Abstract

The fracture of a bronze object is usually accompanied by localized deformation. The deformed part often tends to spring back at an unpredictable moment after its shape is corrected. The reconstruction of the area adjacent to the damage should be sufficiently resistant to the stress derived from springback so that the whole structure can remain stable. However, the choice of gap-filling materials for bronze objects is typically based on personal experience, and there are few available studies on their pertinent properties. The present study focused on a typical situation of deformation, took the flexural modulus as a crucial parameter and explored the development of a protocol for selecting a gap-filling material for bronze restoration in terms of its mechanical property. The flexural modulus was measured for the main classes of materials in use, and the factors related to preparation that influenced performance were studied. Among the various materials tested, carbon fiber reinforced (CFR) materials exhibited an advantageous value of the modulus and notable operational convenience. Further tests were conducted to assess their chemical safety for application in a museum context, as well as their surface workability. After obtaining overall encouraging results, composites reinforced with CF cloth and chopped CF were applied to the reconstruction of different parts of an archaeological bronze vessel. Indications for future improvement in the experimental setup and some practical notes regarding the use of CFR materials were also provided in this paper.

Similar content being viewed by others

Introduction

One of the main challenges in the restoration of bronze objects is deformation that frequently accompanies structural fracture. In cases where the original shape is known with certainty, and its physical restoration is required by the commissioning party, shape correction is a technically demanding yet practicable intervention for bronzes that are not severely mineralized, which is also a prerequisite for the proper implementation of other interventions, such as reassembling and gap filling.

In general, reshaping bronze and metal objects is usually performed by applying a progressive load onto the deformed part in the direction opposite to the deformation using finger pressure, weight, clamps and/or a hammer with the assistance of shaped molds [1,2,3,4,5,6,7,8,9]. Due to the internal stress of the material, the metal sheet tends to spring back after the removal of the load, and overbending is necessary in shaping to compensate and obtain the desired shape [10]. While the amount of springback and necessary overbending can be calculated in industrial applications, the corrosion of bronze over time makes the operation unpredictable and even risky. Reactions between the metal and various agents in air, soil and waterlogged environments, such as moisture, gases, aerosol particles and salts, convert metallic elements into different kinds of corrosion products [11]. This process weakens the elasticity and other mechanical properties of metal to different extents and leads to the formation of internal defects. The ductility of a degraded alloy under cold working conditions can be significantly reduced, and heating above the recrystallization temperature for hot working is ethically unacceptable due to the risks of surface discoloration and metallographic alteration [12]. As a result, the allowed amount of overbending is often limited to prevent damage, which makes it difficult to achieve a "thorough" shape correction, especially for ancient bronze objects subjected to long-term degradation. Springback can occur both immediately and over time, even after subsequent reassembling and gap filling, causing deformation in the reconstruction of adjacent area and destabilizing the whole structure.

Therefore, it is important to fill gaps with materials of sufficient resistance to the stress caused by eventual springback of reshaped part. Whenever the reconstructed part maintains its shape and position, deformation of the contiguous area is prevented. Structural considerations may be one of the reasons why typical traditional strategies for filling gaps in metal objects adopted worldwide include soldering readily shaped metal or alloy sheets with materials that usually have compositions similar to those of the original to reconstruct gaps of larger dimensions [3, 4, 12,13,14]. Although soldering forms a stronger connection than adhesives and remarkably strengthens the joint where stress tends to concentrate, its use is very limited today due to the increasing emphasis on the reversibility of restoration. Thus, materials used to fill gaps are required to provide more effective stabilization of structures.

For filling gaps in deformed bronze and other metal objects, the materials reported in the existing studies include the metal patches above mentioned; soft solder as an auxiliary filler for the interstice between the metal patch and original part or used alone [3, 8, 14]; and resin systems reinforced with filler or cloth materials such as felt and glass fiber cloth [1, 3, 6, 15]. Although the metal restoration community shares a common perception of the importance of the mechanical properties of gap-filling materials, the selection of materials in everyday practice remains largely based on experience. The few available studies provide only some strength and surface hardness data [16,17,18,19,20]. The strength of materials actually indicates its performance at a maximum load before plastic deformation or failure occurs, and it cannot characterize the elastic strain, while the stress provoked by springback is within the elastic limit. The corresponding parameter used to measure the resistance of a material to elastic deformation is the elastic modulus (E), which is calculated as the ratio of stress to strain in the elastic range. A larger E value indicates greater stiffness and resistance to elastic deformation [21]. While this parameter, as well as other pertinent mechanical properties, are under persistent research related to the conservation of paintings [22,23,24,25,26], the concept of the elastic modulus is still unfamiliar to many bronze restorers. A recent study involving this parameter focused on the use of finite element analysis (FEA) to simulate the restoration of a severely mineralized thin-walled bronze object; the issue of deformation and reshaping was not considered [27]. For the topic discussed here, the characterization method and analytical itinerary have not been explored so far.

The present work included both material tests and restoration practices. The first was an explorative study on this mechanical property of various gap-filling materials used for bronze restoration. Instead of FEA, which is precise but case-specific, conventional mechanical testing was conducted in search of references applicable to a broader context. Given the anisotropy of many composite materials, the study focused on a relatively simple but typical situation to specify the mechanical value to measure; the deformation was concentrated in one area of the fracture outlining the missing part. The stress that the reconstructed part undergoes when springback occurs can be approximated to bending stress. Accordingly, the mechanical property for evaluation is the flexural modulus (Eflex) [28]. Although this simplifies the complex nature of stress and stress transfer in real situations, this parameter can express the tendency of a material to resist bending and its effect in stabilizing the structure of a deformed bronze object in long-term storage after restoration.

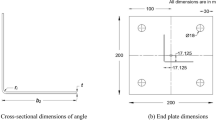

The flexural moduli of four classes of composite materials were measured in this study. Different types of powder reinforced composites, including pre-prepared commercial products, are used worldwide [16, 18, 29,30,31,32,33]. Glass fiber reinforced (GFR) composites are used for structural support and gap filling in metal restoration, although their use is reported less frequently than powder reinforced materials [6, 34,35,36,37,38]. Copper alloy sheet and mesh reinforced materials are frequently used in China currently as a convenient alternative to traditional arduous techniques. Instead of using a whole piece of copper alloy having the same thickness as the original object, thinner sheets that are easier to shape are used, and then resin is applied to fill the discrepancy in thickness. When the gap is large or has a complicated shape, frameworks made of pieces of sheet or metal meshes are also used (Fig. 1) [39, 40]. Carbon fiber reinforced (CFR) composites have been so far mainly used as auxiliary supporting structures in the cultural heritage conservation field [41,42,43,44], while their utilization as gap-filling material is discussed only at the experimental level [17]. These composites were explored here for their large elastic moduli and good deformation resistance that have potential for use in the discussed application scenario. As increasingly used substitutes for metal in industrial fields, the CFR materials have other advantages, such as high strength, light weight, and chemical and thermal stability, while the variety in product type offers versatility of use [45,46,47]. Inside each of the investigated classes, some factors of preparation were intentionally examined to verify their influence on the properties of the whole system and provide further indications for use in daily work.

