Abstract

Interconnected networks of rigid struts are critical for the design of lightweight, load-bearing structures. However, modeling stress distribution in them is difficult due to complex organizational patterns and collective effects. Leveraging visualization of local elastic deformations by birefringence imaging, we investigate how graph theory (GT) provides a framework for stress prediction. We investigate the role that geometric features play in the collective mechanical behavior of anisotropic networks, which also addresses the fundamental problem of applying discrete mathematics to physical structures. We show that modified centrality parameters combining lattice topology with structural metrics describing geometry more accurately predict local stress, as validated through finite element modeling. Further improvements are made by incorporating boundary conditions into the centrality definition, in a manner that simultaneously simplifies the computational cost demonstrating capabilities of GT for predictions of mechanical properties that can be extended to various types of complex soft matter.

Similar content being viewed by others

Introduction

Regular struts latices are ubiquitous in lightweight loadbearing structures. The emergence of metamaterials has highlighted the performance advantages of stochastic strut-based architectures for energy dissipation, long-term resilience, and reliable performance across diverse loading conditions1,2,3,4. Inspired by load-bearing structures ubiquitous in biology, aperiodic strut lattices also provide the possibility of simultaneous optimization of multiple, often contradictory, mechanical properties. This unique capability ensures reliable performance under variable deformation directions as well as both periodic and static loads. Since struts and beams at different scales are common components of different types of soft matter, the same property optimization methods can be extended to numerous materials. However, even small changes in lattice geometry, strut connectivity, or material composition can lead to drastically altered mechanical responses in both regular and stochastic lattices5. These changes often result from phenomena such as shockwave resonances, nonlinear deformations, and long- and short-range collective effects6, which can culminate in catastrophic events like avalanche failures. Conventional computational methods for predicting stresses in complex structures, such as finite element models (FEMs), are often both time-intensive and resource-demanding, requiring numerical solutions for models that integrate rigid and soft elements. The inherent nonlinearity of deformations further complicates these analyses, creating intricate correlations between global stress propagation and localized failures. These challenges underscore the need for complementary approaches to support and enhance FEMs, especially for complex mechanical metastructures combing order and disorder.

Systems of interconnected rigid elements with virtually any degree of complexity can be described as graphs, \({\mathcal{G}}\left({\mathcal{N}},{\mathcal{E}}\right)\), or sets of nodes and edges5,7,8. Graph Theory (GT) allows for predictions of electrical9,10,11,12,13,14,15, thermal, and mechanical16,17,18,19 properties using the notions of charge, heat, and stress transport20 through networks, which result in correlations between physical properties and several GT parameters21. For example, betweenness centrality22,23 and other GT parameters7 characterizing topological distances and connection patterns24 can identify struts where the mechanical stress or electrical current are concentrated at a fraction of the computational cost required for FEMs2,19,25. Furthermore, Schrödinger or wave equations solved on so called quantum graphs26 can describe stress flow through the network27, which can incorporate the methods of quantum chemistry/physics to further facilitate the computations. Importantly, GT methods are applicable to a wide range of loadbearing structures inclusive of networks from spheroidal particles19,23,28,29, auxetic lattices30, and biomimetic composites31.

Although GT may offer highly efficient coarse-graining for material design, geometric features of material networks are usually lost with these approaches. And whilst the need to incorporate geometry into GT descriptions of physical networks has been acknowledged17,32,33, there are scientific problems especially pertinent to material systems that must still be addressed. One of them is the problem of continuity of graph representations. It emerges when methods of discrete mathematics are applied to loadbearing structures with gradually variable geometric parameters exemplified by strut lattices. Then, seemingly identical methodologies for mapping strut lattices onto graphs can lead to reasonable predictions for some structures and topological parameters but not for others7,27,28. Another underexplored problem is that behavior depends on boundary conditions, which has direct implications for stress predictions and hence for thresholds of local failures. This study addresses these fundamental aspects of graph-structure relations for both regular and stochastic lattices by introducing (1) variable node-edge representation of struts accounting for local geometries; (2) structural descriptors combining topological, physical and metric characteristics and (3) targeted selection of shortest paths contributing to betweenness centrality near boundaries. The overall methodology was validated for different configurations of strut lattices using stress birefringence imaging (Fig. 1a) and FEM simulations.

a Laser-cut acrylic network samples are subjected to uniaxial compression. Stressed struts are captured by stress birefringence imaging. b The different type of network structures tested include ordered lattices such as rhombic and (4, 6, 12) Archimedean lattices, a complex auxetic metamaterials generated computationally and complex fiber network extracted from a micrograph of an aramid nanofiber sample. c–e Depiction of network discontinuities in rhombic lattices with different angles of strut intersection, θ, showing that when becomes increasingly small, single strut intersections (red ovals) are represented by multiple nodes in their graph abstraction. Without length weighting, the GT representation of (d) and (e) are identical. f Radial plot comparing the GT descriptors for networks in (b). The different values across the parameter space highlights the differences in the graphs describing the physical networks. g Polarized photograph of 2D complex auxetic network while stressed. The brightness intensity of individual struts is directly proportional to the magnitude of the stress experienced by the strut. The graph, \({\mathcal{G}}\left({\mathcal{N}},{\mathcal{E}}\right)\),corresponding to the 2D auxetic network sample is shown in red.

