Abstract

Metal-polymer heterogeneous architectures enable the integration of mechanical, electrical, and thermal functionalities within a single structure, offering new possibilities in multifunctional systems. With advances in multi-material additive manufacturing (MMAM), it is now feasible to fabricate complex hybrid structures with high spatial resolution by combining dissimilar materials. This review highlights recent innovations across two key fabrication categories: direct printing and hybrid manufacturing. Emerging single-step printing processes, such as electrical field-assisted heterogeneous material printing and polymer-assisted photochemical deposition, allow precise metal patterning on polymers. Hybrid approaches—including electroplating and electroless plating—enhance surface robustness and conductivity through post-processing integration. Alternative strategies like mechanical interlocking, thermomechanical joining, and AddJoining address adhesion challenges in structural applications. These techniques are assessed for process scalability, material compatibility, and functional performance. The review concludes by identifying critical challenges and outlining future research directions toward scalable, high-performance, and sustainable metal-polymer hybrid systems enabled by next-generation MMAM technologies.

Similar content being viewed by others

Introduction

Dependability, shorter lead times, greater material adaptability, and cost-effectiveness are essential characteristics of an ideal manufacturing process in today’s environment of increasing industrialization and globalization of markets. Traditional production methods have found widespread application across many industries, yet they frequently fall short of meeting the demands of modern goods. Additive manufacturing (AM), commonly referred to as 3D printing, is swiftly transforming the realm of bespoke production by directly converting computer-aided design (CAD) data into tangible items1,2,3,4,5,6,7,8. Among the various advancements in this field, multi-material additive manufacturing (MMAM) has emerged as a transformative approach, opening new possibilities for engineering materials and functional components by transitioning from single-material to multi-material processes9,10,11. This shift not only enhances manufacturing and construction capabilities but also necessitates significant changes in design strategies, enabling the creation of complex, multifunctional structures with tailored properties12,13,14,15. However, MMAM techniques can be categorized based on the materials used (Fig. 1a), and recently there has been growing interest in leveraging metal-polymer into a single structure to create active devices and components with enhanced capabilities (Fig. 1b). Among the various material pairings, metal and polymer stand out as they are widely used in engineering applications, particularly in the context of metal-polymer hybrid systems, addresses the limitations of single-material AM by combining the distinct properties of metals and polymers, such as strength, flexibility, conductivity, and lightweight characteristics, into a single structure16,17,18,19. This capability is driving innovations across industries, including aerospace20,21, automotive22, electronics23,24,25, and biomedical applications26,27,28, where multifunctional and lightweight materials are highly desirable. However, integrating metal and polymer into a single structure remains challenging due to the stark differences in their material properties, hindering significant progress in this area.

a Classification of material combinations in MMAM. Copyright from ref. 14 and b Application areas of metal-polymer hybrids across different 3D printing techniques.

Several investigations have been conducted in recent years, leading to the development of diverse manufacturing methodologies for metal-polymer hybrid structures (Table 1), which take advantage of different AM techniques. Broadly, these strategies can be categorized into three main approaches: sequential deposition29,30, simultaneous deposition31,32,33, and hybrid processes34,35. Research concerning the 3D printing of metal-polymer hybrid components is confined to sequential AM procedures, where deposition involves the staged printing of metal and polymer materials, while effective, the method often struggles with strong interfacial bonding due to differences in thermal expansion and chemical compatibility36. However, simultaneous deposition addresses this by concurrently printing metal and polymer materials using dual-extrusion systems or co-sintering techniques, ensuring better integration and alignment of materials but requiring meticulous control of processing parameters to avoid defects30,37. Contemporary hybrid processes incorporate traditional manufacturing steps with additive techniques, such as pre-fabricating a polymer substrate onto which a metal layer is printed, offering advantages for creating conductive traces or reinforcing load-bearing regions38,39. This metallic coating acts as a functional skin, addressing the limitations of polymers while introducing new capabilities that are not inherent to either the polymer or the bulk metal alone.

For creating the metal-polymer hybrid various metallization processes have been explored for specific applications, such as sputtering on polymer membranes and optical devices or electroless plating in semiconductor fabrication40,41. The most promising methods include physical vapor deposition42,43, chemical vapor deposition44,45, electroplating46, and thermal spray (TS)47. Each of these strategies have intrinsic advantages and disadvantages48. Moreover, metal deposition on polymers is a specialized and non-traditional technique that involves several key considerations, including the choice of deposited metal49,50, the thermal stability of the polymer substrate51, the size and shape of the component29,52, process efficiency53, cost factors, compatibility with existing manufacturing systems, and potential environmental impacts54. Furthermore, each metallization technique has limitations, as most methods can only coat a select range of polymers with specific metals and within certain thickness constraints55. As discussed later in this review, this functional layer can significantly improve surface properties, including electrical and thermal conductivity, mechanical strength, and resistance to chemical and photochemical degradation56,57. As a result, polymer-based components benefit from increased durability, stability, and overall performance.

To understand the potential and challenges of MMAM, particularly the metal-polymer hybrid, it is crucial to evaluate the technical capabilities and deficiencies of existing techniques (Fig. 2). This review presents a comprehensive analysis of recent advancements in MMAM, with a particular focus on the fabrication of metal–polymer hybrid structures. The discussed fabrication strategies are broadly categorized into two main approaches: (1) 3D printing based single-process and (2) hybrid manufacturing methods. The review integrates perspectives from 3D printing, coating technologies, and materials science to explore metallization and polymerization techniques applicable across multiple length scales. Each section examines fabrication techniques in the context of material preparation, printing resolution, and functional integration. Specifically, Section “Direct printing of metal-polymer hybrids” focuses on single 3D printing approaches, highlighting direct multi-material printing strategies for metals and polymers. Section “Hybrid manufacturing of metal-polymer hybrids” explores hybrid manufacturing methods, beginning with 3D printing combined with electroplating and electroless plating—common in sequential or hybrid workflows. Additional hybrid approaches that fall outside conventional paradigms are also discussed. Section “Application of metal-polymer hybrids” identifies the most suitable techniques for various application domains, emphasizing their functional capabilities and potential for industrial adoption. By aligning fabrication methods with broader classification frameworks, this review offers a cohesive understanding of the current landscape and future directions for MMAM in metal–polymer systems. A deeper understanding of these integrated processes will support the optimization of design, durability, and performance in next-generation composite structures.

Direct printing of metal-polymer hybrids

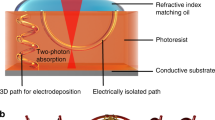

Electrical field-assisted heterogeneous material printing

As researchers continue to explore novel approaches for integrating dissimilar materials in AM, Electrical Field-assisted Heterogeneous Material Printing (EF-HMP) has emerged as a promising technique to enable seamless metal-polymer integration. For instance, Tang et al. proposed a direct printing method that addresses the inherent challenges of fabricating heterogeneous material systems by offering a single-step process at room temperature58. In this approach, the polymer matrix was fabricated using SLA, with the top surface of the printed structure subsequently exposed to a photocurable electrolyte solution for electrodeposition. The optimized solution comprised 32.5 wt% PEGDA, 2 wt% Irgacure 819 photoinitiator, 2 wt% PEDOT:PSS, 35 wt% of 1 mol/L CuSO₄ solution, and 28.5 wt% deionized water. During the EF-HMP process, the printed structure served as the cathode, while copper electrodes placed in a PDMS-coated glass tank acted as the anode (Fig. 3a). Upon application of a direct current, copper ions were released from the anode and migrated toward the printed polymer surface, where they were reduced and deposited as metallic copper particles. Key process parameters such as metal ion concentration, electric field voltage, and deposition time were systematically varied to optimize the process. The PDMS coating enhanced surface roughness, improving metal adhesion, and enabled uniform copper deposition with a thickness of 45–50 µm depending on geometry. This technique presents a compelling route for fabricating high-resolution, functional metal-polymer hybrids in a single integrated step.

a Electrical Field-assisted Heterogeneous Material Printing (EF-HMP), where UV-curable PEGDA-based resin is selectively patterned using a DMD projector, followed by copper ion deposition under an applied electric field. Copyright from ref. 58, b Polymer-assisted Photochemical Deposition (PPD), utilizing a DLP projection system to photochemically reduce silver ions into continuous films without substrate motion or vacuum processes. Copyright from ref. 59, and c Polymerization-Induced Phase Separation (3D PIPS) in vat photopolymerization, illustrating functional material migration and surface localization during curing, enabling the formation of functional coatings on printed parts. Copyright from ref. 60.

