Abstract

The industrial internet acts as a crucial accelerator for driving enterprise digital transformation and plays a vital role in enhancing performance and competitiveness. However, our understanding of how small and medium-sized enterprises (SMEs) leverage the industrial internet to improve their performance and competitiveness remains limited. This study developed a “Digital transformation paths chain” framework to shed light on the key factors that drive SMEs to adopt the industrial internet and its influence on performance and competitiveness. Data from 314 Chinese SMEs were collected and analyzed using fsQCA and PLS-SEM to examine this model. Our findings highlight the positive impact of industrial internet adoption on enterprise performance and competitive advantage. The results highlight that technology, organization, and environment (TOE) drive industrial internet adoption. Industrial internet adoption positively impacts enterprise performance and competitive advantage through integration, application, and drive. This study offers valuable insights for businesses, policymakers, and other stakeholders engaged in digital transformation initiatives through the industrial internet.

Similar content being viewed by others

Introduction

The rapid development of digital technology has accelerated the significant upgrade of the manufacturing industry (Liu et al. 2024; Zhu et al. 2023). As a critical component of digital tech, the industrial internet is vital in promoting enterprise performance and competitive advantage (Qi et al. 2023). Digital transformation is a comprehensive process that encompasses various aspects of an organization (Wang & Esperança, 2023), with the industrial internet acting as a key enabler and accelerator. For small and medium-sized enterprises (SMEs), however, challenges such as immature technology, insufficient resources, and ineffective management of digital transformation stages in the corporate strategy exist (Wu & Li, 2024). Therefore, it is essential to investigate the impact of industrial internet adoption on enterprise performance and competitive advantage through various stages of digital transformation (Frank et al. 2024).

Although it has been suggested that digital transformation is not a technical issue but a dynamic and continuous process of organization and management (Prajapati et al. 2024), existing empirical studies have primarily focused on IT-driven transformation and enterprise performance generated by IT (Belhadi et al. 2024; Kumar et al. 2023; Lin, 2022), while few have verified the complete process of digital transformation. Furthermore, the industrial internet is defined as an open global network based on connecting devices, people, and data analytics to facilitate the convergence of the cyber and physical worlds and is a key support for the digital transformation of enterprises (Yin & Zhao, 2024). As an important subject in the application of the industrial internet (Dou et al. 2022), whether the manufacturing industry has the application measures and application modes of the industrial internet becomes the key to the application of the industrial internet (Troise et al. 2022).

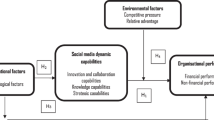

Our study aims to offer a new perspective by leveraging the Technology-Organization-Environment (TOE) framework and the Fuzzy Set Qualitative Comparative Analysis (fsQCA) methodology. The TOE framework, extensively applied in technology innovation adoption research (Tornatzky et al. 1990; Van Phuoc, 2022), offers a comprehensive perspective for examining the technological, organizational, and environmental factors influencing various digital transformation stages, not only the adoption stage but also integration, application, and driven stages. This extension is based on our findings that TOE influences the entire digital transformation process, especially in the context of the industrial internet. This understanding enriches existing literature on TOE’s influence on digital transformation (Eze et al. 2020; Shahzad et al. 2023; Wassie & Lakatos, 2024), extending the applicability of the TOE framework to the research environment of digital transformation via the industrial internet (AlShamsi et al. 2022; Deng et al. 2021). Furthermore, the fsQCA methodology, conversely, suits our research by revealing how these factors combine in complex ways to influence enterprises’ digital transformation (Fiss, 2011; Ragin, 2008; Wang & Esperança, 2023). Therefore, this study focuses on:

RQ1: Whether the technological, organizational, and environmental factors affect industrial internet adoption among SMEs in the manufacturing sector?

RQ2: In what ways does industrial internet adoption enhance the performance and competitive advantage of SMEs?

The objectives of this study are: (1) Develop a conceptual framework to reflect the states of digital transformation combining industrial internet and manufacturing; (2) Identify the key factors for SMEs to start the digital transformation with the help of the industrial internet; and (3) Reveal the impact pathways of the industrial internet on the performance and competitiveness of SMEs. After the introduction, the paper reviews relevant literature, proposes hypotheses, describes design and methods, presents results, and draws conclusions.

Literature review and hypotheses

Theoretical framework

Technology-Organization-Environmental framework

The TOE framework, initially proposed by Tornatzky et al. (1990), offers a comprehensive perspective on how technological, organizational, and environmental factors influence an organization’s decision to adopt technological innovations.

Technological factors encompass the IT capabilities of the enterprise and its members, the collection, storage, management, and application of data, and the establishment and application of IT systems (Wassie & Lakatos, 2024). Organizational factors involve management’s awareness and support for digitalization, enterprise culture, acceptance of technical teams, informatization leadership, and organizational digital technology application experience (Elsharnouby et al. 2024). Environmental factors incorporate government support policies and technical standards related to digitization, such as incentive policies encouraging manufacturing enterprises to adopt the industrial internet and data security usage standards (Van Phuoc, 2022).

The general framework of TOE has been widely applied in organizational IT adoption studies (Gökalp et al. 2022). Al Hadwer et al. (2021) found that the technology dimension is a crucial link affecting enterprise cloud adoption using a systematic review of the TOE framework. Eldalabeeh et al. (2021) proposed a validated cloud accounting model studying the influencing factors of cloud computing adoption in the financial sector using TOE. Van Phuoc (2022) proposed strategies for guiding enterprises to prepare for AI application by extracting key factors affecting the adoption of AI technology from three aspects: technology, organization, and environment. Awuah et al. (2022) confirmed that technical, organizational, and environmental readiness drive the adoption of computer-aided technologies by exploring the transformation of enterprise audit processes using the TOE framework. AlShamsi et al. (2022) pointed out that TOE is one of the most common models for studying blockchain adoption and is also mostly used in organizational-level adoption studies of digital technologies.

Innovation diffusion theory

Innovation diffusion theory (IDT) is primarily used to explain how, why, and how quickly different people and organizations adopt new ideas and technologies (Rogers et al. 2014). Many studies based on IDT have explained the diffusion of new ideas/technologies and related behavioral changes in different research contexts, including technology acceptance or rejection, and these different research scenarios influence the adoption of new technologies through different characteristics (Hartley et al. 2022). IDT identifies five stages in the innovation process: understanding, persuasion, decision, implementation, and confirmation. Tetteh et al. (2022) conducted a study on the adoption of digital management systems by local government agencies based on IDT and found that regulation, environment, and organization are positive factors that promote adoption, while technology and social culture are negative factors that hinder it. Salah et al. (2021) integrated IDT and the TOE framework to identify digital management system adoption determinants from three technical, organizational, and environmental perspectives.

The digital transformation paths chain

The digital transformation paths chain was developed through a literature review and a review of related theories (as shown in Fig. 1). The four boxes represent the four stages of the enterprise digital transformation paths chain: adoption, application, driven, and performance (Yin & Zhao, 2024; Wu et al. 2024). The right arrow indicates the link between the four stages, while the downward arrow indicates the rejection/negative reply in the current stage. In the four-stage theoretical framework of digital transformation, this study defines the following four stages according to IDT and the TOE framework (Liu et al. 2024).