Results

Experimental models and their graphs

In this work, regular and stochastic strut lattices in physical space will be referred to as networks. The key difference between a network and a graph is that the latter is a mathematical abstraction of the former in topological space. To explore graph-structure relations we employed two-dimensional (2D) macroscale networks with both regular and stochastic patterns laser-cut from transparent sheets of poly(methylmethacrylate) (Fig. 1b). The well-known strong photoelastic behavior of poly(methylmethacrylate)23 enables visualization of local stress using polarized light and stress birefringence imaging. Regular networks in this study include rhombic lattices with angle of strut intersection of 90° as well as square (4,6,12) Archimedean lattices. The stochastic networks include auxetic lattices, generated using an algorithm by Reid et al.30 as well as networks representing 2D projections of 3D self-assembled aramid nanofiber (ANF) networks8.

We found that adequate representations of the networks can be surprisingly nonobvious even for relatively simple 2D networks. It might be intuitive to expect that there is a one-to-one mapping of a 2D network onto a graph when struts are represented as edges and their intersections are represented as nodes. However, such models might not be the best for stochastic networks where struts can intersect with a wide range of angles or even through families of ordered lattices with different geometric variations of fixed topological patterns. For example, imagine a pin-jointed rhombic lattice section with struts having a non-zero, fixed thickness (Fig. 1c). Its internal angle, θ, determines the characteristics of the strut intersection. Let us assume that for θ = 90° each strut intersection is represented by a single node. When θ is small (~15–20°), the strut intersection may no longer be represented by a single node, requiring a short edge (and hence extra node) to represent it (Fig. 1d). For 0° < θ < 10°, the edge representing the intersection becomes approximately the same size as the edges representing struts (Fig. 1e). If the struts are thick enough, even a rhombic network with θ = 90° will exhibit this unintuitive behavior. To extract a graph from the network in the most unbiased and reproducible manner we use our open-source package, StructuralGT, without merging any nodes (details in Methods).

Relating stress and structure for strut lattices

Multiple GT parameters can be used to describe strut lattice structures. These parameters include average degree, which is the average number of edges connected to each node; average clustering coefficient, which is higher when it is more likely for connected nodes to share common neighbors; assortativity coefficient, which is higher than zero when similar nodes are connected to each other, and lower when dissimilar nodes are connected; the average nodal connectivity, which is the average number of node removals required to disconnect a randomly selected pair of nodes. Edge length deviation gives a comparison of how the length of edges vary within each network (and is defined as the ratio of the edge length standard deviation to mean). While each individual parameter cannot unequivocally describe a network, their set distinguishes the structure of strut lattices in short-, medium- and long-ranges.

Extending this GT framework to distinguishing different properties, we may develop specialized parameters that combine network topology, geometry, and physical parameters that can be even more specific than topological sets. For conceptual continuity, let us first consider the GT parameter geodesic edge betweenness centrality (\({{EBC}}_{G}\)) defined for edge e as

where e refers to a specific edge, N is the number of nodes. \({\sigma }_{{st}}\) is the number of shortest paths between a given source and target, s, t, respectively. \({\sigma }_{{st}}(e)\) is the number of shortest paths between s, t containing e. This is depicted in Fig. 2a. Typically, the “shortest path” in the context of GT refers to the shortest sequence of adjacent edges that connects two nodes. Similarly to other centrality measures7,22,23,24, \({{EBC}}_{G}\) can be used to identify bottlenecks for transport through networks of current, heat, and stress34.

The aforementioned problem of continuity clearly presents itself when considering a common situation of nodes for intersections with small θ angles, where the struts can also be curved. Such intersections can be represented by one, two, or even more nodes (Fig. 1c–e), which has been pointed out in the past for networks of nanofibers35. In the case of data sets containing many thousands of nodes, one may deliberately merge the closely positioned nodes to simplify the analysis, but the conceptual problem of the mismatch between a network in physical space and its abstraction as a graph in topological space would nevertheless remain. As such, graph representations go through discontinuous changes when nodes are added or removed. The network-graph discontinuity is exacerbated when the struts have thicknesses of similar magnitudes to the voids. In all these cases, the point at which to assign two nodes to a strut is arbitrary.

