Abstract

Dissimilar material 3D printing (DMP) can combine polymers with dissimilar properties into functional parts. However, DMP requires an understanding of adhesion at the interface to ensure performance. To quantify the adhesion between polymers with dissimilar mechanical properties, a modified double cantilever beam (DCB) test was performed between 3D printed thermoplastic layers and a cast layer of hydroxyl-terminated polybutadiene (HTPB). The effect of surface roughness on the fracture toughness was determined with polyvinylidene fluoride (PVDF) samples using one machined and three printed surfaces. There were no significant differences in surface roughness or fracture toughness between the print surfaces, but the failure type changed. The 5 and 10 wt.% polycaprolactone (PCL)/PVDF blends and the stiffness matched polylactic acid (PLA) interfaces rarely failed in mode I, indicating improved adhesion. This work provides a framework to assess the factors driving the adhesion of thermoplastic-elastomeric interfaces produced via polymer DMP, which is underexplored in literature.

Similar content being viewed by others

Introduction

Additive manufacturing (AM) is gaining increased adoption in applications such as biomedicine and aerospace, offering improved agility in manufacturing parts and complex geometries with minimal or no tooling required. However, traditional AM struggles to produce high-quality functional multi-material parts for many applications1. Many multi-material parts, such as sensors and solid rocket motors, benefit from the combination of materials with substantially dissimilar properties (i.e. mechanical, electrical, chemical, etc.) or functional grading. Rigid thermoplastics and rubbery elastomers are common sets of dissimilar materials that often need to be combined in designed products. Approaches to produce parts with complex geometries using dissimilar materials are limited. Conventional multi-material 3D printing, which uses either multiple print heads or a single head capable of in-situ mixing or material switching, can be used to deposit such materials. However, multi-material printing referenced in literature often involves the combination of similar materials rather than the dissimilar ones required, so the construction and assessment methodologies suggested in literature can mislead those who aim to make dissimilar material interfaces.

A more appropriate option would be the use of dissimilar material 3D printing (DMP), which is defined in this paper as a more extreme form of multi-material 3D printing that exclusively involves combining dissimilar materials, such as ceramics, metals, elastomers, and thermoplastics. For example, printing metals and ceramics has typically been identified as multi-material printing, but the authors would classify this more specifically as DMP since it is more challenging than printing similar types of metals due to disparate coefficients of thermal expansion, melt temperatures, and other relevant material processing properties.

Thermoplastics and elastomers can be integrated via DMP by considering AM techniques such as digital light processing (DLP), stereolithography (SLA), fused filament fabrication (FFF), selective laser sintering (SLS), direct ink writing (DIW), inkjet (IJ), material jetting (MJ), etc. In some cases, it is possible to print dissimilar materials on the same printing platform, but these material combinations are limited. The combination of dissimilar materials, however, introduces potential issues, particularly at the resulting interfaces. The formation mechanisms, assessment techniques, and quantitative adhesion values of multi-material interfaces are not well understood, defined, or documented in additive manufacturing literature and there is far less knowledge pertaining to dissimilar material interfaces. In Table 1, various dissimilar material polymer specimens manufactured via DMP are highlighted, and the assessed interfacial properties are discussed. Despite the extensive tensile testing and demonstration of the technology, the quantification of the interfacial properties is extremely lacking. Tensile properties do not quantify mode I fracture toughness failure, which can only be accomplished through tests such as a double cantilever beam (DCB) test. Only Vu et al. conducted DCB tests and focused mostly on testing different configurations as well as the effect of print orientation in a material jetting process2. Despite the detailed analysis in this paper, the two materials are fixed, and there is no discussion of the effect of surface roughness since material jetting is a high-resolution process.

Based on this detailed survey, research on how to control the adhesion using the surface roughness induced by the print process or material selection is non-existent. Quantification of the effect of parameters like surface roughness, print orientation, and material choice on the resulting adhesion is vital to the performance of any resulting part. While some applications require strong adhesion behavior, others may call for controlled debonding3. Printing parameters have well-documented effects on surface roughness, which is likely to affect interfacial adhesion4. The addition of a miscible polymer could also be an avenue to promote adhesion that has not been explored5.

Furthermore, there is no standard process to measure the adhesion of additively manufactured dissimilar materials (AMDMs). The difficulty of investigating the adhesion of AMDMs is compounded by a lack of standards within additive manufacturing. In particular, to quantify adhesion, the mode I fracture (opening mode) is of interest6. While standards exist to measure mode I toughness, such as the DCB test outlined in ASTM D5528 or the peel test outlined in ASTM D6862, these standards do not apply to additively manufactured or dissimilar material samples6,7,8,9. Boeman et al. proposed an adaptation to the standard DCB test to accommodate dissimilar materials, but additive manufacturing was not considered in this process6. Despite such limitations, there is some precedent for using DCB tests, or modifications thereof, on additively manufactured parts2,10,11. In addition, using piano hinges versus wedge loading can be used to provide more reliable results6,11.

Designing, creating, and assessing the formation of an interface between materials that are not inherently compatible, such as a thermoplastic-elastomer system with poor adhesion, is essential to the eventual application of DMP. For example, the combination of polyvinylidene fluoride (PVDF) with elastomers has direct application to propellant and sensor fabrication. 3D printed reactive PVDF filaments filled with aluminum have been embedded into ammonium perchlorate composite propellant with an elastomeric binder to demonstrate tailored burning rates and higher energy density, yet inadequate control of interfacial adhesion leads to erratic burning12,13. Novel, inexpensive piezoelectric sensors that measure pressure or structural health can be 3D printed using PVDF and conductive inks, but poor adhesion can lead to shorts or breaks in a circuit as well as premature failure14,15,16. With the advancement of DMP, it is possible to co-print these materials together in novel ways to increase manufacturability. However, PVDF exhibits poor adhesion with most materials and the adhesion of 3D-printed PVDF with elastomers has not been quantified.

