Abstract

Graphene nanosheets from suspensions are key to applications such as in printable films, battery/supercapacitor electrodes, fillers in composite materials or catalyst supports. We present a straightforward method for achieving high-concentration and long-term stable graphene suspensions by liquid phase exfoliation (LPE) via a combination of ammonia (NH3) as an easily removable additive together with low-boiling point, benign organic-water co-solvent mixtures as suspension media. We find that the addition of small amounts of NH3 as an additive drastically improves the obtainable LPE graphene concentrations by up to 2 orders of magnitude for a wide range of organic-water co-solvent mixtures including with isopropanol, methanol, ethanol, 1-propanol, tetrahydrofuran, acetonitrile, acetone, ethylene glycol and tert-butanol. With our approach we readily reach current benchmark graphene concentration values of ~180 mg·L-1 that are normally only obtainable using hard-to-remove high-boiling-point and hazardous standard solvents like dimethylformamide and 1-methyl-2-pyrrolydone or with hard-to-remove surfactants. Notably, NH3 as an additive is highly volatile and thus, as we show, easily removable without degrading the produced high quality graphene nanosheets.

Similar content being viewed by others

Introduction

Graphene possesses a unique combination of exciting properties that make it promising for a wide variety of applications1,2. Form factors of interest for graphene for its various applications range from monolayered films with cm+ lateral extents for optoelectronics and barrier layers (as typically produced bottom-up in chemical vapor deposition3,4) to two-dimensional (2D) graphene “powders”. The latter is comprised of few-layer graphene 2D nanosheets that typically have thickness distributions from 1 to ~20 layers and lateral sizes in the range of hundreds of nm up to several µm5,6. These graphene “powders” have a plethora of potential applications as 2D building blocks for, e.g., printable films7, electrode materials in batteries or supercapacitors8, fillers in composite materials or heterogeneous catalyst components or supports1,2. These graphene “powders” are typically produced in a top-down fashion by exfoliation from bulk graphite5. For this top-down synthesis, liquid phase exfoliation (LPE) has established itself as a frontrunner synthesis technology9. LPE relies on bringing the bulk starting material in an appropriate liquid suspension medium (often termed “solvent”) and coupling energy into the system to facilitate exfoliation of the bulk material into the few-layered 2D nanosheets5,10. The required energy can be coupled via ultrasonication, tip-sonication, or shear forces from, e.g., shear mixers. Key to LPE is the appropriate choice of suspension medium (solvent), whereby critically, the solvent must facilitate not only exfoliation into 2D nanosheets but also ensure a stable dispersion of the 2D nanosheets, i.e., inhibit restacking of produced 2D sheets for prolonged times even after the energy input ceases5,10. Additionally, an ideal solvent must be readily removable from the 2D nanosheets to bring them into dry 2D powder form or readily exchangeable to incorporate the 2D nanosheets into other chemical environments, all ideally without significant restacking in the process. To date, no such ideal solvent has yet been identified11,12, and the search for appropriate solvents for graphene LPE (and LPE of many other 2D materials) is still ongoing.

In general, for LPE, the solvents can be divided into organic and aqueous solvent systems: for organic solvents, LPE of graphene can often be performed in the neat organic solvent, although commonly used solvents like dimethylformamide (DMF, boiling point (b.p.) 153 °C) and 1-methyl-2-pyrrolydone (NMP, b.p. 203 °C) often have a high-boiling point (hindering drying13 and solvent exchange) and are hazardous to human health14. High-quality graphene can also be obtained by using mixtures of organic solvents, but the concentrations here are usually lower or require longer sonication times15. Lower boiling point organic solvents with a more benign health hazard profile would, therefore, be highly desirable for the LPE of graphene and 2D materials.

In contrast to neat organic solvents, aqueous LPE of graphene does not work in neat water without the addition of suitable surfactants, which are required to allow dispersion of the 2D nanosheets. These surfactants are alkaline salts or polymers, such as sodium dodecylbenzene sulfonate (SDBS), sodium cholate, or poly(vinyl pyrrolidone) (PVP)16,17,18,19. These surfactants are adsorbed onto the 2D nanosheet surface by noncovalent interactions and prevent the nanosheets from reaggregation by electrostatic and/or steric repulsion20. However, due to their high adsorption affinity, these surfactants can lead to unwanted modifications of the graphene surface and are very challenging to remove post-LPE17, which can be particularly hindering in, e.g., catalysis and electrical applications. In particular, in many LPE systems, the concentration of the surfactant can be close to the final 2D nanosheet concentration in the product suspension16,21, which significantly reduces the achievable purity of the 2D nanosheets19. Hence, there is a need to develop easily removable LPE-stabilization additives or surfactants for graphene and 2D materials LPE.

