Abstract

Membranes based on atom-thin porous single-layer graphene (PG) have shown attractive performance for diverse separation applications, especially gas separation and carbon capture. However, despite a decade of research, a scalable synthesis of PG membranes has remained under question. The literature on gas separation using porous graphene membranes is based on complex methods that limit membrane size and reproducibility. Here we introduce several interventions that substantially reduce PG membrane cost, allow uniform pore formation in a large area and enable the preparation of large-area PG membranes with attractive performance. We show that mass transfer of the oxidant plays a crucial role in achieving uniform oxidation of large-area graphene. Crack formation during the transfer of graphene, which also limits reproducibility, is eliminated using a protocol that does not require delicate floating and handling of graphene, allowing the realization of a high-performance 50-cm2 graphene membrane in a cross-flow module.

Similar content being viewed by others

Main

Nanoporous atomically thin membranes (NATMs) have emerged as a promising platform for effectively separating molecules and ions, exploiting mass, size and affinity differences1,2,3,4,5,6. Despite progress on the fundamental aspects of NATM, including transport mechanism, pore incorporation and membrane fabrication, this field faces an outstanding critical challenge on the scalability of NATMs. The most popular and studied NATM is porous single-layer graphene (PG). The successful incorporation of carbon dioxide (CO2)-selective pores in PG has led to attractive performance for carbon capture2,7,8,9. This involves selective separation of CO2 from nitrogen (N2). It is crucial to develop high-performance carbon capture membranes that reduce the energy consumption and the associated cost of carbon capture from point-emission sources. Indeed, techno-economic assessments of the capture process based on high-performance PG membranes indicate that the energy efficiency of capture can be substantially improved compared with the commercial amine-based absorption process10,11. This is mainly because the membrane processes do not require thermal energy but rather rely on electrical energy for feed compression and permeate evacuation12,13. This is also because PG membranes yield extremely high CO2 permeance resulting from their atom-thin selective layer. This minimizes the required membrane area and the capture process footprint. This, combined with the exceptional chemical stability of graphene, makes capture based on PG membranes advantageous for carbon capture compared with the state-of-the-art membranes based on polymers14,15, zeolites16,17, metal–organic frameworks18,19, covalent organic frameworks20,21 and carbon molecular sieves22,23. A low-footprint capture process is attractive for application in the transportation sector, especially the international shipping industry, responsible for 2–3% of global CO2 emissions.

An early proof-of-concept study on the selective transport of CO2 from PG was demonstrated by Bunch and coworkers in 2012 (ref. 2). This was a fundamental study from a micrometer-sized exfoliated graphene with only a couple of pores responsible for gas transport. However, for practical membranes, one must prepare macroscopic films. For this, polycrystalline graphene, produced by chemical vapor deposition (CVD) on Cu foil, has become a standard material24,25,26. Yet, it is challenging to prepare a large-area PG membrane. Several aspects of the PG membrane must be debottlenecked to become commercially attractive for carbon capture. This includes the reduction of membrane element cost, the scalable incorporation of CO2-selective pores in graphene and the crack-free fabrication of membranes. These challenges are elaborated below.

Currently, the cost of commercial CVD graphene is extremely high for its application in carbon capture membranes. It is unclear whether low-cost Cu foils (approximately US$10 m−2), which contain micrometer-sized particulate contaminations from rough processing, can be suitable for producing graphene for CO2-selective membranes. This is mainly because strict control of substrate smoothness and particulate contaminations is needed to achieve attractive CO2/N2 selectivity given the sub-ångström difference in the size of the two molecules. Literature studies often use expensive Cu foils (US$500–10,000 m−2) or delicate processing methods (for example, electropolishing) to prepare high-performance graphene membranes for carbon capture7,9,24,27,28,29. This high raw material cost is prohibitive for the carbon capture application. By comparison, polymeric membranes for carbon capture have a membrane element cost of US$20–50 m−2 (refs. 30,31). Incidentally, the major cost of CVD graphene is related to the expensive Cu foil. However, Cu foils are also produced cheaply (approximately US$10 m−2). An important challenge here is that low-cost Cu foils have surface imperfections in the form of micrometer-sized particles and large grooves and scratches. These imperfections are detrimental to the fabrication of high-quality graphene membranes for carbon capture because they compromise the integrity of the suspended graphene by generating cracks7,32,33.

The second challenge concerns the lack of demonstration of CO2-selective pore incorporation in graphene over a large area. Pores in graphene are carbon vacancy defects incorporated by removing atoms from the basal plane. Chemical routes involving the gasification of the lattice by oxidation are intrinsically more scalable than carbon-knockout routes using energetic beams. For oxidation, oxidative plasma34, oxygen (O2) (refs. 35,36), ultraviolet light/ozone (O3) (ref. 33) or O3 (refs. 9,29) have been demonstrated. However, they involved sophisticated setups that are challenging to scale up. The uniformity of pore incorporation over a large area is not demonstrated.

The third challenge relates to fabricating large-area PG membranes while avoiding cracks in graphene. Cracks typically manifest during the transfer of CVD graphene from the Cu foil to porous support or during pressurization of the PG membrane. Wafer-scale24 and roll-to-roll26 transfer have been demonstrated in fabricating graphene devices for electronic applications. However, while these applications are tolerant to macroscopic cracks in graphene, gas separation membranes are not. Crack-free PG is essential for selective transport between similarly sized gas molecules such as CO2 and N2 under pressurized conditions. Centimeter-scale PG membranes have been demonstrated for nanofiltration after stitching cracks using interfacial polymerization33,37,38. However, this approach has not been demonstrated for gas separation. Prior works have shown that cracks in PG can be avoided by using gas-permeable mechanically reinforcing support film (MRF). Typically, MRF is deposited on PG, and the Cu foil is removed by wet-chemical etching, after which the floating composite PG–MRF is scooped on the desired porous support24,39,40,41. MRF can be a nanoporous carbon (NPC) film7, highly permeable polymers such as poly[1-(trimethylsilyl)-1-propyne] (PTMSP)8, polydimethylsiloxane42 or a composite film such as multiwalled carbon nanotube deposited on NPC43. However, the success rate of achieving centimeter-scale gas-selective membranes (defined as the number of selective membranes normalized by the number of attempts), even using the MRF strategy, remains low. This is mainly because the transfer protocol involves floating and scooping steps where cracks can easily develop in PG. Transfer methods involving careful scooping of floating PG are also extremely challenging to scale up. Therefore, a key challenge is to develop a membrane fabrication route avoiding careful scooping of graphene, and where the success rate is nearly 100%.

