Abstract

Light-driven material systems enable remote control of miniature structures in small-scale manipulation. However, conventional methods often rely on locally focused light, necessitating complex alignment setups and complicating precise modeling. Here, we introduce a versatile framework based on wide-area global illumination to achieve tunable and precise shape control with a simple light setup. By characterizing the feedback loop between light projection and material deformation, we elucidated the fundamental relationship between light field conditions and shape changes in thin-film liquid crystal polymer (LCP) actuators. Based on this, we develop a photo-thermal-mechanical (PTM) kinematic model for accurately predicting actuator deformation. The function of our proposed method has been validated through diverse prototypes, including robotic crawlers, a ball drop-and-catch system with real-time path prediction, and a reconfigurable robotic hand showing 6 different gestures. Our proposed strategy holds great promise for advancing the capabilities of miniature light-driven material systems in robotics and engineering applications.

Similar content being viewed by others

Introduction

Stimuli-responsive soft materials that deform in response to external stimuli offer attractive opportunities for realizing wireless shape control of small-scale structures. By manipulating external stimuli such as temperature1,2, humidity3,4, or magnetic fields5,6, the shape of these materials can be continuously adjusted, enabling a wide range of applications in miniature robotic systems, healthcare, and 4D printing. Among these stimuli-responsive materials, light-driven variants are typically made of light-responsive liquid crystal polymers (LCPs)7,8, hydrogels9,10 and carbon-based bilayers11, stand out as particularly promising candidates for enabling tunable and efficient shape manipulation. This is attributable to the high degree of control afforded by light fields compared to other stimuli, as well as the fast response times of these materials. Leveraging light-driven materials, miniature light-driven robots capable of diverse motions including crawling12,13, walking14,15, jumping16, and oscillation17,18, were developed. The functionality of light-induced deformation has also been validated in energy-harvesting19,20 and self-regulating iris21 systems.

One major challenge in existing light-driven material systems is their reliance on complex external setups. Existing studies typically adopt focused light sources, usually laser beams, to trigger localized deformations at desired position12,14,22,23. However, these light control strategies require highly accurate light alignment and focusing setups, which complicates the system design and reduces robustness for dynamic operations. Moreover, the coupling of light actuation and material position adds non-negligible difficulties in deformation control and modeling. As the material deforms and moves during actuation, the actuation area tends to deviate from its expected position on the surface, making the deformation difficult to predict in precision-required tasks.

In contrast to focused light illumination, global illumination that covers the entire material system, such as torch light, is well-suited for setup simplicity and position-decoupled shape manipulation. Based on global illumination, light-driven walking robots24, rolling robots25, and rotational gear26 were reported, demonstrating milestones in eliminating complex light alignment and focusing setups in light-driven material systems. By simultaneously irradiating the entire structure, the material deforms to a stable state, which offers high robustness compared to the localized deformation caused by focused light in long-term, dynamic, and repeated tasks without potential errors from actuation deviation. However, the spatially uniform illumination is considered less tunable for shape control and has been applied primarily to unidirectional, single-degree-of-freedom motion, or has required multiple wavelengths for enhanced tunability27,28. Additionally, while deformation occurs along the entire structure of the material, existing studies only focus on modeling the tip displacement rather than the deformation across the full structure18,20. Crucially, a fundamental kinematic model of deformation under global illumination, which is essential for precise manipulation, has not been established, leaving the potential for precise shape control of light-responsive materials untapped.

Here, we unlock tunable shape control of light-driven material systems by proposing and utilizing an original kinematic model of light-induced deformation under global illumination-based actuation. The model was established based on the observed feedback loop between material deformation and light actuation, using a platform of light-driven thin-film LCP actuators. This model achieved high accuracy with R2 > 0.9 in predicting deformation along the full length of the material. The characterization of light-driven deformation revealed two distinct deformation phenomena, i.e., positive phototropism and negative phototropism. By controlling the light angle, these behaviors can be generated and tuned, providing guidance for programming tunable deformations in light-driven material systems. We also investigated the influence of light-shielding when opaque structures are installed on the material, which can separate the global illumination to realize extended deformation forms. To demonstrate the tunability of our control strategy, we have developed several robotic systems, including crawlers with predictable deformation and displacement, a ball drop-and-catch system with real-time path estimation, and a robot hand with 6 different hand gestures. All the systems are actuated by global illumination. In contrast to the conventional approach of using focused light for actuation, our improved global illumination-based actuation strategy offers several advantages. It is simpler to set up and also provides greater precision and robustness in shape control. These benefits are enabled by the position-decoupled nature of the global illumination, which eliminates the need for precise light alignment and the potential errors that can arise from light deviation during actuation.

