Abstract

The accompanying health and environmental issues have prompted a renewed effort to find more environmentally friendly substitutes for ammonium perchlorate (AP) as a solid rocket propellant oxidizer. AP Propulsion’s outstanding performance is complemented by environmental concerns, which search for greener options necessary. Ammonium nitrate (AN) has emerged as a viable alternative that provides cost-effectiveness, non-detectable and tractable properties to the adversary, and cleaner combustion products. Structural instability is one of the problems with AN-based propellants. This work aims to overcome this obstacle by creating green energetic molecular perovskite based on nitrate groups (NO3−). NH4(C6H12N2)(NO3)3 (DAN-4) was synthesized by molecular assembly technique. Scanning electron microscope (SEM), X-ray diffraction (XRD), and Fourier transfer infrared (FTIR) were applied to characterize the structure and morphology of AP, AN, and DAN-4. Thermal decomposition of AP, AN, and DAN-4 were investigated using differential scanning calorimetry (DSC), and thermal gravimetric analysis (TGA). The results show that DAN-4 has one exothermic peak at 201 °C with 1420 J/g heat evolved compared to AN which has two endothermic phase transitions at 54 °C, and 128 °C respectively, melting point at 170 °C, and thermal decomposition at 294 °C with no exothermic peak, and heat evolved. DAN-4 shows higher energy released than common oxidizer (AP) which evolved 836 J/g. Decomposition kinetics was investigated via isoconversional (model free) and model fitting. Kissinger, Kissinger–Akahira–Sunose (KAS), integral isoconversional method of Flynn–Wall–Ozawa (FWO). DAN-4 demonstrated an apparent activation energy of 211.1 ± 1.66 kJ/mol compared with 160.8 ± 1.07 kJ/mol for pure AP, and 143.82 ± 3.3 kJ/mol for pure AN. DAN-4 shows higher thermal stability than AP, and AN. This work could promote the application of DAN-4 in the field of composite solid rocket propellant.

Similar content being viewed by others

Introduction

Ammonium nitrate (AN) is a versatile chemical compound that is commonly used as a fertilizer1,2,3. It releases nearly all gaseous products during its decomposition, and has a positive oxygen balance4,5. Recently, propellants manufactured with AN as an oxidizer have attracted substantial attention because of their low cost and easy availability, especially with a growing understanding of environmental issues caused by the current ammonium perchlorate (AP)-based propellants1,6,7. AP combustion releases species that contain chlorine, which can deplete the ozone layer and cause acid rain, both of which have adverse impacts on the environment8. Additionally, the presence of perchlorate in the environment has been linked to the potential development of chronic diseases9. From a strategic perspective, the security of the firing position may be threatened if a large number of gasses are released into the environment, as this could make it easier for the enemy to find and intercept the weapon6,10. AN-based propellants have several technical drawbacks, including low energy content, low burning rate, poor ignitability, high hygroscopicity, and solid–solid thermal transition at room temperature3,11. The Polymorphic phase transition of AN is considered as one of the main causes for cracking and damaging of AN-based propellant, and is considered as the most serious obstacle for its utilization as an oxidizer1,12. Numerous investigations have been conducted in an effort to address the mentioned problems and improve the energetic performance of green oxidizers13. Phase-stabilized ammonium nitrate (PSAN), ammonium dinitramide (ADN), hydrazonium nitroformate (HNF), FOX-7, and its derivatives are among the potential possibilities that have been created in this specific case14,15,16. Despite the fact that ADN, HNF, and FOX-7 are all regarded as high energy crystalline compounds, considering their price, availability, and compatibility with other substances. Using energetic compounds in co-crystallization is one of the most common methods to accomplish this goal8. For instance, co-crystal of AN, and potassium dinitramide (KDN) using the ratio 50/5017. It is shown that KDN improved the burning properties of AN, and performed a great phase stabilizing role in it. Co-crystal of AN and hydrazine 3-nitro-1,2,4-triazol-one (HNTO) using the ratio 50/50. It showed a high energy release of 1483 J/g compared to HNTO with energy release 849 J/g with high excellent performance compared to AN4. Molecular perovskite has received much attention due to their distinctive structures and excellent properties18,19. Energetic molecular perovskite was considered as a potential oxidizer in the high-energy solid propellant due to its high energy and strong oxidation properties20,21. The organic fuel cations and inorganic oxidizer anions made up the energetic molecular perovskite with the ABX3 structure in the cell unit22,23,24. These materials, which have an ABX3 cubic structure similar to inorganic perovskite, could be used to integrate inorganic oxidants with organic fuel molecules by molecular self-assembly to create novel energetic materials (H2dabco)[M(ClO4−)3] with outstanding performance19,25. H2dabco is protonated organic fuel triethylenediamine, M could be NH2NH3+, NH3OH+, and NH4+ for DAP-7, DAP-6, and DAP-4, respectively26. The high energy content is originated from the redox reaction between cations and anions. Furthermore, Significant oxidation capabilities are provided by the abundance of ClO4-ions in molecular perovskite crystals27. Although high energy content which can be obtained from DAP-4, but its depends on the ClO4- ions which produce HCl gases during combustion. In this paper, we synthesis energetic molecular perovskite based on nitrate group (NO3−) for DAN-4. DAN-4 was fully characterized by SEM, FTIR, XRD, TGA, and DSC, and compared with AN, and AP. Decomposition kinetics of AP, AN, and DAN-4 were evaluated using different analysis models including isoconversional (model free) and model fitting. Kissinger, Kissinger–Akahira–Sunose (KAS), integral isoconversional method of Flynn–Wall–Ozawa (FWO), and Kissinger model to evaluate the activation energy (Ea), and pre-exponential factor (A). This work offers an opportunity for DAN-4 to be used practically in the field of solid propellants.