The CFR composites showing an advantage in flexural modulus were further tested to learn about their chemical safety for use on bronze and their surface hardness. The results were overall positive and indicated that these materials could be potentially used to fill gaps in bronze objects situated in a museum context. The CFR composites were applied to a Chinese bronze Ding (cauldron) vessel attributed to the Warring States Period (475 B.C. -221 B.C.) from Shanghai Museum (Fig. 2). The lid had typical bending deformation concentrated in one area along the central fracture. For the reconstruction of the loss adjacent to this deformation, conventional gap-filling materials were considered unqualified because of their mechanical properties or difficulties in their use in previous attempts. The application of CFR materials as an alternative, although with tentative feature and limited by the previous reconstruction partially kept, could be a practical reference for the usage of different types of CF products for interested restorers.

a Lid of the Ding vessel before intervention (d = 28.5 cm). b Side view of the lid with red arrow indicating the predicted direction of eventual springback after reshaping and potential stress that the reconstructed part could undergo; c body of the Ding vessel before intervention (h = approximately 24.5 cm)

Materials and methods

Measurements of flexural modulus

The measurement was conducted through a three-point flexural test with a ZwickRoell Zwick Z100 TEW materials testing machine at a temperature of (23 ± 2) ℃ and a relative humidity of (50 ± 10) % following the procedure defined by the Chinese national standard GB/T 1449–2005 [48]. Most of the samples were prepared as rectangular coupons measuring 40 mm in length, 1 mm in height and 15 mm in breadth. This selected height approximated the average thickness of the deformed part of the lid of the bronze Ding vessel. The only exception was a sample prepared with layers of carbon fiber fabric through vacuum infusion and without further surface treatment, which measured approximately 0.7 mm in height.

All samples were tested with a span-to-depth ratio of 16:1. The strain was measured by a ZwickRoell multiXtens extensometer. The bending speed was set as 0.5 mm/min.

Table 1 lists all the samples with brief descriptions of their preparation and assigned abbreviations. UHU-plus Endfest 300 bicomponent epoxy resin, which was frequently reported for use in bronze and metal restoration, was selected to prepare all the samples [6, 32, 49, 50]. In addition to the common properties of epoxy resins, such as resistance to solvent, low shrinkage, strong adhesion and mechanical strength necessary for structural support [51,52,53], this transparent resin also has the advantages of being solvent-free, resistant to aging and weathering, and it does not develop heat during curing [54].

Further specifications about preparation were as follows:

-

For the resin-cloth system, the resin applied between layers was sufficient to impregnate each layer of cloth but did not form an interlayer accumulation. The resin on the front and back of the laid-up cloths (with a thickness of approximately 0.8 mm) was intentionally made thicker to reach the set thickness of 1 mm and avoid exposure of the cloth texture to the surface, which is undesirable in real situations.

-

For the powdery reinforcing material, 50% in volume was the conventional upper limit adopted in the author's institution, while no other generic criteria were ever reported. The weight percentage at this volume proportion was approximately 53% for talc and 65% for corundum. Half of this quantity was also used to create the differentiation necessary for comparison.

-

For the chopped fiber, "saturated" was defined as the maximum quantity of fiber that could be added before the mixture revealed poor workability (difficult to blend and/or spread). "Unsaturated" meant half of this quantity. Considering that the operation of the restorer is a factor that can never be separated from a real working situation, the experiment adopted this setup conditioned by personal judgment. Nonetheless, the amount of added fiber was found to be sufficiently stable among samples: the chopped CF accounted for approximately 4.7% of the total weight, while the chopped GF accounted for approximately 6.2%.

Five replicates of each sample were prepared in parallel, and the average value was calculated.

Chemical safety test of CFR materials

Risks of galvanic corrosion of engineering metals coupled to or in contact with carbon fiber composites have been reported [55,56,57]. However, this corrosion phenomenon is triggered by certain conditions: high humidity, weathering, salt solution and aggressive agents. In general, the controlled environment in a museum is free of these concerns, while CF materials are immersed in resin when used to fill gaps and not in electrical contact with metal.

The experimental setup used for the verification of chemical safety was inspired by the Oddy test protocol for conservation materials [58, 59], and a recent refined setup was adopted [60]. Three kinds of samples were prepared:

-

UHU-Plus resin saturated with chopped CF applied to the surface of a new bronze coupon.

-

UHU-Plus resin saturated with chopped CF applied to a fracture in an archaeological bronze fragment with alloy composition similar to that of the Ding vessel.

-

Monolayer of CF cloth impregnated with UHU-Plus resin and attached to the surface of a new bronze coupon.

Each sample was sealed in a glass container where 100% relative humidity was created using a semi-enclosed tube filled with distilled water. A blank sample using a bronze coupon without CFR material was also employed for comparison. The containers were placed into heating chambers set at 60 ℃ for 120 days. According to the van’t Hoff law, the reaction rate is 2–4 times the initial rate when the temperature is increased by 10 ℃, and thus this process was equivalent to over 26 years at room temperature [61]. The degradation was probably still more accelerated, considering the saturation of relative humidity.

Surface hardness test

It may be necessary to further polish or carve the surface of the reconstructed part to reproduce the decoration of the missing area. Proper surface hardness is hence required for good workability. A Shore D durometer was used to test the samples prepared in the same way with UH-T600-S, UH-GFF-S and UH-CFF-S as described in Table 1, following the procedure defined by the national standard GB/T 531–1999 [62]. The samples were made into blocks of dimensions 50 mm × 25 mm × 6 mm. On each sample, five points were measured every 6 mm, and the average value was calculated.

Bronze Ding vessel

Prior to this study, preliminary analyses on the alloy composition and condition of the Ding vessel were conducted. Despite the fracture and loss shown in Fig. 2, the vessel appeared to be in good condition, and no loose fragments were found; therefore, the analytical methods were limited to nondestructive methods. The results of portable X-ray fluorescence revealed a typical copper–tin–lead ternary alloy, specifically, approximately 65% copper, 13% tin and 22% lead on average. These data, although obtained with a semi-quantitative method, and a patina was present on the analyzed surface, were within the range of the reported alloy composition of bronze vessels of the same period [63]. Identification through insitu Raman spectroscopy using a fiber optic probe demonstrated that only stable corrosion products of cuprite, malachite and azurite were present.