Here, we present several advances toward scaling up PG membranes for carbon capture. We demonstrate the successful use of a low-cost Cu foil (US$10 m−2) to prepare PG membranes with attractive CO2/N2 separation performance with a near 100% success rate. A simple protocol was developed to eliminate large contaminant particles on the surface of low-cost Cu foil. A large reactor for pore incorporation was implemented, which allowed the incorporation of uniform pores in large-area graphene (500 cm2) in a reproducible manner. A systematic study of graphene oxidation revealed that O3 mass transfer (velocity), as opposed to the commonly studied reaction kinetics (temperature and time), dominates pore formation kinetics. A facile and user-friendly transfer protocol was developed, completely avoiding the floating step, resulting in a highly reproducible synthesis. These interventions yielded attractive performance with a near 100% success rate from PG membranes.

Results

High-quality graphene from low-cost Cu foil

For synthesizing high-quality large-area graphene on a low-cost Cu foil, a CVD system consisting of a 160-cm-long furnace with a uniform heating zone of 110 cm, a gas delivery and a pressure management subsystem was developed to achieve a uniform temperature and to manipulate gas composition and pressure in the reactor from vacuum to 1 bar (Fig. 1a,b and Supplementary Fig. 1). Two dumbbell-shaped blocks made of Cu are placed at the end of the reactor as radiation shields to prevent excessive heating of flanges sealing the reactor. Two large coupons of Cu foils, each with a size of 11 × 26 cm2, could be introduced for graphene synthesis (Fig. 1c).

a, A home-built CVD reactor for the synthesis of large-area graphene. b, Three-dimensional cross-section model of the reaction chamber equipped with radiation shields, an alumina tube and a 110-cm-long sample plate inside the heating zone. c, Two 11 × 26 cm2 single-layer graphene coupons synthesized in a single batch in the CVD reactor. d, The side view of the CVD reactor hosting a 16-cm-diameter alumina tube. e–h, SEM images of graphene surface grown on as-received (e) and acid-treated (f) Cu foil and the corresponding contamination particle density (for as-received (g) and acid-treated (h) Cu foil). The error bar refers to the standard deviation in particle density across three different spots for different particle sizes. The center of the error bar represents the average particle density calculated from the SEM analysis. i–n, Optical microscope images of as-received (i and j) and acid-treated (k and l) Cu foil before (i and k) and after (j and l) graphene growth. Profilometry mapping images of as-received (m) and acid-treated (n) Cu foil after graphene growth. o, The Raman spectrum of graphene transferred on a Si/SiO2 wafer. p, An AC-HRTEM image of single-layer graphene synthesized in this work. q,r, Raman mappings of D and G peak intensity ratio (ID/IG, q) and 2D and G peak intensity ratio (I2D/IG, r) across an area of 48 × 80 µm2. RMS, root mean square.

Imperfection in Cu foil consists of surface contaminations (particles) and grooves. High-purity expensive Cu foils have a low concentration of particles and have been reported to synthesize graphene after simple solvent washing. They are also free of large grooves and scratches. However, their cost is prohibitive for membrane application (Supplementary Table 1). For low-cost Cu, micrometer-sized contamination particles are present on the surface of the Cu foil and are probably deposited during the process of rolling Cu foils. Another source of contamination, irrespective of Cu foil, is the reaction between Cu vapor and the reactor wall made of a fused quartz tube, where SiOx particles are formed. These particles eventually deposit on the Cu foil, affecting graphene quality44 (Supplementary Fig. 2a). These were largely eliminated by placing a high-purity (99.7%) alumina tube (diameter ∅ = 16 cm) inside the quartz tube, which screened off the quartz tube from Cu vapor7,8,43,45 (Fig. 1d).

We chose a low-cost Cu foil (down to US$10 m−2; Supplementary Table 1) and developed a simple protocol for removing contamination, grooves and scratches. Micrometer-sized particles formed by several elements (Ca, K, Al or Cl) could be observed on the as-received Cu foils (Supplementary Fig. 2b). A facile protocol involving submerging Cu foil in a dilute nitric acid solution was developed46,47. Dissolution of the Cu surface in the nitric acid effectively detached the particles from the surface of the Cu foil. An underlying challenge here is the tradeoff between removing particles and pittings of Cu foil as a function of treatment time and acid concentration. A treatment time of 10 min and an acid concentration of 4 wt% were found to be optimal. Scanning electron microscopy (SEM)-based mapping of a relatively large area (~0.2 mm2; Supplementary Figs. 3 and 4) of graphene was used to analyze the particle density on the surface (Fig. 1e–h). Acid treatment significantly reduced the density of particles. The population of particles smaller than 1 µm was reduced by 70%. Importantly, particles larger than 1 µm were eliminated. This is crucial for reducing cracks during graphene transfer because the macroscopic particles lead to pinhole defects during transfer. The acid treatment also smoothened grooves and scratches on the Cu foil. Optical microscopy images (Fig. 1i–l) and profilometry mapping analysis (Fig. 1m,n and Supplementary Fig. 5) demonstrate that graphene produced on acid-treated Cu foil has a significantly lower root-mean-square surface roughness (150 nm) compared with that on as-received Cu foil (261 nm). Therefore, the two interventions, namely acid pretreatment and using the alumina tube in the CVD reactor, effectively reduced the surface contamination of graphene.