Stage 1: Adoption. In this stage, enterprises form adoption and the origin stage of digital transformation. According to TOE, three aspects that influence adoption are shaped by technology, organization and environment (Prajapati et al. 2024). At this stage, enterprises must face two questions, “Why do you need to carry out digital transformation?” and “Is digital transformation worth it?” After that, the enterprise decides to adopt or avoid a digital transformation strategy, terminating or postponing the transformation process.

Stage 2: Application. Adoption is the action phase after the adoption phase (Schöggl et al. 2024). At this stage, enterprises begin integrating digital technology into the enterprise production and operation processes, starting with the application stage. In the application stage, enterprises still need to overcome the resistance from technology, organization, and environment, requiring significant manpower, material, and financial resources. This stage will also lead enterprises to think about related questions such as “What returns can the enterprise get after digital application?”, “Can it achieve the expected goal after digital application?” If the answer is no, it terminates the process.

Stage 3: Driven. After finishing phased digital application and integration, digital transformation comes to a critical period of harvesting results. For example, at this stage, manufacturing enterprises will carry out whole-process changes in design and development, material procurement, manufacturing, quality control, marketing promotion, and after-sales management. Enterprises also begin to drive their operations and decision-making through digitalization gradually (Elsharnouby et al. 2024). Suppose the enterprise at this stage has a negative answer to the questions of “Whether to continue digital application and integration,” “Whether adherence to digital transformation can be rewarded,” and “Is the input and output proportional.” In that case, it will deny the digital driven and terminate digital transformation.

Stage 4: Performance. In this stage, enterprises use digital technology to build a competitive advantage and extract returns through digital transformation. With the support of digital technology, manufacturing enterprises may achieve profitable returns regarding production process upgrades, product life cycle improvements, flexible and intensive production, efficient supply chain collaboration (Sivan et al. 2022), and collaborative manufacturing implementation, thereby enhancing their competitive advantage and enterprise performance (Wu et al. 2024).

Hypotheses

Industrial internet technology, organization, environment and adoption

Industrial internet adoption (IIA) is a strategic move towards digital transformation, enabling enterprises to engage effectively with the industrial internet (Awuah et al. 2022; Wu & Li, 2024). Understanding that individual innovation does not directly impact enterprise technology adoption behavior is important. Instead, this is influenced by technology readiness, organizational readiness, and environmental factors (Awuah et al. 2022). Among the factors affecting the adoption of emerging technologies, organizational policies, organizational culture, lack of knowledge and management support, and lack of collaboration and coordination can create barriers to the use of digital technologies (AlShamsi et al. 2022). Furthermore, the adoption to consolidate the decision further of digital technologies is hindered by several technological aspects, such as technological immaturity, reluctance to change (Sabatini et al. 2022), interoperability issues, and scalability issues (Kim & Kim, 2021). Combining the three aspects involved in the TOE framework, technological compatibility, comparative advantage, technological complexity, technological capabilities, management capabilities, organizational readiness, government participation, market uncertainty, and supplier partnerships will all significantly affect the use of artificial intelligence.

Industrial internet technology (IIT) evaluates technical dimensions such as technical resources, capabilities, and capital enterprises required to adopt the industrial internet (Xiufan et al. 2024). The technological environment is important for improving organizational effectiveness, efficiency (Sivan et al. 2022), productivity, and product/service quality (Chang, 2020). IT infrastructure provides assurance for enterprise digital application development, information sharing across products/services, business processing, and cross-organizational collaboration (Eldalabeeh et al. 2021; Prajapati et al. 2024; Van Phuoc, 2022). IT technical capabilities play a key role in successful digital transformations, and failed digital transformations are caused by complex technologies and inadequate organizational readiness (Awuah et al. 2022). The interrelationships between these factors lead us to propose:

H1: Industrial internet technology has a positive effect on industrial internet adoption.

Industrial internet organization (IIO) embodies the internal evaluation of organizational dimensions such as attitudes, readiness, and experience for adopting the industrial internet (Frank et al. 2024). Organizational characteristics refer to organizational factors that influence innovation adoption decisions and are enablers for the use and success of digital management systems (Tetteh et al. 2022). Successful innovation implementation was found to be significantly related to organizational and environmental contexts (Ahmad et al. 2022). Top management support is key in cloud service adoption, especially in guiding resource allocation, service integration, and process reengineering (Al Hadwer et al. 2021). Top management needs to create a buffer period between new computer-aided systems and current business practices, and a lack of top management commitment becomes a major obstacle to the successful implementation of the system (Awuah et al. 2022). Recognizing these interrelationships, the study hypothesizes:

H2: Industrial internet organization have a positive effect on industrial internet adoption.

The industrial internet environment (IIE) evaluates environmental dimensions such as government support policies, technical standards, and partnerships related to enterprises’ adoption of the industrial internet (Kim & Kim, 2021; Malik et al. 2021). Environmental dimensions also determine the adoption of digital technologies by businesses, among which are competitive pressures, partners, and government incentives (Gökalp et al. 2022). Firms must understand customer needs and requirements to win customer satisfaction, and digital management systems can track customers in real-time and provide timely feedback and personalized recommendations based on customer characteristics (Salah et al. 2021). Competition, customer, and industry pressures that lead business leaders to adopt appropriate competitive strategies to gain maximum market share also force firms to adopt digital technologies (Kareem et al. 2024). Considering these interrelationships, the study hypothesizes:

H3: Industrial internet environment has a positive effect on industrial internet adoption.

Industrial internet adoption, integration, application and driven

Industrial internet integration (III) represents the successful assimilation of industrial internet technologies into an enterprise’s existing ICT infrastructure, encompassing both internal and external integration processes (Chen & Chen, 2021; Lin, 2022). This integration is not merely a technical endeavor but a strategic imperative for organizations seeking to fully leverage the transformative potential of the industrial internet (Vial, 2019). The adoption of the industrial internet, signifying a strategic decision to embrace digital transformation, serves as a critical precursor to effective integration (Oliveira & Martins, 2011; Baker, 2012). Industrial internet adoption serves as a catalyst, enabling enterprises to reimagine and reconfigure their resource allocation and utilization patterns (Wu & Li, 2024). The adoption of industrial internet technologies is not merely a technical upgrade but a strategic imperative that lays the groundwork for comprehensive digital transformation (Frank et al. 2024). It provides the necessary technological foundation and organizational readiness for subsequent integration efforts. The adoption stage is particularly crucial for manufacturing enterprises, as it sets the stage for the seamless incorporation of industrial internet capabilities into their core operations (Yin & Zhao, 2024). This decision to adopt often precedes the allocation of resources and the development of capabilities necessary for successful integration (Wang et al. 2016). The integration of industrial internet technologies necessitates a shift in organizational processes, workflows, and potentially even business models, all of which stem from the initial adoption decision (Verhoef et al. 2021). SMEs that strategically adopt digital technologies are more likely to successfully integrate these technologies into their core business processes, leading to enhanced operational efficiency (Elsharnouby et al. 2024). Similarly, the initial adoption of digital technologies serves as a critical enabler for their subsequent integration into circular economy practices within manufacturing firms (Schöggl et al. 2024). Recognizing this inherent dependency and the foundational role of adoption in enabling integration, we posit:

H4: Industrial internet adoption has a positive effect on industrial internet integration.

