Abstract

Minerals in soil can sequester atmospheric carbon dioxide through natural organic and inorganic processes. Here we consider three soil- and mineral-based methods for carbon dioxide removal: (1) grinding and spreading of calcium- and magnesium-rich silicate rocks for enhanced rock weathering and subsequent inorganic carbon formation, (2) mineral doping of biomass prior to conversion into biochar for enhanced biochar carbon yield and stability, and (3) strategic application of minerals to soil to increase soil organic carbon accrual and stability. We argue that there are powerful synergies between these approaches for carbon dioxide removal through organic and inorganic pathways. We find that primary silicates, as contained in basalt, can benefit both enhanced weathering and soil organic carbon formation, while phyllosilicates and other reactive secondary minerals may have positive synergies for biochar and soil organic carbon. Optimising such synergies may substantially enhance economic and environmental benefits, yet these synergies require accurate quantification.

Similar content being viewed by others

Introduction

To mitigate the severe environmental and economic impacts of climate change, it is critical to reduce global warming to below 2 °C, as recommended by the Paris Agreement1. Climate change and associated temperature extremes, droughts and flooding threaten global food production, the long-term sustainability of human civilization, and the entire biosphere2. In addition to decarbonizing the global economy, it is now necessary to also achieve carbon dioxide removal (CDR) of around 10 Gt CO2 per year by 2050 to keep planetary warming below 2 °C3,4. CDR is required both to remove excess atmospheric CO2, and to offset emissions that cannot be easily abated5. However, the CDR industry has struggled to grow, as individual CDR methods are hindered by economic barriers, as well as social and political limitations. Acceleration of CDR implementation is essential to limit global warming to a mean increase of 2 °C relative to the pre-industrial era3. Therefore, there is a need to enhance the efficacy and potential of CDR methods and their co-benefits, which can partly be achieved by integrating different methods to improve economic and environmental outcomes6,7.

Several CDR methods function by enhancing natural biogeochemical cycles that remove and sequester CO2 from the atmosphere8,9,10,11,12. Minerals play a key role in several of such methods, through interactions with carbon in soil (including inorganic carbon, soil organic matter and plant biomass) that result in CDR7,13. Here, we describe three soil-based CDR approaches that use minerals, namely: (A) inorganic carbon storage through the application of crushed silicate minerals to soil (enhanced rock weathering), (B) mineral ‘doping’ of biochar, to store persistent pyrolyzed, organic carbon, and (C) accrual of soil organic carbon through additions of reactive minerals.

In brief, these three processes occur as follows: (A) During weathering of calcium (Ca)- and magnesium (Mg)-rich silicate minerals, CO2 is removed from the atmosphere and stored as dissolved inorganic carbon in the Earth’s soils, subsurface geological deposit, waterways, and oceans. This natural process results in ~0.5 Gt of CO2 drawdown annually14. Through enhanced rock weathering – i.e. the deliberate crushing and subsequent spreading of silicate dust – between 0.5 and 2 Gt of additional CO2 could be removed15,16,17, or 5–20% of the CDR needed by 20503,4.

(B) When plant biomass is turned into pyrogenic carbon under high temperatures and low oxygen levels, i.e., during fires, the pyrolyzed material can persist for long timescales in soil18. This material is termed biochar when it is intentionally produced for the purpose of environmental management. Biochar production has the potential to remove 0.03–6.6 Gt of CO2 per year19. During pyrogenic carbon/biochar formation, minerals can enhance carbon retention and persistence; i.e., biomass with higher mineral contents produces biochar that comprises a greater proportion of organic carbon in persistent fractions20. Biomass can be doped intentionally with minerals to enhance this effect7.

(C) Organic carbon storage in soils (as soil organic matter; SOM) can persist over long time scales through interactions with soil minerals, which limit oxygen and microbial access to this material. SOM is the largest terrestrial carbon pool (~1500 Gt of carbon equivalents) and the most persistent fractions are mineral-associated and aggregated organic matter21,22. To increase the SOM stock, it is possible to increase organic inputs to soils, or to enhance the capacity of soil to retain more persistent forms of SOM. The latter may be achieved via mineral amendments of soils, though this method that has yet to be quantitatively assessed in the field. However, the total potential for SOM accrual globally (all land uses) is estimated at 0.4–8.6 Gt CO2 per year19.

To date, these different mineral-based CDR methods that are applied to soil have mostly been researched separately7,23,24, even though there are strong potential synergies between them (see Fig. 1). In this perspective article, we describe such potential synergies between these three CDR methods. First, we give an overview of the three individual CDR methods – describing both how they work as well as some of their limitations (Section 2). Next, we discuss general mineral properties and environmental conditions that enable and optimise synergies between these methods (Section 3). Finally, we discuss the suitability of a variety of minerals for each CDR method, and identify potential minerals that may be suitable for sequestering carbon through multiple CDR methods (Section 4).

A Enhancing carbon retention as inorganic carbon through enhanced rock weathering, B enhancing stable biochar formation via pyrolysis facilitated by addition of minerals, and C limiting respiratory CO2 emission by enhanced conversion of plant carbon into persistent soil organic carbon (matter). In panels under 1 (top) the reference scenario is outlined and in panels under 2 (middle) the effect of minerals on these reference scenarios are shown. In the bottom panel, we highlight synergies between the three methods. MAOM stands for mineral-associated organic matter, and AggOM for aggregated organic matter.

Individual CDR methods

Enhanced weathering (EW) of Ca- and Mg-rich silicate rocks

Natural processes weather rock on geological time scales, driving long-term variations in atmospheric CO2 levels, and removing ~0.5 Gt of CO2 from the atmosphere per year25,26. Physical weathering causes rock to be broken apart; during chemical weathering, Ca- and Mg-rich silicate rocks react with carbonic acid (CO2 dissolved in water), ultimately stabilising the dissolved CO2 in the form of bicarbonate and carbonate ions (E 1-3). This dissolved inorganic carbon in waters of soils, rivers, oceans and the earth’s crust, is stored for periods up to thousands to millions of years.

Weathering processes can be enhanced by crushing rock particles to increase the rock surface area and accelerate the rate of chemical weathering, thereby sequestering substantial CO2 amounts on societally relevant timescales25,27,28. In practice, this CDR method involves the crushing of Ca- and Mg-rich silicate rocks, followed by their application in an environment suitable for weathering, such as agricultural soils, oceans, or more controlled closed pits or reactors15. An emerging body of literature has focused on EW in croplands, where the biological activity of soils and plants may accelerate the rate of weathering (e.g., as through the release of organic acids)29 and potentially provide other co-benefits, such as enhanced crop yields and soil nutrients24,30,31.

The reactivity and hence weathering rate of different silicate rock minerals is shown by the Goldich dissolution series27, which is based on mineral formation conditions (cooling temperature and pressure) and associated crystallisation (Bowen’s reaction series). Ultramafic rocks (richest in Ca and Mg) weather most rapidly but often contain elevated levels of Ni and Cr, which are potentially toxic to plants and humans17,32. Hence, application of mafic rocks, such as basalt, has gained particular attention due to their natural abundance, typically low levels of toxic elements24,33, and repeatedly demonstrated capacity to provide nutrients to plants and mitigate soil acidity17,24,34.