Experimental

Materials

Ammonium nitrate (AN), and nitric acid (HNO3, 70%) were purchased from Merck, Germany. Triethylenediamine (DABCO, C6H12N2) was purchased from Thermo Fisher Scientific, USA. Ammonium perchlorate (AP-NH4ClO4) was obtained from Abu Zaabal Company.

Synthesis of DAN-4

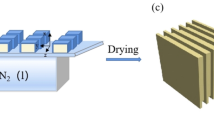

DAN-4 was developed via molecular assembly technique28. DAN-4 was synthesized according to this procedure. Distilled water (20 ml) was combined with 1 mmol of HNO3 (70% wt), 0.5 mmol of AN, and 0.5 mmol of DABCO. The mixture was stirred 2 h for complete solute dissolution at 40 °C. The mixture was allowed to stand for a week. The filtered samples was dried in an oven at 50 °C for 6 h, to obtain dry DAN-4 samples (Fig. 1).

Morphology and composition

SEM, ZEISS SEM EVO 10 MA was used to analyze the morphology and shape of the AN, AP, and synthesized DAN-4. Hiltonbrooks X-ray diffractometer was employed to investigate the crystalline structure of AP, AN, and DAN-4 over the angle range 2Ө from 5 to 65 degrees. The FT-IR spectra of these discs were recorded in the 400–4000 cm−1 range with an automatic signal gain that gathered 500 scans at a 4 cm−1 resolution with a JASCO Model 4100 spectrometer (Japan).

Thermal behaviour

The thermal behavior of AP, AN, and DAN-4 were examined by TA utilizing a DSC Q200; the tested sample was heated to 500 °C at 10 °C/min under a flow of nitrogen 50 ml/min. TGA 55 by TA was used to determine weight loss with temperature; the tested sample was heated to 500 °C at 10 °C/min under a flow of nitrogen 50 ml/min. Each sample that was examined had a mass of 1 mg and was placed in tzero aluminum pans.

Decomposition kinetics

Decomposition kinetics was evaluated using different analysis models including isoconversional (model free) and model fitting. Kissinger, Kissinger–Akahira–Sunose (KAS), and integral isoconversional method of Flynn–Wall–Ozawa (FWO). models were adopted for decomposition kinetic study29,30. Decomposition kinetics of AN, AP, and DAN-4 were assessed using TGA. The weight loss of the tested samples were recorded at different heating rates 4, 6, 8, and 10 K/min.

The equations for the FWO and KAS methods are given below.

To get the Kinetic parameters (Ea, A) a linear equation is obtained by drawing \(ln{\upbeta }_{\text{i}}\) vs 1000/Tα,i , and \(\mathit{ln}\left(\frac{{\beta }_{i}}{{T}_{\alpha ,i}^{2}}\right)\) vs 1000/Tα,i whose slope is the effective activation energy (Ea) and the intercept is the frequency factor (A), where the subscript \(i\) represents the \(i\) th heating rate and the subscript α is the value related to the conversion degree, β is the heating rate, and T is the decomposition temperature.