Herein, we bridge these challenges in graphene LPE by using a combination of an easy-to-remove additive, namely ammonia (NH3), together with relatively low-boiling point, benign organic-water co-solvent mixtures. We demonstrate that the addition of NH3 as an additive drastically improves the obtainable LPE graphene concentrations by up to two orders of magnitude for a wide range of organic-water co-solvent mixtures. Notably, NH3 as an additive is highly volatile and thus, as we show, easily removable without degrading the produced high-quality graphene 2D nanosheets.

Comparing with previous literature, we note that Arao et al. have previously tangentially mentioned a beneficial effect of NaOH and NH3 addition to graphene LPE22 and later reported that ammonium carbonate ((NH4)2CO3) can be used as an additive for organic solvents to improve graphene LPE and reduce agglomeration23. NH3 has also previously been shown to enhance LPE in neat water24,25. Building on these highly useful prior findings, here we, for the first time, deliberately and directly introduce NH3 as the sole additive during graphene LPE in a large range of organic solvent/water mixtures. We show that this NH3 addition has a highly beneficial effect on graphene LPE for a very wide selection of organic components in organic-water co-solvent mixtures, including with isopropanol (IPA), methanol (MeOH), ethanol (EtOH), 1-propanol (NPA), tetrahydrofuran (THF), acetonitrile (ACN), acetone (AC), ethylene glycol (EG) and tert-butanol (TBA), with ammonia being soluble in many organic solvents. This drastically underlines the generality of this approach. Combined, our work demonstrates a facile route to improved graphene LPE yield, thus providing a framework for simpler and safer 2D graphene LPE development.

Results and discussion

We first describe our considerations in selecting the LPE solvent systems to be used. Key considerations for us were low-boiling points to allow easy solvent removal/exchange and a benign health hazard profile. A key factor complicating this search is that the best solvent for LPE of a given 2D material has been found to be highly dependent on the nature of the 2D material11. No generally applicable predictive theory for finding ideal solvents or solvent mixtures for given 2D materials has yet been identified. Instead, the exploration of new solvents is largely based on empirical trial and error. However, as a somewhat general guideline among many influencing factors, it has been found that for LPE solvents, it is beneficial if the surface energy of the solvent matches that of the 2D material in order to obtain good 2D LPE yields5,14. For the particular case of graphene, it has been shown that for neat solvents, the most effective ones for the exfoliation of graphite have a surface tension close to 40 mN m-1 (refs. 14,26). Since the surface energy of water (72.8 mN·m-1) is too high to exfoliate graphite directly efficiently when following this logic, a mixture with common organic solvents, which possess a lower surface energy, has been reported to lead to an optimal mixture when mixed in different ratios27,28,29. We, therefore, test here this co-solvent strategy comparing binary mixtures over a wide composition range of a large number of common organic solvents with water, as well as the neat organic solvents and neat water as reference. The tested co-solvents and their corresponding surface tension values are summarized in Table 1. With these identified co-solvent systems, the effect of NH3 addition as an additive to these co-solvent and neat systems is then studied by adding a series of small NH3 concentrations (0 mmol·L-1 reference baseline and 5, 50, and 500 mmol·L-1 series) to the various co-solvent systems.

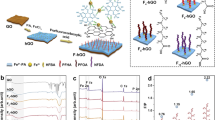

We then test all the various co-solvent mixtures for graphene LPE under otherwise constant exfoliation (6 h in bath ultrasonicator) and centrifugation conditions (30 min at 5500 rpm) using a simple commercial ultrasonic bath and a standard mild centrifugation protocol. The obtained graphene concentrations after centrifugation are then measured using UV–Vis spectroscopy14. In addition, for selected samples, the graphene nanoflakes obtained are further characterized using atomic force microscopy (AFM), transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy (XPS). Further details of the methods are given in the “Methods” section below and in the Supplementary Information. Figure 1 plots our key findings. We first find in Fig. 1a that for our exfoliation protocol without NH3 addition, the obtained graphene concentrations remain low at well below <10 mg·L-1 for neat water and all neat organic solvents as well as selected binary organic solvent-water mixture concentrations with ~50% solvent content. This is significantly lower by two orders of magnitude compared to benchmark, high-boiling point solvents like DMF and NMP, which we also investigated as benchmarks in Fig. 1a. This implies that the here selected co-solvent mixtures alone do not significantly improve graphene LPE concentration under our conditions.