As-synthesized graphene was characterized by Raman spectroscopy. Figure 1o shows a spectrum where the two characteristic peaks of graphene, G and 2D, could be observed at 1,589 and 2,678 cm−1, respectively. The D peak at ~1,350 cm−1, attributed to lattice defects, was negligible, confirming that high-quality graphene can be synthesized on a low-cost Cu foil. A 2D/G peak intensity ratio of ~2.6 confirms that the graphene was a single layer. High-resolution aberration-corrected transmission electron microscopy (AC-HRTEM) further confirmed that graphene was a single layer (Fig. 1p). Raman mappings (48 × 80 µm2 area) of the peak intensity ratio for D/G (ID/IG: 0.05 ± 0.02; Fig. 1q) and 2D/G (I2D/IG: 2.15 ± 0.35; Fig. 1r) confirmed uniformity at this length scale. Characterization of graphene at several locations along the 55-cm-long synthesis zone in the CVD reactor confirmed macroscopic uniformity (Supplementary Fig. 6).

Scalable incorporation of CO2-selective pores in graphene

Oxidation of graphene in an O3 flow leads to the formation of energy-minimizing O clusters on graphene48,49. These clusters yield a pore at their core upon gasification50. Recently, a simplified process of decoupling pore nucleation and expansion involving exposing graphene to O3 followed by heat treatment or light exposure was reported9,50,51. However, this approach has been limited to preparing small coupons. Implementing this concept for large-area PG requires developing a large-area reactor with a uniform reaction zone and the development of a dedicated protocol for incorporating uniform pores.

A 12-cm-diameter tubular reactor was implemented to fabricate a large-area PG (Fig. 2a; experimental setup shown in Supplementary Fig. 7). This reactor could house an 11-cm-wide and 55-cm-long graphene coupon. The reactor was connected to an O3 generator, yielding 8% O3 in O2. An evacuation and gas delivery system was designed to rapidly exchange the gas environment (argon (Ar), hydrogen (H2) and O3) and to attain control over the reaction time. Several critical steps were identified and implemented in sequence. These are the removal of atmospheric contaminations on graphene, oxidation of graphene, gasification for pore generation and, finally, reduction of CuO formed during the O3 exposure step. The corresponding conditions are detailed in Fig. 2b.

a, A schematic illustration of the ozone functionalization setup, where T indicates the sample temperature. b, Oxidation schemes with corresponding temperature profiles used in the process. c,d, Photos of graphene resting on Cu before (c) and after (d) oxidation, where the color change of oxidized Cu can be visualized. e, Raman spectra of graphene under various temperatures for oxidation. The spectra have been normalized to the G-band intensity. f, Raman mapping of D/G peak intensity ratio of graphene oxidized at 90 °C across an area of 20 × 40 µm2.

Atmospheric contaminations deposit on the graphene surface when they are stored. If not removed, they hinder the oxidation of graphene. More importantly, depending on the coverage of contaminations, they make it challenging to achieve reproducible results. We found this to be an extremely critical step. Therefore, graphene was cleaned by heating under a reducing atmosphere of H2/Ar mixture at 600 °C. Although a lower temperature (500 °C) was also effective, improved reproducibility was observed when heating to at least 600 °C. Storage of CVD graphene also tends to generate CuO on the Cu foil, which makes the surface rough52. Heating under a reduced atmosphere helped to smoothen the surface (Supplementary Fig. 8). This step was also crucial to obtain a smooth Cu/graphene surface, which was important for successful membrane fabrication. It should be noted that this step can be avoided when pore formation is implemented immediately after the synthesis of graphene.

For oxidation, the reactor temperature was lowered to the oxidation temperature, and the H2/Ar atmosphere was exchanged with O3. Samples were exposed to O3 for a given period of time, after which they were cooled down to room temperature. O clusters are formed on graphene during this step. The extent of oxidation was increased by increasing the reaction time, temperature or O3 velocity (the latter is discussed in ‘Reaction kinetics versus mass transfer in oxidation reactor’ section). To incorporate pores in the O cluster, the oxidation with O3 was stopped, and the reactor was heated to 150 °C to facilitate the gasification of the clusters.

We observed that the oxidation step also resulted in the oxidation of Cu foil, which could be easily identified by a change in color to an intense red-orange (Fig. 2c,d and Supplementary Fig. 9). This increased the foil’s surface roughness, making graphene transfer challenging. Therefore, a reduction step was implemented at 600 °C.

Pore incorporation in PG is indicated by a monotonic increase in ID/IG to 1.38 ± 0.08 when the oxidation temperature was increased from 40 °C to 90 °C (Fig. 2e). The intensity of the 2D peak decreased as a function of oxidation consistent with the formation of high-density O clusters, which makes graphene nanocrystalline. As oxidation progressed, an obvious D′ peak appeared on the shoulder of the G peak with a D′/G peak ratio higher than 0.8, which confirmed the formation of carbon vacancies in graphene. This was also confirmed by gas permeation studies (see ‘Crack-free transfer of large-area graphene to porous support’ section).

The Ramam mapping (20 × 40 µm2) of ID/IG from the oxidized sample shows that oxidation was uniformly implemented at this length scale (Fig. 2f). A systematic study of the mass transfer led to uniform oxidation in the entire oxidation zone (see ‘Reaction kinetics versus mass transfer in oxidation reactor’ section). Overall, the home-built reactor allowed the oxidation of large graphene coupons (500 cm2) to form large-area PG.

