Abstract

UV detectors have the advantages of simple signal processing, low false alarm rate, and strong anti-interference capability, and are widely used in both defense and civil applications. Gallium oxide (Ga2O3) holds great promise for photodetection, but its slow response rate hinders practical applications, so fast-response alternatives are urgently needed. Here we demonstrated ultrathin quasi-two-dimensional (2D) Ga2O3 vertical UV photodetectors with short channel lengths constructed via liquid metal printing strategy for the first time. The device achieves ultrafast response time (≈1.18 μs), high detectivity (≈2.8 × 1013 Jones), large switching ratio (~107), and low dark current (≈10 pA), which is comparable to commercial materials, demonstrating its considerable capability for photodetection technology field. This high-performance and low-cost photodetector based on liquid metal printing process provides a successful start for a wide range of applications of Ga2O3 in UV detection. It demonstrates the great potential of novel quasi-2D Ga2O3 devices for next-generation photodetection technologies.

Similar content being viewed by others

Introduction

Photodetector (PD) is an instrument that converts an optical signal into an electrical one, which is widely used in flight guidance, environmental monitoring, image sensing, industrial control, optical communication, infrared measurement and other fields1,2,3,4. Response time is an important parameter to measure the performance of a photodetector, which describes the response speed of a photodetector to changes in the input optical signal. Fast response photodetectors are in wide demand in the fields of optical communications, high-speed photography, and biomedical imaging. Although traditional inorganic semiconductor materials have the advantage of high carrier mobility and can realize the fast response of photodetectors, they have the disadvantages of complicated production process and high cost. Ga2O3 has excellent chemical stability, high breakdown field strength (~8 MV/cm), and ultra-wide bandgap (~4.8 eV) and has been extensively utilized in various applications like microelectronics, photodetection, and storage. In the past few years, scholars have attempted to reduce the process cost and improve the photoelectric efficiency of Ga2O3 UV photodetectors and verified the Ga2O3 photodetectors using various frameworks, mainly including metal-semiconductor-metal (MSM) photoconductivity photodetectors, Schottky photodetectors, and heterojunction photodetectors5,6,7,8. However, the combined detection performance of Ga2O3 photodetectors is far from meeting the application requirements due to the large dark current, low detection rate and delayed optical response. The new nanoscale semiconductors represented by 2D materials have resulted in a disruptive photodetection technology that can break through the theoretical limits of traditional thin-film devices in terms of detection sensitivity, very low dark current, high operating temperature, and other indexes, and is one of the strong contenders for the new generation of photodetection technologies9,10,11.

In addition, there is an urgent need for research and development of efficient production methods to meet industrial requirements for low-cost, large-scale device production and preparation. Printing technology significantly reduces device manufacturing costs by simplifying the fabrication process, breaks through the rigidity limitations of traditional silicon-based devices, and provides a new way of thinking for the large-scale production of photodetectors with large-area, which fits the fast-growing demand in multiple fields such as optical communications and smart homes. The current printing process for photodetectors mainly includes the scraping coating method (using a scraper to control the thickness of the solution to achieve a large area uniform film, commonly used in the deposition of organic semiconductor layers on flexible substrates), inkjet printing (through the nozzle spraying functional material solution to achieve high-resolution patterning, applicable to the fork Finger electrode design, screen printing (through the screen plate leakage printing conductive paste, the formation of micron-sized thick film electrodes, suitable for low-cost, flexible device scale production). There are also some emerging printing technologies, e.g., scientists have printed and fabricated multi-faceted photodetectors with asymmetric resonance structures by manipulating the 3D molding of liquid droplets12. A printable graphene plasmonic photodetector array driven by ferroelectric superdomains (superdomain) has also been developed for multi-channel superstructured infrared imaging with enhanced edge recognition13. However, traditional printing technologies for depositing 2D materials and devices are mainly inkjet printing and screen printing. Inkjet printing is difficult to achieve atomic-level uniformity due to the viscosity and thermal stability of the materials. Screen printing/scratch-coating method is suitable for thick film deposition, but the resolution is low (micron level), and high temperature annealing is easy to damage the flexible substrate. The current constraints and challenges are the urgent need to improve the long-term stability of semiconductor layers, enhance printing uniformity, and improve the sensitivity and responsiveness of detectors. In addition, traditional metal deposition approaches like sputtering or electron-beam (e-beam)/thermal evaporation usually require frequent bombardment of the contact area with high-energy hot atoms or atomic clusters, resulting in significant interface destruction, faults, and surface states at the metal–semiconductor connection14,15,16,17. These highly irregular interfaces may lead to leakage current routes underneath the contact area while increasing vertical tunnelling currents that a gate voltage cannot control. The use of low-temperature magnetron sputtering or atomic layer deposition (ALD) instead of high-temperature evaporation technology reduces the thermal load on the substrate and can significantly reduce thermal stress damage.

In this work, we have obtained large-scale, high-quality quasi-2D Ga2O3 films using a developed low-cost liquid metal printing technique, and further constructed a new vertical-structured UV photodetector characterized by ITO/quasi-2D Ga2O3 as the channel layer. This printing process can print directly at room temperature without high temperature annealing or vacuum environment, and the energy consumption is reduced by more than 90% compared to traditional chemical vapor deposition (CVD). Liquid metal inks form ultra-thin oxide interfaces (e.g., Ga₂O₃) through self-limiting oxidation to achieve atomically uniform deposition of 2D semiconductors (e.g., MoS₂, WS₂) down to a minimum feature size of less than 10 nm, with atomic-level precision and material compatibility. This low-temperature printing technology is also compatible with rigid (silicon, glass) and flexible substrates (PET, PI), and supports the full printing process to complete the electrode and functional layer integration at once, as well as wafer-level (8 inches and above) device fabrication, which provides a brand-new path for high-density optoelectronic chips. If combined with self-recovering hydrogel support technology, it can print complex three-dimensional structures such as overhangs and skeletons (e.g., microfluidic channels, curved surface detectors), breaking through the limitations of traditional planar devices. Moreover, the change in device structure can significantly improve the performance parameters by using shorter channels and forming heterojunctions so that the current is transmitted in the perpendicular direction of the device, and the presence of heterojunctions and barriers gives the device an internal gain mechanism, which increases the photocurrent and produces a faster response time. In addition, the detector is fabricated using a low-cost room-temperature liquid-metal 2D printing process that does not require high-voltage and high-vacuum environments and is extremely low-cost, environmentally friendly and energy efficient. Device electrodes are prepared by room temperature magnetron sputtering to avoid material degradation due to metal deposition. Strikingly, this photodetector displays an ultrafast optical response speed with a response time of ≈1.18 μs. This quality factor describes a high record attainable by hybrid photodetectors and even rivals that of top-quality inorganic materials. In addition, the device provides a considerable photodetectivity (≈2.8 × 1013 Jones), a large switching ratio (~107), and a low dark current (≈10 pA), which makes it suitable for high-efficiency photodetection applications.