Results

Kinematics of deformation

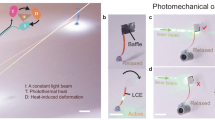

The study of kinematics of deformation under global illumination is based on a thin-film LCP material. The LCP material consists of liquid crystal monomers RM23 and crosslinkers RM82 doped with the light-absorbing dye Disperse Orange 3. The liquid crystal molecules were designed to exhibit a gradient in orientation from vertical to horizontal across the film thickness. Under blue light illumination, the light-absorbing dye absorbs light energy and converts it into heat, causing a local temperature increase. This temperature change then results in a disorder of the liquid crystal molecular alignment, which causes lateral expansion of material layers with designed vertical alignment and shrinkage for horizontal alignment. The different expansion-shrinkage behavior through the thickness in turn induces the local bending motion (Fig. 1a, more detailed illustration see Supplementary Fig. 11). Based on this fundamental light response at the material level, the continuously deformable thin-film structure can be conceptualized as a densely arranged collection of individual bending units (Fig. 1b), the bending motion of each unit contributes to the deformation of the overall structure, which is to be addressed by the kinematic model. Figure 1c illustrates the motion of an LCP actuator, with one end fixed, in response to global illumination. As shown, the light-illuminated region is larger than the material system, enabling position-decoupled actuation without requiring specialized light-alignment and focusing setups. Upon actuation, the material gradually deforms until reaching a steady state, which changes when different light angles are applied (Fig. 1d).

a Light actuation in the light-driven LCP material. b Schematic of the modeling approach of deformation with equivalent actuation units. c Schematic of the position-decoupled global illumination-based actuation. d Schematic of the influence of light angle in steady state deformation. e Snapshots, IR images, measured and modeled deformation, curvature, and temperature distributions of positive phototropism under 60° light angle. f Snapshots, IR images, measured and modeled deformation, curvature, and temperature distributions of negative phototropism under −60° light angle. g Schematic of shape convergence. h Schematic of photo-thermal-mechanical feedback loop and the PTM kinematic model of the steady state deformation. i Calibration of kc value. j Calibration of kT value. k Calibration of c value. l Calibration of kh value in heat up time region and m in cool down region. n Comparison of experimental and simulated transient temperature response based on the PTM model and calibrated value. All results were obtained from n = 3 repeated tests. The default light intensity, if not specified, is 256 mW/cm2. All scale bars are 5 mm.

Figure 1e, f show the deformation of the LCP actuator and its shape and temperature distribution when it reaches a steady state. With the light angle in Fig. 1e, the steady-state shape of the actuator exhibits a light-attracting phenomenon in which the tip points toward the incoming light direction. This behavior is called positive phototropism (P). In contrast, with the light angle in Fig. 1f, the actuator tends to bend opposite to the light direction, a phenomenon called negative phototropism (N). For both observed deformation patterns, whether exhibiting positive or negative phototropism, there always exists a convergent shape toward which the material deforms. The infrared (IR) images of the steady state LCP actuator show a temperature distribution gradient, with the root region being hotter and the tip region being cooler. By comparing this temperature distribution to the curvature distribution, a similar trend is observed (right side of Fig. 1e, f), suggesting an underlying relationship between these two variables.

Through characterization, we found that the observed shape convergence and gradient temperature/curvature distribution arise from a feedback loop between light projection, temperature, and material deformation. In this feedback loop, the light distributes on the material surface and causes photo-thermal conversion that heat up the material. The temperature change then triggers the thermal-mechanical deformation of the LCP material. When the material is deformed, its geometrical relation to the light field is changed, in turn affecting light distribution. As illustrated in Fig. 1g, as the material gradually deforms, the light projection redistributes along the length of the structure. For the near-tip region, the light projection reduces rapidly since the material surface gradually aligns parallel to the light direction. In contrast, the decrease of light projection is insignificant for the near-root region, as the fixed end constrains the deformation. The change in light projection, as illustrated in Fig. 1a, affects the temperature and curvature of the material, resulting in a gradient heat and actuation pattern, where heat and actuation concentrates near the root region of the structure.

Figure 1h shows the photo-thermal-mechanical feedback loop of the deformation. In the figure, the curved shape of the material results in a gradient light projection on the surface, which causes a gradient of temperature distribution due to uneven light absorption. The temperature change then affects the local deformation of the material by triggering photothermal actuation. When the material is deformed from its previous shape, a redistribution of light projection happens, forcing the loop to cycle before reaching a steady convergent state. The convergent state of photo-thermal-mechanical feedback loop can be expressed as the photo-thermal-mechanical (PTM) model:

where the material bending angle \(\theta (l)\), and curvature \(\theta ^{\prime} (l)\), are parameterized by the light intensity \(\text{I}\) and light angle \({\rm{\alpha }}\); constant \({\text{k}}_{\text{T}}\) and \({\text{k}}_{\text{c}}\) represent the conversions between light-induced heating (photo-thermal) and resulted bending (thermal-mechanical) respectively, with \(\text{c}\) representing the initial curvature (for detailed derivations, see Supplementary Method 1.1); and term \(\text{I}|\sin ({\rm{\alpha }}-\theta (l))|\) represents the equivalent local light intensity with the local light projection angle \({\rm{\alpha }}-\theta (l)\).

