Abstract

Indium tin oxide (ITO) is a well-known n-type degenerate semiconductor with a wide variety of electronic and optoelectronic applications. Herein ITO is utilized as a photocathode material in p-type dye-sensitized solar cells in place of the commonly applied and highly colored nickel oxide (NiO) semiconductor. The application of mesoporous ITO photocathodes, [Fe(acac)3]0/− as a redox mediator and a new organic dye afforded an impressive energy conversion efficiency of 1.96±0.12%. Comparative transient absorption spectroscopic studies indicated that the recombination rate at the ITO–electrolyte interface is two orders of magnitude faster than that of NiO. Analysis of the operation mechanism of the ITO-based devices with ultraviolet photon spectroscopy and photoelectron spectroscopy in air showed that ITO exhibits a significant local density of states arising below −4.8 eV, which enables electron transfer to occur from the ITO to the excited dye, thus giving rise to the sustained photocathodic current.

Similar content being viewed by others

Introduction

Transparent conducting oxides have been extensively used in optoelectronic applications.1, 2, 3 One common transparent conducting oxide is indium tin oxide (ITO). ITO is a well-known n-type degenerate semiconductor4 with an optical band gap of 3.5–4.3 eV5 and has a high transmission in the near infrared and visible regions of the electromagnetic spectrum. Owing to their high optical transparency, good electrical conductivity, chemical inertness, hardness and excellent substrate adherence,6, 7, 8 ITO thin films are applied in flat panel displays, antistatic coatings, solar cells, camera lenses and architectural glazing.9, 10, 11, 12 Additionally, high-surface-area mesoporous ITO films have been used as sensors for gases, such as ammonia, nitric oxide, ethanol and methanol.13, 14, 15, 16 Moreover, ITO films and ITO/TiO2 core-shell structures have been utilized as photoanodes in both dye-sensitized solar cells (DSCs) and water oxidation devices.17, 18, 19, 20

A recent spectroscopic investigation into the charge transfer dynamics of dye-coated ITO films revealed that ITO can both accept and donate electrons during photoinduced charge transfer.21, 22 By exploiting the ambivalent property of this degenerate n-type semiconductor, we have developed an efficient p-type DSC (p-DSC) based on sintered films of ITO nanoparticles. The DSC is an intensely investigated photovoltaic technology that is based on the photoinduced charge transfer from a dye into a mesoporous semiconducting film. Following charge separation, a redox couple present in the electrolyte regenerates the dye. The traditional choice of semiconductor is TiO2 for n-type and NiO for p-type solar cells, and efficiencies of up to 13% and 2.5%, respectively, have been achieved.23, 24 The n- and p-type DSCs (n-DSCs and p-DSCs, respectively) are differentiated by the nature of the charge separation process following photoexcitation. For n-DSCs, photoexcitation of the sensitizer induces electron injection into the conduction band of the semiconductor, whereas for p-DSCs the photoexcitation is followed by hole injection into the valence band.

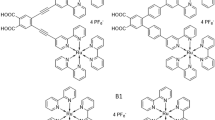

The lower performance of p-DSCs compared with n-DSCs can be attributed to the lack of a suitable p-type semiconductor that has a wide band gap, low absorptivity of sunlight and suitable charge transport properties. To address these inadequacies, Huang et al.21 recently reported that p-DSCs can be constructed by using photocathodes that consist of a Ru-dye adsorbed onto mesoporous ITO films. Although high photocurrents were achieved, the device efficiency was limited by the low photovoltages that can be achieved with I3−/I−-based electrolytes. In this work, we have developed p-DSCs based on ITO films bearing a new organic dye, PMI-8T-TPA (Figure 1), that was designed specifically for use in these devices. By applying the [Fe(acac)3]0/− redox couple, power conversion efficiencies (1.96±0.12% under a simulated one sun irradiance using AM1.5 at 1000 W m−2) have been achieved that rival the best reported result of 2.5% for devices based on NiO.24 Because ITO is a degenerate n-type semiconductor, the charge separation mechanism for the ITO-based p-type device is less obvious and is thus investigated here. Ultraviolet photon spectroscopy (UPS) and photoelectron spectroscopy in air (PESA) were used to identify the electronic states involved in this photovoltaic process. The availability of local density of states (LDOS) below −4.8 eV facilitates both hole transfer from ITO to photoexcited dyes and charge transport within the mesoporous ITO film, resulting in photocathodic currents.