Due to the impossibility of conducting destructive metallographic analysis as recommended in some studies [64, 65], the evaluation of the elasticity and possibility of reshaping was conducted manually in an experiential way. In response to finger pressure, the deformed part of the lid could return to its original position, while with an adjustable clamp, temporary overbending of modest extent could already be obtained without any heating when the screw was not fully tightened. Reshaping was hence considered feasible.

The conservation history of the bronze Ding vessel was unclear due to the lack of documentation; nevertheless, traces of past intervention were observed during surface cleaning. Alongside the main fracture of the lid, solder residues and surface discoloration due to heating were found (Fig. 3), which indicated unsuccessful or removed past intervention. The solder, carvable with a scalpel, was identified as tin–lead soft solder by scanning electron microscopy and energy dispersive X-ray spectroscopy. During the removal of the solder and the underlying oxidation, it was found that the fracture still had metallic luster, which also indicated the survival of metal underneath surface corrosion and hence, bending to a greater extent was possible.

After cleaning the whole surface with the nonionic surfactant Tween 20 (5% in deionized water) and removing local loose corrosion products with an ultrasonic ablator, the central deformation was corrected by applying a progressive load in the direction opposite to the bending until achieving adequate overbending to compensate for the springback that occurred several times to different extents in this procedure (Fig. 4). Although the deformed part returned to the same level as the adjacent area after the operation, the laborious process of reshaping is often an indication of larger probability of springback over time. Thus, gap-filling material for the reconstruction of the loss should be more mechanically resistant to this risk.

Past interventions were also revealed on the body of the Ding vessel; the main losses were found on three pods. The fractured part of one pod was connected with iron wires, while copper sheet was rolled and soldered outside to provide further support (Fig. 5). All these improperly added elements were removed. Fortunately, it was possible to identify their original height and shape from the remaining parts of the pods.

Results and discussion

Flexural moduli

The average values of the flexural moduli of the examined samples are shown in Fig. 6 in increasing order. The same figure also shows the coefficient of variation to indicate the uniformity of the values for the replicates. Although the coefficients of variation of most samples were more than 5% and occasionally larger than 10% due to the inevitable nonuniformity derived from manual preparation, these values provided significant indications of differences in mechanical properties among the various classes.

The composites reinforced with CF cloth revealed values significantly larger than those of the other samples, indicating a minor displacement under elastic stress. In the context of filling gaps in bronze objects, these materials would be the most resistant to the eventual springback of the original bronze part among all the materials taken into examination, therefore demonstrating the potential to be used for reconstruction.

For the rest of the samples, the Eflex values of those reinforced with GF cloth (UH-GFC-4), with copper alloy sheets of 0.5 mm (UH-BS05 and UH-ZS05) and the commercial product QuickCopper were the highest, which were equivalent to approximately half the values of the CF cloth reinforced samples. It should be noted that it was difficult to form the copper alloy sheet of this thickness into a continuous curved surface under cold working. When using thinner sheets or meshes that were easier to shape, the values of the flexural moduli were small (UH-BS02, UH-ZM20 and UH-BM20), and they were even inferior to those of the samples reinforced with mineral powder and chopped fiber. The reason might have been the small flexural modulus of the resin. It was also observed that for the same kind of composite, a larger content of resin led to a lower resistance to elastic deformation of the whole system.

In addition to these general conclusions, some influencing factors in each class of samples were also observed, as illustrated in Fig. 7. Specifically:

-

The cloth type was the decisive factor for the cloth reinforced system. The CF product, although it appeared to be less dense than the GF counterpart used here, was apparently advantageous for providing stiffness. The influence of the number of layers was not clear in the current study, given that the values of UH-CFC-4 and UH-CFC-8 were similar. The resin type should have been influential, theoretically. However, manual preparation introduced uncertainty in the applied quantity, which might explain why sample CY-CFC-4 did not have higher Eflex. Vacuum infusion using less resin produced a composite with the greatest flexural modulus. However, the sample thus prepared was thinner, with the fabric texture exposed to the surface. When more resin was applied on the surface to reach the desired thickness, the mechanical property was significantly weakened, as observed for sample CY-CFC-4-VI-UH.

-

When using a metal sheet to form internal reinforcement, the sheet of greater stiffness and thickness led to higher Eflex. Instead, thinner sheets or metal meshes might function as auxiliary supports for the application of resin but they did not enhance the elastic resistance due to the small modulus of the composite thus prepared. Using metal strips as a framework while leaving considerable gaps to fill with resin, as shown in Fig. 1, should provide little resistance, especially if the strips were not soldered.

-

For the powder-reinforced composites, the hardness of the powder proved to be irrelevant. A larger amount of filler corresponded to a higher Eflex. The influence of its particle size was unclear because the nominal size of the talc powders used here was found to be inaccurate during preparation through sieving.

-

The chopped CF, when added in a large quantity, produced a composite with a flexural modulus comparable to that of the powder-reinforced resin. Even with half the quantity, the modulus was still larger than that of the sample saturated with chopped GF.

Through the sample preparation for this test, further physical properties of some composites were observed:

-

The weights of the CFR materials were significantly less than those of all the other composites, i.e., equivalent to approximately 70% of the GFR or talc powder reinforced materials and approximately 50% of the resin with 0.2 mm brass sheet in the core. The light weight could reduce the risk of detachment when used for reconstruction.

-

The chopped fiber could notably reduce the flow of resin and facilitate forming during the curing of resin, which could take several hours. Moreover, the coefficient of variation of this class was found to be smaller than that of the powderreinforced composite, which indicated greater uniformity in the structure and mechanical properties. The reason might have been the sedimentation of the mineral powder [66]. Although the application of fiber as a reinforcing element has rarely been reported in the art conservation field [67, 68], this type of material demonstrated the potential to be used in the preparation of an easily formable gap filler.

