Abstract

Forty-six ceramic shards from the Early Bronze Age (EBA) archaeological site of Tappeh Gabri (the archaeological site 013), dated back to the latter half of the third millennium BCE and located at the Varzaneh Plain, central Iran, were studied using micro energy dispersive X-ray fluorescence (µ-EDXRF) and petrographic analysis. The precision and accuracy of quantitative data obtained by µ-EDXRF were tested using a series of geological certified reference materials (CRM). The expanded uncertainty and the Mantel test on data obtained by µ-EDXRF showed accurate and precise quantitative µ-EDXRF estimation of elements present in the CRMs above their quantification limit. We show that the majority of the ceramics at the Varzaneh Plain is most probably local product. Discussions prompted collecting further compositional data and performing petrographic investigation from the ceramic shards from southern and south-western Iran in order to shed light on the origin of the ceramic shards excavated at the Varzaneh Plain.

Similar content being viewed by others

Introduction

A variety of methods have been adopted to shed light on the provenance of ancient ceramics. Instrumental neutron activation analysis (INAA) has been an unrivalled approach in this aspect [1]. However, since nuclear facilities are not readily available and non-invasiveness is a requisite of many museums and collections, other approaches have been developed and applied to acquire quantitative data from archaeological pottery the most important of which is energy dispersive X-ray fluorescence (EDXRF). EDXRF has been widely used in the study of archaeological pottery and a significant body of knowledge in hand describes how EDXRF data contribute to a better understanding of ancient pottery technology, use and provenance [2]. Common instrumentation of EDXRF widely used for studying ancient ceramics and sediments is portable EDXRF (p-EDXRF) used on site for resolving problems associated with technology and provenance of ancient pottery. Thus, a large set of compositional data can be collected from archaeological pottery by p-EDXRF. As a result, a significant effort has been made to evaluate the quality of the quantitative data obtained by p-EDXRF from a large number of ceramic shards retrieved from archaeological sites worldwide [3]. Since p-EDXRF devices are often sold with built-in quantification algorithms, attempts have been made to investigate the quality of quantitative data from p-EDXRF devices [4,5,6]. Efforts have also been made to enhance the precision and accuracy of analytical data acquired from p-EDXRF by introducing reference materials to produce interlaboratory quality analytical data [7].

Another widely available EDXRF instrumentation is micro EDXRF (µ-EXDRF), which enables analysts to focus the X-ray beam on a micron-size spot and to collect compositional data from small objects [8]. Being non-invasive and able to analyse samples down to micron size, µ-EDXRF has received attention in studying archaeological objects and, in particular, archaeological soils [9] and ancient ceramics [10]. µ-EDXRF devices have been mostly used to focus the X-ray beam line in very small spots and to acquire elemental maps from the inclusions embedded in ancient artefacts [11], painted heritage objects [12], archaeological ceramics [13], enamel [14] and ancient metal-related objects [15, 16]. Although efforts have also been made to obtain quantitative data from geological samples [17], cultural heritage materials [18], ancient metal artefact [19] and ceramics by µ-EDXRF [11, 20], less attention has been paid to check the quality of µ-EDXRF quantitative data for performing a proper provenance study on ancient ceramic. This study aims not only to investigate the precision and accuracy of quantitative data acquired by µ-EDXRF and a set of certified reference materials (CRM) but also to evaluate the quality of µ-EDXRF quantitative data for sourcing ancient ceramics from an archaeological site at Varzaneh Plain.

Archaeological setting

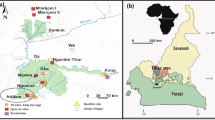

The Varzaneh Plain is located at the heart of Iran and to the west of Gavkhuni Playa. This strategic location makes it an essential intersection of ancient cultures from both the east and west of the Iranian Plateau. The archaeological sites situated here are of significant importance as they provide critical information about cultural and economic connections between Early Bronze Age cultures that appeared in the 3rd millennium BCE in the lower parts of the Zayandehrud basin. The archaeology of the Iranian Plateau in the 3rd millennium BCE is not well explored. Some regions, such as the Fars Plain in the south of the Iranian Plateau and the central Iranian plateau in the north, underwent an unknown archaeological period after around 2800 BCE. However, the Varzaneh Plain experienced a prosperous period after this time, resulting in a large number of archaeological sites that are spread in the plain today [20,21,22].