Given the lack of standards and studies on the interfacial properties of dissimilar materials, this study aims to establish an improved methodology for the measurement of the adhesion of AMDMs. In this paper, the type of DMP system targeted is a combination of Direct Ink Writing and Fused Filament Fabrication since it offers a wide range of flexibility, varying surface roughnesses, and large differences in the material properties of the constituents. To the authors’ knowledge, this is the first study to use a DCB to quantify the fracture toughness between thermoplastics printed using FFF and elastomers towards AMDM applications. This study explores how surface roughness, different material combinations, and polymer blending can influence interfacial strength and failure types. The methodology and analysis provided in this paper can be applied to other polymer-based AMDM structures and serve as a guideline for the design of DMP structures that are currently absent from the literature.

Results

PVDF and PCL filament quality

The DSC curve of neat PVDF is shown in Fig. 1. One melting point peak is observed for the neat PVDF at 173.03 °C, which is consistent with literature values for the melting point17.

The DSC curves of the physically mixed 5%, 7.5%, and 10% PCL and the solvent-mixed 10% PCL filaments at different locations along the length of the extrusion are shown in Fig. 2. Corresponding thermal gravimetric analysis (TGA) curves can be found in Fig. S1 in the Supporting Information. The effect of extrusion on the filament properties was assessed by comparing the solvent-mixed feedstock prior to extrusion. Solvent mixed 5% and 10% PCL feedstocks melted at 168.15 and 167.71 °C, respectively.

DSC curves around the PVDF melting point for the physically mixed 5% (A), 7.5% (B), and 10% (C) PCL filaments and the solvent-mixed 10% (D) PCL filament. Given the melting point of neat PVDF (173.03 °C), the melting point depression is seen in all filaments and all locations to varying degrees. The 5% (168.15 °C) and 10% (167.71 °C) solvent mixed feedstocks showed lower melting points than their respective filaments.

The 5% PCL physically mixed filament had the least variation in the melting temperature, with a variation of 0.25 °C observed across the filament. The 7.5% and 10% physically mixed filament both had higher observed variations, at 1.04 and 0.74 °C, respectively. The 10% solvent-mixed filament showed a higher variation within the filament (0.92 °C) than the physically mixed 10% filament (0.74 °C).

The variation seen in the filaments, particularly between the solvent and extrusion mixed 10%, suggests that the extrusion process led to variations in PCL content, leading to variation in the melting point. Because the filaments have higher melting points than the solvent-mixed feedstock, the filament extrusion process likely leads to higher PVDF content than expected. This could partly be attributed to the density mismatch of PCL (1.145 g/cm3) to PVDF (1.78 g/cm3), which could lead to segregation. Different pellet shapes for PCL (roughly round) and PVDF (flat) may also affect the segregation. Solvent mixing seems to deliver filament closer to the expected PCL content based on the lower melting point, but variation is still seen within the filament.

The interaction parameter found in the literature for PCL-rich PCL/PVDF systems was −1.518. Literature for PVDF-rich systems was not found. Using the depression in melting points observed for the solvent mixed feedstock and Eq. (1), the melting point depression interaction parameter would be more than an order of magnitude larger. This interaction parameter would not be reasonable. As such, the assumptions of Eq. (1) around negligible entropic effects are possibly untrue for this polymer system, or Flory–Huggins theory is inadequate to explain the interaction between PVDF and PCL for PVDF-rich systems, as was observed in poly-ethylene oxide (PEO) and poly methyl methacrylate (PMMA) systems19.

Considering the interaction and observed miscibility in other PCL/PVDF blends, miscibility may explain some results, but miscibility is not in the scope of this paper. Specifically, our goal was to modify the bulk adhesion behavior in DCB samples by using modified PVDF. More tests would be needed to confirm or refute the miscibility of the PVDF-rich PVDF/PCL blends with PCL content up to 10%. While the morphology of the blended filaments is outside of the scope of this study, the morphology of some PCL/PVDF blends is explored in other studies, including Kong et al. and Jo et al. 17,20. Kong et al. explored spherulite formation and crystallization in a 70/30 PVDF/PCL blend, showing a nucleation effect of PVDF spherulites on PCL crystallization17. Jo et al. studied the miscibility behavior of PCL-rich PDVF/PCL blends and observed an increased crystallization rate with increased PVDF content20.

Dimensional accuracy of the thermoplastic layers

The average dimensions of the thermoplastic layers are shown in Table 2. The variation in observed thickness is due to printer resolution for all samples except PLA. For PLA, two thicknesses were used: one compliant with the stiffness matching thickness (denoted as PLA-T), and the other below the required thickness for matching the thermoplastic sample (denoted as PLA-U). The 5% PCL thermoplastic layers showed a greater degree of variability in final dimensions than other sample types, likely owing to inconsistencies in printing due to the variable melting temperatures documented above. The 5% PCL thermoplastic layers showed a greater degree of variability in the print dimensions than the 10% PCL, likely attributable to increased difficulty in tuning the printing parameters of the 10% PCL, which had more variation in the melting temperature than the 5% PCL.

Thermoplastic layer surface roughness and surface features

The surface profiles of PVDF with three print surfaces and one milled surface showed visible differences, as shown in Fig. 3. The top side of the XY orientation (PVDF-T) shows clear repetitive depth changes owing to the print beads. The side surface from the XZ print orientation (PVDF-S) shows some depth changes from different layers. While still visible, these depth changes are faint. The bottom surface of the XY orientation (PVDF-B) shows a similar repetition to the top surface but with less depth change between peaks and valleys and with less pronounced peaks. The milled surface (PVDF-M) showed minimal variation compared to the printed surfaces.

Images (A, C, E, G) and heat maps (B, D, F, H) of the PVDF thermoplastic layers. The top surface of an XY orientation (PVDF-T) (A, B), the side surface of an XZ orientation (PVDF-S) (C, D), the bottom surface of an XY orientation (PVDF-B) (E, F), and milled surface (PVDF-M) (G, H) are compared. Faint black marks seen in the figure are used to determine the locations of image overlap. The small height difference from the marks (typically ~20 μm for most printed sample types) is visible through slight changes in the heat maps (B, D, F).