Polymer-assisted photochemical metal deposition

As part of ongoing efforts to develop high-resolution, cost-effective approaches for hybrid material integration, the Polymer-assisted Photochemical Deposition (PPD) process has emerged as a compelling method for printing metallic structures within optical devices such as Fabry-Perot (FP) cavities. This technique enables the direct formation of metallic reflectors without the need for conventional vacuum-based deposition or photolithography. In the reported approach, a UV dynamic light projector was employed to initiate a photochemical reduction reaction from a precursor solution composed of silver nitrate (metal salt), sodium citrate dihydrate (reducing agent), and polyacrylamide (pAAm, acting as a polymeric stabilizer and reactant)59. Upon UV irradiation, silver ions were reduced to silver nanoparticles (AgNPs), which were subsequently assembled into continuous films facilitated by the presence of pAAm. This additive process not only bypassed the need for complex lithographic patterning but also allowed for flexible design freedom in shaping the FP cavity. To construct the complete optical stack, the bottom metallic reflector was printed via PPD, and the top dielectric layer was fabricated using spin-coated polymethyl methacrylate (PMMA), followed by the printing of the top reflector (Fig. 3b). The resulting structure exhibited an asymmetric FP cavity with tunable optical properties, where parameters such as film thickness and layer resolution governed by exposure time and projector pixel size controlled the resonance behavior and structural color output. This enabled the generation of vivid, saturated colors ranging from blue to red, with excellent spatial resolution down to 6.5 µm. The smooth surface morphology and substrate compatibility further allowed for successful printing on various flexible platforms, including glass, PDMS, and plastic substrates, highlighting the versatility and precision of the PPD process in functional device fabrication.

3D polymerization-induced phase separation

Polymerization-Induced Phase Separation (3D PIPS) has recently garnered attention for its potential in enhancing the spatial control of functional material distribution within 3D printed structures, particularly in vat photopolymerization processes. This approach leverages the interplay between phase separation and polymer network formation to engineer surface-localized functionalities. Such gradients are particularly effective in reducing thermal mismatch stresses at metal–polymer interfaces, thereby improving the structural integrity and reliability of hybrid components. In addition to mechanical advantages, FGMs also facilitate multifunctionality. Deore et al. systematically investigated the role of resin formulation, specifically gelation kinetics and crosslinking density in directing material phase distribution during printing60 (Fig. 3c). The resin system utilized polyethylene glycol (PEG) diacrylate as a crosslinker and 2-ethylhexyl acrylate as the monomer, combined with a non-polymerizable silver precursor comprising silver neodecanoate (AgND) and 2-ethyl-2-oxazoline. Their findings indicated that shorter crosslinkers limited the mobility of AgND, reducing their presence on the surface, while formulations with lower crosslinker concentrations and delayed gelation allowed Ag to segregate toward the surface, resulting in effective coating. Demonstrations on 3D printed dipole antennas and bacterial inhibition zones confirmed the formation of surface-functionalized coatings with sufficient silver content for performance.

Together, EF-HMP, PPD, and 3D PIPS represent significant advancements in the direct fabrication of metal-polymer hybrid structures, each contributing unique advantages to this emerging field. EF-HMP enables high-resolution, conductive structures through room-temperature, single-step processing, utilizing electric fields to precisely direct metal ion deposition onto printed polymer matrices. The technique enhances interfacial bonding and supports the creation of complex, multifunctional architectures. PPD, on the other hand, offers a photochemical route for the deposition of ultra-thin, smooth silver films under ambient conditions. It facilitates patterning through image projection without substrate movement or precursor replenishment, and future improvements in spatial resolution such as through the enhancement of projection system numerical aperture could significantly broaden its application scope. While 3D PIPS stands out for its ability to reduce interfacial stresses between dissimilar materials while enabling the fabrication of functionally graded surfaces in a single step. Future work may explore the integration of diverse functional materials and resin chemistries to tailor surface characteristics and expand the design freedom of metal-polymer hybrid components. Collectively, these technologies emphasize the transformative potential of novel material-phase control strategies in advancing MMAM.

Hybrid manufacturing of metal-polymer hybrids

3D printing combined with electroplating

3D printing offers significant advantages in polymer and composite manufacturing, including design flexibility, rapid prototyping, and the ability to fabricate complex geometries. However, it faces limitations when it comes to metal fabrication. To overcome these challenges, electroplating technology has been integrated with AM, combining the precision and versatility of 3D printing with the functionality of metal deposition. This hybrid approach enables selective metal coating on conductive polymer substrates, expanding the potential applications of electroplating. As a widely used surface treatment technique, electroplating allows the deposition of one or more layers of metals or alloys onto a variety of substrates, enhancing surface properties such as conductivity, corrosion resistance, and mechanical strength61,62. This technique employs chemical or electrochemical methods to deposit a thin metal film on the surface of metals or other conductive materials, thereby enhancing their physical and chemical properties63. This metallic film can be pure metals, such as copper64,65, nickel66, silver67, or gold67, or alloys like zinc-nickel alloy68, tailored to meet diverse application needs. The fundamental principle of electroplating is based on electrolytic reactions61,62. During the electroplating process, the item to be plated serves as the cathode, while the plating solution is enriched with the metal cations to be deposited. These cations gain electrons at the cathode surface, reducing to metal atoms and forming a solid metal coating on the substrate. Electroplating offers protective, decorative, hardness enhancement, conductivity improvement, and friction reduction benefits69,70,71.

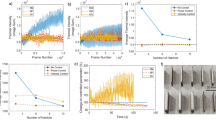

For example, dual-material extrusion printing technology was initially developed to selectively electroplate materials in conductive areas during the electroplating process. Lazarus et al. utilized both conductive and non-conductive filaments, printing polymer substrates using a dual extrusion fused filament fabrication (FFF) 3D printer to selectively electroplate circuits on printed parts, as depicted in Fig. 4a72. This low-cost, high manufacturing freedom, selective electroplating printing technology can be used to manufacture complex electronic devices, such as surface-mount packages and oscillator circuits. The resistance of the printed parts could be reduced by four orders of magnitude after plating, providing excellent electrical properties to printed electronics. Based on the same technology, Kim et al. demonstrated that only the Electrify material could achieve a uniformly thick and smooth plating layer, reducing the linear RMS roughness from 9.3 μm to 6.9 μm33. It also indicated that organic additives PEG-MPSA-JGB could significantly reduce the roughness of the electroplated surface (further reduced to 3.9 μm) and enhance conductivity (94 times lower than the as-printed structure). This manufacturing process holds great promises for fabricating complex structures such as inductive coils, horn antennas, heat spreaders, and sinks, as shown in Fig. 4b.

a Dual extrusion fused filament fabrication method and 3D printed circuit via electroplating. Copyright from ref. 72, b Inductive coils fabricated via selective electroplating. Copyright from ref. 33, c Selective electroplating on 3D surface. Copyright from ref. 32, d Selective electroplating on the interpenetrated lattice structure. Copyright from ref. 73, e The lattice structures manufactured by laser-based stereolithography 3D printing and electroplating possess both mechanical strength and conductivity, making them suitable for integration into unmanned aerial vehicles. Copyright from ref. 57.