According to the mathematical representations, the left side of the equation represents the deformation of the LCP actuator, while the right side represents the light actuation of the material. The convergent state occurs when the deformation aligns with the light actuation, and the two sides are equal. The terms kc and kT in the PTM model can be calibrated from the curvature-temperature and temperature-intensity curves (Fig. 1i, j) by assuming a linear relationship (see Supplementary Method 1.2-1.4 for measurement process and more discussion). The term c, which is the initial curvature of the material at room temperature, can be fitted by calibrating the material shape to a circle (Fig. 1k). The PTM model (1) is established for calculating the steady-state deformation of the material.

In Fig. 1e, f, the PTM model provides accurate predictive results of deformation and temperature distribution when compared with the experimental data. In addition, the observed feedback loop can also be utilized in transient form, enabling time-related deformation modeling (Supplementary Method 3). To take actuation time into consideration, a heating coefficient kh is calibrated by analyzing the heat-up and cool-down performance of the material (Fig. 1l, m, detailed information in Supplementary Method 3.5). As shown in Fig. 1n, the transient form precisely simulates the temperature change of material when turning on and off the light, and it can be applied in simulating dynamic processes such as robot’s locomotion, which will be shown in the followed sections.

Positive and negative phototropism

As described above, positive phototropism (P) and negative phototropism (N) can occur in the same LCP actuator when different light angles are applied. According to the experiments, N phototropism happens when the light illuminates the bottom surface of the actuator (Fig. 2a), while P phototropism occurs when the top surface is irradiated (Fig. 2b). This different deformation behavior is due to the material being programmed to bend in one direction, while the light can be applied to both surfaces. Figure 2c illustrates the regions of incoming light angles that cause N and P phototropism.

a Schematic of N phototropism. b Schematic of P phototropism. c Schematic of corresponding light angle regions of N and P phototropism. d Visual comparisons between the experimental and PTM model results under different light angles. e Graphs showing the relationship between the steady-state tip bending angle and light angle. f Schematic of the relationship between light angle and actuator’s deformation. 3D plot of the bending angle-length curve under different light angles, comparing the experimental and PTM model results at light intensities of g 167 mW/cm2, h 212 mW/cm2, and i 256 mW/cm2. j Schematic of the relationship between light intensity and actuator’s deformation. 3D plot of the bending angle-length curve under different light intensities, comparing the experimental and PTM model results at light angles of k −90°, l −60°, and m 60°. R2 for the bending angle-length curve of the PTM model for o N phototropism and p P phototropism. The default light intensity, if not specified, is 256 mW/cm2. All scale bars are 5 mm.

To examine the phototactic deformation, we placed a 3 ×10 mm LCP actuator with one end fixed to a glass substrate and illuminated it with 455 nm blue light (experiment setup see Supplementary Method 2). Figure 2d shows the images of the steady-state deformation of the LCP actuator with different light angles, clearly demostrating the transition from N to P phototropism. These light-angle-related deformation behaviors can be addressed by our PTM model, as shown by the comparison in the same figure. Figure 2e summarizes the tip bending angle as a function of light angle, revealing three distinct regions: N phototropism, P phototropism, and a transition region (T). In the N and P regions, the tip bending angle increases linearly with the light angle, while in the T region (−40° to −10°), a sudden drop of the tip bending angle appears. The PTM model closely matches the experimental results, except for the highly sensitive T region where potential errors in the experimental setup can be magnified. Figure 2n tracks the bending of the tip over time, illustrating the actuator’s ability to reach the steady deformed state within 3 s and recover its initial shape within 10 s after the light is turned off.

Light angle and light intensity are the two key parameters of the global illumination field that affect the deformation of the LCP actuator. Figure 2f demonstrates the change in deformations under different light angles. The 3D plots in Fig. 2g–i visualize the measured and PTM model-predicted distribution of material deformation along the length under diverse light angles from −90° to 90° (5° per step, n = 3), with fixed light intensities of 167 mW/cm2, 212 mW/cm2, and 256 mW/cm2. Similarly, Fig. 2j shows the change in deformations under different light intensities, and Fig. 2k–m visualize the measured and PTM model-predicted distribution of material deformation along the length under different light intensities from 0 to 256 mW/cm2 (22.3 mW/cm2 per step), with fixed light angles of −90°, −60°, and 60°.