The activation energy (Ea) of AP, AN, and DAN-4 were evaluated from Kissinger model (Eq. 3)31,32,

where β is the heating rate, Tp is the decomposition temperature and R is universal gas constant.

Results and discussion

Characterization of AP, AN, and DAN-4

SEM images show AN particles (Fig. 2a) demonstrated an agglomerated structure with uneven shapes, and irregular form. For AP, the SEM images (Fig. 2b) reveal a nearly spherical structure without any agglomeration and a smooth surface of the particles. The SEM images of DAN-4 (Fig. 2c, d) demonstrated a rod-shaped structure without any porosity and smooth surface of the particles.

EDAX provide an elemental mapping of the compound that confirm the presence of (N, O, and C) elements in DAN-4 without any impurities existed in the compound (Fig. 3).

The XRD patterns of the AP, AN, and DAN-4 were investigated (Fig. 4a). For AP, the XRD diffractogram of AP revealed an orthorhombic crystalline structure with centrosymmetric crystal symmetry. The AP crystalline structure, which has seven characteristic peaks at 2θ of 15.04°, 19.28°, 24.56°, 27.32°, 30.58°, 34.26°, and 40.62°, which correspond to planes (101), (001), (210), (211), (112), (121), and (401). It was found to be in good accord with the International Center of Diffraction Data (ICDD) card number 01-070-06291.

XRD diffractogram of AN exhibited clear sharp peaks at 2θ = 18.02°, 22.4°,28.9°, 32.98°, 39.8°, matching with all main characteristic peaks of AN corresponding to phase IV (PDF card No. 85-1093)33. The structure solution of the novel compound was performed, based on its powder diffraction pattern, using Biova Materials studio 2020 (ver. 20.1.0.2728). The indexing process showed that the compound evolves in a cubic crystal structure with a space group of P21/A-3 (IT number = 205). (Fig. 4a) depicts the XRD spectra of both the synthesized sample and its proposed crystal structure over the 2θ range (5.01–89.99°). It is clear that there is a good match between the two patterns (Rwp = 12.39), implying the success of the structure solution process. The crystallographic data and refined parameters for the synthesized DAN-4 are listed in (Table 1).

There are four characteristic peaks at 10.25°, 16.95°, 46.75°, and 65.73° for DAN-4. The coordination environment of the small positive ions (NH4+) which occupy the B-sites in the crystal. There are six oxygen atoms, from nitrate ions, surrounding NH4+ ions and forming octahedral structure (BX6) as shown in (Fig. 4b). It is clear that the large positive ions (H2dabco+2) occupy the A-sites, which are located at the vacancies between the octahedral units (BX6) as shown in (Fig. 4c).

FTIR tests were carried out on AP, AN, Dabco, and DAN-4 using KBr pelleting method and the results are shown in (Fig. 5). For AP, 619, 1037 cm−1 correspond to ClO4− and peaks at 1409 and 3274 cm−1 to NH4+. For Dabco, Dabco skeletal motion has three main peaks at 1054, 908, and 835 cm−1. The peak at 1313 cm−1 belongs to C–N, while the peaks at 3232, 2935, 2868, 1677, 1455, and 991 cm−1 are associated with CH218. For AN, the peaks at 3253, and 3075 cm−1 correspond to the anti-symmetric stretch and deformation vibration modes of the NH4+. The peaks at 1424, and 1328 cm−1 are characteristic of NH4+, and NO3− ion respectively. It is suggested these peaks are attributed to the triple degenerated NH4+deformation and double degenerated stretching vibration of the NO3−. The peaks at 1753, 1043, 827, and 715 cm−1, which have been attributed to symmetric stretching vibration, out-of-plane, and in-plane deformation of the nitrate ion respectively34. For DAN-4, the vibration peaks at 1311, and 830 cm−1 originated from main oxidant group NO3−. The peaks at 1426, 3050, and 3135 correspond to NH4+. The peaks of the protonated H2dabco+2 skeleton at 1052, 889, 810, and 1186 cm−1 have a clear shifting because of hydrogen bond interaction between protonated H2dabco+2 and cage-like skeleton. The above results also indicated that ternary molecules perovskite DAN-4 have a stable chemical structure.