Industrial internet application (IIAP) encompasses the business operations by which manufacturing enterprises apply the industrial internet in R&D, production, sales, after-sales, and others (Belhadi et al. 2024). The infrastructure and technical resources in the digital environment are the antecedents of enterprise digitalization activities (Salah et al. 2021). The application of the industrial internet is also inseparable from IT hardware, software, and networks. Therefore, when enterprises implement the industrial internet, they should include it in their top-level strategy, adopt it, and prepare for the basic conditions required for deploying it (Hartley et al. 2022). Adopting advanced digital technologies, building data analysis capabilities, and effective governance mechanisms can enhance enterprises’ digital innovation and application capabilities (Chatterjee et al. 2024). Adopting the industrial internet can facilitate access to financial resources (Hasani et al. 2017). Only when a consensus can be formed on adopting the industrial internet strategy from senior managers to grass-roots users within the enterprise can the application of the industrial internet be successfully promoted in enterprises (Van Phuoc, 2022). However, these assumptions have not been fully tested in SMEs’ adoption of the industrial internet (Jones et al. 2021; Wang & Esperança, 2023). Therefore, we consider it necessary to verify the applicability of these hypotheses in the specific context of this study. Considering these interconnected variables, the study hypothesizes:

H5: Industrial internet adoption has a positive effect on industrial internet application.

The industrial internet driven (IID) enterprise development process can systematically collect, organize, analyze, and generate decision-making suggestions for manufacturing enterprises, thereby improving the overall efficiency and quality of the enterprise (Chen et al. 2022; Haftor et al. 2021). Industrial internet integration can improve processes and practices and drive enterprises to adapt to a highly uncertain and rapidly changing business environment (Kim & Kim, 2021). Industrial internet integration plays a central role in the acquisition, release, and integration of enterprise resources and is a core factor in promoting and improving the driving effect of the industrial internet (Eldalabeeh et al. 2021). The internal integration of the industrial internet includes forming a cross-departmental collaboration system within the enterprise for resources, production, and processes to fulfill customer needs. In contrast, external integration is the close collaboration between the enterprise and its partners to support enterprise development (Chen & Chen, 2021). For the industrial internet to generate value, enterprises must adopt the industrial internet to use it in the processes that drive the enterprise’s growth (Reis et al. 2020). SMEs can take advantage of digital transformation opportunities to enhance their competitiveness (Wang & Esperança, 2023). Drawing from the literature above review, this study posits:

H6: Industrial internet integration has a positive effect on industrial internet driven.

H7: Industrial internet application have a positive effect on industrial internet driven.

Industrial internet driven, enterprise competitive advantage and performance

Enterprise performance (EP) is an evaluation index to measure an enterprise’s operational efficiency and results (Ali, 2023; Kalaitzi & Tsolakis, 2022). Adopting new platforms and systems based on digital technologies can bring many benefits to improved business performance (Salah et al. 2021). The industrial internet can collect a large amount of data in the production process of manufacturing enterprises in real-time, saving many labor costs (Salah et al. 2021). In addition, enterprises can generate reports required for business operations based on the industrial internet and make decision-making suggestions for enterprises based on automated analysis (AlShamsi et al. 2022). Manufacturing enterprises implementing digital transformation with the help of the industrial internet can accumulate digital assets, which can help enterprises analyze how to improve financial and innovation performance (Deng et al. 2021). The study hypothesizes:

H8: Industrial internet driven has a positive effect on enterprise performance.

Enterprise competitive advantage (ECD) is a comprehensive reflection of an enterprise’s market and non-market competitive advantage in social development (Chatterjee et al. 2024; Rahman et al. 2022). The industrial internet, based on digital technology and a large amount of data, is an important driving force for enterprises to quickly update products, which also helps enterprises to improve product development efficiency and potential commercial value (Kim & Kim, 2021; Peng et al. 2021). Companies adopting digital strategies will also tend to digitally drive business operations to improve performance, competitiveness, and value (Chen et al. 2022). Industrial internet-driven enterprises can improve performance and maximize competitive advantage (Chatterjee et al. 2024). Drawing from the interrelationships observed in the literature review, we posit:

H9: Industrial internet driven has a positive effect on enterprise competitive advantage.

When an enterprise conducts digital transformation to achieve higher enterprise performance, it can also bring greater competitive advantage to the enterprise (Kumar et al. 2023). Digital transformation opportunities can create opportunities for enterprises to re-improve their processes and products, improving their overall performance and value (Chang, 2020). The industrial internet is an important driving force for transforming the manufacturing industry. Through the application of the industrial internet, enterprises will move from machine manufacturing to digital manufacturing to realize the transition of enterprise value (David et al. 2022). After integrating the industrial internet, enterprise management becomes more efficient and evidence-based, and improving enterprise management capabilities also increases competitive advantage (Chen & Chen, 2021). In light of the interrelationships observed among the variables, the study hypothesizes:

H10: Enterprise performance has a positive effect on enterprise competitive advantage.

A hypothetical model of the four phases of enterprise digital transformation (Fig. 2).

Methods

Instrument

Data were collected through a questionnaire divided into two parts. The first contains the measurement scale of the four-stage research model of enterprise digital transformation, and the questionnaire includes a marker variable (perceived habit) to test the common variance of the research model. The content of the first part contains a total of 9 latent variables, a total of 39 items; for the scale items, the Likert 5-level scale was measured (values 1–5 indicate strongly disagree to strongly agree, respectively). The second part is the basic statistical information of the interviewed enterprises.

To ensure the content validity, all measurement items were adopted or contextualized from published literature (Table 1). Industrial internet technology was adapted from Pinheiro et al. (2022) and Na et al. (2022); Industrial internet organization was adapted from Chatterjee et al. (2024), Zhang et al. (2021), and Malik et al. (2021); Industrial internet environment was adapted from Malik et al. (2021), Kalaitzi and Tsolakis (2022); Industrial internet adoption was adapted from Zhang et al. (2021), and Fonseka et al. (2022); Industrial internet integration was adapted from Chen and Chen (2021), and Lin (2022); Industrial internet application was adapted from Bag et al. (2021), and Belhadi et al. (2024); Industrial internet driven adapted from Haftor et al. (2021), and Chen et al. (2022); Enterprise competitive advantage adapted from Chatterjee et al. (2024), and Rahman et al. (2022); Enterprise performance was adapted from references in Kumar et al. (2023), and Ali (2023); perceived habit (marker variable) was adapted from Zha et al. (2013).

Data collection and sample

After the initial completion of the questionnaire based on pertinent literature, a meticulous pre-test was implemented to ensure the questionnaire’s clarity and applicability (Eldalabeeh et al. 2021; Van Phuoc, 2022). Before the pre-testing, an expert panel of five scholars and entrepreneurs was invited to review the questionnaire. They provided valuable suggestions on aspects like the clarity of specific terminologies such as “Industrial internet driven”, potential ambiguities in the phrasing of certain variables, and the arrangement of variables. Accordingly, we made the necessary revisions:

-

1.

Definitions for key terms like “Industrial internet driven” were added in the Variables section for better comprehension.

-

2.

Adjustments were made in phrasing six variables to express their connotations accurately.

-

3.

The collection of enterprise characteristic data was placed at the end of the scale, serving as control variables.

