. In: Smart and Functional Soft Materials, IntechOpen, London, UK. 147–180, (2019).

Bastola, A. K. & Hossain, M. A review on magneto-mechanical characterizations of magnetorheological elastomers. Compos. B Eng. 200 https://doi.org/10.1016/j.compositesb.2020.108348 (2020).

Bastola, A. K., Paudel, M., Li, L. & Li, W. Recent progress of magnetorheological elastomers: a review. Smart Mater. Struct. 29 (12), 123002. https://doi.org/10.1088/1361-665X/abbc77 (2020).

Li, Y., Li, J., Li, W. & Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 23 (12), 123001. https://doi.org/10.1088/0964-1726/23/12/123001 (2014).

Sutrisno Ubaidillah, J., Purwanto, A. & Mazlan, S. A. Recent progress on magnetorheological solids: materials, fabrication, testing, and applications. Adv. Eng. Mater. 17 (5), 563–597. https://doi.org/10.1002/adem.201400258 (2015).

Padalka, O. et al. Stiffness and damping in Fe, Co, and Ni Nanowire-Based magnetorheological elastomeric composites. IEEE Trans. Magn. 46, 2275–2277. https://doi.org/10.1109/TMAG.2010.2044759 (2010).

Hapipi, N. et al. The field-dependent rheological properties of plate-like carbonyl iron particle-based magnetorheological elastomers. Results Phys. 12, 2146–2154. https://doi.org/10.1016/j.rinp.2019.02.045 (2019).

Yang, P. et al. Improved rheological properties of dimorphic magnetorheological gels based on flower-like carbonyl iron particles. Appl. Surf. Sci. 416, 772–780. https://doi.org/10.1016/j.apsusc.2017.04.151 (2017).

Tong, Y., Dong, X. & Qi, M. Improved tunable range of the field-induced storage modulus by using flower-like particles as the active phase of magnetorheological elastomers. Soft Matter. 14, 3504–3509. https://doi.org/10.1039/C8SM00359A (2018).

Upadhyay, R. V., Laherisheth, Z. & Shah, K. Rheological properties of soft magnetic flake shaped iron particle based magnetorheological fluid in dynamic mode Smart Mater. Struct. 23 (1) 015002. (2013).

Shah, K., Seong, M. S., Upadhyay, R. V. & Choi, S. B. A low sedimentation magnetorheological fluid based on plate-like iron particles, and verification using a damper test. Smart Mater. Struct. 23 (2), 027001. https://doi.org/10.1088/0964-1726/23/2/027001 (2013).

Pisuwala, M. S., Parekh, K. H. & Upadhyay, R. V. Contribution of the positional and orientational ordering in anisotropic particle-based MR fluids: static and dynamic rheological study. Rheol Acta. 59, 887–904. https://doi.org/10.1007/s00397-020-01251-3 (2020).

Tong, Y., Dong, X. & Qi, M. Improved tunable range of the field-induced storage modulus by using flower-like particles as the active phase of magnetorheological elastomers. Soft Matter. 14, 3504–3509 (2018).

Yu, M., Qi, S., Fu, J., Zhu, M. & Chen, D. Understanding the reinforcing behaviour of polyaniline-modified carbonyl iron particles in magnetorheological elastomer based on polyurethane/epoxy resin IPNs matrix. Compos. Sci. Technol. 139, 36–46 (2017).

Upadhyay, R. V. & Choi, S. B. Modeling, measurements and validation of magnetic field dependent flow behavior of magnetorheological fluids; static and dynamic yield stress. Smart Mater. Struct. 30, 117002. https://doi.org/10.1088/1361-665X/ac2ba8 (2021).

Patel, D., Upadhyay, R. V. & Mazlan, S. A. Particle-reinforced elastomer model to analyse viscoelastic properties of flake-shaped electrolyte iron particle-based magnetorheological elastomer. Smart Mater. Struct. 32, 095011. https://doi.org/10.1088/1361-665X/ace573 (2023).