Material safety

At the end of the 120-day experiment, the blank sample and the exposed surface of the bronze coupons with CFR materials demonstrated significant darkening, while the areas surrounding the applied CFR materials were protected, probably due to contamination of the resin during sample preparation. After part of the composite was removed, the underlying surface was observed to remain glossy, and no evidence of corrosion was observed. The composite did not provoke any corrosion on the fracture of the archaeological fragment (Fig. 8).

a and c Bronze coupons with CFR materials before the experiment. b and d Bronze coupons after the experiment, with half of the CFR composites removed. e and f Blank sample before and after the experiment. g Archaeological bronze sample before the experiment. h Archeological bronze sample after the experiment, with half of the CFR composite removed. i Enlarged view of the fracture of the same archaeological bronze sample after the experiment, with half of the CFR composite removed

The relative humidity of the experimental setup was actually much higher than most indoor environments. Therefore, the results indicated that the examined CFR materials were chemically safe for use on bronze objects in a museum context with environmental monitoring and control.

Surface workability

The average Shore D hardness values of the three samples are shown in Table 2. For the points tested on each sample, the coefficients of variation did not exceed 2.5%. The results were also in accordance with subjective perception during the carving trial: it was easier to sculpt the surface of the sample prepared with chopped CF than the other two samples, while the relatively lower hardness of the CFR composite with the reinforcement of cloth form has been reported [69]. For reconstruction of surfaces with decorations in relief, the workability of the CFR composite was hence considered advantageous.

Gap filling of Ding vessel

The decision to apply CFR materials to the Ding vessel was made after deliberation and an unsuccessful attempt prior to the present study.

First of all, the simpler solution of taking the mold from the original counterpart and subsequent resin casting was unlikely not only because of the asymmetry and irregularity in the profile of the lid (Fig. 9) but also because this type of gap filler was considered mechanically unreliable in terms of resistance to the springback of the adjacent part.

Since Ding vessel was previously taken as an object for the didactics of traditional restoration techniques inside the institution, conventional methods were adopted using a few pieces of copper alloy sheet to approximately form the shape of the missing part, followed by application of resin to the gaps in the joints and the surface of the sheet to obtain the desired thickness and a more exact profile.

The central part with an approximately flat profile was reconstructed with a brass sheet of 0.5 mm thickness. However, for the curved marginal area, even with a ductile brass sheet as thin as 0.2 mm, the hammering and bending necessary for forming already led to localized unevenness that protruded from the expected shape (Fig. 10). Further division into more pieces and leaving more gaps, as shown in Fig. 1, at the risk of weakening the structure was not undertaken. Moreover, the UHU-plus resin used, similar to other epoxy resins preferred in bronze conservation, was a slow-curing material; the fluidity made the formation of a curved surface difficult, even when the resin was reinforced with 50% talc powder by volume. Therefore, only the reconstruction of the flat central part was realized properly and kept. For the connection between this part and the original, localized tin–lead soldering was applied to some spots, and resin was used subsequently to fill the remaining gaps in joint. The choice to use soldering, albeit based on experience and institutional conventions, was also guided by practical factors. The significant probability of springback of the reshaped part necessitated a strong connection method. In comparison, resin bonding forms weaker connection than soldering, and its efficacy will be further compromised due to the excessive gaps in the joint of the original and the metal sheet which is difficult to cut precisely. Some of the old soldering craters were used after chemically removing the surface oxidation using ion-exchange resin (the strong cation exchanger AMBER SH of Bresciani s.r.l., a styrene–divinylbenzene copolymer with the sulfonic group) [70, 71]. This prevented destruction caused by making new craters. To search for a gap-filling material that could balance adequate mechanical properties and convenience in applications, the restoration plan of Ding vessel was suspended.

Based on the results of the present study, a new solution with CFR materials was proposed. The CF cloth reinforced composites demonstrated a large flexural modulus, which was desired for the structural stabilization of bronze. For ease of handling, the chopped CF reinforced material also revealed some particular advantages. For reversibility, according to the experiences during the material tests, these composites were comparable with the commonly used resin reinforced with powdery fillers.

The missing part of the lid was reconstructed following these steps (Fig. 11):

-

The outer surface of the missing part was formed with sculpture clay.

-

The gypsum mold was taken from the sculpture clay, and the clay was removed afterward.

-

A thin layer of UHU-Plus resin saturated with chopped CF was applied inside the mold.

-

Four layers of CF cloth were subsequently applied, and then the inner surface was finished with another thin layer of resin saturated with chopped CF.

Considering that the previously soldered brass sheet in the central part was still effective and its removal could eventually bring new risk to the object, this partial reconstruction was kept. All the metal surfaces and fractures in contact with CFR materials were sealed with epoxy resin beforehand to further ensure isolation.

Every layer of CF cloth was applied before the curing of the resin in the previous application to obtain a more compact structure, as performed in sample preparation. The reconstruction with the brass sheet in the center was already close to the level of the inner bronze surface after the application of the first layer, and the following three layers were applied only to the marginal area. The CF cloth was no doubt much easier to form, and only a few small detachments were found between the layers at the edge of the lid (Fig. 12). It was much less arduous to cut this material than metal sheet, but the edge frayed easily, and this material must be handled very carefully.

Despite the need to improve the abovementioned operational details, the overlapped CF cloth system demonstrated significant stiffness that was perceived as comparable to metal. Although not placed directly to the central part of the original surface, it was reasonable to suppose that, according to the mechanical test results, this reconstruction would have a greater resistance to the springback stress transferred through the brass sheet than any other materials tested here, including the brass frame in pieces, and hence could contribute to the stabilization of the whole structure as expected.

On the outer surface composed of chopped CF reinforced composite, the missing rope motif was successfully reproduced using manual carving tools. Although this material was originally dark in hue, its surface was easy to color. A mimetic pictorial retouch, as required by the institution, was executed using colored acrylic varnishes (Fig. 13).

a Reconstructed part retouched for grounding color and painted with the decorative motif. b Reconstructed part during carving of the decorative motif. c Upper surface of the lid after restoration. The small gap on the margin was filled with a piece of brass using the traditional technique before this study. d and e Side views of the lid before and after filling gaps

The reconstruction of the pods should not only restore the shape but also provide sufficient support for the weight of the body. The conventional technique using metal sheets was not practiced to avoid foreseeable similar difficulties in forming. It was also doubtful whether sufficient support could be achieved in that way.