For applicability of EW as CDR method, greenhouse gas emissions associated with rock mining, grinding and transport need to be outweighed by CDR from Ca and Mg silicate reaction with CO2 (Fig. 2.1). Such emissions are calculated in life cycle GHG emission assessments, which show an overall net removal in various studies15,31,35. Based on the rock mineral composition, theoretical CDR from reaction of minerals with carbonic acid (and, thus the carbon dioxide bound within) can be calculated27,36. However, one key limitation for the use of EW as a CDR method is uncertainty in the rate of weathering in natural systems and the amount of net CO2 removed due to complex reactions within soil and further downstream. These uncertainties arise from challenges associated with tracking carbon from the site of weathering (i.e. surface soil) to the ultimate site of sequestration (i.e., the deep ocean), inconsistent measurement approaches37,38, and substantial natural variability with weathering rates impacted by a range of factors including water availability, soil chemistry, biological activity, and temperature.

To assess EW-associated CDR, the weathering products, Ca/Mg and bicarbonate/carbonate, are typically measured within soil leachate. Difficulties arise, however, due to soil’s cation exchange capacity that can delay the leaching of EW products and their durable sequestration from years to decades39,40. EW products can also be measured in soil, yet this relies on isolation of the weathering signal from the significant background effects from rock and soil cations and carbonates39,40. Further complications are associated with non-carbonic acid weathering of silicate minerals producing Ca and Mg without bicarbonate, secondary reactions of Ca and Mg (e.g., carbonate formation) and outgassing of CO2 within the soil column and through riverways to the ocean that reduce CDR efficiency40,41. Ultimately, while our understanding of the complex soil processes and spatiotemporal delays in EW CDR are still developing, the most effective approach to EW measurement is likely to be maximising sampling and measurement, including of the soil fraction (assessing precipitated carbonates, exchangeable cations and net cation loss), the leachate fraction (assessing alkalinity, inorganic carbon, cations and anions) and perhaps even the gaseous fraction (e.g., assessing CO2 in- and out-gassing through flux chambers)42. There are also key unknowns for how EW will interact with SOM cycling in soils (discussed further below in Section 3.1).

The uncertainty in the rate of net CO2 removal, beyond natural processes, leads to measurement and modelling variability and uncertainty in the cost per tonne of CO2 sequestered. In general, application rates of silicate rock-based soil amendments are in the range of 10–220 t ha−1 (typically 10–50 t ha−1), which is very high relative to application rates of other agricultural soil amendments, such as lime (<5 t ha−1)30. The mining, grinding, transport, and distribution of rocks at such high volumes may limit the scalability of EW, as do discussed challenges around measurement, reporting and verification43. However, at a fundamental level, EW appears to be a promising approach as CO2 is sequestered on effectively permanent timescales, and there may be concomitant benefits to soil health and crop productivity24.

Mineral-enriched biochar from biomass

Biochar is produced via pyrolysis, the heating of biomass at temperatures between 350 and 750°C in the absence of oxygen. This process stabilises on average just over half of the carbon within biomass (across different pyrolysis temperatures)44, which subsequently persists in the environment for decades to millennia45. However, on average ~45% of the carbon within biomass is lost during pyrolysis and not all carbon within biochar is stable on such time scales; a small proportion (3%) decomposes relatively rapidly46. The amount of net sequestered carbon per tonne of biochar spread on land depends on GHG emissions associated with feedstock acquisition, biochar production, transport and spreading, and biochar carbon content and stability7,47 (Fig. 2.2, 2.3).

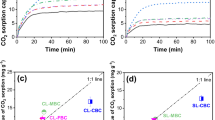

(1) Addition of minerals to soil for enhanced weathering (EW) and soil organic matter (SOM) formation, (2) biochar/mineral-biochar production and addition to soil for inorganic carbon formation through enhanced weathering, (3) biochar/mineral-biochar production and addition to soil for soil organic matter formation.

Biochar properties, including its carbon content and stability, are governed by pyrolysis temperature and biomass feedstock with some, but smaller, effects of particle heating rate and residence time at the highest treatment temperature48,49. The biochar yield decreases with pyrolysis temperature while the carbon stability within biochar increases. Across both these effects, pyrolysis temperature only has a marginal influence on biochar stable carbon yield48,50,51. Mineral doping, however, appears to have a notable effect on biochar stable carbon yield, especially in the temperature range 500–700 °C52,53, while pyrolysis temperature in turn affects mineral stability and associated chemical reactions (see Buss et al.7).

The distribution of organic matter (and thus, carbon) and minerals (ash) in biomass feedstock also influences biochar’s carbon sequestration potential7. While a higher carbon content proportion allows for more sequestered carbon per tonne of biochar produced, minerals can also increase biochar’s CDR potential per tonne of biomass feedstock. The latter operates through two mechanisms: catalytic reactions and physical protection of carbon release. First, minerals present within biomass increase biochar carbon retention and stability through catalytic effects that reduce the activation energy for biomass conversion processes54,55. Such minerals can also be added externally during pyrolysis to increase carbon retention and increase biochar stable carbon yield7. Different minerals are suitable for this effect, including K-, Na-, Ca-, Mg-, P- and Fe-containing minerals, and can be added in refined and unrefined form and residues7. To be cost-effective and enable large-scale use, unrefined minerals are preferred7. Second, minerals can act as physical barriers during biochar production, reducing carbon losses due to suppressed release of organic molecules52,56,57. This is mainly attributed to oxides and carbonates of Ca and Mg formed during biochar production, but also P and Si that crosslink with the main carbon framework and thus reduce the release of small carbon compounds57. These processes are different to the catalytic biochar formation described before, and protect the carbon both during pyrolysis, and after application to soil.

Minerals can be added to biomass dissolved in water53 or in solid form, mixed with biomass and subsequently pelletised, although this adds further costs to the process58. Mineral addition to biomass prior to biochar production is economically viable if the savings due to increased carbon conversion efficiency (and associated lower feedstock requirements to produce the same amount of stable carbon) outweigh the costs of mineral procurement, potential pelletisation, biochar production and application7. The added non-carbon (mineral) material increases pyrolysis unit running times and biochar application mass to produce and spread the same amount of stable carbon. However, with lower production costs due to economy of scale (lower costs for biochar production units), the method should become more economically viable over time7.

Mineral addition to soils to boost SOM accrual and stabilisation

While a portion of organic carbon in soil cycles quickly (minutes to years), another portion cycles much more slowly – with turnover times of decades to millennia59. For organic carbon to persist over long time scales in soil, there must be physical and/or chemical mechanisms that limit microbial access to this carbon (excluding pyrolytic carbon)22. Such protection can occur by physical separation from microbial decomposers in soil aggregates (AggOM), or through physical and chemical association with the soil mineral matrix (known as mineral-associated organic matter; MAOM)60. On average, MAOM is the slowest-cycling SOM fraction, and it forms when organic matter is in association with reactive secondary minerals in soil. These reactive secondary minerals are one of the products of weathering of primary minerals (such as contained in basalt rock). Over long-time scales, rock weathering leads to accrual of MAOM in soils61.

There is overlap in the processes that hold organic matter and minerals together in both MAOM and AggOM62. Aggregate formation involves flocculation of negatively charged soil particles by diverse cations (Fe, Al, Ca and Mg) that form positively charged bridges between negatively charged soil surfaces (polyvalent cation bridging). Aggregates can also be formed by cementation of soil particles facilitated by crystallised minerals, such as Fe oxides and carbonates and poorly crystallised minerals62,63. During MAOM formation, primarily negatively charged soil minerals interact with mainly negatively charged organic matter to form bonds of different strengths62,64 through weaker adsorption reactions and more stable coprecipitation reactions64. Besides providing negatively charged surfaces for MAOM formation, minerals release cations that link negatively charged surfaces with negatively charged SOM (polyvalent cation bridging)62. Therefore, the specific mineralogy and the quantity of soil exchangeable cations together determine SOM content; i.e., soil exchangeable Ca correlates well with SOM content in alkaline soils, while Fe and Al-oxyhydroxide contents correlate well in acidic soils61,62,65,66.