Kumar, V. & Lee, D. J. Iron particle and anisotropic effects on mechanical properties of magneto-sensitive elastomers. J. Magn. Magn. Mater. 441, 105–112. https://doi.org/10.1016/j.jmmm.2017.05.049 (2017).

Patel, D. & Upadhyay, R. V. Fractional Maxwell viscoelastic model to explain dynamic magneto-viscoelastic properties of an isotropic magnetorheological elastomer containing flake-shaped magnetic particles. Soft Mater. 21, 346–357. https://doi.org/10.1080/1539445X.2023.2247002 (2023).

Patel, D. & Upadhyay, R. V. Influence of normal force on magnetic-field-induced shear modulus of isotropic and anisotropic magnetorheological elastomers having spherical and non-spherical shape iron particles. Soft Mater. https://doi.org/10.1080/1539445X.2024.2370249 (2024).

Patel, D., Upadhyay, R. V., Mazlan, S. A. & Choi, S. B. A modified parametric model to predict visco-elastic properties of magneto-rheological elastomers at non-LVE region. J. Intell. Mater. Syst. Struct. 35 (17), 1–17. https://doi.org/10.1177/1045389X241272994 (2024).

Pickering, K. L., Khimi, S. R. & Ilanko, S. The effect of silane coupling agent on iron sand for use in magnetorheological elastomers part 1: surface chemical modification and characterisation. Compos. Part. Appl. Sci. Manuf. 68, 377–386. https://doi.org/10.1016/j.compositesa.2014.10.005 (2015).

Flory, P. J. & Rehner, J. J. Statistical mechanics of Cross-Linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 11, 512–520. https://doi.org/10.1063/1.1723791 (1943).

Laun, H. M., Gabriel, C. & Kieburg, C. Wall material and roughness effects on transmittable shear stresses of magnetorheological fluids in plate–plate magnetorheometry. Rheol Acta. 50, 141–157. https://doi.org/10.1007/s00397-011-0531-8 (2011).

Fan, Y., Gong, X., Xuan, S., Qin, L. & Li, X. Effect of Cross-Link density of the matrix on the damping properties of magnetorheological elastomers. Ind. Eng. Chem. Res. 52, 771–778. https://doi.org/10.1021/ie302536e (2013).

Jiles, D. Introduction To Magnetism and Magnetic Materials (Chapman & Hall, 1991).

Walter, B. L., Pelteret, J. P., Kaschta, J., Schubert, D. W. & Steinmann, P. Preparation of magnetorheological elastomers and their slip-free characterisation by means of parallel-plate rotational rheometry. Smart Mater. Struct. 26, 085004. https://doi.org/10.1088/1361-665X/aa6b63 (2017).

Mao, R., Wang, X., Cai, S., Zhang, G. & Wang, J. Quantitative investigation on the nonlinear viscoelasticity of magnetorheological gel under large amplitude oscillatory shear. Colloids Surf., A. 655, 130293. https://doi.org/10.1016/j.colsurfa.2022.130293 (2022).

Qi, S., Yu, M., Fu, J. & Zhu, M. Stress relaxation behavior of magnetorheological elastomer: experimental and modeling study. J. Intell. Mater. Syst. Struct. 29, 205–213. https://doi.org/10.1177/1045389X17730913 (2017).

Acknowledgements

Authors are thankful to CHARUSAT, Changa for providing the research facilities.

Author information

Authors and Affiliations

Contributions

Nupur Rathod: data curation (equal), writing – review and editing (equal). Dipal Patel: Conceptualization (lead); Methodology, data curation (equal), formal analysis (lead); writing – review and editing (equal). Kinnari Parekh: resources, supervision, visualization, formal analysis; writing – review and editing (equal). R V Upadhyay: Conceptualization (lead); Methodology, data curation (equal), resources, supervision, visualization, formal analysis; writing – original draft and review and editing (equal).

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Author statement

Confirming that data/materials/code presentation accurately reflects the original.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rathod, N., Patel, D., Parekh, K. et al. Particle matrix interfacial interaction effect on the viscoelastic properties of electrolyte iron particle based elastomer. Sci Rep 15, 33774 (2025). https://doi.org/10.1038/s41598-025-99691-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99691-5