Experimental procedure

Solvents and reagents were purchased from Sigma-Aldrich (Castle Hill, NSW, Australia), Merck Pty Ltd (Bayswater, VIC, Australia) and ABCR (Karlsruhe, Germany), unless otherwise stated, and were purified and dried using standard methods prior to use. The fluorine-doped tin oxide (FTO) glass (Nippon Sheet Glass (NSG)—8 Ω/□, 3.2 mm thick) was purchased from Dyesol (Queanbeyan, NSW, Australia). The PMI-2T-TPA and PMI-6T-TPA dyes were synthesized according to published procedures.25 The synthesis of PMI-8T-TPA is described in Supplementary Information.

Working electrode preparation

An ITO screen-printing paste was prepared by mixing 15 g of an ITO nanoparticle dispersion (particle diameter <100 nm, 30 wt% in isopropanol, Sigma-Aldrich) with 25 ml of an ethylcellulose-binder solution (10 wt% in ethanol) and 20 ml terpineol. The ITO paste was printed onto cleaned FTO glass using a semiautomatic screen printer. The printed ITO films were sintered on a hot plate at 400 °C for 30 min. The NiO paste and films were prepared as described previously.26 The thicknesses of the sintered electrodes were measured using a Veeco Dektak 6M stylus profilometer (Plainview, NY, USA).

ITO blocking layer

Some of the devices utilized an ITO blocking layer that was prepared by spray pyrolysis on cleaned FTO glass prior to screen printing. The blocking layer precursor solution consisted of 25 mM of InCl3 and 2 mM of SnCl4•5H2O in 20% ethanol in water (the pH of the solution was adjusted to 0.5).27 The hot (400 °C) substrates were sprayed with 5 ml of the precursor solution.

Preparation of electrolytes

[Fe(acac)3]0/− electrolyte

An acetonitrile solution containing 0.10 M tetrabutylammonium hydroxide (Bu4NOH) and 0.10 M of acetylacetone (acacH) was added to bis(acetylacetonato)iron(II) ([Fe(acac)2]) to form Bu4N[Fe(acac)3] in situ. A typical electrolyte was prepared by adding various components to the in situ prepared 0.20 M acetonitrile solution of Bu4N[Fe(acac)3] such that the final concentrations were 0.20 M Bu4N[Fe(acac)3], 0.05 M tris(acetylacetonato)iron(III) ([Fe(acac)3)]), 0.05 M lithium bis(trifluoromethanesulfonyl)imide (LiTFSI), 0.25 M 4-tert-butylpyridine (tBP) and 0.01 M chenodeoxycholic acid. Oxygen was excluded from the electrolyte during preparation by working in a nitrogen atmosphere glove box.

[Co(en)3]3+/2+ electrolyte

A [Co(en)3](BF4)2 solution (0.30 M) was prepared in situ by mixing appropriate quantities of Co(BF4)2•6H2O and 1,2-diaminoethane in acetonitrile to achieve final concentrations of 0.30 and 1.67 M, respectively. Then [Co(en)3](BF4)3 (0.07 M) and LiTFSI (0.10 M) were added to complete the [Co(en)3]3+/2+ electrolyte. The electrolyte was prepared in a glove box (nitrogen atmosphere) to exclude oxygen.

I3−/I− electrolyte

The I3−/I− electrolyte consisted of 0.03 M I2, 0.60 M 1-butyl-3-methylimidazolium iodide, 0.50 M tBP and 0.10 M guanidium thiocyanate in acetonitrile.

Device assembly

Prior to device assembly, the ITO films were re-sintered at 400 °C for 30 min and immersed hot (~60 °C) into a 0.30-mM N,N-dimethylformamide solution of PMI-2T-TPA, PMI-6T-TPA or PMI-8T-TPA for 3 h at room temperature. The sensitized WE was then sealed with a platinized counter electrode using a 25-μm-thick 6 × 5 mm Surlyn gasket (Solaronix, Aubonne, Switzerland). The electrolyte was inserted into the devices through a predrilled hole by vacuum backfilling in the glovebox. The hole was then sealed with a square of aluminum-backed Surlyn that was prepared by melting 25 μm of Surlyn onto aluminum foil at 120 °C.