Thermal behaviour

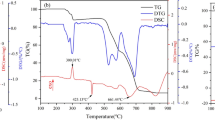

DSC experiments were performed for the two raw materials (AP, and AN), and the as-synthesized DAN-4 to investigate their thermal properties. (Fig. 6) illustrates DSC curves of the AP, AN, and DAN-4 at heating rate of 10 °C/min. For AP, there is an endothermic phase transition from orthorhombic to cubic at 243 °C with 103 J/g heat absorbed, a low temperature decomposition (LTD) at 298 °C with 346 J/g heat evolved, and high temperature decomposition (HTD) at 453 °C with 490 J/g heat evolved35,36,37,38. The total heat of AP decomposition is 836 J/g. For AN, the peaks located at 54 °C, and 128 °C correspond to the phase transition of AN (first phase transition III orthorhombic, and second phase transition II tetragonal) with heat absorbed 28 J/g, and 65 J/g respectively. The peak located at 170 °C represents the melting point of AN with heat absorbed 90 J/g. The large peak at elevated temperature 294 °C relates to the thermal decomposition of AN with heat absorbed 1358 J/g. There is no exothermic peak occurs or heat evolved in the thermal decomposition of AN1,4.

For DAN-4, the peak temperature of decomposition is observed at 201 °C with 1420 J/g heat evolved. DAN-4 doesn’t undergo any phase transition or melting process before decomposition. The current study brings new insights to use DAN-4 in solid propellant formulation, since the new oxidizer doesn’t present any polymorphs, which display drawbacks at ordinary temperature. As it is well-known, the phase transformation of AN that occurs at room temperature may be accompanied by a substantial volume expansion and contraction, which gives rise to undesirable crack formation within the propellant grain6. DAN-4 presents a high heat released 1420 J/g compared to the common oxidizer AP (836 J/g), and AN, which doesn’t present any exothermic decomposition. The width of exothermic peaks in DSC curve for AP, AN, and DAN-4 were used to determine the violent reaction decomposition. AP, and AN has a wider decomposition peak with 50 °C for HTD, 47 °C for LTD, and 28 °C for AN compared to 18 °C for DAN-4. These results show violent decomposition with large amounts of released heat of DAN-4 than AP, and AN. The violent decomposition may be attributed to the fact that the molecular perovskite structure is constructed by highly oxidative active NO3− anions and fuel components fully mixed at the molecular level with strong coulomb and hydrogen bonding interactions. TGA was applied to AP, AN, and DAN-4 to discuss the weight loss of the samples with the temperature. AP showed two thermal decomposition temperatures which related to LTD, and HTD. LTD shows partial decomposition with 30% weight loss, and HTD shows a complete decomposition with 99.9%, which confirmed that pure AP is all transformed to a gaseous phase (Fig. 7a). AN shows one peak of decomposition with complete weight loss equal to 98.43% (Fig. 7b). DAN-4 shows one decomposition peak with 99.89% weight loss (Fig. 7c). From the above results, TGA results are confirmed with our results in the DSC experiments.

A propesed catalytic mechanism for DAN-4 is shown in (Fig. 8)18,39,40. DAN-4 has a stable crystal structure. NH4+ and NO3− form a stable cage ion framework. The H2dabco+2 occupies the central point and generates a strong coloumb force with NH4+ and NO3- to maintain the stability of the framework structure. At higher temperatures, the structure of DAN-4 is destroyed, and released NH4+, NO3−, and H2dabco+2. Then H+ of H2dabco+2, and NH4+ transfers into NO3− to form dabco, NH3, and HNO3. Lower reaction activation energy and accelerated e- flow from activated H2dabco+2 will facilitate HNO3 molecular reductive decomposition together to produce superoxide radical ion O2-The thermo generated O2- can react with DABCO and NH3 more completely to form H2O, NO2, N2O, CO2, and so on. Compared to the component AN, more organic fuel (DABCO) from A-sites in the molecular perovskite units participated in the thermal decomposition reaction, so that more heat. release energy was obtained.

DAN-4 outperforms all other oxidizers, including AP and AN, in terms of heat release and low decomposition temperature (Table 2), but ADN exhibits the maximum energy release of 1970 J/g; however, ADN was constrained in practical application because of expensive and harsh synthesis procedure. Also, compared to other catalysts used in conjunction with AN to improve the heat release and phase stabilization of AN. DAN-4 revealed a high energy released, and no phase transition which displays drawbacks at ordinary temperature, which leads to cracks, and pores in the propellant grain. DAN-4 revealed higher performance than AN/KClO4, and NC@AN in heat release, and phase transitions.