In other words, minor structural variations in the network manifest as inadequately abrupt changes in the parameter being used for critical assessment of the local flow of current, heat, and stress and thus, reliability of the structure. We therefore argue that GT parameters must depend on continuous material changes to adequately map the continuity of the geometry.

With geometric and topological characteristics of the lattice being important for their mechanical properties, we weight the edges by their length, which also contributes to the continuity of the GT representation of the lattice. The resulting definition of shortest path corresponds to the sequence of adjacent edges connecting two nodes with minimal total Euclidean distance traveled along the edges comprising the list.

The appropriate terminology for a betweenness centrality weighted by length, is to substitute “geodesic” for “length weighted”. In Fig. 2b, c, we use a simple network to compare \({{EBC}}_{G}\) with length-weighted edge betweenness centrality (\({{EBC}}_{L}\)), respectively. While all edges are equal for \({{EBC}}_{G}\), \({{EBC}}_{L}\) distinguishes between the edges based on their length, which is certainly essential for stress transfer. We note that for networks with edges of approximately equal length (e.g., those from packings of equally sized particles), length weighting is less important, and \({{EBC}}_{G}\) and \({{EBC}}_{L}\) perform similarly.

a Calculation of geodesic edge betweenness centrality (\({{EBC}}_{G}\)). On each iteration, the algorithm identifies the edges comprising the shortest path between the highlighted pair of nodes (red). The \({{EBC}}_{G}\) values of these edges are increased according to Eq. (1) (green). b, c Comparison between unweighted and weighted betweenness. Weighting allows distinction between short and long paths. d, e Comparison between \({{EBC}}_{G}\) and length-weighted edge betweenness centrality (\({{EBC}}_{L}\)) for the K1,4 graph. f Comparison of computation time as a function of number of nodes for both \({{EBC}}_{G}\) and \({{EBC}}_{{LB}}\) parameters.

While \({{EBC}}_{G}\) and \({{EBC}}_{L}\) capture organization of the network on a global scale because of the summation of all the short paths through each edge, they are invariant to boundary conditions, i.e. the actual geometry of a specific strut lattice, which is problematic for an array of properties and external stimuli (e.g. direction of uniaxial compression). In fact, this problem also shows up at the intuitive level. To show it distinctly, we calculate \({{EBC}}_{G}\) for a square lattice unit cell (or K1,4 complete graph) in Fig. 2d. In the K1,4 graph, every edge has the same value of \({{EBC}}_{G}\). Under uniaxial compression, however, one would intuitively expect stress to concentrate along the edges aligned with the direction of compression. Therefore, our parameter should also be some function of the boundary conditions applied to the material. To incorporate this, instead of summing over all source-target pairs (as in 1), we select the subset of source-target pairs in contact with the perturbed boundaries and call our parameter edge boundary betweenness centrality (\({{EBC}}_{B}\)). In this definition, we designate all nodes in contact with the source of stress as source nodes. All nodes along the opposite plane are designated as target nodes. The use of length weighting gives the parameter a “length weighted” prefix, denoted \({{EBC}}_{{LB}}\), for simplicity:

where S and T are the number of source and target nodes \({\mathcal{S}}\) and \({\mathcal{T}}\) are sets of source and target nodes, respectively. \({\sigma }_{{st}}^{w}(e)\) is the number of length-weighted shortest paths between s and t containing e. The marked difference between \({{EBC}}_{G}\) with \({{EBC}}_{{LB}}\) can easily appreciated in Fig. 2d, e.

To further highlight the difference between \({{EBC}}_{G}\) with \({{EBC}}_{{LB}}\), we compare the computation time for both across a series of samples (Fig. 2f). Because the modification we use here reduces the number of pairs of vertices between which shortest paths must be found from ∼\({N}^{2}\) to ∼\({ST}\), the scaling for number of shortest path calculations required is reduced approximately by a factor of N for square samples. Even after accounting for the more expensive weighted shortest path algorithm (Dijkstra algorithm instead of breadth first search), \({{EBC}}_{{LB}}\) remains favorable to \({{EBC}}_{G}\), scaling as O(n1.5log(n)), as opposed to O(n2) for \({{EBC}}_{G}\); details for scaling and benchmarking calculations are given in the SI.