I–V and incident photon to current conversion efficiency (IPCE) measurements

I–V (current–voltage) curves were recorded with an Newport Oriel solar simulator (Irvine, CA, USA) and Keithley 2400 source meter (Cleveland OH, USA) fitted with a filtered 1000 W xenon lamp to generate the simulated irradiation (AM1.5, 1000 W cm−2). The light intensity was calibrated using a silicon photodiode fitted with a KG3 filter (Fraunhofer ISE Institute, Freiburg, Germany). Different light intensities were achieved with a filter wheel equipped with a series of mesh filters. I–V characteristics were recorded using a Keithley 2400 source meter.

For the IPCE spectra, a xenon lamp (Newport Oriel, 150 W) and a monochromator (Monochromator Cornerstone 260, Newport Oriel) were used to generate the monochromatic light. The monochromatic output from the light source was calibrated with a silicon photodiode (Fraunhofer) and a Keithley 2400 source meter was used to measure the photocurrent under short circuit conditions. A slightly smaller area than the active area of the test cell was used as the illumination spot size.

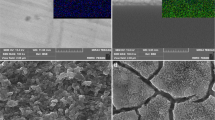

Scanning electron microscopy

Scanning electron microscopic micrographs were obtained using a JEOL 6300F (JEOL, Tokyo, Japan) field emission gun electron microscope.

Ultraviolet-visible spectrophotometric measurements

The absorption of bare and dyed ITO or NiO films was measured using a spectrophotometer (Cary 5G, Varian Australia Pty Ltd, Mulgrave, VIC, Australia) with an integrating sphere attachment (Varian Internal DRA 2500, Varian Australia Pty Ltd).

Transient absorption (TA) spectroscopy

Two types of devices were used for TA spectroscopic measurements: one with the optimized electrolyte (I3−/I−, [Co(en)3]3+/2+ or [Fe(acac)3]0/−) and the other with an inert electrolyte (an acetonitrile solution containing all the components excluding the redox couple of the electrolyte). Devices with an inert electrolyte were fabricated by sandwiching a 25-μm Surlyn gasket between the sensitized ITO (~2.0-μm film thickness) or NiO (~1.8-μm film thickness) film (7 × 7 mm2 active film area) and a microscopic glass slide with a predrilled hole. The inert electrolyte was backfilled in the glovebox, and the hole was sealed with aluminum-backed Surlyn. Measurements involving these devices are presented in Figure 4. The fabrication of the devices utilizing optimized electrolytes was similar to the prior devices, except a predrilled electrochemically platinized FTO glass was used as the counter electrode instead of a microscopic glass slide. Electrochemically platinized electrodes were prepared following the literature procedures.28 Measurements were conducted at short circuit conditions (presented in Figure 5) following procedures detailed elsewhere.28 Inert electrolyte measurements were collected utilizing a three electrode spectro-electrochemical setup while applying the respective electrolyte rest potential to emulate short circuit conditions. TA spectroscopy was carried out on two custom-built spectrometers, one that was optimized for nanosecond and the other optimized for microsecond measurements. Details on the spectrometers have been previously published.29 An excitation wavelength of 550 nm was chosen with a pulse energy of 66 μJ cm−2. The probe light was set to 850 nm, and the repetition rate was 10 Hz.

X-ray photoelectron spectroscopic measurements

X-ray photoelectron spectroscopic measurements were carried out on a Kratos Axis-HSi (Kratos Analytical Ltd, Manchester, UK) using He, I and Al K-alpha radiation sources. The samples, which were all deposited on FTO/glass substrates, did not exhibit any charging behavior. All spectra were calibrated to the nominal C 1s binding energy of 284.5 eV.

UPS and PESA measurements

UPS measurements were carried out on a Kratos Axis-HSi using He, I and Al K-alpha radiation sources. The samples, which were all deposited on FTO/glass substrates, did not exhibit any charging behavior. UPS measurements were carried out using pass energy of 5 eV and a channel width of 25 meV. A −9-V bias was applied to the samples to separate the sample photoelectron signal from the analyzer. The samples were referenced to the Fermi energy of argon-etched gold. PESA measurements were carried out on a Riken Keiki AC-2 photoelectron spectrometer (Riken Keiki Co., Ltd., Nagoya, Japan). The samples were grounded to avoid charging behavior and the error in the photoelectron onset energy was estimated to be 0.05 eV. The relative LDOS between In2O3 and ITO nanocrystalline films was determined by taking the derivative of the photoelectron yield of each sample at identical power across the spectral range 3.6–6.0 eV.