Results and discussion

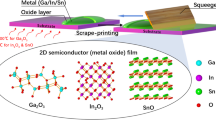

Direct printing of liquid metal-based quasi-2D Ga2O3

A schematic of the preparation of ultrathin quasi-2D Ga2O3 films is shown in Fig. 1a via the liquid metal van der Waals stripping method. The eutectic GaInSn melt is placed on a SiO2/Si substrate at 50 °C. According to the Cabrera-Mott growth kinetics model, for GaInSn alloys, a single Ga element occupies the surface of GaInSn liquid alloys because the capability of Ga to construct Ga2O3 is higher than the ability of In and Sn to construct In2O3 and SnO, and the Ga content of GaInSn alloys is higher than the content of In and Sn, so the GaInSn liquid alloy surface is occupied by a single Ga element, GaInSn liquid alloys can form self-limiting ultrathin Ga2O3 layers at the air-metal interface, a natural 2D material. We adopted a flexible PDMS squeegee to roll droplets on the substrate, effectively printing the droplet squeegee into a uniform film. Since there are no covalent bonds between Ga and Ga2O3, there is a minimum interaction between the Ga2O3 and the liquid metal. As a result, quasi-2D amorphous Ga2O3 can be obtained on SiO2/Si substrates considering the powerful van der Waals forces. Ultrathin Ga2O3 films with lateral dimensions of more than a few centimeters were achieved on 2-inch SiO2 wafers by this process. In order to microscopically explore the morphology characteristics of the synthesized Ga2O3 sample, the most intuitive metallographic microscope was used to observe the sample, it can be seen from Fig. 1b that the quasi-2D Ga2O3 thin-film printed at room temperature has a good morphology, the surface is smooth and dense, which exhibits flat and uniform planes, and there are no obvious particle impurities. Atomic force microscopy (AFM) of the transfer layer (Fig. 1c) shows that the thickness distribution of this printed Ga2O3 was uniform, and the surface of the films was extremely clean and had an atomically smooth flatness (the root mean square value of Rq, ~0.16 nm), containing an ultra-thin thickness of about 4 nm (Fig. 1c, d). The quasi-2D Ga2O3 thickness at various positions was approximately distributed in the 3.8–4.6 nm (Fig. 1d), indicating excellent thickness uniformity distributed in the film attained by the liquid metal nanoprinting technology. It is noteworthy that the Ga2O3 film with a thickness below 1.5 nm can be harvested by single printing when placed for an oxidation time of less than 10 s (Supplementary Fig. 1), which can be defined as 2D Ga2O3. However, due to the oxidation of the initial reaction rate is very fast, resulting in the diffusion of oxygen atoms and metal atoms reconstruction is not synchronized, the oxide film lattice arrangement is incomplete, prone to local stress concentration, which is likely to cause the oxide film coverage is incomplete. In addition, the presence of continuous thermal fluctuations and capillary waves on the liquid metal surface also tends to hinder the uniform diffusion of the oxide film, forming a weak point of the oxide film coverage. Therefore, the uniformity and continuity of the prepared 2D Ga2O3 are not always good enough due to the presence of cracks. In contrast, the 4-nm-thick quasi-2D Ga2O3 films obtained with a slightly longer oxidation time are extremely dense and uniform. Therefore, the 4 nm Ga2O3 films obtained after 6 min of treatment is employed in subsequent microstructure observation and optical analysis, etc. It is also shown that our proposed printing process can easily control the thickness of synthesized Ga2O3 films and is very practical in engineering.

a Schematic description of 2D Ga2O3 thin-film preparation from liquid GaInSn through liquid metal nanoprinting process. An optical image of large-area Ga2O3 layer on the 2 in. SiO2 substrate is shown on the bottom right. b Optical image of the printed Ga2O3 on 300 nm SiO2/Si. c AFM image of Ga2O3 film, where the inset was the height profile. d Thickness distribution of the printed 2D Ga2O3 at different locations.

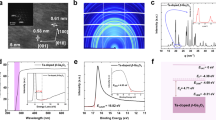

In order to gain a deeper understanding of the chemical combination and crystal framework of the printed quasi-2D Ga2O3 film, transmission electron microscopy (TEM) and X-ray photoelectron spectroscopy (XPS) analyses were accomplished, in which the TEM grid was used as a substrate to prepare the TEM sample. As presented in Fig. 2a, the majority of the quasi-2D Ga2O3 film is highly translucent, with occasional wrinkles and dark areas of residual gallium metal particles. Elemental mapping outcomes of energy dispersive X-ray spectroscopy (EDS) (Fig. 2b,c) show that gallium and oxygen are uniformly distributed on the film. From Energy-dispersive X-ray spectroscopy (EDS) results (Supplementary Fig. 2), the films contain no elements In and Sn except elements Ga and O. High-resolution TEM (HRTEM) images and selected-area electron diffraction (SAED) patterns show periodic atomic arrangements and diffraction patterns, revealing the polycrystalline nature of the quasi-2D Ga2O3 film (Fig. 2d). We printed 2D Ga2O3 thin films on the ITO substrates, as shown in Fig. 2e, the TEM images of the monolayer Ga2O3 clearly show that there is a clear boundary between the ITO and printed Ga2O3 film, and the thickness of monolayer Ga2O3 is ∼4 nm, confirming the AFM outcomes in Fig. 1c, d. Moreover, the film formation is dense and uniform, which lays a solid foundation for the successful realization of the quasi-2D Ga2O3 photodetector device. Figure 2f describes the XPS of the films, indicating the existence of O, Ga, C and N elements, while the C and N elements are attributed to surfaced sorbates. The typical binding energy of 20.4 eV in the Ga 3d area indicates the valence state of Ga3+, and the essential broad peak at 530.6 eV corresponds to the O 1s state of Ga2O3 in the prepared film. The printed Ga2O3 has a direct bandgap of up to 4.8 eV, the absorption edge is about 260 nm and its peak photoresponse falls exactly in the solar-blind band without the need for energy band modulation, making it a highly desirable natural solar-blind UV detection material (Fig. 2g). Expecting to open up the application of this quasi-2D Ga2O3 for high-sensitivity photodetection, we constructed quasi-2D Ga2O3 UV photodetector. In view of the shortcomings of the lateral structure device, which suffers from the long transmission time of the photogenerated carriers, we use a vertical structure. Other of the idea in designing vertically structured devices is to find a material with a carrier concentration greater than Ga2O3 to form a heterojunction with Ga2O3. We chose ITO (Sn-doped In2O3), which has a forbidden bandwidth similar to that of In2O3 (~3.5 eV). As a dopant material, it can provide sufficient carrier concentration, which is theoretically a suitable material to form a high-performance heterojunction with Ga2O3.

a TEM and (b, c) EDS elemental mapping images of 2D Ga2O3 films. d HRTEM image of the Ga2O3 film, where the inset was the corresponding SAED pattern. e HRTEM cross-section image of a monolayer 2D Ga2O3 on the ITO substrate. f XPS spectrum of the Ga2O3 films. XPS spectra of the synthesized Ga2O3 films in Ga 3d and O 1s regions. g The Ga2O3 films’ absorption spectrum. The inset is the Tauc plot of the absorption curve.

Quasi-2D Ga2O3 vertical photodetectors

Quasi-2D Ga2O3-based field effect transistors (FETs) were first prepared and tested, and the electrical characteristics of the transistors showed typical n-type behavior with zero back-gate voltage (Supplementary Fig. 3), which were measured using the source measurement module of the Keithley 4200 Semiconductor Parameter Analysis System due to the probe limitations of the Keithley 6487 Picoammeter. To study the contact between the Ga2O3 film and the Au electrodes, we probe the electron transport in the device by measuring the characteristic I–V curve. When semiconductor contacts with metal, a Schottky barrier is constructed at the interface, where the Schottky–Mott rule18,19 can be employed to calculate its height as φB = φmetal − χsemiconductor, where φmetal indicates the metal work function and χsemiconductor describes the semiconductor electron affinity. A metal-semiconductor-metal (MSM) device comprises two back-to-back series-connected metal-semiconductor diodes with a resistance R, as presented in Fig. 3a, b.

a The schematic illustration of the 2D Ga2O3 based FETs. b The circuit diagram where the MSM configuration can be modeled by two back-to-back Schottky diodes, including a forward-biased and a reverse-biased diode, connected in series with a resistor. c An experimental dark I–V characteristic curve plotted with the thermionic emission fit. Good consistency between the experimental and fitted data indicates that the thermionic emission theory entirely supports electron transmission.

