Abstract

Microbial uptake of free cathodic electrons presents a poorly understood aspect of microbial physiology. Uptake of cathodic electrons is particularly important in microbial electrosynthesis of sustainable fuel and chemical precursors using only CO2 and electricity as carbon, electron and energy source. Typically, large overpotentials (200 to 400 mV) were reported to be required for cathodic electron uptake during electrosynthesis of, for example, methane and acetate, or low electrosynthesis rates were observed. To address these limitations and to explore conceptual alternatives, we studied defined co-cultures metabolizing cathodic electrons. The Fe(0)-corroding strain IS4 was used to catalyze the electron uptake reaction from the cathode forming molecular hydrogen as intermediate, and Methanococcus maripaludis and Acetobacterium woodii were used as model microorganisms for hydrogenotrophic synthesis of methane and acetate, respectively. The IS4-M. maripaludis co-cultures achieved electromethanogenesis rates of 0.1–0.14 μmol cm−2 h−1 at −400 mV vs standard hydrogen electrode and 0.6–0.9 μmol cm−2 h−1 at −500 mV. Co-cultures of strain IS4 and A. woodii formed acetate at rates of 0.21–0.23 μmol cm−2 h−1 at −400 mV and 0.57–0.74 μmol cm−2 h−1 at −500 mV. These data show that defined co-cultures coupling cathodic electron uptake with synthesis reactions via interspecies hydrogen transfer may lay the foundation for an engineering strategy for microbial electrosynthesis.

Similar content being viewed by others

Introduction

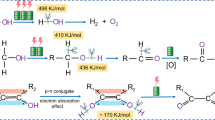

Microbial metabolism of electrons that are not associated with a chemical element, that is, ‘free’ electrons, is an intriguing metabolic capacity that has been primarily investigated in insoluble metal-reducing microorganisms, such as Shewanella or Geobacter species (Bond and Lovley, 2003; Hartshorne et al., 2009; Coursolle et al., 2010; Clarke et al., 2011; Lovley, 2012; Liu et al., 2014; Malvankar and Lovley, 2014; Pirbadian et al., 2014; TerAvest et al., 2014). In addition to these anodic microbial processes, recent studies have revealed that some microorganisms can take up ‘free’ cathodic electrons from conductive minerals during interspecies electron transfer (Kato et al., 2012) or from abiotically reduced surfaces such as deep sea hydrothermal vent chimneys (Nakamura et al., 2010). This use of ‘free’ electrons as electron donor in microbial catabolism finds also relevance in engineered bioelectrochemical systems, which have been emerging as promising platforms for a sustainable energy landscape. In particular, biocathodes in microbial electrosynthesis reactors are of interest, where microorganisms at the cathode convert electricity plus CO2 into useful chemical products. From a fundamental perspective, the mechanisms involved in cathodic electron uptake are most intriguing, however, largely unknown. The most basic biocathode is the hydrogen-evolving biocathode. Most studies on hydrogen-evolving biocathodes in a microbial electrosynthesis reactor have been carried out using mixed microbial cultures (Jafary et al., 2015), and the ecology of the different microorganisms in a community is poorly understood. A few studies showed hydrogen formation by pure cultures of Geobacter sulfurreducens (Geelhoed et al., 2010) or Desulfovibrio species (Croese et al., 2011; Aulenta et al., 2012), and the molecular mechanism of the electron uptake reaction in most hydrogen-evolving, biocathodic microorganisms is unknown (Jafary et al., 2015). A more specialized type of biocathode is found in microbial electrosynthesis. In this process, microorganisms convert cathode-derived electrons plus CO2 into organic compounds rather than free molecular hydrogen. Electrosynthetic methane formation has been achieved using mixed cultures (Cheng et al., 2009, Siegert et al., 2015) or pure strains such as Methanococcus maripaludis and Methanobacterium sp. (Lohner et al., 2014; Beese-Vasbender et al., 2015a). Multi-carbon compounds such as acetate have been synthesized on biocathodes using a diversity of homoacetogenic strains (Nevin et al., 2010, 2011; Deutzmann et al., 2015).

Low electron transfer rates from the cathode during microbially catalyzed electrosynthesis were generally considered to be limiting the feasibility of this process on a commercial scale (Blanchet et al., 2015). Moreover, overpotentials of >200 mV had to be applied repeatedly to achieve significant electron transfer rates (Villano et al., 2010; Aulenta et al., 2012). At these low potentials, the electrochemical formation of small reduced molecules as potential electron carriers such as H2, CO or formate at the cathode cannot be excluded (Villano et al., 2010; Yates et al., 2014; Deutzmann et al., 2015). To our knowledge, all methanogens and homoacetogens studied for their electrosynthetic properties are able to metabolize at least some of these small reduced molecules.

Besides methanogenic archaea and homoacetogenic bacteria, Fe(0)-corroding microorganisms have been intensively investigated for their outstanding electron transfer capabilities (Dinh et al., 2004; Uchiyama et al., 2010; Enning et al., 2012; Venzlaff et al., 2013; Enning and Garrelfs, 2014; Kato et al., 2015; Beese-Vasbender et al., 2015b). Although direct electron uptake has been proposed in these microorganisms, no mechanism has been identified to date (Enning et al., 2012; Venzlaff et al., 2013; Enning and Garrelfs, 2014; Beese-Vasbender et al., 2015b). Recently, Fe(0)-corroding microorganisms, in particular strain IS4 (‘Desulfopila corrodens’, previously named Desulfobacterium corrodens (Dinh et al., 2004), but no name has been validly published to date) have been investigated in electrode systems, and a direct electron transfer mechanism has been repeatedly postulated (Venzlaff et al., 2013; Beese-Vasbender et al., 2015b).

