Abstract

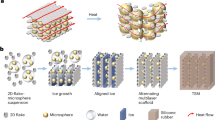

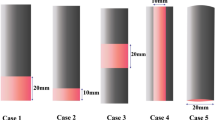

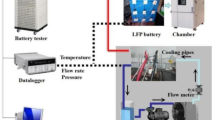

Thermal runaway, a major battery safety issue, is triggered when the local temperature exceeds a threshold value resulting from slower heat dissipation relative to heat generation inside the cell. However, improving internal heat transfer is challenged by the low thermal conductivity of metal current collectors (CCs) and challenges in manufacturing nonmetal CC foils at large scales. Here we report a rapid temperature-responsive nonmetallic CC that can substitute benchmark Al and Cu foils to enhance battery safety. The nonmetallic CC was fabricated through a continuous thermal pressing process to afford a highly oriented Gr foil on a hundred-meter scale. This Gr foil demonstrates a high thermal conductivity of 1,400.8 W m−1 K−1, about one order of magnitude higher than those of Al and Cu foils. Importantly, LiNi0.8Co0.1Mn0.1O2||graphite cells integrated with these temperature-responsive foils show faster heat dissipation, eliminating the local heat concentration and circumventing the fast exothermic aluminothermic and hydrogen-evolution reactions, which are critical factors causing the thermal failure propagation of lithium-ion battery packs.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the main text or Supplementary Information. Source data are provided with this paper.

References

Liu, H. et al. A disordered rock salt anode for fast-charging lithium-ion batteries. Nature 585, 63–67 (2020).

Turcheniuk, K., Bondarev, D., Singhal, V. & Yushin, G. Ten years left to redesign lithium-ion batteries. Nature 559, 467–470 (2018).

Needell, Z. A., McNerney, J., Chang, M. T. & Trancik, J. E. Potential for widespread electrification of personal vehicle travel in the United States. Nat. Energy 1, 16112 (2016).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2010).

Song, L., Zheng, Y., Xiao, Z., Wang, C. & Long, T. Review on thermal runaway of lithium-ion batteries for electric vehicles. J. Electron. Mater. 51, 30–46 (2022).

Feng, X., Ren, D., He, X. & Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 4, 743–770 (2020).

Wang, Z., Yang, H., Li, Y., Wang, G. & Wang, J. Thermal runaway and fire behaviors of large-scale lithium ion batteries with different heating methods. J. Hazard. Mater. 379, 120730 (2019).

Li, Y. et al. Thermal runaway triggered by plated lithium on the anode after fast charging. ACS Appl. Mater. Interfaces 11, 46839–46850 (2019).

Longchamps, R. S., Yang, X. G. & Wang, C. Y. Fundamental insights into battery thermal management and safety. ACS Energy Lett. 7, 1103–1111 (2022).

Yang, X.-G., Liu, T. & Wang, C.-Y. Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat. Energy 6, 176–185 (2021).

Wang, C. Y. et al. Lithium-ion battery structure that self-heats at low temperatures. Nature 529, 515–518 (2016).

Wang, C., He, L., Sun, H., Lu, P. & Zhu, Y. Battery pack, vehicle and energy storage device. China Patent CN110165118B (2019).

Huang, W., Feng, X., Han, X., Zhang, W. & Jiang, F. Questions and answers relating to lithium-ion battery safety issues. Cell Reports Phys. Sci. 2, 100285 (2021).

Janna, W. S. Engineering Heat Transfer (CRC Press, 2018).

Ye, Y. et al. Ultralight and fire-extinguishing current collectors for high-energy and high-safety lithium-ion batteries. Nat. Energy 5, 786–793 (2020).

Liu, Z. et al. Stretchable separator/current collector composite for superior battery safety. Energy Environ. Sci. 15, 5313–5323 (2022).

Choudhury, R., Wild, J. & Yang, Y. Engineering current collectors for batteries with high specific energy. Joule 5, 1301–1305 (2021).

Dai, W. et al. Metal-level thermally conductive yet soft graphene thermal interface materials. ACS Nano 13, 11561–11571 (2019).

Balandin, A. A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 10, 569–581 (2011).

Balandin, A. A. et al. Superior thermal conductivity of single-layer graphene. Nano Lett. 8, 902–907 (2008).

Faugeras, C. et al. Thermal conductivity of graphene in corbino membrane geometry. ACS Nano 4, 1889–1892 (2010).

Han, Z. & Ruan, X. Thermal conductivity of monolayer graphene: convergent and lower than diamond. Phys. Rev. B 108, L121412 (2023).

Xin, G. et al. Highly thermally conductive and mechanically strong graphene fibers. Science 349, 1083–1087 (2015).