Angel et al. also employed dual-material printing technology to electroplate nickel or copper in pre-designed conductive areas, which can be used to manufacture complex 3D structures like 2D or 3D circuits, as shown in Fig. 4c32. The resistance of the solenoid inductor dramatically decreased from 3 kΩ to 18.7 mΩ after plating, exhibiting a low-frequency inductance of 191 nH. Xue et al. utilized projection-based stereolithography 3D printing to create Kelvin cell–body-centered cell interpenetrated structures, which were then selectively coated with Zn and MnO2/PEDOT through a combination of electroless plating and electroplating, as shown in Fig. 4d73. These structures showcased a 221% increase in volumetric energy density and superior capacity retention compared to traditional designs, paving the way for advancements in future electrochemical energy storage technologies. He et al. proposed a hybrid AM approach based on Stereolithography 3D printing, surface treatment, activation, and electroplating57. As shown in Fig. 4e, a 40 μm thick copper layer could be electroplated on the surface of complex lattice structures printed, with resistivity as low as 1.9 × 10−8 Ω⋅m. These structures can be directly integrated into the frames of unmanned aerial vehicles due to their excellent mechanical and electrical properties, offering new ideas for the integrated manufacturing of mechanical and electrical structures.

Polymer AM combined with selective electroplating enables the fabrication of metal–polymer hybrid structures that are lightweight, geometrically complex, and exhibit enhanced electrical performance. The current capabilities in fabrication techniques and material selection are summarized in Table 2. This innovation represents a transformative advancement for the production of integrated circuits, 3D circuitry, and electronic devices, offering unprecedented design flexibility and functional integration across a broad range of high-tech applications. However, there is a growing demand for environmentally friendly electroplating processes capable of producing complex shapes in a single step. The integration of electroplating with AM technology needs further enhancement from developing new eco-friendly printing and electroplating materials, improving the smoothness of electroplated metals, and enhancing the bonding between metal and polymer interfaces. These improvements will substantially boost the durability and quality of products, ensuring that manufacturing processes are environmentally sustainable.

3D printing combined with electroless plating

In addition, electroless plating (ELP) is another surface metallization technique where metal deposition occurs spontaneously through an autocatalytic reaction to form a thin metal or alloy coating on the desired substrate74. ELP has attracted great interest recently, in contrast to electroplating methods, since it provides a cost-effective and facile manufacturing approach to form homogeneous metal coatings with enhanced electrical conductivity, high hardness, good chemical resistance, and improved surface roughness on various substrates75,76. Specifically, surface metallization of polymeric, ceramic, and dielectric materials via ELP has been demonstrated with metals such as Ni, Ni-P, Ni-B, Cu, and Ag exhibiting promising applications like lightweight antennas77, microelectronics78, and electromagnetic shielding devices79. Traditional electroplating methods integrate electrical currents to perform surface metallization on conductive substrates. However, ELP metal deposition is triggered by placing a substrate with activated catalytic sites into an electroless plating solution containing metal ions (i.e., Ni2+, Cu2+, Ag+, etc.) which subsequently react at the active sites to selectively deposit a metal coating on the surface of the substrate79,80. To address emerging challenges and limitations of polymer AM81, integrating it with ELP offers a promising solution. ELP enables high-resolution metal deposition on intricately shaped 3D substrates composed of various materials. This combination paves the way for the fabrication of uniquely shaped 3D circuits and microelectronic components, potentially driving significant breakthroughs in the design and manufacturing of next-generation smart sensors and flexible electronic devices81,82,83.

Electroless plating of 3D printed substrates is typically conducted via two different hybrid manufacturing approaches to place 2D patterned catalytic sites onto the substrates which are laser-activation assisted electroless plating and directly embedding catalytic materials or precursors within the printing material84,85. Zhang et al. utilized direct light processing (DLP) 3D printing and laser-activated selective ELP method to fabricate customizable Ag and Ni-P circuits on photopolymer substrates by dispersing catalytic precursors to form CuI, SnII, or Pd0 plating seeds86. Functional Ni-P and Ag structures exhibited microscale resolutions and electrical resistivities of 9.5(10-7) Ω·m and 2.2(10−8) Ω·m, respectively, for low-cost LED circuit boards, temperature sensors, and strain gauges, see Fig. 5a86. Similarly, Lee et al. showed that zinc oxide (ZnO) nanoparticles could be homogenized within UV-curable resin to fabricate complex 3D geometries that when activated with a UV-laser (λ = 355 nm) and placed in a copper ELP solution form highly conductive circuits with excellent surface adhesion86. Typical plating materials for laser-activated 3D printed substrates include Cu, Ni, Au, and Ag that have practical use in waveguides and flexible electronics, see Table 387,88. Instead of incorporating lasers for activating catalytic sites on 3D printed substrates, Ryspayeva et al. developed a multi-material 3D printing method using pristine and catalytic printing resin (AgClO4) to selectively deposit copper on the surface of photopolymer substrates with a thickness and electrical resistivity of 10.6–11.4 µm and 0.74(107) S·m−1, respectively (see Fig. 5b)89. Spatial resolution of 197 µm for plated copper was observed and could produce intricate and dimensionally precise temperature sensors, such as spiral, gear, or lego brick, with improved electrical performance89.

a laser assisted activation and DLP-based 3D printing of circuits with silver and nickel coatings. Copyright from ref. 86, b DLP-based 3D printing of embedded catalytic precursors for selective copper electroless plating of polymer substrates such as lightweight gears. Copyright from ref. 89, c multi-material DLP-based 3D printing of charged photopolymers to generate intricate Ni-P and dielectric 3D objects. Copyright from ref. 90, and d fabrication of laser-assisted activation of substrates utilizing a myriad of AM technologies such as SLA, Polyjet, SLS, and MJF. Copyright from ref. 94.

Furthermore, negative and neutral charge carrying cross linking solutions can be solidified into an interwoven 3D lattice structure utilizing multi-material DLP to produce dielectric/Ni-P after subsequently absorbing Pd (II) ions, within the negatively charged regions, and selectively depositing metal in an ELP process onto the substrate, as depicted in Fig. 5c90. Multi-material 3D printing of catalyst loaded printing material has been extended to include FFF and direct ink writing (DIW) approaches that can generate electronics with a wide range of metals including Ni, Cu, and Ag91,92,93. For example, Lazarus et al. utilized dual material extrusion to 3D printed a thermoplastic material (PLA/ABS) coated in copper through electroless plating for toroidal inductors with resistance measurements of ~0.31 Ω for Electrify conductive filament92. In a similar manner, laser-assisted activation of 3D printed structures can be realized through a myriad of AM process such as selective laser melting (SLM), DLP, FFF, and binder jetting (BJ) for complex electronics that are cost-effective with practical applications as mechatronic devices with conformal circuits on arbitrary 3D shapes (see Fig. 5d)94. The unique ability to combine AM technology and electroless seed plating to selectively metallization 3D surface features open intriguing insights into future microelectronics and flexible sensors for aerospace and biomedical applications. Table 3 provides a summary of the current materials, fabrication methods, and applications explored in recent research on the hybrid manufacturing of metal-polymer structures using 3D printing combined with electroless plating.

To sum up, electroplating and electroless plating offer distinct advantages and trade-offs for the metallization of 3D-printed polymer substrates. Electroplating utilizes an external power source and necessitates a conductive substrate, facilitating accelerated deposition rates and enhanced thickness control, thus rendering it appropriate for applications that require durable and uniform metal layers61,62. Nonetheless, its reliance on surface conductivity and the necessity for more complex masking procedures may restrict its applicability to intricate, non-conductive geometries. While ELP functions through an autocatalytic reaction that eliminates the need for external electrical current, facilitating uniform metal deposition on various substrates, including non-conductive and geometrically intricate structures74,75,76. ELP facilitates the metallization of dielectric materials; however, its chemical precursors, including sensitizers and catalysts, may elevate operational costs and necessitate stringent process control. Moreover, ELP demonstrates greater scalability for industrial applications owing to its versatility and diminished requirement for electrical connections or post-processing78,79,80. Therefore, the choice of an appropriate metallization technique must take into account the specific requirements of the application, including material compatibility, feature resolution, cost, and scalability.