While we arrived at this form of \({{EBC}}_{{LB}}\) without imposing any constitutive relations or any other mechanical characteristics on the networks, the results agree with the classical theories of beams. Definitions and analysis of length-weighting has a direct connection to the definition of axial forces in strut-based lattices. For example, the axial force, P of a pin-jointed member of the network is P ~ EA/l, where E is the Young’s modulus, A is the cross-sectional area and l is the length of the strut4,36. This connection can be investigated numerically for virtually any structure using finite element analysis (FEA). FEA is a commonly used numerical method to approximate solutions to boundary value problems in materials and structural mechanics. The method relies on the discretization of continuous structures into a finite number of interconnected elements. A global system of equations is assembled from the governing equations at each individual element, which in our linear elastic case corresponds to Hooke’s law. Upon application of boundary conditions, the system is solved for unknown displacements. Stresses and strains are then computed from the displacement field and strain-displacement relations. Details on the specific model utilized can be found in the Methods section. For additional information, Zienkiewicz, Taylor and Zhu offer a detailed review of the method and its applications37.

Consider the kite structure in Fig. 3a, subjected to a uniaxial compressive stress, ST, applied on the top as indicated. The stresses to the left and right side of the top of the structure are Sl and Sr, respectively. To illustrate how strut length affects stress distribution in a structure in static equilibrium we performed FEA of the structure and plotted the ratio of average axial stresses in the right and left struts, Sr/Sl, as a function of increasing elongation of one half of the kite, l/l0 (Fig. 3b). As the initial length of the two struts on the right side of the structure increases, the magnitude of the stresses on the right side rapidly decreases. Figure 3b also shows the ratio of GT parameters, \({{EBC}}_{{LB}}\) and \({{EBC}}_{G}\), for the left and right struts. A perfect GT parameter would be identical to the FEA Sr/Sl curve. As expected, \({{EBC}}_{G}\) does not change as a function of l/l0. Although \({{EBC}}_{{LB}}\) does not follow Sr/Sl exactly, it provides a step-function approximation to the nearly discontinuous redistribution of stress.

a Example of rigid-jointed struts forming a rhombus. Uniaxial compressive stress, ST, imposed on the top. Stresses, Sl and Sl represent the stresses experienced by the left and right members of the rhomboid structure, respectively. The vertical dimension of the structure is 2l0, and the horizontal, l0 + l. The graph (b) shows the ratio Sr/Sl and the ratio between values of GT parameters in the left and right members:\({{EBC}}_{G}\) and \({{EBC}}_{{LB}}\).

While we have discussed the benefits of mitigating of discreteness of GT parameters (Fig. 3), modification of \({{EBC}}_{{LB}}\) to smooth the discontinuity also has notable disadvantages, elaborated in the SI. An analytical solution for the axial stresses of a similar family of structures under load is developed in the SI and the results give similar trends to Fig. 3.

Predictions of stressed edges

Following Berthier et al.19, the relative magnitude of an edge’s GT parameter can be used to predict its response to stress based on network topology. Stressed edges can be classified for an array of different network structures using our stress birefringence imaging technique (a1 through d1, Fig. 4). The edges are expected to carry greater stress when \({{EBC}}_{{LB}}\) > \(\left\langle {{EBC}}_{{LB}}\right\rangle\), where \(\left\langle .\right\rangle\) denotes the average parameter value over all edges within a strut lattice. In the middle column of Fig. 4 (a2 through d2), edges with \({{EBC}}_{{LB}}\) > \(\left\langle {{EBC}}_{{LB}}\right\rangle\) are highlighted in yellow. \(\left\langle {EBC}\right\rangle\) can be adapted to each lattice: when the stress classification cutoff for \(\left\langle {EBC}\right\rangle\) is decreased, more edges are classified as stressed, which is important for understanding the likelihood of consequential misclassification and potential edge failure. Overall, the impact of the cutoff values on classification can be compiled as a receiver operating characteristic (ROC) curve to assess overall performance30. The greater the area under the curve, the better the performance (Fig. 4a3 through d3). In all cases, \({{EBC}}_{{LB}}\) outperforms \({{EBC}}_{G}\), because of inclusion of the boundary conditions and length weighting. The performance discrepancy increases from Fig. 4a3 to d3, as the strut lattices become increasingly ordered and, consequently, anisotropic. Therefore, the inclusion of the boundary conditions becomes increasingly important.