In the present study, we investigated the Fe(0)-corroding sulfate-reducing strain IS4 as a biocatalyst to enhance the electron uptake rate in a bioelectrosynthesis system. Strain IS4 was previously shown to form molecular hydrogen transiently during cultivation on Fe(0) (Dinh et al., 2004). To provide the proof of concept that the overall rates of electrosynthesis can be increased by co-cultivation of a specialized electron-uptaking strain with another microbe capable of producing a desired product, we constructed and examined electron flow in defined co-cultures of strain IS4 with the methanogen M. maripaludis and the homoacetogen Acetobacterium woodii. Our data demonstrate the importance of interspecies hydrogen transfer in cathode-associated microbial communities and highlights a primary role of electron uptake strains as ecosystem engineers in these communities.

Materials and methods

Microbial strains and cultivation

Strain IS4 (DSM 15630) and A. woodii (DSM 1030) were obtained from the German Collection of Microorganisms and Cell Cultures. M. maripaludis strain MM901 was obtained from the laboratory of Dr John Leigh, UW (Costa et al., 2013).

Strain IS4 was routinely cultivated in artificial seawater medium containing 28 mM sodium sulfate as electron acceptor (Dinh et al., 2004). A. woodii was initially cultivated in a modified DSMZ medium 311. M. maripaludis was routinely cultured in a modified DSMZ medium 141. A detailed description of the media can be found in the Supplementary Information.

For co-cultivation, A. woodii and M. maripaludis were transferred to artificial seawater medium medium (amended with 0.1% yeast extract in case of A. woodii) and transferred at least twice in this medium before the co-culture experiment.

All cultures were maintained in butyl-rubber stopper sealed 120 ml or 160 ml serum vials containing 50 ml of medium with a headspace of 80% H2 and 20% CO2 as electron donor and sole carbon source, respectively.

Electrochemical experiments

Electrochemical reactors were setup as described previously (Lohner et al., 2014). The electrochemical cell consisted of a two chambered, gas-tight borosilicate H-cell, in which anode and cathode chambers (150 ml each) were separated by a Nafion 117 proton-exchange membrane as described previously (Lohner et al., 2014). The medium exposed area of the graphite electrodes (conductive graphite bars ¼ × ¼ inch, McMaster-Carr) was 8 cm2, and this area was used to calculate specific electron transfer and product formation rates. The reference electrodes used were Ag/AgCl electrodes (model RE-5B, BASi, West Lafayette, IN, USA) in 3 M NaCl. Autoclaved reactors were flushed with a sterile mix of 80% N2 and 20% CO2 until oxygen was completely flushed out, the reference electrode was inserted and 90 ml sulfate-free artificial seawater medium was anoxically and aseptically transferred into the anode and cathode compartments with a N2/CO2 flushed plastic syringe while continuously flushing the reactor. Reactors were disconnected from the gas stream and maintained at 30 °C. A volume of 3–6 ml of early stationary phase culture of the indicated organisms was added to the cathode compartment, resulting in an initial gas phase volume of 43–46 ml. The change in gas to liquid ratio due to sampling was considered when calculating absolute amounts of different substances in the reactor. In all, 250 μM sulfate was added to reactors containing strain IS4. The cathode was poised at the indicated potentials after inoculation. Electric current and product formation were followed over time. Cyclic voltammograms were recorded after a steady current or product formation rate had established, that is, after the establishment of the IS4 biocathode shown in Figure 1 and the subsequent cultivation time needed to establish a stable co-culture with M. maripaludis in a subset of the reactors and after rate measurements shown in Figure 3 (total of 312 h cultivation time). The gas phase of all reactors was flushed with N2/CO2 at the time of introducing a second organism. Platinum foil (17.5 cm2 immersed surface) was used as cathode in the same setup to obtain hydrogen evolution rates for a model inorganic catalyst under identical conditions.

Startup of a bioreactor with strain IS4 as biocathode. Strain IS4 was inoculated into a bioelectrochemical reactor with a cathode potential of −400 mV vs standard hydrogen electrode and compared with an un-inoculated control. (a) Current consumption of strain IS4 (black) and uninoculated control (gray). (b) Hydrogen accumulation by strain IS4 (black squares) and uninoculated control (open squares). (c) Sulfide accumulation by strain IS4 (gray circles; red in online version) and control (open circles) and sulfate consumption by strain IS4 (black squares) and control (open squares). For clarity, one representative reactor out of ten replicates (five for controls) is shown. The trend is identical in all replicates, but the onset of current consumption and activity is shifted among the replicates (see Supplementary Figure S2 for all replicates).

Hydrogen and methane formation as well as current consumption by strain IS4 (black) and strain IS4 in co-culture with M. maripaludis (gray; red in online version) at different potentials. Methane (circles) and hydrogen (squares) are shown in μmol electron equivalents (μmol eeq) per reactor; current consumption (in μmol electrons consumed) by strain IS4 (black) or the co-culture (gray; red in online version) is shown as dotted line. Note the different scales between (a) and (b) or (c).

Analytical procedures

Methane and high concentrations of hydrogen were determined using a gas chromatograph with nitrogen as the carrier gas (equipped with both a thermal conductivity detector and a flame ionization detection detector). Low concentrations of H2 were determined using a reductive trace gas analyzer, and soluble compounds such as formate and acetate were determined using high-performance liquid chromatography as described previously (Lohner et al., 2014). To allow for a better comparison of formation rates of different products and electron flux, concentrations were converted to concentrations in electron equivalents (for example, μmol eeq) where appropriate. Concentrations in μmol eeq were calculated by multiplying the concentration of a given compound by the number of electrons required for its formation from CO2.

Electron microscopy

Samples were fixed in 4% paraformaldehyde with 2% glutaraldehyde in 0.1 M sodium cacodylate buffer (pH 7.4) for 24–48 h at 4 °C, rinsed in the same buffer and post-fixed in 1% aqueous OsO4 for 2 h before dehydration in an increasing ethanol series (50–70–90–100%, 15 min each). Samples were then critical point dried (Tousimis 815B, Rockville, MD, USA) with liquid CO2, mounted on aluminum pin stubs and sputter-coated with Au/Pd using a Denton Desk II sputter-coater (Denton Vacuum, Moorestown, NJ, USA) before visualizing with a Zeiss Sigma FESEM (Carl Zeiss Microscopy, Thornwood, NY, USA) using InLens secondary electron detection at 2–3 kV. At least three different positions encompassing at least 5000 μm2 electrode surface have been analyzed to estimate cell counts on the electrode surface.

