Abstract

Anisotropic materials, such as intracellular nanochains in magnetotactic bacteria, exhibit significant potential in biomedicine and technology due to their magnetic, direction-dependent properties. However, their synthesis is limited due to scalability and purification issues. Here, we present an alternative route to bioinspired magneto-responsive nanostructures, specifically chain-like arrangements composed of truncated cubic cobalt-doped ferrite particles. The magnetic nanoparticles are synthesized in an eco-friendly manner via coprecipitation and hydrothermal conversion of silica-coated nanorods with varying shell thicknesses. A distinct relationship emerged between the cobalt-to-iron ratio, nanoparticle dimensions, and mass magnetization, revealing that these parameters increase with silica shell thickness and reaction temperature. When an external magnetic field is applied, the randomly distributed particles align themselves into nanochains, facilitating the determination of the number of particles in both parallel and perpendicular orientations, as calculated from Small-Angle X-ray Scattering analysis. It is observed that the cluster numbers vary in comparison to the dipole-dipole interaction energy and particle size due to the formation of these chain-like structures and bundles. A critical evaluation of the characteristics of both individual particles and chains summarizes their suitability for biomedical applications.

Similar content being viewed by others

Introduction

It has already been demonstrated in nature that anisotropic materials can serve as an extraordinary tool due to their direction-dependent properties when examining intracellular nanochains found in magnetotactic bacteria1,2,3. These structures consist of isotropic building units formed from ferrimagnetic nanoparticles, which enable navigation in a minimal magnetic field H < 0.067 mT (e.g., the Earth’s magnetic field)4,5,6 and open discussions on their potential for medical use2,7,8. Doping with cobalt ions has also been investigated to study the effects of increased magnetic anisotropy on the magnetic behavior of the magnetosomes9. However, it should be noted that their application remains controversial, primarily because of the limited scalability of cultivation and purification10. Nonetheless, this research area is highly prominent, and the imitation of these nanostructured systems has aroused considerable interest due to their diverse applications in biomedicine (medical therapies11,12, directed cell growth13, cell separation14, hyperthermia treatment15, etc.) and technology (sensors16, nanorobotics17, telecommunication18, catalysis19, microfluidics20, etc.).

Nanochain assemblies can be achieved by various methods, such as spontaneous self-assembly21,22,23, chemical-directed bonding24,25, forth-directed alignment26,27,28,29, and others30,31. For example, Nandakumaran et al. demonstrated a reversible process by adjusting the length of self-assembled nanostructures through changes in the magnetic field strength22. However, these structures exhibit less control during synthesis and less stability without a magnetic field, as the primary force originates from the dipole-dipole interaction of the magnetic particles32. This depends on factors such as volume, concentration, magnetization, viscosity, and fluidic stability32,33,34,35. By incorporating various moieties on the particle´s surface, molecular interactions such as electrostatic, hydrogen bonding, DNA-mediated, or hydrophobic confinement can be utilized to arrange magnetic nanostructures in a directed way31,36. Nonetheless, these interaction-directed methods are mainly combined with the application of a magnetic field during crosslinking (e.g., magnetic-field-assisted Diels-Alder reaction or copper-catalyzed alkyne-azide cycloaddition click reaction) and necessitate a more intricate approach24,25. The force-directed alignment predominantly necessitates the application of an external magnetic field in conjunction with the subsequent incorporation of a polymer or silicon layer surrounding these structures26,27,28,29. This additional layer is essential for stabilizing the magnetic nanoparticles (MNPs) within their configuration, owing to their relatively weaker magnetic properties or when removing the external magnetic field37. Several studies demonstrate the successful design of chains of varying lengths made from magnetic materials surrounded by silica or oxide layers of different thicknesses to address the stability problem15,27,38,39. Moreover, including shells can enhance such a system’s biocompatibility38. In particular, we would like to refer to works focused on the construction of silica-coated, at least magnetically-responsive nanochain structures, which demonstrate their applications across the various fields mentioned above. This high variation arises from the enhanced magnetic and shape anisotropy, the reversibility through external fields, the increased (rough) surfaces, the magnetic coupling effects, and other properties of the bioinspired magnetic nanochains20,27,40,41,42,43.

The magnetic components of these systems are primarily based on iron oxides such as magnetite (Fe3O4) or maghemite (γ-Fe2O3) due to their various advantages, including size-dependent magnetic properties44,45,46, low synthesis costs47, and biocompatibility48. However, they have a low anisotropy constant, low thermal efficiency, or tend to oxidize49. Since the magnetic anisotropy of the particles influences hyperthermia efficiency, expressed by specific absorption rates (SAR), an increase can be achieved through modification, e.g., by altering the particle shape (anisotropy of particle shape) or the crystal structure (anisotropy of crystal structure)50,51,52. Using shape-anisotropic Fe3O4 nanoparticles, such as cubic, octahedral, or star-like, increases the coercivity, saturation magnetization, and SAR45,49,51,53,54. The exchange of Fe(II) ions with Co(II) ions in an inverse spinel structure increases the magneto-crystalline anisotropy and, thus, in the case of cobalt ferrite, results in a more stable material against oxidation and exhibits adequate thermal stability compared to magnetite45,52,55,56. As a result of higher magneto-crystalline anisotropy, cobalt ferrite particles should already be dominated by the Brownian relaxation mechanism in the high single-digit nanometer range (around 7 nm), compared to magnetite nanoparticles (around 14 nm). The combination of both anisotropy effects can be realized via a partial ion exchange of Fe(II) with Co(II) ions in shape-anisotropic iron oxide particles to obtain CoxFe3-xO4 (x < 1) particles57. For example, Shebha Anandhi et al. achieved an increase in SAR by doping magnetite with cobalt to produce CoxFe3-xO4 within the concentration range of x ≤ 0.555. This also relates to potential applications in medical cancer treatments, where the hyperthermal effect is arguably the most intriguing aspect58. Regarding the toxicity of cobalt-doped particles, it should be noted that these particles exhibit a reduced toxicity within the range of 0.2 < x < 0.6 compared to magnetite and cobalt ferrite59. A more detailed analysis of toxicity and biodegradability will be addressed in the final section of this work. In conclusion, considering the different relaxation processes and the hyperthermal effect, this work focuses on the synthesis of cobalt-doped ferrite (CF) particles with a lower cobalt amount (x ≤ 0.5) to increase the magneto-crystalline anisotropy and reduce the toxicity as presented in previous work57.

Monodisperse cobalt-doped ferrite nanoparticles are mainly synthesized through a thermal decomposition process using toxic metal acetylacetonates or metal pentacarbonyls with lower cobalt content. Despite their exceptional SAR of up to 14,686 W g–1 Fe, as exemplified for cubical bipyramids, octahedrons, and hexagons by Singh et al. and Demessie et al., these syntheses require harmful solvents and surface-active surfactants, such as oleylamine60,61. Therefore, the development of green or aqueous methods for preparing cobalt-doped ferrite is continuously increasing62. Novel environmentally friendly approaches utilize extracts from hibiscus, tea, sesame, honey, cardamom, etc., or are conducted using microorganisms and fungi63. However, these methods mostly result in particles with a high size distribution and low yields. Microwave-assisted syntheses are also possible, particularly in combination with combustion or hydrothermal methods, which significantly reduce reaction times and thus energy consumption. However, microwave hybrid synthesis is often limited to small volumes due to the complicated setup and challenges with slow reaction kinetics64. In our group, we have specialized in hydrothermal syntheses, which, although requiring specialized equipment, produce highly crystalline particles with excellent composition characteristics from low-cost precursors57,64. Due to the multitude of adjustable parameters, these methods enable a wide variety of particle morphologies, even in aqueous systems without the requirement for toxic solvents, surfactants, or precursors65,66.

Additionally, the synthetic pathway aims to simultaneously arrange the CF particles in nanochain-like structures by implementing a silica shell around the iron precursors during the synthesis. Therefore, a modification of the well-known precursor-based hydrothermal reaction was carried out. For this purpose, the spindle-like precursor β-Fe(III)OOH (akaganeite) was first produced from Fe(III) chloride in an aqueous system67. Afterward, the precursor was functionalized with the sodium salt of polyacrylic acid (PAA) so that the subsequent silica shell synthesis on the surface of the akaganeite nanorods succeeds without the formation of agglomerates or silica NPs68,69,70,71. The use of silica-coated akaganeite particles in the subsequent precipitation and ion exchange reaction with cobalt and ferric chloride salts enables a size-tunable synthesis of cobalt ferrite particles in dependence on the silica shell thickness. Using a one-step hydrothermal reaction, these slightly anisotropic NPs will be arranged in nanochains by thin decondensed silica shells around the ordered system. This would also enable the subsequent functionalization of the silica surface, enabling frequently used stabilization in biological media or functionalization with linkers, spacers, and fluorescent substances for magnetic imaging applications12,72. Furthermore, the arrangement in long chains results in higher shape anisotropy of the particle system and enables the enhancement of hyperthermia efficiency for cancer treatments due to the higher thermal fluctuations through viscous drag26.