Subsequently, an online questionnaire was disseminated among 30 managers from various manufacturing industries for a preliminary survey. The feedback indicated that the respondents clearly understood the scale variables, and the questionnaire was smoothly filled out, demonstrating good validity (Cronbach’s alpha >0.7). Afterward, a formal large-scale survey was carried out.

The purpose sampling technique was adopted in this study to select enterprises from China, to improve the theory of the research results and the flow of the data collection process (Chaudhuri et al. 2021). Since the government of China issued the call to promote enterprise digitalization in 2021, it has successfully carried out many publicity and public welfare training activities, and even awarded 15% of investment funds to enterprises that carry out enterprise digitalization transformation. A series of measures by the local government has made many achievements in enhancing the intentions and effectiveness of enterprises in digital transformation (He et al. 2022).

Questionnaire Star produced and distributed the questionnaires online among the entrepreneurs association and the professional managers association. A total of 401 questionnaires were distributed, with a response rate of 78.3%. The survey lasted a month, and 314 manufacturing enterprises returned with valid responses (Table 2). The questionnaire also collected data about the age and size of the enterprises.

Common method variance

Acknowledging the potential for common method variance (CMV), we implemented strategies to mitigate its impact based on previous literature, spanning pre-survey, during-survey, and post-survey phases (Wang & Esperança, 2023). Post hoc tests indicate that CMV does not significantly influence our results, lending validity to the causal relationships between the antecedents and outcomes. Concretely, we made efforts to reduce the influence of CMV in three aspects:

-

1.

Before the survey, we organized expert panel discussions and conducted pre-surveys to ensure the clarity and relevance of the questions.

-

2.

During the survey, we emphasized that all data would be kept strictly confidential and used solely for research purposes. The survey did not involve any personally identifiable information, and participants were informed that their participation was voluntary, with the freedom to withdraw at any time.

-

3.

After the survey, we conducted post hoc tests, including the single factor test and the marker variable technique (Wang & Esperança, 2023). The “Perceived habit,” unrelated to the research content, was selected as the marker variable, and we tested the relationship between this marker variable and other variables in the model. The results revealed no significant relationship between the marker variable and other latent variables in the model, indicating that there was no CMV in the results of this study (Hair et al. 2022).

Data analysis technology

To enhance the methodological rigor of our study, we employed a mixed-method approach combining partial least squares structural equation modeling (PLS-SEM) and fsQCA. This methodological triangulation allows us to capture both linear relationships and complex configurational patterns in our data (Zhang, 2024). We selected these analytical techniques based on their suitability for our research context and their ability to provide complementary insights (Wang & Esperança, 2023). PLS-SEM is particularly appropriate for our exploratory study, which involves developing a new theoretical model with multiple mediating variables. It is well-suited for theory development and can handle complex models with minimal demands on measurement scales and sample size (Chatterjee et al. 2024). fsQCA, on the other hand, allows us to identify complex causal patterns that may not be apparent through traditional linear analyses, providing a nuanced understanding of the factors influencing digital transformation in SMEs (Fiss, 2011; Ragin, 2008; Schöggl et al. 2024).

PLS is particularly well-suited for our research, which is exploratory and involves developing a new theoretical model (Zhang, 2024). PLS, a structural equation modeling technique, is frequently employed in exploratory studies due to its minimal demands on measurement scales, sample size, and residual distributions (Wang and Zhang, 2024a). It is especially useful for theory development as it can handle complex models with multiple mediating variables and has better predictive power than other techniques (Wang & Zhang, 2024b). PLS-SEM has also been widely used in similar studies (Kalaitzi & Tsolakis, 2022; Schöggl et al. 2024).

To circumvent the limitations of relying on a single method, we also utilized fsQCA in our research. fsQCA is a method that identifies causal patterns in the data that lead to an outcome (Fiss, 2011; Ragin, 2008). The fsQCA approach is particularly useful when uncovering complex causal relationships that may not be readily apparent with other analytical techniques. Combining PLS and fsQCA uncovered more nuanced and interesting insights, providing a richer understanding of the phenomena under study.

The combination of PLS and fsQCA in our data analysis approach allowed for a robust and comprehensive exploration of our research questions (Wang & Esperança, 2023).

Analyses and results

Structural equation modelling analysis

Measurement model

The PLS-SEM measurement model was tested for discriminant, content, and convergent validity (Hair et al. 2022). All measurement items in this study are derived from existing literature or adapted from previous research results and have been verified by pre-research. Therefore, the measurement model of this study can be considered to have good content validity. The reliability of the measurement model can be judged by testing the composite reliability (CR) and Cronbach’s alpha. Table 3 shows that both values are greater than 0.8, which is much higher than the critical value of 0.7, so the measurement model in this study has good reliability. The convergent validity of the measurement model was judged by verifying the average variance extracted (AVE) value. Table 3 shows that the average extraction variance of each latent variable is greater than 0.594, and none is less than 0.5, indicating that the measurement model in this study has good convergent validity. The discriminant validity can be obtained by comparing the square root of the AVE of each latent variable and the correlation coefficient between the other latent variables (Table 4). Therefore, the discriminant validity of the measurement model in this study is ideal (Zhang, 2024).

Factor loading between each latent variable and its measurement item is greater than the cross-factor loading between the latent variable and other latent variables (Table 5). It can be concluded that the measurement model of this study has ideal convergent and discriminant validity (Hair et al. 2022). The analysis results with the help of SmartPLS 3 show that the heterotrait-monotrait ratio (HTMT) of the measurement model in this study is less than 0.663, further indicating that the discriminant validity of the measurement model is relatively good.

Structural model

The research results of the four-stage research model of enterprise digital transformation are shown in Fig. 3.

The coefficients of determination (R2) of industrial internet driven, enterprise performance and enterprise competitive advantage are 42.5%, 37.1%, and 46.4%, respectively, indicating that the model in this study has a moderate explanatory power (Hair et al. 2022). Standardized root mean square residual (SRMR) can evaluate the fit of the research model. The result of SRMR is 0.046, less than the critical value of 0.08, indicating that the model fits well (Hair et al. 2022). In this study, the model Q2 was calculated using the blindfolding algorithm. The Q2 of enterprise competitive advantage in the current four-stage model of enterprise digitization is 0.293 (greater than 0.15), showing a moderate predictive correlation.

Hypotheses H1 to H10 in the basic model were supported (Fig. 3). Control variables, including enterprise age, enterprise size, and the enterprise’s development stage, had no significant effect on enterprise competitive advantage.

Cross-stage analysis

This study tested the rationality of the four stages of digital transformation through cross-stage analysis. The results of the data analysis show that IIA has no effect on IID (p > 0.5), IIA has no effect on ECA (p > 0.5), and IIAP has no effect on ECA (p > 0.5). The above results indicate that Stage 1 cannot directly influence Stages 3 and 4, which further justifies the division of the four stages in the digital transformation of enterprises.

fsQCA

Calibration

In the first stage of using fsQCA, this study uses the calibration function in the fsQCA 3.0 software to calibrate the sample data to a continuous set from 0 to 1, and then convert the data into degrees of full membership, cross-over, and full non-membership (Wang & Esperança, 2023). The calibration results are shown in Table 6.