In Fig. 1b we show the effect of adding a small amount of NH3 (50 mmol·L-1) to the various neat solvents and the binary organic solvent-water mixtures (measured at more closely spaced concentration intervals than in Fig. 1a). For the neat water and the neat organic solvents, the effect of NH3 addition is rather small in terms of increased graphene concentration (negligible increase for neat water, maximum increase by factor of 10 for some neat organic solvents).

In very drastic contrast, however, for the binary organic solvent-water mixtures, we obtain increases in graphene concentration of up to two orders of magnitude via the addition of NH3. Figure 1b shows that for most mixtures, this increase is most pronounced around ~50% organic content, yielding up to 180 mg·L-1 graphene concentration. These values are well comparable with the concentrations resulting from the use of DMF or NMP (Fig. 1a) or concentrations obtainable using water with hard-to-remove surfactants like SDBS, cholates, or PVP16,17. We emphasize that we clearly see this beneficial effect for a very wide range of organic co-solvents, which underscores the generality of our approach of using NH3 to improve LPE graphene concentration.

We also note that for several of the here investigated co-solvent mixtures with NH3, the dependence of the highest graphene concentration on the solvent mixture forms a broad plateau (i.e., not a narrow peak). This suggests that the highly advantageous effect of NH3 addition to the organic-water co-solvents is a very robust phenomenon over a reasonably wide co-solvent composition range, which eases technical implementation. Furthermore, the highest concentrations are obtained for mixtures of IPA-water for 40% to 60%, which is also technologically hugely advantageous since IPA is very easy to handle, safe, and a cheap organic solvent.

For most organic-water mixtures (IPA, EtOH, NPA, THF, ACN, AC, TBA), the highest concentration values with NH3 addition are obtained around ~50% organic solvent to water ratio. We suggest that this is related to the observation from Table 1 that all of these organic solvents have surface energies ~20 to 25 mN·m-1. From a simple rule of mixtures, their ~50% mixtures with water (surface energy: 72.8 mN·m-1) are expected to have a surface energy of ~45 mN·m-1, which is close to the surface energy of graphite ( ~ 40 mN·m-1). Such a match of surface energies has previously been identified as being beneficial to LPE yield16,26,30. Our findings here, thus, stress that such surface energy match reasoning can also be a guideline for co-solvent mixture selection when using the reported NH3 additive. We underscore, however, that all organic-water solvent mixtures without NH3 showed only much lower LPE yield alone, irrespective of surface energy (Fig. 1a). This again underscores the here identified key role of NH3 addition to increasing graphene LPE concentration in our study.

We also note that two solvents show distinct differences in this behavior of best graphene yield at ~50% organic-water mixture: EG and MeOH. For EG, the highest graphene yield is found at ~70%. This can again be ascribed to surface energy matching, since EG has a distinctly higher surface energy (47.7 mN·m-1), thus requiring less water to match graphite’s surface energy. For MeOH the best relative graphene concentration was obtained at ~30%. Since MeOH has a surface energy of 22.7 mN·m-1, which is in line with the majority of the above-discussed solvents, from pure surface energy consideration, the best concentration would also be expected at ~50%. This suggests that further factors other than surface energy are also of importance in solvent selection for NH3-assisted LPE, which at present remains unknown for MeOH with NH3. This is in line with the state of the general incomplete understanding of general LPE solvent chemistry on other systems without NH3 addition11.

In Fig. 2 we further explore how compositionally wide the beneficial effect of NH3 addition to our organic-water co-solvents is. To this end, we chose the highest graphene concentration yielding organic-water mixture concentrations for each organic solvent from Fig. 1b, while varying the concentration of NH3 logarithmically from 0 (baseline), 5, 50 to 500 mmol·L-1 NH3. We find that despite the logarithmic variation of NH3 concentration, the graphene LPE yield only slightly varies as a function of NH3 concentration for the optimized organic-water mixtures. This clearly shows that the addition of NH3 has a compositionally very wide effect, useable over a wide NH3 concentration range. This is of significant technological benefit, as close control over NH3 additive/surfactant concentration is not necessary to benefit from the NH3 stabilization in the various co-solvents.