Results

In Fig. 1a, the schematic synthesis protocol is shown for obtaining nanorod precursors with a defined silica shell, which are then converted into cobalt-doped ferrite nanoparticles using a hydrothermal step. In the first section, the synthesis of the silica-coated nanorod precursor via PAA modification and subsequent Stöber process is illustrated. The silica shell is thoroughly characterized to clarify its impact on the subsequent synthesis of cobalt ferrite. In the following section, the influence of reaction temperature of the hydrothermal step, the filling volume of the reactor, and silica thickness of the precursor on the morphology, particle size, and cobalt content of the magnetic particles is investigated. This is followed by a discussion of the proposed formation mechanism depending on the precursors used. The magnetic characterization, including saturation magnetization, squareness ratio, coercivity, and static susceptibility, is presented in the next part. As the magnetic nanoparticles predominantly form chain-like nanostructures, this study was conducted in aqueous media and in 80% glycerol/water mixtures to investigate the effect of viscosity on potential chain formation, depending on the magnetic field strength. A detailed investigation follows in the subsequent section, as illustrated in Fig. 1b, where the visualization of chain formation and cluster size of the structures as a function of the applied magnetic field strength was achieved through analysis of small-angle X-ray scattering (SAXS) data, depending on the field direction (perpendicular, parallel, and overall). The results obtained regarding the size, size distribution, anisotropy, and chain formation of the synthesized magnetic particles were critically evaluated in comparison to the current state-of-the-art literature, considering their potential biomedical applications.

a The synthesis protocol for obtaining core-shell nanorods is presented, which involves three steps: the hydrolysis of iron(III) chloride hexahydrate (FeCl3 ∙ 6 H2O) to akaganeite (β-FeOOH), the modification with sodium polyacrylate (PAA), and the deposition of a thin silica layer (SiO2). In a subsequent hydrothermal step, these precursor particles are converted into cobalt-doped ferrite nanoparticles (CoxFe3-xO4). The boxes visualize the surface coating of the nanoparticles in each step, respectively (orange: akaganeite with hydroxy (–OH) groups, grey: PAA layer with carboxy (–COOH) groups, blue: silica layer with –OH groups). b The SAXS images of the random (left) or chain-like (right) particle arrangements in dependence on the magnetic field strength H, which is perpendicular to the X-ray beam, are visualized. The chain-like orientation will manifest as an anisotropic pattern, whereas random orientations are generally more isotropic. The patterns were analyzed over all azimuthal angles φ, perpendicular, and parallel to the field to assess the extent of the anisotropy and to examine the chain-like structures in terms of width and length.

Synthesis of modified precursors with different silica shell thicknesses

Synthesis of the akaganeite nanorod precursors

Initially, a standard protocol by Hinrichs et al. was used to synthesize well-defined cigar-shaped nanorods of β-FeOOH (see Supplementary Fig. 1.1a, 1.1b)67. These nanoparticles are produced through the hydrolysis of ferric chloride in the presence of Na2HPO4. As a result, nanorods with an average length of (32 ± 8) nm and a width of (7 ± 2) nm were obtained (see Supplementary Fig. 1.1c, 1.1d). The synthesized akaganeite crystal structure is based on double chains that form 2 × 2 (and less 1 × 2) channels stabilized by typically chloride ions within these tunnel structures. The double chains consist of Fe(O, OH)6 octahedra, which are edge-shared and connected via oxo-bridges at the corners. The structure is oriented along the [001] direction, promoting the formation of rod-like structures, schematically illustrated in Supplementary Fig. 1.1e68,73,74,75. The structure-directed role of the chloride ions at the cluster-based akaganeite formation process is well established76. This is composed of the thermodynamic driving force to remove chloride ions during dehydration and cluster aggregation of oxyhydroxide clusters, as well as the kinetic hindrance of this process due to the rigidity of the formed subunits with channels77. Furthermore, the presence of 4.3 to 6.0 wt.% chloride ions within the tunnel structure (Supplementary Fig. 1.2) prevents the formation of the compositionally comparable goethite at low pH, which is a comparable concentration range as given in the literature78. Due to the pH, the temperature, the anion´s presence, and the requirement for Na2HPO4 (as discussed in detail in Supplementary Note 1.1), the phase transformation to hematite is prevented as the phosphate ions bind preferentially on (hk0) faces, simultaneously promoting the anisotropic growth along the c-axis74,79,80,81. The diffraction pattern matches the 2θ angles and intensities with reference to JCPDS PDF No. 00-034-1266 in good agreement (see Supplementary Fig. 1.3). The observed diffraction reflexes at 2θ values of 11.8°, 16.8°, 26.7°, 34.0°, 35.2°, 39.3°, 46.5°, and 55.9° correspond to (110), (200), (310), (400), (211), (301), (411), and (521) planes which align with the tetragonal structure (room group I4/m) of akaganeite (see Supplementary Table 1.1). Through the analysis of reflection intensity ratios (see Supplementary Table 1.1) in combination with High-Resolution (HR) TEM analysis (Fig. 2a, Supplementary Fig. 1.4), insights into the crystal orientation concerning the preferred exposed facets of the akaganeite nanorods can be obtained, which is discussed in detail in Supplementary Note 1.2.

a HR-TEM image of an akaganeite nanorod with crystal planes analyzed by Fast Fourier Transformation (inset). b The hydrodynamic size of the particle system increases with the polymer modification (@pH = 7.0, 0.12 mg mL−1, grey) of the akaganeite rods (initial @pH = 2.5, orange). In reference, an akaganeite solution at pH 7 (bright orange) is shown. The hydrodynamic radius was measured thrice for each sample, and the Z-average was calculated. c The change of the surface charge in aqueous particle solutions from positively charged iron oxide hydroxide (@pH = 2.5) to negatively charged acrylic acid end groups (@pH = 7.0, 0.12 mg mL−1) is indicated by the change of the zeta potential. d The silica thicknesses dSiO2 are depicted as a function of the molar amount of tetraethoxysilane per surface area and per volume of the reaction solution, exemplified for the aka@0.12PAA precursors. TEM images in different magnetizations and corresponding photos (inlet) of akaganeite@0.12PAA@SiO2 particle solutions with e dSiO2 = 2.2 nm, f dSiO2 = 4.7 nm, and g dSiO2 = 6.8 nm are shown, exemplarily. The precursors with silica shells with h dSiO2 < 4 nm and j dSiO2 > 4 nm do not show significant differences in crystallinity, as both cases are assumed to be amorphous, as indicated in the HR-TEM images and by the shape of the line profile scans. Despite the silica shells of i dSiO2 < 4 nm and k dSiO2 > 4 nm, the presence of akaganeite is detectable, as confirmed by nanorod areas (top) and corresponding EDX line-scan profiles (bottom).

The hydrodynamic diameter dH of the akaganeite nanorods is measured to be (23.0 ± 0.2) nm with a dispersity index (PDI) of 0.15, indicating a monodisperse suspension (Fig. 2b). An aqueous suspension of akaganeite nanorods exhibit a positive surface charge at pH 2.5 (the conditions utilized in the reaction), characterized by a zeta potential ζ of (46.8 ± 2.3) mV, which arises from the presence of protonated hydroxyl groups –OH2+ (orange box in Fig. 1a). In contrast, an akaganeite sample adjusted to a pH of 7.0 using 0.1 M sodium hydroxide solution (the pH value of the subsequent Stöber process) showed an increase in the average hydrodynamic radius to (105 ± 1) nm. This increase may be attributed to enhanced particle agglomeration resulting from reduced stability, as the particles now exhibit a negatively charged surface with ζ = (−39.0 ± 0.6) mV (Fig. 2c), resulting from –FeO- groups on the surface. Although a ζ value of ±30 mV is considered a moderately stable suspension, the size of the blood cells measured by Riddick et al. on the micron scale of this historical value should not be overlooked, where only static interactions are assumed82. For particles with a smaller diameter, the attractive Van der Waals forces become more prominent, necessitating higher surface charges to maintain stability83. It should also be noted that positive, neutral, and negative groups can simultaneously occur around the isoelectric point, which can lead to particle agglomeration84.