Necessity analysis

The second phase of fsQCA is necessity condition analysis (NCA), which analyzes the combination of causal conditions through measures of consistency and coverage (Dahms et al. 2023), to explore eight prerequisites on the existence of derived dependent variables. The results of the necessity analysis in Table 7 show that no single condition is necessary to produce the “Enterprise competitive advantage” result.

Sufficient condition analysis

In our fsQCA analysis, we employed a raw consistency threshold of 0.80 and a PRI (Proportional Reduction in Inconsistency) consistency threshold of 0.50, with a minimum case frequency of 2. These thresholds were chosen based on recommendations in the fsQCA literature to ensure robust and meaningful results (Fiss, 2011; Ragin, 2008). Table 8 shows the 12 groups of configurations of the sufficient condition analysis results, the solution consistency is 0.877 (greater than 0.8), and the solution coverage rate is 0.519 (above 0.5), indicating that the results have acceptable reliability and interpretation power (Wang & Esperança, 2023). The results of groups 4, 5, 6, 11, and 12 indicate that the combination of the above conditions is a sufficient condition to bring about the competitive advantage of the firm. Groups 1, 4, 5, 10, 11, and 12 cover the four stages of digital transformation, although they are less than eight conditions. Most of the groups also indicate that the drive for enterprise competitive advantage cannot be separated from the elements in the TOE framework.

To ensure the robustness of our findings, we conducted several additional analyses. For the fsQCA results, we conduct a robustness test on the configuration of the competitive advantage of enterprises, increasing the PRI consistency threshold from 0.50 to 0.60 and increasing the case frequency from 2 to 3, resulting in similar configuration results. Therefore, the findings are robust (Shehzad et al. 2024).

Discussion and academic contribution

Digital transformation paths chain

This research proposes a “Digital transformation paths chain” framework, and a research model of enterprise industrial internet adoption and impacts based on the TOE framework and IDT through cross-analysis of relevant literature.

Existing research on enterprise industrial internet adoption mainly focuses on the adoption of the technology or the impact of the industrial internet on enterprise performance (Prajapati et al. 2024; Wassie & Lakatos, 2024), lacking empirical support for the processes and linkages that facilitate the two separate stages. Our findings on the multi-stage nature of digital transformation align with and extend recent work by Wu and Li (2024), who emphasized the dynamic and continuous nature of digital transformation in Chinese enterprises. While they focused on entrepreneurship and disruptive innovation, our study provides a more granular view of the transformation stages, particularly in the context of SMEs adopting the industrial internet. Our research on the positive impact of industrial internet adoption on enterprise performance and competitive advantage aligns with recent work by Sivan et al. (2022), who highlighted the critical role of Industry 4.0 technologies in driving efficiency and competitiveness in the logistics sector.

This study considers enterprise industrial internet adoption as a process of technological innovation development. Drawing on the excellent results of many TOE frameworks (AlShamsi et al. 2022) and IDT (Hartley et al. 2022), we propose a four-stage model to study the complete process of enterprises from industrial internet adoption, integration, and application to finally driving enterprise development.

The research results confirm that adopting the industrial internet significantly positively affects enterprise performance and competitive advantage (Wu et al. 2024). It is important to note the stages of industrial internet adoption, application, driven, and performance, which need to be completed to impact the competitive advantage of enterprises. The four-stage model of industrial internet adoption is an important theoretical contribution of this study, which helps to increase the research literature in the field of enterprise industrial internet adoption. This study provides a framework and evidence for manufacturing enterprises to implement industrial internet adoption and enriches the research results on industrial internet adoption in manufacturing enterprises. We have further elucidated the applicability and importance of our findings in SMEs adopting the industrial internet (Wang & Esperança, 2023).

Industrial internet can play the effect through four stages of adoption, application, driven, and performance, ultimately affecting enterprise performance and competitive advantage. This finding opens up the enterprise industrial internet adoption black box for stakeholders, detailing what and how each stage is related. This result shows that the implementation of industrial internet adoption by enterprises can improve enterprise performance (Inegbedion et al. 2024) and competitive advantage (Chen et al. 2022). While previous research on industrial internet adoption has focused more on the influencing factors of enterprise performance (Lin, 2022), this study expands on the specific impact and process of industrial internet adoption on enterprise performance and competitive advantage.

Roles of technology, organization and environment

Digital technology, organization, and environment are three essential dimensions influencing enterprise industrial internet adoption (Awuah et al. 2022). This study reaffirms that these three dimensions play a pivotal role as the antecedents of industrial internet adoption. Moreover, our research has discovered that these dimensions also represent the initial stage of the adoption process. Our investigation into the critical role of technological, organizational, and environmental factors throughout the digital transformation process supports and builds upon recent findings by Elsharnouby et al. (2024), who identified critical internal enablers for SMEs’ export performance in Qatar. While their study focused on export performance, our research extends these insights to the specific context of industrial internet adoption and its impact on overall enterprise performance and competitive advantage. We also found that organizational factors play a crucial role in the adoption and implementation of digital technologies, which is consistent with Sabatini et al. (2022), who emphasized the importance of organizational vision and strategy in driving business model innovation through digital technologies in Italian SMEs.

Applying the TOE framework, our study underscores its importance for enterprises adopting industrial internet strategies. We propose a pathway to enhance enterprise performance and competitive advantage through these three dimensions. Importantly, our study leverages the fsQCA methodology to reveal complex combinations of these factors that influence the enterprise’s digital transformation (Fiss, 2011; Ragin, 2008). This approach is particularly suitable for our research, as it allows us to account for multiple causal pathways and provides a more nuanced understanding of the factors driving industrial internet adoption. The findings on the positive impact of industrial internet adoption on enterprise performance and competitive advantage are consistent with recent work by Wang and Esperança (2023), who found that digital transformation can improve market and ESG performance in Chinese SMEs. However, our study goes further by delineating the specific pathways through which this impact occurs, namely through the stages of adoption, application, driven, and performance.

Considering the optimal strategy for enhancing enterprise competitive advantage, our fsQCA results indicate that one or several TOE elements are included in most of the portfolio regardless of the sufficient combination of conditions. This finding further attests to the critical role of digital technology, organization, and environment in the inception and outcome of enterprise industrial internet adoption. These study’s findings are consistent with and extend the work of Elsharnouby et al. (2024), who studied critical internal enablers of SME export performance. While they focused on general organizational factors, our study specifically highlights how these factors interact in the context of industrial internet adoption. Furthermore, our results complement the research of Wassie and Lakatos (2024) on the future of internal audit functions in the era of artificial intelligence by demonstrating how similar technological, organizational, and environmental factors influence the broader digital transformation process in SMEs.

Our research found that the TOE framework affects companies’ adoption of digital transformation and corporate performance through integration and application. This finding enriches the existing literature on the impact of TOE in various stages of digital transformation and extends the applicability of the TOE framework in research on the digital transformation of the industrial internet (AlShamsi et al. 2022). Our results on the importance of the industrial internet for enhancing SME competitiveness align with recent work by Schöggl et al. (2024), who examined the role of digital technologies in implementing circular economy practices in manufacturing firms. While their focus was on sustainability, our study complements their findings by highlighting how similar digital technologies can drive overall performance and competitive advantage. We emphasize that this finding expands the scope of the application of the TOE framework in research on enterprise digital transformation and accumulates new evidence for research in this field (Gökalp et al. 2022).