In the analysis of the main transport mechanism of carriers at the Au-Ga2O3 interface, the tunneling-related characteristic energy E00 is a very important characteristic parameter, so it is crucial to obtain the value of E00 for the Ga2O3 material, and the expression for the calculation of E00 is given by

where q, N, m* and εr refer to the unit charge, carrier concentration in the semiconductor material, electron effective mass and dielectric constant, respectively. In our calculations, m* and εr use values reported in the literature, which are 0.34 m0 and 10, respectively20,21. Due to the high resistivity of the samples as obtained, we were unable to utilize the Hall test system for carrier concentration, it was difficult to obtain a specific value for the carrier concentration N. So we used the values of q, m* and εr for the present calculations. However, based on the carrier concentration limit required by the Hall test, the carrier concentration within this series of Ga2O3 films is much less than 1 × 1015 cm-3. Assuming N = 1 × 1015 cm−3, the value of E00 obtained by substituting all the values into Eq. (1) is 0.17 meV, and KBT = 26 meV at room temperature, so KBT ≫ E00. When KBT ≫ E00, the carrier transport process at the interface of metal-semiconductor contact is dominated by the thermal emission mechanism. When the transport of carriers at the metal-semiconductor interface is dominated by the thermal emission model, the current density through the metal-semiconductor interface can be expressed as follows:

Then the current through the Schottky junction consisting of two back-to-back contacts can be expressed as

In which

In the above equations, A1 indicates the contact area between the electrode and the semiconductor, and A*n is the effective Richardson’s constant, which for Ga2O3 it takes the value of 41 A cm−2 K−2. qΦB1 and qΦB2 are the heights of the barriers at the contact between the two metal-semiconductor interfaces. Since the Au electrode has high conductivity and high carrier concentration, the current through the two Au/Ga2O3 structures in back-to-back contact can be calculated using the above equation. Equation (3) is employed to fit the dark current-voltage relationship curve to calculate the I1 and I2 values. The energy values of the Schottky barrier heights at the two interfaces can then be obtained by substituting into Eq. (4) and Eq. (5). Figure 3c presents a schematic of the experimental setup to measure the PD I–V characteristics, which demonstrates the fitting of the dark current to the printed fabricated device, and the fitted curves overlap well with the actual test results, indicating the accuracy of the thermal emission model analysis for carrier transport and the fitting of Eq. (3) for conduction current. We also have further explored and verified the Schottky barriers by the current-voltage-temperature curve (J–V–T) method (see Supplementary Note 1 and Supplementary Fig. 4).

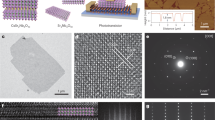

We demonstrate a longitudinally vertically structured photodetector employing quasi-2D Ga2O3. The semiconductor thickness is a core parameter of vertically structured photodetectors and needs to be weighed in a number of ways. Too large a thickness of the channel layer can lead to a reduction in the detector response speed and a decrease in the effective gain. Too small a thickness can lead to an increase in leakage current between the source and drain, or even lead to a short circuit between the source and drain, affecting the normal operation of the device. In addition, the absorption of high-energy photons is weakened. We need to optimize the thickness to balance the sensitivity and response speed to obtain a device with the best overall performance. We select 20 nm thick films (Supplementary Fig. 5) achieved through five precisely controlled print passes using our printing process because our experimental results show that the device has the best overall performance when the thickness of the Ga2O3 film is about 20 nm. In photodetectors, converting as many photogenerated carriers as possible into photogenerated currents is an important method to enhance the efficiency of photodetectors. When the vertical structure is used in photodetectors, due to the characteristics of the short channel, when the electrons and holes in the photogenerated carriers are separated, the electrons in the channel will run a very short distance, the chances of electrons and holes encounters and reunions is reduced, at the same time, the chance of electrons being scattered or trapped due to collisions with grain boundaries and defects is also reduced, which will significantly increase the photogenerated carriers into a photogenerated current conversion of the chance to improve its photodetection performance.

The structure of the ITO/quasi-2D Ga2O3 vertical UV photodetector is shown in Fig. 4a, in which the top electrode adopts a fork-finger structure. The main purpose of preparing the fork-finger electrodes in the vertical device is to improve the collection efficiency of the photogenerated carriers generated under the UV illumination. Figure 4b presents the logarithmic dark current–voltage (I–V) traces acquired under 254 nm laser irradiation. The dark current (Idark) was 9.3 × 10−12 A at a 10 V bias. Using the dark current as the main source of detector noise, such a low Idark indicates that the prepared detector has low noise, which is a key parameter for the sensitivity of the detector device. Under illumination, the photocurrent (Ilight) increases sharply due to photoexcitation’s impact. For example, Ilight reaches 3.2 × 10−6 A under a 200 μW cm−2 laser intensity (V = 10 V). The mentioned significant Ilight and very low Idark generate a significant switching ratio (SR = Iphoto/Idark = (Ilight–Idark)/Idark) of around 107. The photocurrent reaches 1.6 × 10−8 A under very weak illumination intensity (≈0.06 μW cm−2), demonstrating its ability to distinguish a weak light.

a The schematic illustration of the ITO/2D Ga2O3 photodetectors. b The detector’s I–V curves acquired in the dark environment under a 254 nm illumination intensity. c Responsivity of the photodetector under light illumination of wavelengths ranging from 200 to 800 nm. d Photocurrent of the device versus the light intensity under 254 nm illumination at 10 V. e The device’s responsivity versus the light intensity under 254 nm illumination at 10 V. f The detector’s detectivity for several irradiances at 254 nm. g Transient photoresponse of device. Energy band diagrams at the interface of ITO/Ga2O3 under (h) dark and (i) UV illumination. ECBM and EVBM represent the conduction band edge and valence band edge, respectively.

Optical responsivity reflects the size of the photodetector’s ability to convert light energy into electrical energy, and is one of the core parameters of the detector, defined as the size of the photocurrent produced by the device per unit of incident optical power, with the expression

In the calculation, when the unit of the incident wavelength λ is nm, the resulting responsivity has a magnitude of A/W. From the Eq. (6), the optical responsivity R is proportional to the external quantum efficiency ηe. Assuming that there is no optical response gain in the device, when the external quantum efficiency takes the maximum value of 1, the maximum value of the optical responsivity R is \(\frac{\lambda (nm)}{1240.68}(A/W)\). If the actual optical responsivity obtained is larger than the value of \(\frac{\lambda (nm)}{1240.68}(A/W)\), it indicates that there is an internal gain mechanism in the device. The photodetectors’ response characteristics were acquired through a 150 W UV-enhanced Xe lamp containing a monochromator. Figure 4c shows the photodetectors’ response profiles for various forward bias voltages, and the inset indicates the response profiles in logarithmic coordinates at 10 V bias voltage, from which it can be observed that the device is only responsive in the solar-blind ultraviolet region, and there is no obvious response signal in both the near-ultraviolet and visible regions, and the responsivity reaches its maximum at 250 nm, with a maximum value of 115.5 A/W, which is higher than other previously reported Ga2O3 photodetectors22,23,24. The cutoff edge of the spectral response is the wavelength of light at which the responsivity declines to 1/e (e ≈ 2.718) of its maximum value, and the cutoff edge can be calculated from the figure to be located at 265 nm, which is less than 280 nm, and the device has excellent UV detection performance. The UV/visible suppression ratio, i.e., the ratio of the optical response at 256 nm and 400 nm, is about 1 × 104, demonstrating the high spectral selectivity of the photodetector for the UV light. We calculated the specific detectivity (D*), another key performance parameter of a photodetector using the equation:

The optimized photodetectivity (D*) measured to be 2.8 × 1013 Jones. This high D* is similar to other photodetectors using standard inorganic 2D materials like WSe2 (D* = 1.0 × 1014 Jones), PbS (D* = 7.0 × 1013 Jones), and MoS2/Si (D* = 1.89 × 1013 Jones)25,26,27.