Results and Discussion

Mesoporous ITO films and DSCs were fabricated as described in the Experimental Procedure section (scanning electron microscopic image shown in Figure 2). X-ray photoelectron spectroscopy demonstrated that the composition of the ITO films did not change as a function of either the annealing temperature or time (Supplementary Table S1).

Previously, we introduced a series of donor-π-bridge-acceptor dyes designed specifically for applications in p-DSCs (n=2, 4, 6; Figure 1).25 The oligothiophene spacer group was shown to have a vital role in suppressing charge recombination between holes (vacancies) in the NiO valence band and the photoreduced state of the dye formed by photoinduced hole injection.25 In anticipation of a significant charge recombination in ITO-based DSCs, a new photocathodic sensitizer (PMI-8T-TPA) with an extended oligothiophene π-bridge was specifically designed and synthesized.

Semiconductor films with optimized thicknesses of 3.5 μm (ITO) and 3.1 μm (NiO) were used to assemble all p-DSCs reported in this study (Supplementary Figures S1 and S2). A comparison of the photovoltaic performance of PMI-8T-TPA to that of the previously applied sensitizer, PMI-6T-TPA, revealed that extension of the π-bridge in PMI-8T-TPA generated a 100-mV increase in the photovoltage and an efficiency increase of 56% for ITO-based devices made with the [Co(en)3]3+/2+ electrolyte (Supplementary Figures S3–S5 and Table 1). The efficiency improvement was more moderate (27%) for the NiO-based p-DSCs.

For both the I3−/I−- and [Co(en)3]3+/2+-based electrolytes (Table 2), the efficiencies of the ITO- and PMI-6T-TPA-based devices matched the best achieved for p-type DSCs based on NiO photocathodes.24 In contrast, for the [Fe(acac)3]0/− electrolyte, the efficiency for the ITO devices was lower than our previously reported value for NiO devices of 2.51±0.08%.24 It is postulated that, for this redox couple, the charge recombination at the collecting electrode/electrolyte interface was affecting device performance, as noted in a recent publication.24 The introduction of an ITO-blocking layer increased the device efficiency to 1.96±0.12% (Supplementary Figures S6 and S7,Supplementary Table S2 and Table 1), whereas it had little or a detrimental effect for the other two redox couples. The open-circuit voltage (VOC) of 758 mV for the ITO devices (with the blocking layer) based on [Co(en)3]3+/2+ is the highest VOC ever reported for a p-DSC.

The best performing ITO device showed an efficiency of >2% (Figure 3a). This was achieved when PMI-8T-TPA-sensitized ITO films were utilized in conjunction with the state-of-the-art [Fe(acac)3]0/− electrolyte. The efficiency measured here rivals that of the best performing p-DSC, which achieved 2.51%.24 The direction of the current flow (photocathodic) and the shape of the photocurrent–voltage (I–V) curve, which features fill factors of 0.45–0.60, show that the ITO is an effective photocathode material (see Figure 3a for the I–V curve of best performing ITO p-DSC based on [Fe(acac)3]0/−). The dark current behaved as a rectifying diode with a moderate shunt resistance (1.9 kΩ cm−2), indicating that the recombination losses across the ITO electrolyte interface were limited and led to photovoltages >700 mV. It is noted that no photocurrent was observed when ITO-based DSCs were fabricated using a high-efficiency donor–acceptor n-type sensitizer (MK2). This indicates that efficient charge separation across the dye/ITO interface is only feasible for p-type operations (Supplementary Figure S8,Supplementary Table S3).

(a) I–V characteristics measured in the dark and at simulated one sun (AM1.5, 1000 W m−2) for the best performing PMI-8T-TPA-sensitized p-DSC employing a [Fe(acac)3]0/− electrolyte. (b) IPCE spectra of p-DSCs based on I3−/I−, [Co(en)3]3+/2+ and [Fe(acac)3]0/− electrolytes sensitized with PMI-8T-TPA.

To elucidate the origin of the variation in the photocurrent density, detailed optical and photoelectrical studies were carried out. The IPCE spectra shown in Figure 3b resemble the absorption spectrum of the dye (Supplementary Figure S9) and demonstrate that dye sensitization has occurred and that the measured currents are due to the photoinduced hole transfer from the dye into the ITO film. The p-DSCs based on I3−/I−, [Co(en)3]3+/2+ and [Fe(acac)3]0/− reached IPCE maxima of 24, 32 and 37%, respectively, indicating surprisingly high quantum efficiencies. Although these IPCE maxima fall short of those for devices based on p-type NiO photocathodes, they exceed expectations for devices in which hole collection is facilitated by a degenerate n-type semiconductor electrode.