The inside of the remaining part of each pod contained a fired and solidified clay core used during mold casting of the bronze [72]. This allowed the addition of an insert structure without direct contact with the bronze. To further prevent the risk of drilling, a "sheathing" structure was designed: a thin 4-mm-diameter solid CF rod was inserted into the clay core inside the upper part of the pod for approximately 15 mm, and its other end extended directly to the estimated bottom of the pod. A CF tube of 4 mm in internal diameter and 6 mm in external diameter was used as a sheath for the part of the rod exposed from the clay core (Fig. 14). Both the rod and tube were TORAY PAN-based 3 K plain weave wrapped products. The UHU-Plus resin mixed with chopped CF was applied to the rod-clay and rod-tube interfaces.

a Schematic diagram of the internal structure of the pod seen in Fig. 6. b CF inserts and restoration of the same pod. c Inserts in the other two pods, where the CF tube also extended to the bottom since the lower parts were missing

A strengthened support was thus obtained with holes of limited dimension formed in the clay core, which allowed the selection of a gap-filling material purely based on operational convenience. Provided that the three pods differed slightly in shape, the UHU-Plus resin saturated with chopped CF was used, which could remain sufficiently plastic for molding for several hours with minimum fluidity. It was easy to perform the subsequent polishing step. Pictorial restoration was also carried out to imitate the original condition of the surface (Fig. 15).

Thus far, the gap filling process of the Ding vessel illustrated an application scenario of the CFR materials, with the related technical details being informative in terms of handling properties and behavior. It is important to note, however, that some strategies in this study were conditioned by the requirements of the institution and are now used in a limited range. For example, the techniques of soldering and surface finishing to achieve mimetic visual effects are still preferred in China, while they are now applied only to objects of more recent date or private commissions internationally [73, 74]. Moreover, the decision of preserving the previously added brass sheet is an expedient resulting from the difficult binary choice between the immediate risk of removing the newly applied solder and the potential long-term risk associated with this preservation, which may raise queries. This dilemma also highlights the drawbacks of the traditional technique’s lack of reversibility when compared to CFR materials.

At the end of the intervention, surface protection was not applied because only innocuous patina was present on this vessel. The strictly monitored and controlled microclimate of the institution provided further guarantees of conservation. Periodic examination of the condition of this object has been planned.

Conclusions

The present study explored a protocol for the selection of gap-filling materials for bronze restoration in terms of their mechanical properties. Although the load condition is specific and more complicated for each case of deformed bronze, it was still possible to define the crucial property for the selection of a material according to the main mechanical risk and provide objective indications for daily work.

The preliminary protocol presented here was based on comparative analysis. Depending upon the preparation of the sample, these results for flexural modulus and surface hardness should not be considered standard values but a means to characterize differences between classes of materials. Some findings are nonetheless valid for samples with sizes and/or preparations different from those considered in this study: the weakening of mechanical properties with increasing resin content, the influential factors for each class specified in 3.1, and the superior reinforcement effect of CF cloth.

Future studies are expected to provide more precise values and further discoveries about the influence mechanisms of various factors with the improvement of the experimental setup, such as:

-

Increasing the number of parallel replicates of each sample to increase the accuracy of the measurement.

-

Improving the controls of the experiment for better comprehension of the influence mechanisms of some factors, e.g., quantifying the resin added to each layer of CF or GF cloth, monitoring the particle size of mineral powder through a laser analyzer, and comparing the effects of fibers of different length [75, 76]. A model of the relationship between the amounts of powder and fiber reinforcing element and mechanical properties can be obtained with more refined experimentation to understand the upper limit of addition of filler. For both types of materials, the available literature showed that a larger quantity does not necessarily correspond to better elastic modulus or strength [77,78,79], although increasing hardness with increasing quantity of fiber was reported [80, 81].

-

Adopting modulus test equipment compatible with thinner samples (e.g., a Dynamic Mechanical Analyzer) and comparison of data obtained using different test procedures. In this study, the minimum sample thickness permitted by the test machine was 1 mm. However, the study of composites containing fewer layers of CF cloth is potentially useful for the restoration of many thin-walled bronze objects that easily deform.

-

Including more product types for testing, in particular, cloth with twill weave is more adaptable to complicated shapes to prevent detachment at the edges among layers, and cloths of various densities [82,83,84], etc.

-

Comparison of long-term performance to provide a more comprehensive vision. For example, the creep properties, and change in the chemical and mechanical properties of different materials after accelerated degradation [85, 86].

In terms of practical applications for gap filling, the CFR materials studied here could be utilized in situations where soldering is not permitted yet resistance to elastic deformation is necessary. The reshaping process aimed at plastic forming as described in this study may not be practiced in many institutions that only permit moderate reshaping, for example, reducing the height discrepancy in a joint through temporary loading and subsequent fixation with adhesive. In such cases, springback is more likely to occur in the short term, making it necessary to reconstruct adjacent losses with a material of larger elastic modulus. There are numerous potential application scenarios, for instance, for bronzes that have not undergone deformation but have experienced material loss in critical areas subjected to elastic stress. All these considerations are equally applicable to objects made from metals other than bronze. While further research is necessary, as is the case with any newly employed materials, this type of composite offers an alternative method for restorers, which may not necessarily be the optimal choice, but possesses notable advantages in terms of certain mechanical properties and operational convenience. Prior to and during its application, considerations should be taken into account as follows:

-

A deliberate evaluation of the necessity for reshaping should serve as the first step based on the certainty of object’s original shape, ethical guidelines specific to the context, exhibition intentions, skills of personnel, and so forth. It should be noted that in many institutions, graphic representations and replicas capable of effectively conveying the original aspects of an object are now preferred over directly conducting this intervention on an original object.

-

Two technical prerequisites should be considered. First, does the bronze still demonstrate sufficient elasticity for reshaping? Its suitability should be verified because it may be impossible to correct the deformation of a fragile bronze object. Second, is the bronze object kept in a museum with a controlled environment? These materials are not recommended for use outdoors. The institution owning the Ding vessel has optimal and comprehensive control of the environment, while in some museums where the control of condition is less strict, a GF composite for total or partial substitution in the interface can be considered. Acidic environments are reported to be especially risky for CFR materials [87].

-

Cloth should be precisely cut to match the profile of the fracture in a bronze object in order to minimize gaps in the joint where is subject to the concentration of stress. The larger quantity of resin contained in the poorly matched joints will lead to inferior mechanical property, as revealed in this study. The margin of the CF cloth is prone to fraying, which can alter the contour. This can be prevented by pretreatment with adhesive [88].

-

The light weight of CFR materials can reduce the risk of detachment of the reconstructed part during handling of the object, especially in situations similar to this Ding vessel studied here. However, in cases where the weight difference between the reconstruction and original part may cause unsteadiness of the object, the application of CRF materials should be reassessed or avoided.

Availability of data and materials

The datasets generated and analyzed as part of this study are available from the corresponding author on reasonable request.

Abbreviations

- CF:

-

Carbon fiber

- CFR:

-

Carbon fiber reinforced

- FEA:

-

Finite element analysis

- GF:

-

Glass fiber

- GFR:

-

Glass fiber reinforced

References

Plenderleith HJ. The conservation of antiquities and works of art: treatment, repair and restoration. London: Oxford University Press; 1957. p. 210–1, 218–9, 254–5.