The relationship between the detector’s light intensity and photocurrent is shown in Fig. 4d and Supplementary Fig. 6. With the increase of optical power, its photocurrent is also enhanced, which is one of the important phenomena of the photoconductivity effect. The relationship between them was fitted using the law equation Iphoto = APθ, where A indicates a constant, P describes the light intensity, and θ is the power law exponent28,29. The θ values of the detector are close to 1, indicating that the Ga2O3 films prepared by our 2D printing process have fewer traps and interfacial fault states, which reduces the chances of carrier trapping and recombination30. We also investigated the angle-dependent photoelectric properties of the photodetector to test its recognition function for polarized light. A polarizer and a one-half waveplate were successively added between the laser transmitter and the device, and the laser was passed through the polarizer to obtain the line-polarized light, and then the one-half waveplate was used to realize the control of the direction of the line-polarized light. The angularly resolved polarization I–V curve of the output current of the device was measured at 200 μW cm−2 light intensity (light intensity before passing through the polarizer) at an interval of 30°, starting from a direction with an angle of 45° with respect to the ZZ direction of the μ thin film (x-axis starting direction). The output current of the detector is highly dependent on the rotation angle as the rotation angle of the half-wave sheet varies. At a 10 V selected bias voltage, the device photocurrent shows a 180° variation cycle, as shown in Supplementary Fig. 7a. Its maximum photocurrent occurs at θ = 135°, 315°, while the minimum value of photocurrent occurs at θ = 45°, 225°. We further investigated the polar plot of the device’s photocurrent at 10 V bias voltage and 200 μW cm−2 light illumination, as shown in Supplementary Fig. 7b. Calculations show that the anisotropy ratio Imax/Imin of the detector photocurrent is 1.13, indicating that the device has certain sensitivity and selectivity for polarization detection, further suggesting that it possesses the typical physicochemical behavior of a 2D material.

We further explored the optical power density dependence of the responsiveness and detectability of the photodetectors. Figure 4e, f show the device’s responsivity and detectivity versus the optical power density. As the device’s optical power density increases, both R and D* decrease, probably due to the autothermal effect associated with intense illumination, which leads to increased scattering and complexation of photogenerated carriers. Besides, increasing R and D* with gradually decreasing optical power density indicates that the device is more sensitive to the detection of weak light. Specifically, under 254 nm optical illumination with a low power density of 200 μW cm−2, the detector’s R and D* values were as high as 115.5 A/W and 2.8 × 1013 Jones, respectively.

Response time (τ) is essential in optoelectronic usages, like ultrafast dynamic processes simulation, high-frequency optical communication, and fast imaging. In this study, the transient response method is used to obtain the response speed of the detector. The response time was defined as the interval between 10% and 90% of the highest amplitude. As presented in Fig. 4g, by fitting the rise/decay curves of photodetector, we obtained a characteristic response time of 1.18/3.09 μs. This superfast response discloses the significant ability of ITO/quasi-2D Ga2O3 for fast photodetection. As we know, the above value is higher than other hybrid Ga2O3 photodetectors presented in the literature and is similar to the top-ranking inorganic materials, like PbSe-TiO2-G (τ = 50/283 ns)31, MoS2/Si (τ = 56/825 ns)27, and black phosphorus (τ = 0.52 ms)32. This ultra-fast response merit can be explained by good material quality and an optimized vertical electrode structure. For Schottky contact MSM-PDs, the response speed is related to the RC time constant τc, the carrier crossing time τi, and the total time constant τ is given by

It can be seen that the carrier crossing time is proportional to the electrode spacing L. The closer the spacing L is, the shorter the response time is. And the electrode spacing L and electrode thickness t are inversely proportional to the circuit RC time constant τc. The smaller the electrode spacing L or electrode thickness t is, the larger τc is and the faster the response is. According to Eq. Decreasing L or decreasing t (one of the two ways) will lead to an increase in τc. In our work, we adopt the strategy of decreasing L rather than varying the electrode thickness to improve the device responsiveness. In our devices with a vertical structure, the distance between the electrodes can be maintained in an extremely short range, which significantly reduces the photogenerated carriers’ acquisition time while improving the devices’ performance, so it can effectively accelerate the response speed of the device.

Figure 4h, i show the energy band schematic of Ga2O3/ITO heterojunction to explain the photoresponse characteristics and gain mechanism of the detector. The photocurrent generation and photogenerated carrier transport mechanisms are analyzed using the Anderson model, where the forbidden band widths of Ga2O3 and ITO are 4.8 eV and 3.7 eV, respectively. This is a heterostructure with a staggered form of type II energy band arrangement, which contributes to the separation and migration of photogenerated carriers, and can effectively reduce the carrier complexation chances, thus generating a larger photocurrent at the same applied bias voltage. The bandgap of the Ga2O3 was determined to be 4.8 eV, the band gap for the sputtered ITO was 3.7 eV. The valence band offset is 0.80 eV and the conduction band offset is then calculated to be 1.90 eV. When Ga2O3 and ITO are in contact to form a heterojunction, the electrons in the conduction bands on both sides of the contact interface will drift due to the difference in the Fermi levels of the two, and electrons will flow from Ga2O3 to ITO, and an electron accumulation region will form on the ITO side. When the forward bias voltage is applied to the heterojunction, the direction of the applied electric field is opposite to the direction of the built-in electric field, which has a weakening effect on the built-in electric field, and the space charge region will be narrowed, and the height of the potential barrier between the conduction bands of Ga2O3 and ITO will decrease, and the electrons will be more easily flowed from the side of the high energy of the conduction band to the side of the low energy of the conduction band, and at this time the current increases, and the heterojunction shows an open state. Under the irradiation of UV light at 254 nm, electrons will be excited and jump from the valence band to the conduction band. The photogenerated electron-hole pairs in the valence band are separated by the built-in electric field. The carrier concentration in the space charge region increases, and more photo-excited electrons are added to the conduction band, leading to an increase in the photocurrent. And the applied bias voltage enables more photogenerated electron-hole pairs to be separated, resulting in an increase in the concentration of photogenerated carriers and an increase in the current. In addition, ITO and Ga2O3 are both n-type semiconductors, and the hanging bond plays the role of acceptor. At the heterojunction interface, the Fermi energy level is shifted downward, and the energy band bends downward, forming a potential barrier at the conduction band and a potential well at the valence band. The holes at the valence band are bound in the potential well, and the optical gain effect is obvious. When the ITO/Ga2O3 device is subjected to sufficient UV illumination, a large number of electron-hole pairs are generated in the Ga2O3. Under the effect of bias voltage, the electrons in the Ga2O3 will cross the potential barrier at the interface and inject into the ITO. At the same time, the high light conversion properties of the Ga2O3 layer and the high carrier transport properties of the ITO layer are utilized to enhance the optoelectronic performance of the device.