Black marks were used to label and mark the thermoplastic layers. Some of those marks can be resolved in the heat maps, but the magnitudes of those marks (typically <50 μm) are small and do not significantly influence surface roughness results. A focused view of these markings is shown in Fig. S2 with increased marking visibility. Furthermore, detailed profilometer scans of the thermoplastic layers before testing are available for access in Supporting Information.

Despite visible differences in the printed surface features, significantly large differences in the measured arithmetic surface roughness (Ra) are lacking in Fig. 4a. While Ra is frequently used to characterize the relationship between adhesion and surface roughness, other surface roughness parameters may capture differences not observable in Ra. The arithmetic peak curvature (Spc) is a measure of how sharp the peaks are, with larger numbers indicating sharper peaks. This was chosen as it should show differences in how peaked the beads are on different surfaces. The Spc showed significant differences between the PVDF-S and PVDF-T surfaces whereas the Ra differences were small. The PVDF-B surface showed no significant difference from PVDF-S or PVDF-T for both Ra and Spc, as can be seen in Fig. 4a and b. The PVDF-M had both lower Ra and Spc than all of the printed PVDF surfaces.

The lack of difference in Ra for any print surface suggests that the differences between the printed PVDF surfaces are not shown in Ra, but rather in surface roughness metrics concerning the peaks. Machining led to surfaces with smaller Ra and Spc consistent with ABS, but lower than any other printed material. Subtractive manufacturing was able to produce significantly lower surface Ra than printing for PVDF.

The lack of significant differentiation in Ra and Spc of the PVDF-B surface may be the result of print parameters, such as Z offset. The surface roughness observed here is substantially higher than the roughness observed in previous studies21,22. A closer look at the Spc profiles of the PVDF-B surface shows the presence of two distinct groupings. Of 8 specimens, 5 had Spc between 3.6 and 5.7 \(1\,\mu {\rm{m}}\), while 3 had Spc between 9.1 and 10.6 \(1\,\mu m\). These two groups are likely the result of a threshold in the print Z offset. When the offset is lower, the beads are compressed into the bed more, leading to lower Spc. At higher offsets, the bead may not be fully pressed into the bed, leading to a larger Spc. Two cross-section surface profiles supporting this observation can be seen in the Supporting Information (Fig. S3).

The PVDF-S surface shows significantly less variation in Spc than the PVDF-T and PVDF-B surfaces. The variation observed in the PVDF-T surface may be due to small print defects leading to an increase in the roughness. As a product of the printing process, limited delamination between beads at the top or bottom surfaces in a completed print is more likely than at the side surfaces. By contrast, the side surface is less likely to have delamination between layers and the print is more likely to fail when such delamination occurs. The dispersion in surface roughness values suggests that small changes in printing may lead to large differences in surface profiles.

Variations in Ra were more significant between the thermoplastic materials, with ABS and PLA both having lower Ra than the 10% PCL as seen in Fig. 4c. ABS was the least rough of the printed thermoplastic layers, with all other materials being significantly rougher. The larger spread seen in the printed PVDF surfaces and the 5% and 10% PCL materials is likely the result of less well-controlled printing. This inconsistency seems to be partially driven by inconsistent melt temperatures in the filament and the reduced geometric resolution of the printing process compared to milling. Furthermore, the Spc of ABS was significantly smaller than PLA, PVDF, 5% PCL, and 10% PCL as seen in Fig. 4d. ABS is widely used in FFF and, compared to PVDF, is easier to print consistently. Unexpectedly PLA, which is also widely used in FFF, did not deliver the same degree of consistency as ABS. However, it is known that local processing parameters in an FFF process will affect the melting and solidification of thermoplastics differently, which will ultimately affect the final surface roughness of the printed part.

Effect of thermoplastic material and surface roughness on fracture toughness

DCB specimen failures were largely between the thermoplastic and HTPB layer, a “mode I” failure. Several DCB specimens failed in other ways, and since these failures are not valid for obtaining fracture toughness, they are not included in Fig. 5. All of the individual values in Fig. 5 can be seen in more detail in Fig. S4. The failure types for all samples tested are tabulated in Table S2 in the Supporting Information.

PVDF specimens that failed adhesively between the HTPB and the backing include 4/8 PVDF-B, 1/9 PVDF-S, and 1/5 PVDF-M specimens. All other PVDF specimens, including all the PVDF-T, failed in mode I. While no significant changes in fracture toughness were observed, the change in failure type is indicative of greater adhesion between the thermoplastic and HTPB layers.

In general, 6/8 ABS specimens failed in mode I, none of the PLA-T specimens failed in mode I, and 7/9 PLA-U specimens failed in mode I. The failure type change between PLA-T and PLA-U suggests that stiffness matching is important in determining the fracture toughness and fracture type since there is not a large spread in Ra and no significant difference in Spc. The matching of the two materials is particularly important when additive manufacturing is considered, given the anisotropic performance of printed parts.

In the case of the 5% PCL specimens, 1/4 failed via bead delamination within the thermoplastic layer (thermoplastic failure), while the other 3 failed between the backing and HTPB layer (backing adhesion). For the 10% PCL specimens, 1/4 failed via crack propagation in the HTPB layer (HTPB failure), 2/4 failed between the backing and HTPB, and 1/4 failed in mode I. The observed bead delamination within the thermoplastic layer occurred near the hinge, remote from the interface with the HTPB layer. The change in failure type suggests an improvement in adhesion behavior compared to the other materials. Because of the change in failure type, PCL blends likely provide better adhesion with HTPB than neat PVDF.

The fracture toughness was calculated using Eq. 2 from measured sample dimensions and force–displacement curves for specimens that broke in mode I. The plots can be seen in Fig. 5a and c. To compare the effect of surface roughness across specimens, the normalized fracture toughness (\(\frac{G}{{R}_{{\rm{a}}}}\)) is presented in Fig. 5b and d. Representative force–displacement curves are shown in Figs. S5 and S6 in the Supporting Information.