The PTM model demonstrates high predictive accuracy, with the bending angle-length distribution closely matching the experimental data. The coefficients of determination (R2) values for the PTM model-predicted N and P deformations were calculated to be averaging 0.97 and 0.91, respectively, excluding the transition and near-transition region (−40° to 25°) (Fig. 2o, p). In the near-transition region (−10° to 25°), the model provides a close prediction of the tip bending angle (Fig. 2e) but deviates from the experimental results near the fixed end (\(l\)≈0) (Fig. 2g–i). This deviation could be due to the impact of material elasticity on the deformation, which could restrict the light-induced deformation when the actuator is receiving low light intensity near the fixed end.

Supplementary Movie 1 shows the positive and negative phototropism of the LCP actuator and the PTM model-predicted results under different light angles.

Light shielding

The N and P phototropism can be utilized for the tunable shape control of the light-driven material structure. To enhance the tunability, an opaque structure, i.e., light shield, can be installed on the LCP actuator to eliminate deformation in certain regions of the material (Fig. 3a). As shown in Fig. 3b, the region where the light is blocked by the opaque structure is not actuated, and the shape convergence occurs only at the illuminated region, resulting in extended S-shaped forms of deformation. Figure 3c demonstrates the light-shielding deformation of a 3 × 10 mm LCP actuator with a 9 mm tall opaque light shield. When shone by 110° blue light, the tip region of the actuator bent gradually toward the steady shape, while the root region experienced negligible deformation due to the light obstruction by the shield. The graph in Fig. 3e depicts the changing bending angle-length curve of the actuator over a 20-s on/off cycle, where the projected shadow area, illustrated by dotted lines, exhibits insignificant variation.

a Schematic of light shielding effect. b Schematic of shape convergence when light shielding occurs. c Snapshots, IR images, measured and modeled deformation (θ, °), curvature (κ, mm-1), and temperature distributions (ΔT, °C) of the light shielding response under a 110° light angle. d Visual comparisons between the experimental and PTM model results of light shielding under different light angles. e Evolution of the bending angle-length curve over time under a 110° light angle. f R2 for the bending angle-length curve of the PTM model. g 3D plot of the bending angle-length curve under different light angles, comparing the experimental and PTM model results. All results were obtained from n = 3 repeated tests. The light intensity is 256 mW/cm2. All scale bars are 5 mm.

The comparison between the experiment and the PTM model in Fig. 3c validates the PTM model’s ability to accurately predict the light shielding motion. The modeling of the shadow area is achieved by simply ignoring the light intensity in the light-shielded region (I = 0). Although the PTM model matches the experimental deformation geometry (θ), a smoother transition of curvature (κ) and temperature (ΔT) between the shaded and illuminated regions was observed experimentally, likely due to the heat transfer effects in the material, which were neglected by the model.

The light shielding area changes when the light angle is varied, as shown in Fig. 3d, resulting in different forms of deformations. The light shielding deformation for light angles from 88° to 120°, expressed by the bending angle-length relation, is depicted in the 3D plots of Fig. 3g (1° per step, n = 3), where the experimental and PTM model exhibit similar results. When the light angle is less than 90°, no shadow of the light shield is projected on the actuator, displaying only phototropism deformation. Conversely, when the light angle exceeds 118°, the LCP is not defromed due to the light being entirely obstructed by the shield. The average R2 of the PTM model-predicted bending angle-length curves between 88° and 112° was 0.93 (Fig. 3f). The PTM model is not recommended for light angles greater than 112°, where the LCP actuator receives only a small amount of light due to shielding. Under such low illumination, the influence of light actuation on deformation becomes negligible, and other mechanisms, such as the material’s intrinsic elasticity, become more dominant, reducing the accuracy of the model.

Supplementary Movie 2 demonstrates the light shielding of the LCP actuator and the corresponding PTM model-predicted results under different light angles.

Light-Driven Caterpillar-inspired Crawlers

The tunable motion of the LCP actuator can be leveraged for biomimetic locomotion. In nature, caterpillars achieve crawling motion by smoothly varying the bending shape of their body. To replicate the crawling motion in miniature robots, we developed two light-driven crawlers that are controlled by tuning their phototrophic and light-shielded deformation properties. The design framework of the light-driven crawlers are shown in Fig. 4a. First, the assembly of multiple LCP actuators and installation of opaque light-shielding structures can be adopted in designing robot’s structures. By global illuminating the robot structure with programmed light angles and on/off cycles, the robots deform toward asymmetric convergent shapes, which can be predicted by the PTM model. This deformation results in asymmetric friction, thus generating directional locomotion. The relation between deformation and locomotion can be addressed by an anchor-friction mechanism.

a Schematic of the design framework. b Actuation, c phototactic deformation, d movement across multiple actuation cycles, e sequential arrival task, and f simulated displacement and anchor mechanism, of the light-driven crawler. g Actuation, h phototactic deformation, i movement across multiple actuation cycles, j sequential arrival task, and k simulated displacement and anchor mechanism, of the light-shielded crawler. l Schematic of the anchor-friction mechanism. m Schematic of the change of anchor angles in locomotion. n Image of the light-driven crawlers. o Schematic of the light-driven ball drop-and-catch system. p The ball-dropping path across two runs of light-controlled drop-and-catch. q Movement of the ball-collecting robot. The unspecified scale bars are 10 mm.