Fagg W, Nimmo BA, Smith PJ. The restoration of a bronze bowman from Jebba, Nigeria. Br Mus Q. 1964;28(1/2):51–6.

Organ RM, Werner AE. The restoration of the Relic Casket from Shāh-jī-kī-ḍherī. Br Mus Q. 1964;28(1/2):46–51.

Langton LR. The restoration of a bronze plaque from Benin. Expedition. 1968;10(4):2–7.

Steiner A. Restaurierungsarbeiten an drei römischen Infanterierhelmen aus Xanten-Wardt (The restoration of three Roman infantry helmets from Xanten-Wardt). In: Schalles HJ, Schreiter C, editors. Geschichte aus dem Kies: neue Funde aus dem Alten Rhein bei Xanten (History from the gravel: new finds from the Alten Rhein near Xanten). Cologne: Rheinland-Verlag GmbH; 1993: p. 107–11 (in German).

Zauner-Mayerhofer S. Objekt aus dem Wüstensand: Bronzeständer mit Kupferschale (Deir Abu Fano/Mittelägypten) (Object from the desert sands: bronze pillared stand with copper bowl from the Coptic monastery of S. Fana, Middle Egypt). In: Krist G, Griesser-Stermscheg M, editors. Metallkonservierung, Metallrestaurierung: Geschichte, Methode, Praxis: Sammelband anlässlich der Fachtagung "Metallrestaurierung--Metallkonservierung" der Universität für Angewandte Kunst Wien 2007 (Metal preservation, metal restoration: history, method, practice: volume on the occasion of the "Metal Restoration--Metal Conservation" conference at the University of Applied Arts, Vienna, 2007). Vienna (Austria): Böhlau Verlag GmbH & Co. KG; 2009: p.355–59. (in German).

Chi Y. The shape correction restoration of bronze cultural relics and discussion on relevant issues. Restor Study Cult Relics. 2009;00:7–10 (in Chinese).

Markaly Z. Galvanoplasztikai eljárással készült fedeles serleg restaurálása (Restoration of a lidded beaker made using the electrotyping procedure). Műtárgyvédelem (Conservation of artworks). 2011. p. 129–137. (in Hungarian).

Ma X. Multi-angle positioning repairing and reshaping device for damaged and deformed bronze ware. Chinese National Patent CN102357769A, 2013.

Wagoner RH. Sheet springback. In: Raabe D, Roters F, Barlat F, Chen LQ, editors. Continuum scale simulation of engineering materials: fundamentals-microstructures-process applications. New York: Wiley; 2004. p. 757–74.

Scott DA. Copper and bronze in art: corrosion, colorants, conservation. Los Angeles: Getty publications; 2002. p. 32–75.

Zhang G. Study on the shape correction of the cowrie-container with tiger-handles and eight yaks of Han Dynasty. Sci Conserv Archaeol. 2012;24(2):102–5 (in Chinese).

Jia W. Traditional restoration techniques of ancient Chinese bronze. Chin Mus. 1997;01:89–92 (in Chinese).

Risser E, Saunders D. The restoration history of the bronze Apollo and Diana from Pompeii. In: Risser E, Saunders D, editors. The Restoration of Ancient Bronzes: Naples and Beyour. Los Angeles: Getty Publications; 2013. p. 40–55.

Huang X. The restoration and conservation of bronze Lian from the Han tombs of Wenchang Tower in Hepu. J Guangxi Normal Univ Nationalities. 2015;32(04):32–5 (in Chinese).

Tsirita K. The Selection of the gap-filling material for the conservation of a Chinese Shang Dynasty bronze vase. Poster of Vienna Congress - The Decorative: Conservation and the Applied Arts. Vienna, Austria, 9–13 September 2012.

Singh S. Investigation of a traditional metal adhesive: a case study of lac-based resin used by swordsmith in India. In: Proceedings of the ICOM Committee for Conservation 18th Triennial Meeting. Copenhagen, Denmark, 4–8 September 2017.

Ahmed S, Abdelbar M, Sabry W, Ali A. Experimental study of gap-filling of ancient completely corroded copper bowl via nano-polymers. Int J Conserv Sci. 2020;11(1):97–108.

Feng N, Cai Y, Wen J, Ni Y. Primary exploration on the application of wax-resin formula to the bronze reintegration. Identif Apprec Cultural Relics. 2020;24:56–64 (in Chinese).

Tsvetkov S. Testing gap fillers for archaeological metal. Poster of the Interim Meeting of the ICOM-CC Metals Working Group. Helsinki, Finland, 5–9 September 2022.

Ghavami P. Mechanics of materials: an introduction to engineering technology. Cham: Springer; 2015. p. 143–6.

Young C, Ackroyd P, Hibberd R, Gritt S. The mechanical behaviour of adhesives and gap fillers for re-joining panel paintings. Natl Gallery Tech Bull. 2002;23:83–96.

Lopez FL, Mecklenburg MF, Castell M, Guerola V. Filling materials for easel paintings: when the ground reintegration becomes a structural concern. In: Townsend JH, Doherty T, Heydenreich G, Ridge J, editors. Preparation for painting: the artist’s choice and its consequences. London: Archetype; 2008. p. 180–6.

DePolo G, Walton M, Keune K, Shull KR. After the paint has dried: A review of testing techniques for studying the mechanical properties of artists’ paint. Herit Sci. 2021;9(1):1–24.

Bridarolli A, Freeman AA, Fujisawa N, Łukomski M. Mechanical properties of mammalian and fish glues over range of temperature and humidity. J Cult Herit. 2022;53:226–35.

Łukomski M, Bridarolli A, Fujisawa N. Nanoindentation of historic and artists’ paints. Appl Sci. 2022;12(3):1018.

Torv H. Planung von Ergänzungen an Metallobjekten mittels Finite-Element-Analysis (Planning of reconstructions of metal objects using finite element analysis). Master thesis. Berlin: Hochschule für Technik und Wirtschaft Berlin; 2022. (in German).

Licari JJ, Swanson DW. Adhesives technology for electronic applications: materials, processing, reliability. Norwich: William Andrew; 2011. p. 366–7.

Thorton J. A brief history and review of the early practice and materials of gap-filling in the West. J Am Inst Conserv. 1998;37(1):3–22.

Liu Y. Restoration of a bronze Yong Zhong bell from Donghai County Museum and discussion of the agreement of modern restoration ideas and traditional restoration of Chinese bronzes. Chin J Hist Sci Technol. 2010;31(3):309–22 (In Chinese).