Fracture toughness results do not show clear differences between most material types; however, the surface roughness differences complicate the comparison of materials. Because of the wide range of surface roughnesses observed, isolation of surface roughness as a variable separate from material choice is required to see the effect of material choice. Fracture toughness divided by Ra provides normalization of the fracture toughness for variations in surface roughness between samples. Applying this normalized fracture toughness results in much clearer differences in fracture toughness between materials, such as the ABS and PVDF-T.

In addition to an observable difference between materials, the normalized fracture toughness shows a significant difference between the PVDF surfaces. Notably, PVDF-S and PVDF-B are fairly distinct, and PVDF-M is extremely high. The lack of difference in roughness normalized fracture toughness between top and bottom orientations is likely attributable to the effect of z offset on surface roughness discussed earlier.

Mode I fracture surface analysis

Figure 6 shows profilometry scans of several thermoplastic and corresponding HTPB layers that all failed in mode I. None of the scans showed visible signs of cohesive failure in the thermoplastic layers. Some of the observed fracture surfaces showed microtearing in the HTPB layer, while others showed little evidence of microtearing. While the PLA-U, ABS, and PVDF-T failures were typically classified as mode I based on the standard, the profilometry analysis showed clear differences in how that failure occurred. As seen in Fig. 6-1(A,B), the PLA-U thermoplastic layer showed substantial residual HTPB which separated while fracturing. The corresponding missing material is observed via microtearing in the HTPB layer in Fig. 6-1(C,D). In Fig. 6-2(A–D) and 6-4(A–D), the ABS and PVDF-T layers showed no obvious signs of residual HTPB. The 10% PCL thermoplastic surface (Fig. 6-7(A–D)) showed significant residual HTPB, which was noticeably more than what was observed on the PLA-U sample. Therefore, the material choice had a pronounced effect on the failure type and on the appearance of the failure surfaces.

Thermoplastic failure surface images (column A) and profile heat maps (column B) are shown with corresponding HTPB failure surface images (column C) and profile heat maps (column D). The red line on the images denotes the end of the initial delamination. Mode I failures are shown for PLA-U (row 1), ABS (row 2), PVDF-M (row 3), PVDF-T (row 4), PVDF-S (row 5), PVDF-B (row 6), and 10% PCL (row 7). Some HTPB layers have subsurface bubble artifacts.

It is clear that the ABS and PVDF-T have the worst adhesion to HTPB compared to the PLA-U and the 10% PCL. The increased residual HTPB present on the 10% PCL layer compared to the PLA-U layer could indicate a stronger bond. However, given that all PLA-T (stiffness matched) samples failed along the backing and one 10% PCL blend failed in mode I, it may also be the case that PLA, on average, has stronger adhesion with HTPB than the 10% PCL.

The print surface also appeared to affect the failure of the samples. The PVDF-M (Fig. 6-3(A–D)), PVDF-T (Fig. 6-4), and PVDF-S (Fig. 6-5(A–D)) samples that failed in mode I did not have visible residual HTPB. However, the PVDF-B samples that failed in mode I as shown in Fig. 6-6(A–D) had significant HTPB residue. Given the similar average Ra for PVDF-B and PVDF-T seen in Fig. 4, surface roughness does not appear to explain this change in the failure surface between print surfaces.

While the reason for this change in failure surface appearance between print surfaces is not known, it may be attributable to the adhesive applied before printing. The PVDF-B samples were washed with isopropyl alcohol after printing. However, this wash may not have been sufficient to remove all the adhesive from the thermoplastic. Alternatively, this wash may have caused swelling in the PVDF, leading to different adhesion behavior. When printing specialized polymers that require adhesives to stick to the print bed, it is important to consider how incomplete removal of adhesives might affect the design of interfaces with predictable strength.

Discussion

This paper aimed to explore the effect of surface roughness and material choice, including polymer blending, on the adhesion behavior between HTPB and 3D-printed thermoplastics. The melting point of PVDF-rich PVDF/PCL blends was observed to study the polymer interactions. DCB tests, modified to match bending stiffness between the HTPB and thermoplastic layers, were used to determine the mode I fracture toughness as a proxy for adhesion.

The change in melting point was seen in all the tested PCL/PVDF filaments and feedstocks. The melting point depression indicates polymer interactions between PVDF and PCL at low (<10 wt%) PCL content, though additional tests would be required to determine the nature of these interactions. The observed melting point depression was much larger than the predicted value based on studies looking at PCL -rich PVDF/PCL systems. The filament extrusion process led to varying melt temperatures throughout the filament that likely increased the difficulty of 3D printing them into high-fidelity samples.

The arithmetic surface roughness (Ra) was used to compare the print surfaces and thermoplastic materials. In general, some differences between the materials were observed, such as a larger Ra for 10% PCL and a lower Ra for ABS. Small differences were observed between the PVDF-T, PVDF-B, and PVDF-S print surfaces, but there was a very large decrease in the Ra of the PVDF-M layers. The arithmetic peak curvature (Spc) showed more significant differences between the PVDF-S and PVDF-T surfaces. The PVDF-B surface was found to have two distinct groups of Spc, one with more pronounced beads and one with less pronounced beads. This was largely attributed to a variable Z offset. Significant variations in Spc based on material type and machining were also observable.

Measurements of the mode I fracture toughness via modified DCB testing showed little differentiation between materials and print surfaces, although the spread of data varied. In the case of PLA-U vs. PLA-T, it was observed that the spread was sensitive to the actual manufactured thermoplastic layer thickness. If the specimens are undersized, then the failure occurs in mode I whereas it transitions to a backing failure if correctly stiffness matched. The fracture toughness, however, when normalized by Ra, showed differences between PVDF-S and PVDF-T surfaces. Furthermore, the ABS value was generally higher than PVDF-T and comparable to PLA-U, whereas the PVDF-M values were significantly higher than all other cases.