The IPCE is the product of the light-harvesting efficiency and the absorbed photon to electron conversion efficiency (APCE, internal quantum efficiency). Peak APCEs of 28, 38 and 44% were calculated for the PMI-8T-TPA-sensitized devices employing [Co(en)3]3+/2+, I3−/I− and [Fe(acac)3]0/− electrolytes, respectively (Supplementary Figures S9–S13), highlighting that nearly every second absorbed photon was converted to an electron–hole pair under ideal conditions. Although these results are noteworthy, further improvements are necessary to boost device efficiency, which can lead to a viable technology. Electron injection from excited dye molecules into the ITO conduction band and the subsequent recombination of these carriers with photoinjected holes is a plausible mechanism that could explain the lower APCE values observed for ITO-sensitized films.

The APCE is dependent on the charge collection efficiency, dye regeneration yield and charge injection yield. To elucidate the origins of the low APCE and characterize both the charge injection and the dye regeneration yield further, TA spectroscopy was utilized. The recombination dynamics of different photoreduced dye anions (PMI-nT-TPA, n=2, 6 and 8) with vacancies in the mesoporous ITO by using inert electrolytes that did not contain any redox active species are shown in Figure 4. The positive TA feature at the respective observation wavelength was dominated by the absorption of the photoreduced dye.25 The observable decay in the TA signals were therefore a measure of the recombination dynamics of the photoreduced dye anions via interfacial electron transfer to the metal oxide electrode. Whereas PMI-6T-TPA and PMI-8T-TPA showed a significant signal, no signal was observed for PMI-2T-TPA. The recombination process for PMI-6T-TPA and PMI-8T-TPA was extraordinarily fast, with observed rate constants of 3.8 × 106 and 1.0 × 106 s−1, respectively. For comparison, the rate constant for NiO films sensitized with PMI-8T-TPA measured under identical conditions was two orders of magnitude smaller (Figure 4). The initial TA signal immediately after laser excitation (t=10−8 s) of the PMI-8T-TPA-sensitized ITO film was significantly higher than that of the PMI-8T-TPA-sensitized NiO film. This is a result of the larger film thickness of the ITO films (see Experimental Procedure section), the generally stronger dye uptake and the smaller parasitic light absorption (see Supplementary Figure S10) of the ITO compared with the NiO films.

To summarize, the dye anion lifetime depends on the oligothiophene conjugation length, with the PMI-8T-TPA showing a longer lifetime than the PMI-6T-TPA and the decay being too fast to measure with our instrumentation for the PMI-2T-TPA. A similar trend in dye anion lifetimes was observed in our previous study on NiO films.25 TA experiments were then conducted on the PMI-8T-TPA-sensitized ITO electrodes in contact with an inert electrolyte not containing any redox active species and the three redox active electrolytes (Figure 5).

Temporal dependence of the optical density of the PMI-8T-TPA dye anion on (a) [Co(en)3]3+, (b) I3− and (c) [Fe(acac)3] in the electrolytes under short circuit conditions. The inert electrolyte consists of all the components of the electrolyte except the redox couple (observation wavelength 850 nm, excitation wavelength 550 nm, pulse intensity 66 μJ cm−2).

In the case of I3−/I− and [Fe(acac)3]0/−, dye regeneration by the redox electrolyte is clearly visible owing to the faster decay rate in the active electrolyte. Fast dye regeneration rate constants of 1.3 × 107 and 1.3 × 108 M−1 s−1 were determined for I3−/I− and [Fe(acac)3]0/−, respectively (Supplementary Table S4). For [Co(en)3]3+/2+, the two decay curves overlap, showing that the dye regeneration yield was <50% (to observe a regeneration yield of 50%, the rate constant would need to be twofold higher; simulations revealed that these TA spectroscopic traces, considering the experimental noise, are difficult to distinguish and lie nearly on top of each other). For I3−/I− and [Fe(acac)3]0/−, the dye regeneration rate was 5–10 times faster than the recombination reaction, thus providing an explanation for the higher photocurrent measured for these devices. Nevertheless, the recombination losses between the injected holes and the dye anions are still significant and need to be addressed by either slowing down the recombination reaction or facilitating faster dye regeneration. As reported in a recent work by Huang et al.,21 improved dye designs based on novel electrolyte systems, including solid state electron conductors and interfacial blocking layers, may also be beneficial for this purpose.