By constructing an ITO/quasi-2D Ga2O3-based photoconductor with liquid metal printing technology, the maximum response speed was attained among Ga2O3 photodetectors. The figures of merit for some previously reported photodetectors and our device were presented for a detailed comparison. Table 1 lists the key performance parameters of UV PDs based on our 2D Ga2O3 and other Ga2O3 materials. The present device has a fall time of 3.09 μs and a rise time of 1.18 μs, both of which are orders of magnitude higher than reported Ga2O3-based detectors. Meanwhile, Fig. 5 summarize and compare the performance of Ga2O3-based detectors with other types of detectors. Our devices also lead in performance compared to other semiconductor-based detectors. The combined performance of responsivity and response time is also compared in Fig. 5, where our detector overcomes the difficulty of achieving a balance between fast response time and high responsivity in Ga2O3 detectors. The superiority of our device is demonstrated by its ultra-low dark current, high detectivity, fast response speed, and feasibily of large-area preparation. The enhanced performance of our photodetector compared to conventional devices made from the same material is attributed to the seven synergistic design strategies: (1) The ultra-wide bandwidth (~4.8 eV) of quasi-2D Ga₂O₃ enables its optical absorption range to precisely match the sun-blind UV band (200–280 nm), which effectively suppresses the visible and infrared background noise and significantly improves the signal-to-noise ratio of UV detection. (2) The vertical heterojunction interface formed by Ga₂O₃ and ITO generates a strong built-in electric field, and the photogenerated carriers (electron-hole pairs) are rapidly separated and directionally transported to the electrodes under the action of the electric field, which dramatically reduces the composite probability and improves the quantum efficiency. (3) The vertically stacked quasi-2D Ga₂O₃/ITO heterojunction dramatically shortens the carrier transport path and improves the response speed, while the high conductivity of ITO reduces the contact resistance and enhances the photocurrent output efficiency. In contrast to the conventional planar structure, the vertical design avoids scattering loss in transverse transport. (4) The low-dimensional nature of quasi-2D Ga₂O₃ reduces the grain boundary defect density, which, in combination with the atomically flat interface of ITO, effectively reduces the dark current and improves the photocurrent gain, enhancing the low-light detection capability. (5) By optimizing sputtering power and the sputtering vacuum, we achieved a 20 nm ultra-thin gold layer with minimal ion bombardment energy, effectively avoiding lattice distortion or defect generation in the underlying semiconductor film. The reduced mechanical stress and thermal impact during room temperature sputtering ensure the integrity of the semiconductor’s band structure, maintaining its high carrier mobility and photoresponsivity. (6) The nanoscale thickness (~20 nm) Au allows partial light penetration in the visible to near-infrared (NIR) range due to plasmonic effects and reduced electron density in thin metallic films. The optimized sputtering parameters ensure a continuous yet optically semi-transparent gold layer, enabling efficient light absorption in the semiconductor while maintaining electrode conductivity. (7) The multi-finger-like structure of the fork-finger electrode can reduces the lateral carrier migration path to micrometer-scale gaps and significantly increase the contact interface area between the electrode and the semiconductor material and reduce the contact resistance.

In the future, the comprehensive performance of the detector can be further improved by using techniques such as optimizing the channel layer and improving the quality of the semiconductor-metal contact interface. Admittedly, there are also some other emerging technologies to realize the printed preparation of photodetectors. Gu et al. proposed a method of preparing chalcogenide single-crystal thin films based on printed crystal seed templates to realize the printed fabrication of large-area, high-performance photodetectors33. Duan et al. developed a hybrid electrofluidic printing technique (M-ePrinting), which enables high-resolution printing of gradient chalcogenide structures for multispectral detection through multi-channel solution mixing modulation34. Flexible polarization-sensitive detectors were also prepared by solution method printing using AsP/MoS₂ heterojunction35. Sun et al. have improved the responsiveness and stability of the photodetectors through the optimization of the printing process for the large-scale production of PbI₂ microcrystals36.

Compared to other technologies, liquid metal 2D printing technology does not require a high-temperature vacuum environment and prints semiconductor films directly at room temperature, reducing energy consumption by more than 90% compared to traditional chemical vapor deposition (CVD). This printing technology supports large-area (>1 m diameter) printing, far beyond the traditional wafer (300 mm) limit, film thickness can be controlled, and electrical properties are uniform. It is also compatible with flexible electronics and can be printed directly on flexible substrates (e.g., PET, fabric), making it suitable for wearable devices and bioelectronics. It has unique core advantages and irreplaceability in terms of low-temperature and high-efficiency manufacturing, material and performance advantages, and compatibility with flexible electronics.

We further constructed 8 × 8 rectangular Ga2O3 array detectors and systematically characterized them. The corresponding statistical results are shown in Fig. 6. It can be seen that the photoresponse current of each detector element floats between 3 and 5 μA under this test condition, and the dark current falls in the range of 31–34 pA, indicating that the photoresponse performance of each detector element of the array displays a good homogeneity. Such a small deviation is mainly attributed to the low RMS of the printed Ga2O3 films and the stability of the process, which proves the great potential of the constructed arrays in applications such as deep-ultraviolet optical imaging. To assess the stability of the photodetector, a plot of the photocurrent of the device versus time was measured. As depicted in Fig. 4f and Supplementary Fig. 8, as the light source is turned on, the current is rapidly maximized, then decreases rapidly and finally stabilizes. As the UV light was turned off, the current dropped sharply. By analyzing the amplitude of the device’s response waveforms to square-wave incident light signals of different frequencies, the response bandwidth can be obtained as shown in Supplementary Fig. 9. As the frequency increases, the response bandwidth of the device gradually from 0 dB to a 3 dB decline, when the frequency of the optical signal reaches 0.3 MHz when the device reaches a 3 dB point, when the frequency is further increased, the device’s photocurrent response amplitude has been lower than the maximum magnitude of 0.707 times in the distortion state below −3 dB bandwidth. Therefore, the device can operate in the passband range up to 0.3 MHz. The fast response time of about 1.2 μs and the wide passband of more than 105 Hz demonstrate again the excellent optical detection performance of the detector from the device’s point of view. Besides, the device photocurrent was not significantly degraded over 104 switching cycles, demonstrating the excellent stability and reliability of the photodetector’s cyclic dynamic response over time. As shown in Supplementary Fig. 10, the ageing detector’s I–V curves are only slightly different from the fresh device (after 30 days and under the relative humidity of 50% ± 5% at room temperature). The switching ratio is constant for three days (Supplementary Fig. 11), demonstrating our device’s considerable air stability. At the same time, the device exhibits long-time stability without apparent fatigue under constant illumination (Supplementary Fig. 12).

Overall, the above work has fully demonstrated that the Ga2O3-based photodetector array owns great potential for UV imaging. The consistency of performance variation of individual components of a pixel under the same conditions is critical if array-based devices are to be used in an imaging system. In order to evaluate the overall optoelectronic capability of the photodetector array, we characterized the 16 pixels one by one, excited each of the 16 device cells with a xenon lamp at different powers and voltages, and counted the variations of the photocurrents. Firstly, the power of the light source was fixed, and the photocurrents of the 16 pixels at different supply voltages when the incident light power was 200 μW cm−2 are shown in Supplementary Fig. 13. The photocurrent values of all cells are approximately at a similar level under a similar voltage, indicating that all cells can work under the same power supply. The photocurrent of each device under different voltages increases with the increase of voltage, and there is no crossover phenomenon of photocurrent of each device under different voltages. In addition, the photocurrent statistics of 16 pixel cells under 10 V bias at different light incident powers were also investigated. As shown in Supplementary Fig. 14, under the same light intensity, the photocurrents between the 16 cells differ very little and are almost the same. Under different optical powers, the photocurrent of each device increases with the increase of optical power, and there is no photocurrent crossover phenomenon under different powers. These properties indicate the high uniformity of array, which lays the foundation for its usage in array imaging systems.