Concentration of graphene as measured by UV–Vis after LPE incl. centrifugation for various organic-water mixtures at concentrations optimized with respect to the highest graphene yield from Fig. 1b as a function of NH3 additive concentration 0 (baseline), 5, 50, and 500 mmol·L-1 NH3.

To show the visual appearance of the graphene during the various stages of the LPE process, i.e., directly after sedimentation, after different sedimentation times, and after centrifugation, photographs at the various stages are shown in Supplementary Fig. 1 for the optimized 50% IPA-water with 50 mmol·L-1 NH3 alongside its neat components and the neat co-solvent mixture without NH3. This data again visualizes that without NH3 addition, non-centrifuged suspensions sediment, and after centrifugation only for the co-solvent with NH3, significant graphene remains in the suspension (in line with the quantitative concentration measurements in Figs. 1 and 2).

We also note that the obtained optimized organic-water with NH3 additive suspensions remain stable over months without any appreciable signs of loss of concentration, agglomeration or sedimentation (see example image in Fig. 3a). This observed long-term stability of our graphene suspensions is of high technical benefit.

a Photo of IPA-water 50% with 50 mmol·L-1 NH3 suspension in vial after 6 months storage. b Bright-field TEM overview image of IPA-water 50% with 50 mmol·L-1 NH3 suspension after drying, showing several graphene flakes on lacey carbon support. Note the observed high electron transparency of the flakes is indicative of low thickness.

For the IPA-water 50% with 50 mmol·L-1 NH3 samples, which are amongst the highest obtained graphene concentrations in this study, we investigate the obtained flakes microscopically in additional detail. TEM images in Fig. 3b and Supplementary Fig. 2 and AFM images in Supplementary Fig. 3 reveal that we obtain few-layer graphene nanoflakes with thicknesses in the range of 1 nm to 10 nm, corresponding to ~3 to ~30 layers thickness. Selected area electron diffraction (SAED) in Supplementary Fig. 2a confirms that our obtained few-layer graphene nanosheets are of high crystalline quality, as evidenced by very sharp six-fold symmetric spots in the SAED patterns14. Lateral flake sizes are found with an average of ~1 µm with a maximum of up to ~3 µm (see lateral flake size histogram in Supplementary Fig. 2c). Both thickness distribution and lateral sizes are comparable to similar work with benchmark NMP and established water/surfactant systems31.

We now briefly discuss possible mechanisms behind our results: With respect to our use of water-organic co-solvent mixtures, prior work suggested that the use of water and a co-solvent modifies the surface tension to a for LPE reasonable good value around 40 mN·m−1, which improves wettability of graphite particles and makes the exfoliation possible12,14. For instance, Li et al. showed that a equivolumetric solution of IPA-water ruptured pristine graphite flakes into flatter pieces in contrast to a water control32. This is particularly interesting because poor dispersion of graphene does not necessarily mean poor yield of few-layer graphene during exfoliation33.

With respect to possible mechanistic reasons behind the observed highly beneficial effect of NH3 addition on graphene concentration, we note that we here do not aim to conclusively identify the underlying mechanisms in this report but rather place our new experimental findings in the context of the current understanding of alkaline additives in graphene LPE34. As the first argument, the stabilization mechanism for the graphene solutions is suggested to be based on electrostatic repulsion. The surface of few-layer graphene is negatively charged in many solvents (presenting a Zeta potential of ‒30 to ‒40 mV)35, whereby tuning the Zeta potential via modification of the pH can reduce restacking and agglomeration24. In order to obtain more detailed information about the influence of NH3 on this mechanism, we performed Zeta potential measurements of different dilutions of the best working graphene suspensions exfoliated in 50% IPA-water with 50 mmol·L-1 NH3. The measurements of these highly stable graphene suspensions yielded Zeta potentials between ‒27.1 and ‒28.1 mV, which are values close to the above-reported range, which is encouraging since Zeta potentials of +/‒ 30 mV are often considered sufficient for stabilizing colloidal dispersions among particle technology in general. Consequently, these values indicate a beneficial influence of electrostatic stabilization of the graphene flakes. This suggests that the here employed ammonia hereby optimizes the Zeta potential and, hence the stability of the exfoliated graphene24. Additionally, via the NH3 a “wedge” effect on freshly formed fracture surfaces can also be suggested during exfoliation24,36,37.