Strategic amendments of reactive secondary minerals (such as allophane or iron oxides) may increase the SOM storage capacity of soil by enhancing the MAOM and AggOM pools23. Such application of small mineral quantities to plant root zones can effectively improve stabilisation of plant exudates67. For such a method to be environmentally and economically sustainable, it needs to be reliable and predictable, yet there is little to no research in this area to date. Given the large interest in SOM accrual in agricultural areas for both agronomy and environmental (including climate) benefits, and a large body of research into mineral involvement in SOM storage64,66, there is considerable potential for expanding research into soil amendment with selected minerals for SOM increase68. Such research should focus on degraded and highly-weathered soils, which are limited in their ability to retain plant carbon due to low exchangeable cation concentrations and few ion exchange sites61. These soils may benefit most from mineral amendments for extra SOM accrual61

Synergies between methods to enhance CDR

While these three soil-based CDR methods that use minerals (EW, biochar, SOM accrual) have traditionally been viewed in isolation from one another, there is clear scope for synergies between them. That is, strategic deployments of mineral amendments have the potential to sequester carbon through more than one CDR method; e.g., by directly sequestering inorganic carbon through EW, increasing the carbon sequestration efficiency of biochar, and by enhancing the capacity of soil to store organic carbon as MAOM and AggOM (Fig. 1). Allowing for both inorganic carbon and SOM formation in soil does not require any additional preparation, only rock mining, grinding and spreading. Therefore, no extra costs are associated with simultaneous inorganic carbon and SOM formation (Fig. 2.1); yet any increase in the CDR impact directly reduces the costs per CDR unit, which makes this an economically attractive strategy. The costs for producing mineral-biochars can be higher than the costs for producing biochars not doped with minerals. However, doping can also reduce biochar CDR costs due to a lower requirement for biomass feedstock to produce the same amount of stable carbon (further discussed in section 2B and Buss et al.7) (Fig. 2.2, 2.3). Inorganic carbon and SOM formation adds extra CDR on top of CDR associated with the carbon content within biochar (Fig. 2.2, 2.3). This section discusses how such synergies between the CDR methods can be achieved, specifically examining optimal mineral type and environmental/climate properties.

EW - SOM synergies

Finely ground Ca- and Mg-rich silicate rocks that remove atmospheric CO2 during weathering and store it in inorganic forms, can also help form MAOM through the release of reactive secondary minerals that bind SOM, and promote retention of SOM in aggregates through mechanisms like cation bridging. Although limited research exists in this area, the interaction between these processes has been posited in various studies6,17,69, and the concept was directly tested in a laboratory study using a blend of basalt and granite68 as well as recent field studies applying meta-basalt in the Central Valley of California, USA70 and wollastonite in a forest in the southeast of China71. At the same time, negative interactions can occur between EW and SOM cycling, such as when SOM loss is stimulated by pH increases associated with rock amendments. These pH increases (or other mechanisms) can lead to increased microbial priming of SOM72 and SOM loss73 or may simply reduce accrual rates of MAOM over time. As there is very limited field data to date, it is critical for the interactions between EW and SOM cycling to be better studied and characterized, especially across different environmental contexts (soil and plant type, climate) and multi-year timescales.

Plant productivity is positively associated with SOM accrual, since greater productivity is typically associated with greater plant carbon inputs into the mineral soil, which can then form SOM74. Therefore, carbon removal via EW and SOM accrual may be best suited for climates with high net primary productivity and fast rates of weathering (e.g. acid soils in tropical regions). Biological activity accelerates rock weathering through various mechanisms, such as the exudation of organic acids that increase mineral dissolution, and through plant uptake of weathered ions that disrupt the dissolution equilibrium and thus allow for more rock dissolution34,75. Microbes are also intimately involved in the formation of MAOM, as they process plant carbon into simpler biomolecules that form MAOM, and because microbial necromass (dead microbial bodies) is a key constituent of MAOM76,77. Greater microbial growth and activity thus are often associated with greater MAOM accrual78,79. Hence, greater microbial activity should help accelerate both rock weathering and MAOM accrual rates. New research is needed to advance understanding of how different primary and secondary mineral amendments may be added together to optimise rates of rock weathering and MAOM accrual rates, and how biological activity may be harnessed to maximize organic and inorganic carbon drawdown rates.

EW - biochar synergies

Mineral doping, i.e., mineral addition to plant biomass, can lead to higher carbon content and stability of the subsequent biochar, after pyrolysis. The added minerals could also help draw down carbon via EW, if they have significant Ca and Mg silicate or oxide contents. Fast-weathering minerals that are used for EW comprise easily soluble (reactive) Ca and Mg that interact readily with carbon during pyrolysis. Using such minerals can protect carbon both during pyrolysis and after biochar soil application57. No research exists in this area so far that would enable quantification of such effects.

High soil water availability and biological activity promote high rates of rock weathering, but also increase biochar decomposition rate46. However, weathering rates are several times higher in wet and warm climates than in arid environments80,81, while biochar decomposition is increased by only 20–30%82,83. Thus, application in wet and warm conditions should still leads to increased net carbon accrual. Areas with high soil moisture availability and biological activity should be suitable environments for co-application of rock amendments and biochar (or biochar doped with rock powder prior to pyrolysis). Co-application of rock amendments and mineral-enriched biochar should also enhance soil nutrients, increase pH, and benefit water and nutrient retention7.

SOM - biochar synergies

Among the interactions between the three CDR methods discussed above, reduced SOM decomposition and increased SOM accrual in response to biochar application to soils has been investigated in the most detail45. This process has been shown to have greater potential to build SOM than cover crop use, stubble retention, or other climate-smart agricultural practices84,85. In agriculturally productive soils in Iowa (US), for example, biochar addition sequestered as much additional SOM as was added with the biochar itself86. On average, the SOM accrual effect induced by biochar addition amounted to 0.5–1.2 t C ha−1 yr−1, yielding a total mean SOM increase of 13 t ha−1 in field trials that lasted 1–10 years18,87. While biochar application initially may promote some SOM decomposition due to the labile carbon component in biochar, this initial extra SOM decomposition is outweighed over time by extra SOM accrual45.

A key mechanism responsible for biochar SOM accrual is sorption of organic matter onto biochar that increases the upper limit of SOM storage18,88. So far, this SOM accumulation has been attributed mainly to biochar’s high surface area and carbon content, which provide new active surface sites for SOM accrual18,89. However, interactions between biochar and soil minerals also mediate this process90. Therefore, it is likely that strategic doping of biochar with minerals with a high sorption capacity, such as goethite, could accelerate this effect and boost the biochar effect on SOM accrual. We are not aware of any studies that have attempted to optimise biochar for this effect. We suggest that the same minerals responsible for natural SOM accrual in soils (Table 1) would likely also increase biochar-based SOM accrual if biomass is doped with such minerals prior to pyrolysis. The environmental factors that could maximise synergies include soils with low SOM sorption capacities and systems with high plant carbon input.

Mineral suitability for synergies between CDR methods

In this section, we discuss a range of minerals in detail with respect to their suitability for mineral-based CDR approaches, including global availability and cost, which are prerequisites for large-scale application of mineral-based CDR. Table 1 shows a detailed evaluation of mineral suitability for the three main CDR methods, and Fig. 3 summarises key results for different mineral classes.

A Enhanced weathering (EW), B biochar production and utilisation and C soil organic matter (SOM) accrual. Relative positioning of mineral classes (red squares) demonstrates their suitability for use for respective carbon dioxide removal method, including potential synergies when located at the overlap of two or even three circles, i.e., secondary silicates are suitable for soil organic matter and biochar, while primary silicates mainly for enhanced weathering with some potential for both other methods (based on assessment in Table 1).