Results

Establishment of an active strain IS4 biocathode

After inoculation of the biocathode in the presence of 250 μM sulfate, electron uptake in form of electrical current consumption by strain IS4 cells increased over time when the cathode was poised at −400 mV (vs standard hydrogen electrode) (see Figure 1 for one representative experiment, Supplementary Figure S1 for coulombic efficiencies, and Supplementary Figure S2 for all other replicates). No current consumption was observed using cell-free spent culture medium or without initial sulfate addition (data not shown), indicating that strain IS4 cells initially required sulfate as electron acceptor to establish a working biocathode. Current consumption increased for several days in the presence of sulfate before current consumption decreased sharply. Within this time period, sulfate concentration decreased and sulfide formed in equimolar concentrations as expected based on an active metabolism of this sulfate-reducing bacterium (Figure 1c). The sharp decrease in current consumption coincided with sulfate depletion and hydrogen accumulation in the cathode compartment, indicating that strain IS4 cells utilized cathode-derived electrons for sulfate reduction. We also observed that electrochemical reactors containing cells of strain IS4 transiently accumulated molecular hydrogen even in the presence of sulfate (Figure 1b). Notably, after sulfate depletion, rates of molecular hydrogen accumulation increased to ca. 0.2 μmol h−1 cm−2 relative to the initial rates of ca. 0.08 μmol h−1 cm−2 in the presence of sulfate. This indicates that upon depletion of sulfate electron uptake continued and electrons were used to reduce H+ to form H2, while sulfate reduction as H2 (or electron) sink was blocked. Hydrogen accumulated to partial pressures of up to 0.08 bar at −400 mV vs standard hydrogen electrode. These partial pressures approached in our experimental setup the thermodynamic equilibrium concentration of the reaction 2 H++2 e−→H2, which prevented further consumption of cathodic electrons and explains the sharp decline of current consumption at −400 mV once sulfate was consumed (see Supplementary Figure S3 and Supplementary Information for detailed calculation).

The transient accumulation of H2 raised the interesting possibility that H2 formation at the cathode may be reversible in this bioelectrochemical system. If this were the case, we expected the formation of electric current from molecular hydrogen at a suitable electrode potential. Indeed, cyclic voltammetry revealed the typical wave pattern for reversible hydrogen evolution (Figure 2, Supplementary Figure S4). This cyclic voltammetry (CV) profile also showed the absence of a noteworthy overpotential (<5 mV) for the hydrogen evolution reaction: the equilibrium potential of reversible hydrogen formation and hydrogen oxidation in our system was at about −425 mV under our experimental conditions, which is close to the calculated thermodynamic equilibrium potential of −421 mV at pH=7 and 30 °C. At more positive potentials, current was produced indicating hydrogen oxidation, whereas at more negative potentials hydrogen was formed. Sulfide produced by strain IS4 during the incubation (<250 μM after flushing) did not result in a pronounced signal in the CVs and did not interfere with the catalytic wave of hydrogen production or oxidation (see Supplementary Figure S5).

Cyclic voltammograms of graphite electrodes colonized by strain IS4 (black), strain IS4+M. maripaludis (medium gray; red in online version) and pure M. maripaludis (light gray) after incubation at −400 mV vs standard hydrogen electrode. Scanning speed was 1 mV s−1. For clarity one out of three replicates is shown. See Supplementary Figure S4 for CVs of all replicates.

Product formation rates at different electrode potentials

To investigate hydrogen formation by strain IS4 cells in greater detail, we performed experiments under sulfate-free conditions at different cathode potentials and followed hydrogen formation and current consumption over time. Before each experiment, all reactors containing previously established strain IS4 biocathodes were thoroughly flushed with N2/CO2 for 30 min to eliminate any residual hydrogen. Thereafter, hydrogen was formed at rates of 0.4–0.5 μmol cm−2 h−1 at a cathode potential of −400 mV (Figure 3a). Hydrogen formation rates increased by one order of magnitude to 4–7 μmol cm−2 h−1 when the potential was lowered to −500 mV, but a further decrease in potential did not result in a significant change of hydrogen formation rate (Figures 3b and c). Under these conditions, strain IS4 formed hydrogen from cathodic electrons at a coulombic efficiency of 90–110% in all experiments. These hydrogen formation rates were more than one order of magnitude higher than hydrogen evolution rates obtained with platinum foil (0.002 μmol cm−2 h−1 at −400 mV and 0.14 μmol cm−2 h−1 at −500 mV, respectively (Supplementary Figure S6)) instead of the IS4 biocathode in an identical setup.

Electrosynthetic formation of methane by a co-culture of strain IS4 and M. maripaludis

To investigate whether the observed highly efficient hydrogen formation by strain IS4 cells can be coupled to the hydrogenotrophic production of carbon compounds from CO2, we constructed a defined co-culture of strain IS4 with the methanogenic archaeon M. maripaludis. When M. maripaludis was added to a thoroughly N2/CO2-flushed, sulfate-depleted cathode chamber with an established strain IS4 biocathode, no accumulation of hydrogen but formation of methane was observed. Presumably, hydrogen was consumed rapidly to steady state concentrations of <500 p.p.m. in the gas phase due to methanogenesis. At −400 mV cathode potential this led to a small increase in current consumption (0.7–1.1 μmol electrons cm−2 h−1) compared with the reactors without methanogens (0.5–0.7 μmol electrons cm−2 h−1), most likely because the end product of the electron uptake step, hydrogen, was effectively scavenged by the methanogen (Figure 3a). Lowering the cathode potential from −400 to −500 mV increased the rates of methane formation from 0.10–0.14 μmol cm−2 h−1 to 0.6–0.9 μmol cm−2 h−1 (Figure 3b). This change in rate, however, was slightly lower than the change in the rate of hydrogen formation in the axenic IS4 culture (Figure 3b). In agreement with those findings, a further decrease in potential to −600 mV did only result in a small increase in methanogenesis rate in the methanogenic co-culture (Figure 3c). Notably, at cathode potentials of −400 mV and −600 mV, the rate of methane formation by the co-culture corresponded to the hydrogen formation rate by axenic strain IS4. No product formation was detected in un-inoculated controls or with an axenic M. maripaludis culture, and only marginal background current of 0.005 −0.007 μmol electrons cm−2 h−1 was observed (Supplementary Figure S7). Collectively, these data show that a co-culture of strain IS4 and M. maripaludis efficiently converted cathodic electrons plus CO2 into methane without the accumulation of intermediates.