Our first design is the modular light-driven crawler. This robot comprises three LCP actuators, with the middle one placed upside down (Supplementary Fig. 5). Under 30° wide-area directional blue light (~455 nm, 223 mW/cm2), the actuators near the front tip generate the most significant bending motion, while the rear actuators become relatively flat (Fig. 4b). By cyclically turning the light on (6 s) and off (6 s), the spatially-varied asymmetric deformation propels the robot approximately 0.2 body lengths (BL) per cycle. Figure 4d shows the motion of the modular light-driven crawler over multiple actuation cycles. The moving direction of the crawler can be altered by applying different light directions, enabling sequential arrival at different destinations (Fig. 4e).

The deformation of the crawler can be precisely simulated by the PTM model, as shown in the comparison in Fig. 4c. According to experiments, we found the locomotion arises from the change in the tips’ anchor angle, which can be controlled by programming the deformation. The anchor angle is the angle between the front/rear tip of the robot and the ground surface. With a larger anchor angle, the static friction of the tip tends to increase, likely attributed to a larger local pressure generated on the ground surface by “pinning” the tip to the ground with light-induced deformation (Fig. 4l). When the light is on, the asymmetric deformation makes the front anchor angle larger than the rear anchor angle, while the reverse occurs when the light is turned off (Fig. 4m). The upper part of Fig. 4f shows the PTM-simulated front and rear anchor angles of the modular light-driven crawler. When the front anchor angle is larger than the rear anchor angle (0.5–6 s and 9.8–12 s), the front tip is fixed due to higher static friction, and the deformation induces movement of the rear tip, as shown in the displacement-time graph in the lower part of Fig. 4f. Similarly, the front tip moves when rear anchor angle is larger. The figure also validates that the anchor-friction mechanism, together with PTM-based deformation modeling, provides accurate simulation results of the robot’s displacement (more details regarding the simulation process see Supplementary Method 3).

When actuated by multiple continuous cycles, the locomotion stability can be occasionally affected by tip sliding or incomplete shape recovery, potentially due to uneven ground surfaces. However, the average speed can be improved to 0.34 mm/s (0.02 BL/s) by using two light sources - one providing the main deformation and another intermittently activated to assist the trailing tip in overcoming static friction and accelerating deformation. The sequential arrival task (Fig. 4e) utilized this two-light-source control method. Supplementary Movie 3 demonstrates the locomotion, simulation, and sequential arrival of the modular light-driven crawler.

Another light-driven crawler design utilizes the light-shielding effect. Under 45° directional light with 2 s on and 6 s off cycles (201 mW/cm2), the robot moves 0.05 BL/cycle. This is based on the asymmetric bending of the front tip, while the rear tip is obstructed (Fig. 4g, h). Figure 4i, j show the locomotion of the shield light-driven crawler over multiple cycles, as well as its sequential arrival task. Simulated displacement and anchor mechanisms again aligned with the experimental motion (Fig. 4k). By adopting coordinated actuation of two light sources in the sequential arrival task, the shield light-driven crawler reached an average speed of 0.42 mm/s (0.03 BL/s). Supplementary Movie 4 demonstrates the locomotion, simulation, and sequential arrival task of the crawler.

The two light-driven crawler designs demonstrate the viability of using global illumination to produce biomimetic locomotion. These robots can be fabricated on small scales (Fig. 4n) while maintaining continuous deformation capabilities.

Light-controlled Drop-and-catch System for Object Manipulation

The robustness and accuracy of the phototactic control of the LCP can facilitate precise manipulation of small-scale objects, as validated in the light-driven ball drop-and-catch system. As shown in Fig. 4o, the system consists of two light-driven components: an LCP strip and a ball-collecting robot. The LCP strip is a 10 × 12 mm actuator attached to the end of a straight sliding rail. When a ball is released from the top of the rail, it accelerates down to the LCP strip. The deformation of the LCP strip regulates the ball’s moving direction, resulting in a controlled dropping path. This dropping path can be predicted in real-time using our PTM-based mathematical model (Supplementary Method 4) and displayed on the LCD screen.