Seol, J. H. et al. Two-dimensional phonon transport in supported graphene. Science 328, 213–216 (2010).

Peng, L. et al. Ultrahigh thermal conductive yet superflexible graphene films. Adv. Mater. 29, 1700589 (2017).

Chen, Y. et al. Reduced graphene oxide films with ultrahigh conductivity as Li-ion battery current collectors. Nano Lett. 16, 3616–3623 (2016).

Beidaghi, M., Wang, Z., Gu, L. & Wang, C. Electrostatic spray deposition of graphene nanoplatelets for high-power thin-film supercapacitor electrodes. J. Solid State Electrochem. 16, 3341–3348 (2012).

Qian, W. et al. Superhigh electromagnetic interference shielding of ultrathin aligned pristine graphene nanosheets film. Adv. Mater. 32, 1907411 (2020).

Savchak, M. et al. Highly conductive and transparent reduced graphene oxide nanoscale films via thermal conversion of polymer-encapsulated graphene oxide sheets. ACS Appl. Mater. Interfaces 10, 3975–3985 (2018).

Chen, X. et al. Graphitization of graphene oxide films under pressure. Carbon N. Y. 132, 294–303 (2018).

Zhang, G., Shaffer, C. E., Wang, C.-Y. & Rahn, C. D. Effects of non-uniform current distribution on energy density of Li-ion cells. J. Electrochem. Soc. 160, A2299–A2305 (2013).

Zhao, Y. et al. Highly reduced graphene assembly film as current collector for lithium ion batteries. ACS Sustain. Chem. Eng. 9, 8635–8641 (2021).

Peng, L. et al. Multifunctional macroassembled graphene nanofilms with high crystallinity. Adv. Mater. 33, 2104195 (2021).

Fu, H. et al. Rapid soldering of flexible graphene assembled films at low temperature in air with ultrasonic assistance. Carbon N. Y. 158, 55–62 (2020).

Fu, H. et al. Ultrasonic-assisted soldering for graphite films as heat sinks with durably superior heat dissipating efficiency. Adv. Compos. Hybrid Mater. 5, 2154–2162 (2022).

Du, X. et al. Visualizing two-dimensional internal temperature distribution in cylindrical Li-ion cells. J. Power Sources 446, 227343 (2020).

Huang, L. et al. Uncovering LiH triggered thermal runaway mechanism of a high-energy LiNi0.5Co0.2Mn0.3O2/graphite pouch cell. Adv. Sci. 8, 2100676 (2021).

Wang, H. et al. Fire and explosion characteristics of vent gas from lithium-ion batteries after thermal runaway: a comparative study. eTransportation 13, 100190 (2022).

Scott, G. S., Jones, G. W. & Scott, F. E. Determination of ignition temperatures of combustible liquids and gases. Anal. Chem. 20, 238–241 (1948).

Dadbakhsh, S., Mertens, R., Hao, L., Van Humbeeck, J. & Kruth, J. P. Selective laser melting to manufacture ‘in situ’ metal matrix composites: a review. Adv. Eng. Mater. 21, 1801244 (2019).

La, P. et al. Bulk nanocrystalline Fe3Al-based material prepared by aluminothermic reaction. Adv. Mater. 18, 733–737 (2006).

Udhayabanu, V., Singh, N. & Murty, B. S. Mechanical activation of aluminothermic reduction of NiO by high energy ball milling. J. Alloys Compd. 497, 142–146 (2010).

Hosseini, S. N., Karimzadeh, F. & Enayati, M. H. Mechanochemical synthesis of Al2O3/Co nanocomposite by aluminothermic reaction. Adv. Powder Technol. 23, 334–337 (2012).

Li, M. et al. Graphene: preparation, tailoring, and modification. Exploration 3, 20210233 (2023).

Soo, X. Electrospun PEO/PEG fibers as potential flexible phase changematerials for thermal energy regulation. Exploration 4, 2023001 (2024).

Dong, L. et al. A large-area, flexible, and flame-retardant graphene paper. Adv. Funct. Mater. 26, 1470–1476 (2016).

Attia, N. F., Elashery, S. E. A., Zakria, A. M., Eltaweil, A. S. & Oh, H. Recent advances in graphene sheets as new generation of flame retardant materials. Mater. Sci. Eng. B 274, 115460 (2021).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (22279097, 52127816 and 52172217), Natural Science Foundation of Guangdong Province (2021A1515010144) and Shenzhen Science and Technology Program (JCYJ20210324120400002), the National Key Research and Development Program of China (2020YFA0715000), ‘Coated current collector for battery performance improvement’ (CONTACT, Ref/10041084), ‘Thin and lightweight current collector for lithium-ion battery’ (CONDUCTOR, Ref/10047927). The authors acknowledge K. Liu and M. Wu for providing single-crystal graphite. The authors thank W. Liu for providing HOPG and XRD ϕ-scan measurements. The authors acknowledge B. Gao and S. Li for assistance with the assembly of large cells and S. Margadonna for helpful data discussions.