However, to ensure successful metallization in electroplating and electroless plating processes, surface functionalization of polymer substrates plays a critical role in promoting metal adhesion and interfacial strength. Polymers are inherently chemically inert and lack the functional groups necessary for metal ion interaction; thus, surface activation techniques are essential. Common strategies include plasma treatment, chemical etching, and UV/ozone exposure, which introduce polar functional groups such as hydroxyl, carboxyl, and amine moieties on the polymer surface62,74,75. These groups enhance surface energy and create favorable conditions for metal nucleation during deposition. As illustrated in Fig. 2, such functionalization serves as a precursor step in electroless plating workflows, where catalytic sites-often activated via tin-palladium or silver seeding-enable uniform and adherent metal films. For example, Lee et al. embedded ZnO nanoparticles into UV-curable resins to facilitate localized surface activation and subsequent copper electroless plating with improved bonding performance95. Similarly, Ryspayeva et al. employed catalytic photopolymers to induce site-specific copper deposition via multi-material DLP printing89. These examples underscore the necessity of integrating surface chemistry principles with AM techniques to achieve robust, scalable metal-polymer hybrids.

3D printing combines with other manufacturing approaches

In addition to widely studied direct and hybrid deposition strategies, alternative manufacturing approaches such as mechanical interlocking, thermomechanical joining, and hybrid AM systems have gained traction for their potential to overcome interfacial limitations in metal–polymer integration96,97,98. For instance, based on AM and materials joining concepts, Falck et al. proposed a new assembly method “Addjoining” for creating multilayer metal-polymer hybrid structures99. Using polymer 3D printing techniques (FDM), the process creates layered hybrid structures. Where the metallic substrate is set in a slot on a constructing platform in the first stage and the extrusion head melts the polymer filament, which a nozzle deposits to create a complete layer over the metal substrate (Fig. 6a). They investigate the process feasibility by using two material combinations - aluminum 2024-T3 with acrylonitrile butadiene styrene and aluminum 2024-T3 with alternating layers of polyamide-6 and carbon-fiber-reinforced polyamide-6 and found that an ultimate lap-shear strength of 21.9 ± 1.1 MPa, indicating 19% better performance over the adhesively bonded joints. Using a roll-pressing technique, Sun et al. created a new scalable approach to manufacture metal-polymer hybrid protective layer on lithium (Li) metal called LiF@Po100. Where they press a polytetrafluoroethylene (PTFE) layer over Li metal using mechanochemically induced fluorination-defluorination reaction (Fig. 6b). PTFE’s highly electronegative fluorine atoms interact with lithium ions under this mechanical energy to create a composite layer made up of an inner LiF-rich area (in contact with the Li surface) and an outside polymer-rich layer including polyene and unsaturated fluoropolymers. This dual-layer design improves interfacial stability by offering mechanical flexibility and ionic conductivity. The resulting LiF@Po layer showed better electrochemical performance, including dendrite suppression, reduced interfacial resistance, and long-term cycle stability in lithium metal batteries.

a Schematic of the steps of the joining process. Copyright from ref. 99, b Schematic illustration of the layer formation on the Li metal by the roll pressing process between Li metal and PTFE film. Copyright from ref. 100, c Schematic of a thermomechanical joining process. Copyright from ref. 101, d Schematic of hybrid 3D printer with an integrated StarJet printhead. Copyright from ref. 35, e Schematic of FDM process to join metal-polymer layer. Copyright from ref. 102, f Schematic of compression overmolding of polymer composite on top of metal lattice to create hybrid structure. Copyright from ref. 96.

Furthermore, Fig. 6c shows a thermocompression joining technique that reflects the basic concept of thermomechanical joining methods employed in hybrid structure construction by means of simultaneous application of heat and pressure to enhance adhesion between metal and polymer or composite substrates101. In another study, Khan et al. presents a novel hybrid AM platform that integrates FFF and drop-on-demand (DoD) molten metal printing to fabricate 3D electronic structures in a single process (Fig. 6d)91. Using this method, conductive tin alloy features were directly printed on polymer substrates at ambient conditions without post-treatment, achieving low electrical resistance (5.7 mΩ/mm) and excellent shape fidelity with droplet spacing of 100 μm. Moreover, Fig. 6e demonstrates another method of producing metal-polymer hybrid by mechanical interlocking in which FDM deposits polypropylene (PP) filament onto a pre-drilled Al 5083 sheet; the molten filament not only fuses with the polymer base but also locks into the metal through the perforated geometry102. Figure 6f illustrates another hybrid fabrication process of metal-polymer composite structures using a novel additive manufacturing–compression overmolding (AM-CM) approach96. The top images show the fabrication of a metal mesh lattice using laser powder bed fusion (LPBF). Following lattice formation, the compression overmolding process is conducted. The central image shows the setup, where a thermocouple-equipped mold and heated platform apply temperature (~240 °C) and pressure (~6.4 MPa) to overmold a polymer composite onto the metal lattice. The polymer used is long fiber thermoplastic, specifically carbon fiber reinforced polyamide-6,6 (40% wt. CF/PA66), which is extruded using Big Area Additive Manufacturing (BAAM). This hybrid AM-CM process enables strong mechanical interlocking between the metal and polymer without adhesives or surface treatments. Compared to other metal-polymer joining techniques (e.g., chemical bonding or mechanical fasteners), this method achieves higher stiffness, improved tensile strength (~76.4 MPa), and tailored fiber orientation by leveraging the design freedom and controlled deposition of AM processes. To provide a consolidated view of these alternative strategies, Table 4 presents a summary of reported methods, highlighting the joining mechanism, materials used, and potential applications. This broader perspective not only fills a gap in current literature but also serves as a foundation for future innovation in MMAM technologies. These approaches taken together show the growing toolset for producing high-performance metal-polymer hybrids by combining mechanical anchoring, material compatibility, and process flexibility to solve the problems of metal-polymer integration.

Application of metal-polymer hybrids

Metal-polymer hybrid systems have emerged as a transformative platform for fabricating multifunctional devices that combine the structural flexibility and processability of polymers with the superior electrical and thermal properties of metals. Across various applications, these hybrids demonstrate significant performance enhancements. For instance, the EF-HMP process enables the integration of conductive copper layers onto photopolymer substrates, as seen in Fig. 7a, producing functional LED circuits with strong electrical continuity58. Similarly, in Fig. 7b, surface-modified ZrO₂ dielectrics in organic thin-film transistors (OTFTs) exhibit improved charge transport and threshold voltage due to better interfacial engineering in the hybrid system103. In MMAM, metal-polymer integration is exemplified in Fig. 7c, where electroless copper plating enables the direct soldering of electronic components onto 3D-printed photopolymers, achieving reliable miniaturized circuitry104. The flexible temperature sensor shown in Fig. 7d, e, created via silver nanoparticle printing on shape-memory polymers, highlights reconfigurable functionality enabled by hybrid designs89. Charge-programmed deposition (CPD) techniques further demonstrate the potential of hybrid architecture in RF applications; Fig. 7f, g and Fig. 7h, i show lightweight, copper-coated antennas with high directivity and thermal stability, suited for aerospace and communication systems105,106. In energy storage, metal-organic frameworks (MOFs) embedded in polymer electrolytes enhance ionic conductivity and suppress dendrite growth in lithium-ion batteries, offering safer, high-performance alternatives for next-generation devices (Fig. 7j)107. Lastly, Fig. 7k demonstrates the power of electroplated metal-polymer hybrids in 3D-printed solenoids, reducing resistance from 3 kΩ to 18.7 mΩ and delivering 191 nH inductance, confirming their effectiveness in producing compact, high-efficiency electronic components72. Collectively, these examples underline the versatility and superior performance of metal-polymer hybrid systems across electronics, energy, sensing, and RF domains.

a Circuit conductivity demonstration, and the circuit made by pure polymer with a copper layer. Copyright from ref. 58, b The digital photograph of the flexible OTFTs. Copyright from ref. 103, c Temperature sensor. Copyright from ref. 104, d A 3D printed temperature sensor fabricated by inkjet printing of silver nanoparticles. Copyright from ref. 89, e The 3D printed temperature sensor in its off state (top) and on state (bottom). Copyright from ref. 89, f A tree fractal antenna. Copyright from ref. 105, g A horn antenna with a septum polarizer. Copyright from ref. 105, h Polyimide (PI) with selectively patterned copper. Copyright from ref. 105, i A 3D folded electrically small antenna. Copyright from ref. 106, j Metal-organic frameworks (MOFs) embedded in polymer electrolytes. Copyright from ref. 107, k 3D printed a stable 555 timer circuits. Copyright from ref. 72.

