Abstract

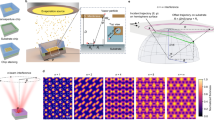

This protocol provides an introduction to soft lithography—a collection of techniques based on printing, molding and embossing with an elastomeric stamp. Soft lithography provides access to three-dimensional and curved structures, tolerates a wide variety of materials, generates well-defined and controllable surface chemistries, and is generally compatible with biological applications. It is also low in cost, experimentally convenient and has emerged as a technology useful for a number of applications that include cell biology, microfluidics, lab-on-a-chip, microelectromechanical systems and flexible electronics/photonics. As examples, here we focus on three of the commonly used soft lithographic techniques: (i) microcontact printing of alkanethiols and proteins on gold-coated and glass substrates; (ii) replica molding for fabrication of microfluidic devices in poly(dimethyl siloxane), and of nanostructures in polyurethane or epoxy; and (iii) solvent-assisted micromolding of nanostructures in poly(methyl methacrylate).

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Whitesides, G.M. The right size: nanobiotechnology. Nat. Biotech. 21, 1161–1165 (2003).

Beaudet, A.L. & Belmont, J.W. Array-based DNA diagnostics: let the revolution begin. Annu. Rev. Med. 59, 113–129 (2008).

Zhang, Y. & Ozdemir, P. Microfluidic DNA amplification—a review. Anal. Chim. Acta 638, 115–125 (2009).

Herold, K.E. & Rasooly, A. (eds.). Lab-on-a-Chip Technology: Fabrication and Microfluidics. (Caister Academic Press, Hethersett, Norwich, UK, 2009).

Cui, H.F. et al. Microelectrode array biochip: tool for in vitro drug screening based on the detection of a drug effect on dopamine release from PC12 cells. Anal. Chem. 78, 6347–6355 (2006).

Li, N., Tourovskaia, A. & Folch, A. Biology on a chip: microfabrication for studying the behavior of cultured cells. Crit. Rev. Biomed. Eng. 31, 423–488 (2003).

Moreau, W.M. Semiconductor Lithography: Principles and Materials (Plenum, New York, 1998).

Fodor, S.P. et al. Light-directed, spatially addressable parallel chemical synthesis. Science 251, 767–73 (1991).

Xia, Y. & Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. Engl. 37, 551–575 (1998).

Kumar, A. & Whitesides, G.M. Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol ink followed by chemical etching. Appl. Phys. Lett. 63, 2002–2004 (1993).

Xia, Y. et al. Replica molding using polymeric materials: a practical step toward nanomanufacturing. Adv. Mater. 9, 147–149 (1997).

Zhao, X.-M., Xia, Y. & Whitesides, G.M. Fabrication of three-dimensional microstructures: microtransfer molding. Adv. Mater. 8, 837–840 (1996).

Kim, E., Xia, Y. & Whitesides, G.M. Polymeric microstructures formed by moulding in capillaries. Nature 376, 581–584 (1995).

Kim, E., Xia, Y., Zhao, X.-M. & Whitesides, G.M. Solvent-assisted microcontact molding: a convenient method for fabricating three-dimensional structures of polymeric materials. Adv. Mater. 9, 651–654 (1997).

Rogers, J.A., Paul, K.E., Jackman, R.J. & Whitesides, G.M. Using an elastomeric phase mask for sub-100 nm photolithography in the optical near field. Appl. Phys. Lett. 70, 2658–2660 (1997).

Jeon, S. et al. Three-dimensional nanofabrication with rubber stamps and conformable photomasks. Adv. Mater. 16, 1369–1371 (2004).

Childs, W.R. & Nuzzo, R.G. Decal transfer microlithography: a new soft-lithographic patterning method. J. Am. Chem. Soc. 124, 13583–13596 (2002).

Xu, Q., Rioux, R.M., Dickey, M.D. & Whitesides, G.M. Nanoskiving: a new method to produce arrays of nanostructures. Acc. Chem. Res. 41, 1566–1577 (2008).

Gates, B.D. et al. New approaches to nanofabrication: molding, printing, and other techniques. Chem. Rev. 105, 1171–1196 (2005).

Ginger, D.S., Zhang, H. & Mirkin, C.A. Angew. Chem. Int. Ed. Engl. 43, 30–45 (2004).

Geissler, M. & Xia, Y. Patterning: principles and some new developments. Adv. Mater. 16, 1249–1269 (2004).