To unravel the mechanism of the operation of the ITO-based p-type DSCs, a combination of UPS and PESA was utilized. UPS is a suitable technique for mapping the valence band of a semiconductor. PESA is more sensitive to the band edge and allows the measurement of more shallow densities of mid-gap-filled states. Figure 6 shows the measured local density of states determined by UPS and PESA for ITO and In2O3. Whereas In2O3 features a distinct band gap with no measurable LDOS between −3.0 and −6.7 eV, ITO shows a significant LDOS arising below −4.8 eV. These states stem from the tin doping and are the same states that lead to the conductivity of ITO utilized in countless applications. In2O3 is a well-known n-type semiconductor and has been used as a photoanode material to fabricate efficient DSCs.30

Naturally, the ITO in this work is also a degenerated n-type material; however, for the successful operation of the dyes, the D*/D− potentials must be aligned with the LDOS of ITO to provide 600–700 meV of driving force for hole injection. This enables electron transfer to occur from the ITO to the excited dye, thus giving rise to a photocathodic current. The driving force for this electron transfer will be reduced as holes accumulate in the ITO layer under illumination, shifting the Fermi level into the band of filled mid-gap states. Reducing the driving force, either by engineering the ITO or improved dye design, may lead to higher efficiencies of future p-DSCs through the minimization of kinetic redundancy. To examine whether this phenomenon is unique to ITO or whether it applies to other degenerate n-type semiconductor transparent conducting oxides, we prepared antimony-doped tin oxide-based p-DSCs (Supplementary Figure S14). Similar results to ITO based p-DSCs were observed, thus showing the generality of this behavior.

Conclusions

We have reported the application of mesoporous ITO as a photocathode material in p-DSCs. TA spectroscopic measurements clearly showed efficient hole injection from the new dye PMI-8T-TPA into the ITO. Three different redox shuttles were tested in conjunction with ITO-based p-DSCs. A maximum efficiency of 2.08% under AM1.5 at 1000 W m−2 conditions was measured for devices applying [Fe(acac)3]0/− as a redox mediator. Photoelectron spectroscopy in air revealed that the local density of states <−4.8 eV in the ITO was sufficient to facilitate electron transfer to the photoexcited dye. Respectable cathodic photocurrents of 5.65 mA cm−2 and open circuit voltages in excess of 700 mV also indicated that the mid-gap states observed between −5.0 and −6.0 eV facilitate the efficient transport of photoinjected charges to the back contact of the device.

Traditional p-DSCs are limited owing to the lack of a suitable wide band gap p-type semiconductor with sufficient transparency and good charge transport properties. The discovery of p-type semiconductivity in degenerate n-type semiconductors could potentially solve this problem, provided that recombination losses can be curbed. The application of redox shuttles with faster dye regeneration kinetics and dyes with longer lifetimes for the charge separated state may further improve the performance in ITO-based p-DSCs. Highly efficient photocathodes are a prerequisite for pursuing the fabrication of tandem DSCs, which could hold the key to improving DSC efficiencies beyond the current limit of 13%.23 Furthermore, charge separation across the ITO/dye interface could find application in photocatalysis. Finally, the observation of p-type semiconductivity in degenerate n-type semiconductors may not only inspire novel applications of these materials but also be relevant to the existing ITO-based devices.

References

Sun, X., Shi, Y., Ji, H., Li, X., Cai, S. & Zheng, C. Nanocasting synthesis of ordered mesoporous indium tin oxide (ITO) materials with controllable particle size and high thermal stability. J. Alloys Compd. 545, 5–11 (2012).

Slocombe, D., Porch, A., Pepper, M. & Edwards, P. P. The Mott transition and optimal performance of transparent conducting oxides in thin-film solar cells. Energy Environ. Sci. 5, 5387–5391 (2012).

Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 6, 809–817 (2012).

Kim, H., Gilmore, C. M., Piqué, A., Horwitz, J. S., Mattoussi, H., Murata, H., Kafafi, J. H. & Chrisey, D. B. Electrical, optical, and structural properties of indium-tin-oxide thin films for organic light-emitting devices. J. Appl. Phys. 86, 6451–6461 (1999).