The first column (a1–d1) displays birefringence images of laser cut samples while being uniaxially compressed. a1 Macroscale network laser cut from poly(methylmetacrylate) sheets with 2D architecture extracted from the 2D projection of aramid nanofiber network imaged by scanning electron microscopy. b1 Complex auxetic network generated from the pruning of struts from a sphere packing algorithm (c1) (4, 6, 12) Archimedean lattice and (d1) corresponds to 90◦ diamond lattice. The prediction of struts experiencing high stress are shown in the second column (a2–d2) highlighted in yellow over experimental photographs. The third column (a3–d3) shows ROC curves comparing predictions of \({{EBC}}_{G}\) and \({{EBC}}_{{LB}}\) for each of the tested network structures. Predictions are improved for \({{EBC}}_{{LB}}\) for all cases. The graph models were extracted using StructuralGT. No node merger or pruning options were applied.

For example, the network in Fig. 4c1 is an (4,6,12) Archimedean lattice with a discrete edge orientation distribution (EOD, Supplementary Fig. S4c). To demonstrate the necessity of considering boundary conditions in this instance, we note that, in the absence of geometric considerations, a strut in the infinite (4,6,12) Archimedean lattice can be in one of only three environments. However, some edges that are topologically equivalent (or degenerate) will be in different geometric environments under uniaxial compression because they will be more aligned with the direction of compression, and so will experience different amounts of stress, thus lifting the degeneracy. Furthermore, every edge in the rhombic lattice is topologically and geometrically equivalent when the direction of compression is aligned the vertical axis (Fig. 4d1). For a finite sample, their degeneracy is lifted by their proximity to the lattice boundary. In both the stress and \({{EBC}}_{{LB}}\), this simplicity and order causes high values to predictably distribute themselves in the shape of an hourglass (Fig. 4d2).

In prior works, we showed that aramid nanofibers (ANFs, Fig. 4a1) can self-assemble into stochastic networks with uniform EOD (Supplementary Fig. S4a). But because the other networks in this study were generated in a less random manner, their EODs are less uniform which translates into a more anisotropic mechanical response. For example, the network in Supplementary Fig. 4b1 was obtained using an algorithm for generating complex auxetic lattices30. By calculating the EOD, we see this algorithm aligns the majority of edges with the reference axes of the image (i.e. 0° and 90° (Supplementary Fig. S4b). Because of this, the edges under stress strongly depend on the direction of compression. Figure 5a, b shows how the stressed edges change when the sample is compressed in different directions. To obtain a prediction of stressed edges from graph models, the GT parameter should be adjusted according to this boundary condition. Figure 5e, f show how \({{EBC}}_{{LB}}\) redistributes itself across stressed edges when the source and target nodes are changed, because of the different direction of compression. The value of \({{EBC}}_{G}\) remains similar for two copies of the same network one cut horizontally, one vertically (Fig. 5c, d). The sensitivity and accuracy of this analysis of stress distribution could be assessed from the fact that the high \({{EBC}}_{G}\) edges are not identical between Fig. 5c and Fig. 5d. Compressing in a different direction requires cutting a different sample. Albeit following the same geometrical model, the samples have minor differences, which is picked up by the image analysis.

Supplementary Fig. S5 shows how this sample cutting effect is removed by carrying out FEA for networks from ANF structures, confirming both accuracy and sensitivity of the GT analysis in this framework.

Finally, we note the distinction between our approach combining topological and geometric parameters with spring networks38. While both approaches can be used for predicting mechanics in complex systems, spring network models are mathematically equivalent to a modified form of \({{EBC}}_{G}\). Importantly, it was shown to fail in predicting accurate distributions of stress in strut lattices which is discussed in the SI along with the specific limitations of spring models.

Discussion

Here we elaborate the problem of adequacy of graph models and GT parameters for predicting stress distribution in architected strut lattices based on the notions of percolation29 and flow39 of stress through complex networks. An essential requirement for such models is continuity of GT parameters for determining stress concentration points, which conflict with the framework of discrete mathematics, while being essential for material design. It can be addressed by the adaptive placement of nodes in graph models using dedicated software packages, such as StructuralGT40. This task also requires utilization of parameters combining topological, geometric, and physical characteristics of materials. From a practical perspective, it is important to point out that the incorporation of boundary conditions can be most efficiently achieved by removing computations from the parameter definition, as opposed to adding them, based on geometric reasoning. This study shows that the removal of less important shortest paths for betweenness centrality, reduces the number of required computations by an order of magnitude, while simultaneously improving the classification of stressed edges.

Two limitations of the graph models should also be noted (see details in SI). First, the uniformity of regular lattices makes them more susceptible to experimental error and implicit, but often incorrect, assumptions exemplified by the uniformity of the applied loads. Such assumptions could be easily enshrined in the GT models, which directly impacts the accuracy of stress predictions. Second, this approach is particularly suitable for the design of materials with high void fractions being optimized for lightweight and, for instance, Young’s modulus. The GT methodology becomes progressively less applicable for strut lattices with gradually decreasing void fraction. For example, ‘lattices’ with thick struts start behaving like a continuous sheet and thus, should not be represented as a graph. Both of these limitations highlight the necessity of integration of topological GT descriptors with geometry-based metrics.