Quantitative fracture toughness measurements of 5% and 10% PCL with HTPB were limited in this experiment since they did not typically fail in mode I. While this limits the quantitative conclusions, the change in failure type compared to neat PVDF indicates a likely improvement in adhesion with HTPB. In addition, the PVDF-T surfaces all failed in mode I, whereas only half of the PVDF-B specimens broke in mode I, indicating a transition. Although not all of the reasons for this transition are fully explained, there is an effect of the print surface roughness on the failure type.

Profilometry analysis of the fracture surfaces revealed clear differences between samples that failed in mode I. ABS and PVDF-T samples showed very little or no residual HTPB, while PLA and 10% PCL samples showed significant residual HTPB, indicating better adhesion. The fracture surfaces of PVDF-T, PVDF-M, and PVDF-S showed little evidence of residual HTPB. Conversely, PVDF-B fracture surfaces showed significant residual HTPB. The change in fracture surface appearance is possibly attributable to residual adhesive from the printing process.

The experiments performed here indicate that the adhesion between HTPB and a thermoplastic, as quantified by DCB tests, is influenced to some degree by the print surface and more strongly by the thermoplastic material choice for the first time in a systematic study. Given the failure type change observed for PVDF/PCL blends, polymer blends may have promise for controlling adhesion between dissimilar polymers for DMP. However, variation in blend melting temperatures can affect the print quality, as seen in the large variation in surface roughness of the 10% PCL compared to PVDF. Overall, this methodology can be broadly applied to other thermoplastic-elastomeric polymers manufactured in application to DMP.

Experimental Section/Methods

PVDF and PCL polymer interactions

To study the effect of material choice on the interfacial adhesion, filaments of polycaprolactone (PCL) and PVDF blends were created via extrusion. PCL was chosen because it is expected to improve the adhesion properties of PVDF as it is potentially miscible with PVDF23. Additionally, PCL use in additive manufacturing is well-established23,24. Prior to extrusion, the PCL (Thermo Scientific, 80,000 MW) and PVDF (Arkema, Kynar 710) were measured in 100 g batches in blends of 5 wt% PCL and 10 wt% PCL (denoted hereafter as 5% and 10% PCL). The polymer blends were shaken (denoted as physically mixed) to attain a relatively even pellet distribution. Extrusion was performed at 215–225 °C using a Filabot EX2 with the included die for 1.75 mm diameter filament. After extrusion, the filaments were pulled using a Felfil spooler with included fans. For filaments intended for printing, a diameter of 1.4–1.5 mm was targeted to minimize over-extruded filament, which causes jamming when printing. To evaluate polymer distribution in the filament, samples were taken from the beginning, middle, and end of the 5% and 10% PCL filaments, which were about ~10 m long. An additional 7.5% PCL filament was made to further study the polymer interactions but was not used for any of the DCB specimens.

To assess the effects of extruder mixing on the resulting filament, additional PCL and PVDF blends were combined via solvent mixing prior to extrusion rather than physically. 10 g batches of pellets with 5% and 10% PCL were used. Approximately 50 ml of N,N-dimethylformamide (DMF) (Thermo Scientific, ACS, 99.8+%), was added. The mixture was heated and stirred until no pellets were visible and the mixture appeared uniform. The mixture was poured into evaporating dishes and left until solid pucks of the blended polymer were obtained. Some pucks were reserved to test the feedstock melting temperature whereas the rest of the pucks were broken into pieces small enough for extrusion with a spatula. The 10% solvent mixed PCL was then extruded using the same parameters as the other blended filaments.

The interaction of PCL with PVDF was tested using differential scanning calorimetry (DSC)25. Samples were run on a TA SDT 650 combination DSC/TGA from 30 °C to 450 °C at 10 °C min−1 with 100 mL min−1 flow of argon. DSC curves were taken of samples from the beginning, middle, and end of the physically mixed 5%, 7.5%, and 10% PCL filaments. Data were also obtained from solvent mixed with 10% PCL filament. For comparison, DSC curves were taken for neat PVDF.

The melting point depression is generally observed in miscible systems18. This melting point depression can be expressed as

where \({T}_{{\rm{m}}{\rm{b}}}^{\circ }\) is the melting point of the blend, \({T}_{{\rm{m}}}^{\circ }\) is the melting point of the neat polymer, R is the universal gas constant, \({V}_{{xu}}\) is the molar volume, \({{\rm{\Delta }}h}_{{\rm{u}}}\) is the heat of fusion per mole, \({\chi }_{12}\) is the interaction parameter for the polymer system (−1.5 for PCL rich system up to 30% PCL), and \({\phi }_{2}\) is the volume fraction18. The subscript 1 refers to the amorphous portion and subscript 2 refers to the crystalline portion18. This equation assumes the crystalline morphology is not affected by composition18.

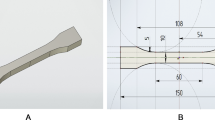

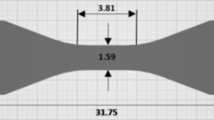

DCB specimen geometry

The DCB test sample geometry was based on ASTM D5528 and is pictured in Fig. 7a9. A similar modification to Boeman et al. was used to better suit the polymers with dissimilar stiff and rubbery mechanical properties (HTPB and thermoplastics) used here6. Rather than using aluminum backing plates, stiffness matching in this work was attained using a polylactic acid (PLA) backing to stiffen the HTPB layer. Layer thicknesses were determined using the same function as outlined in Boeman et al. implemented in MATLAB, as seen in supporting information6. Note that these calculations do not account for anisotropic bending stiffness due to the print orientation. The combined thermoplastic, backing, and HTPB layer thickness was fixed at 12.7 mm. Intended sample dimensions can be seen in Table 3. Mechanical properties, namely Young’s modulus, were assumed not to change significantly between the neat PVDF and the 5% and 10% PCL. This assumption is supported by work showing similar (within 1%) Young’s modulus for 30% PCL blends24. Given this, the same thermoplastic thickness was used for blends and PVDF. A spacer was included between the backing and thermoplastic layers to maintain separation between the layers during casting and was removed after curing. The resultant sample had two major thermoplastic pieces: the thermoplastic layer, with the interface between this layer and the HTPB layer as the measurement zone of interest, and the backing which is meant to reinforce the HTPB layer.