Hamberg, I., Granqvist, C. G., Berggren, K. F., Sernelius, B. E. & Engström, L. Band-gap widening in heavily Sn-doped In2O3 . Phys. Rev. B 30, 3240–3249 (1984).

Zhang, Q., Dandeneau, C. S., Zhou, X. & Cao, G. ZnO nanostructures for dye-sensitized solar cells. Adv. Mater. 21, 4087–4108 (2009).

Sun, Z., He, J., Kumbhar, A. & Fang, J. Nonaqueous synthesis and photoluminescence of ITO nanoparticles. Langmuir 26, 4246–4250 (2010).

Lee, S., Noh, J. H., Bae, S.-T., Cho, I.-S., Kim, J. Y., Shin, H., Lee, J.-K., Jung, H. S. & Hong, K. S. Indium-tin-oxide-based transparent conducting layers for highly efficient photovoltaic devices. J. Phys. Chem. C 113, 7443–7447 (2009).

Hartnagel, H. L., Dawar, A., Jain, A. & Jagadish, C. Semiconducting Transparent Thin Films (Institute of Physics Publishing, Bristol, UK, Philadelphia, PA, USA, 1995).

Lee, M.-K. & Fan, C.-H. Electrochromic characterization of nickel oxide films grown on ITO/glass by liquid phase deposition. J. Electrochem. Soc. 156, D395–D399 (2009).

Tsai, T.-H. & Wu, Y.-F. Organic acid mixing to improve ITO film etching in flat panel display manufacturing. J. Electrochem. Soc. 153, C86–C90 (2006).

Wang, H.-W., Ting, C.-F., Hung, M.-K., Chiou, C.-H., Liu, Y.-L., Liu, Z., Ratinac, K. R. & Ringer, S. P. Three-dimensional electrodes for dye-sensitized solar cells: synthesis of indium-tin-oxide nanowire arrays and ITO/TiO2 core-shell nanowire arrays by electrophoretic deposition. Nanotechnology 20, 055601 (2009).

Mbarek, H., Saadoun, M. & Bessaïs, B. Screen-printed Tin-doped indium oxide (ITO) films for NH3 gas sensing. Mater. Sci. Eng. C 26, 500–504 (2006).

Patel, N. G., Patel, P. D. & Vaishnav, V. S. Indium tin oxide (ITO) thin film gas sensor for detection of methanol at room temperature. Sens. Actuators, B 96, 180–189 (2003).

Zeng, K., Zhu, F., Hu, J., Shen, L., Zhang, K. & Gong, H. Investigation of mechanical properties of transparent conducting oxide thin films. Thin Solid Films 443, 60–65 (2003).

Sberveglieri, G., Groppelli, S. & Coccoli, G. Radio frequency magnetron sputtering growth and characterization of indium-tin oxide (ITO) thin films for NO2 gas sensors. Sens. Actuators 15, 235–242 (1988).

Garvey, T. R., Farnum, B. H. & Lopez, R. Pulsed laser deposited porous nano-carpets of indium tin oxide and their use as charge collectors in core-shell structures for dye sensitized solar cells. Nanoscale 7, 2400–2408 (2015).

Kato, M., Cardona, T., Rutherford, A. W. & Reisner, E. Photoelectrochemical water oxidation with photosystem II integrated in a mesoporous indium-tin oxide electrode. J. Am. Chem. Soc. 134, 8332–8335 (2012).

Alibabaei, L., Farnum, B. H., Kalanyan, B., Brennaman, M. K., Losego, M. D., Parsons, G. N. & Meyer, T. J. Atomic layer deposition of TiO2 on mesoporous nanoITO: conductive core-shell photoanodes for dye-sensitized solar cells. Nano Lett. 14, 3255–3261 (2014).

Alibabaei, L., Brennaman, M. K., Norris, M. R., Kalanyan, B., Song, W., Losego, M. D., Concepcion, J. J., Binstead, R. A., Parsons, G. N. & Meyer, T. J. Solar water splitting in a molecular photoelectrochemical cell. Proc. Natl. Acad. Sci. USA 110, 20008–20013 (2013).

Huang, Z., He, M., Yu, M., Click, K., Beauchamp, D. & Wu, Y. Dye-controlled interfacial electron transfer for high-current indium tin oxide photocathodes. Angew. Chem. Int. Ed. 54, 6857–6861 (2015).