Crack-free transfer of large-area graphene to porous support

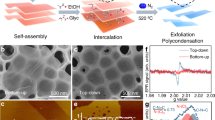

The MRF approach has been reported to address the crack formation in graphene during its transfer (Supplementary Fig. 10). Although centimeter-scale membranes have been reported, the success rate has been low (Supplementary Note 1) because of the stress generated in the film during wet-chemical etching of the film where the film is floated. To address this issue, we developed a facile transfer strategy involving a membrane module architecture (Fig. 3a,b). This involved coating an MRF (PTMSP) on PG with a target thickness close to 1 µm (Fig. 3c). The resulting Cu–PG–MRF was placed on a porous membrane support (polyethersulfone (PES), ~0.2-µm pores; Fig. 3d) resting on a macroporous stainless-steel (SS; Fig. 3e) mesh. Step-by-step assembly of the module with a stacking order of Cu–PG–MRF–PES–SS mesh is illustrated in Fig. 3f. The module was sealed by two rubber gaskets (Fig. 3b) and was compressed by two cover plates (Fig. 3f(i,ii)).

a,b, A schematic illustration of the graphene transfer strategy (a) and the architecture of the membrane module (b). c, An optical microscope image of the MRF transferred on a Si/SiO2 wafer. Inset: the film thickness characterization. d,e, SEM images of commercial PES support (d) and SS mesh (e). Insets: pictures of the two supports. f, Pictures of stacked membrane assembly hosting Cu–PG–MRF–PES–SS mesh (i and ii), etching setup for Cu (iii) and as-prepared graphene membrane module after etching Cu foil (iv). g–i, Optical (g) and SEM (with high (h) and low (i) magnification) images of graphene surface after removal of Cu. j,k, A ~8 × 12 cm2 graphene coupon (j) is cut into twenty-four 2 × 2 cm2 small coupons (k). l, All 24 coupons in j lead to successful 1-cm-scale membranes. Half of the membrane modules were assembled with transparent cover plates to reveal the sealing.

The stacking order, Cu–PG–MRF–PES–SS mesh, exposes Cu foil on one side of the module, allowing one to etch and remove Cu directly from the assembled module. This effectively eliminated the need to float graphene. After sealing the module, the exposed Cu was placed in contact with a cell hosting a Cu etchant (1 M FeCl3; Fig. 3f(iii)). During etching, PG reinforced by MRF was secured in the module. The thickness of MRF film played a crucial role. It was optimized as a function of the concentration of the PTMSP solution in toluene and spin-coating speed (Supplementary Fig. 11). A 1.2-µm-thick MRF film markedly improved the transfer of graphene. This is mainly because it allows residual SiOx contaminants (<1 µm in size) to be covered on graphene.

Optical microscope (Fig. 3g) and SEM (Fig. 3h,i) images of the graphene surface exposed after removing Cu reveal the absence of any visible cracks. The white particles observed in Fig. 3h are a combination of Cu foil impurities and residues from the etching of Cu foil. They have a negligible effect on the membrane performance (Supplementary Fig. 12). The reproducibility of this transfer strategy was probed by cutting a ~8 × 12 cm2 graphene coupon (Fig. 3j) into 24 pieces of 2 × 2 cm2 coupons (Fig. 3k) and fabricating membranes from each coupon (Fig. 3l). An unsuccessful transfer typically leaves yellow residues on the white PES support because the Cu etchant (FeCl3) penetrates the broken graphene (Supplementary Fig. 13). This is a useful and quick method to check the success of the transfer. We did not observe the yellow stain in these samples, indicating a successful transfer. Selective gas permeation from all membranes confirmed that the success rate of the gas transfer was 100% (Supplementary Table 2). The variation in CO2 permeance in these samples is attributed to nonoptimized O3 velocity for these samples (see ‘Reaction kinetics versus mass transfer in oxidation reactor’ section).

The simple design of this module allowed the upscaling of the membrane element. However, the circular disk design of the above module limits the ability to achieve the practical cross-flow configuration. Therefore, larger decimeter-scale modules were designed by including cross-flow permeation channels (Fig. 4). The membrane stacking order and Cu etching strategy were identical (Fig. 4a). The module consisted of a symmetrical body frame and two identical cover plates to pack two 5-cm2-sized membrane elements in a single module to increase the packing density. A cross-flow channel was created using slits on the side of the module (Fig. 4b). Cu foil in the assembled module could be removed by flowing the etchant through the cross-flow slits (Fig. 4c). This exposed graphene and generated a feed channel for gas permeation experiments. The cover plate on both sides had a central opening serving as a permeate window. This module could be further scaled into a larger one capable of hosting two 5 × 10 cm2 membrane elements (Fig. 4d). Detailed pictures of a step-by-step assembly are shown in Supplementary Figs. 14 and 15. No yellow stain was observed in the transfer to this large module, which indicated a successful transfer.

The integrity of the graphene membranes transferred directly in the module was examined by gas permeation studies (setup shown in Supplementary Figs. 14 and 15). As-synthesized CVD graphene, without the oxidation step, yielded a low CO2 permeance of 29 gas permeation units (GPU; 1 GPU = 3.35 × 10−10 mol m−2 s−1 Pa−1) with a CO2/N2 ideal selectivity of 15.6, consistent with the literature on intrinsic vacancy defects in graphene, confirming that cracks were avoided during transfer (Supplementary Fig. 16 and Supplementary Table 3). Successful crack-free transfer was also obtained from as-synthesized graphene transferred to the 5 cm2 and 50 cm2 cross-flow modules (Supplementary Table 3). This establishes the robustness of this crack-free transfer approach in preparing large-area PG membranes.