Managerial implications

Implications for business

Enterprises should formulate strategies for digital transformation, enhance learning within and outside the organization, and improve their digital capabilities to adapt to the rapid development of the current digital wave (Xiufan et al. 2024). Enterprises must be aware that digital transformation does not happen overnight as this is a path chain. Therefore, enterprises can develop long-term, medium-term, and short-term phased strategies in the digitalization process to alleviate the pressure of digital transformation in capital, workforce, and technology (Elsharnouby et al. 2024). From outside the organization, enterprises should focus on customer needs to improve business agility and the success rate of digital transformation.

Enterprises should flexibly adjust their organizational structure from inside the organization to accommodate digital transformation (Sivan et al. 2022). First, in terms of human resources, enterprises should recruit new professionals and share the latest digital knowledge with veteran employees to help them prepare for digital transformation (Liu et al. 2024). Second, in terms of organizational culture, enterprises encounter internal resistance to new technologies and strategies and should foster a culture that encourages digital innovation and helps enterprises remove the burden of thinking about digital transformation (Sabatini et al. 2022). A culture of innovation can help enterprises be more willing to experiment with new technologies and ideas, thus gaining more opportunities to improve corporate performance and competitive advantage (Kareem et al. 2024). Third, in terms of organizational security, enterprises need to develop a data security manual, standardize data permission settings, strengthen data backup and management, and protect their digital assets and trade secrets.

Implications for relevant stakeholders

First, the R&D enterprises of the industrial internet should improve technical solutions, provide technical support and training promptly, and help enterprises solve technical problems (Frank et al. 2024). The service providers of the industrial internet should not only provide hardware and software equipment, but also provide training for technical application talents to provide complete solutions for enterprises relying on digital transformation. Digital solutions service providers must help enterprises complete security training to address data security issues. Digital solution providers should also be able to innovate the way they charge. For example, providers can use digital technologies like cloud services to provide enterprises with on-demand services such as SaaS, thus avoiding large upfront hardware investments (Schöggl et al. 2024).

Second, to solve enterprises’ weak digital technology capabilities, the government can support the agglomeration of industrial internet R&D enterprises to improve the technical service capabilities of the industrial internet. Governments should speed up formulating data security laws and regulations and coordinate multiple departments to issue data security standards based on sufficient research to ensure the security of enterprise digital assets and business secrets (Dou et al. 2022). The competent government departments can entrust industry associations to organize group and bulk purchases to obtain lower purchase costs and, at the same time, introduce corresponding industrial internet implementation incentive plans to give corresponding subsidies (Bordoloi et al. 2022). The government’s bulk procurement measures and subsidies can help enterprises alleviate their digital transformation concerns and financial pressure and help companies improve the success rate of digital transformation.

Limitations and future research

This study achieves a set of significant results. However, it also highlights the need for further research. This study collects cross-sectional data and does not address the differences between enterprises before and after digital transformation; subsequent research can consider adopting a hierarchical tracking method, that is, using a multi-group structural equation model to analyze the impact of the two samples on improving enterprises’ performance and competitive advantage. Research subjects with different characteristics may produce more interesting research results. Future research could delve more deeply into the differences between enterprises at different development stages and in different industries during the digital transformation process. While our sample is representative of Chinese SMEs, the generalizability of our findings to other contexts should be tested in future research. Cross-cultural comparisons could provide valuable insights into how the digital transformation process may vary across different institutional environments.

Conclusion

This study has contributed to our understanding of digital transformation pathways in SMEs, particularly in the context of the industrial internet. Through the development of a “Digital transformation paths chain” framework and research model, we have illuminated the key factors driving SMEs to adopt digital transformation and the impact pathways through which the industrial internet influences performance and competitiveness. Our research has revealed that the adoption of the industrial internet is not a single event but a complex, multi-stage process comprising adoption, application, driven, and performance stages. Each of these stages plays a crucial role in the overall digital transformation journey of SMEs. The study underscores the positive impact of industrial internet adoption on enterprise performance and competitive advantage, highlighting the importance of a holistic approach to digital transformation. The findings emphasize the critical roles of TOE in driving industrial internet adoption. The application of the TOE framework in this context provides a comprehensive perspective on the factors influencing various digital transformation stages. This insight is particularly valuable for SMEs, which often face unique challenges in their digital transformation efforts due to resource constraints and organizational characteristics. The use of both PLS-SEM and fsQCA methodologies has allowed us to uncover nuanced relationships and complex combinations of factors influencing digital transformation. This multi-method approach provides a more comprehensive understanding of the digital transformation process in SMEs. Our study offers valuable insights for businesses, policymakers, and other stakeholders involved in digital transformation initiatives. For businesses, it provides a roadmap for navigating the complex process of digital transformation, highlighting the need for a staged approach and the importance of considering technological, organizational, and environmental factors. For policymakers, our findings underscore the need for supportive policies and initiatives that address the specific challenges faced by SMEs in their digital transformation journeys. This research not only advances our theoretical understanding of digital transformation in SMEs but also provides practical guidance for implementing effective digital strategies. By emphasizing the importance of a comprehensive approach to digital transformation, our study underlines the potential for SMEs to enhance their performance and competitive advantage through the strategic adoption and implementation of industrial internet technologies.

Data availability

Due to a commitment to the confidentiality of respondent data, data are not shared publicly.

References

Ahmad M, Khayal MSH, Tahir A (2022) Analysis of Factors Affecting Adoption of Volunteered Geographic Information in the Context of National Spatial Data Infrastructure. ISPRS Int J Geo-Inf 11(2):120

Ali Z (2023) Predicting SMEs performance through green supply chain practices: a mediation model link of business process performance. Asia Pac J Mark Logist 35(2):432–450

Al Hadwer A, Tavana M, Gillis D, Rezania D (2021) A systematic review of organizational factors impacting cloud-based technology adoption using Technology-organization-environment framework. Internet Things 15:100407

AlShamsi M, Al-Emran M, Shaalan K (2022) A Systematic Review on Blockchain Adoption. Appl Sci 12(9):4245

Awuah B, Onumah JM, Duho KCT (2022) Determinants of adoption of computer‐assisted audit tools and techniques among internal audit units in Ghana. Electron J Inf Syst Dev Ctries 88(2):e12203

Bag S, Dhamija P, Pretorius JHC, Chowdhury AH, Giannakis M (2021) Sustainable electronic human resource management systems and firm performance: an empirical study. Int J Manpow 43(1):32–51

Baker J (2012) The technology–organization–environment framework. Inf Syst Theory: Explain ng Predict. Our Digital Soc, 1:231–245

Belhadi A, Mani V, Kamble SS, Khan SAR, Verma S (2024) Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation. Ann Oper Res 333(2):627–652

Bordoloi T, Shapira P, Mativenga P (2022) Policy interactions with research trajectories: The case of cyber-physical convergence in manufacturing and industrials. Technol Forecast Soc Change 175:121347

Chang YW (2020) What drives organizations to switch to cloud ERP systems? The impacts of enablers and inhibitors. J Enterp Inf Manag 33(3):600–626

Chatterjee S, Chaudhuri R, Vrontis D (2024) Does data-driven culture impact innovation and performance of a firm? An empirical examination. Ann Oper Res 333(2):601–626