Thermocatalytic degradation study

Thermocatalytic degradation study of DAN-4 was investigated using TGA analysis (Fig. 9), and compared with pure AP, and AN. Linear heating rate studies were carried out at various heating rates.

The \({\text{ln}} {\beta}_{{\text{i}}}\) vs 1000/Tα,i, and \(\ln \left( {\frac{{{\upbeta }_{{\text{i}}} }}{{{\text{T}}_{{{\upalpha },{\text{i}}}}^{2} }}} \right)\) vs 1000/Tα, curves related to FWO, and KAS over the range of α = 0.05 ~ 0.9, with a step size of 0.05, are demonstrated in (Fig. 10).

For AP-HTD, AP-LTD, AN, and DAN-4. FWO and KAS isoconversional plots revealed similar tendencies. Consequently, similar Ea values from the slopes correspond to the straight lines. This is demonstrated by the trends of the global kinetic plots (Fig. 11).

The Eα values of AP-LTD, and AP-HTD by the KAS were found to be 101.1 ± 0.52 kJ/mol, and 160.8 ± 1.07 kJ/mol respectively. For AN, The Eα value is 143.8 ± 3.31 kJ/mol by KAS method. Finally, the Eα value of DAN-4 is 211.1 ± 1.66 kJ/mol. The activation energy of DAN-4 is higher than AN by 68 kJ/mol, indicating that DAN-4 has more thermal stability than AN, LTD, and HTD of AP separately. Ea was evaluated for pure AP, AN, and DAN-4 via Kissinger model (Fig. 12).

Ea values using Kissinger were evaluated to FWO, and KAS. Ea values are less closely to FWO, and KAS for both AP-HTD, AN, and DAN-4, and more closely to FWO, and KAS for AP-LTD. AP-LTD, AP-HTD, AN, and DAN-4 demonstrated similar Ea values using FWO, and KAS models respectively (Table 3).

Conclusion

In this work, DAN-4 was successfully synthesized by the self-assembly technique. DAN-4 displayed a distinct morphology than AN. It had a rod-shaped structure without any porosity, unlike AN, which has an agglomerated structure with irregular forms. DAN-4 shows interesting features compared to AP, and AN. It decomposed at 201 °C with 1420 J/g heat evolved compared to AN which decomposed at 294 °C with no heat evolved, and AP which decomposed with two exothermic decompositions at 298 °C with 346 J/g for LTD, and 453 °C with 490 J/g for HTD with total heat evolved equal to 836 J/g. DAN-4 does not experience any phase transition, unlike AN, which occurs at ambient temperature and causes undesirable crack formation within the propellant. Also, DAN-4 is a chlorine-free compound, unlike AP, which produces chlorine-containing species, which has a negative impact on the environment or detection of the firing position. Kinetic decomposition was investigated via isoconversional analysis based on FWO, KAS, and Kissinger method. DAN-4 exhibited higher activation energy (211.1 ± 1.66 kJ/mol) than AN (143.82 ± 3.3 kJ/mol), and AP (160.8 ± 1.07 kJ/mol), revealing its efficient thermal stability. The used process can be considered simple for manufacturing huge amounts of DAN-4 with high energy. DAN-4 demonstrated excellent thermal stability and high energy for practical use in the field of composite solid rocket propellant.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Abdelaziz, A. et al. Application of co-crystallization method for the production of ammonium perchlorate/ammonium nitrate oxidizer for solid rocket propellants. Chem. Eng. J. 487, 150654 (2024).

Chen, F. et al. Theoretical simulation research on the hygroscopicity, stability, sensitivity, and mechanical properties of the cocrystals of ammonium nitrate with typical high energetic molecules. Mater. Today Commun. 38, 107688 (2024).

Oommen, C. & Jain, S. Ammonium nitrate: a promising rocket propellant oxidizer. J. Hazard. Mater. 67(3), 253–281 (1999).

Hanafi, S. et al. Synthesis, characterization and thermal decomposition behavior of a novel HNTO/AN co-crystal as a promising rocket propellant oxidizer. Chem. Eng. J. 417, 128010 (2021).

Dave, P. N. & Sirach, R. Thermal decomposition study of ammonium nitrate in the presence of nickel-zinc ferrite additive. Catal. Commun. 177, 106639 (2023).