Love, J.C. et al. Self-assembled monolayers of thiolates on metals as a form of nanotechnology. Chem. Rev. 105, 1103–1170 (2005).

George, J. Preparation of Thin Films (Marcel Dekker, New York, 1992).

Chen, C.S., Mrksich, M., Huang, S., Whitesides, G.M. & Ingber, D.E. Geometric control of cell life and death. Science 276, 1425–1428 (1997).

von Philipsborn, A.C. et al. Microcontact printing of axon guidance molecules for generation of graded patterns. Nat. Protoc. 1, 1322–1328 (2006).

McDonald, J.C. et al. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 21, 27–40 (2000).

Chung, K., Crane, M. & Lu, H. Automated on-chip imaging and sorting of C. elegans. Nat. Protoc. 4 (2009); DOI: 10.1038/nprot.2009.105.

Sidorova, J.M., Li, N., Schwartz, D.C., Folch, A. & Monnat, R.J. Microfluidic-assisted analysis of replicating DNA molecules. Nat. Protoc. 4, 849–861 (2009).

Ogunniyi, A.O., Story, C.M., Papa, E., Guillen, E. & Love, J.C. Screening individual hybridomas by microengraving to discover monoclonal antibodies. Nat. Protoc. 4, 767–782 (2009).

Paguirigan, A.L. & Beebe, D.J. Protocol for the fabrication of enzymatically crosslinked gelatin microchannels for microfluidic cell culture. Nat. Protoc. 2, 1782–1788 (2007).

Park, J.W., Vahidi, B., Taylor, A.M., Rhee, S.W. & Jeon, N.L. Microfluidic culture platform for neuroscience research. Nat. Protoc. 1, 2128–2136 (2006).

Tourovskaia, A. & Figueroa-Masot, X. & Floch, A . Long-term microfluidic cultures of myotube microarrays for high-throughput focal simulation. Nat. Protoc. 1, 1092–1104 (2006).

Semlyen, J.A. & Clarson, S.J. (eds). Silicone Polymers (Prentice-Hall, Englewood, New Jersey, 1993).

Hillborg, H. et al. Crosslinked polydimethylsiloxane exposed to oxygen plasma studied by neutron reflectometry and other surface specific techniques. Polymer 41, 6851–6863 (2000).

Whitesides, G.M. The origins and the future of microfluidics. Nature 442, 368–373 (2006).

Zheng, B., Tice, J.D. & Ismagilov, R.F. Formation of arrayed droplets by soft lithography and two-phase fluidic flow, and application in protein crystallization. Adv. Mater. 16, 1365–1368 (2004).

Xia, Y., Rogers, J.A., Paul, K.E. & Whitesides, G.M. Unconventional methods for fabricating and patterning nanostructures. Chem. Rev. 99, 1823–1848 (1999).

Anderson, B.B., Burgess, L.W. & Brodsky, A.M. Grating light reflection spectroscopy of colloids and suspensions. Langmuir 13, 4273–4279 (1997).

Lee, K.-H. et al. Microfluidic systems integrated with two-dimensional surface plasmon resonance phase imaging systems for microarray immunoassay. Biosens. Bioelectron. 23, 466–472 (2007).

Stewart, M.E. et al. Quantitative multispectral biosensing and 1D imaging using quasi-3D plasmonic crystals. Proc. Natl. Acad. Sci. USA 103, 17143–17148 (2006).

Backofen, U., Matysik, F.-M. & Lunte, C.E. A chip-based electrophoresis system with electrochemical detection and hydrodynamic injection. Anal. Chem. 74, 4054–4059 (2002).

Qin, D., Xia, Y. & Whitesides, G.M. Rapid prototyping of complex structures with feature sizes larger than 20 μm. Adv. Mater. 8, 917–919 (1996).

Xia, Y., Tien, J., Qin, D. & Whitesides, G.M. Non-photolithographic methods for fabrication of elastomeric stamps for use in microcontact printing. Langmuir 12, 4033–4038 (1996).

Odom, T.W. et al. Improved pattern transfer in soft lithography using composite stamps. Langmuir 18, 5314–5320 (2002).

Xia, Y., Kim, E. & Whitesides, G.M. Microcontact printing of alkanethiols on silver and its application in microfabrication. J. Electrochem. Soc. 143, 1070–1079 (1996).