Reaction kinetics versus mass transfer in oxidation reactor

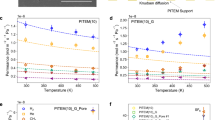

The oxidation of graphene was studied as a function of reaction conditions (temperature and oxidation time) and mass transfer (ozone velocity). To understand the effect of reaction conditions on graphene porosity, the gas transport resistance model53 was used to extract permeance from the graphene layer (Supplementary Note 2 and Supplementary Tables 2, 4 and 5). For PG membranes, the increase in porosity due to oxidation was indicated by an obvious increase in gas permeance compared with the membranes based on as-synthesized graphene (Fig. 5a, colored data points).

a, Gas permeation results of as-synthesized graphene (black) and PG (colored) membranes at 1 cm2 and 50 cm2 scale. The ozone oxidation was optimized by different reaction routes: temperature, processing time and mass transport routes. The permeance of PG is extracted from the membrane using the resistance model. The error bar refers to the standard deviation in CO2/N2 ideal selectivity and CO2 permeance across three (as-synthesized graphene and PG under 85 °C, 1 h, slow O3) and two (rest of the conditions) membranes, respectively. The center of the error bar represents the average selectivity and permeance calculated from graphene membranes. b, COMSOL CFD simulation results from the unmodified reactor: extracted gas velocity 1 mm above the substrate in the middle of the reactor with a sample size of 6 × 16 cm2. c, A picture of the modified ozone oxidation reactor hosting a quartz semi-cylindrical block (12 cm in diameter). Inset: is the side view of the reactor with the quartz block. d, COMSOL CFD simulation results from the modified reactor at the same sample position in b. e, AC-HRTEM images of pores generated under an oxidation condition using fast ozone velocity. f, The density of CO2-permeable pores as a function of the ozone velocity. The error bar refers to the standard deviation in permeable pore density across five AC-HRTEM images. The center of the error bar represents the average pore density calculated from the AC-HRTEM image. g, The size distribution of CO2-permeable pores under fast ozone velocity obtained from the AC-HRTEM images.

A monotonic increase in CO2 permeance as a function of reaction temperature for a fixed reaction time of 1 h could be observed (Fig. 5a). An average increase in permeance from 1,091 GPU to 2,444 GPU was observed when the temperature increased from 85 °C to 90 °C. The average CO2/N2 selectivity increased from 20.2 to 22.8. This favorable increase in CO2 permeance, as well as CO2/N2 selectivity, can be attributed to a higher density of O clusters achieved at an elevated reaction temperature, given that cluster nucleation follows an energy barrier50 and is consistent with the literature on millimeter-scale PG membranes50,51. Increasing the epoxidation time to 3 h at 85 °C led to a further increase in CO2 permeance of 2,850 GPU with a CO2/N2 selectivity of 19.3.

Previous studies on the oxidation of graphene have focused on reaction kinetics. Mass transfer limitation in the O3-led oxidation reaction is important to consider because of the formation of an O2 boundary layer next to graphene. The O3 generator used in this study produces a dilute composition of O3 (8% in O2). Upon oxidation, a molecule of O2 is produced per molecule of O3, which further limits the concentration of O3 near the graphene surface48. Computational fluid dynamics (CFD) simulations were performed using COMSOL Multiphysics to understand the resulting mass transfer. Supplementary Fig. 17a shows the simulated iso-surface plot of the gas velocity with an inlet flow rate of 2 l min−1 in the tubular reactor where a substrate holding Cu/graphene was placed. The highest velocity was near the center of the reactor. This is because of the small cross-sectional area of the gas delivery system relative to the reactor. The former was essentially a tube with an inner diameter of 2.2 cm. A boundary layer could be observed near the substrate where the gas velocity was significantly reduced. A two-dimensional plot of the gas velocity, 1 mm above the substrate, on a 6 × 16 cm area at the center of the substrate is shown in Fig. 5b. The influence of the reactor geometry is apparent with varying gas velocity in different parts of the reactor. The gas flow was highest in the center and decreased at the edges of the reactor. The average gas velocity near graphene was 0.06 ± 0.04 cm s−1 (\({\upsilon }_{{{\mathrm{O}}}_{3},{{\mathrm{slow}}}}\)), indicating an uneven flow. A high standard deviation in velocity is not desired for obtaining uniformly porous graphene in scaled-up samples. To address this, a quartz semi-cylindrical block (12 cm in diameter) was placed in the reactor, occupying and blocking the bottom half of the unnecessary space for the ozone reaction. Figure 5c shows the tubular reactor hosting the semi-cylindrical block and a 55-cm-long graphene substrate plate. Attributed to the reduction in the cross-sectional area of the flow by the block, the gas develops a laminar flow at a short distance after the inlet (Supplementary Fig. 17b). A two-dimensional plot of the gas velocity near graphene reveals a uniform flow profile (Fig. 5d). The velocity increased threefold to 0.17 ± 0.02 cm s−1 (\({\upsilon }_{{{\mathrm{O}}}_{3},{{\mathrm{fast}}}}\)). This led to a noticeable improvement in the porosity of graphene, reflected by a drastically improved CO2 permeance. An average CO2 permeance from the 1-cm-scale membranes of 13,105 GPU and CO2/N2 selectivity of 15.1 could be achieved. Furthermore, 50-cm2-sized PG membranes in the 5 × 10 cm2 cross-flow module yielded attractive separation performance with CO2 permeance of up to 11,799 GPU and CO2/N2 selectivity of up to 17.6 (Fig. 5a, Supplementary Fig. 18, Supplementary Table 5 and Supplementary Video 1). This performance is highly competitive to those from the state-of-the-art and commercial membranes (Supplementary Fig. 19 and Supplementary Table 6). AC-HRTEM images of graphene under an oxidation condition using fast and slow ozone gas velocity were collected. Several CO2-selective pores were observed on porous graphene (Fig. 5e and Supplementary Fig. 20). Pores formed by missing N carbon atoms are denoted as pore-N, where N is an integer. Pores smaller than pore−10 are considered to be CO2-impermeable. The density of CO2-permeable pores under the fast ozone was two times higher than the slow ozone condition (Fig. 5f). The pore size distribution (Fig. 5g) shows that the fast ozone velocity is optimal. Above all, a carefully designed scaled-up reactor and transfer strategy allows one to achieve attractive performance from large-area graphene membranes.