Dîrloman, F.-M. et al. Ballistic and thermal characterisation of greener composite solid propellants based on phase stabilized ammonium nitrate. Case Stud. Therm. Eng. 54, 103987 (2024).

Zhu, K. et al. Co metal-decorated carbon nanotubes with excellent thermal catalytic performance. J. Mater. Sci. 58(36), 14315–14325 (2023).

Trache, D. et al. Recent advances in new oxidizers for solid rocket propulsion. Green Chem. 19(20), 4711–4736 (2017).

Srinivasan, A. & Viraraghavan, T. Perchlorate: Health effects and technologies for its removal from water resources. Int. J. Environ. Res. Public Health 6(4), 1418–1442 (2009).

Chan, M.L. and A.D. Turner, Minimum signature propellant. 2005, Google Patents.

Naya, T. & Kohga, M. Burning characteristics of ammonium nitrate-based composite propellants supplemented with Fe2O3. Propellants, Explos., Pyrotech. 38(4), 547–554 (2013).

Wu, H. B. & Chan, C. K. Effects of potassium nitrate on the solid phase transitions of ammonium nitrate particles. Atmos. Environ. 42(2), 313–322 (2008).

Kumar, P. An overview on properties, thermal decomposition, and combustion behavior of ADN and ADN based solid propellants. Def. Technol. 14(6), 661–673 (2018).

Chen, F.-Y. et al. A review on the high energy oxidizer ammonium dinitramide: Its synthesis, thermal decomposition, hygroscopicity, and application in energetic materials. Def. Technol. 19, 163–195 (2023).

Jos, J. & Mathew, S. Ammonium nitrate as an eco–friendly oxidizer for composite solid propellants: Promises and challenges. Crit. Rev. Solid State Mater. Sci. 42(6), 470–498 (2017).

Zhang, L.-N. et al. Effect of hexanitroethane (HNE) and hydrazinium nitroformate (HNF) on energy characteristics of composite solid propellants. FirePhysChem 1(2), 116–122 (2021).

Kumar, P. Advances in phase stabilization techniques of AN using KDN and other chemical compounds for preparing green oxidizers. Def. Technol. 15(6), 949–957 (2019).

Deng, P. et al. Thermal decomposition and combustion performance of high-energy ammonium perchlorate-based molecular perovskite. J. Alloy. Compd. 827, 154257 (2020).

Deng, P., Ren, H. & Jiao, Q. Enhanced the combustion performances of ammonium perchlorate-based energetic molecular perovskite using functionalized graphene. Vacuum 169, 108882 (2019).

Zhu, S. et al. Metal-doped (Fe, Nd, Ce, Zr, U) graphitic carbon nitride catalysts enhance thermal decomposition of ammonium perchlorate-based molecular perovskite. Mater. Des. 199, 109426 (2021).

Ismael, S., Yehia, M. & Elbasuney, S. Ammonium perchlorate-based energetic molecular perovskite DAP-4 deposited on CNTs: Catalytic decomposition behavior, mechanisms, and kinetics. J. Inorg. Organomet. Polym Mater. 34(5), 1944–1956 (2024).

Deng, P. et al. The combustion behavior of boron particles by using molecular perovskite energetic materials as high-energy oxidants. Combust. Flame 241, 112118 (2022).

Xiao, G. et al. The thermal decomposition and combustion properties of DAP-4/FG composite materials. Fuel 384, 133988 (2025).

Deng, P. et al. One-pot hydrothermal synthesis of flower-like MnO2 nanostructure with rich oxygen vacancy for catalysis thermal-induced pyrolysis of energetic molecular perovskite. Vacuum 203, 111234 (2022).

Chen, S.-L. et al. Optimizing the oxygen balance by changing the A-site cations in molecular perovskite high-energetic materials. CrystEngComm 20(46), 7458–7463 (2018).

Shang, Y. et al. Metal-free hexagonal perovskite high-energetic materials with NH3OH+/NH2NH3+ as B-site cations. Engineering 6(9), 1013–1018 (2020).

Fang, H. et al. The effects of TiH2 on the thermal decomposition performances of ammonium perchlorate-based molecular perovskite (DAP-4). J. Energ. Mater. 41(1), 86–98 (2023).

Chen, S.-L. et al. Molecular perovskite high-energetic materials. Sci. China Mater 61(8), 1123–1128 (2018).