Author information

Authors and Affiliations

Contributions

L.L., J.Y., R.T., L.M. and D.H. conceived and directed the project. L.L. and W.S. carried out the syntheses, characterizations and battery testing. L.L. wrote the original draft. R.T., X.L. and Z.Z. assisted in visualizing the manufacturing process and working principles. C.L., Y.Z. and H.W. helped perform the thermal runaway tests and analyze the data. Y.Z. and Y. X. guided the welding of CCs with metal tabs. R.T., C.T.J.L. and H.Z. contributed to theory and model development. L.L., J.Y., R.T, X.Z., Z.K., F.V., L.M. and D.H. revised the manuscript and suggested experiments. All authors participated in the discussion of the results, commented on the implications and fully approved the content of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemical Engineering thanks Peter Bøggild, Donal Finegan and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Fabrication of the large-area Gr using GO+3wt.% PEA precursor.

a, Coating. b, Drying. c, Dried precursor film. d, Cutting. e, Annealing, f, Rolling compression.

Extended Data Fig. 2 Characterization of the oriented structure of Gr foils.

SAXS patterns and corresponding azimuthal angle plots of a, b, GO film. c, d, pristine Gr film without addition of PEA and e, f, Gr foil with addition of PEA.

Extended Data Fig. 3 Electrochemical performance of high-capacity pouch cells.

a, b, Photograph of 5 and 10 Ah pouch cell with Gr CCs. c, Charge-discharge curves of 10 Ah pouch cell with Gr||Gr foils at 0.05 C. d, Fast charging and discharging profiles at 2 C. e, Corresponding temperature distributions at different stages from II to IX. f, Nail penetration test on 5 Ah Gr||Gr cell.

Extended Data Fig. 4 The electrochemical activity of Gr CCs after cycling in Gr||Gr pouch cells.

a, Photograph of the unfolded electrode disassembled from a pouch cell after cycling. b, XRD patterns of Gr foil CCs before and after cycling. c, Cross-sectional SEM image of the anode layer after cycling at 0.2 C. d, Corresponding cross-sectional SEM image of Gr foil CC. e, The cross-sectional SEM image of the anode layer before cycling. f, The original cross-sectional SEM image of Gr foil before cycling.

Extended Data Fig. 5 Physical characterization and practical application of 10 µm-thick Gr foil.

a, Top-view and b, cross-sectional SEM images of 10 µm-thick Gr foil. c, Stress-strain curves of 10 µm-thick Gr foil. d, f, h, SAXS patterns and corresponding azimuthal angle plots of Gr foils with thickness of (d) 10, (f) 17, and (h) 40 µm. e, g, i, WAXS patterns and corresponding azimuthal angle plots of Gr foils with thickness of (e) 10 µm, (g) 17 µm, and (i) 40 µm. j-m, Application of 10 µm-thick Gr foil as CC for (j) adapting in coating machine (Cu foil for traction), (k) electrode coating, (l) electrode drying, and (m) subsequent calendaring process.

Supplementary information

Supplementary Information

Supplementary Figs. 1–47, Tables 1–9, Notes 1–3 and References 1–42.

Supplementary Video 1

Continuous and large-scale coating process.

Supplementary Video 2

Automated rolling process.

Supplementary Video 3

Portable charger charging a cell phone.

Supplementary Video 4

Nail penetration of 2 Ah Al–Cu cell.

Supplementary Video 5

Nail penetration of 2 Ah Gr–Gr cell.

Supplementary Video 6

Nail penetration of 5 Ah Gr–Gr cell.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Extended Data Fig. 2

Statistical source data.

Source Data Extended Data Fig. 3

Statistical source data.

Source Data Extended Data Fig. 4

Statistical source data.

Source Data Extended Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, L., Yang, J., Tan, R. et al. Large-scale current collectors for regulating heat transfer and enhancing battery safety. Nat Chem Eng 1, 542–551 (2024). https://doi.org/10.1038/s44286-024-00103-8

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s44286-024-00103-8

This article is cited by

-

Upscaling high-areal-capacity battery electrodes

Nature Energy (2025)

-

Fabrication of graphene sheets coated with silver nanorods nanocomposite lubricant and their tribological behavior under current carrying

Journal of Materials Science (2025)