Conclusion

Over a decade, the development of atom-thin graphene membranes has been limited by the lack of a scalable and reproducible membrane preparation method. This work shows that the synthesis of graphene membranes can be scaled up, with the potential of reduced cost and attractive performance in the important application of carbon capture. We address three key challenges: developing high-quality graphene and membranes from low-cost Cu foil, scaling up a reactor that allows the generation of porosity uniformly, and developing a transfer technique that allows the realization of a 50-cm2-sized graphene membrane in the cross-flow module. The reported method obtained a near 100% success rate, which will allow rapid proliferation of this technology. The methods discussed here, especially on the use of low-cost Cu foil and the importance of mass transfer of O3 in the oxidation of graphene, will form the basis of roll-to-roll production of graphene membranes where various steps of graphene processing are comparable. The rapidly growing field of two-dimensional porous materials will probably adopt the floating-free transfer approach introduced here.

Methods

Synthesis of CVD graphene

Commercial copper foils (Supplementary Table 1) were pretreated with nitric acid (4 wt%) for 10 min to remove the surface contamination. Cu foils were washed with deionized water four times and stored in isopropanol before use. A customized CVD furnace (Carbolite, TS1/3-1200, heating zone 1.2 m) hosting a quartz tube and an alumina tube (Zibo Highlion New Material) was built for graphene synthesis.

The synthesis protocol of CVD graphene followed the previous reports24,26,45. First, the Cu foil was treated at 1,020 °C for 2 h under 1 bar CO2 flow to remove surface carbonaceous contaminations. After exchanging the gas to Ar and H2 with a flow rate of 500 and 50 sccm, respectively, the furnace was slowly heated to 1,065 °C and the temperature was maintained for 3 h. The graphene synthesis was conducted at 1,020 °C using 9 sccm of CH4 and 3 sccm of H2 under a pressure of 180 mTorr for 30 min. Detailed temperature and pressure profiles are shown in Supplementary Fig. 1.

Characterization of graphene

SEM imaging was conducted on a FEI Teneo scanning electron microscope at a working voltage of 1 kV. Graphene grown on Cu foil was directly imaged without further surface treatment. Energy-dispersive X-ray spectroscopy was used to analyze the elements of the contamination particles. The macroscopic surface features of the Cu substrate and graphene were obtained from an optical microscope. Graphene sample roughness and polymer thickness measurements were performed on Bruker DektakXT stylus profilometer with a 2-µm stylus radius and 3 mg force. The data were processed by Bruker Vision 64 v5.51 software. AC-HRTEM imaging of graphene was realized on a ThermoFisher Titan Themis operated at 80 kV. Images of CO2-permeable pores on graphene are processed by the revolve sphere leveling method to enhance the graphene atomic lattice54.

The quality of graphene was examined by a Reinshow inVia micro-Raman spectroscope. A 457-nm laser was used to characterize graphene grown on the Cu substrate, and a 532-nm laser was used for graphene transferred on a Si/SiO2 wafer by the conventional wet-transfer method. The peak intensity ratio was analyzed by fitting the spectra using least-squares curve fitting tools in MATLAB.

Oxidation of graphene in ozone

O3-based oxidation of graphene was conducted in a tubular furnace (Nabertherm, 90-cm heating zone) hosting a 1.5-m-long, 12-cm-diameter quartz tube (Supplementary Fig. 6). O3 (2 l min−1) was produced from a commercial O3 generator (Absolute Ozone, Atlas 60) and stabilized for at least 30 min to reach 8 wt% (O3/O2) as analyzed by an O3 monitor (2B Technologies, model 106-H).

Transfer of graphene to membrane module

PG was first spin-coated with a layer of PTMSP (abcr). The solution was prepared by dissolving 3 g of PTMSP into 97 g of toluene and subsequently centrifuged to remove the impurities. The spin coating was carried out at 1,000 rpm for 1 min in a large-area spin coater (Laurell Technologies Corporation, WS-650Hz-15NPPB). After drying overnight, the polymer-reinforced graphene was first attached to a commercial porous PES support (Haining, China, 0.1 mm thickness, 0.22 µm pore opening) film, then to SS meshes (TWP Inc.), and the assembly was sealed into the custom-made membrane module described in this work. FeCl3 (1 M) solution was used to etch the Cu foil, followed by cleaning using HCl (1 M) solution and deionized water.

Gas permeation measurement

Single-component gas permeation measurement was performed using a constant-volume, variable-pressure method. The scheme and pictures of the experimental setup are shown in Supplementary Fig. 16. Before the measurement, the membrane module was sealed with an impermeable Cu foil to measure the system leak rate. The leak rate was negligible (~1 GPU). The permeance was calculated by

where Ji is the molar flow rate of the gas component i, A is the membrane area, R is the ideal gas constant, ΔPi is the pressure difference of gas component i from the feed and the permeate side, T is the temperature of the permeate volume, V is the constant permeate volume, and \(\frac{{{\mathrm{d}}P}}{{{\mathrm{d}}t}}\) is the pressure change in the constant permeate volume. Different feed gases were used to probe the permeation performance of the membrane. For each gas measurement, a sufficient gas flow controlled by a mass flow controller was supplied to the feed side of the membrane. For membranes that have a high flux, the permeate flux was measured using a bubble flow meter according to

where \(\frac{{{\mathrm{d}}V}}{{{\mathrm{d}}t}}\) is the permeate flow rate (ml s−1) at the ambient condition (25 °C and 1 bar). A forced air convection oven was equipped to measure the gas permeance at elevated temperatures. Supplementary Video 1 shows the experimental setup. All membrane data were collected after heating the membrane to 130 °C for 1 h followed by cooling to 25 °C. This allowed the removal of any atmospheric contaminations in the sample.

CFD simulation

CFD simulations on the gas profile in the tubular furnace were performed using a COMSOL Multiphysics 6.1 package. The model geometry was created in the software as shown in Supplementary Fig. 17. O2 was selected as the fluid material. A laminar flow study was applied to the model, with a gas inlet and outlet specified on the left and right ends of the reactor. Other domains of the model were all defined as wall boundaries. The boundary condition for the inlet was set as a fully developed flow with a flow rate of 2 l min−1, and that for the outlet was set as a static pressure of 0 Pa. The results were analyzed by COMSOL.