Cyclic voltammetry measurements of the methanogenic co-culture indicated hydrogen formation was irreversible (Figure 2). No current production was recorded in this co-culture at potentials more positive than the thermodynamic equilibrium potential for H2 formation and oxidation. This confirmed that the methanogenic archaeon efficiently scavenged the molecular hydrogen formed at negative potentials during the sweep and prevented hydrogen from reaching the electrode surface during hydrogen-oxidizing conditions. In addition, the onset potential of current consumption and presumably hydrogen formation shifted by >60 mV to more positive potentials, indicating a decrease in hydrogen partial pressure of more than two orders of magnitude. CVs of un-inoculated reactors (Supplementary Figure 2) or reactors inoculated with axenic M. maripaludis (Figure 2) only showed marginal catalytic currents.

Colonization of the graphite surface by strain IS4

When the cathode chamber of an electrochemical H-cell was inoculated with strain IS4, electron microscopy revealed after 1 week of incubation (corresponding to current consumption rate of 0.1 A m−2 at this time) that cells on the electrode surface formed a patchy monolayer (Figure 4). Cells were found clustered in ‘cracks’ and ‘crevices’ in the graphite surface, suggesting that cells might only be irregularly attached to the graphite surface. No pronounced production of visible extracellular polymeric substance was observed. A rough estimation of cell number on the electrode surface yielded cell densities of 107–108 cells cm−2 electrode surface. However, these cell counts and extrapolated values have to be treated with caution, because the graphite surface is very rough and cells can be buried below the visible surface of the electrode.

Electron micrograph of plain graphite electrodes (a and c) and graphite electrodes colonized with strain IS4 after incubation in electrochemical reactors (b and d). Graphite electrodes were fixed after current consumption rates had reached a plateau that was stable for several days. Scale bars represent 10 μm (a and b) and 1 μm (c and d), respectively.

Formation of acetate by a co-culture of strain IS4 and A. woodii

To generalize the finding that a co-culture of strain IS4 and a hydrogenotrophic ‘production strain’ results in enhanced microbial electrosynthesis, we co-cultured the homoacetogenic bacterium A. woodii and strain IS4 in the electrochemical setup. Due to higher concentrations required for experimental detection of acetate (>1 μM), no short-term product formation rates were determined, but we estimated a formation rate from long term incubations. When A. woodii cells were added to reactors preincubated with strain IS4, acetate was produced after a lag-phase at rates of 0.21–0.23 μmol cm−2 h−1 (Figure 5a). In the lag-phase, hydrogen and formate accumulated transiently and were subsequently consumed correlating with acetate synthesis (Figures 5c and e). Upon changing the potential to −500 mV, current consumption as well as rate of acetate formation increased significantly to 0.57–0.74 μmol cm−2 h−1 (Figure 5b). Also here, a transient accumulation of formate and hydrogen was observed (Figures 5d and f). Coulombic efficiencies of acetate formation were low during the initial phase of the co-cultivation, but approached 90% at the end of the incubation. Presumably, the population size of A. woodii was insufficient to consume all electron donor generated by strain IS4 at the start of the co-culture and after the decrease of the potential to −500 mV. We surmise that the population size of A. woodii adapted to the supply of electron donor via strain IS4 after a few days of incubation. Formate presumably accumulated due to a formate hydrogen lyase activity catalyzed by A. woodii (Kantzow and Weuster-Botz, 2016). Acetate synthesis by the co-culture of strain IS4 and A. woodii was stable for more than 2 weeks (Figure 5). Under the conditions used in this study, a pure culture of A. woodii was unable to consume current and produce acetate at the potential range investigated.

Co-cultures of strain IS4 and A. woodii in the cathode compartment of electrochemical reactors. Acetate formation (filled symbols and solid lines) and cumulative charge (dotted lines) consumed at −400 mV (a) and −500 mV (b) in μmol electron equivalents (μmol eeq) per reactor. Hydrogen accumulation at −400 mV (c) and −500 mV (d) and formate formation at −400 mV (e) and −500 mV (f) are shown in μmol eeq for comparison. Two replicate reactors are shown in different shades of gray (red in the online version) and using different symbols to allow identification of each replicate across graphs. The continuous experiment is displayed in two separate parts for reasons of clarity due to the different scales required to display the product formation at different potentials. Diamonds: co-cultures of strain IS4 and A. woodii; triangles: A. woodii pure cultures; circles: un-inoculated controls.

Discussion

H2 evolution by microorganisms that take up cathodic electrons

Our study showed that molecular hydrogen was effectively formed at high rates and in the absence of practically any overpotential at a biocathode containing strain IS4 cells (Figures 2 and 3a). Electron uptake and hydrogen evolution rates of the established biocathode were an order of magnitude higher than rates obtained with an abiotic platinum cathode. Comparisons to other inorganic catalysts are difficult, because most catalysts are not evaluated in the potential range suitable for microbial growth. In addition, biofouling of inorganic catalysts and the influence of medium components is not well studied for most inorganic catalysts. As cells attached directly to the electrode surface, and cell-free culture supernatant or cell-free extracts did not catalyze H2 formation (data not shown), cathodic electron uptake is likely not facilitated by cathode-sorbed enzymes as demonstrated in M. maripaludis (Deutzmann et al., 2015). The findings on electron uptake by Fe(0)-corroding microorganisms such as strain IS4 suggest that these microbes are obvious candidates for mediating the initial biological uptake of cathodic electrons with several fundamental and technological implications.