Gu L, Yang X, Ye L, Jin P, Sun S. Conservation and restoration of two Han Dynasty gilt bronze vessels of Fengdu, Chongqing. Wenwu Chunqiu. 2018;165(06):48–53, 74 (in Chinese).

Basilissi V, Pannuzi S, Rivaroli L. The retouching on archaeological metal artifacts: reflections and proposals, between theory and practice. Ge-conservacion. 2020;18:356–61.

Hu W. Fast and non-destructive restoration of the missing part of bronze. In: Hu W, editor. Proceedings of 10th academic conference of China association for conservation technology of cultural heritage. Beijing: Science Press; 2020. p. 37–42 (in Chinese).

Sekino M. Restoration of the great Buddha statue at Kamakura. Stud Conserv. 1965;10(2):39–46.

Lane H. The restoration of thin metal vessels using glass-fibre and polyester resin. Stud Conserv. 1972;19(4):227–32.

Nosek E. The investigation and conservation of early medieval silver chalices and paten. In: Proceedings of ICOM Committee 8th Triennial Meeting. Sydney, 6–11 September 1987.

Wang J. Application of Quickcopper putty of PSI Company to the restoration of cultural relics. Southeast Cult. 1995;110(04):67–8 (in Chinese).

Balboa A, Mestres I, Duran M, Fernàndez J. Restoration and archeometallurgical study of a Roman Cauldron made of copper alloy. In: Hyslop E, Gonzalez V, Troalen L, Wilson L, editors. Metal 2013 Proceedings of the Interim Meeting of the ICOM-CC Metals Working Group. September 16-20, 2013 Edinburgh, Scotland. Edinburgh: Historic; 2020. p. 319–26.

Zhang G. Integration of missing parts of a Shang Dynasty pig-shaped bronze You. Sci Conserv Archaeol. 2018;30(2):63–72 (in Chinese).

Lei L. Reintegration with copper sheet: an effective restoration method for cultural relics with missing part. In: Wang C, editor. Selected papers on cultural relics conservation and restoration of National Museum of China. Beijing: Beijing Shi Dai Hua Wen Shu Ju; 2019. p. 163–9 (in Chinese).

Pan L. The restoration of the Khitan gilded silver saddle of Liao Dynasty. Hundred Sch Arts. 2013;29(S2):442–3 (in Chinese).

Riccardelli C, Soultanian J, Morris M, Becker L, Wheeler G, Street R. The treatment of Tullio Lombardo’s Adam: a new approach to the conservation of monument marble sculpture. Metropol Mus J. 2014;49(1):48–116.

Riccardelli C. Carbon fiber fabric and its potential for use in objects conservation. In: Objects specialty group postprints. 2017;24:147-67

Ciabattoni R. Divinità con diadema. Progetto e realizzazione di un element di rinforzo e protezione (Project and realization of an element of reinforcement and protection). In: Cerioni A, Laurenti MC, editors. Immageini di Dea, Due Teste Colossali dei Musei Capitolini: Studi e Restauro (Two Colossal Head Sculptures of Capitolini Museum). Rome: Gangemi Editore; 2018. p. 79–84 (in Italian).

Huang X. Fabrication and properties of carbon fibers. Materials. 2009;2(4):2369–403.

Liu Y, Kumar S. Recent progress in fabrication, structure, and properties of carbon fibers. Polym Rev. 2012;52(3):234–58.

Das TK, Ghosh P, Das NC. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review. Adv Compos Hybrid Mater. 2019;2:214–33.

Chinese National Standard. GB/T 1449–2005 Fibre-reinforced plastic composites-determination of flexural properties (in Chinese).

Zhou Y. The conservation and restoration of “Wealth and longevity” bronze mirror of song dynasty of Yunfu Museum. Hakka Cult Herit Vision. 2021;32(02):19–22 (in Chinese).

Regoli G, Pagani N. Conservation and restoration. In: Clarizia V, editor. Ancient weapons of oman: volume 1-edged weapons. Oxford: Archaeopress; 2022. p. 174–90.

Freitag J. Zinnsarkophage: Material und Konstruktion, Schäden und Erhaltungsmaßnahmen (Tin sarcophagi: material and construction, damages and conservation measures). In: Michaelsen H, editor. Potsdamer Beiträge zur Konservierung und Restaurierung: 10 Jahre Studiengang Restaurierung 1995–2005 (Potsdam’s contributions to conservation and restoration: 10 years of restoration studies 1995–2005). Potsdam: Fachhochschule Potsdam; 2005. p. 73–92 (in German).

Pan Z. Polymer Chemistry. Beijing: Chemical Industry Press; 2007. p. 57 (in Chinese).

Guo Q, Huang Y, Zhang YY, Zhu LR, Zhang BL. Curing behavior of epoxy resins with a series of novel curing agents containing 4,4’-biphenyl and varying methylene units. J Therm Anal Calorim. 2010;102(3):915–22.

UHU GmbH & Co. Technical documentation of UHU®-plus Endfest 300 resin. 2023. https://www.uhu.com/content/dam/boltonadhesives/products/import/57/en/63251/50.pdf. Accessed 1 May 2023.

Pan Y, Wu G, Cheng X, Zhang Z, Li M, Ji S, Huang Z. Galvanic corrosion behaviour of carbon fibre reinforced polymer/magnesium alloys coupling. Corros Sci. 2015;98:672–7.

Hakansson E. Galvanic corrosion of aluminum/carbon composite systems. PhD dissertation. Denver: University of Denver; 2016.

Song GL, Zhang C, Chen X, Zheng D. Galvanic activity of carbon fiber reinforced polymers and electrochemical behavior of carbon fiber. Corros Comm. 2021;1:26–39.

Thickett D, Lee DR. Selection of materials for the storage or display of museum objects. London: The British Museum Press; 2004.

Korenberg C, Keable M, Phippard J, Doyle A. Refinements introduced in the Oddy test methodology. Stud Conserv. 2018;63(1):2–12.

Shen J, Shen Y, Xu F, Zhou X, Wu L. Evaluating the suitability of museum storage or display materials for the conservation of metal objects: a study on the conformance between the deposited metal film method and the Oddy test. Environ Sci Pollut Res. 2018;25:35109–29.

Wan H, Zhan Z. Physical Chemistry. Beijing: Higher Education Press; 2002. p. 312 (in Chinese).

Chinese National Standard. GB/T 531–1999 Rubber-Determination of indentation hardness by means of pocket hardness meters (in Chinese).