The importance of the presence of NH3 on the dispersion stability of the graphene suspensions is also further experimentally confirmed in a further test experiment in Supplementary Fig. 4: While with NH3 addition, our graphene suspensions remain stable over months (see above Fig. 3a), with acidic neutralization of the ammonia the graphene suspension becomes immediately unstable (Supplementary Fig. 4). The result of NH3 neutralization is a visible agglomeration of the graphene flakes to macroscopic aggregates within a few seconds, which gravitationally sediment over the course of a few hours, leaving only a clear supernatant once NH3 is neutralized. This again emphasizes the key role of NH3 in making our graphene suspension stable in the organic-water mixtures.

A key presumption for choosing NH3 as an additive for graphene LPE was that the NH3 is highly volatile and hence is expected to be readily removable from the graphene nanosheets by, e.g., a mild evaporation step (unlike classical surfactants like SDBS, sodium cholate or PVP)16,17,18,21,38. To confirm this hypothesis, we measured XPS on dried (60 °C in air) graphene nanoflakes from IPA-water 50% with 50 mmol·L-1 NH3 (Supplementary Fig. 5). The detail C1s spectrum (Supplementary Fig. 5b) exhibits a main peak at 284 eV assigned to sp2 carbon atoms39,40,41,42. The C1s spectrum further shows the typical asymmetric spectral shape with the π-π* shake-up component ( ~ 292 eV) of graphitic carbon41,43. The remaining minor C1s components are assigned to sp3-like flake edges and adventitious carbon adsorption, typical for graphene produced via the LPE route44,45,46. Hence the C1s spectrum is consistent with high-quality graphene few-layer flakes and in line with the high structural graphene quality seen in SAED (Supplementary Fig. 2a). With respect to NH3 presence in the dried film, the N1s spectra (Supplementary Fig. 5d) reveals only a negligible residual amount of N signal in the final dried product, close to the detection limit of the XPS ( < < 1 atom-%). This thereby fully confirms our hypothesis that NH3 is easily removed via simple ambient drying from the LPE graphene, after enabling high-concentration and long-term stable LPE of high-quality graphene nanosheets.

Conclusions

In conclusion, we demonstrated LPE of suspensions of graphene nanosheets at high graphene concentrations and long-term stability (>6 months) in different organic-water co-solvent mixtures with NH3 as an easy-to-remove additive. Importantly, most of the screened organic solvent mixtures have a relatively low boiling point of ≤100 °C and a benign health hazard profile. For most organic solvents, optimal exfoliation was obtained using a mixture of organic solvent with around 50% water, with an addition of small amounts of NH3 being critically necessary to improve exfoliated graphene concentration up to two orders of magnitude. We thereby demonstrate a high-yield graphene LPE synthesis via a very readily removable additive (NH3) in a wide range of solvent mixtures incl., low-boiling point and benign mixtures, that readily reaches current benchmark graphene concentration values of ~180 mg·L-1 (that are normally only obtainable for hard-to-remove high-boiling and hazardous standard solvents like DMF or NMP or with hard-to-remove surfactants). Thereby, our findings contribute to the ongoing search for simpler, easily removable, and safer solvent systems in graphene and 2D materials LPE development.

Methods

As precursor material, pristine graphite flakes (325 mesh, <45 µm) were purchased from Alfa Aesar. Aqueous ammonia solution (17%), NPA, IPA, AC, MeOH, EtOH, THF, EG, TBA, ACN, NMP, and DMF were analytical quality and used without additional purification. Only deionized water was used from an in-house deionization system. To ensure that possible trace contaminations in the water did not influence LPE results, for selected sample combinations also reference measurements with ultrapure benchmark MilliQ water were undertaken. These yielded the same results with the MilliQ as with the otherwise used in-house water, ensuring that possible trace contaminations in the water are no significant factor in the results of this study. We have furthermore also tested the generality of our approach as a function of various graphite sources (as in these different impurities could potentially also influence results). As shown in Supplementary Fig. 6, we test beyond our otherwise used pristine graphite flakes (325 mesh, <45 µm) from Alfa Aesar four additional graphite sources (natural UF4 from Graphit Kropfmühl GmbH, TIMCAL TIMREX® KS6 Synthetic Graphite, TIMCAL TIMREX® KS75 Primary Synthetic Graphite, and TIMREX® SFG 75 Graphite). Fully underscoring the generality of our results, we find that all these additional sources yield similarly successful and stable exfoliation with our optimized 50% IPA-water with 50 mmol·L-1 NH3 recipe. This further underscores the generality of our exfoliation strategy beyond any particular graphite precursor source.