By tuning the light angle within the range of −30° to 40° (100.4 mW/cm2), the dropping path can be precisely adjusted by the LCP strip. At the bottom, a ball-collecting robot with front and rear 10 × 10 mm LCP legs separated by a basket, which also acts as a light shield, is controlled manually to catch the ball at its predicted dropping point. The robot’s motion is controlled by alternately illuminating the LCP legs (Fig. 4q). Figure 4p shows the dropping paths of the ball in two different drop-and-catch runs. By adjusting the light angle, the dropping path was varied but accurately followed the predicted path displayed on the background screen, which pointed to the basket of the collecting robot. Supplementary Movie 5 demonstrates three successive drop-and-catch runs through the coordinated control of the dropping path and robot motion. Furthermore, the ball-collecting robot can handle loads up to 4.5 times its own body weight (13.2 times the LCP material weight), as demonstrated in Supplementary Fig. 9.

Phototropic robot hand for signaling

This study reveals two distinct deformation modes: P and N phototropism that can be tuned by applying different light angles. Exploiting this capability, we developed a robot hand and an array with programmed sequential switching of P and N phototropism modes in response to varied light angles.

The robot hand consists of 5 LCP fingers with different initial inclinations (Fig. 5a). The varied inclinations allow a global light field to induce different P and N deformation modes in each finger. As shown in Fig. 5b, when a finger is aligned flat to the ground (e.g., finger 5), only light from nearly flat angles can trigger its N mode, while a finger with a larger angle to the ground (e.g., finger 1) has a wider region of light angles that can trigger its N mode.

This varied mode-switching performance of the fingers enables 6 different hand gestures to be generated from the global light actuation (Fig. 5c). When the light angle is within the P mode region of all fingers, a half-gripping gesture appears, and the degree of gripping can be tuned by altering the light angle. When the light angle is in the N mode region of finger 1 and the P mode region of the rest, only finger 1 bends inward while the others point toward the light. Increasing the number of fingers in the N mode by adjusting the light angle can generate a range of gripping gestures, culminating in a fist when a close-to-flat light triggers the N mode of all fingers.

Supplementary Movie 6 shows the multimodal motion of the phototactic robot hand. Notably, all these multimodal motions were generated merely based on a simple global light illumination. Using the same principles, we also developed a phototactic array that can be used for miniaturized displays or metamaterial manipulation (Supplementary Fig. 10).

Discussion

In conclusion, we presented a method for tunable and precise manipulation of light-driven LCP material based on revealing and utilizing the fundamental kinematics of global illumination-based actuation. By characterizing the feedback loop between light projection and material shape deformation, we elucidated the fundamental relationship between light field and the resulting deformation in thin-film LCP actuators. Our investigation revealed two basic deformation modes of the LCP actuator: P phototropism and N phototropism, in response to varying light angles. We also investigated the influence of light shielding on the deformation. Leveraging this understanding of the light-driven material systems, we developed a range of applications, including robotic crawlers, a ball drop-and-catch system, a robotic hand, and an array, that exploit the flexibility and multimodal tunable phototactic deformation capabilities of the system.

Importantly, the deformation in our PTM model is highly predictable, which provides precise actuation control with low computational requirements. This predictability is a key advantage over many other wireless field actuation approaches, where the deformation is often difficult to model and control.

Looking ahead, our proposed global illumination-based actuation method offers significant potential for application in miniature robotic systems. Firstly, the PTM model can be readily adapted to work with other thin-film light-driven materials, such as carbon-based bilayers, as long as they exhibit similar local photothermal deformation characteristics. This expandability broadens the range of materials that can be integrated into our approach. Secondly, the actuation in our method is based solely on global illumination, which can be easily set up and integrated into existing remote actuation systems. Importantly, this light-based approach does not require precise alignment, enabling the miniature light-driven systems to be easily scaled without adding complexity to the actuation mechanism. Furthermore, even for light-driven systems with specialized requirements, such as focused light actuation, our actuation modeling and control approach can still offer valuable insights. By providing a deeper understanding of the local deformation dynamics, our method can help improve the controllability and predictability of these light-driven systems.

While our proposed framework offers significant potential, it is crucial to acknowledge the ongoing challenges, particularly regarding the strength and response speed of light-driven actuators. These limitations can hinder the efficiency required for some applications. However, we are confident that continued advancements in materials science and engineering will be key to overcoming these challenges and expanding the range of viable use cases. Moreover, our current study has focused exclusively on actuators with uniaxial bending deformations. To unlock even greater potential in harnessing the phototactic manipulation for complex soft material systems, future research should explore new programmable deformation profiles, such as twisting and patterned deformations. Despite these remaining challenges, we anticipate that our method will open exciting new avenues in the development of untethered miniature light-driven systems.