Primary silicates

Primary minerals formed by magma crystallisation can vary from unreactive and nearly inert minerals (quartz) to highly reactive minerals (olivine, wollastonite). Depending on their minerology, primary minerals can be suitable for all three CDR methods. Highly reactive primary minerals facilitate: (i) rapid weathering that could sequester carbon as inorganic carbon when Ca- and Mg-silicates are present, (ii) cation release (mainly Ca, Mg, Fe and Al) that can facilitate soil aggregation and organic matter sorption to minerals (e.g., polyvalent cation bridging for MAOM formation and aggregation processes66), (iii) potential formation of secondary minerals capable of forming MAOM, and (iv) catalysis/carbon protection during pyrolysis. However, increased SOM mineralization has also been observed after primary silicate (wollastonite) addition to soils, due to a soil pH increase from the acidic to neutral range, which increased microbial metabolism72. Furthermore, fast-weathering Fe-rich minerals, such as fayalite, are not suitable for inorganic carbon formation since secondary reactions in an oxic environment form and precipitate Fe hydroxide91. This is an acid producing reaction since OH- is incorporated into the precipitate, which counteracts the CO2 consumption of the initial reaction91.

Olivine (nesosilicates, orthosilicates) can catalyse biochar formation92, and Mg-rich olivine (forsterite) has very high potential for EW and associated inorganic carbon formation (Table 1). However, olivine can be contaminated with Cr and Ni, both of which are potentially toxic to plants, limiting the use of olivine in soils17. Globally, olivine is mined in quantities of ~9,000,000 tonnes annually at costs of around $18–90 per tonne7. Wollastonite (inosilicate-single chain; CaSiO3; present in metamorphic rock) can weather quickly and has strong potential for inorganic carbon formation27,93 (Table 1), though it is expensive (300 US$ t−1)7 and may not be economically viable in a pure form. Serpentine is a Mg-Fe-phyllosilicate that derives from metamorphosed ultramafic rock. It typically has a >10-time slower weathering rate than olivine, yet treatment at 600–700 °C increases the weathering rate substantially to values higher than those of olivine94,95. The efficiency of serpentine conversion into its reactive form is enhanced in the presence of an inert atmosphere (i.e., absence of oxygen), as is also required for biochar production96. Therefore, biomass feedstock doping with serpentine could bring synergies for biochar production (catalysis) as well as subsequent EW of serpentine in soils. The micas biotite, phlogopite, and muscovite (phyllosilicate) have medium weathering rates according to the Goldich dissolution series27, low Ca and Mg silicate contents and little functionality (exchange capacity) for SOM accrual, but may have some potential for catalysing biomass pyrolysis7 (Table 1). Also, weathering rates (in the form of K-release) were found to increase after thermal treatment97. Micas are mined with an annual production of only 287,000 tonnes globally at a price of 121 US$ t−17. Structurally stable alkali feldspars (e.g., orthoclase), a major part of igneous rocks, are typically poorly reactive and do not contain Ca and Mg27. Therefore, they are unsuitable for inorganic carbon formation through EW and have little effect on biomass pyrolysis98 or abiotic SOM sorption99. Thermal treatment could increase feldspar reactivity for biochar catalysis100.

To enable large-scale application of primary minerals for carbon drawdown, rock processing must be minimised to reduce economic costs and associated CO2 emissions15. In the natural environment, minerals exist as rocks with complex compositions. Basalt is a Ca- and Mg-rich, mafic, igneous rock that contains minerals, such as olivine, micas, plagioclase feldspars and alkali feldspars. In a recent study, 50 t ha−1 of partially weathered basalt and granite mining residues were applied to a sandy soil, which reduced SOM losses by up to 32%68. This effect was related partly to the formation of MAOM and AggOM, as a result of readily available Ca and Mg. Calcium carbonate that can precipitate in soils during weathering of Ca- and Mg-rich silicate rocks plays an important role in SOM stabilisation in aggregates. Another benefit of using mining residues as a source of rock dust is economic viablility (>4 billion tonnes of crushed rock is mined globally, at values of ~12 US$ t−1 ref. 7), yet this area remains poorly explored.

Secondary phyllosilicates (clay minerals)

Secondary phyllosilicates form in soil through weathering of primary silicate minerals. Despite some (low) levels of Ca and Mg silicates (Table 1), such secondary (clay) minerals have low capacity for further weathering and, hence, are not expected to drawdown significant amounts of carbon through inorganic carbon formation (Table 1). However, they have a high surface area with (predominantly negative) charges that associates with SOM, and could also be suitable for doping biomass prior to pyrolysis.

To enable efficient MAOM formation, minerals need to have a large surface area and surface charge, which is the case for the three-layer illite, smectites (e.g., montmorillonite), and vermiculite clay minerals that have a high capacity to protect SOM and facilitate its accrual64 (Table 1). Conversely, the two-layer clay mineral kaolinite has lower capacity to protect SOM66. While organic matter sorption to different phyllosilicates has been relatively well investigated, only some minerals have been tested for biomass doping to increase biochar yield and stability. Thus far, promising results have been observed primarily with minerals with high reactivity in soils, such as vermiculite and montmorillonite (and bentonite)52,101. Vermiculite, for example, has a K content of 0–1.7%102 that could catalyse biochar formation and a Ca and Mg content of 12–18%102 that could protect and hence retain carbon during pyrolysis. Addition to straw prior to pyrolysis increased both carbon retention and stability with largest effects observed in the temperature range 600–700 °C52. The effects of kaolinite on biochar carbon yield and stability are less certain with both no effect103 and positive effects observed104.

Some clay minerals are commercially mined and may be suitable for large scale application, such as bentonite that comprises mainly smectite minerals with global production rates of 20,900,000 t per year at 98 US$ t−1, or vermiculite with global production rates of ~533,000 t per year at 140 US$ t−1 ref. 7.

Ordered Fe and Al oxides and short-range ordered aluminosilicates

Oxides and (oxy) hydroxides of Al and Fe (sesquioxide) and poorly crystalline Al and Fe phases (short-range ordered aluminosilicates) have a high capacity for SOM stabilisation. Due to their high surface area and reactivity, these minerals have greater capacity than phyllosilicate clay minerals for storing SOM61,65,105,106,107,108. Therefore, such reactive secondary minerals could be ideal ingredients to enhance MAOM accrual. These minerals might also be suitable for biochar doping due to their reactivity, although negative effects on biochar carbon yield have been reported109 and they have no potential for inorganic carbon formation since they don’t contain Ca and Mg silicates and oxides (Table 1). Due to their ability to bind large amounts of organic matter, these minerals can be applied in relatively small amounts, ideally focussed in the root zones of plants, to protect plant exudates.

Minerals with ordered structure, such as the Fe minerals lepidocrocite, goethite, hematite and magnetite, typically have a lower ability to protect SOM than poorly crystalline Fe minerals, yet are more stable110. Therefore, they may have a longer-lasting effect on SOM accrual than poorly crystalline minerals. Goethite, for example, has been successfully applied for extra SOM accrual in soils (notably, stabilisation of rhizodeposits) at an application rate of only 1.2 t ha−1 ref. 67. Goethite and the Al oxide gibbsite can both sorb SOM and form stable aggregates by cementation of other minerals, fostering SOM protection66. Biomass doping with two minerals – hematite and montmorillonite – increased biochar carbon stability101, whereas goethite facilitated thermal decomposition and hence carbon loss during pyrolysis, decreasing biochar yield109,111. Given that Fe-ore that mainly consists of hematite and magnetite is already mined commercially on large scales (3,000,000,000 t per year), its apparent promise for CDR warrants urgent further study. However, given its current use, socio-economic assessments need to be conducted to evaluate the effect of competing Fe-ore uses and potential risks and benefits of opening new mines. In addition, Fe-ore mining waste and steel waste contain Fe and Ca oxides (1–40% Fe and 7–35% Ca), and show potential for CO2 capture through EW112,113,114. These widely available materials may increase SOM accrual110 but likely decrease stable biochar yield109. Finally, we emphasize that future studies need to include consideration of the negative environmental implications of heavy metal contamination in iron ore, iron-ore waste, and steel slag.