Love, J.C. et al. Self-assembled monolayers of alkanethiolates on palladium are good etch resists. J. Am. Chem. Soc. 124, 1576–1577 (2002).

Geissler, M., Chen, J. & Xia, Y. Comparative study of monolayers self-assembled from octadecylisocyanide and octadecanethiol on polycrystalline Pt substrates. Langmuir 20, 6993–6997 (2004).

Xia, Y., Mrksich, M., Kim, E. & Whitesides, G.M. Microcontact printing of octadecylsiloxane on the surface of silicon dioxide and its application in microfabrication. J. Am. Chem. Soc. 117, 9576–9577 (1995).

Mrksich, M. & Whitesides, G.M. Using self-assembled monolayers to understand the interactions of man-made surfaces with proteins and cells. Ann. Rev. Biophys. Biomol. Struct. 25, 55–78 (1996).

Jiang, X., Bruzewicz, D.A., Thant, M.M. & Whitesides, G.M. Palladium as a substrate for self-assembled monolayers used in biotechnology. Anal. Chem. 76, 6116–6121 (2004).

Bernard, A. et al. Printing patterns of proteins. Langmuir 14, 2225–2229 (1998).

Weibel, D.B. et al. A bacterial printing press that regenerates its ink: contact printing bacteria using hydrogel stamps. Langmuir 21, 6436–6442 (2005).

Stevens, M.M. et al. Direct patterning of mammalian cells onto porous tissue engineering substrates using agarose stamps. Biomaterials 26, 7636–7641 (2005).

Gates, B.D. & Whitesides, G.M. Replica molding of vertical features smaller than 2 nm by soft lithography. J. Am. Chem. Soc. 125, 14986–14987 (2003).

Xia, Y. et al. Complex optical surfaces by replica molding against elastomeric masters. Science 273, 347–349 (1996).

Chou, S.Y., Krauss, P.R. & Renstrom, P.J. Imprint lithography with 25-nanometer resolution. Science 272, 85–87 (1996).

Xia, Y., Zhao, X.-M., Kim, E. & Whitesides, G.M. A selective etching solution for use with patterned self-assembled monolayers of alkanethiolates on gold, silver and copper. Chem. Mater. 7, 2332–2337 (1995).

Delamarche, E., Schmid, H., Michel, B. & Biebuyck, H. Stability of molded polydimethylsiloxane microstructures. Adv. Mater. 9, 741–746 (1997).

Xia, Y. & Whitesides, G.M. Use of controlled reactive spreading of liquid alkanethiol on the surface of gold to modify the size of features produced by microcontact printing. J. Am. Chem. Soc. 117, 3274–3275 (1995).

Palacin, S. et al. Patterning with magnetic materials at the micron scale. Chem. Mater. 8, 1316–1325 (1996).

Biebuyck, H., Larsen, N.B., Delamarche, E. & Michel, B. Lithography beyond light: macrocontact printing with monolayer resist. IBM J. Res. Develop. 41, 159–170 (1997).

Acknowledgements

Both Washington University and Harvard University are members of the National Nanotechnology Infrastructure Network (NNIN), which is supported by the National Science Foundation under award no. ECS-0335765.

Author information

Authors and Affiliations

Contributions

D.Q. is responsible for all the experiments described in this article and preparation of the paper; Y.X. is partially responsible for experimental planning and preparation of the paper; and G.M.W. is responsible for providing guidance for the experiments and for editing and proofreading the paper.

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, D., Xia, Y. & Whitesides, G. Soft lithography for micro- and nanoscale patterning. Nat Protoc 5, 491–502 (2010). https://doi.org/10.1038/nprot.2009.234

Published:

Issue date:

DOI: https://doi.org/10.1038/nprot.2009.234

This article is cited by

-

Intensity Histogram-Based Reliable Image Analysis Method for Bead-Based Fluorescence Immunoassay

BioChip Journal (2024)

-

Modified capillary number to standardize droplet generation in suction-driven microfluidics

Microfluidics and Nanofluidics (2024)

-

Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications

Discover Nano (2023)

-

Realization of high aspect ratio metalenses by facile nanoimprint lithography using water-soluble stamps

PhotoniX (2023)

-

Microfluidic thrombosis analysis system: possibilities and limitations

Micro and Nano Systems Letters (2023)