Chaudhuri, R, Chatterjee, S, Vrontis, D, Thrassou, A (2021) Adoption of robust business analytics for product innovation and organizational performance: the mediating role of organizational data-driven culture. Annals of Operations Research, 1-35

Chen D, Esperança JP, Wang S (2022) The Impact of Artificial Intelligence on Firm Performance: An Application of the Resource-Based View to e-Commerce Firms. Front Psychol 13:884830

Chen CHV, Chen YC (2021) Influence of intellectual capital and integration on operational performance: big data analytical capability perspectives. Chin Manag Stud 16(3):551–570

Dahms S, Zutshi A, Puri S (2023) Service sector subsidiary performance in emerging markets: is it who or what you know? Int J Emerg Mark 18(11):4843–4864

David LO, Nwulu NI, Aigbavboa CO, Adepoju OO (2022) Integrating fourth industrial revolution (4IR) technologies into the water, energy & food nexus for sustainable security: A bibliometric analysis. J Clean Prod 363:132522

Deng Q, Lu J, Zeng Z, Zheng Y, Liu W (2021) Dynamics of Health Technology Diffusion in the Integrated Care System (DHTDICS): A Development and Validation Study in China. Risk Manag Healthc Policy 14:331–344

Dou K, Li J, Zhou Y (2022) Research on Design and Monitoring of a Development Index of an Industrial Internet Platform Based on a Fixed-Base Index Method. Electronics 11(2):274

Eldalabeeh AR, Al-Shbail MO, Almuiet MZ, Bany Baker M, E’Leimat D (2021) Cloud-based accounting adoption in Jordanian financial sector. J Asian Financ, Econ Bus 8(2):833–849

Elsharnouby TH, Elbanna S, Farha AA, Mauji N (2024) Exploring critical internal enablers to SMEs export performance: evidence from Qatar. Humanit. Soc Sci Commun 11(1):1–12

Eze SC, Chinedu-Eze VCA, Okike CK, Bello AO (2020) Critical factors influencing the adoption of digital marketing devices by service-oriented micro-businesses in Nigeria: A thematic analysis approach. Humanit. Soc Sci Commun 7(1):1–14

Fiss PC (2011) Building better causal theories: A fuzzy set approach to typologies in organization research. Acad Manag J 54(2):393–420

Fonseka K, Jaharadak AA, Raman M (2022) Impact of E-commerce adoption on business performance of SMEs in Sri Lanka; moderating role of artificial intelligence. Int J Soc Econ 49(10):1518–1531

Frank, AG, Thürer, M, Godinho Filho, M, Marodin, GA (2024). Beyond Industry 4.0–integrating Lean, digital technologies and people. International Journal of Operations & Production Management

Gökalp E, Gökalp MO, Çoban S (2022) Blockchain-based supply chain management: understanding the determinants of adoption in the context of organizations. Inf Syst Manag 39(2):100–121

Hair, JF, Hult, GTM, Ringle, CM, Sarstedt, M (2022) A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM) (3rd ed.). Thousand Oaks, CA: Sage

Haftor DM, Climent RC, Lundström JE (2021) How machine learning activates data network effects in business models: Theory advancement through an industrial case of promoting ecological sustainability. J Bus Res 131:196–205

Hartley JL, Sawaya W, Dobrzykowski D (2022) Exploring blockchain adoption intentions in the supply chain: perspectives from innovation diffusion and institutional theory. Int J Phys Distrib Logist Manag 52(2):190–211

Hasani T, Bojei J, Dehghantanha A (2017) Investigating the antecedents to the adoption of SCRM technologies by start-up companies. Telemat Inform 34(5):655–675

He Z, Kuai L, Wang J (2022) Driving mechanism model of enterprise green strategy evolution under digital technology empowerment: A case study based on Zhejiang Enterprises. Bus Strategy Environ 32(1):408–429

Inegbedion HE, Thikan PR, David JO, Ajani JO, Peter FO (2024) Small and medium enterprise (SME) competitiveness and employment creation: the mediating role of SME growth. Humanit. Soc Sci Commun 11(1):1–10

Jones MD, Hutcheson S, Camba JD (2021) Past, present, and future barriers to digital transformation in manufacturing: A review. J Manuf Syst 60:936–948

Kareem HM, Alsheikh AH, Alsheikh WH, Dauwed M, Meri A (2024) The mediating role of accounting information systems in small and medium enterprise strategies and organizational performance in Iraq. Humanit. Soc Sci Commun 11(1):1–12

Kalaitzi D, Tsolakis N (2022) Supply chain analytics adoption: Determinants and impacts on organisational performance and competitive advantage. Int J Prod Econ 248:108466

Kim Y, Kim B (2021) The effective factors on continuity of corporate information security management: Based on TOE framework. Information 12(11):446

Kumar P, Dwivedi YK, Anand A (2023) Responsible artificial intelligence (AI) for value formation and market performance in healthcare: The mediating role of patient’s cognitive engagement. Inf Syst Front 25(6):2197–2220

Lin HF (2022) IT resources and quality attributes: The impact on electronic green supply chain management implementation and performance. Technol Soc 68:101833

Liu W, Wang Z, Shi Q, Bao S (2024) Impact of the digital transformation of Chinese new energy vehicle enterprises on innovation performance. Humanit. Soc Sci Commun 11(1):1–11

Malik S, Chadhar M, Vatanasakdakul S, Chetty M (2021) Factors affecting the organizational adoption of blockchain technology: extending the technology–organization–environment (TOE) framework in the Australian context. Sustainability 13(16):9404

Na S, Heo S, Han S, Shin Y, Roh Y (2022) Acceptance Model of Artificial Intelligence (AI)-Based Technologies in Construction Firms: Applying the Technology Acceptance Model (TAM) in Combination with the Technology–Organisation–Environment (TOE) Framework. Buildings 12(2):90

Oliveira T, Martins MF (2011) Literature review of information technology adoption models at firm level. Electron J Inf Syst Eval. 14(1):110–121

Prajapati DK, Mathiyazhagan K, Agarwal V, Khorana S, Gunasekaran A (2024) Enabling industry 4.0: Assessing technologies and prioritization framework for agile manufacturing in India. J Clean Prod 447:141488

Peng T, He Q, Zhang Z, Wang B, Xu X (2021) Industrial Internet-enabled resilient manufacturing strategy in the wake of COVID-19 pandemic: a conceptual framework and implementations in China. Chin J Mech Eng 34(1):1–6

Pinheiro MAP, Jugend D, Lopes de Sousa Jabbour AB, Chiappetta Jabbour CJ, Latan H (2022) Circular economy‐based new products and company performance: The role of stakeholders and Industry 4.0 technologies. Bus Strategy Environ 31(1):483–499

Qi Q, Xu Z, Rani P (2023) Big data analytics challenges to implementing the intelligent Industrial Internet of Things (IIoT) systems in sustainable manufacturing operations. Technol Forecast Soc Change 190:122401

Ragin, CC (2008) Redesigning social inquiry: Fuzzy sets and beyond. University of Chicago Press

Rahman MS, Hossain MA, Chowdhury AH, Hoque MT (2022) Role of enterprise information system management in enhancing firms competitive performance towards achieving SDGs during and after COVID-19 pandemic. J Enterp Inf Manag 35(1):214–236