Modification of the akaganeite precursors with sodium polyacrylate

The subsequent surface modification of akaganeite was carried out using sodium polyacrylate (PAA, Mw = 2100 g mol−1) (see Supplementary Section 2). Considering a cylindrical geometry, the bare nanoparticles exhibit surface areas of approximately 750 nm² to 800 nm² per particle batch. Three concentrations of PAA (0.40 mg mL−1, 0.12 mg mL−1, and 0.04 mg mL−1) were tested, referring to the surface area of the particle fractions of 2.0 ∙ 10−28 mol nm−², 1.9 ∙ 10−29 mol nm-², or 5.2 ∙ 10−30 mol nm−², respectively (see Supplementary Fig. 2.1). The successful modification can be attributed to the changes in the surface coating and the hydrodynamic diameter. In contrast to bare akaganeite, the further increase in the hydrodynamic diameter to (224 ± 3) nm illustrates the successful modification of akaganeite with sodium polyacrylate (PAA, pH 7.0) (Fig. 2b). This is further evidenced by the negative zeta potential of (−56.3 ± 1.9) mV (Fig. 2c). The pKa value of polyacrylic acid85 around 4.5 indicates the deprotonated carboxylic acid end groups of the polymer being present at the surface of the particles at pH 7.0. If steric effects are introduced through a ‘protective’ shell, such as the anionic polymer PAA with the general formula [–CH2CH(COONa)–], lower surface charges may be adequate, because particle interactions are hindered by the steric barrier (grey box in Fig. 1a). This may also indicate that the fraction with dH ≈ 220 nm corresponds to individually PAA-stabilized particles. However, due to the significantly increased agglomeration observed during TEM preparation in comparison to bare akaganeite, this explanation is rather unlikely. A second size fraction around 2800 nm shows the presence of large agglomerates due to the functionalization with PAA. As a result, the PDI increases to 0.48 for this particle sample, indicating a polydisperse suspension or moderate aggregation, which can also result from the higher pH due to the reaction conditions (in comparison: PDI = 0.31 for akaganeite@pH7.0). Furthermore, Fourier Transform Infrared (FTIR) spectroscopy demonstrated successful surface modification by measuring the characteristic C=O carboxylic acid (1760–1690 cm−1) and C–O (1320–1210 cm−1) stretching vibrations, as well as the increasing O–H stretching (3780 – 2750 cm−1) vibrations (see Supplementary Note 2.1, Supplementary Fig. 2.2a) while the Fe–O bending modes remain unchanged86,87,88. However, it should be noted that all fractions retain their specific akaganeite reflexes, and the crystalline phase is unaltered (see Supplementary Note 2.2, Supplementary Figs. 2.2b, 2.2c).

Silica functionalization of the PAA-modified nanorod precursors

In the subsequent step, the silica functionalization was conducted based on a Stöber sol-gel process (see Supplementary Section 3.1). Ammonia was added as a basic catalyst for the PAA condensation and to generate NH4+ counterion charges at the unbound carboxyl group of the PAA. The base-catalyzed hydrolysis forms silanol groups utilizing the silica precursor tetraethoxysilane (TEOS) near the NH4+ charges. During the condensation reaction, siloxane bridges are formed, resulting in the production of a silica network (blue box in Fig. 1a) around the PAA-modified nanorods. The silica shell formation controlled by PAA with NH₄⁺ functional groups was also investigated in detail by Nakashima et al.89,90 Furthermore, previous research shows that the use of polar solvents leads to a smaller size distribution of the silica shells or silica particles91,92. Stöber already demonstrated that this polarity effect results in the smallest particles and size distributions for methanol93. However, this solvent was excluded due to its toxicity. A mixture of water and ethanol was used instead, leading to effectively encapsulated nanorods stabilized with PAA in ethanol, as shown in Fig. 2e–g for three different silica shell thicknesses, which would agglomerate intensely in ethanol without PAA modification. The calculation of the silica layer thickness was performed by analyzing TEM images using Supplementary Equation 3.1, assuming that the diameter of the embedded akaganeite rods corresponds to the mean value obtained from Supplementary Fig. 1.1 (see Supplementary Note 3.1, Supplementary Fig. 3.1). The formation of silica shells with a thickness of approximately 2–7 nm, depending on the TEOS amount per surface and per mass concentration, is exemplarily depicted for the particle samples aka@0.12PAA in Fig. 2d. Due to the more intense particle agglomeration of akaganeite at high PAA concentrations because of salting out effects of the polyelectrolytes, as shown in Supplementary Fig. 2.1, the fractions with 0.40 mg mL-1 PAA show larger silica-functionalized particle agglomerates with high deviations in the silica thicknesses (see Supplementary Figs. 3.2a, 3.2b). However, the silica layer thickness can be well adjusted using a smaller amount of PAA, represented by aka@0.12PAA or aka@0.04PAA precursors (see Supplementary Figs. 3.2c–3.2o). The volume of ethanol and the amount of TEOS are critical parameters for this process. An excessive quantity of TEOS results in significant aggregation of the nanorods, which is accompanied by the precipitation of particles. This phenomenon is also observed with insufficient dilution of the synthesis solutions, as the particles are not sufficiently spatially separated, and the silica layers are formed around a bulk of nanorods. A concentration of 2.6 mg nanorods per mL ethanol yields reproducible and visually non-agglomerated particle suspensions; no precipitation was observed in this case (see photos in Fig. 2e–g). Furthermore, when utilizing identical ratios of the amount of TEOS to the product of (product of particle surface area and volume of ethanol), the resulting silica thicknesses by using low PAA concentrations are slightly smaller compared to those at medium or high PAA concentrations (see Supplementary Fig. 3.2p, Supplementary Fig. 3.3). This occurrence is hypothesized to be attributed to reduced particle agglomeration at low PAA concentrations, as a higher amount of TEOS is consumed per particle (or surface) than in an agglomerate formed by multiple particles (see Supplementary Note 3.2).

To demonstrate the presence of akaganeite in the core of the silica precursors and to evaluate the porosity of the silica layers, two fractions were analyzed with dSiO2 < 4 nm and dSiO2 > 4 nm (see Supplementary Note 3.3). In the HR-TEM images, a clear distinction between akaganeite and silica can be observed (Fig. 2h and j, see Supplementary Fig. 3.4). Additionally, Energy Dispersive X-ray spectroscopy (EDX) analysis reveals silicon signals at the surface and edges of the particle, whereas iron is primarily present in the core, especially for the sample with the thicker shell. The transition is clearly visible in the line-scan profiles (Fig. 2k, see Supplementary Fig. 3.5). However, in the sample with the thin silica shell, where the line scans do not appear to be very conclusive (Fig. 2i, see Supplementary Fig. 3.6), a Si/Fe ratio of 0.28 is observed based on the distribution in the sum spectra (see Supplementary Fig. 3.7). This is significantly different from the Si/Fe ratio of 0.09 that was determined in the bare akaganeite sample (see Supplementary Fig. 1.2). In the sample with a thicker shell, the silicon content correspondingly increases, resulting in a Si/Fe ratio of 2.7 (see Supplementary Fig. 3.7). Chloride atoms, located within the tunnel structures of akaganeite, can also be detected. This confirms that akaganeite remains stable and is neither dissolved nor transformed into another phase during the PAA functionalization and the Stöber process. Additionally, the HR-TEM analysis enables a cautious interpretation of the porosity of the silica shells, which lack crystal planes and are therefore more likely to exhibit an amorphous structure. Additionally, the line scan profiles do not show a single mountain profile of Si and O. Therefore, they cannot be assigned to a crystalline phase. Instead, they exhibit an amorphous structure with non-ordered mesopores, as demonstrated in Rades et al. for silica spheres94. This is attributed to differences in the local particle density, corresponding to silica with either aligned or non-aligned mesoporous structures94. Comparable porosities were also investigated and determined using gas adsorption measurements in combination with Brunauer-Emmett-Teller analysis for similarly synthesized silica shells via the Stöber process (see Supplementary Note 3.4). Such a structure could dissolve under alkaline conditions, with the dissolution time depending on the thickness of the silica layer95. Given that the reproductive formulations for the silica functionalization were conducted using 110 mg of nanorods and 100 mg or 55 mg per batch were required for the hydrothermal synthesis, the analysis of the other silica fractions used for hyperthermal steps was restricted to TEM.

Size-dependent synthesis and arrangement of cobalt ferrite chain-like structures

Overview

The synthesized nanoparticles, resulting from the subsequent conversion of different precursors, were investigated in terms of their morphology, size, and elemental composition. The calculated values for size obtained by TEM and X-ray diffraction (XRD, calculated via the Debye-Scherrer equation and the Williamson-Hall plot, see Supplementary Note 4.1) and cobalt content obtained by flame atomic absorption spectroscopy (F-AAS, see Supplementary Note 4.2) are summarized in the Supplementary Table S4.1. The dispersity is given in Supplementary Table S4.2. Reference samples were prepared using either bare akaganeite or aka@PAA precursors, resulting in cobalt-doped particles designated as CF-A or CF-P. The designations are combined with a series number, which is explained by the reactor parameters used, where “1” describes a conversion at a maximum temperature of 160 °C and filling volume of 100%, “2” a conversion at 190 °C and filling volume of 100%, and “3” a conversion at 190 °C and filling volume of 55%. Cobalt-doped particles obtained from the reaction of aka@PAA@SiO2 precursors are designated as CF-S. For series 1 and 2, the silica layer is 2.5 nm. In series 3, the silica thickness of the different precursors varies by approximately 2 – 7 nm.