Labeled schematic of the modified DCB specimen (A). The backing was made of PLA (black), while the thermoplastic was made of PLA, ABS, PVDF, 5% PCL, or 10% PCL (white). A PLA spacer (black) was included to maintain separation between the backing and thermoplastic layer during casting but was removed before testing. The interface (initial crack) was created by inserting 6 cm of packing tape across the thermoplastic layer surface before casting. The HTPB layer (clear) was cast between the thermoplastic layer and the backing. The XY orientation (B) was used to create all thermoplastic layers except for the PVDF-S and PVDF-M specimens. All thermoplastic layers printed in the XY orientation, except for the PVDF-B specimen, used the top surface (including PVDF-T). The XZ orientation (C) was used to create the PVDF-S surfaces.

Most thermoplastic layers were printed in the XY orientation, as seen in Fig. 7b. In this orientation, the top surface, or the last 3D printed layer, was used at the interface with HTPB for all material types, including PVDF (i.e. PVDF-T). The bottom surface, or the first printed layer, was used at the interface in PVDF-B thermoplastic layers. An additional XZ orientation (shown in Fig. 7c) was used to obtain a side surface comprised of multiple print layers, which was used for the PVDF-S thermoplastic layers.

Production and characterization of the thermoplastic layers

Thermoplastic layers were made of either PLA (3DXTech, Ecomax), ABS (3DXTech), neat PVDF (3DXTech, FluorX homopolymer), or the physically mixed 5% and 10% PCL filaments mentioned earlier in this section. The backings were only made of PLA (3DXTech, Ecomax) due to difficulty in printing PVDF. Furthermore, it was not required for the backing to be made with the same material if it fulfilled its function of reinforcing the HTPB layer. Backings and spacers were printed on a Bambu Lab P1P.

The thermoplastic layers were printed on an Ender 5 Plus with a higher wattage bed heating element using Super Slicer with 100% rectilinear infill. Other print parameters are included in Table S1 in the Supporting Information. ABS, PLA, 5% PCL, and 10% PCL layers were printed in an XY orientation, and the top surface was the interface as seen in Fig. 7b. The 5% and 10% PCL layers were generally printed from the beginning and middle of the filament, but all parts were used where possible.

A nano polymer adhesive (Vision Miner) was used to maintain bed adhesion and prevent warping of the PVDF, 5% PCL, and 10% PCL layers. Layers that required the nano polymer adhesive were briefly (~30 s) washed with isopropanol to remove any visible adhesive before casting.

PVDF, 5% PCL, and 10% PCL were especially vulnerable to warping or delamination during the printing process. Consequently, some of the printed thermoplastic layers were rejected to maintain consistency. Layers printed in the XY orientation could not have visible warping before being taken off the bed. Warping during printing was tolerated in samples printed in the XZ orientation, provided that the part did not warp by more than ~0.5 mm relative to the print bed. This level of warpage limits the deformed area beyond the hinges and initial crack location, which will have minimal effect on the ultimate performance of the complete DCB sample.

To isolate the effect of additive manufacturing, PVDF samples were also made from 1/4” (6.35 mm) PVDF sheet (McMaster-Carr) and milled down to 4.7 mm using a DMC 2 at a speed of 1200 mm/min and feed of .002 In./Tooth. Masking tape and JB Weld plastic epoxy were used to secure the sheet PVDF for machining. The thickness was further controlled by sanding with 60-grit sandpaper. The samples (denoted as PVDF-M going forward) were then cut into the proper shape for casting.

In addition to material and orientation, the effect of varying thickness on stiffness matching was also tested. Two batches of PLA, one with a thickness of ~4.1 mm (stiffness unmatched) and one with thickness ~4.5 mm (stiffness matched), were compared. The specimens are denoted as PLA-U and PLA-T, respectively. A summary of the thermoplastic surfaces and materials is provided in Table 4.

In summary, samples were tested to determine the effect of print surface, manufacturing method, stiffness matching, and material choice. The 3D-printed PVDF surfaces tested were PVDF-B, PVDF-T, and PVDF-S. Subtractively manufactured PVDF samples (PVDF-M) were compared. ABS, PLA-T, PVDF-T, 5% PCL, and 10% PCL thermoplastic layers using the same print surface were tested to determine the effect of material choice. Finally, the effect of thermoplastic layer thickness on bending stiffness matching was tested using PLA-T (matched or correct thickness) and PLA-U (unmatched or undersized thickness) samples.

After printing or cutting, the surface profiles of the thermoplastic layers were taken using a Keyence VR 6000 profilometer. The scan area was limited to ~2 cm × 2 cm, so several scans were taken to cover the entire area. Samples were marked with dry-erase markers to allow identification of the interface between images. The surface roughness was determined by using the surface roughness area tool in the analysis software for the VR 6000. A rectangular area was chosen to exclude the edges of the layer and include most of the visible sample area. The dimensions of the thermoplastic layers were taken using calipers.

DCB specimen assembly

A mold for casting HTPB was made using a lower plate and an upper plate, both made of PLA. The upper plate had an area allowing the sample to be placed vertically, to allow bubbles to escape the sample before curing. The upper and lower plates are sandwiched in a rubber gasket. The sandwich was then bolted together, tightened by hand, and torqued to approximately ¼ turn. The DCB thermoplastic, spacer, and backing were then placed in the mold vertically.