The dimensional scale of metal-polymer hybrid structures, spanning from millimeters to meters, is crucial in influencing the appropriate manufacturing process, material choice, and application. At the microscale (1–1000 µm), techniques such as PμSL, PPD, and 3D PIPS demonstrate high resolution and precision control, rendering them suitable for applications in microelectronics, optical devices, and biomedical sensors59,60,108. While hybrid processes, including EF-HMP and electroless plating, are extensively employed at the millimeter to centimeter scale for the fabrication of functional circuits, antennas, and flexible sensors on intricate 3D surfaces32,33,58,72,73. These processes provide a balance between resolution and throughput, facilitating integration into soft robotics, wearable electronics, and energy devices. Additive manufacturing methods, when combined with metal reinforcement strategies such as electroplating, mechanical interlocking, and AddJoining, provide the necessary mechanical robustness and scalability for larger-scale applications, including UAV structures and automotive components, particularly for structural reinforcement and electromagnetic shielding70,92,95. Therefore, manufacturing decisions in MMAM are intrinsically connected to component scale, necessitating that process selection corresponds with the resolution, mechanical requirements, and functional needs of the intended application.

Summary and perspectives

The advancement of MMAM, particularly in the realm of metal-polymer hybrid fabrication, marks a pivotal moment in the evolution of modern manufacturing. By bridging the gap between metals and polymers, MMAM unlocks design and functional capabilities that are unattainable with single-material systems. The ability to combine the strength, conductivity, and durability of metals with the flexibility, light weight, and versatility of polymers provides a pathway toward the creation of highly integrated, multifunctional structures across a wide array of industries from aerospace and automotive to biomedical engineering and consumer electronics. This review has outlined the foundational principles, state-of-the-art techniques, and applications of metal-polymer hybrid MMAM. It categorizes the fabrication strategies into direct printing (such as EF-HMP, PPD, and 3D PIPS), hybrid printing (including electroplating and electroless plating), and other methods such as Addjoining, thermocompression joining, and roll-to-roll manufacturing. Each approach has unique advantages and limitations in terms of process complexity, interfacial bonding strength, structural resolution, scalability, and material compatibility.

Direct printing strategies have shown significant promise in achieving complex geometries and functional coatings with high precision and minimal post-processing. Technologies like EF-HMP enable room-temperature deposition of conductive metals directly onto polymer substrates, significantly improving manufacturing simplicity and material integration. However, challenges such as metal-polymer interfacial adhesion, surface roughness, and scalability still pose limitations. Similarly, the PPD and 3D PIPS processes introduce novel ways to integrate functionality directly into printed structures, offering unique solutions for optical, electrical, and antibacterial applications. Hybrid printing techniques that combine AM with post-processing steps like electroplating and electroless plating offer another pathway to metal-polymer integration. These methods leverage the high surface fidelity of polymer AM techniques and apply conductive metallic layers selectively onto desired regions. Dual-material extrusion printing followed by selective metallization has enabled the fabrication of embedded electronics, antennas, and microelectromechanical systems. Despite their potential, these hybrid approaches are constrained by the requirement for conductive surfaces, additional processing steps, and environmental concerns related to plating chemicals.

Moreover, there is no indication in MMAM that the benefits of any material can necessarily be utilized for applications that are desirable. In certain instances, researchers have taken advantage of the drawbacks associated with the creation of metal-polymer hybrid structures. This is because polymers and metals are fundamentally incompatible with one another in terms of their electrical, thermal, and chemical characteristics. Conventional polymers are insulators, and in order to permit electroplating, they need to undergo sophisticated chemical or physical treatments that include many steps. These treatments include surface etching, activation, and oxidation treatment. These methods are not only detrimental to the environment, but they are also economically infeasible since they involve the use of toxic chemicals and specialized industrial machinery. Even with conductive polymer composites, the electrical conductivity is frequently insufficient for uniform metal deposition. Additionally, potential drops along the surface limit the efficiency of the deposition process. The incompatibility of thermal expansion coefficients and the lack of interfacial adhesion between metals and polymers frequently results in a number of problems during the production and utilization of the material. Doping photocurable polymers with conductive fillers such as PEDOT:PSS or Ni nanoparticles, producing dopamine-functionalized resins, or utilizing self-catalyzing systems to enable direct or selective metal depositions are some of the innovative techniques that are receiving a growing amount of attention in the field of research. The enhancement of conductivity, the improvement of metal adhesion, and the reduction of process steps are all areas in which these approaches show promise. The issue that still exists, however, is to strike a balance between the electrical performance and the mechanical integrity of the system. The optimization of filler content and distribution over different scales (nano to macro), the improvement of interfacial chemistry, and the development of scalable, environmentally friendly metallization processes that retain the polymer’s processability for industrial applications should be the primary focus of future research.

Besides, the future of MMAM lies not only in material and process innovation but also in the intelligent orchestration of manufacturing workflows using data-driven methodologies. Machine learning (ML) and neural networks can be employed to predict metal–polymer interfacial strength, optimize deposition parameters such as electric field intensity in EF-HMP, and enable inverse design of hybrid structures with tailored performance. For instance, AI models trained on experimental datasets could identify hidden correlations between surface activation chemistry and plating quality, reducing trial-and-error cycles in electroless plating processes. Additionally, recent advances in laser-assisted deposition techniques81 exemplify how real-time sensor feedback combined with predictive algorithms can guide process control in dynamic environments. Also, the creation of novel polymer composites, functional inks, and surface treatments can improve interfacial compatibility and mechanical performance. The integration of nanoscale fillers, compatibilizers, and adhesion promoters may alleviate stress concentrations and enhance metal adherence. Real-time regulation of printing settings, facilitated by sophisticated sensing and feedback mechanisms, may ensure quality and consistency. Machine learning algorithms and digital twins can be utilized to enhance deposition trajectories, thermal regulation, and construction methodologies. The creation of industry-wide standards for assessing the mechanical, thermal, and electrical characteristics of metal-polymer hybrids would expedite certification and regulatory acceptance for industrial applications. Environmentally sustainable alternatives to conventional electroplating and electroless plating methods, together with recyclable materials, will be essential in mitigating environmental and health issues linked to hybrid manufacturing processes. Leveraging MMAM’s design flexibility, researchers and engineers may create multifunctional components that incorporate electrical circuits, sensors, actuators, and energy storage elements directly into structural elements. In conclusion, metal-polymer AM stands at the frontier of next-generation engineering and product design. As the field continues to mature, interdisciplinary collaboration among materials scientists, mechanical engineers, chemists, and computer scientists will be essential to unlocking its full potential. With sustained research efforts, thoughtful process innovation, and responsible design approaches, MMAM is poised to redefine manufacturing paradigms enabling smarter, lighter, and more sustainable solutions for the industries of tomorrow.

Data availability

No datasets were generated or analyzed during the current study.

References

Mobarak, M. H. et al. Recent advances of additive manufacturing in implant fabrication—a review. Appl. Surf. Sci. Adv. 18, 100462 (2023).

Zhu, Y. et al. Recent advancements and applications in 3D printing of functional optics. Addit. Manuf. 52, 1–50 (2022).

Charoensook, D. et al. Three-dimensional printing of bioinspired hierarchical structures for enhanced fog collection efficiency in 3D space via vat photopolymerization. Biomimetics 9, 734 (2024).

Sepasgozar, S. M. E., Shi, A., Yang, L., Shirowzhan, S. & Edwards, D. J. Additive manufacturing applications for industry 4.0: a systematic critical review. Buildings 10, 1–35 (2020).