There are several avenues which this work can be taken further. Extension to more complex boundary conditions would necessitate modifications to the parameter definition. For example, multiaxial compression would involve summing over several node pair sets from Cartesian products: \({{\mathcal{S}}}_{1}\times {{\mathcal{T}}}_{1}\) and \({{\mathcal{S}}}_{2}\times {{\mathcal{T}}}_{2}\), where \({{\mathcal{S}}}_{1},\,{{\mathcal{T}}}_{1},\) \({{\mathcal{S}}}_{2},\) and \({{\mathcal{T}}}_{2}\) are nodes along the top, bottom, left, and right boundaries. Extension to shear deformation would likely require biasing shortest paths to traverse the direction of shear, potentially via augmenting length weights with edge orientation information. Our GT-based method does not depend on the dimensionality of the network and can be applied to three-dimensional problems, if a digital representation of said structure is available. If the three-dimensional structure is not known a priori, appropriate imaging techniques are needed for both for mapping the structure and visualizing the deformation of internal members. To this end, tomographic techniques can be applied to obtain three-dimensional maps of structures and several techniques including, mechanochemically responsive molecules and ultrasound can be used for deformation visualization41. These techniques open a promising pathway that allows for the extension of the analysis from 2D to 3D networks.

Additionally, the development of material and time dependent parameters, exemplified by \({{EBC}}_{{LB}}\) (t), will be helpful for propagation of waves in strut lattices, which is of great practical importance. From the conceptual standpoint, struts at millimeter, micrometer, nanometer, and molecular scales are a fundamental building block of numerous materials. It would be technologically important and fundamentally exciting to evaluate the validity of our approaches at different scales. The GT approach presented here enables seamless translation across scales. Due to its structural universality and simplicity of extraction of GT parameters from images, it can be potentially useful for the development of AI/ML-based foundational models of different types of soft matter for prediction of mechanical and other properties. Note however, special care will need to be taken for careful parametrization of these models that will need to be validated for different types of struts and their organizational patterns.

Methods

Certain instruments and materials are identified in this paper to specify the experimental details adequately. Such identification does not imply a recommendation by the National Institute of Standards and Technology (NIST) or that the materials are necessarily the best available for the purpose.

Sample fabrication

Strut samples were laser cut from 1.5 mm thick acrylic sheets (McMaster-Carr), using a Full Spectrum Laser, Muse 3D laser cutter. The samples based on aramid nanofibers (ANFs) were made as was described in ref. 42.

Mechanical measurements

Quasi-static, uniaxial compression experiments were performed on acrylic network structures using a Stable Microsystems Texture Analyzer TA, XTplus. Experiments were displacement-controlled at a rate of 0.1 mm s−1 for both loading and unloading. The sample was illuminated using linearly polarized light and a cross-polarized digital camera (JAI BM-500GE) captured images of the deformed sample.

Computational details

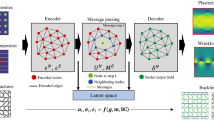

Graph theory

Extraction of the graphs from images of experimental samples and FE was carried out with our package StructuralGT35,40. Calculation of betweenness centrality parameters were also carried out using functions that are part of this package. The package first binarizes images, according to user-specified image processing options. Skeletonization then reduces the binarized image to a one-pixel wide representation of the networks structure. Pixels are then categorized as representing nodes or edges, depending on their number of neighbors. From this information, the graph is extracted. The graph is exposed via a python-API so that various structural parameters, and different forms of betweenness, with different cutoffs can be trialed on the different images. \({{EBC}}_{{LB}}\) and related betweenness centrality calculations are available from the betweenness module, which makes use of the igraph library43.

Finite element analysis

Two-dimensional domains representing disordered network sample was modeled using Finite element analysis (FEA) COMSOL Multiphysics (v6.2) and built-in Solid Mechanics module. The ANF structures modeled were 55 mm × 65 mm and were analyzed under plane strain conditions. Boundary fixed constraints are applied at the bottom of the geometry to emulate experimental conditions. The left and right edges of the network were kept free of constraints. A uniaxial, compressive boundary load ranging from 0 to 1 MPa was applied to the top edge of the sample, simulating an external load applied quasistatically. The network samples ware modeled as an isotropic, linear elastic material. The constituent material of the network was polymethylmethacrylate (PMMA), with Young’s modulus of 3.0 GPa, and Poisson’s ratio of 0.4.