After assembly and placement of the printed parts, a 150 g mixture of low molecular weight HTPB resin (RCS) (55.56 wt%), isodecyl pelargonate (IDP) (RCS) (15.00 wt%), and dimeryl diisocyanate (DDI) (RCS) (29.44 wt%) was poured into the molds between the thermoplastic and backing. The filled mold was placed in a vacuum chamber at a pressure of ~0.1 atm for ~5 min until no bubbles were visibly leaving the mixture. The DCB specimens were cured at 40 °C for 96 h and then demolded. The curing temperature of 40 °C was chosen to minimize creep in the thermoplastic parts.

Additionally, casting sometimes resulted in samples with warped thermoplastic layers. Some warpages were acceptable; however, the sample warpage must result in an HTPB layer 2 mm or thicker in all places. Additionally, warping must be limited to the first 3 cm (initial crack position was 6 cm in) of the sample. This warpage was considered acceptable because this warping largely occurred before the load point of the hinges, so it should have low impact on the fracture toughness observed.

The acrylic hinges, as well as the outer regions of the thermoplastic layer and backing that they were adhered to, were preconditioned by scoring with a hobby knife. The hinges were adhered to using Lord epoxy (McMaster, 305-1/2). The epoxy was cured for at least 48 h at room temperature before testing.

Interfacial adhesion mechanical testing

DCB specimens were tested using a Mark 10 ESM 1500 with a 250 N load cell. The UTM used a rate of 2 mm/min to pull the sample apart and the force and travel were measured. A schematic showing the test setup is shown in Fig. 8.

The mode I fracture toughness was determined using the modified beam theory equation,

from ASTM D5528, where GI is the fracture toughness, P is the force applied, δ is the load point displacement, a is the delamination length, and b is the sample width9. The mode I fracture toughness was determined for all samples using the maximum force and the corresponding travel at the maximum force.

Failure of the samples was categorized as normal mode I, backing adhesion, HTPB failure, or thermoplastic failure. Categorization was performed visually, as a clear separation emerged between the bulk thermoplastic and HTPB layers in the case of mode I, or between the backing and HTPB layers in the case of backing adhesion. HTPB failure was visible as a large-scale tearing resulting in the breakthrough of the HTPB layer, while thermoplastic failure was visible as a separation between the print beads within the thermoplastic layer. Fracture toughness was only included in plots when the failure was mode I for ABS, PLA, and PVDF (-T, B, S, or M). Only one 10% PCL sample failed in mode I and none of the 5% PCL samples failed in mode I, so those results are not included in the fracture toughness figures. After testing, the failure surfaces of representative samples were imaged using a VR-6000 profilometer. These images and profiles were then analyzed for changes in the appearance of the HTPB and thermoplastic layers, particularly the deformation of thermoplastic layers and HTPB attached to the thermoplastic layers. All HTPB layers and some thermoplastic layers were sprayed with a uniform layer of chalk to allow profiling of the clear HTPB.

Data availability

Toughness/failure mode data are available in the Supplemental Information. Surface roughness data are publicly available on GitHub at the following link: https://github.com/McClain-Team/SurfaceRoughnessAdhesion. Other data are available upon request from the authors.

Code availability

The MATLAB code used in this work is available at the following link: https://github.com/McClain-Team/SurfaceRoughnessAdhesion.

References

Manero, A. et al. Implementation of 3D printing technology in the field of prosthetics: past, present, and future. Int. J. Environ. Res. Public Health 16 https://doi.org/10.3390/ijerph16091641 (2019).

Vu, I. Q., Bass, L. B., Williams, C. B. & Dillard, D. A. Characterizing the effect of print orientation on interface integrity of multi-material jetting additive manufacturing. Addit. Manuf. 22, 447–461 (2018).

Bhandaru, N., Sharma, A. & Mukherjee, R. Programmable nanopatterns by controlled debonding of soft elastic films. ACS Appl. Mater. Interfaces 9, 19409–19416 (2017).

Sammaiah, P., Rushmamanisha, K., Praveenadevi, N. & Rajasri Reddy, I. The influence of process parameters on the surface roughness of the 3d printed part In FDM process. IOP Conf. Ser.: Mater. Sci. Eng. 981, 042021 (2020).

Moussaif, N., Maréchal, P. & Jérôme, R. Ability of PMMA to improve the PC/PVDF interfacial adhesion. Macromolecules 30, 658–659 (1997).

Boeman, R. G., Erdman, D. L., Klett, L B., Lomax, R D. A Practical Test Method for Mode I Fracture Toughness of Adhesive Joints with Dissimilar Substrates. SAMPE-ACCE-DOE Advanced Composites Conference, Detroit, MI, September 27-28, 1999

Whitney, J. M., Browning, C. E. & Hoogsteden, W. A double cantilever beam test for characterizing mode I delamination of composite materials. J. Reinf. Plast. Compos. 1, 297–313 (1982).

ASTM. D6862: Standard Test Method for 90 Degree Peel Resistance of Adhesives (ASTM, 2021).

ASTM. D5528: Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. (ASTM, 2022).

Lopes, A. C. et al. The double cantilever beam test applied to mode I fracture characterization of polyamide 12 processed by selective laser sintering technology. Eng. Fract. Mech. 269, 108555 (2022).

Donoughue, M., Plotzke, J., Namboodiri, S., Seshadiri, R. & McClain, M. in AIAA SCITECH 2023 Forum (American Institute of Aeronautics and Astronautics 2023).

Collard, D. N., Fleck, T. J., Rhoads, J. F. & Son, S. F. Tailoring the reactivity of printable Al/PVDF filament. Combust. Flame 223, 110–117 (2021).

Collard, D. N. et al. Solid propellant with embedded additively manufactured reactive components. 4443 (2019).

Shirinov, A. V. & Schomburg, W. K. Pressure sensor from a PVDF film. Sens. Actuators A: Phys. 142, 48–55 (2008).

Gu, H., Zhao, Y. & Wang, M. L. A wireless smart PVDF sensor for structural health monitoring. Struct. Control Health Monit. 12, 329–343 (2005).

Huang, T., Liu, W., Su, C., Li, Y.-Y. & Sun, J. Direct ink writing of conductive materials for emerging energy storage systems. Nano Res. 15, 6091–6111 (2022).