The high rate of H2 formation from H+ and electrons by strain IS4 at −400 mV corresponds to a high cellular electron uptake rate of 106–107 e− s−1 cell−1 based on estimated cell counts obtained by electron microscopy in this study. These rates agree well with electron uptake rates of 6·106–1.5·107 e− s−1 cell−1 estimated from H2 formation from elemental Fe measured with washed strain IS4 cells (Enning, 2012). Another Fe(0)-corroding microorganism, the methanogenic archaeon strain IM1 was also shown to take up electrons at a high rate of 6·106 and 6·107 e− s−1 cell−1 at −400 and −600 mV, respectively (Beese-Vasbender et al., 2015a). Interestingly, these rates are roughly in the same order of magnitude as the single cell anodic reduction reaction in Shewanella oneidensis (105–106 e− s−1 cell−1) (Gross and El-Naggar, 2015). Notably, only some Fe(0) corroding strains form hydrogen from cathodic electrons while other strains such as strain IS5 do not accumulate hydrogen (Dinh et al., 2004). Therefore, only H2 producing strains, including strain IS4, represent a promising biocatalyst for the generation of H2 at a cathodic surface. Another benefit of using sulfate reducers lies in the fact that growth of the microorganism can be controlled by limiting the sulfate concentration in the reactor solution. Thus, during the electrosynthesis phase, only a negligible fraction of the electrical energy and electrons are directed towards biomass production of strain IS4, and the coulombic efficiency of hydrogen formation can achieve values of close to 100%. Thus, during long-term operation a continuous or batch fed system with additions of small amounts of sulfate could sustain a stable population of strain IS4 thriving on sulfate reduction while slowly re-supplying a reduced sulfur source for anaerobic microorganisms unable to assimilate sulfate. During continuous operation at neutral pH, the gas stream will slowly strip sulfide out of solution and, thus, deplete the sulfur source.

Due to the differences in the reporting of product formation rates in the literature (for example,, as specific rate per electrode surface area, reactor volume or total amount per reactor), associated projected areal current densities are used in this study for normalization to allow direct comparisons. However, faradaic efficiencies are not always reported and, thus, projected areal current densities might slightly overestimate actual product formation rates. Current densities of 1.1–3.3 A m−2 at −700 mV were reported during hydrogen formation using mixed cultures in microbial electrolysis cells (Rozendal et al., 2008; Jeremiasse et al., 2010; Croese et al., 2011; Jeremiasse et al., 2012), and current densities of 0.76 A m−2 were measured using a pure culture of the non-corroding sulfate reducer Desulfovibrio G11 (Croese et al., 2011). In our study, strain IS4 achieved similar current densities of 1.5 A m−2 already at a cathode potential of −500 mV and, thus, at a potential 200 mV more positive than in previously published studies. In addition, we used plain graphite electrodes which likely provide a lower effective surface area than graphite felt electrodes used in other studies (Rozendal et al., 2008; Jeremiasse et al., 2010; Croese et al., 2011; Jeremiasse et al., 2012). Besides electrode surface area, the cell density on the electrode surface impacts overall electron transfer rates. However, all isolates described to perform electrical microbially influenced corrosion, including strain IS4, do not form thick biofilms but form dispersed patchy monolayers of cells (Beese-Vasbender et al., 2015a, b). Thus, improving attachment and biofilm growth of these strains might greatly increase areal current densities and should be addressed in future research.

Efficient interspecies hydrogen transfer in mixed electrosynthetic cultures

The rates of electromethanogenesis by a co-culture of strain IS4 and M. maripaludis presented here are the highest reported to date. Compared with a recent study using Methanobacterium strain IM1 (Beese-Vasbender et al., 2015a), methanogenesis rates reported here were about one order of magnitude higher at −400 mV (100–140 nmol h−1 cm−2 compared with 12–14 nmol h−1 cm−2 in (Beese-Vasbender et al., 2015a)). However, electron uptake rates were comparable between both studies, and molecular hydrogen was likely a side product during electromethanogenesis by strain IM1, which became obvious at more negative potentials (Beese-Vasbender et al., 2015a). The rates obtained here with the co-culture are about 20 times higher compared with electromethanogenesis using axenic M. maripaludis at −600 mV (Lohner et al., 2014) (0.6–1.2 μmol h−1 cm−2 compared with 0.05 μmol h−1 cm−2). In addition, the overpotential for electromethanogenesis by the co-culture was >200 mV lower, thus resulting in less energy loss in this cathodic reaction. Few studies have shown microbial electrosynthesis of acetate, butanol or other multi-carbon compounds by pure cultures of homoacetogenic microorganisms. Electron transfer rates at a potential of −400 mV in these systems varied between strains and ranged from no electron uptake using A. woodii to 0.01 A m−2 using Moorella thermoacetica and to 0.2 A m−2 using Sporomusa ovata (Nevin et al., 2010, 2011). Thus, the electron uptake rates achieved by our co-culture of strain IS4 with A. woodii (0.2–0.5 A m−2 at −400 mV) are slightly higher than the rates published with pure cultures of homoacetogens (Nevin et al., 2011). Other studies using mixed cultures achieved high electrosynthesis rates when applying large overpotentials (3–20 A m−2 at −800 mV, (Ganigue et al., 2015)) at which the apparent ‘electro’synthetic activity is most likely due to the abiotic formation of hydrogen. At the cost of high overpotentials and higher energy losses, hydrogen is formed under these conditions even at electrodes with low catalytic activity for H2 evolution. This overpotential can be reduced when cell-derived enzymes or cofactors adsorb to the surface (Yates et al., 2014; Deutzmann et al., 2015). In our defined co-culture, hydrogen was formed already at −400 mV, which enabled electrosynthesis with A. woodii that has been shown previously to be unable to carry out electrosynthesis (Nevin et al., 2011) due to efficient interspecies hydrogen transfer.