Poorly-crystalline Al and Fe phases are primarily represented by short-range ordered aluminosilicates, which include the Al-minerals allophane (hollow sphere-shaped particles), imogolite (well-defined tube-shaped particles) and non-crystalline gibbsite, and Fe-minerals ferrihydrite and nano-crystalline goethite61,115. These all have a high capacity for organic matter storage in soils, but data are lacking on their potential for biomass doping for biochar production, and for potential combined benefits on biochar and soil carbon stability.

Non-silicate rock minerals and residues

Soil exchangeable Ca correlates well with SOM62 and has been shown to be the best predictor of SOM in alkaline soils65. Therefore, the addition of Ca-containing minerals to soils may increase SOM storage. Ca decreases respiration rates and increases SOM protection in MAOM and aggregates62. Lime, calcite, and gypsum application increases soil structure and hence the SOM protection potential62. Ca-bearing minerals in the form of liming agents have been applied for centuries, yet the effects of liming agents on SOM content are still not clearly understood. Negative, neutral, and positive effects have been reported, based on improved SOM decomposition due to pH increase, increased soil aggregation due to Ca supply, and better plant growth and hence more carbon inputs into soil, respectively116,117,118. Overall, on average 4.5% SOM increase was reported in acidic soils as a result of liming agent addition119. Such application can be economical and sustainable given the expected increase in crop yield as a result of pH shifting in acidic soils into a range optimal for plant growth119. Specifically, Ca- and Mg-depleted soils could be suitable for amendment with Ca-containing minerals to facilitate SOM protection through AggOM and MAOM.

Biomass combustion ashes have complex chemical composition that mainly comprise metal oxides, with the largest proportion attributed to Ca, followed by K, Mg, Al, and Fe120. Different studies of wood ash application to soils have shown a range of effects, from SOM loss121,122, neutral effects on SOM123, to even SOM accrual and decreased soil CO2 emissions124,125,126. This requires further investigation, with emphasis on soil chemical changes induced by wood ash in different soil types. Due to the presence of CaO and MgO, biomass combustion ashes can also result in the formation of carbonates in soils126,127. Wood ash can also increase biochar stable carbon yield and biochar economics58. Notably, biochar-wood ash composites can efficiently supply potassium to plants128,129. Given the potential of wood ash to offer a win-win-win scenario, it is a promising material for future studies. Although combustion ashes are not available in large quantities globally, they can become a locally important application where they are available, instead of going to landfill130. It may offer an attractive application of combustion waste from biomass energy with carbon capture and storage (BECCS) installations if and when these become operational.

Conclusions

Here, we reviewed three soil-based CDR methods that use minerals, including (A) enhanced rock weathering for inorganic carbon formation, (B) mineral doping of biochar, for biomass carbon retention and (C) accrual of soil organic matter. We highlighted their potential use and limitations when applied individually for CDR. We then assessed the potential for synergies between inorganic carbon, soil organic carbon, and stable biochar carbon formation through strategic applications of primary and secondary minerals to soil, or as additive to biomass (biomass doping) before biochar production. We describe the suitability of a variety of minerals for these synergistic approaches and highlight how carbon can be drawn down simultaneously through multiple soil-based CDRs. We suggest that such synergies can reduce the economic costs of atmospheric CDR by concurrent draw down into organic carbon and inorganic carbon forms. The minerals with most potential for further investigations include primary minerals for SOM-EW synergies, phyllosilicates for SOM-biochar synergies, and combustion ashes for synergies across all CDR methods. Further research is urgently needed into optimising mineral formation through co-application of several minerals, i.e., primary and secondary minerals, to accelerate carbon draw down through several pathways. Optimisation of synergies between the CDR methods could boost CDR rates and increase economic feasibility, and hence favour large-scale rollout of land-based carbon sequestration.

Data availability

Table 1 represents all data used in this study.

References

United Nations. Adoption of the Paris Agreement. U.N. Doc. FCCC/CP/2015/L.9/Rev/1 (United Nations, 2015).

IPCC. Climate Change 2021 - The Physical Science Basis. Working Group I Contribution to the Sixth Asssessment Report of the Intergovernmental Panel on Climate Change (Cambridge University Press, 2021).

IPCC. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change https://doi.org/10.1017/9781009157926. (Cambridge University Press, 2022).

Hansen, J. E. et al. Global warming in the pipeline. Oxford Open Climate Change 3, kgad008 (2023).

Minx, J. C. et al. Negative emissions - Part 1: Research landscape and synthesis. Environ. Res. Lett. 13, 063001 (2018).

Buss, W., Yeates, K., Rohling, E. J. & Borevitz, J. Enhancing natural cycles in agro-ecosystems to boost plant carbon capture and soil storage. Oxford Open Climate Change 1, kgab006 (2021).

Buss, W. et al. Mineral-enriched biochar delivers enhanced nutrient recovery and carbon dioxide removal. Commun. Earth Environ. 3, 67 (2022).

Roe, S. et al. Contribution of the land sector to a 1.5 °C world. Nat. Clim. Chang. 9, 817–828 (2019).

Hepburn, C. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Fuss, S. et al. Negative emissions - Part 2: Costs, potentials and side effects. Environ. Res. Lett. 13, 063002 (2018).

Griscom, B. W. et al. Natural climate solutions. PNAS 114, 11645–11650 (2017).

Rohling, E. J. Rebalancing Our Climate: The Future Starts Today (Oxford University Press, 2021).

Pratt, C., Mahdi, Z. & El Hanandeh, A. ‘Climate Healing Stones’: Common Minerals Offer Substantial Climate Change Mitigation Potential. Environ. Manage 73, 1167–1179 (2024).

Zhang, S. et al. Global CO2 Consumption by Silicate Rock Chemical Weathering: Its Past and Future. Earths Fut. 9, e2020EF001938 (2021).

Beerling, D. J. et al. Potential for large-scale CO2 removal via enhanced rock weathering with croplands. Nature 583, 242–248 (2020).

Campbell, J. S. et al. Geochemical Negative Emissions Technologies: Part I. Review. Front. Clim. 4, 879133 (2022).

Beerling, D. J. et al. Climate, Food and Soil Security. Nat Plants 4, 138–147 (2018).

Lehmann, J. et al. Biochar in climate change mitigation. Nat Geosci 14, 883–892 (2021).

Smith, P. et al. Which practices co-deliver food security, climate change mitigation and adaptation, and combat land degradation and desertification? Glob. Chang. Biol. 26, 1532–1575 (2020).

Antal, M. J. & Grønli, M. The art, science, and technology of charcoal production. Ind. Eng. Chem. Res. 42, 1619–1640 (2003).

Scharlemann, J. P. W., Tanner, E. V. J., Hiederer, R. & Kapos, V. Global soil carbon: Understanding and managing the largest terrestrial carbon pool. Carbon Manag. 5, 81–91 (2014).

Sokol, N. W. et al. Global distribution, formation and fate of mineral-associated soil organic matter under a changing climate: A trait-based perspective. Functional Ecol. 36, 1411–1429 (2022).