The simple strut structure in Fig. 3 was constructed using the built-in 2D geometry editor. The auxetic disordered network was generated using computational methods outlined by Reid et al. 30. The ANF structure was extracted from a 2D projection of an electron micrograph. A free triangular mesh was applied in all models with element sizes ranging from 0.02 to 4.49 mm. Symmetry was not used to reduce the model in any of the simulations performed in this study. The simulation was carried out as a stationary study using the using the COMSOL-integrated MUMPS (Multifrontal Massively Parallel Sparse) solver. The constitutive behavior was modeled using Hooke’s law for linear elasticity:

where \({\boldsymbol{\sigma }}\) is the Cauchy stress tensor, \({\bf{C}}\) is the fouth-order elasticity tensor, \({\rm{\varepsilon }}\) is the small strain tensor, and \({\bf{u}}\) displacement vector field. Von Mises equivalent stresses were extracted and compared to polarized light experiments of networks and GT results.

Data availability

The original data reported in the figures of this manuscript is available from the DeepBlue data server at the university of Michigan as open source data http://deepblue.lib.umich.edu/data/concern/data_sets/f7623d71s.

Code availability

The code for StructuralGT software package is available at https://github.com/compass-stc/StructuralGT.

References

Fulco, S., Budzik, M., Xiao, H., Durian, D. & Turner, K. Disorder enhances the fracture toughness of mechanical metamaterials. PNAS Nexus, 4, pgaf023 (2025).

Jia, Z., Liu, F., Jiang, X. & Wang, L. Engineering lattice metamaterials for extreme property, programmability, and multifunctionality. J. Appl. Phys. 127, 150901 (2020).

Zaiser, M. & Zapperi, S. Disordered mechanical metamaterials. Nat. Rev. Phys. 5, 679–688 (2023).

Goodrich, C. P., Liu, A. J. & Nagel, S. R. The principle of independent bond-level response: tuning by pruning to exploit disorder for global behavior. Phys. Rev. Lett. 114, 225501 (2015).

Shen, M. et al. An autonomous design algorithm to experimentally realize three-dimensionally isotropic auxetic network structures without compromising density. npj Computational Mater. 10, 113 (2024).

Krishnaraj, K. Emergence of preferred subnetwork for correlated transport in spatial networks: On the ubiquity of force chains in dense disordered granular materials. Preprint at https://arxiv.org/abs/2102.07130 (2021).

Vecchio, D. A. et al. Spanning network gels from nanoparticles and graph theoretical analysis of their structure and properties. Adv. Mater. 34, 2201313 (2022).

Zhang, H. et al. Graph theoretical design of biomimetic aramid nanofiber composites as insulation coatings for implantable bioelectronics. MRS Bull. https://doi.org/10.1557/s43577-021-00071-x (2021).

Wu, W. et al. Layer-by-layer assembled nanowire networks enable graph-theoretical design of multifunctional coatings. Matter 8, 101870 (2025).

Kim, D. & Nam, J. Analyzing conducting rod networks using centrality. Electrochim. Acta 370, 137725 (2021).

Noruzi, R., Lim, E., Pokuri, B. S. S., Chabinyc, M. L. & Ganapathysubramanian, B. A. graph based approach to model charge transport in semiconducting polymers. npj Computational Mater. 8, 38 (2022).

Jackson, N. E., Savoie, B. M., Chen, L. X. & Ratner, M. A. A simple index for characterizing charge transport in molecular materials. J. Phys. Chem. Lett. 6, 1018–1021 (2015).

Nirmalraj, P. N. et al. Manipulating connectivity and electrical conductivity in metallic nanowire networks. Nano Lett. 12, 5966–5971 (2012).

Tarasevich, Y. Y. U., Vodolazskaya, I. V. & Eserkepov, A. V. Electrical conductivity of random metallic nanowire networks: an analytical consideration along with computer simulation. Phys. Chem. Chem. Phys. 24, 11812–11819 (2022).

Chang, L., Friedrich, K., Ye, L. & Toro, P. Evaluation and visualization of the percolating networks in multi-wall carbon nanotube/epoxy composites. J. Mater. Sci. 44, 4003–4012 (2009).

Broedersz, C. P., Mao, X., Lubensky, T. C. & MacKintosh, F. C. Criticality and isostaticity in fibre networks. Nat. Phys. 7, 983 (2011).

Liu, Y., Dehmamy, N. & Barabási, A.-L. Isotopy and energy of physical networks. Nat. Phys. 17, 216–222 (2021).

Patel, R. et al. A transdisciplinary approach for analyzing stress flow patterns in biostructures. Math. Comput. Appl. 24, 47 (2019).