General benefits of a decoupled microbial electron uptake—microbial synthesis system

In a microbial electrosynthesis system, the combination of an efficient electron uptake step with an efficient synthesis step of a compound of interest has several distinct advantages over a single microorganism process: (1) It becomes possible to engineer and operate two fundamentally different metabolic processes independently. Each microorganism can be optimized for its purpose, for example, through genetic engineering, without the need to consider additional tradeoffs imposed by the other process, and there are numerous efforts to engineer homoacetogenic microorganisms to produce, for example, ethanol, butanol and isobutanol (Köpke et al., 2010; Leang et al., 2013; Banerjee et al., 2014; Cho et al., 2015); (2) Only the electron uptaking strain has to contact the cathode while end product formation can proceed in the bulk liquid, which allows better use of the volume of the cathode compartment; (3) two microbial organisms adapt to each other’s metabolic capabilities via a thermodynamic-kinetic feedback loop resulting in an optimized metabolic flux without accumulation of intermediates. In addition, mixed communities are often reported to show higher electron transfer rates or higher current efficiencies than pure cultures (Dinh et al., 2004; Nevin et al., 2008; Call et al., 2009; Fast and Papoutsakis, 2012; Ganigue et al., 2015). Thus, especially with the possibility to engineer and improve each specialist in the co-culture, a stable and probably faster electrosynthesis system can be achieved compared with engineering existing iron corroding methanogens or homoacetogens (Uchiyama et al., 2010; Kato et al., 2015).

Electron uptake strains as ecosystem engineers in cathodic communities

Our finding that electrosynthesis rates can be improved substantially by co-cultivating an electron uptake strain that produces hydrogen with hydrogenotrophic strains prompts the question about the ecological relevance of such strains and their role in more natural environments. Successful co-cultivation of strain IS4 with a homoacetogen and a methanogen shows that interspecies hydrogen transfer can effectively distribute cathodic electrons to microorganisms that by themselves do not have the capacity for direct electron uptake. According to Jones, organisms directly or indirectly modulating the availability of resources (other than themselves) to other species by causing state changes in biotic or abiotic materials are called ‘ecosystem engineers’ in ecology (Jones et al., 1994). Microbial strains that facilitate electron uptake from a cathodic surface and supply electrons to the surrounding community can, therefore, be considered ecosystem engineers. Although this possibility has already been mentioned in one of the first studies on electrosynthesis by mixed species biofilms (Marshall et al., 2012), it lacked evidence for single strains catalyzing hydrogen formation at high rate. Based on the high cellular electron uptake rates (>106 e− s−1 cell−1), even a relatively small number of electroactive cells could result in substantial current consumption rates and thereby provide an effective electron donor for a diverse microbial ecosystem. Accordingly, the hydrogen evolution rate of a single strain IS4 cell (up to 30 fmol h−1) would be sufficient to supply all the hydrogen consumed by one M. maripaludis cell under optimum growth conditions (2 h doubling time), and provides hydrogen at a rate an order of magnitude higher than hydrogen uptake rates of other more slowly growing organisms (Goyal et al., 2015). Besides intact cells that transform cathodic electrons into a widely accessible substrate, such as hydrogen, strains that release electroactive enzymes such as hydrogenases have to be considered in cathodic communities. Even small amounts of electrocatalytically active enzymes could be sufficient to sustain biofilms on a cathodic surface due to the high turnover rates of hydrogenases.

Examples for candidate strains (‘ecosystem engineers’) mediating the key electron uptake to support complex cathodic biofilms can be found in the literature. The genus Methanobacterium became enriched in several studies investigating electromethanogenesis (Pozo et al., 2015; Siegert et al., 2015) and it has been shown in pure culture that Methanobacterium strain IM1 not only catalyzed electrosynthetic methanogenesis but also accumulated hydrogen during electromethanogenesis (Beese-Vasbender et al., 2015a), which can create a niche for other microorganisms. In homoacetogenic communities the role of distinct electron uptake strains seems to be more elusive. A variety of homoacetogenic bacteria were shown to use cathodic electrons in pure culture (Nevin et al., 2010, 2011). However, in acetate-producing electrosynthesis reactors inoculated with undefined mixed cultures the cathode-associated community was often dominated by Acetobacterium spp., which had been reported to lack the ability to utilize cathodic electrons (Nevin et al., 2011). Often, sulfate reducers such as Desulfovibrio sp. are also present in these enrichments (Marshall et al., 2013; LaBelle et al., 2014; Patil et al., 2015), suggesting that hydrogen produced by the sulfate reducers might have a role in these biofilms. However, the role of individual strains in mixed communities and the molecular mechanism of microbial electron uptake from the cathode is unclear in most cases. Thus, further research is needed on the electron uptake mechanism(s) acting in different electron uptake strains and identification of these key ‘ecosystem engineers’.

In summary, this study shows that an electrosynthesis system relying on interspecies hydrogen transfer is able to outperform mono-culture electromethanogenesis based on direct electron transfer and it emphasizes the importance of an efficient biological hydrogen evolution step for effective electrosynthesis for example, using M. maripaludis. Furthermore, certain microbial strains can transmute cathodic electrons to reduced diffusible compounds such as hydrogen at rates exceeding their own metabolic capacity to use these compounds. As a consequence, these compounds become available as substrates to other hydrogenotrophic strains and could potentially sustain a diverse cathodic biofilm. Thus, defined co-cultures may represent a foundation for an engineering strategy for microbial electrosynthesis and provide a means to understand complex cathodic biofilms.

References

Aulenta F, Catapano L, Snip L, Villano M, Majone M . (2012). Linking bacterial metabolism to graphite cathodes: electrochemical insights into the H2-producing capability of Desulfovibrio sp. Chemsuschem 5: 1080–1085.

Banerjee A, Leang C, Ueki T, Nevin KP, Lovley DR . (2014). Lactose-inducible system for metabolic engineering of Clostridium ljungdahlii. Appl Environ Microbiol 80: 2410–2416.

Beese-Vasbender PF, Grote J-P, Garrelfs J, Stratmann M, Mayrhofer KJJ . (2015a). Selective microbial electrosynthesis of methane by a pure culture of a marine lithoautotrophic archaeon. Bioelectrochemistry 102: 50–55.