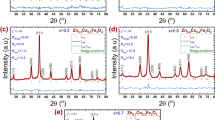

Overall, the resulting magnetic particles are slightly anisotropic, exhibiting cubic or quasi-spherical shapes in the 2D projection (see Supplementary Figs. 5.1, 5.2, and 6.1 for series 1, 2, and 3, respectively). The observed diffraction reflections at 18.2°, 30.0°, 35.5°, 43.0°, 56.9°, and 62.2° at the diffraction patterns (see Supplementary Figs. 5.3a, 5.3b and 6.2 for series 1, 2, and 3, respectively) correspond to the (111), (220), (311), (400), (511), and (440) planes, respectively, which closely match the cubic spinel structure of cobalt ferrite reference (JCPDS No. 00-003-0864) for all approaches. The elemental analysis results indicate the formation of cobalt ferrite with a cobalt-to-iron ratio of 0.16 to 0.20, which means a stoichiometric cobalt coefficient of approximately 0.40 to 0.51, respectively (see Supplementary Table 4.1). The effect of different temperatures and silica layer thicknesses will be discussed in the following two sections.

Effect of the hydrothermal temperature

TEM images of the particles are shown in Fig. 3a, b in dependence on the used precursor. As the shape of the particle fractions differs slightly by using akaganeite only or akaganeite with silica shells, the particle initiation and growth mechanism must change, which will be discussed in detail in the Section ‘Explanation of the Proposed Mechanism.’ Comparison of the magnetic particle shapes synthesized with aka and aka@PAA shows a more angular morphology at lower temperatures. In contrast, at higher temperatures, the particles tend to become more rounded. However, it is particularly well known that Ostwald ripening predominantly occurs at the edges and corners of cubic and octahedral particles. Consequently, the morphology changes to significantly truncated particles with higher temperatures, as can be observed in the TEM images. Additionally, the overall particle distribution changes (see Supplementary Figs. 5.1, 5.2) to slightly structured nanochain orders using akaganeite-core/silica-shell particle systems.

The bare akaganeite (hollow), aka@0.40PAA (half-filled), or aka@0.40PAA@2.5SiO2 (filled, with a shell thickness of 2.5 nm) precursors were converted in a hydrothermal step with a filling volume of 100%. The conversion of aka@0.40PAA@2.5SiO2 precursors was performed twice. a At a maximum reaction temperature of 160 °C, the shape changed from cubic to truncated cubic shapes. b By increasing the reaction temperature to 190 °C, the shape is more truncated. In comparison to the use of bare akaganeite, the size and cobalt-to-iron ratio of the cobalt-doped particles decrease when using PAA-modified precursors, and increase when a silica shell is added around the precursors for both setups, performing the reaction at either c 160 °C or d 190 °C.

A comparison of the particle size values determined from TEM images and the calculated crystallite size dDS observed from the diffraction patterns via the Debye-Scherrer equation, in dependence on the cobalt-to-iron ratio, is illustrated in Fig. 3c and d. The dispersity index from the TEM data, at approximately 0.10, is comparable across all experiments, suggesting no explicit dependency of the reaction temperature on the size distribution. Observations from both temperature approaches indicate that the diameter determined from the diffraction pattern is notably smaller than the diameter from the TEM images. The particle size distribution has been reproducible.

The diffraction patterns are presented in Supplementary Fig. 5.3, showing that the most intense peaks closely match those of the reference sample (JCPDS No. 00-003-0864), confirming the formation of cobalt ferrite and the experiment’s reproducibility. The exact cobalt content obtained via F-AAS ranges indicates the formation of cobalt-doped particles with x < 1, showing minor discrepancies from the initial trial but within the error range of ±0.01, and increases with the particle size. While the blank samples exhibit the lowest cobalt content in both temperature profiles, the cobalt content in the repeated experiments shows slight deviations.

The mean values from the replicate experiments (see Supplementary Table 4.1) using silica-functionalized precursors at 160 °C and 190 °C confirm an increase in cobalt content and diameter with higher temperatures. The mean values and deviations for the Co/Fe ratios and the diameter of both samples are κ = 0.188 ± 0.008 and 0.188 ± 0.006, as well as dTEM = (35.1 ± 8.2) nm and (40.9 ± 6.1) nm and dWH = (37.6 ± 3.0) nm and (41.9 ± 3.8) nm for 160 °C and 190 °C, respectively (see Supplementary Fig. 5.4 for WH plots). Comparable cobalt coefficients ranging from 0.46 to 0.49 are identified at both temperatures. However, the distribution of nanoparticle sizes at both temperatures is quite similar, making it difficult to draw significant conclusions. Reproducibility appears to improve at high temperatures, with cobalt contents and diameters aligning more closely. The temperature difference is a crucial factor, particularly when using a filling volume of 100%, as higher temperatures enable higher heating rates (see Supplementary Fig. 5.5), allowing for crystalline cobalt ferrite formation 15 minutes earlier96,97. This enables the synthesis of thicker cobalt ferrite shells or an improved ion exchange with higher reaction temperatures, leading to slightly larger diameters and higher cobalt contents. The impact of this temperature difference is more prominent with a filling volume of 55%, where a temperature above 80 °C is attained after 15 minutes of heating. This explains the use of higher temperatures with a smaller filling volume for series 3.

The discussion of the temperature effect will be based on the mean values of both trials. The particle fractions produced using silica precursors suggest that the low temperature (160 °C) favor the formation of smaller sizes. This could be related to the dissolution of silica structures under alkaline conditions, with the dissolution rate depending on the thickness of the silica layer95. The amount of dissolved silica increases at high temperature (190 °C), due to an enhanced dissolution rate and higher saturation concentration of silica during the reaction in water95. At high temperature, coupled with increased amounts of dissolved silica, there is less spatial separation of nuclei during the particle growth process, allowing for the formation of larger particle diameters. Conversely, increased salinity of the solution enhances the stability of the silica shells, which may preferentially occur at low temperature and the associated lower kinetic energy in the system. This would result in a higher proportion of ionic compounds, such as unreacted Fe(III), Fe(II), and Co(II) ions, remaining in the aqueous solution with a lower activity coefficient of water over a longer period of time. The silica layers would still be present in the solution and support the formation of magnetic particles close to these silica shells, thereby favoring the development of more chain-like structures.