We investigated the photodetector array’s imaging ability. The photocurrent imaging test is realized by collecting electrical signals from different devices and corresponding to the device position coordinates. The imaging object is located on top of the photodetector array, light is irradiated to the photodetector array through the target object, forming a pattern with the same contrast of light and dark as the target object, the photocurrent of pixels illuminated by light on the array increases, and pixels covered by light are in the dark state and do not generate photocurrent, so the current on different devices is different. We constructed a system as shown in Supplementary Fig. 15, which mainly consists of a UV light source, a diaphragm, a UV lens, various imaging objects, a photodetector array, and a signal acquisition device. The use of diaphragm is to limit the beam, the use of lenses is to focus the beam, the role of the imaging object is to produce a light and dark light field on the plane of the detector surface array, the signal reading and output is the use of the signal acquisition system, a semiconductor analyzer. During the imaging test, we place the letters “T”, “I”, “P”, “C” and so on in front of the photodetector array to produce different light and dark light fields on the photodetector array plane. During the imaging process, we manually select the pixels to be measured in turn, and a signal collector and a semiconductor analyzer are used to collect the current output signal of each photodetector unit, and then the Matlab software recovers the image by combining the output current of the photodetectors with the corresponding position coordinates. Figure 7 shows the imager and the corresponding imaging results, we can see that all these images can be clearly identified with better imaging quality, which indicates that the ITO/quasi-2D Ga2O3-based photodetector face array has excellent potential application prospects in solar-blind UV imaging, and better imaging results can be obtained by further improving the film quality of Ga2O3 in the next step.

In summary, we have successfully obtained large-scale high-quality quasi-2D Ga2O3 by a liquid metal printing process, based on which we have unprecedentedly constructed the vertically structured ITO/2D Ga2O3 photodetector. We have achieved significant improvements in photodetector performance through device structure innovation. The structure of ITO/quasi-2D Ga2O3 contributes to the generation of photogenerated carriers, which are efficiently collected prior to compounding due to the shortened length of the semiconductor channel. These advantages enable our photodetector to achieve faster optical response (a characteristic response time of 1.18/3.09 μs) than in-plane devices. To the best of our knowledge, this quality factor stands among the peak of all known Ga2O3 photodetectors and is comparable with the top inorganic commercial counterparts (e.g., PbSe-TiO2-G, MoS2/Si, and black phosphorus). At the same time, the present thin-film detectors show excellent photodetection properties, involving high responsivity (115.5 A/W at 200 μW cm−2 light intensity), significant switching ratios (~107), and low dark current (≈10 pA). We also fabricated an array device containing 36 photodetector cells with excellent uniformity and stability in the photoelectric performance of the detector cells. We further constructed a UV light imaging system using this photodetector array as a light-sensing element and obtained clear UV 2D images. This work resolves the shackles of Ga2O3 detectors that have been difficult to combine high responsivity and fast response speed, and shows that quasi-2D Ga2O3 device has great potential for efficient photodetection applications. It is expected that these photodetectors will find important values in a wide range of ultrafast photodetection applications.

Methods

Materials

Gallium (Ga, 99.99%), indium (In, 99.98%) and tin (Sn, 99.8%) were bought from Sigma Aldrich and adopted without additional correction, while the other materials were bought from standard suppliers and utilized without correction.

Preparation of GaInSn liquid alloys

In this study, the prepared GaInSn alloy weighs 100 g. The GaInSn alloy comprises 67 wt% Ga, 20.5 wt% In, and 12.5 wt% Sn. The weighed Ga, In, and Sn were put into a glass beaker located on a hotplate with temperature regulated at 250 °C. After melting Ga, In, and Sn, a glass rod was adopted to stir the molten alloy for around 10 min. The uniformly mixed GaInSn alloy was then cooled to room temperature. Since the eutectic GaInSn’s melting point is below 10.5 °C, the prepared GaInSn alloy is still liquid.

Printing process of 2D Ga2O3

The SiO2/Si substrates were cleaned by ultrasonic waves in deionized water, isopropanol, acetone and ethanol for 10 min, then ozonized after nitrogen purge for 5 min. They were located on a heating plate whose temperature was set at 50 °C, and liquefied GaInSn alloy droplets were applied to the substrates with a syringe. When the GaInSn droplets are exposed to the atmosphere, a self-limiting atomic level quasi-2D Ga2O3 ultrathin layer is formed on their surface. The droplets were gently scraped from one end of the substrate to the other end using a PDMS scraper under heated conditions, and the quasi-2D Ga2O3 film formed could be successfully peeled off from the alloy surface and transferred to the substrate, considering the stronger van der Waals interactions between Ga2O3 and the substrate than with the surface of the alloy GaInSn. Ga2O3 films of different thicknesses can be harvested by scratch printing with different numbers of layers. The obtained substrate containing Ga2O3 and residual liquid GaInSn is then immersed in an ethanol solution heated to 60 °C ~ 80 °C, and the residual metal particles are wiped with a wiping tool (cotton ball). During the wiping process, Ga2O3 will always be firmly attached to the surface of the substrate due to the adhesion between Ga2O3 and the substrate through strong van der Waals forces. On the other hand, liquid GaInSn is only weakly bonded to the deposited Ga2O3, which can be easily removed by wiping, thus allowing the quasi-2D Ga2O3 film to be cleaned without causing any damage. Ultimately, uniform and smooth large-area quasi-2D Ga2O3 films are obtained on the substrate.

Fabrication of ITO/2D Ga2O3 photodetectors

We used a glass plate coated with ITO (in the visible range, its transmittance is more than 85%) as a substrate. Firstly, the ITO substrate was put into the acetone ultrasonic cleaning for 15 min to clean the dust and organic pollutants attached on the surface, and then it was put into the ethanol ultrasonic cleaning for 15 min to dissolve the residual acetone in the previous step, and then it was ultrasonically cleaned with the deionized water for 15 min to wash away the residual ethanol to make it completely clean, and then finally, the surface of the ITO substrate was dried with nitrogen. Double-sided tape was used to attach the substrate to the printing abutment. In order to make the subsequent ITO upper electrode easy to fabricate without being affected by the Ga2O3 film, one side of the ITO was masked with high-temperature-resistant tape, so that a part of the ITO would not be printed on the Ga2O3 film and form a step. Then we printed Ga2O3 on the substrate, by adjusting the number of printing to obtain different thicknesses of Ga2O3, the Ga2O3 layer thickness used in this experiment is 20 nm, in the printing process, the previous masking tape on the ITO side was not torn off. After printing, a small square hole was carved in the tape to vaporize an Au electrode on the ITO film. A small sputtering instrument was used to vaporize an Au film with a thickness of 20 nm in the area of the square hole, the sputtering vacuum is usually set to 10 Pa, the sputtering current is usually set to 20 mA, the sputtering time is usually set to 5 min. Then a suitable size of weighing paper was cut to cover the square hole after gold vaporization. Next, we used a customized shadow mask to photolithograph the fork finger electrode on the Ga2O3 film, in which the length of the fork finger is 1000 μm, the width is 50 μm, and the spacing of the fork finger is 100 μm. Finally, the devices were heat-treated at 400 °C to enhance the crystallinity of Ga2O3, the quality of the contact interface with ITO, as well as to reduce the contact resistance between the Au electrode and the semiconductor layer.