Minasny, B., Fiantis, D., Hairiah, K. & Van Noordwijk, M. Applying volcanic ash to croplands – The untapped natural solution. Soil Security 3, 100006 (2021).

Beerling, D. J. et al. Enhanced weathering in the U.S. Corn Belt delivers carbon removal with agronomic benefits. PNAS 121, e2319436121 (2024).

Hartmann, J. et al. Enhanced chemical weathering as a geoengineering strategy to reduce atmospheric carbon dioxide, supply nutrients, and mitigate ocean acidification. Rev. Geophys. 51, 113–149 (2013).

Gernon, T. M. et al. Global chemical weathering dominated by continental arcs since the mid-Palaeozoic. Nat. Geosci. 14, 690–696 (2021).

Renforth, P. The potential of enhanced weathering in the UK. Int. J. Greenhouse Gas Control 10, 229–243 (2012).

Holdren, G. R. & Speyer, P. M. Reaction rate-surface area relationships during the early stages of weathering. I. Initial observations. Geochim. Cosmochim. Acta 51, 2311–2318 (1985).

Vicca, S. et al. Is the climate change mitigation effect of enhanced silicate weathering governed by biological processes? Glob. Chang. Biol. 28, 711–726 (2022).

Kantola, I. B., Masters, M. D., Beerling, D. J., Long, S. P. & DeLucia, E. H. Potential of global croplands and bioenergy crops for climate change mitigation through deployment for enhanced weathering. Biol. Lett. 13, 20160714 (2017).

Kantola, I. B. et al. Improved net carbon budgets in the US Midwest through direct measured impacts of enhanced weathering. Glob. Chang. Biol. 29, 7012–7028 (2023).

Amann, T. et al. Enhanced Weathering and related element fluxes - A cropland mesocosm approach. Biogeosciences 17, 103–119 (2020).

Skov, K. et al. Initial agronomic benefits of enhanced weathering using basalt: A study of spring oat in a temperate climate. PLoS One 19, e0295031 (2024).

Kelland, M. E. et al. Increased yield and CO2 sequestration potential with the C4 cereal Sorghum bicolor cultivated in basaltic rock dust‐amended agricultural soil. Glob. Chang. Biol. 1–19, https://doi.org/10.1111/gcb.15089 (2020).

Goll, D. S. et al. Potential CO2 removal from enhanced weathering by ecosystem responses to powdered rock. Nat. Geosci. 14, 545–549 (2021).

Renforth, P. The negative emission potential of alkaline materials. Nat. Commun. 10, 1401 (2019).

Amann, T. & Hartmann, J. Carbon Accounting for Enhanced Weathering. Front. Clim. 4, 849948 (2022).

Almaraz, M. et al. Methods for determining the CO2 removal capacity of enhanced weathering in agronomic settings. Front. Clim. 4, 970429 (2022).

Kanzaki, Y., Planavsky, N., Zhang, S., Jordan, J. & Reinhard, C. T. Soil cation storage as a key control on the timescales of carbon dioxide removal through enhanced weathering (ESS Open Archive, 2024).

Clarkson, M. O. et al. A review of measurement for quantification of carbon dioxide removal by enhanced weathering in soil. Front. Clim. 6, 1345224 (2024).

Dietzen, C. & Rosing, M. T. Quantification of CO2 uptake by enhanced weathering of silicate minerals applied to acidic soils. Int. J. Greenhouse Gas Control 125, 103872 (2023).

Hasemer, H., Borevitz, J. & Buss, W. Measuring Enhanced Weathering: inorganic carbon-based-approaches may be required to complement cation-based approaches. Front. Clim. 6, 1352825 (2024).

Holzer, I., Slessarev, E. & Sokol, N. Quantifying enhanced weathering" CarbonPlan https://carbonplan.org/research/ew-quantification-explainer (2023).

Crombie, K. & Mašek, O. Pyrolysis biochar systems, balance between bioenergy and carbon sequestration. GCB Bioenergy 7, 349–361 (2015).

Joseph, S. et al. How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenergy 13, 1731–1764 (2021).

Wang, J., Xiong, Z. & Kuzyakov, Y. Biochar stability in soil: meta-analysis of decomposition and priming effects. GCB Bioenergy 8, 512–523 (2016).

Shackley, S., Hammond, J., Gaunt, J. & Ibarrola, R. The feasibility and costs of biochar deployment in the UK. Carbon Manag. 2, 335–356 (2011).

Ronsse, F., van Hecke, S., Dickinson, D. & Prins, W. Production and characterization of slow pyrolysis biochar: influence of feedstock type and pyrolysis conditions. GCB Bioenergy 5, 104–115 (2013).

Crombie, K. & Mašek, O. Investigating the potential for a self-sustaining slow pyrolysis system under varying operating conditions. Bioresour. Technol. 162, 148–156 (2014).

Crombie, K., Mašek, O., Cross, A. & Sohi, S. Biochar - synergies and trade-offs between soil enhancing properties and C sequestration potential. GCB Bioenergy, 1–15, https://doi.org/10.1111/gcbb.12213 (2014).

Mašek, O., Brownsort, P., Cross, A. & Sohi, S. Influence of production conditions on the yield and environmental stability of biochar. Fuel 103, 151–155 (2013).

Liu, Y. et al. Vermiculite modification increases carbon retention and stability of rice straw biochar at different carbonization temperatures. J. Clean Prod. 254, 120111 (2020).

Mašek, O., Buss, W., Brownsort, P., Rovere, M. & Alberto, T. Potassium doping increases biochar carbon sequestration potential by 45 %, facilitating decoupling of carbon sequestration from soil improvement. Sci. Rep. 9, 5514 (2019).

Nan, H. et al. Different alkaline minerals interacted with biomass carbon during pyrolysis: Which one improved biochar carbon sequestration? J. Clean Prod. 255, 120162 (2020).

Giudicianni, P. et al. Inherent Metal Elements in Biomass Pyrolysis: A Review. Energy Fuels 35, 5407–5478 (2021).

Yang, F., Zhao, L., Gao, B., Xu, X. & Cao, X. The Interfacial Behavior between Biochar and Soil Minerals and Its Effect on Biochar Stability. Environ. Sci. Technol. 50, 2264–2271 (2016).

Nan, H. et al. Minerals: A missing role for enhanced biochar carbon sequestration from the thermal conversion of biomass to the application in soil. Earth Sci. Rev. 234, https://doi.org/10.1016/j.earscirev.2022.104215 (2022).

Buss, W., Jansson, S., Wurzer, C. & Mašek, O. Synergies between BECCS and biochar - maximizing carbon sequestration potential by recycling wood ash. ACS Sustain. Chem. Eng. 7, 4204–4209 (2019).

Heckman, K. et al. Beyond bulk: Density fractions explain heterogeneity in global soil carbon abundance and persistence. Glob. Chang. Biol. 28, 1178–1196 (2022).

Hemingway, J. D. et al. Mineral protection regulates long-term global preservation of natural organic carbon. Nature 570, 228–231 (2019).

Slessarev, E. W., Chadwick, O. A., Sokol, N. W., Nuccio, E. E. & Pett-Ridge, J. Rock weathering controls the potential for soil carbon storage at a continental scale. Biogeochemistry 157, 1–13 (2022).

Rowley, M. C., Grand, S. & Verrecchia, É. P. Calcium-mediated stabilisation of soil organic carbon. Biogeochemistry 137, 27–49 (2018).

Xue, B. et al. Effects of organic carbon and iron oxides on soil aggregate stability under different tillage systems in a rice–rape cropping system. Catena 177, 1–12 (2019).

Kleber, M. et al. Mineral-Organic Associations: Formation, Properties, and Relevance in Soil Environments. Adv. Agronomy 130, 1–140 (2015).