Furmansky, Y., Sasson, H., Liddell, P., Gust, D., Ashkenasy, N. & Visoly-Fisher, I. Porphyrins as ITO photosensitizers: substituents control photo-induced electron transfer direction. J. Mater. Chem. 22, 20334–20341 (2012).

Mathew, S., Yella, A., Gao, P., Humphry-Baker, R., Curchod, B. F. E., Ashari-Astani, N., Tavernelli, I., Rothlisberger, U., Nazeeruddin, M. K. & Grätzel, M. Dye-sensitized solar cells with 13% efficiency achieved through the molecular engineering of porphyrin sensitizers. Nat. Chem. 6, 242–247 (2014).

Perera, I. R., Daeneke, T., Makuta, S., Yu, Z., Tachibana, Y., Mishra, A., Bäuerle, P., Ohlin, C. A., Bach, U. & Spiccia, L. Application of the tris(acetylacetonato)iron(III)/(II) redox couple in p-type dye-sensitized solar cells. Angew. Chem. Int. Ed. 54, 3758–3762 (2015).

Nattestad, A., Mozer, A. J., Fischer, M. K. R., Cheng, Y.-B., Mishra, A., Bäuerle, P. & Bach, U. Highly efficient photocathodes for dye-sensitized tandem solar cells. Nat. Mat. 9, 31–35 (2010).

Powar, S., Daeneke, T., Ma, M. T., Fu, D., Duffy, N. W., Götz, G., Weidelener, M., Mishra, A., Bäuerle, P., Spiccia, L. & Bach, U. Highly efficient p-type dye-sensitized solar cells based on tris(1,2-diaminoethane)cobalt(II)/(III) electrolytes. Angew. Chem. Int. Ed. 52, 602–605 (2013).

Aouaj, M. A., Diaz, R., Belayachi, A., Rueda, F. & Abd-Lefdil, M. Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater. Res. Bull. 44, 1458–1461 (2009).

Daeneke, T., Yu, Z., Lee, G. P., Fu, D., Duffy, N. W., Makuta, S., Tachibana, Y., Spiccia, L., Mishra, A., Bäuerle, P. & Makuta, S. Dominating energy losses in NiO p-type dye-sensitized solar cells. Adv. Energy Mater. 5, 1401387 (2015).

Daeneke, T., Mozer, A. J., Uemura, Y., Makuta, S., Fekete, M., Tachibana, Y., Koumura, N., Bach, U. & Spiccia, L. Dye regeneration kinetics in dye-sensitized solar cells. J. Am. Chem. Soc. 134, 16925–16928 (2012).

Mori, S. & Asano, A. Light intensity independent electron transport and slow charge recombination in dye-sensitized In2O3 solar cells: in contrast to the case of TiO2 . J. Phys. Chem. C 114, 13113–13117 (2010).

Acknowledgements

We thank the financial support from the Australian Centre for Advanced Photovoltaics, the Australian Government through the Australian Renewable Energy Agency and Monash University (for providing IRP with an IPRS and an Australian Postgraduate Award). This study has been supported by CSIRO through the OCE Science Leader program and the Australian research Council through an Australian Research Fellow grant (DP110105312) to UB. This work was performed in part at the Melbourne Centre for Nanofabrication, the Victorian Node of the Australian National Fabrication Facility (a company established under the National Collaborative Research Infrastructure Strategy to provide nano- and micro-fabrication facilities for Australia’s researchers).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yu, Z., Perera, I., Daeneke, T. et al. Indium tin oxide as a semiconductor material in efficient p-type dye-sensitized solar cells. NPG Asia Mater 8, e305 (2016). https://doi.org/10.1038/am.2016.89

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/am.2016.89

This article is cited by

-

Recent progress in CZTS (CuZnSn sulfide) thin-film solar cells: a review

Journal of Materials Science: Materials in Electronics (2024)

-

Role of deposition parameters on optoelectronic properties of ITO films and its application in MoO3−x/c-Si(n) heterojunction solar cells

Journal of Materials Science: Materials in Electronics (2023)

-

Design and development of modified tin oxide nanostructures for structural and optical applications

International Journal on Interactive Design and Manufacturing (IJIDeM) (2023)

-

Optical, structural, and electrical properties of modified indium-tin-oxide (ITO) films on glass surface by low energy ion implantation

Applied Physics A (2022)

-

The use of marine microalgae in microbial fuel cells, photosynthetic microbial fuel cells and biophotovoltaic platforms for bioelectricity generation

3 Biotech (2022)