Wong, K. V. & Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 1–10 (2012).

Bhuvanesh Kumar, M. & Sathiya, P. Methods and materials for additive manufacturing: a critical review on advancements and challenges. Thin Walled Struct. 159, 107228 (2021).

Hajare, D. M. & Gajbhiye, T. S. Additive manufacturing (3D printing): recent progress on advancement of materials and challenges. Mater. Today Proc. 58, 736–743 (2022).

Dhand, A. P. et al. Additive manufacturing of highly entangled polymer networks. Science 385, 566–572 (2024).

Zhang, C. et al. 3D printing of functional magnetic materials: from design to applications. Adv. Funct. Mater. 31, 1–38 (2021).

Goh, G. L. et al. A 3D printing-enabled artificially innervated smart soft gripper with variable joint stiffness. Adv. Mater. Technol. 8, 1–15 (2023).

Nadgorny, M. & Ameli, A. Functional polymers and nanocomposites for 3D printing of smart structures and devices. ACS Appl. Mater. Interfaces 10, 17489–17507 (2018).

Han, D. & Lee, H. Recent advances in multi-material additive manufacturing: methods and applications. Curr. Opin. Chem. Eng. 28, 158–166 (2020).

Pajonk, A., Prieto, A., Blum, U. & Knaack, U. Multi-material additive manufacturing in architecture and construction: a review. J. Build. Eng. 45, 103603 (2022).

Nazir, A. et al. Multi-material additive manufacturing: a systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 226, 111661 (2023).

Singh, R. et al. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 11, 1–14 (2019).

Blala, H. et al. Advances and applications of metal-polymer hybrid for load-bearing body-in-white structural components: a comprehensive review. Int. J. Adv. Manuf. Technol. 133, 3023–3057 (2024).

Wang, L. et al. Mechanical Characterization of multifunctional metal-coated polymer lattice structures. Materials 17, 741 (2024).

Phiri, R., Mavinkere Rangappa, S., Siengchin, S., Oladijo, O. P. & Ozbakkaloglu, T. Advances in lightweight composite structures and manufacturing technologies: a comprehensive review. Heliyon 10, e39661 (2024).

Fidan, I. et al. Recent inventions in additive manufacturing: holistic review. Inventions 8, 103 (2023).

Marques, A. et al. 3D multi-material laser powder bed fusion: Ti6Al4V–CuNi2SiCr parts for aerospace applications. Prog. Addit. Manuf. 9, 391–400 (2024).

Vakharia, V. S., Leonard, H., Singh, M. & Halbig, M. C. Multi-material additive manufacturing of high temperature polyetherimide (PEI)–based polymer systems for lightweight aerospace applications. Polymers 15, 561 (2023).

Tuli, N. T., Khatun, S. & Rashid, A. Bin. Unlocking the future of precision manufacturing: a comprehensive exploration of 3D printing with fiber-reinforced composites in aerospace, automotive, medical, and consumer industries. Heliyon 10, e27328 (2024).

Dzogbewu, T. C., Amoah, N., Afrifa Jnr, S., Fianko, S. K. & de Beer, D. J. Multi-material additive manufacturing of electronics components: a bibliometric analysis. Results Eng. 19, 101318 (2023).

Persad, J. & Rocke, S. Multi-material 3D printed electronic assemblies: a review. Results Eng. 16, 100730 (2022).

Goh, G. L. et al. Fabrication of design-optimized multifunctional safety cage with conformal circuits for drone using hybrid 3D printing technology. Int. J. Adv. Manuf. Technol. 120, 2573–2586 (2022).

Sharma, S. K., Saxena, K. K., Dixit, A. K., Singh, R. & Mohammed, K. A. Role of additive manufacturing and various reinforcements in MMCs related to biomedical applications. Adv. Mater. Process. Technol. 10, 231–248 (2024).

Riffe, M. B. et al. Multi-material volumetric additive manufacturing of hydrogels using gelatin as a sacrificial network and 3D suspension bath. Adv. Mater. 36, 2309026 (2024).

Mohammed, A. H. Biomedical Multi-materials Bone Scaffolds with Tuneable Properties Using Additive Manufacturing (The School of Engineering, 2023).

Fafenrot, S., Grimmelsmann, N., Wortmann, M. & Ehrmann, A. Three-dimensional (3D) printing of polymer-metal hybrid materials by fused deposition modeling. Materials 10, 1199 (2017).

Chueh, Y.-H., Wei, C., Zhang, X. & Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Addit. Manuf. 31, 100928 (2020).

Seol, S. K. et al. Electrodeposition-based 3D printing of metallic microarchitectures with controlled internal structures. Small 11, 3896–3902 (2015).

Angel, K., Tsang, H. H., Bedair, S. S., Smith, G. L. & Lazarus, N. Selective electroplating of 3D printed parts. Addit. Manuf. 20, 164–172 (2018).

Kim, M. J. et al. One-step electrodeposition of copper on conductive 3D printed objects. Addit. Manuf. 27, 318–326 (2019).

Silva, M., Felismina, R., Mateus, A., Parreira, P. & Malça, C. Application of a hybrid additive manufacturing methodology to produce a metal/polymer customized dental implant. Procedia Manuf. 12, 150–155 (2017).

Ozlati, A., Movahedi, M., Tamizi, M., Tartifzadeh, Z. & Alipour, S. An alternative additive manufacturing-based joining method to make Metal/Polymer hybrid structures. J. Manuf. Process. 45, 217–226 (2019).

Yuan, S., Shen, F., Chua, C. K. & Zhou, K. Polymeric composites for powder-based additive manufacturing: materials and applications. Prog. Polym. Sci. 91, 141–168 (2019).

Matsuzaki, R., Kanatani, T. & Todoroki, A. Multi-material additive manufacturing of polymers and metals using fused filament fabrication and electroforming. Addit. Manuf. 29, 100812 (2019).

Li, J. et al. Direct activation of copper electroplating on conductive composite of polythiophene surface-coated with nickel nanoparticles. Compos. Part B Eng. 154, 257–262 (2018).

Surjadi, J. U., Gao, L., Cao, K., Fan, R. & Lu, Y. Mechanical enhancement of core-shell microlattices through high-entropy alloy coating. Sci. Rep. 8, 1–10 (2018).

Delkhosh, F., Qotbi, A., Hossein Behroozi, A. & Vatanpour, V. Magnetron sputtering in membrane fabrication and modification: applications in gas and water treatment. J. Ind. Eng. Chem. 143, 85–108 (2025).

Elanjeitsenni, V. P., Vadivu, K. S. & Prasanth, B. M. A review on thin films, conducting polymers as sensor devices. Mater. Res. Express 9, 22001 (2022).

Ferreira, A. A., Silva, F. J. G., Pinto, A. G. & Sousa, V. F. C. Characterization of thin chromium coatings produced by PVD sputtering for optical applications. Coatings 11, 1–21 (2021).

Mavukkandy, M. O. et al. Thin film deposition techniques for polymeric membranes—a review. J. Memb. Sci. 610, 118258 (2020).

Ghosh, S. Electroless copper deposition: a critical review. Thin Solid Films 669, 641–658 (2019).

Shacham-Diamand, Y., Osaka, T., Okinaka, Y., Sugiyama, A. & Dubin, V. 30years of electroless plating for semiconductor and polymer micro-systems. Microelectron. Eng. 132, 35–45 (2015).

Li, X., Ming, P., Ao, S. & Wang, W. Review of additive electrochemical micro-manufacturing technology. Int. J. Mach. Tools Manuf. 173, 103848 (2022).

Gonzalez, R., Ashrafizadeh, H., Lopera, A., Mertiny, P. & McDonald, A. A review of thermal spray metallization of polymer-based structures. J. Therm. Spray. Technol. 25, 897–919 (2016).

Fotovvati, B., Namdari, N. & Dehghanghadikolaei, A. On coating techniques for surface protection: a review. J. Manuf. Mater. Process. 3, 28 (2019).

Che, H. et al. Metallization of polymers by cold spraying with low melting point powders. Surf. Coat. Technol. 418, 127229 (2021).