Rasmussen, C. et al. Beyond clay: towards an improved set of variables for predicting soil organic matter content. Biogeochemistry 137, 297–306 (2018).

Singh, M. et al. Stabilization of Soil Organic Carbon as Influenced by Clay Mineralogy. Adv. Agronomy 148, 33–84 (2018).

Jeewani, P. H. et al. Rusty sink of rhizodeposits and associated keystone microbiomes. Soil Biol. Biochem. 147, 107840 (2020).

Buss, W., Hasemer, H., Ferguson, S. & Borevitz, J. Stabilisation of soil organic matter with rock dust partially counteracted by plants. Glob. Chang. Biol. https://doi.org/10.1111/gcb.17052 (2023).

Amann, T. & Hartmann, J. Ideas and perspectives: Synergies from co-deployment of negative emission technologies. Biogeosciences 16, 2949–2960 (2019).

Sokol, N. W. et al. Reduced accrual of mineral-associated organic matter after two years of enhanced rock weathering in cropland soils, though no net losses of soil organic carbon. Biogeochemistry, https://doi.org/10.1007/s10533-024-01160-0 (2024).

Xu, T. et al. Enhanced silicate weathering accelerates forest carbon sequestration by stimulating the soil mineral carbon pump. Glob. Chang. Biol. 30, e17464 (2024).

Yan, Y. et al. Wollastonite addition stimulates soil organic carbon mineralization: Evidences from 12 land-use types in subtropical China. Catena 225, 107031 (2023).

Klemme, A., Rixen, T., Müller, M., Notholt, J. & Warneke, T. Destabilization of carbon in tropical peatlands by enhanced weathering. Commun. Earth Environ. 3, 212 (2022).

Spohn, M. et al. The positive effect of plant diversity on soil carbon depends on climate. Nat Commun 14, 6624 (2023).

Bormann, B. T. et al. Rapid, plant-induced weathering in an aggrading experimental ecosystem. Biogeochemistry 43, 129–155 (1998).

Whalen, E. D. et al. Clarifying the evidence for microbial- and plant-derived soil organic matter, and the path toward a more quantitative understanding. Global Change Biol. 28, 7167–7185 (2022).

Sokol, N. W. et al. Life and death in the soil microbiome: how ecological processes influence biogeochemistry. Nat. Rev. Microbiol. 20, 415–430 (2022).

Kallenbach, C. M., Grandy, A. S., Frey, S. D. & Diefendorf, A. F. Microbial physiology and necromass regulate agricultural soil carbon accumulation. Soil Biol. Biochem. 91, 279–290 (2015).

Kallenbach, C. M., Frey, S. D. & Grandy, A. S. Direct evidence for microbial-derived soil organic matter formation and its ecophysiological controls. Nat. Commun. 7, 1–10 (2016).

Brady, P. V. et al. Direct measurement of the combined effects of lichen, rainfall, and temperature onsilicate weathering. Geochim. Cosmochim. Acta 63, 3293–3300 (1999).

White, A. F. & Blum, A. E. Effects of climate on chemical weathering in watersheds. Water Rock Interaction Proc. Symp. 59, 57–60 (1995).

Nguyen, B. T. & Lehmann, J. Black carbon decomposition under varying water regimes. Org. Geochem. 40, 846–853 (2009).

Nguyen, B. T., Lehmann, J., Hockaday, W. C., Joseph, S. & Masiello, C. A. Temperature sensitivity of black carbon decomposition and oxidation. Environ. Sci. Technol. 44, 3324–3331 (2010).

Bai, X. et al. Responses of soil carbon sequestration to climate ‐ smart agriculture practices: A meta ‐ analysis. Glob. Chang. Biol. 2591–2606, https://doi.org/10.1111/gcb.14658 (2019).

Zhang, A. et al. Biochar more than stubble management affected carbon allocation and persistence in soil matrix: a 9-year temperate cropland trial. J. Soils Sediments, https://doi.org/10.1007/s11368-023-03546-3 (2023).

Blanco-Canqui, H., Acharya, B. S., Laird, D. A. & Heaton, E. A. Soil carbon increased by twice the amount of biochar carbon applied after 6 years: Field evidence of negative priming. Glob. Change Biol. Bioenergy 240–251, https://doi.org/10.1111/gcbb.12665 (2020).

Gross, A., Bromm, T. & Glaser, B. Soil organic carbon sequestration after biochar application: A global meta-analysis. Agronomy 11, https://doi.org/10.3390/agronomy11122474 (2021).

Weng, Z. et al. Biochar built soil carbon over a decade by stabilizing rhizodeposits. Nat. Clim. Chang. 7, 371–376 (2017).

Ding, F. et al. A meta-analysis and critical evaluation of influencing factors on soil carbon priming following biochar amendment. J. Soils Sediments 18, 1507–1517 (2018).

Weng, Z. H. et al. Microspectroscopic visualization of how biochar lifts the soil organic carbon ceiling. Nat. Commun. 13, 5177 (2022).

Griffioen, J. Enhanced weathering of olivine in seawater: The efficiency as revealed by thermodynamic scenario analysis. Sci. Total Environ. 575, 536–544 (2017).

Choi, G. G., Oh, S. J. & Kim, J. S. Scrap tire pyrolysis using a new type two-stage pyrolyzer: Effects of dolomite and olivine on producing a low-sulfur pyrolysis oil. Energy 114, 457–464 (2016).

Haque, F., Santos, R. M. & Chiang, Y. W. Optimizing Inorganic Carbon Sequestration and Crop Yield With Wollastonite Soil Amendment in a Microplot Study. Front. Plant Sci. 11, 1–12 (2020).

Kelemen, P. B. et al. Rates and mechanisms of mineral carbonation in peridotite: Natural processes and recipes for enhanced, in situ CO2 capture and storage. Annu. Rev. Earth Planet Sci. 39, 545–576 (2011).

Gerdemann, S. J., O’Connor, W. K., Dahlin, D. C., Penner, L. R. & Rush, H. Ex situ aqueous mineral carbonation. Environ. Sci. Technol. 41, 2587–2593 (2007).

Balucan, R. D. & Dlugogorski, B. Z. Thermal activation of antigorite for mineralization of CO2. Environ. Sci. Technol. 47, 182–190 (2013).

Kumar, A., Tanvar, H., Pratap, Y. & Dhawan, N. Evaluation of Mica as a Source of Potash. Min. Metall Explor. 36, 547–555 (2019).

Demiral, I. & Şensöz, S. The effects of different catalysts on the pyrolysis of industrial wastes (olive and hazelnut bagasse). Bioresour. Technol. 99, 8002–8007 (2008).

Creamer, C. A. et al. Mineralogy dictates the initial mechanism of microbial necromass association. Geochim. Cosmochim. Acta 260, 161–176 (2019).

Haseli, P., Majewski, P., Christo, F. C., Hammond, B. & Bruno, F. Thermochemical and Experimental Kinetic Analysis of Potassium Extraction from Ultrapotassic Syenite Using Molten Chloride Salts. Ind. Eng. Chem. Res. 58, 7397–7407 (2019).

Lu, J. et al. Iron-montmorillonite treated corn straw biochar: Interfacial chemical behavior and stability. Sci. Total Environ. 708, 134773 (2020).

Blume, H.-P. et al. Scheffer/Schachtabel: Soil Science, https://doi.org/10.1007/978-3-642-30942-7 (Springer, 2016).

Li, F., Cao, X., Zhao, L., Wang, J. & Ding, Z. Effects of mineral additives on biochar formation: Carbon retention, stability, and properties. Environ. Sci. Technol. 48, 11211–11217 (2014).