Characterization

The AFM images of printed quasi-2D Ga2O3 were obtained with a MultiMode 8 AFM with a “Scanasyst air” AFM tip, and the TEM characterization was accomplished via a JEM-2100 transmission electron microscope from Nippon Electron Co. A Hitachi 5–4800 scanning electron microscope was utilized to characterize the films’ surface morphology. Besides, EDS measurements accomplished through an X-ray photoelectron spectrometer (Thermo Scientific K-alpha) were adopted to obtain the elemental mapping of the as-prepared samples. Among them, the analysis chamber’s vacuum was 5 × 10−9 mBar, the excitation source was Al Kα-rays (hν = 1486.6 eV), the working voltage was 15 kV, the filament current was 10 mA, and the signal accumulation was conducted for 5–10 cycles. The full-spectrum test flux energy (passing energy) was 100 eV with a 1 eV step; the narrow-spectrum passing energy was 50 eV with a 0.1 eV step, and C1s = 284.80 eV combined with energy was chosen as a standard for charge modification. UV-vis spectra and Tauc plots of printed Ga2O3 films were obtained using a Hitachi U3600 UV-vis spectrophotometer with an imposed absorption wavelength range of 200–800 nm. The electrical conduction characterization of photodetectors involves the testing of the I–V relationship in both dark and light environments. Based on the high-resistance property of Ga2O3, the device’s dark current is extremely weak, therefore, the device’s I–V test is performed using a high-precision Keithley 4200 semiconductor parameter analyzer. Response spectra were performed via a spectral measurement system consisting of a lock-in amplifier, monochromator, chopper, and 150 W UV-enhanced xenon lamp. The transient response test system for the detector includes a current source, sample holder, oscilloscope and transient light source. Of these, a Keithley 6487 picoammeter was used for the current source. In the transient response test, a laser with an optical wavelength of 265 nm was used as the light source, with a test voltage of 10 V and an optical frequency of 10 Hz.

Data availability

The data that support the findings of this work are available from the corresponding authors upon reasonable request.

References

Adinolfi, V. & Sargent, E. H. Photovoltage field-effect transistors. Nature 542, 324–327 (2017).

Assefa, S., Xia, F. & Vlasov, Y. A. Reinventing germanium avalanche photodetector for nanophotonic on-chip optical interconnects. Nature 464, 80–84 (2010).

Bao, C. et al. High performance and stable all-inorganic metal halide perovskite-based photodetectors for optical communication applications. Adv. Mater. 30, 1803422 (2018).

Liu, Y. et al. A 1300 mm2 ultrahigh-performance digital imaging assembly using high-quality perovskite single crystals. Adv. Mater. 30, 1707314 (2018).

Xu, Y. et al. Squeeze-printing ultrathin 2D gallium oxide out of liquid metal for forming-free neuromorphic memristors. ACS Appl. Mater. Interfaces 15, 25831–25837 (2023).

Yoon, Y., Kim, Y., Hwang, W. S. & Shin, M. Biological UV photoreceptors-inspired Sn-doped polycrystalline β-Ga2O3 optoelectronic synaptic phototransistor for neuromorphic computing. Adv. Electron. Mater. 9, 2300098 (2023).

Zhang, Z. et al. In-sensor reservoir computing system for latent fingerprint recognition with deep ultraviolet photo-synapses and memristor array. Nat. Commun. 13, 6590 (2022).

Li, R. et al. Multi-modulated optoelectronic memristor based on Ga2O3/MoS2 heterojunction for bionic synapses and artificial visual system. Nano Energy 111, 108398 (2023).

Long, M., Wang, P., Fang, H. & Hu, W. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 29, 1803807 (2019).

Cai, S., Xu, X., Yang, W., Chen, J. & Fang, X. Materials and designs for wearable photodetectors. Adv. Mater. 31, 1808138 (2019).

Wang, P. et al. Sensing infrared photons at room temperature: from bulk materials to atomic layers. Small 15, 1904396 (2019).

Pan, Q. et al. Omnidirectional photodetectors based on spatial resonance asymmetric facade via a 3D self-standing strategy. Adv. Mater. 32, 1907280 (2020).

Guo, J. et al. Type-printable photodetector arrays for multichannel meta-infrared imaging. Nat. Commun. 15, 5193 (2024).

Liu, Y., Huang, Y. & Duan, X. Van der Waals integration before and beyond two-dimensional materials. Nature 567, 323–333 (2019).

Jung, Y. et al. Transferred via contacts as a platform for ideal two-dimensional transistors. Nat. Electron. 2, 187–194 (2019).

Wang, Y. et al. Van der Waals contacts between three-dimensional metals and two-dimensional semiconductors. Nature 568, 70–74 (2019).

Liu, Y. et al. Approaching the Schottky–Mott limit in van der Waals metal–semiconductor junctions. Nature 557, 696–700 (2018).

Rhoderick, E. & Williams, R. Metal-Semiconductor Contacts, 2nd edn (Clarendon Press, 1988).

Lince, J. R., Carré, D. J. & Fleischauer, P. D. Schottky-barrier formation on a covalent semiconductor without Fermi-level pinning: the metal-MoS2(0001) interface. Phys. Rev. B 36, 1647 (1987).

He, H. et al. First-principles study of the structural, electronic, and optical properties of Ga2O3 in its monoclinic and hexagonal phases. Phys. Rev. B 74, 195123 (2006).

Passlack, M. et al. Ga2O3 films for electronic and optoelectronic applications. J. Appl. Phys. 77, 686–693 (1995).

Ding, W. & Meng, X. High performance solar-blind UV detector based on β-Ga2O3/GaN nanowires heterojunction. J. Alloy. Compd. 866, 157564 (2021).

Chen, W. et al. A fast self-powered solar-blind ultraviolet photodetector realized by Ga2O3/GaN PIN heterojunction with a fully depleted active region. Adv. Optical Mater. 11, 2202847 (2023).

Zhang, M. et al. High-temperature reliability of all-oxide self-powered deep UV photodetector based on epsilon-Ga2O3/ZnO heterojunction. J. Phys. D Appl. Phys. 55, 375106 (2022).

Zhang, W. et al. Role of metal contacts in high-performance phototransistors based on WSe2 monolayers. ACS Nano 8, 8653–8661 (2014).

Konstantatos, G. et al. Hybrid graphene–quantum dot phototransistors with ultrahigh gain. Nat. Nanotechnol. 7, 363–368 (2012).

Qiao, S. et al. A vertically layered MoS2/Si heterojunction for an ultrahigh and ultrafast photoresponse photodetector. J. Mater. Chem. C 6, 3233–3239 (2018).

Wang, Y. et al. Ultrasensitive flexible solar-blind photodetectors based on graphene/amorphous Ga2O3 van der Waals heterojunctions. ACS Appl. Mater. Interfaces 12, 47714–47720 (2020).

Mo, H. et al. Two-dimensional alloying molybdenum tin disulfide monolayers with fast photoresponse. ACS Appl. Mater. Interfaces 11, 39077 (2019).

Gao, C. et al. Solar blind avalanche photodetector based on a n-β-Ga2O3/n-Si heterojunction via an introduction of AlN buffer layer for interface lattice and band engineering. Mat. Today Phys. 45, 101474 (2024).

Manga, K. K. et al. High-performance broadband photodetector using solution-processible PbSe–TiO2–graphene hybrids. Adv. Mater. 24, 1697 (2012).