Data availability

All data are available in the article and its Supplementary Information and source data files.

References

Drahushuk, L. W. & Strano, M. S. Mechanisms of gas permeation through single layer graphene membranes. Langmuir 28, 16671–16678 (2012).

Koenig, S. P., Wang, L., Pellegrino, J. & Bunch, J. S. Selective molecular sieving through porous graphene. Nat. Nanotechnol. 7, 728–732 (2012).

O’Hern, S. C. et al. Selective molecular transport through intrinsic defects in a single layer of CVD graphene. ACS Nano 6, 10130–10138 (2012).

Cohen-Tanugi, D. & Grossman, J. C. Water desalination across nanoporous graphene. Nano Lett. 12, 3602–3608 (2012).

Li, H. et al. Ultrathin, molecular-sieving graphene oxide membranes for selective hydrogen separation. Science 342, 95–98 (2013).

Guo, L. et al. Emerging advances around nanofluidic transport and mass separation under confinement in atomically thin nanoporous graphene. Small 20, 2404087 (2024).

Huang, S. et al. Single-layer graphene membranes by crack-free transfer for gas mixture separation. Nat. Commun. 9, 2632 (2018).

He, G. et al. High-permeance polymer-functionalized single-layer graphene membranes that surpass the postcombustion carbon capture target. Energy Environ. Sci. 12, 3305–3312 (2019).

Huang, S. et al. Millisecond lattice gasification for high-density CO2- and O2-sieving nanopores in single-layer graphene. Sci. Adv. 7, eabf0116 (2021).

Soo, X. Y. D. et al. Advancements in CO2 capture by absorption and adsorption: a comprehensive review. J. CO2 Util. 81, 102727 (2024).

Mota-Martinez, M. T., Hallett, J. P. & Dowell, N. M. Solvent selection and design for CO2 capture—how we might have been missing the point. Sustain. Energy Fuels 1, 2078–2090 (2017).

Sholl, D. S. & Lively, R. P. Seven chemical separations to change the world. Nature 532, 435–437 (2016).

Darunte, L. A., Walton, K. S., Sholl, D. S. & Jones, C. W. CO2 capture via adsorption in amine-functionalized sorbents. Curr. Opin. Chem. Eng. 12, 82–90 (2016).

Du, N., Park, H. B., Dal-Cin, M. M. & Guiver, M. D. Advances in high permeability polymeric membrane materials for CO2 separations. Energy Environ. Sci. 5, 7306–7322 (2012).

Han, Y. & Ho, W. S. W. Polymeric membranes for CO2 separation and capture. J. Membr. Sci. 628, 119244 (2021).

Varoon Agrawal, K. et al. Dispersible exfoliated zeolite nanosheets and their application as a selective membrane. Science 334, 72–75 (2011).

Rangnekar, N., Mittal, N., Elyassi, B., Caro, J. & Tsapatsis, M. Zeolite membranes—a review and comparison with MOFs. Chem. Soc. Rev. 44, 7128–7154 (2015).

Chen, G. et al. Zeolites and metal–organic frameworks for gas separation: the possibility of translating adsorbents into membranes. Chem. Soc. Rev. 52, 4586–4602 (2023).

Babu, D. J., He, G., Villalobos, L. F. & Agrawal, K. V. Crystal engineering of metal–organic framework thin films for gas separations. ACS Sustain. Chem. Eng. 7, 49–69 (2019).

Li, H., Dilipkumar, A., Abubakar, S. & Zhao, D. Covalent organic frameworks for CO2 capture: from laboratory curiosity to industry implementation. Chem. Soc. Rev. 52, 6294–6329 (2023).

Patel, H. A. et al. Unprecedented high-temperature CO₂ selectivity in N2-phobic nanoporous covalent organic polymers. Nat. Commun. 4, 1357 (2013).

Huang, S. et al. Ultrathin carbon molecular sieve films and room-temperature oxygen functionalization for gas-sieving. ACS Appl. Mater. Interfaces 11, 16729–16736 (2019).

Rungta, M. et al. Carbon molecular sieve structure development and membrane performance relationships. Carbon 115, 237–248 (2017).

Li, X. et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324, 1312–1314 (2009).

Polsen, E. S., McNerny, D. Q., Viswanath, B., Pattinson, S. W. & John Hart, A. High-speed roll-to-roll manufacturing of graphene using a concentric tube CVD reactor. Sci. Rep. 5, 10257 (2015).

Bae, S. et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 5, 574–578 (2010).

Li, X. et al. Large-area graphene single crystals grown by low-pressure chemical vapor deposition of methane on copper. J. Am. Chem. Soc. 133, 2816–2819 (2011).

Amontree, J. et al. Reproducible graphene synthesis by oxygen-free chemical vapour deposition. Nature 630, 636–642 (2024).

Agrawal, K. V. et al. Fabrication, pressure testing, and nanopore formation of single-layer graphene membranes. J. Phys. Chem. C 121, 14312–14321 (2017).

Ramasubramanian, K., Verweij, H. & Winston Ho, W. S. Membrane processes for carbon capture from coal-fired power plant flue gas: a modeling and cost study. J. Membr. Sci. 421–422, 299–310 (2012).

Merkel, T. C., Lin, H., Wei, X. & Baker, R. Power plant post-combustion carbon dioxide capture: an opportunity for membranes. J. Membr. Sci. 359, 126–139 (2010).

Yuan, Z., Benck, J. D., Eatmon, Y., Blankschtein, D. & Strano, M. S. Stable, temperature-dependent gas mixture permeation and separation through suspended nanoporous single-layer graphene membranes. Nano Lett. 18, 5057–5069 (2018).

Cheng, P. et al. Facile size-selective defect sealing in large-area atomically thin graphene membranes for sub-nanometer scale separations. Nano Lett. 20, 5951–5959 (2020).

Zhang, D. et al. Bioinspired large-area atomically-thin graphene membranes. Adv. Funct. Mater. 34, 2307419 (2024).