Kong, Y., Ma, Y., Lei, L., Wang, X. & Wang, H. Crystallization of poly(ε-caprolactone) in poly(vinylidene fluoride)/poly(ε-caprolactone) blend. Polymers 9, https://doi.org/10.3390/polym9020042 (2017).

Groeninckx, G., Vanneste, M. & Everaert, V. In Polymer Blends Handbook Ch. 3 (eds Utracki, L., Wilkie, C.) 203–294 (Springer, 2003).

Martuscelli, E. & Demma, G. B. in Polymer Blends: Processing, Morphology, and Properties (eds Martuscelli, E., Palumbo, R. & Kryszewski, M.) 101–121 (Springer US, 1980).

Jo, W. H., Park, S. J. & Kwon, I. H. Phase behavior of poly(ε-caprolactone)/poly (vinylidene fluoride) blends. Polym. Int. 29, 173–178 (1992).

Buj-Corral, I., Domínguez-Fernández, A. & Durán-Llucià, R. Influence of print orientation on surface roughness in fused deposition modeling (FDM) processes. Materials 12, (2019).

Buj-Corral, I., Bagheri, A. & Sivatte-Adroer, M. Effect of printing parameters on dimensional error, surface roughness and porosity of FFF printed parts with grid structure. Polymers 23, 3834 (2020).

Meng, Z. et al. Design and additive manufacturing of flexible polycaprolactone scaffolds with highly-tunable mechanical properties for soft tissue engineering. Mater. Des. 189, 108508 (2020).

Bagherzadeh, E., Sherafat, Z., Zebarjad, S. M., Khodaei, A. & Amin Yavari, S. Stimuli-responsive piezoelectricity in electrospun polycaprolactone (PCL)/polyvinylidene fluoride (PVDF) fibrous scaffolds for bone regeneration. J. Mater. Res. Technol. 23, 379–390 (2023).

Icoz, D. Z. & Kokini, J. L. Probing the boundaries of miscibility in model carbohydrates consisting of chemically derivatized dextrans using DSC and FTIR spectroscopy. Carbohydr. Polym. 68, 68–76 (2007).

Zhang, P., Xu, P., Chung, S., Bandari, S. & Repka, M. A. Fabrication of bilayer tablets using hot melt extrusion-based dual-nozzle fused deposition modeling 3D printing. Int. J. Pharm. 624, 121972 (2022).

Khondoker, M. A. H., Asad, A. & Sameoto, D. Printing with mechanically interlocked extrudates using a custom bi-extruder for fused deposition modelling. Rapid Prototyp. J. 24, 921–934 (2018).

Yin, J., Lu, C., Fu, J., Huang, Y. & Zheng, Y. Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion. Mater. Des. 150, 104–112 (2018).

Lopes, L. R., Silva, A. F. & Carneiro, O. S. Multi-Material 3D Printing: the Relevance of Materials Affinity on the Boundary Interface Performance. 23, 45-52 (Additive Manufacturing, 2018).

Mustafa, I. & Kwok, T.-H. Development of intertwined infills to improve multi-material interfacial bond strength. J. Manuf. Sci. Eng. 144 https://doi.org/10.1115/1.4051884 (2021).

Dairabayeva, D., Perveen, A. & Talamona, D. Investigation on the mechanical performance of mono-material vs. multi-material interface geometries using fused filament fabrication. Rapid Prototyp. J. 29, 40–52 (2023).

Baca, D. & Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 106, 4509–4520 (2020).

Adib, A. Z. et al. Flexural strength of the sandwich-structured parts made of polylactic-acid and thermoplastic-polyurethane fabricated by using extrusion-based multi-material additive manufacturing. Int. J. Adv. Manuf. Technol. 132, 4805–4827 (2024).

Arifvianto, B. et al. Mechanical properties of the FFF sandwich-structured parts made of PLA/TPU multi-material. Prog. Addit. Manuf. 7, 1213–1223 (2022).

Peng, X. et al. Integrating digital light processing with direct ink writing for hybrid 3D printing of functional structures and devices. Addit. Manuf. 40, 101911 (2021).

Muralidharan, A., Uzcategui, A. C., McLeod, R. R. & Bryant, S. J. Stereolithographic 3D printing for deterministic control over integration in dual-material composites. Adv. Mater. Technol. 4, 1900592 (2019).

Roach, D. J. et al. The m4 3D printer: a multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 29, 100819 (2019).

Liu, F. et al. The effect of material mixing on interfacial stiffness and strength of multi-material additive manufacturing. Addit. Manuf. 36, 101502 (2020).

Acknowledgements

The authors would like to acknowledge support from the NDSEG fellowship (2022 #ND-2985420502) and the Purdue University School of Mechanical Engineering. We would also like to thank Adin Dove and Jessica Howell for the early mold design. Additionally, we would like to thank Rishie Seshadri for helping with the stiffness matching code. Our thanks are also due to Ismar Chew and Andrew Bok for help with machining. We are grateful for the use of the UTM in Herrick labs owned by Prof. Jeffrey Rhoads and the use of the DSC/TGA and co-owned profilometer from Prof. Steven Son.

Author information

Authors and Affiliations

Contributions

M.D. and M.M. conceived and designed the experiments performed. M.D., C.L., and J.P. produced samples for testing. M.D. performed tests and analyzed data. M.D. wrote the main manuscript with substantial input from M.M. All authors reviewed and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Donoughue, M., Lumpp, C., Pakulski, J. et al. Material and surface roughness effects on adhesion of thermoplastic-elastomeric interfaces for dissimilar material 3D printing. npj Adv. Manuf. 2, 12 (2025). https://doi.org/10.1038/s44334-025-00023-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44334-025-00023-2

This article is cited by

-

Optimization of material and extrusion parameters for wood flour–epoxy composites with potential additive-manufacturing applications in construction

European Journal of Wood and Wood Products (2026)