Berthier, E., Porter, M. A. & Daniels, K. E. Forecasting failure locations in 2-dimensional disordered lattices. Proc. Natl Acad. Sci. USA 116, 16742–16749 (2019).

Smart, A., Umbanhowar, P. & Ottino, J. Effects of self-organization on transport in granular matter: a network-based approach. Europhys. Lett. 79, 24002 (2007).

Bassett, D. S., Owens, E. T., Daniels, K. E. & Porter, M. A. Influence of network topology on sound propagation in granular materials. Phys. Rev. E 86, 041306 (2012).

Newman, M. E. J. A measure of betweenness centrality based on random walks. Soc. Netw. 27, 39–54 (2005).

Kollmer, J. E. & Daniels, K. E. Betweenness centrality as predictor for forces in granular packings. Soft Matter 15, 1793–1798 (2019).

Lulli, A., Ricci, L., Carlini, E. & Dazzi, P. Distributed current flow betweenness centrality. In: 2015 IEEE 9th international conference on self-adaptive and self-organizing systems 71–80 (IEEE, 2015).

Rocks, J. W., Ronellenfitsch, H., Liu, A. J., Nagel, S. R. & Katifori, E. Limits of multifunctionality in tunable networks. Proc. Natl Acad. Sci. 116, 2506–2511 (2019).

Berkolaiko, G. & Kuchment, P. Introduction to quantum graphs. (American Mathematical Society, 2013).

Dager, R. & Enrique, Z. Wave progagation, observation and control in 1-d flexible multi-structures (2006, Springer).

Nabizadeh, M. et al. Network physics of attractive colloidal gels: Resilience, rigidity, and phase diagram. Proc. Natl Acad. Sci. 121, e2316394121 (2024).

Zhang, S. et al. Correlated rigidity percolation and colloidal gels. Phys. Rev. Lett. 123, 58001 (2019).

Reid, D. R. et al. Auxetic metamaterials from disordered networks. Proc. Natl Acad. Sci. 115, E1384–E1390 (2018).

Wang, M. et al. Biomorphic structural batteries for robotics. Sci. Robot. 5, eaba1912 (2020).

Dehmamy, N., Milanlouei, S. & Barabási, A. L. A structural transition in physical networks. Nature 563, 676–680 (2018).

Pósfai, M. et al. Impact of physicality on network structure. Nat. Phys. 20, 142–149 (2024).

Pournajar, M., Zaiser, M. & Moretti, P. Edge betweenness centrality as a failure predictor in network models of structurally disordered materials. Sci. Rep. 12, 11814 (2022).

Vecchio, D. A., Mahler, S., Hammig, M. D. & Kotov, N. A. Structural analysis of nanoscale network materials using graph theory. ACS Nano 15, 12847–12859 (2021).

Timoshenko, S. & Young, D. Theory of structures (McGraw-Hill, 1965).

Zienkiewicz, O. C., Taylor, R. L. & Zhu, J. Z. The finite element method: its basis and fundamentals (Elsevier Butterworth-Heineman, Amsterdam, 2005).

Curtin, W. A. & Scher, H. Mechanics modeling using a spring network. J. Mater. Res. 5, 554–562 (1990).

Patel, R. R. et al. Stress flow analysis of bio-structures using the finite element method and the flow network approach. Finite Elem. Anal. Des. 152, 46–54 (2018).

compass-stc/StructuralGT. GitHub https://github.com/compass-stc/StructuralGT (Accessed 2025).

Centellas, P. J. et al. Mechanochemically responsive polymer enables shockwave visualization. Nat. Commun. 15, 8596 (2024).

Jian, J. et al. Branched aramid nanofibers. Angew. Chem. Int. Ed. 56, 1433–7851 (2017).

igraph – Network analysis software. https://igraph.org/ (Accessed 2025).

Acknowledgements

All authors are grateful for support from the U.S. National Science Foundation under Cooperative Agreement No. 2243104, “Center for Complex Particle Systems (COMPASS)” Science and Technology Center.

Author information

Authors and Affiliations

Contributions

M.A.R.-M. performed experimental component of this study. A.K. was the primary contributor to the computational part of this work with assistance of S.D. S.C.G. supervised S.D. and co-supervise A.K. together with N.A.K. C.L.S and N.A.K. conceived and supervised the study. All authors read and approved the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Reyes-Martinez, M.A., Kadar, A., Dunne, S. et al. Graph-theoretical description and continuity problems for stress propagation through complex strut lattices. npj Soft Matter 1, 3 (2025). https://doi.org/10.1038/s44431-025-00004-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44431-025-00004-7