Wang, F. et al. Co-pyrolysis of wood chips and bentonite/kaolin: Influence of temperatures and minerals on characteristics and carbon sequestration potential of biochar. Sci. Total Environ. 838, 156081 (2022).

Singh, M., Sarkar, B., Biswas, B., Bolan, N. S. & Churchman, G. J. Relationship between soil clay mineralogy and carbon protection capacity as influenced by temperature and moisture. Soil Biol. Biochem. 109, 95–106 (2017).

Parfitt, R. L. Allophane and imogolite: role in soil biogeochemical processes. Clay Miner. 44, 135–155 (2009).

Poeplau, C. et al. Isolating organic carbon fractions with varying turnover rates in temperate agricultural soils – A comprehensive method comparison. Soil Biol. Biochem. 125, 10–26 (2018).

Abramoff, R. Z. et al. How much carbon can be added to soil by sorption? Biogeochemistry 152, 127–142 (2021).

Wurzer, C. & Mašek, O. Feedstock doping using iron rich waste increases the pyrolysis gas yield and adsorption performance of magnetic biochar for emerging contaminants. Bioresour. Technol. 321, 124473 (2021).

Song, X. et al. Towards a better understanding of the role of Fe cycling in soil for carbon stabilization and degradation. Carbon Res. 1, 5 (2022).

Adeoye, A. O., Quadri, R. O. & Lawal, O. S. Wet synthesis, characterization of goethite nanoparticles and its application in catalytic pyrolysis of palm kernel shell in TGA. Results Surfaces Interfaces 11, 100118 (2023).

Ramli, N. A. A., Kusin, F. M. & Molahid, V. L. M. Influencing factors of the mineral carbonation process of iron ore mining waste in sequestering atmospheric carbon dioxide. Sustainability 13, 1–17 (2021).

Molahid, V. L. M., Kusin, F. M., Hasan, S. N. M. S., Ramli, N. A. A. & Abdullah, A. M. CO2 Sequestration through Mineral Carbonation: Effect of Different Parameters on Carbonation of Fe‐Rich Mine Waste Materials. Processes 10, 432 (2022).

Pullin, H. et al. Atmospheric Carbon Capture Performance of Legacy Iron and Steel Waste. Environ. Sci. Technol. 53, 9502–9511 (2019).

Lenhardt, K. R. et al. Synthesis of short-range ordered aluminosilicates at ambient conditions. Sci. Rep. 11, 4207 (2021).

Aye, N. S., Sale, P. W. G. & Tang, C. The impact of long-term liming on soil organic carbon and aggregate stability in low-input acid soils. Biol. Fertil. Soils 52, 697–709 (2016).

Paradelo, R., Virto, I. & Chenu, C. Net effect of liming on soil organic carbon stocks: A review. Agric. Ecosyst. Environ. 202, 98–107 (2015).

Haynes, R. J. & Naidu, R. Influence of lime, fertilizer and manure applications on soil organic matter content and soil physical conditions: A review. Nutr. Cycl. Agroecosyst. 51, 123–137 (1998).

Wang, Y. et al. Potential benefits of liming to acid soils on climate change mitigation and food security. Glob. Chang. Biol. 27, 2807–2821 (2021).

Vassilev, S. V., Baxter, D., Andersen, L. K. & Vassileva, C. G. An overview of the composition and application of biomass ash. Part 1. Phase – mineral and chemical composition and classification. Fuel 105, 40–76 (2013).

Rosenberg, O., Persson, T., Högbom, L. & Jacobson, S. Effects of wood-ash application on potential carbon and nitrogen mineralisation at two forest sites with different tree species, climate and N status. For. Ecol. Manage 260, 511–518 (2010).

Mortensen, L. H., Cruz-Paredes, C., Schmidt, O., Rønn, R. & Vestergård, M. Ash application enhances decomposition of recalcitrant organic matter. Soil Biol. Biochem. 135, 316–322 (2019).

Augusto, L., Bakker, M. R. & Meredieu, C. Wood ash applications to temperate forest ecosystems - Potential benefits and drawbacks. Plant Soil 306, 181–198 (2008).

Reed, E. Y., Chadwick, D. R., Hill, P. W. & Jones, D. L. Critical comparison of the impact of biochar and wood ash on soil organic matter cycling and grassland productivity. Soil Biol. Biochem. 110, 134–142 (2017).

Zhao, H. et al. Effect of Straw and Wood Ash on Soil Carbon Sequestration and Bacterial Community in a Calcareous Soil. Front. Microbiol. 13, 926506 (2022).

Zhao, H. et al. Enhancing organic and inorganic carbon sequestration in calcareous soil by the combination of wheat straw and wood ash and/or lime. PLoS One 13, e0205361 (2018).

Green, H., Larsen, P., Liu, Y. & Nelson, P. N. Carbon dioxide removal via weathering of sugarcane mill ash under different soil conditions. Appl. Geochem. 165, 105940 (2024).

Buss, W., Jansson, S. & Mašek, O. Unexplored potential of novel biochar-ash composites for use as organo-mineral fertilizers. J. Clean Prod. 208, 960–967 (2019).

Grafmüller, J. et al. Wood Ash as an Additive in Biomass Pyrolysis: Effects on Biochar Yield, Properties, and Agricultural Performance. ACS Sustain. Chem. Eng. 10, 2720–2729 (2022).

Hannam, K. D. et al. Wood ash as a soil amendment in Canadian forests: What are the barriers to utilization? Can. J. Forest Res. 48, 442–450 (2018).

Blume, H.-P. et al. Chapter 2: Inorganic soil components - minerals and rocks. In Scheffer/Schachtschabel: Soil Science 7–37 (Springer, 2016).

Palandri, J. L. & Kharaka, Y. K. A Compilation of Rate Parameters of Water-Mineral Interaction Kinetics for Application to Geochemical Modeling (U.S. GEOLOGICAL SURVEY, 2004).

Acknowledgements

The authors acknowledge the funding provided by the Australian National University Grand Challenges Scheme. Work at LLNL by N.W.S. was supported by Lawrence Livermore National Laboratory’s ‘Terraforming Soil’ Energy Earthshot Research Center, funded by the U.S. Department of Energy (award # SCW1841 to LLNL) and performed under the auspices of the DOE, Contract DE-AC52-07NA27344.

Author information

Authors and Affiliations

Contributions

W.B. conceptualised the idea for the manuscript in collaboration with H.H. and N.W.S. W.B. prepared figures and wrote the manuscript. H.H., N.W.S, E.J.R., J.B. reviewed and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Earth & Environment thanks Fatima Haque, Anhuai Lu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Fiona Tang, Clare Davis, and Carolina Ortiz Guerrero. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Buss, W., Hasemer, H., Sokol, N.W. et al. Applying minerals to soil to draw down atmospheric carbon dioxide through synergistic organic and inorganic pathways. Commun Earth Environ 5, 602 (2024). https://doi.org/10.1038/s43247-024-01771-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43247-024-01771-3

This article is cited by

-

Bio-accelerated weathering of ultramafic minerals with Gluconobacter oxydans

Scientific Reports (2025)

-

Challenges and opportunities in scaling enhanced weathering for carbon dioxide removal

Nature Reviews Earth & Environment (2025)

-

Effects of biochar and nitrogen fertilizer on microbial communities, CO2 emissions, and organic carbon content in soil

Scientific Reports (2025)

-

Overlooking dynamics and multi-functionality of reactive minerals in soil organic carbon stabilization

Soil Ecology Letters (2025)

-

Unlocking the potential of whole-profile carbon sequestration in agricultural soils

Frontiers of Earth Science (2025)