Effect of the silica shell thickness

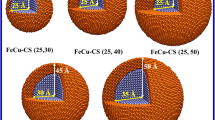

The TEM images of the cobalt ferrite samples synthesized with varying shell thicknesses (series 3, see Supplementary Section 6) are displayed in Fig. 4a, and overviews of different magnifications are shown in Supplementary Fig. 6.1. As indicated in the HR-TEM images, it can be assumed that the particles exhibit octahedral morphologies as presented for the sample CF-S3-8 (see Supplementary Fig. 6.2). Specifically, the cobalt ferrite diameters notably increase with the silica thickness of the utilized precursors, except for the bare precursor (Fig. 4b). This deviation could be attributed to the additive (PAA polymer), which is used for the samples with a silica shell. The literature suggests that additives can result in smaller crystallite sizes98,99,100,101. Therefore, we also synthesized a blank sample with a precursor without a silica shell but containing PAA instead. This precursor results in the smallest diameters for these NPs. Further support of this trend is observed by the crystallite size determined by the Gaussian fit of the (311) reflex of the diffraction patterns (see Supplementary Fig. 6.3) as well as by the Williamson-Hall plot for all reflexes (see Supplementary Fig. 6.4). Furthermore, the cobalt content of the samples increased with the silica layer thickness and the nanoparticles´ size, respectively (Fig. 4c). However, the sample using aka@PAA showcased another observation as the diameter shrinks and the cobalt content increases. Compared to this blank sample, the diameters and cobalt contents increase with increasing shell thickness. A significant enhancement is observed at a silicon thickness of 4 nm. Furthermore, a shift in the 2θ angles of the XRD patterns can be observed (see Supplementary Fig. 6.3b). When plotting the most intense peaks at the (311) reflex of the cubic inverse spinel (Fig. 4c), a slight shift of approximately 0.1° to smaller angles is initially observed with the addition of PAA. This continues with the use of precursors with a silica thickness of up to 4 nm up to 35.44°. As soon as the layer thickness exceeds 4 nm, a jump back to 35.57° can be recognized, and it starts shifting again to 35.44° with increasing silica thickness. If cobalt ferrite (ICPDS No. 00-022-1086, 2θ(311) at 35.44°) is referenced, agreement with this can be found for almost all samples. Magnetite shows a maximum of 2θ(311) at 35.42° (ICPDS No. 00-019-0629). The deviating sample at 3.4 nm (2θ(311) = 35.34°) can be explained by the lower Co/Fe ratio of 0.16, which would explain a shift in the reflexes to more magnetite-like ferrites. Because X-rays primarily resolve the surface of the crystal lattice structure, cobalt-rich surfaces will exhibit a shift of the (311) reflection to a 2θ value of 35.44°. To confirm the Co/Fe ratio, line scans and EDX mappings were additionally performed on three samples, namely CF-A3 (Fig. 4d), CF–P3–1 (Fig. 4e), and CF–S3–8 (Fig. 4f). The CF samples show the same trend as in the F-AAS measurements, namely increasing Co/Fe ratio with PAA addition and further enhancement with increasing particle diameter. However, it can be observed that the absolute κ values of 0.205, 0.213, and 0.222 observed from the map sum spectra are higher than those determined by AAS. This discrepancy is due to the partial overlap of the Co and Fe Kα1 lines, given inherent uncertainties in the intensity values. Additionally, differences in the average values observed through the line sum spectra and the map sum spectra can be identified (see Supplementary Figs. 6.5–6.10). The mapping, which analyzes above a larger number of particles, yields a value that approaches the AAS value (according to the significantly larger particle number). Furthermore, the atom percent distribution of the line scans enables an interpretation of the silicon presence. Interestingly, in the case of CF-S3-8, the silicon intensity at the particle edges increases, which can be attributed to a local increase in silicon concentration (see Supplementary Fig. 6.9). This indicates the presence of a thin silica shell surrounding the particles, which stabilizes them within the chains or at least influences their formation mechanism (see the following section).

The akaganeite (hollow, orange), aka@0.12PAA (half-filled, grey), or aka@0.12PAA@SiO2 (filled, blue) precursor with a shell thickness varying between 2.2 nm and 6.8 nm was converted in a hydrothermal step with a filling volume of 55% at a temperature of 190 °C. a TEM images indicate a change in the shape from cubic to truncated cubic particles by increasing the silica shell of the precursors. b The morphological and crystallite diameter, as well as c the cobalt-to-iron ratio of the resulting cobalt-doped particles, increase with the silica shell thickness. EDX mapping and corresponding intensity line scan profiles of the cobalt-doped particles synthesized with d akaganeite, e aka@0.12PAA, or f aka@0.12PAA@5.6SiO2 confirm the presence of Co (green), Fe (yellow), O (red), and Si (turquoise). However, the distribution includes only the intensities of Si, Co, Fe, and O, which were normalized to 100 atom%. Therefore, the absolute values should be lower when considering all elements, as other components are not included in this normalization. g The formation of MNPs from bare akaganeite indicates the presence of a magnetite-like phase (brown particle). Smaller MNPs with a high cobalt content, indicated by a green color, can be synthesized by adding a polymer additive. The diameter and cobalt content per unit volume can be adjusted by converting a precursor system with a silica shell. As the cobalt content in the suspension increases, along with the thickness of the silica shell and the diameter of the particles, the mechanism of formation of the magnetite core changes. h Fig. 4c is depicted in dependence on the size and cobalt content per volume, summarizing the data from F-AAS, XRD, and TEM.

In particular, it should be noted that all trends regarding the size, the cobalt amount, and the 2θ angle at the maximum of the (311) reflex show a jump in the data trends as soon as a silica thickness of around 4 nm is exceeded. To understand the interplay of the parameters, the cobalt content was calculated over the entire particle volume, assuming a simplified cubic particle shape (Fig. 4g). The theoretical value of the iron-to-cobalt content of 0.20 is derived from the amount of Co(II) ions used concerning the maximum usable Fe(III) and Fe(II) content (see Supplementary Note 7.1). If it is further assumed that the particle shape is approximately cubic, the cobalt content per cubic volume of a particle decreases in relation to the increasing silica thickness or size of the particle. It is evident that the theoretical value of cobalt content per particle volume is nearly achieved, with only a minor deviation observed for smaller diameters. This could be explained by minor deviations in the determination of weight percentages, which could result in slight discrepancies in the mass concentration of 10 mg MNP per g solution in the AAS measurements. Additionally, it is conceivable that small amounts of Co(II) ions in solution may not be incorporated due to an ion exchange at high temperatures, which could lead to a more significant deviation from the theoretical value with a higher number of smaller particles. A clear inverse relationship exists between particle size and cobalt distribution, with cobalt-rich particles depicted in green and iron-rich phases in brown. Considering only the distribution over the total volume, it is evident that, at the same amount of cobalt in the reaction solution but with different resulting particle sizes, the cobalt content should decrease with increasing particle size. Additional analysis of the (311) reflections provides indications of the iron- or cobalt-rich surfaces of the particles, which differ from the simplified depiction in Fig. 4g (see comparison in Fig. 4c and discussion above). In Fig. 4h, the particle size and cobalt distribution over the particle volume are illustrated, along with the cobalt-to-iron ratio, which summarizes the trends discussed above. The effects on particle size, cobalt content, and arrangement due to the addition of PAA and increasing silica thickness are shown in Supplementary Fig. 7.1.

Explanation of the proposed mechanism

We hypothesize that the combined effects of the size, cobalt content, and surface occur because different formation mechanisms for magnetite in the initiation phase are feasible within the present reaction solution, along with a varying dissolution process of the akaganeite rods due to different silica shell thicknesses (Fig. 5). The initiation phase proceeds at room temperature within the first seconds of NaOH addition, in which nuclei spheres of magnetite occur. The spherical shape is present because the surface energy and surface area should be minimized, as surface tension is the dominant parameter in the initiation process102. Magnetite can be formed through a basic coprecipitation reaction of Fe(II) and Fe(III) hydroxides (Massart reaction), depicted via reaction 1. Moreover, akaganeite can be converted to magnetite with Fe(II) hydroxide, provided the Fe(III) concentration in the solution remains above the solubility limit of akaganeite of 10 mmol L−1 (reaction 2)66. Both mechanisms take place at room temperature. In the absence of an additional silica layer around the akaganeite nanorods, these transformations are scarcely affected, and magnetite seeds are generated upon the addition of sodium hydroxide. Subsequently, particle growth proceeds via diffusion of metal ions toward the nuclei. This process induces a decrease in the concentration of the metal ions within the solution, which exerts a significant influence on the solid precursor, particularly in the case of Fe(III). The precursor dissolves when Fe(III) concentrations fall below 10 mmol L−1, provided it has not been entirely precipitated during reaction 2 (see below for discussion on the molar ratio between the precursor and the metal salt). This dissolution establishes an additional Fe(III) reservoir during the growth phase, often referred to as an extended LaMer model (reaction 3)103,104. Furthermore, Ostwald ripening, which is driven by the higher surface energy of smaller particles, facilitates their dissolution and subsequent redeposition onto larger particles (reaction 5)105,106. This phenomenon promotes particle size focusing, resulting in a narrowing of the particle size distribution over time. During the entire duration of the hydrothermal step, Co(II) ions can be integrated into the crystal lattice (ion exchange with Fe(II) ions), leading to a uniform distribution of Co(II) throughout the particle volume (reaction 6).

Reaction (1) depicts the Massart reaction from Fe2+ and Fe3+ hydroxide to obtain a number of magnetite seeds Nseeds,1. The precipitation (2) of bare akaganeite with Fe(OH)2 leads to the formation of magnetite seeds Nseeds,2. The extended LaMer process (3) takes place at c(Fe2+) < 10 mmol L−1, where excess akaganeite rods dissolved to Fe(OH)4- to ensure a consistent supply with Fe3+. Additionally, the Oswald ripening process (5) can occur, whereby the smaller particles dissolve to promote the growth of the larger particles. During the hydrothermal step, the ion exchange reaction (6) between Fe2+ and Co2+ results in the synthesis of cobalt-doped particles. If the akaganeite precursor is protected by a silica shell, (2) does not occur, and the dissolution of the nanorods (4) is significantly delayed. As a result, a decreased number of nuclei and a markedly increased particle growth are presented.