Mu D, Luo W, Song G, Qiao B, Wang F. The features as a county of Chu State: chemical and metallurgical characteristics of the bronze artifacts from the Bayilu site. Archaeol Anthropol Sci. 2019;11:1123–9.

Jedrzejewska H. The conservation of ancient bronzes. Stud Conserv. 1964;9(1):23–31.

Jett PR. Two examples of the treatment of ancient silver. In: Jett PR, editor. Current problems in the conservation of metal antiquities: international symposium on the conservation and restoration of cultural property (13), Tokyo, October 4-October 6, 1989. Tokyo: Tokyo National Research Institute of Cultural Properties; 1993. p. 173–86.

Samal S. Effect of shape and size of filler particle on the aggregation and sedimentation behavior of the polymer composite. Powder Technol. 2020;366:43–51.

Organ RM. The consolidation of fragile metallic objects. Stud Conserv. 1961;6(1):128–34.

Fulcher K. The diverse use of AJK dough in conservation. J Inst Conserv. 2014;37:32–42.

Vinay HB, Govindaraju HK, Banakar P. Evaluation of glass/carbon reinforced polymer composites. Polym Polym Compos. 2016;24(7):469–72.

Kumar S, Jain S. History, introduction and kinetics of ion exchange materials. J Chem. 2013;2013:957647.

Shen Y, Aramini F, Basilissi V, Guida G, Priori G, Paderni P. Edo-period bronze mirrors: technical investigation and conservation of their reflective side. In: Bridgeland J, editor. Transcending boundaries: integrated approaches to conservation. ICOM-CC 19th Triennial Conference Preprints, Beijing, 17–21 May 2021. Paris: International Council of Museums; 2021.

Wu Y, Jin Z, Fan A, Fang H. Firing temperature of a clay core sample in a bronze tripod from Daxinzhuang site in China using TL techniques. Geochronometria. 2013;40(4):317–21.

Ponce E. Restoration of ancient bronze bells. Part II: welding. Ing Rev Chil Ing. 2015;23(1):30–7.

Brian Owens Restoration. Equestrian Bronze Statue Repair. 2023. https://www.brianowensrestoration.com/repair-restoration-statues-sculpture/bronze-statue-repair. Accessed 20 May 2023.

Rao Y, Vempati SR, Srinivasulu R, Gopinath V, Sumanth K. Estimation of mechanical properties of carbon fiber/epoxy hybrid composites with various fiber length and orientation. IJARET. 2020;11(12):702–17.

Nugroho G, Budiyantoro C. Optimization of fiber factors on flexural properties for carbon fiber reinforced polypropylene. J Compos Sci. 2022;6(6):160.

Kant S, Urmila JK, Pundir G. Study of talc filled polypropylene: a concept for improving mechanical properties of polypropylene. Int J Res Eng Technol. 2013;2(4):411–5.

Li M, Luo R. Effect of carbon fiber content on mechanical and tribological properties of carbon/phenolic resin composites. In: Yang Y, Shao W, editors. Proceedings of 5th International conference on information engineering for mechanics and materials. Dordrecht: Atlantis Press; 2015. p. 539–42.

Nga PTH, Nguyen VT. Experimental study on mechanical behavior of polypropylene-based blends with talc fillers. Adv Sci Technol Eng Syst J. 2020;5(6):571–6.

Ozsoy N, Ozsoy M, Mimaroglu A. Mechanical properties of chopped carbon fiber reinforced epoxy composites. Acta Phys Pol A. 2016;130(1):297–9.

Suryawan IGPA, Suardana NPG, Winaya IS, Suyasa I. Hardness analysis of epoxy composite reinforced with glass fiber compared to nettle fibers. Int J Eng Emerg Technol. 2020;5(1):1–4.

Campos MC, Soufen CA, Bueno MP, Imaizumi M. Comparative study of mechanical properties of woven of carbon fiber twill and plain weave in laminates with epoxy matrix. In: Proceedings of 2nd Brazilian Conference on Composite Materials–BCCM. São José dos Campos-SP, Brazil, 15–18 September 2014.

Kiss P, Schoefer J, Stadlbauer W, Burgstaller C, Archodoulaki VM. An experimental study of glass fibre roving sizings and yarn finishes in high-performance GF-PA6 and GF-PPS composite laminates. Compos Part B. 2021;204: 108487.

Yang T, Hu L, Xiong X, Wang Y, Wang X, Petrů M, Zhang S, Mishra R, Militký J. A comparison of fabric structures for carbon fiber reinforced composite: laminated and orthogonal woven structures. Polym Composit. 2021;42(10):5300–9.

Down JL. The evaluation of selected poly(vinyl acetate) and acrylic adhesives: a final research update. Stud Cons. 2015;60(1):33–54.

Helmi FM, Abu Ayana YM, Omar SM. Nano-copper composite conservation of an Egyptian bronze sacred ibis bird statue: case study. Mediterr Archaeol Ar. 2019;19(1):61–9.

Uthaman A, Xian G, Thomas S, Wang Y, Zheng Q, Liu X. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers. 2020;12(3):614.

Snape AE, Turner JL, El-Dessouky HM, Saleh MN, Tew H, Scaife RJ. Stabilising and trimming 3D woven fabrics for composite preforming applications. Appl Compos Mater. 2018;25:735–46.

Acknowledgements

The author expresses sincere gratitude to Prof. Ya Zhou, Prof. Jinhong Ma and Prof. Yue Wang of the Bronze Study Department of Shanghai Museum for allowing the author to work on this bronze Ding, Prof. Guangmin Zhang of the Conservation Center of Shanghai Museum and Prof. Yonghai Fu of the National Center of Underwater Cultural Heritage for the precious guidances on the restoration of bronze vessel. The author highly acknowledges Dr. Jiajie Wu of Shanghai Research Institute of Materials for the consistent help in material tests. Sincere thanks also go to Mr. Xiaohua Zhu of the Conservation Center of Shanghai Museum for the assistance in the documentation of the decoration motif of the bronze, and to Ms. Xinyue Yao, graduate student of Shanghai Urban Construction Vocational College, who generously shared one photo illustrating the application of metal sheet framework.

Funding

This research is financially supported by Shanghai Museum and received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, methodology, sample preparation and analysis of the results of flexural moduli measurement, test and analysis of the material safety test and surface hardness test, restoration of the bronze object, and manuscript draft, were performed by YS. The author has read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Shen, Y. Exploration of a crucial mechanical property of gap-filling materials for restoration of deformed bronze and tentative application of carbon fiber reinforced composites. Herit Sci 11, 153 (2023). https://doi.org/10.1186/s40494-023-01004-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1186/s40494-023-01004-4