Reis, J, Amorim, M, Melão, N, Cohen, Y, Rodrigues, M (2020) Digitalization: A literature review and research agenda. In International Joint conference on industrial engineering and operations management. Springer, Cham

Rogers, EM, Singhal, A, Quinlan, MM (2014) Diffusion of innovations. In An integrated approach to communication theory and research. Routledge

Sabatini A, Cucculelli M, Gregori GL (2022) Business model innovation and digital technology: The perspective of incumbent Italian small and medium-sized firms. Entrepreneurial Bus Econ Rev 10(3):23–35

Salah OH, Yusof ZM, Mohamed H (2021) The determinant factors for the adoption of CRM in the Palestinian SMEs: The moderating effect of firm size. PloS one 16(3):e0243355

Schöggl JP, Stumpf L, Baumgartner RJ (2024) The role of interorganizational collaboration and digital technologies in the implementation of circular economy practices—Empirical evidence from manufacturing firms. Bus Strategy Environ 33(3):2225–2249

Shehzad MU, Zhang J, Dost M, Ahmad MS, Alam S (2024) Knowledge management enablers and knowledge management processes: a direct and configurational approach to stimulate green innovation. Eur J Innov Manag 27(1):123–152

Shahzad A, Bin Zakaria MS, Kotzab H, Makki MA, Hussain A, Fischer J (2023) Adoption of fourth industrial revolution 4.0 among Malaysian small and medium enterprises (SMEs). Humanit. Soc Sci Commun 10(1):1–14

Sivan S, Ghadiri SM, Rajagopal P, Bahrin AS, Sundram VPK (2022) Adoption and Benefit of Industrial Revolution 4.0 in Logistics Industry: A Conceptual Paper. J Entrepreneurship. Bus Econ 10(2S1):79–94

Tetteh LA, Muda P, Susuawu D, Sunu P, Aneyire TK (2022) Exploring the Use of an Integrated Financial Management Information System (IFMIS) in the Local Government Institutions in Ghana. Inf Resour Manag J (IRMJ) 35(1):1–25

Tornatzky, LG, Fleischer, M, Chakrabarti, AK (1990) Processes of technological innovation. Lexington books

Troise C, Corvello V, Ghobadian A, O’Regan N (2022) How can SMEs successfully navigate VUCA environment: The role of agility in the digital transformation era. Technol Forecast Soc Change 174:121227

Van Phuoc N (2022) The Critical Factors Impacting Artificial Intelligence Applications Adoption in Vietnam: A Structural Equation Modeling Analysis. Economies 10(6):129

Verhoef PC, Broekhuizen T, Bart Y, Bhattacharya A, Dong JQ, Fabian N, Haenlein M (2021) Digital transformation: A multidisciplinary reflection and research agenda. J Bus Res 122:889–901

Vial G (2019) Understanding digital transformation: a review and a research agenda. J Strat. Inf Syst 28(2):118–144

Wang S, Esperança JP (2023) Can digital transformation improve market and ESG performance? Evidence from Chinese SMEs. J Clean Prod 419:137980

Wang YS, Li HT, Li CR, Zhang DZ (2016) Factors affecting hotels’ adoption of mobile reservation systems: A technology-organization-environment framework. Tour Manag 53:163–172

Wang S, Zhang H (2024a) Inter-Organizational Cooperation in Digital Green Supply Chains: A Catalyst for Eco-Innovations and Sustainable Business Practices. J Clean Prod 472:143383. https://doi.org/10.1016/j.jclepro.2024.143383

Wang, S, Zhang, H (2024b) Promoting sustainable development goals through generative artificial intelligence in the digital supply chain: Insights from Chinese tourism SMEs. Sustain. Dev. 1–18. https://doi.org/10.1002/sd.3152

Wassie FA, Lakatos LP (2024) Artificial intelligence and the future of the internal audit function. Humanit. Soc Sci Commun 11(1):1–13

Wu Y, Li Z (2024) Digital transformation, entrepreneurship, and disruptive innovation: evidence of corporate digitalization in China from 2010 to 2021. Humanit. Soc Sci Commun 11(1):1–11

Wu W, Shi J, Liu Y (2024) The impact of corporate social responsibility in technological innovation on sustainable competitive performance. Humanit. Soc Sci Commun 11(1):1–13

Xiufan Z, Xiaomin W, Wenhai Z, Ningning F (2024) Research on the green innovation effect of digital economy network–Empirical evidence from the manufacturing industry in the Yangtze River Delta. Environ Technol Innov 34:103595

Yin S, Zhao Y (2024) Digital green value co-creation behavior, digital green network embedding and digital green innovation performance: moderating effects of digital green network fragmentation. Humanit. Soc Sci Commun 11(1):1–12

Zha X, Li J, Yan Y (2013) Information self-efficacy and information channels: Decision quality and online shopping satisfaction. Online Inf Rev 37(6):872–890

Zhang Z (2024) Exploring the green edge: the role of market orientation and knowledge management in achieving competitive advantage through creativity. Humanit. Soc Sci Commun 11(1):1–16

Zhang W, You J, Lin W (2021) Internet plus and China industrial system’s low-carbon development. Renew Sustain Energy Rev 151:111499

Zhu J, Baker JS, Song Z, Yue XG, Li W (2023) Government regulatory policies for digital transformation in small and medium-sized manufacturing enterprises: an evolutionary game analysis. Humanit. Soc Sci Commun 10(1):1–18

Acknowledgements

This work was supported by the Zhejiang Provincial Philosophy and Social Sciences Planning Project [45]; Youth Fund for Humanities and Social Science Research by the Ministry of Education [24YJC630213]; National Statistical Science Research Project of China [2024LY060]; 2024 Fuzhou Philosophy and Social Science Key Research Base Project under Grant [2024FZB26]. Thank all respondents for participating in this survey. Thanks to our colleagues and Digital Tools for their help with the article’s language.

Author information

Authors and Affiliations

Contributions

Conceptualization, SW; methodology, SW; writing-original draft preparation, SW, HZ and MG; writing—review and editing, MG, HZ and SW; visualization, SW; project administration, SW, and MG; funding acquisition, SW All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that the research was conducted without any commercial or financial relationships that could be construed as a potential conflict of interest.

Ethical approval

This study, aligned with articles published in Humanities & Social Sciences Communications and similar surveys that preserve organizational anonymity without revealing sensitive data, was determined by the Research Ethics Committee of the International Business School of Fuzhou University of International Studies and Trade to be exempt from requiring ethical approval. Additionally, since the collected data on Digital Drive, Digital Adoption, and Digital Culture did not involve identifiable information, a written ethical endorsement from the academic institution was not necessary. Nonetheless, the confidentiality of individual respondents and their respective organizations was diligently upheld. Participation in the survey was voluntary, respondents could withdraw at any time, and no identifiable information was collected throughout the survey process.

Informed consent

Before the study began, all participants were provided with their informed consent, confirming their voluntary involvement and understanding of the study’s aims, goals, and how their data would be used. They received comprehensive details about the study’s nature and objectives, and their agreement to participate was given freely, without any pressure or improper influence.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, S., Gao, M. & Zhang, H. Strengthening SMEs competitiveness and performance via industrial internet: Technological, organizational, and environmental pathways. Humanit Soc Sci Commun 11, 1366 (2024). https://doi.org/10.1057/s41599-024-03903-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1057/s41599-024-03903-8