For the LPE process, first pristine graphite flakes (300 mg) were added into screw cap exfoliation vials (20 mL total capacity). The solvent mixtures (combined volume 15 mL) were added first, followed by 5, 50, or 500 mmol, respectively, of the aqueous ammonia solution. The vial caps were sealed using tape to prevent loosening and unscrewing of the caps during sonification. Exfoliation was performed by using a low-power sonification bath (Bandelin Sonorex Digitec DT 156 BH (9,0)) filled with water. The sample vials were sonicated for 6 h each. To ensure reproducibility, the ultrasonic bath was constantly kept at 2–7 °C via the addition of small portions of ice to the water during all experiments. Additionally, every sample position was cycled between bath positions uniformly during each run to ensure equal ultrasonication regardless of hot spots in the bath. As a reference check between runs of various compositions, an additional reference sample (50% IPA in H2O + 50 mmol·L-1 ammonia) was exfoliated in each run. After exfoliation, the obtained suspension was left to settle by gravity overnight. 3 mL of the supernatant was then taken and centrifuged for 30 min at 5500 rpm for a mild size selection5. See Supplementary Figs. S1 for an exemplary visualization of the suspensions from the various stages of the LPE process.

The resulting supernatant was then further characterized using UV–Vis spectroscopy (Jasco UV-670 UV–VIS Spectrophotometer, polymer cuvettes, >230 nm), always incl. empty solvent background removal from the UV–Vis spectrum. The concentrations were determined from UV–Vis absorbance spectra via the absorption at a wavelength of 660 nm. A value of 2460 L·g-1·m-1 was chosen for the absorption coefficient14. This value is considered relatively low and represents a modest estimate of our results to compare them with the results from other studies. We note that for the relative comparison of concentrations within our study, the chosen absorption coefficient value does not change the relative relation of values to each other. To benchmark our result to the state-of-the-art, we also performed benchmark exfoliations in NMP and DMF (Fig. 1a). When graphene concentrations were too high for UV–Vis measurements, samples were diluted in water and measured immediately after dilution with water.

An exemplary measurement of pH for the IPA-water co-solvent system with various IPA-water concentrations and various NH3 concentration is shown in Supplementary Fig. 7.

For TEM, three drops of the supernatant were drop-cast onto lacey carbon TEM grids and left to dry naturally. For selected samples, AFM samples were prepared by dropping about 50 µL of the supernatant onto a heated (60 °C) 90 nm SiO2-coated silicon wafer. For XPS, selected suspensions were dried in an oven at 60 °C on a polytetrafluoroethylene (PTFE) film, and the resulting powder was used for XPS analysis. For further details on TEM, AFM, XPS, and Zeta potential measurements see Supplementary Information.

Data availability

All relevant data are available from the authors.

References

Ferrari, A. C. et al. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 7, 4598–4810 (2015).

Backes, C. et al. Production and processing of graphene and related materials. 2D Mater. 7, 022001 (2020).

Meyer, J. et al. Metal oxide induced charge transfer doping and band alignment of graphene electrodes for efficient organic light emitting diodes. Sci. Rep. 4, 5380 (2014).

Sagade, A. A. et al. Graphene-based nanolaminates as ultra-high permeation barriers. Npj 2D Mater. Appl. 1, 35 (2017).

Backes, C. et al. Guidelines for exfoliation, characterization and processing of layered materials produced by liquid exfoliation. Chem. Mater. 29, 243–255 (2017).

Amiri, A., Naraghi, M., Ahmadi, G., Soleymaniha, M. & Shanbedi, M. A review on liquid-phase exfoliation for scalable production of pure graphene, wrinkled, crumpled and functionalized graphene and challenges. FlatChem 8, 40–71 (2018).

Clifford, K. et al. Emergent high conductivity in size-selected graphene networks. Carbon 218, 118642 (2024).

Galhena, D. T. L., Bayer, B. C., Meyer, J. C., Hofmann, S. & Amaratunga, G. A. J. Reduced graphene oxide as a monolithic multifunctional conductive binder for activated carbon supercapacitors. ACS Omega 3, 9246–9255 (2018).

Lavin-Lopez, M. P., Valverde, J. L., Sanchez-Silva, L. & Romero, A. Solvent-based exfoliation via sonication of graphitic materials for graphene manufacture. Ind. Eng. Chem. Res. 55, 845–855 (2016).

Tyurnina, A. V. et al. Ultrasonic exfoliation of graphene in water: a key parameter study. Carbon 168, 737–747 (2020).