Beese-Vasbender PF, Nayak S, Erbe A, Stratmann M, Mayrhofer KJJ . (2015b). Electrochemical characterization of direct electron uptake in electrical microbially influenced corrosion of iron by the lithoautotrophic SRB Desulfopila corrodens strain IS4. Electrochimica Acta 167: 321–329.

Blanchet E, Duquenne F, Rafrafi Y, Etcheverry L, Erable B, Bergel A . (2015). Importance of the hydrogen route in up-scaling electrosynthesis for microbial CO2 reduction. Energ Environ Sci 8: 3731–3744.

Bond DR, Lovley DR . (2003). Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69: 1548–1555.

Call DF, Wagner RC, Logan BE . (2009). Hydrogen production by geobacter species and a mixed consortium in a microbial electrolysis cell. Appl Environ Microbiol 75: 7579–7587.

Cheng SA, Xing DF, Call DF, Logan BE . (2009). Direct biological conversion of electrical current into methane by electromethanogenesis. Environ Sci Technol 43: 3953–3958.

Cho C, Jang YS, Moon HG, Lee J, Lee SY . (2015). Metabolic engineering of clostridia for the production of chemicals. Biofuels, Bioprod Biorefin 9: 211–225.

Clarke TA, Edwards MJ, Gates AJ, Hall A, White GF, Bradley J et al. (2011). Structure of a bacterial cell surface decaheme electron conduit. Proc Natl Acad Sci USA 108: 9384–9389.

Costa KC, Lie TJ, Jacobs MA, Leigh JA . (2013). H2-independent growth of the hydrogenotrophic methanogen Methanococcus maripaludis. MBio 4: e00062–00013.

Coursolle D, Baron DB, Bond DR, Gralnick JA . (2010). The Mtr respiratory pathway is essential for reducing flavins and electrodes in Shewanella oneidensis. J Bacteriol 192: 467–474.

Croese E, Pereira MA, Euverink GJW, Stams AJM, Geelhoed JS . (2011). Analysis of the microbial community of the biocathode of a hydrogen-producing microbial electrolysis cell. Appl Microbiol Biotechnol 92: 1083–1093.

Deutzmann JS, Sahin M, Spormann AM . (2015). Extracellular enzymes facilitate electron uptake in biocorrosion and bioelectrosynthesis. Mbio 6: e00496–15.

Dinh HT, Kuever J, Mussmann M, Hassel AW, Stratmann M, Widdel F . (2004). Iron corrosion by novel anaerobic microorganisms. Nature 427: 829–832.

Enning D . (2012), Bioelectrical corrosion of iron by lithotrophic sulfate-reducing bacteria. Dissertation, University of Bremen, Germany.

Enning D, Venzlaff H, Garrelfs J, Dinh HT, Meyer V, Mayrhofer K et al. (2012). Marine sulfate-reducing bacteria cause serious corrosion of iron under electroconductive biogenic mineral crust. Environ Microbiol 14: 1772–1787.

Enning D, Garrelfs J . (2014). Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl Environ Microbiol 80: 1226–1236.

Fast AG, Papoutsakis ET . (2012). Stoichiometric and energetic analyses of non-photosynthetic CO2-fixation pathways to support synthetic biology strategies for production of fuels and chemicals. Curr Opin Chem Eng 1: 380–395.

Ganigue R, Puig S, Batlle-Vilanova P, Balaguer MD, Colprim J . (2015). Microbial electrosynthesis of butyrate from carbon dioxide. Chem Commun 51: 3235–3238.

Geelhoed JS, Hamelers HVM, Stams AJM . (2010). Electricity-mediated biological hydrogen production. Curr Opin Microbiol 13: 307–315.

Goyal N, Padhiary M, Karimi IA, Zhou Z . (2015). Flux measurements and maintenance energy for carbon dioxide utilization by Methanococcus maripaludis. Microb Cell Fact 14: 146.

Gross BJ, El-Naggar MY . (2015). A combined electrochemical and optical trapping platform for measuring single cell respiration rates at electrode interfaces. Rev Sci Instrum 86: 064301.

Hartshorne RS, Reardon CL, Ross D, Nuester J, Clarke TA, Gates AJ et al. (2009). Characterization of an electron conduit between bacteria and the extracellular environment. Proc Natl Acad Sci USA 106: 22169–22174.

Jafary T, Daud WRW, Ghasemi M, Kim BH, Jahim JM, Ismail M et al. (2015). Biocathode in microbial electrolysis cell; present status and future prospects. Renew Sust Energ Rev 47: 23–33.

Jeremiasse AW, Hamelers EVM, Buisman CJN . (2010). Microbial electrolysis cell with a microbial biocathode. Bioelectrochemistry 78: 39–43.

Jeremiasse AW, Hamelers HVM, Croese E, Buisman CJN . (2012). Acetate enhances startup of a H2-producing microbial biocathode. Biotechnol Bioeng 109: 657–664.

Jones CG, Lawton JH, Shachak M . (1994). Organisms as ecosystem engineers. Oikos 69: 373–386.

Kantzow C, Weuster-Botz D . (2016). Effects of hydrogen partial pressure on autotrophic growth and product formation of Acetobacterium woodii. Bioprocess Biosyst Eng 39: 1325–1330.

Kato S, Hashimoto K, Watanabe K . (2012). Microbial interspecies electron transfer via electric currents through conductive minerals. Proc Natl Acad Sci USA 109: 10042–10046.

Kato S, Yumoto I, Kamagata Y . (2015). Isolation of acetogenic bacteria that Iinduce biocorrosion by utilizing metallic iron as the sole electron donor. Appl Environ Microbiol 81: 67–73.

Köpke M, Held C, Hujer S, Liesegang H, Wiezer A, Wollherr A et al. (2010). Clostridium ljungdahlii represents a microbial production platform based on syngas. Proc Natl Acad Sci USA 107: 13087–13092.

LaBelle EV, Marshall CW, Gilbert JA, May HD . (2014). Influence of acidic pH on hydrogen and acetate production by an electrosynthetic microbiome. PloS one 9: e109935.

Leang C, Ueki T, Nevin KP, Lovley DR . (2013). A genetic system for Clostridium ljungdahlii: a chassis for autotrophic production of biocommodities and a model homoacetogen. Appl Environ Microbiol 79: 1102–1109.