As a result of the left pathway depicted in Fig. 5, particles with an approximate size of 27 nm and an average cobalt content of 0.2 mmol per nm3 are formed by using akaganeite precursors only. As the particles become more monodisperse and smaller (approximately 17 nm) due to the addition of PAA, the surface-to-volume ratio increases significantly, resulting in a relatively intensified cobalt incorporation at the surface. The cobalt content per volume increases to an average value of 0.7 mmol per nm3. Both the decreased size and size deviation value can be attributed to the specific interactions of additives, which primarily serve to inhibit excessive agglomeration of the seeds and particles. By enabling spatial separation, the number of nuclei increases, leading to a decrease in particle size. Based on this mechanistic understanding, the addition of PAA by modification of the akaganeite precursors is expected to significantly reduce the agglomeration of magnetite seeds, with nanorods acting as a source of iron ions during the particle growth process.

Additionally, not only the PAA effect must be considered, but also the silica thickness of the precursors. As the silica thickness increases up to a value of approximately 3.3 nm, the particle size remains relatively constant ( ~ 20 nm). We assume that the transformation of akaganeite is delayed, regarding the dissolution process as well as the precipitation process, leading to a smaller number of nuclei. In order to achieve this decrease, the smaller number of nuclei can grow to larger ones compared to the particles synthesized via the mechanism without a silica shell. This can also allow ion exchange to occur simultaneously during the conversion, leading to a more consistent distribution of the cobalt amount throughout the entire particle volume. This distribution value decreases to a value in the range of 0.6 and 0.4 mmol per nm³, and the 2θ values also decrease to iron-rich surfaces. At a thickness of 3.3 nm, there is a pronounced drop in cobalt content, which we attribute to a potential reversal of the mechanism. The temporally delayed release of the akaganeite particles following the silica “protective” layer’s dissolution results in the formation of a more iron-rich layer around the cobalt-doped MNPs. This is accompanied by a significant reduction of the 2θ angle. However, a markedly reduced total cobalt content (determined via AAS) was detected in this sample, which may correlate with an anomalous mass concentration determination of MNPs of 1 wt.%. At a silica thickness of 4 nm, the silica layer surrounding the akaganeite nanoparticles becomes sufficiently thick. Thus, the nanorods are protected from conversion with Fe(II) to magnetite. Consequently, only magnetite nuclei are initially available, which are formed through the Massart reaction (right pathway). The subsequently available akaganeite is then utilized with Fe(II) hydroxide for crystal growth at elevated temperatures, resulting in the formation of significantly larger particles up to 30 nm due to the smaller number of nuclei (reaction 4). Akaganeite could also act as a solid reservoir and be dissolved through a decrease in Fe(III) concentration in the solution, as explained above. However, this process would occur with a delay compared to the pathway on the right. Both effects would exhibit a reduced surface-to-volume ratio due to the higher volume, leading to a pronounced overestimation of the cobalt ions at the surface via XRD compared to the cobalt amount-to-volume ratio. This ratio decreases to around 0.20 mmol per nm³ for the largest particles. As the cobalt-to-iron ratio (κ ≤ 0.20) of the particle fractions decreases with the addition of PAA and increases with the thickness of the silica shell, we can presume a correlation between the size and cobalt content within the crystal structure.

Furthermore, the metal salts and akaganeite precursor amounts are employed in a 2:1 ratio, which should be considered in the mechanistic discussion. Following the addition of NaOH, magnetite is formed from the akaganeite precursor at room temperature. However, the nucleation phase is prolonged instead of the typical rapid initiation and nucleation phases. With a thicker silica shell, nucleation is delayed, leading to the development of magnetite core particles of different sizes. Cobalt is integrated into the magnetite phase through ion exchange, provided there are no excess Fe(III) or Fe(II) ions in the solution. This process results in creating a mixed ferrite layer on the magnetite surface, as evidenced by the reduced cobalt content compared to stoichiometric co-precipitation experiments. The delayed initiation step also accounts for the increased size distribution in all reactor experiments compared to the blank samples. Moreover, with a higher proportion of Co(II), Fe(II), and Fe(III) ions than necessary for akaganeite consumption, a cobalt ferrite shell can encase the mixed ferrites, leading to a more spherical shape of the mixed ferrites in contrast to the cubic shape observed in the blank samples. Assuming that all akaganeite is converted to magnetite (0.619 mmol of akaganeite with 0.310 mmol of Fe(II)), a mixed ferrite shell composed of magnetite:cobalt ferrite could be formed in ratios ranging from 2:1 to 1:2. Further mechanistic change might be, that the silica shell inhibits the formation of magnetite due to the basic precipitation of akaganeite precursors and Fe(II) ions. The nucleation of magnetite will take place preferentially via the basic coprecipitation reaction between Fe(III)- and Fe(II)-ions. As a result, the akaganeite precursors would be present at higher temperatures in the reaction solution and could be converted to magnetite or cobalt ferrite particles. However, this is unlikely, as we do not observe additional spherical particle species via DLS or TEM. More likely, the akaganeite nanorods dissolve and are now forming the mixed cobalt ferrite shell around the magnetite cores using excess Co(II), Fe(II), and Fe(III) ions. If the conversion of akaganeite is delayed by the silica shell and magnetite cores are formed from the iron salts present in the solution, the magnetite:cobalt ferrite ratio for the magnetic shell would change only marginally.

The cobalt-doped ferrite formation process explains the enhancement of the nanoparticle size and the reduction of the cobalt content per volume with increasing silica shell thickness, as discussed above. Since the chain formation, which is observable via TEM (though with limited conclusiveness), appears to increase with the silica shell of the precursor, it is likely that this layer influences the process. Given that the pH value of 12 is established after the addition of NaOH to the reaction solution, the silica shell should gradually dissolve over time95. This also explains the dissolution of the akaganeite particles at a later stage of the reaction than without a silica layer. As the formation of the silica layer is a dynamic, base-catalyzed process, we assume that this occurs concurrently during the synthesis of cobalt ferrite particles. After the reaction, the pH value should be lowered due to the dissolution of silica species and the presence of chloride ions. Consequently, a reformation of the silica shell surrounding the magnetically interacting particles should arise. During the extended LaMer process, aggregation occurs spatially close to the particles, facilitating increased chain formation. If more silica is present, this process could be amplified, leading to enhanced chain formation, as the silica shells promote re-coating by hydrolysis and condensation reaction and magnetic interaction between the simultaneously synthesized particles.

Magnetic behavior of self-arranged nanochains in dependency on the viscosity

To investigate the magnetic properties of the chain-like structures, vibrational sample magnetometry (VSM) measurements were performed from the 1 wt.% sample dispersions in water (Fig. 6a, see Supplementary Note 8.1, Supplementary Fig. 8.1). These investigations enable the calculation of size-dependent interactions, which are contributed by, e.g., magnetic dipole-dipole interactions and Van der Waals forces. These interactions affect the self-assembly behavior of the nanoparticles25,107,108.

a The magnetic behavior comprises stabilizing exchange interactions among the individual particles and the stabilizing effects of the nanochains themselves. The alignment of the nanochains results in an additional drop in magnetization with increasing magnetic field strength (see dashed inlet), exemplified for an aqueous or an 80 wt.% glycerol/water dispersion of sample CF-S2-1 (bright blue), synthesized with the precursor aka@0.40PAA@2.5SiO2. b The squareness ratios and coercivity values in water exhibit the same parabola trend, with these values increasing with the cobalt-to-iron ratio until a maximum is reached at approximately 0.18, synthesized at a temperature of 160 °C and a filling volume of 100%. With increasing c diameter and d Co/Fe ratio of the samples dispersed in 80 wt.% glycerol/water, the squareness ratios and coercivities of the CF-S samples (synthesized with different silica thicknesses, filled) are adjustable compared to those of CF-A (synthesized with aka, hollow) and CF-P samples (synthesized with aka@PAA, half-filled). e Using the hysteresis loops, the differential magnetization of the exemplary CF-S2-1 curves can be calculated, which shows a maximum at H = 0 (static mass susceptibility). The saturation magnetization and the static mass susceptibility of all samples in 80 wt.% glycerol/water are depicted in dependence on the f diameter and g Co/Fe ratio, recording a rising trend for each.