Methods

Materials

The liquid crystal monomers RM23 and RM82 were purchased from Kindchem (Nanjing) Co., Ltd and used as received. Disperse Orange 3 (DO3; 90%) and Irgacure 2959 were purchased from Sigma-Aldrich to function as the photothermal agent and photoinitiator, respectively. The polyimide liquid for alignment liquid crystal in horizontal alignment ZKPI-4000 (STN-PI) and vertical alignment ZKPI-4070 (VA-PI) was purchased from POME Sci-tech Co., Ltd. Organic solvents dichloromethane (DCM, >99.8%) was purchased from Sigma-Aldrich.

LCP actuator fabrication

To prepare the LCP film, two glass slides were spin-coated with ZKPI-4000 and ZKPI-4070 respectively, and baked in an oven. Then the spin-coated surfaces were rubbed uniaxially with a flannel surface. The two slides were put together to form a cell with the rubbed surfaces facing each other, and a layer of aluminum tape (~72 μm) was placed in between as a spacer. The cell was then infiltrated on a 100 °C hotplate with molten LC mixture, which was prepared by dissolving 40.8 wt% RM23, 56.3 wt% RM82, 0.9 wt% Disperse Orange 3, and 2 wt% Irgaucure 2959 in DCM and evaporating the solvent on a 150 °C hotplate with magnetically stirring at 300 rpm. The LC mixture was filtered with a filter paper before infiltration. After fully infiltrated, the temperature of the hot plate was decreased to 40 °C. A 365 nm UV lamp was used to cure the film for 90 min. The LCP film was then peeled off from the opened cell.

The as-prepared LCP film was then cut to LCP actuators of specified sizes by a commercially available cutter (Silhouette Cameo 4). The three actuators of modular crawler were taped together using double-sided PET tape.

Characterization

The images and movies of LCP actuators and robots were recorded with a digital camera (Eos R6II, Canon) with a 100 mm macro lens. An orange-colored filter (LIPA) was installed on the lens to prevent overexposure to blue lights. The images in Figs. 2–5 were processed by removing the background color for a clear view. The temperature of the material was measured by an infrared camera (TiX580, Fluke). We used Python code to process the digital and IR images in attaining the bending angle and temperature distribution along the length of the material. The motion of robots was analyzed using the software Tracker (version 6.1.3). The light intensity was measured by an optical power meter (FieldBest). The Young’s modulus of the LCP was tested on a tensile machine (Z2.5, ZwickRoell).

Actuation of actuators and robots

We used a 20 W royal blue LED (λ ≈ 455 nm) with a 50 mm reflector (beam angle of 5°) in the actuation of LCP actuators. The light intensity was PWM controlled by an Arduino Uno. Another Arduino Uno controlled the light angle with a servo rotating the light source. The control signals of the two boards were sent from a PC with a Python program (the setup design see Supplementary Method 2.1). The analysis of the modular and shield light-driven crawlers was based on blue LEDs (20 W, ~455 nm, 50 mm reflector with beam angle of 5°) placed at 30° and 45° to the ground, respectively. The on-off actuation cycles were automatically applied by an Arduino Uno. In recording the bidirectional motion video, two blue LEDs with the same specification (20 W, ~455 nm, 50 mm reflector with beam angle of 5°) were installed at the left and right sides of the robot at 30° to the ground, the on-off of which were manually controlled. In the ball drop-and-catch system, the LCP actuator was controlled by a blue LED (20 W, ~455 nm, 50 mm reflector with beam angle of 5°) that linked to a servo, the light intensity and angle of which were controlled by Arduino Uno boards. The control signal was sent from a Python program, which also controlled the LCD screen display (Supplementary Method 4).

The ball-collecting was actuated manually by two flashlights (15 W, ~455 nm) in drop-and-catch, and manually by two LEDs (20 W, ~455 nm, 50 mm reflector with beam angle of 5°) placed at 30° to the ground in load capacity test.

The robot hand and array were actuated by a blue LED (20 W, ~455 nm, 50 mm reflector with beam angle of 5°).

Data Availability

No datasets were generated or analysed during the current study.

References

Kotikian, A. et al. Untethered soft robotic matter with passive control of shape morphing and propulsion. Sci. Robot. 4, eaax7044 (2019).

Zhao, Y. et al. Twisting for soft intelligent autonomous robot in unstructured environments. Proc. Natl. Acad. Sci. USA 119, e2200265119 (2022).

Shin, B. et al. Hygrobot: a self-locomotive ratcheted actuator powered by environmental humidity. Sci. Robot. 3, eaar2629 (2018).

Fu, L. et al. A humidity-powered soft robot with fast rolling locomotion. Research 2022, 9832901 (2022).