Yamada, Y. et al. Subnanometer vacancy defects introduced on graphene by oxygen gas. J. Am. Chem. Soc. 136, 2232–2235 (2014).

Wang, X. & Dai, H. Etching and narrowing of graphene from the edges. Nat. Chem. 2, 661–665 (2010).

Cheng, C., Iyengar, S. A. & Karnik, R. Molecular size-dependent subcontinuum solvent permeation and ultrafast nanofiltration across nanoporous graphene membranes. Nat. Nanotechnol. 16, 989–995 (2021).

Kidambi, P. R. et al. A scalable route to nanoporous large-area atomically thin graphene membranes by roll-to-roll chemical vapor deposition and polymer support casting. ACS Appl. Mater. Interfaces 10, 10369–10378 (2018).

Reina, A. et al. Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett. 9, 30–35 (2009).

Suk, J. W. et al. Transfer of CVD-grown monolayer graphene onto arbitrary substrates. ACS Nano 5, 6916–6924 (2011).

Lin, Y.-C. et al. Clean transfer of graphene for isolation and suspension. ACS Nano 5, 2362–2368 (2011).

Hsu, K.-J. et al. Graphene membranes with pyridinic nitrogen at pore edges for high-performance CO2 capture. Nat. Energy 9, 964–974 (2024).

Lee, W.-C. et al. Centimeter-scale gas-sieving nanoporous single-layer graphene membrane. J. Membr. Sci. 618, 118745 (2021).

Lisi, N. et al. Contamination-free graphene by chemical vapor deposition in quartz furnaces. Sci. Rep. 7, 9927 (2017).

Rezaei, M., Li, S., Huang, S. & Agrawal, K. V. Hydrogen-sieving single-layer graphene membranes obtained by crystallographic and morphological optimization of catalytic copper foil. J. Membr. Sci. 612, 118406 (2020).

Kim, S. M. et al. The effect of copper pre-cleaning on graphene synthesis. Nanotechnology 24, 365602 (2013).

Murdock, A. T. et al. Targeted removal of copper foil surface impurities for improved synthesis of CVD graphene. Carbon 122, 207–216 (2017).

Vahdat, M. T. et al. Mechanistic insights on functionalization of graphene with ozone. J. Phys. Chem. C 127, 22015–22022 (2023).

Lee, G., Lee, B., Kim, J. & Cho, K. Ozone adsorption on graphene: ab initio study and experimental validation. J. Phys. Chem. C 113, 14225–14229 (2009).

Huang, S. et al. In situ nucleation-decoupled and site-specific incorporation of Å-scale pores in graphene via epoxidation. Adv. Mater. 34, 2206627 (2022).

Bondaz, L. et al. Selective photonic gasification of strained oxygen clusters on graphene for tuning pore size in the Å regime. JACS Au 3, 2844–2854 (2023).

Zhou, F., Li, Z., Shenoy, G. J., Li, L. & Liu, H. Enhanced room-temperature corrosion of copper in the presence of graphene. ACS Nano 7, 6939–6947 (2013).

Fu, Q. et al. A novel cross-linked nano-coating for carbon dioxide capture. Energy Environ. Sci. 9, 434–440 (2016).

Bandyopadhyay, D., Sun, Y., Griffin, R. & Lee, L. Y. Advancing graphene imaging for clear identification of lattice defects: the application of revolve sphere levelling to scanning tunnelling microscopy images. ACS Omega 9, 43447–43452 (2024).

Acknowledgements

We acknowledge GAZNAT, Swiss Federal Office of Energy (SFOE, Pilot & Demonstration Project, EfficientCapture) and the administration of Swiss Canton of Valais (Valais Energy Demonstration Fund) for funding the project. M.R. acknowledges funding from Bridge Proof of Concept for optimizing low-cost Cu foil. We also acknowledge the host institute, École Polytechnique Fédérale de Lausanne (EPFL), for funding aspects of the project related to characterization and support optimization. We thank the EPFL mechanical workshop for fabricating membrane modules.

Funding

Open access funding provided by EPFL Lausanne.

Author information

Authors and Affiliations

Contributions

K.V.A. and J.H. conceived the project and wrote the paper. J.H. prepared the samples for membrane permeation test, SEM, Raman spectroscopy, AC-HRTEM and profilometry. J.H. and P.M. Gebolis designed and assembled the CVD setup. J.H., P.M. Gebolis and P.M. Gach designed the membrane module. M.C. collected profilometry images. L.S.B. collected the AC-HRTEM images. L.S.B. and C.K. analyzed the AC-HRTEM images. J.H. assembled the ozone reactor. J.H., K.-J.H. and K.B. optimized the ozone reaction condition. J.H. and D.J.B. conceived the idea of graphene transfer. J.H. performed the COMSOL simulation and data analysis. All authors discussed the results and commented on the paper.

Corresponding author

Ethics declarations

Competing interests

A patent application has been filed based on the findings in this work. Patent application number: EP24207662.8. Applicant: GAZNAT SA, Switzerland (industrial sponsor of the project). Filing date: 18 October 2024 (status: filed). Name of inventors: Kumar Varoon Agrawal, Jian Hao. Title of invention: Method of preparing CO2 selective pores in graphene & uses thereof.

Peer review

Peer review information

Nature Chemical Engineering thanks Byung Hee Hong and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1 and 2, Figs. 1–20, Tables 1–5, and References.

Supplementary Video 1

A movie of the gas permeation measurement for a 50-cm2 graphene membrane.

Supplementary Data 1

Source data for calculating the average and standard deviation.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hao, J., Gebolis, P.M., Gach, P.M. et al. Scalable synthesis of CO2-selective porous single-layer graphene membranes. Nat Chem Eng 2, 241–251 (2025). https://doi.org/10.1038/s44286-025-00203-z

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s44286-025-00203-z

This article is cited by

-

Pre-pilot-scale porous graphene membrane for CO2 separation

Nature Chemical Engineering (2025)