Shen, J. et al. Liquid phase exfoliation of two-dimensional materials by directly probing and matching surface tension components. Nano Lett. 15, 5449–5454 (2015).

Manna, K., Huang, H.-N., Li, W.-T., Ho, Y.-H. & Chiang, W.-H. Toward understanding the efficient exfoliation of layered materials by water-assisted cosolvent liquid-phase exfoliation. Chem. Mater. 28, 7586–7593 (2016).

Zhang, X. et al. Dispersion of graphene in ethanol using a simple solvent exchange method. Chem. Commun. 46, 7539 (2010).

Hernandez, Y. et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 3, 563–568 (2008).

Khan, U., O’Neill, A., Lotya, M., De, S. & Coleman, J. N. High-concentration solvent exfoliation of graphene. Small 6, 864–871 (2010).

Lotya, M. et al. Liquid phase production of graphene by exfoliation of graphite in surfactant/water solutions. J. Am. Chem. Soc. 131, 3611–3620 (2009).

Lotya, M., King, P. J., Khan, U., De, S. & Coleman, J. N. High-concentration, surfactant-stabilized graphene dispersions. ACS Nano 4, 3155–3162 (2010).

Wajid, A. S. et al. Polymer-stabilized graphene dispersions at high concentrations in organic solvents for composite production. Carbon 50, 526–534 (2012).

Kaindl, R. et al. Aerosol jet printing of graphene and carbon nanotube patterns on realistically rugged substrates. ACS Omega 6, 34301–34313 (2021).

Smith, R. J., Lotya, M. & Coleman, J. N. The importance of repulsive potential barriers for the dispersion of graphene using surfactants. N. J. Phys. 12, 125008 (2010).

Cui, J. et al. Exfoliation of graphite to few-layer graphene in aqueous media with vinylimidazole-based polymer as high-performance stabilizer. Carbon 99, 249–260 (2016).

Arao, Y., Mori, F. & Kubouchi, M. Efficient solvent systems for improving production of few-layer graphene in liquid phase exfoliation. Carbon 118, 18–24 (2017).

Arao, Y. et al. Direct exfoliation of layered materials in low-boiling point solvents using weak acid salts. Carbon 142, 261–268 (2019).

Ma, H. et al. Direct exfoliation of graphite in water with addition of ammonia solution. J. Colloid Interface Sci. 503, 68–75 (2017).

Ahmad, N. J., Mohamed, R., Malek, M. F., Ikhsan, N. I. & Rusop, M. Ultrasonic-assisted exfoliation of pristine graphite into few layers of graphene sheets using NH3 as intercalation agent. Mater. Sci. Forum 1055, 111–121 (2022).

Shen, J. et al. Surface tension components based selection of cosolvents for efficient liquid phase exfoliation of 2D materials. Small 12, 2741–2749 (2016).

Yi, M., Shen, Z., Ma, S. & Zhang, X. A mixed-solvent strategy for facile and green preparation of graphene by liquid-phase exfoliation of graphite. J. Nanopart. Res. 14, 1003 (2012).

Morton, J. A. et al. An eco-friendly solution for liquid phase exfoliation of graphite under optimised ultrasonication conditions. Carbon 204, 434–446 (2023).

Habib, T. et al. Cosolvents as liquid surfactants for boron nitride nanosheet (BNNS) Dispersions. Langmuir 32, 11591–11599 (2016).

Coleman, J. N. Liquid-phase exfoliation of nanotubes and graphene. Adv. Funct. Mater. 19, 3680–3695 (2009).

Backes, C. et al. Equipartition of energy defines the size–thickness relationship in liquid-exfoliated nanosheets. ACS Nano 13, 7050–7061 (2019).

Li, Z. et al. Mechanisms of liquid-phase exfoliation for the production of graphene. ACS Nano 14, 10976–10985 (2020).

Ng, K. L. et al. Direct evidence of the exfoliation efficiency and graphene dispersibility of green solvents toward sustainable graphene production. ACS Sustain. Chem. Eng. 11, 58–66 (2022).

Lin, C.-W. et al. Interactions between liquid ammonia and graphitic materials. RSC Appl. Interfaces 1, 194–205 (2024).

Liu, W. W., Wang, J. N. & Wang, X. X. Charging of unfunctionalized graphene in organic solvents. Nanoscale 4, 425–428 (2012).

Guidetti, G. et al. Photocatalytic activity of exfoliated graphite–TiO2 nanoparticle composites. Nanoscale 11, 19301–19314 (2019).