Long, M. et al. Room temperature high-detectivity mid-infrared photodetectors based on black arsenic phosphorus. Sci. Adv. 3, e1700589 (2017).

Gu, Z., Huang, Z., Li, C., Li, M. & Song, Y. A general printing approach for scalable growth of perovskite single-crystal films. Sci. Adv. 4, eaat2390 (2018).

Duan, Y. et al. Programmable, high-resolution printing of spatially graded perovskites for multispectral photodetectors. Adv. Mater. 36, 2313946 (2024).

Ren, Z. et al. A polarization-sensitive photodetector based on a AsP/MoS2 heterojunction. Chin. Opt. 14, 135–144 (2021).

Sun, H. et al. Kilogram-scale high-yield production of PbI2 microcrystals for optimized photodetectors. J. Mater. Chem. C. 12, 6433–6442 (2024).

Han, Y. et al. Rapid response solar blind deep UV photodetector with high detectivity based on graphene: N/β-Ga2O3: N/GaN p-i-n heterojunction fabricated by a reversed substitution growth method. Small Methods 7, 2300041 (2023).

Cai, Z. et al. Enhancing performance of GaN/Ga2O3 P-N junction UVC photodetectors via interdigitated structure. Small Methods 8, 2301148 (2023).

Wang, Y. et al. p-GaSe/n-Ga2O3 van der Waals heterostructure photodetector at solar-blind wavelengths with ultrahigh responsivity and detectivity. ACS Photonics 8, 2256–2264 (2021).

Xi, Z. et al. Comprehensive study on ultra-wide band gap La2O3/ε-Ga2O3 p–n heterojunction self-powered deep-UV photodiodes for flame sensing. ACS Appl. Mater. Interfaces 15, 40744–40752 (2023).

Wu, C. et al. High sensitive and stable self-powered solar-blind photodetector based on solution-processed all inorganic CuMO2/Ga2O3 pn heterojunction. Mat. Today Phys. 17, 100335 (2021).

Feng, S. et al. Dual-mode conversion of photodetector and neuromorphic vision sensor via bias voltage regulation on a single device. Adv. Mater. 35, 2308090 (2023).

Chen, T. et al. High-speed and ultrasensitive solar-blind ultraviolet photodetectors based on in situ grown β-Ga2O3 single-crystal films. ACS Appl. Mater. Interfaces 16, 6068–6077 (2024).

Li, X. –X. et al. High responsivity and flexible deep-UV phototransistor based on Ta-doped β-Ga2O3. npj Flex. Electron. 6, 47 (2022).

Wang, Y. et al. Multifunctional solar-blind ultraviolet photodetectors based on p-PCDTBT/n-Ga2O3 heterojunction with high photoresponse. InfoMat 6, e12503 (2024).

Lu, C. et al. Freestanding crystalline β-Ga2O3 flexible membrane obtained via lattice epitaxy engineering for high-performance optoelectronic device. ACS Nano 18, 5374–5382 (2024).

Meitei, S. R., Devi, L. S. & Singh, N. K. Ag nanoparticle decorated β-Ga2O3 nanowires on Si substrates: advancing photodetector technology. J. Phys. D: Appl. Phys. 57, 175103 (2024).

Zhou, Y. et al. Solar-blind photodetector arrays fabricated by weaving strategy. ACS Nano 18, 7610–7617 (2024).

Prasad, C. V., Labed, M., Park, J. H., Kim, K. J. & Rim, Y. Charge-carrier engineering of staggered-gap p-CuAlO2/β-Ga2O3 bipolar heterojunction for self-powered photodetector with exceptional linear dynamic range and stability. Mat. Today Phys. 40, 101327 (2024).

Zhang, Z. et al. Solar-blind imaging based on 2-inch polycrystalline diamond photodetector linear array. Carbon 173, 427–432 (2021).

Hou, Y. et al. MgZnO based ultraviolet photodetector with high photoresponsivity achieved by fluorine doping. Thin Solid Films 634, 165–168 (2017).

Young, S. –J. & Liu, Y. –H. Low-frequency noise properties of MgZnO nanorod ultraviolet photodetectors with and without UV illumination. Sens. Actuators A Phys. 269, 363–368 (2018).

Yu, J., Tian, N., Deng, Y. F. & Zhang, H. H. Ultraviolet photodetector based on sol–gel synthesized MgZnO nanoparticle with photoconductive gain. J. Alloy Compd. 667, 359–362 (2016).

Ping, Y. et al. Polarization sensitive solar-blind ultraviolet photodetectors based on ultrawide bandgap KNb3O8 nanobelt with fringe-like atomic lattice. Adv. Funct. Mater. 32, 2111673 (2022).

Zhang, Q. et al. Large-area self-assembled hexagonal boron nitride nanosheet films for ultralow dark current vacuum-ultraviolet photodetectors. Adv. Funct. Mater. 34, 2315149 (2024).

Lee, Y. et al. High-performance perovskite–graphene hybrid photodetector. Adv. Mater. 27, 41–46 (2015).

Yu, J. et al. Amorphous gallium oxide nanosheets with broad absorption and spin polarization for Si-based UV‒Vis‒NIR photodetectors. Adv. Optical Mater. 12, 2302410 (2024).

Han, D. et al. Performance enhancement of a p-Si/n-ZnGa2O4 heterojunction solar-blind UV photodetector through interface engineering. J. Mater. Chem. C. 9, 10013–10019 (2021).

Zhang, Z. –F. et al. Wafer-sized polycrystalline diamond photodetector planar arrays for solar-blind imaging. J. Mater. Chem. C. 10, 6488–6496 (2022).

Liu, Y. et al. Planar carbon nanotube–graphene hybrid films for high-performance broadband photodetectors. Nat. Commun. 6, 8589 (2015).

Qiao, H. et al. Broadband photodetectors based on graphene–Bi2Te3 heterostructure. ACS Nano 9, 1886–1894 (2015).

Wu, S. –C., Wu, M. –J. & Chen, Y. –F. Nanolayered graphene/hexagonal boron nitride/n-algan heterostructures as solar-blind deep-ultraviolet photodetectors. ACS Appl. Nano Mater. 3, 7595–7603 (2020).

Zhang, Z. –H. et al. Air-stable self-driven UV photodetectors on controllable lead-free CsCu2I3 microwire arrays. ACS Appl. Mater. Interfaces 16, 10398–10406 (2024).

Zhang, N. et al. High-performance self-powered photoelectrochemical ultraviolet photodetectors based on an In2O3 nanocube film. ACS Appl. Mater. Interfaces 16, 19167–19174 (2024).

Acknowledgements

This work was partially supported by the NSFC Grant (No. 91748206).

Author information

Authors and Affiliations

Contributions

The project was designed by Q.L. and J.L. Q.L. developed the synthesis and printing procedure for quasi-2D Ga2O3 while also conducted the structure and properties measurements with contributions from R.F.L. Q.L. led the PD devices fabrication and characterized the devices with contributions from R.F.L., X.Q.C. and X.W.M. Q.L. analyzed the material and device characteristics and drafted the manuscript. M.H.G. helped to prepare schematics for the experimental setup for PDs and diagram of detector array imaging testing system. J.L. substantively revised the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Q., Li, R., Chen, X. et al. Printing ultrathin Quasi-2D Ga2O3 for fast yet highly responsive vertical photodetectors. npj 2D Mater Appl 9, 51 (2025). https://doi.org/10.1038/s41699-025-00574-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41699-025-00574-0