For increasing magnetic field strengths H up to 1.5 T in water, the hysteresis behavior of a ferrimagnetic material occurs as expected1. This indicates that the effect (orientation of the magnetic moments of the particles) lags behind the cause (application of a magnetic field of specific strength). Above these magnetic field strengths, the material’s magnetization initially increases spontaneously until saturation is reached (Fig. 6a (inlet): transition from phase II to phase III with increasing H). We assume that with increasing field strength, the individual particles aggregate into ordered nanochains. Microscopically, this behavior is analogous to the Barkhausen jumps of electron spins in a magnet, where individual regions (Weiss domains) collectively reorient their alignment109,110,111. Concerning the present ordered system of the nanochain arrangement, the stabilization of the individual magnetic moments of the particles within this structure occurs in addition to the exchange interaction, resulting in a higher energy requirement for flipping the moments compared to individual nanoparticles. Upon reaching a critical magnetic field strength of approximately 1.5 T, the magnetic moments of the individual particles are collectively realigned in nanochains, forming a head-to-tail arrangement of magnetic dipole moments, resulting in a discontinuous increase in the magnetic moments32. Using HR-TEM images, Sturm et al. demonstrated that the chain elongation of magnetite particles aligns along the strongest (111) magnetization easy axis112. The use of cobalt-doped particles is expected to orient along the [001] axis. In the saturation region, saturation magnetizations are achieved, where all magnetic moments and chains are aligned with the field direction. Upon subsequent reduction of the magnetic field strength to approximately 0.5 T, the magnetic moments initially stabilize due to exchange interactions among themselves, resulting in a minimal observable reduction in magnetization. Following this, a drop in magnetization occurs, which is now attributed to the separation of the nanochain structures, resulting in the presence of individual nanoparticles at H < 0.5 T (Fig. 6a (inlet): transition from phase II to phase I with decreasing H). This can also be confirmed by Hu et al., who demonstrated in their work that the high magnetic moment of the nanoclusters makes them highly responsive to a magnetic field, allowing for their alignment in the range of 0.4–5 mT39.

In the saturation region of the aqueous samples, MS values of 55 Am2 kg-−1 to 90 Am2 kg−1 are achieved, depending on the heating temperature, the filling volume, and the thickness of the silica precursor (see Supplementary Fig. 8.1). With increasing reaction temperature, the saturation magnetization increases slightly (see Supplementary Fig. 8.1a, 8.1b). This can be attributed to the crystallinity of the nanoparticles, which increases with temperature, resulting in higher MS as long as no magneto-crystalline stress due to surface defects occurs57. However, the diameter of these samples of series 1 and series 2 increases in the order CF-S1-1 < CF-S2-1 < CF-S1-2 < CF-S2-2, showing no significant trend with MS (see Supplementary Fig. 8.1a).

The samples of series 3 prepared with the precursor with a silica layer exceeding 4 nm exhibit an increasing MS value with increasing diameter. An exception is CF-S3-6, as this sample has a significantly higher cobalt content, which is associated with lower MS values due to the lower MS of bulk cobalt ferrite (85 Am2 kg−1) compared to bulk magnetite (100 Am2 kg−1). To reduce the surface energy in the medium, nanoparticles exhibit a higher degree of surface spin disorder compared to the bulk material, resulting in MS values of approximately 85 Am2 kg−1 for cobalt ferrite1,111. With the approximation of MS = MSbulk ∙ [(rP-dL)∙rP-1)]3, where rP describes the particle radius and dL the thickness of the misaligned layer, dL is typically on the order of 1 to 2 nm32,113. Nevertheless, Gerina et al. calculated the volume of the magnetized and non-magnetic parts of cobalt ferrite samples with different physical sizes, unveiling the size dependence of surface misalignments114. As the diameter of the nanoparticles increases, the surface-spin misalignment contribution increases, resulting in higher degrees of non-magnetic volume at the highest examined magnetic field strength of 1.34 T114. They also showed that an increase in H reduces the thickness of the unmagnetized layer for all particle sizes, but increases the disorder energy required to polarize the surface spins. However, the surface contribution is strongly temperature-dependent, reaching zero at room temperature measurements113,115. Thus, the nanoparticle suspensions with larger diameters approach the saturation value of bulk cobalt ferrite MS,CFbulk, which can be observed for the nanoparticles prepared from the precursors with a greater silica thickness (see Supplementary Fig. 8.1c). The higher iron content of the cobalt-doped ferrites increases the saturation magnetization values, which can reach 100 Am2 kg-1 for bulk magnetite116. This is also the case for magnetite-like particles with a low cobalt content in the CF-A samples (see Supplementary Fig. 8.1c).

If the aqueous samples are compared at different temperatures and filling volumes, the remanence MR ranges from 1 Am2 kg−1 to 34 Am2 kg−1 and the coercivity HC from 1 mT to 4.5 mT for all samples (Fig. 6b). The squareness ratios MR/MS and coercivities depending on the cobalt content can be reasonably well described using a parabolic fit, regardless of the temperature or filling volume. Both properties seem to tend to be higher when the temperature is kept low or the filling volume is high within a cobalt ratio of 0.183 ± 0.003. Moreover, magnetite-like particles with low Co/Fe ratio values (κ < 0.18) exhibit low MR and HC at room temperature. By increasing the Co/Fe ratio up to 0.18, the ‘hardness’ of the particles increases, and the squareness ratio MR/MS reaches a maximum at this point. Due to the increasing diameter and further increasing Co/Fe ratio with thicker silica layers of the precursors, as well as increasing saturation magnetization, the MR/MS decreases from this point. It should be noted that the maximum MR/MS value for randomly oriented, uniaxial systems is 0.5117. Considering single-domain particles with cubic magneto-crystalline anisotropy (K > 1) that do not interact with each other, this value can reach 0.83117. In all cases, the MR/MS values obtained in this work remain below this maximum value, which is influenced by factors such as particle size and standard deviation. As the MR/MS values range between 0.1 and 0.4, the material´s domain state can be considered as pseudo-single-domain for all samples. Furthermore, it is essential to note that the remanence is highly sensitive to interaction effects117, and the current structures do not constitute a non-interacting system. Based on the determined coercivity values, the particles can be classified as soft magnetic material with HC < 51 mT118,119,120,121. Initially, HC increases with rising Co/Fe ratio and diameter, a phenomenon well-documented in the literature122,123,124. As the diameter (or Co/Fe ratio) of the samples increases to values above 40 nm, HC decreases again, which can be explained by the presence of domain walls expected during the transition from the single-domain to the multi-domain range at a diameter of 40 nm in CF with a maximum HC of 530 mT125. Interestingly, all HC values do not exceed 4.5 mT. This value is much lower compared to values reported for CF particles within the specified size range and stoichiometric ratio within the literature, where HC values ranging from 55 mT to 120 mT are reported120,124,126. As the aqueous samples showed partial sedimentation after the measurement, the nanoparticles were stabilized in glycerol. Furthermore, these samples and the data obtained offer comparability with the small-angle X-ray scattering measurements, which were only carried out with an 80 wt.% aqueous glycerol mixture (see Supplementary Fig. 8.2).

By dispersing the nanoparticles in an 80 wt.% aqueous glycerol mixture, the hysteresis curve still exhibits a splitting, exemplarily shown for CF-S2-1 in Fig. 6a (bottom). However, the measurements no longer show significant jumps at 1.5 T under increasing field strength and 0.5 T under decreasing field strength. With increasing viscosity, the rotational motion of individual particles, and especially that of nanochains, is hindered. The viscosity of the medium hinders the aggregation of single-domain nanoparticles into nanoparticle chains, requiring higher magnetic field strengths to orient them in the direction of the magnetic field. Individual particles are also affected, although their spin movement is only slightly impaired. In contrast to the aqueous samples, linear correlations of MR/MS and HC in dependence on κ (Fig. 6d) as well as the diameter (Fig. 6c) can be recognized. The sample synthesized with pure akaganeite (dTEM = 25.7 nm, κ = 0.163) has a MS of ⁓50 Am2 kg−1, increasing to ⁓72 Am2 kg−1 for the sample with PAA (dTEM = 18.7 nm, κ = 0.180) (Fig. 6f). Afterward, the MS decreases to values of approximately 20 Am2 kg−1, as the use of a silica shell influences the crystal phase in such a way that particles with cobalt-rich cores and iron-rich shells are formed. The thickness of this magnetite-like shell is thinner for smaller particles, so that a maximum of MS,CFbulk is assumed. Furthermore, the presence of akaganeite during the particle growth can lead to maghemite formation on the surface, which would result in a reduction of the MS values. Due to the previously described increase in diameter with the thickness of the silica shell, the MS values increase again to values up to 87 Am2 kg−1 and, in consequence, MR/MS does. Overall, the MR/MS values range between 0.4 and 0.5, indicating that the particles are close to the single-domain range. These values are slightly higher than in water, which is not surprising, as the interparticle interaction will decrease due to the higher viscosity, thereby approaching the maximum theoretical value of 0.83. HC values ranging from 3 mT to 5 mT exhibit the same trend, and the particles can still be classified as soft magnetic material. When examining the dependence on κ, the trends of MS, MR, and HC are comparable.