Galhena, D. T. L., Bayer, B. C., Hofmann, S. & Amaratunga, G. A. J. Understanding capacitance variation in sub-nanometer pores by in situ tuning of interlayer constrictions. ACS Nano 10, 747–754 (2016).

Skaltsas, T. et al. Graphene exfoliation in organic solvents and switching solubility in aqueous media with the aid of amphiphilic block copolymers. J. Mater. Chem. 22, 21507 (2012).

Naumkin, A. et al. NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database 20, Version 3.4. 20899 (National Institute of Standards and Technology, Gaithersburg, MD, 2003).

Biesinger, M. C. Accessing the robustness of adventitious carbon for charge referencing (correction) purposes in XPS analysis: Insights from a multi-user facility data review. Appl. Surf. Sci. 597, 153681 (2022).

Morgan, D. J. Comments on the XPS analysis of carbon materials. C 7, 51 (2021).

Moeini, B. et al. Definition of a new (Doniach‐Sunjic‐Shirley) peak shape for fitting asymmetric signals applied to reduced graphene oxide/graphene oxide XPS spectra. Surf. Interface Anal. 54, 67–77 (2022).

Mezzi, A. & Kaciulis, S. Surface investigation of carbon films: from diamond to graphite. Surf. Interface Anal. 42, 1082–1084 (2010).

Güler, Ö., Tekeli, M., Taşkın, M., Güler, S. H. & Yahia, I. S. The production of graphene by direct liquid phase exfoliation of graphite at moderate sonication power by using low boiling liquid media: the effect of liquid media on yield and optimization. Ceram. Int. 47, 521–533 (2021).

Liu, M. et al. One-step chemical exfoliation of graphite to ∼100% few-layer graphene with high quality and large size at ambient temperature. Chem. Eng. J. 355, 181–185 (2019).

Janowska, I. et al. Microwave synthesis of large few-layer graphene sheets in aqueous solution of ammonia. Nano Res. 3, 126–137 (2010).

Lange, N. A. & Dean, J. A. Lange’s Handbook of Chemistry. (McGraw-Hill, New York, 1973).

Rumle, J. CRC Handbook of Chemistry and Physics. (CRC Press, Boca Raton London New York, 2021).

Linstrom, P. NIST Chemistry WebBook, NIST Standard Reference Database 69. (National Institute of Standards and Technology, 1997).

Lide, D. R. CRC Handbook of Chemistry and Physics 88TH Edition 2007–2008. (CRC Press, 2007).

Fan, Z. D., Zhang, X. B., Zhao, L. Y., Cai, W. F. & Wang, F. M. Study on the separation of azeotrope of tetrahydrofuran-water using a combined method of extractive and general distillation. Adv. Mater. Res. 803, 149–152 (2013).

Acknowledgements

B.C.B. and J.S. acknowledge funding via project DekoSchirm (886304) under the FORTE program from the Austrian Ministry of Finance and administrated by the Austrian Research Promotion Agency (FFG) and in close cooperation with the Austrian Ministry of Defense. I.W. and B.C.B. acknowledge funding for a research visit via an Erasmus+ traineeship from the European Commission. This research was also funded in part by the Austrian Science Fund (FWF) (Grant-DOI 10.55776/DOC142 and Grant-DOI 10.55776/Y1174). For open access purposes, the authors have applied a CC BY public copyright license to any author accepted manuscript version arising from this submission. We acknowledge the use of facilities at the University Service Center for Transmission Electron Microscopy (USTEM) and the Analytic Instrumentation Center (AIC) at TU Wien. We thank Prof. Christian Gierl-Mayer, TU Wien, for providing commercial graphite samples for exfoliation tests.

Author information

Authors and Affiliations

Contributions

M.N. and B.C.B. conceived and planned the study. M.N. carried out synthesis and characterization with assistance from P.P. and I.W. J.R. and B.F. performed TEM; W.I., A.B., G.M.—Zeta potential; G.S. and R.A.W.—AFM measurements, respectively. J.S.S. performed XPS analysis. D.E. and J.S. contributed to data interpretation. B.C.B. supervised the work. M.N. and B.C.B. wrote the paper with input from all co-authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks Xiaojing Zhang and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nastran, M., Peschek, P., Walendzik, I. et al. Liquid phase exfoliation of graphene using ammonia as an easy-to-remove additive in low-boiling organic-water co-solvent suspensions. Commun Chem 8, 161 (2025). https://doi.org/10.1038/s42004-025-01517-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-025-01517-y