Che, H. Q., Liberati, A., Vo, P. & Yue, S. Cold spray of mixed Sn-Zn and Sn-Al powders on carbon fiber reinforced polymers. Mater. Sci. Forum 941, 1892–1897 (2019).

Singh, H., Sidhu, T. S. & Kalsi, S. B. S. Cold spray technology: future of coating deposition processes. Fract. Struct. Integr. 6, 69–84 (2012).

Xue, J. et al. Stereolithographic 3D printing-based hierarchically cellular lattices for high-performance quasi-solid supercapacitor. Nano Micro Lett. 11, 1–13 (2019).

Kelly, P. J. & Arnell, R. D. Magnetron sputtering: a review of recent developments and applications. Vacuum 56, 159–172 (2000).

Singh, P., Itankar, N. & Patil, Y. Biomanagement of hexavalent chromium: current trends and promising perspectives. J. Environ. Manag. 279, 111547 (2021).

Ishizuka, N., Yamada, T., Izui, K. & Nishiwaki, S. Topology optimization for unifying deposit thickness in electroplating process. Struct. Multidiscip. Optim. 62, 1767–1785 (2020).

Rohani Nejad, S., Hesari, S. & Mirbagheri, S. M. H. Effect of nickel and copper shells on mechanical properties of advanced lightweight TPU metamaterials during uniaxial compression. Sci. Rep. 14, 1–16 (2024).

He, L. et al. Multifunctional polymer-metal lattice composites via hybrid additive manufacturing technology. Micromachines 14, 2191 (2023).

Tang, T., Ahire, B. & Li, X. Scalable multi-material additive manufacturing of bioinspired polymeric material with metallic structures via electrically assisted stereolithography. J. Manuf. Sci. Eng. 145, 1–9 (2023).

Choi, S. et al. Structural color printing via polymer-assisted photochemical deposition. Light Sci. Appl. 11, 84 (2022).

Deore, B. et al. Direct printing of functional 3D objects using polymerization-induced phase separation. Nat. Commun. 12, 1–12 (2021).

Kanani, N. Electroplating: basic principles, processes and practice. In Electroplating: Basic Principles, Processes and Practice 1–353. https://doi.org/10.1016/B978-1-85617-451-0.X5000-3 (2005).

Schlesinger, M. Deposition on Nonconductors. in Modern Electroplating 5th edn. 413–420. https://doi.org/10.1002/9780470602638.ch15 (2011).

Abbott, A. P., Frisch, G. & Ryder, K. S. Electroplating Using Ionic Liquids. Annu. Rev. Mater. Res. 43, 335–358 (2013).

Tang, T., Li, X. Additive manufacturing of polymeric material with metallic structures. U.S. Patent Application 18/358,725 [P]. (2024).

Miura, S. & Honma, H. Advanced copper electroplating for application of electronics. Surf. Coat. Technol. 169–170, 91–95 (2003).

Sellers, W. W. Nickel plating. Plat. Surf. Finish. 71, 64–70 (1984).

Satpathy, B., Jena, S., Das, S. & Das, K. A comprehensive review of various non-cyanide electroplating baths for the production of silver and gold coatings. Int. Mater. Rev. 68, 825–861 (2023).

Vasilache, T. et al. Electrochemical mechanism of nickel and zinc-nickel alloy electrodeposition. Recent Pat. Corros. Sci. 2, 1–5 (2010).

Giurlani, W. et al. Electroplating for decorative applications: recent trends in research and development. Coatings 8, 1–25 (2018).

Gugua, E. C., Ujah, C. O., Asadu, C. O., Von Kallon, D. V. & Ekwueme, B. N. Electroplating in the modern era, improvements and challenges: a review. Hybrid. Adv. 7, 100286 (2024).

Yelton, W. G. & Harper, J. C. Electroplated coatings for friction, lubrication, and wear technology. Friction, Lubrication, and Wear Technology Vol. 18 0 at https://doi.org/10.31399/asm.hb.v18.a0006395 (2017).

Lazarus, N. et al. Selective electroplating for 3D-printed electronics. Adv. Mater. Technol. 4, 1900126 (2019).

Xue, X. et al. Interpenetrated structures for enhancing ion diffusion kinetics in electrochemical energy storage devices. Nano Micro Lett. 16, 1–11 (2024).

Zhang, Y. et al. Electroless plating cycle process for high-conductivity flexible printed circuits. ACS Sustain. Chem. Eng. 9, 11991–12004 (2021).

Akin, S., Nath, C. & Jun, M. B.-G. Selective surface metallization of 3D-printed polymers by cold-spray-assisted electroless deposition. ACS Appl. Electron. Mater. 5, 5164–5175 (2023).

Khairullina, E. M. et al. High rate fabrication of copper and copper-gold electrodes by laser-induced selective electroless plating for enzyme-free glucose sensing. RSC Adv. 11, 19521–19530 (2021).

Koul, S. K., Swapna, S. & Karthikeya, G. S. Additive Manufacturing in Antenna Development BT—Antenna Systems for Modern Wireless Devices. In (eds Koul, S. K., Swapna, S. & Karthikeya, G. S.) 283–319. https://doi.org/10.1007/978-981-97-3369-9_9 (Springer Nature Singapore, Singapore, 2024).

Rektor, A. et al. Electroless plating of copper on laser-induced graphene for flexible hybrid electronic applications. Adv. Mater. Technol. 10, 2401901 (2025).

Kwak, B.-S., Jeong, G.-W., Choi, W.-H. & Nam, Y.-W. Microwave-absorbing honeycomb core structure with nickel-coated glass fabric prepared by electroless plating. Compos. Struct. 256, 113148 (2021).

Nakasuji, A., Gohda, S. & Kawasaki, H. Graphene-oxide-assisted electroless Cu plating on a glass substrate. Langmuir 41, 729–738 (2025).

Li, J. et al. Rapid production of customized 3D electronics via hybrid additive manufacturing technology. In Proc. IEEE 69th Electronic Components and Technology Conference (ECTC) 135–140. https://doi.org/10.1109/ECTC.2019.00028 (2019).

Song, K. et al. Multi-material 4D printing and 3D patterned metallization enables smart architectures. Compos. Part B Eng. 295, 112218 (2025).

Rehman, U. et al. 3D-Printed pyramidal honeycomb structures plated with silver and infused with Fe3O4–epoxy composite for microwave absorption applications. Adv. Eng. Mater. 27, 2402030 (2025).

Wang, P. et al. Laser-activated selective electroless plating on 3D structures via additive manufacturing for customized electronics. Adv. Mater. Technol. 8, 2300516 (2023).

Katsantonis, I. et al. Strong and broadband pure optical activity in 3D printed THz chiral metamaterials. Adv. Opt. Mater. 11, 2300238 (2023).

Zhang, H. et al. Functional metallic circuitries created by laser-activated selective electroless plating for 3D customized electronics. Mater. Des. 248, 113513 (2024).

Li, J. et al. Laser-activated metallization-based hybrid additive manufacturing technology for 3D flexible electronics. ACS Appl. Polym. Mater. 7, 1969–1978 (2025).

Bretosh, K., Hallais, S., Chevalier-Cesar, C., Zucchi, G. & Bodelot, L. Gold metallization of hybrid organic-inorganic polymer microstructures 3D printed by two-photon polymerization. Surf. Interfaces 39, 102895 (2023).

Ryspayeva, A., Zhakeyev, A., Desmulliez, M. P. Y. & Marques-Hueso, J. Multimaterial 3D printing technique for electronic circuitry using photopolymer and selective metallization. Adv. Eng. Mater. 24, 2201243 (2022).

Wang, Z. et al. Charge-programmable photopolymers for 3D electronics via additive manufacturing. Adv. Funct. Mater. 34, 2313839 (2024).

Lee, S. et al. Electroless deposition-assisted 3D printing of micro circuitries for structural electronics. ACS Appl. Mater. Interfaces 11, 7123–7130 (2019).