Khawam, A. & Flanagan, D. R. Basics and applications of solid-state kinetics: A pharmaceutical perspective. J. Pharm. Sci. 95(3), 472–498 (2006).

Trache, D., Abdelaziz, A. & Siouani, B. A simple and linear isoconversional method to determine the pre-exponential factors and the mathematical reaction mechanism functions. J. Therm. Anal. Calorim. 128(1), 335–348 (2017).

Vyazovkin, S. et al. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 520(1–2), 1–19 (2011).

Trache, D. et al. Physicochemical properties of microcrystalline nitrocellulose from Alfa grass fibres and its thermal stability. J. Therm. Anal. Calorim. 124(3), 1485–1496 (2016).

Zi, R. et al. Properties of mixed crystal coprecipitation substances of ammonium nitrate and potassium perchlorate prepared by the evaporative solvent method. ACS Omega 9(1), 1573–1590 (2023).

Suppajariyawat, P. et al. Classification of ANFO samples based on their fuel composition by GC–MS and FTIR combined with chemometrics. Forensic Sci. Int. 301, 415–425 (2019).

Yang, L. et al. Fabrication of highly catalytic active α-Fe2O3-carbon nanotube composites for thermal decomposition of ammonium perchlorate by light and temperature control strategy. Surf. Interfaces 44, 103642 (2024).

Zhao, Z. et al. MgCo2O4 microflower with excellent thermocatalytic properties for ammonium perchlorate decomposition. J. Mater. Sci. 59(10), 4136–4151 (2024).

Yehia, M. et al. Ammonium perchlorate catalyzed with novel n-Al modified on ZIF-67 with silane coupling agent: Superior catalytic activity, advanced decomposition kinetics and mechanisms. Ceram. Int. 50(24), 55065–55084 (2024).

Dave, P. N. & Sirach, R. Investigating the catalytic effect of nanoferrites additives on the thermal decomposition of ammonium perchlorate and burning rate modification of the composite solid propellants. Mater. Sci. Eng., B 301, 117136 (2024).

An, E. et al. The role of Fe nanospheres in energy releasing of DAP-4. Combust. Flame 257, 113014 (2023).

Li, Q.-X. et al. Thermal decomposition and combustion performance of the organic-inorganic hybrid crystal structure oxidant DAN-2. FirePhysChem 4(3), 245–251 (2024).

Dave, P. N. & Sirach, R. Comparative study of the thermal decomposition of ammonium nitrate in the presence of nanocrystalline copper ferrite. Mater. Adv. 4(24), 6665–6672 (2023).

Dave, P. N. & Sirach, R. Thermal analysis study of ammonium nitrate in the presence of NiCuCr2O4 additive. Mater. Lett.: X 18, 100194 (2023).

Cabrera, A. F. et al. Effect of nanostructured ferrites MFe2O4 (M= Cu Co, Mg, Zn) on the thermal decomposition of ammonium nitrate. Appl. Energy and Combustion Science 6, 100026 (2021).

Abdelaziz, A. et al. Synergistic effect of nitrocellulose coating on structural and reactivity stabilization of ammonium nitrate oxidizer. Def. Technol. 43, 35–43 (2025).

Author information

Authors and Affiliations

Contributions

M.Y.: Writing—review & editing, Writing—original draft, Visualization, Validation, Supervision, Software, Project administration, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. M.A.C.-D. Supervision, Resources, Project administration, Methodology, Investigation, Funding acquisition, review & editing, Writing. M.V.G.: Supervision, Resources, Project administration, Methodology, Investigation, Funding acquisition. A.S.-C.: Supervision, Resources, Project administration, Methodology, Investigation, Funding acquisition. S.I.: Writing—review & editing, Writing—original draft, Visualization, Validation, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. I.N. : Writing—review & editing, Writing—original draft, Visualization, Validation, Methodology, Investigation. S.E.: Writing—review & editing, Writing—original draft, Visualization, Validation, Supervision, Investigation, Funding acquisition, Formal analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yehia, M., Ismael, S., Naeem, I. et al. Facile synthesis and decomposition kinetics of novel green energetic molecular perovskite based on nitrate group DAN-4 as an alternative for ammonium nitrate oxidizer. Sci Rep 15, 17733 (2025). https://doi.org/10.1038/s41598-025-99700-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99700-7