Liu Y, Wang Z, Liu J, Levar C, Edwards MJ, Babauta JT et al. (2014). A trans-outer membrane porin-cytochrome protein complex for extracellular electron transfer by Geobacter sulfurreducens PCA. Environ Microbiol Rep 6: 776–785.

Lohner ST, Deutzmann JS, Logan BE, Leigh J, Spormann AM . (2014). Hydrogenase-independent uptake and metabolism of electrons by the archaeon Methanococcus maripaludis. ISME J 8: 1673–1681.

Lovley DR . (2012). Electromicrobiology. Annu Rev Microbiol 66: 391–409.

Malvankar NS, Lovley DR . (2014). Microbial nanowires for bioenergy applications. Curr Opin Biotechnol 27C: 88–95.

Marshall CW, Ross DE, Fichot EB, Norman RS, May HD . (2012). Electrosynthesis of commodity chemicals by an autotrophic microbial community. Appl Environ Microbiol 78: 8412–8420.

Marshall CW, Ross DE, Fichot EB, Norman RS, May HD . (2013). Long-term operation of microbial electrosynthesis systems improves acetate production by autotrophic microbiomes. Environ Sci Technol 47: 6023–6029.

Nakamura R, Takashima T, Kato S, Takai K, Yamamoto M, Hashimoto K . (2010). Electrical current generation across a black smoker chimney. Angew Chem Int Ed Engl 49: 7692–7694.

Nevin KP, Richter H, Covalla SF, Johnson JP, Woodard TL, Orloff AL et al. (2008). Power output and columbic efficiencies from biofilms of Geobacter sulfurreducens comparable to mixed community microbial fuel cells. Environ Microbiol 10: 2505–2514.

Nevin KP, Woodard TL, Franks AE, Summers ZM, Lovley DR . (2010). Microbial electrosynthesis: feeding microbes electricity to convert carbon dioxide and water to multicarbon extracellular organic compounds. MBio 1: e00103–e00110.

Nevin KP, Hensley SA, Franks AE, Summers ZM, Ou J, Woodard TL et al. (2011). Electrosynthesis of organic compounds from carbon dioxide is catalyzed by a diversity of acetogenic microorganisms. Appl Environ Microbiol 77: 2882–2886.

Patil SA, Arends JB, Vanwonterghem I, Van Meerbergen J, Guo K, Tyson GW et al. (2015). Selective enrichment establishes a stable performing community for microbial electrosynthesis of acetate from CO2. Environ Sci Technol 49: 8833–8843.

Pirbadian S, Barchinger SE, Leung KM, Byun HS, Jangir Y, Bouhenni RA et al. (2014). Shewanella oneidensis MR-1 nanowires are outer membrane and periplasmic extensions of the extracellular electron transport components. Proc Natl Acad Sci USA 111: 12883–12888.

Pozo G, Jourdin L, Lu Y, Ledezma P, Keller J, Freguia S . (2015). Methanobacterium enables high rate electricity-driven autotrophic sulfate reduction. RSC Advances 5: 89368–89374.

Rozendal RA, Jeremiasse AW, Hamelers HVM, Buisman CJN . (2008). Hydrogen production with a microbial biocathode. Environ Sci Technol 42: 629–634.

Siegert M, Yates MD, Spormann AM, Logan BE . (2015). Methanobacterium dominates biocathodic archaeal communities in methanogenic microbial electrolysis cells. ACS Sustain Chem Eng 3: 1668–1676.

TerAvest MA, Zajdel TJ, Ajo-Franklin CM . (2014). The Mtr pathway of Shewanella oneidensis MR-1 couples substrate utilization to current production in Escherichia coli. Chemelectrochem 1: 1874–1879.

Uchiyama T, Ito K, Mori K, Tsurumaru H, Harayama S . (2010). Iron-corroding methanogen isolated from a crude-oil storage tank. Appl Environ Microbiol 76: 1783–1788.

Venzlaff H, Enning D, Srinivasan J, Mayrhofer KJJ, Hassel AW, Widdel F et al. (2013). Accelerated cathodic reaction in microbial corrosion of iron due to direct electron uptake by sulfate-reducing bacteria. Corros Sci 66: 88–96.

Villano M, Aulenta F, Ciucci C, Ferri T, Giuliano A, Majone M . (2010). Bioelectrochemical reduction of CO2 to CH4 via direct and indirect extracellular electron transfer by a hydrogenophilic methanogenic culture. Bioresour Technol 101: 3085–3090.

Yates MD, Siegert M, Logan BE . (2014). Hydrogen evolution catalyzed by viable and non-viable cells on biocathodes. Int J Hydrogen Energ 39: 16841–16851.

Acknowledgements

We thank Lydia-Marie Joubert and the Cells Science Imaging Facility at Stanford University for providing support in preparing the samples and acquisition of the SEM images. We thank David Kleiman for his help in conducting experiments. This research was supported by the Global Climate and Energy Project (GCEP) and the Office of Naval Research (ONR) through grants to AMS.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies this paper on The ISME Journal website

Rights and permissions

About this article

Cite this article

Deutzmann, J., Spormann, A. Enhanced microbial electrosynthesis by using defined co-cultures. ISME J 11, 704–714 (2017). https://doi.org/10.1038/ismej.2016.149

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/ismej.2016.149

This article is cited by

-

From Electricity to Products: Recent Updates on Microbial Electrosynthesis (MES)

Topics in Catalysis (2024)

-

Copper foam supported g-C3N4-metal–organic framework bacteria biohybrid cathode catalyst for CO2 reduction in microbial electrosynthesis

Scientific Reports (2023)

-

Metabolic engineering strategies for microbial utilization of C1 feedstocks

Systems Microbiology and Biomanufacturing (2023)

-

Electron transfer of extremophiles in bioelectrochemical systems

Extremophiles (2022)

-

Microbial electrosynthesis of methane and acetate—comparison of pure and mixed cultures

Applied Microbiology and Biotechnology (2022)