Lazarus, N. et al. Direct electroless plating of conductive thermoplastics for selective metallization of 3D printed parts. Addit. Manuf. 55, 102793 (2022).

Zhan, J. et al. Metal-plastic hybrid 3D printing using catalyst-loaded filament and electroless plating. Addit. Manuf. 36, 101556 (2020).

Vieten, T., Weser, S., Schilling, A., Gläser, K. & Zimmermann, A. Integration of mechatronic functions on additively manufactured components via laser-assisted selective metal deposition. Adv. Funct. Mater. 34, 2312833 (2024).

Lee, D. et al. Photocurable three-dimensional printing resin to enable laser-assisted selective electroless metallization for customized electronics. ACS Appl. Polym. Mater. 3, 4735–4745 (2021).

Pokkalla, D. K. et al. A novel additive manufacturing compression overmolding process for hybrid metal polymer composite structures. Addit. Manuf. Lett. 5, 100128 (2023).

Pokkalla, D. K. et al. Design optimization of lightweight automotive seatback through additive manufacturing compression overmolding of metal polymer composites. Compos. Struct. 349–350, 118504 (2024).

Kumar, D. et al. Anisotropic mechanical properties of polymer composites from a hybrid additive manufacturing-compression molding process using x-ray computer tomography. 46. https://doi.org/10.1117/12.2614620 (2022).

Falck, R., Goushegir, S. M., dos Santos, J. F. & Amancio-Filho, S. T. AddJoining: a novel additive manufacturing approach for layered metal-polymer hybrid structures. Mater. Lett. 217, 211–214 (2018).

Sun, S. et al. Facile: Ex situ formation of a LiF-polymer composite layer as an artificial SEI layer on Li metal by simple roll-press processing for carbonate electrolyte-based Li metal batteries. J. Mater. Chem. A 8, 17229–17237 (2020).

Lambiase, F., Scipioni, S. I., Lee, C. J., Ko, D. C. & Liu, F. A state-of-the-art review on advanced joining processes for metal-composite and metal-polymer hybrid structures. Materials 14, 1894 (2021).

Khan, Z., Koltay, P., Zengerle, R., Kartmann, S. & Shu, Z. One-stop hybrid printing of bulk metal and polymer for 3D electronics. Adv. Eng. Mater. 26, 2300922 (2024).

Wang, Z. et al. Ultra-light antennas via charge programmed deposition additive manufacturing. Nat. Commun. 16, 427 (2025).

Jeong, J. W. et al. Hybrid polymer/metal oxide thin films for high performance, flexible transistors. Micromachines 11, 264 (2020).

Yang, H., Leow, W. R. & Chen, X. 3D printing of flexible electronic devices. Small Methods 2, 1–7 (2018).

Yang, C. L., Tsai, C. L. & Chen, S. H. Implantable high-gain dental antennas for minimally invasive biomedical devices. IEEE Trans. Antennas Propag. 61, 2380–2387 (2013).

Le, P. A., Nguyen, N. T., Nguyen, P. L., Phung, T. V. B. & Do, C. D. A mini review of current studies on metal-organic frameworks-incorporated composite solid polymer electrolytes in all-solid-state lithium batteries. Heliyon 9, e19746 (2023).

Hensleigh, R. et al. Charge-programmed three-dimensional printing for multi-material electronic devices. Nat. Electron. 3, 216–224 (2020).

Mohammadi Abokheili, R., Kordani, N., Aghajani Derazkola, H. & Nejadali, J. Experimental investigation of the polymer-metal hybrids interfacial bonding fabricated by fused deposition modeling. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 239, 127–137 (2024).

Khan, Z. et al. Iterative printing of bulk metal and polymer for additive manufacturing of multi-layer electronic circuits. npj Adv. Manuf. 1, 1 (2024).

Credi, C., Bernasconi, R., Levi, M. & Magagnin, L. Self-activating metal-polymer composites for the straightforward selective metallization of 3D printed parts by stereolithography. J. Mater. Res. Technol. 22, 1855–1867 (2023).

Nouri, A., Rohani Shirvan, A., Li, Y. & Wen, C. Surface modification of additively manufactured metallic biomaterials with active antipathogenic properties. Smart Mater. Manuf. 1, 100001 (2023).

Xiao, J. et al. 3D printing of metallic structures using dopamine-integrated photopolymer. J. Mater. Res. Technol. 19, 1355–1366 (2022).

Ryspayeva, A., Zhakeyev, A., Desmulliez, M. P. Y. & Marques-Hueso, J. Multimaterial 3D printing technique for electronic circuitry using photopolymer and selective metallization. Adv. Eng. Mater. 24, 1–8 (2022).

Azar, G. T. P., Danilova, S., Krishnan, L., Fedutik, Y. & Cobley, A. J. Selective electroless copper plating of ink-jet printed textiles using a copper-silver nanoparticle catalyst. Polymers 14, 3467 (2022).

Sadeqi, A., Rezaei Nejad, H., Owyeung, R. E. & Sonkusale, S. Three dimensional printing of metamaterial embedded geometrical optics (MEGO). Microsystems Nanoeng. 5, 16 (2019).

Vaněčková, E. et al. Copper electroplating of 3D printed composite electrodes. J. Electroanal. Chem. 858, 113763 (2020).

Bernasconi, R. et al. Magnetically navigable 3D printed multifunctional microdevices for environmental applications. Addit. Manuf. 28, 127–135 (2019).

James, S. & Contractor, R. Study on nature-inspired fractal design-based flexible counter electrodes for dye-sensitized solar cells fabricated using additive manufacturing. Sci. Rep. 8, 1–12 (2018).

Bahr, R. A. et al. Novel uniquely 3D printed intricate Voronoi and fractal 3D antennas. In Proc. IEEE MTT-S International Microwave Symposium (IMS) 1583–1586. https://doi.org/10.1109/MWSYM.2017.8058934 (2017).

Falco, A., Petrelli, M., Bezzeccheri, E., Abdelhalim, A. & Lugli, P. Towards 3D-printed organic electronics: planarization and spray-deposition of functional layers onto 3D-printed objects. Org. Electron. 39, 340–347 (2016).

Ansari, K., Van Kan, J. A., Bettiol, A. A. & Watt, F. Stamps for nanoimprint lithography fabricated by proton beam writing and nickel electroplating. J. Micromech. Microeng. 16, 1967–1974 (2006).

Melentiev, R. et al. Towards decoupling chemical and mechanical adhesion at the electroplated metal/polymer interface via precision surface texturing. Surf. Interfaces 38, 102875 (2023).

Islam, A., Hansen, H. N. & Tang, P. T. Direct electroplating of plastic for advanced electrical applications. CIRP Ann. 66, 209–212 (2017).

Acknowledgements

The authors acknowledge ASU Startup Funding, National Science Foundation (NSF grants No. CMMI-2114119, CMMI-2338752).

Author information

Authors and Affiliations

Contributions

All authors contributed to the writing, review, and editing of the manuscript. S.N. led the preparation of Sections “Introduction” and “Summary and perspectives”, as well as Figures 1 and 2 Table 1. M.Y. was responsible for Section “Direct printing of metal-polymer hybrids” and Figure 3, while T.T. contributed to Sections “Direct printing of metal-polymer hybrids” and “Hybrid manufacturing of metal-polymer hybrids”, along with Figure 4 and Table 2. D.J. prepared Section “Hybrid manufacturing of metal-polymer hybrids”, Figure 5, and Table 3. R.L. and S.N. collaborated on Section “Hybrid manufacturing of metal-polymer hybrids” and Figure 6, and T.L. and S.N. prepared Section “Application of metal-polymer hybrids”, Figure 7, and Table 4. All authors reviewed and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Nipu, S.M.A., Tang, T., Joralmon, D. et al. Advances and perspectives in multi-material additive manufacturing of heterogenous metal-polymer components. npj Adv. Manuf. 2, 31 (2025). https://doi.org/10.1038/s44334-025-00045-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00045-w

This article is cited by

-

Environment–process–structure–property linkages in additive manufacturing

Nature Reviews Clean Technology (2025)