By plotting the differential magnetizations against H, graphs are obtained as shown in Fig. 6e. The stronger the magnetic moments of a particle can respond to the magnetic field, the steeper the slope of the hysteresis curve in the linear region of the expression M = χP ∙ H127. This gives rise to the static magnetic susceptibility χP, which can be recognized from the plot of dM/dH at H = 0 (Fig. 6f and g). It is clearly evident that the static χP is also dependent on the size of the particles and the Co/Fe content, exhibiting the same trend as MS. Furthermore, the magnetic domain size dVSM can be expressed through dM/dHH = 0 using the following Eq. 1128

with kB as the Boltzmann constant (1.38 ∙ 10−23 J K−1), T as the temperature (293.15 K), and ρ as the density of the cobalt ferrite sample (5.30 kg m−3)128. As summarized in Fig. 7a, the domain size of the particles decreases slightly with the PAA addition and increases again with the silica thickness. The difference between dTEM and dVSM is most likely due to the presence of a magnetically dead layer on the surface of the nanoparticles. As previously stated, an increase in the diameter of the nanoparticles leads to a heightened contribution of surface-spin misalignment, which in turn results in greater amounts of non-magnetic volume. This could provide an explanation for the decrease in the domain size of the particles to about 13 nm when the silica layer exceeds 4 nm, even though the particles have a morphological size of approximately 35 to 40 nm. The crystallite sizes obtained from WH and DS plots are also comparably large (Fig. 7b), indicating that altered crystallinity is unlikely to have an influence. Within this size range, there seems to be a shift in the classification of the particles from the single-domain range to the pseudo-single-domain (or possibly even multi-domain) range. This observation aligns with other studies that show this transition around 40 nm.

a The domain sizes (squares) of the particles synthesized without a silica layer are smaller than the sizes obtained via TEM (aka: orange, aka@PAA: grey). With a silica thickness of up to 4 nm (color changes from bright blue to dark blue with increasing silica shell thickness of the precursors), the magnetic domain sizes dVSM seemed to be larger compared to dTEM, indicating that they are overestimated. When the silica layer exceeds 4 nm, the particles are categorized into the pseudo-single-domain or multi-domain range, resulting in a decrease in the magnetic domain size to 13 nm due to the presence of domain walls. b The crystallite size and morphological size of the particles are comparable. There are only slight deviations for the larger particles that indicate differing trends depending on the method of determination (Williamson-Hall: circles, or Debye-Scherrer: triangles). c The size-dependent magnetic interaction is depicted by calculating the dipole-dipole interaction energy (squares) at contact, which increases significantly for particles where the silica coating exceeds 4 nm during synthesis.

As previously mentioned, magnetic self-assembly processes can be described in terms of magnetic interactions25,107,108. In the absence of a magnetic field, the magnetic moments of a magnetic particle can align with the magnetic moments of neighboring particles at small separations, resulting in an “in-line” configuration of the dipoles108. The dependence of the strength of the dipolar interaction can be described by the Keesom potential, which determines the energy of the interaction108,111. This energy scales with ri-3 caused by chain alignments, where ri denotes the interparticle distance and transitions to ri-6 at larger separations caused by non-magnetic Van der Waals interaction without applying a magnetic field. The maximum dipole-dipole energy at contact, Udd,max, describes the magnitude of the magnetic interaction represented as 1/9∙π ∙ μ0 ∙ (d/2)3 ∙ MS2, which has been calculated for each particle suspension with their respective MS value and is illustrated in Fig. 7c. For the reference particle suspensions, a value of approximately 12 – 16 kT is obtained, which would allow for a “head to tail” dipole configuration (exceeding 8 kT) in dilute solutions. The samples synthesized with a silica coating ≤ 4 nm yield values ranging from 0.7–1.5 kT, placing them in a range to overcome the thermal energy of 1 kT where no chain-assembly of the particles is expected due to insufficient dipole-dipole interactions. This is also evidenced by the lack of splitting in the VSM curves and the TEM images. The larger particles (dSiO2 > 4 nm) exhibit a significantly increased MS, thereby demonstrating chain assembly across multiple nanoparticles as visualized by TEM. It is important to note that at such high Udd,max, particle agglomeration would also be observable, provided that stabilizing effects through repulsive dipole-dipole interactions or electrostatic stabilization via ligands are not ensured129. Furthermore, the aggregation of nanochains can occur by attractive interaction between antiferromagnetic coupling of antiparallel ordered chains or a gradient of interaction, which may result in the formation of bundles and network-like structures25. In summary, the magnetic behavior of the nanoparticles can be described by an interplay of the cobalt content, size, surface disorders, and arrangement of the nanoparticles.

Cluster formation of magnetic nanochains in dependency on the magnetic field strength

The alignment of the magnetic moments of the particles in the presence of a magnetic field can be described by stronger dipole-dipole interactions, resulting in an interaction energy scale of ri-3 at all interparticle distances. Because of the magnetic coupling of the magnetic moments, a head-to-tail configuration of the nanochains should be present, separated by a chain distance due to repulsive interactions of the magnetic moments along neighboring chains. E.g., Toulemon et al. were able to assemble iron oxide nanoparticles on a gold substrate using a click reaction while applying a magnetic field, resulting in an interchain distance of 70–80 nm, where the chains consist of several small subunits made up of 6 to 8 particles25. The visualization of the chain formation and cluster size of the structures as a function of an applied magnetic field strength in this work was achieved through the analysis of small-angle X-ray scattering (SAXS) data, depending on the field direction, perpendicular, parallel, and overall angles averaged (Fig. 8 (inlet), see Supplementary Note 9.1, Supplementary Figs. 9.1, 9.2, Supplementary Table 9.1). The SAXS data were fitted using the Beaucage model130,131,132, which Paula et al. had already used for magnetic nanoparticle clusters133. In this case, the intensity can be described by Eq. 2:

with \({{h}}_{1}\,=\frac{{q}}{{\left({erf}\left({q}\left[\frac{\left({{R}}_{{{g}}_{1}}\right)}{\sqrt{6}}\right]\,\right)\right)}^{3}}\) and \({{h}}_{2}\,=\frac{{q}}{{\left({erf}\left({q}\left[\frac{\left({{R}}_{{{g}}_{2}}\right)}{\sqrt{6}}\right]\right)\right)}^{3}}\).

The scattering intensities (hollow squares) and Beaucage fit (red dashed line) results are depicted for sample CF-P3-1, where the cluster (G1: green line, P1: green dashed line) and single nanoparticle (G2: blue line, P2: blue dashed line) contributions are described by the Guinier and Porod parts, respectively. The fits are calculated a for the lowest field strength of approximately 3 mT, averaged over all angles, and for the highest field strength of approximately 930 mT b perpendicular, and c) parallel to the magnetic field. The 2D SAXS patterns (inlets) are presented with the respective applied masks. The scattering curves and Beaucage fits are shown for different magnetic field strengths d averaged over all angles, e perpendicular to the field, and f parallel to the field. The increasing influence of the structural factor (grey dashed line) is demonstrated by rising magnetic field strength. The schematic representation of the nanoparticle spatial structures elucidates the dependence of the cluster size on the magnetic field strengths of g 3 mT and h 930 mT visualized for the fits given in Fig. 8a and Fig. 8b, c, respectively. The mean distance of the clusters (\({\xi }_{\perp }\)) perpendicular to the field remains nearly constant as the field strength increases. In contrast, the length of the clusters increases significantly with the number of particles arranged parallel to the field (\({N}_{{{{\rm{cluster}}}}}^{\parallel }\)).

Here, erf is the error function. Guinier’s pre-factors are represented by B1 and B2, and Porod’s by G1 and G2. P1 and P2 are the indices of the power law. The exponential pre-factor \(\exp \left(\frac{{-{q}^{2}R}_{{g}_{2}}^{2}}{3}\right)\) describes the small-scale structural limit130. Index 1 belongs to the primary clusters of some NPs, and index 2 is related to the isolated NPs. The wave vector q (Eq. 3) is defined as

with 2θ as the angle between the incident beam and the scattered beam with the wavelength \(\lambda\).

To describe the particle correlation, an additional multiplicative term S(q) has to be considered with133

S(q) is the so-called structure factor. The degree of the correlation is represented by k and ξ describes the interparticle distance.

The calculated contributions of the Guinier (cluster) and Porod (single particle) parts of the Beaucage fits according to Eq. 2 are summarized in Supplementary Fig. 9.3–9.9 for five samples with different silica thicknesses, as well as the comparison samples without and with PAA of series 3. An exemplary analysis with the different contributions of the Beaucage fits is presented in Fig. 8a–c for sample CF-P3-1 synthesized with the akaganeite precursor stabilized with PAA. The average scattering intensities are averaged over all field directions at 3 mT (Fig. 8a), averaged over the section parallel to the field at 930 mT (Fig. 8b), and averaged over the section perpendicular to the field at 930 mT (Fig. 8c). The inlet shows 2D SAXS pattern with the applied masked for each analysis.