Hu, W., Lum, G. Z., Mastrangeli, M. & Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 554, 81–85 (2018).

Kim, Y., Parada, G. A., Liu, S. & Zhao, X. Ferromagnetic soft continuum robots. Sci. Robot. 4, eaax7329 (2019).

Da Cunha, M. P., Debije, M. G. & Schenning, A. P. Bioinspired light-driven soft robots based on liquid crystal polymers. Chem. Soc. Rev. 49, 6568–6578 (2020).

Dong, L. & Zhao, Y. Photothermally driven liquid crystal polymer actuators. Mater. Chem. Front. 2, 1932–1943 (2018).

Chen, P. et al. Light-fueled hydrogel actuators with controlled deformation and photocatalytic activity. Adv. Sci. 9, 2204730 (2022).

Ma, C. et al. A multiresponsive anisotropic hydrogel with macroscopic 3D complex deformations. Adv. Funct. Mater. 26, 8670–8676 (2016).

Yang, Y. & Shen, Y. Light-driven carbon-based soft materials: principle, robotization, and application. Adv. Opt. Mater. 9, 2100035 (2021).

Rogoz, M., Zeng, H., Xuan, C., Wiersma, D. S. & Wasylczyk, P. Light-driven soft robot mimics caterpillar locomotion in natural scale. Adv. Opt. Mater. 4, 1689–1694 (2016).

Li, C. et al. Supramolecular–covalent hybrid polymers for light-activated mechanical actuation. Nat. Mater. 19, 900–909 (2020).

Miskin, M. Z. et al. Electronically integrated, mass-manufactured, microscopic robots. Nature 584, 557–561 (2020).

Han, M. et al. Submillimeter-scale multimaterial terrestrial robots. Sci. Robot. 7, eabn0602 (2022).

Li, M., Wang, X., Dong, B. & Sitti, M. In-air fast response and high speed jumping and rolling of a light-driven hydrogel actuator. Nat. Commun. 11, 3988 (2020).

Zhao, Y. et al. Soft phototactic swimmer based on self-sustained hydrogel oscillator. Sci. Robot. 4, eaax7112 (2019).

Zhao, Y. et al. Sunlight-powered self-excited oscillators for sustainable autonomous soft robotics. Sci. Robot. 8, eadf4753 (2023).

Yan, Y. et al. Artificial phototropic systems for enhanced light harvesting based on a liquid crystal elastomer. Adv. Intell. Syst. 3, 2000234 (2021).

Qian, X. et al. Artificial phototropism for omnidirectional tracking and harvesting of light. Nat. Nanotechnol. 14, 1048–1055 (2019).

Zeng, H., Wani, O. M., Wasylczyk, P., Kaczmarek, R. & Priimagi, A. Self-regulating iris based on light-actuated liquid crystal elastomer. Adv. Mater. 29, 1701814 (2017).

Zhu, Q. L. et al. Light-steered locomotion of muscle-like hydrogel by self-coordinated shape change and friction modulation. Nat. Commun. 11, 5166 (2020).

Palagi, S. et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 15, 647–653 (2016).

Zeng, H. et al. Light-fueled microscopic walkers. Adv. Mater. 27, 3883–3887 (2015).

Hu, Y. et al. A graphene-based bimorph structure for design of high performance photoactuators. Adv. Mater.27, 7867–7873 (2015).

Wang, W. et al. Direct laser writing of superhydrophobic PDMS elastomers for controllable manipulation via Marangoni effect. Adv. Funct. Mater. 27, 1702946 (2017).

Hou, K. et al. Programmable light-driven swimming actuators via wavelength signal switching. Sci. Adv. 7, eabh3051 (2021).

Zuo, B., Wang, M., Lin, B.-P. & Yang, H. Visible and infrared three-wavelength modulated multi-directional actuators. Nat. Commun. 10, 4539 (2019).

Acknowledgements

Y.J.T. acknowledges NUS start-up grant (Singapore Ministry of Education Academic Research Fund Tier 1).

Author information

Authors and Affiliations

Contributions

J.Z. and Y.J.T. conceptualized this work. J.Z. carried out experiments, collected and analyzed the overall data. J.Z., J.W., and J.S.K. contributed to mathematical and FEM models. J.Z. and K.Y. formulated the approach for the measurement of LCP actuator’s deformation and temperature. J.Z. and J.W. designed the light-driven robots and robotic systems. J.Z. and Y.J.T. wrote the manuscript. Y.J.T. supervised this study. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, J., Wan, J., Yu, K. et al. Unlocking holistic control of a phototropic liquid crystal polymer by global illumination. npj Robot 3, 7 (2025). https://doi.org/10.1038/s44182-025-00024-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44182-025-00024-5