The Varzaneh Plain have received little attention in the archaeological investigations. Salehi-Kakhki [23] and Esameili-Jolodar [24] carried out archaeological surveys while Saeidi-Anaraki [25] performed an excavation in an archaeological site in the Varzaneh Plain. Our recent surveys and excavations at one of archaeological site in the Varzaneh Plain, Tappeh Gabri (ZRMS.013), revealed various archaeological layers and features, including potteries, small finds, and animal and human bones [26, 27]. A stylistic study of the ceramic shards found at the site indicates that they were manufactured around the middle to the second half of the 3rd millennium BCE. The pottery at the site shares similarities with those at other archaeological sites in south-western Iran, central Zagros, and southern Iran, particularly the Kerman region [28]. Also, the pottery shards found at the site share similar style with those from the Godin III/6, 5, Susa IV, transitional phases of Banesh-Kaftari, and Tappeh Yahya IVB6. These similarities suggest a connection between these different archaeological sites and the Varzaneh Plain.

The Tappeh Gabri archaeological site, which was looted for ca. fifty years (Fig. 1, top-left), covers an area of three hectares with the highest point of approximately 1 m above the plain (Fig. 1). Three trenches have been opened at the site, revealing evidence of daily activities such as metallurgical processing, ash from burners, lithics, and remnants of architectural spaces. Human remains have also been discovered at the site, indicating the presence of burial sites in or around the settlement.

Materials and methods

Samples

The excavated shards from ZR.MS.013 (Tappeh Gabri) can be classified into seven main types. Forty-six shards, which represented these seven types and encompassed at least one sample from all types, were selected for sampling. For obtaining compositional data from the shards by µ-EDXRF, samples were homogenised by powdering and by creating pressed pellets from the bodies. To do so, the broken edge of the shards was first scrapped and cleaned using a Dremel drill and tungsten drill bit. A hole was then made inside the shards parallel to the walls of the shards and the extracted powder was subsequently transferred to an agate mortar and milled. The powdered samples were then pressed in a pellet die (3 mm in diameter) using no binder under a load of 14 tons. It should be noted that the homogenisation was essential in our study because the ceramic shards were heterogenous in terms of minerals included in their body.

Archaeological typology of the samples

As mentioned earlier, the shards under study can be classified into seven categories (Fig. 2). Their typology is based on the fabric, the colour and the tempers embedded in the body (Supplementary Material 1).

Type 1

These potsherds have a carinate body with turned-out rims and a closed mouth. The bodies of the potsherds are pale red, brown, and buff in colour with a thin slip in the interior and exterior surfaces. All potsherds of this type are coloured using a range of red and brown colours on the exterior surface, parts of the rims, and the interior shoulder. Some potsherds are decorated with cream or red motifs in parallel horizontal lines and waves. There are also decorations in the form of shallow carved horizontal and parallel lines in some potsherds. Fine mineral temper has been used in the core. Potteries of this type are made using the wheel.

Statistically, the potsherds of this group have the highest number among the potsherds identified from Tappeh Gabri. Also, this type has the highest number of potsherds obtained from the surface of other contemporary EBA sites in the Varzaneh Plain. Therefore, ceramics of this type could be considered as local products.

Type 2

The potshards of Type 2 are grey-ware and included two potsherds with a turned-out rim and a carinate body and a boat-shape body with turned out rim while the rest potshards from this type have a smooth rim and body. The core of these potsherds is grey and contains fine and coarse mineral temper. All potsherds of this group have a wet hand slip that can be seen on both surfaces. However, one sample (No. 22) needs clarification as the interior surface is worn, and it is unclear whether it had a slip. In another shard (No. 1), a thick mud slip method is used on the interior surface. None of the potsherds in this group have any decorations, and all are not wheel thrown. This type of pottery does not seem to be suitable for commercial purposes and trading because of its low quality and weak strength. Therefore, it is probable that pottery from this type is made locally.

Type 3

This type features a light grey core with thick, muddy slip inside and outside. A coarse mineral temper was used in the single member of this type. In fact, in this shard (No. 38), the interior surface appears worn and smoked, whereas the exterior surface is burnished. This type of pottery is entirely hand-made and probably produced locally.

Type 4

Type 4 pottery is identified by its red colour, black paste and mineral temper. One of the potsherds (No. 11) has a slip coating on both surfaces while the other has a deformed exterior due to the exposure to elevated temperature but a red slip on the interior. Additional decoration is present on one of the potsherds. These potteries were made by hand and are not wheel thrown. The presence of low-quality and deformed pottery of this type suggests they are likely produced locally.

Type 5

This type of pottery is characterised by its red and black core, buff-coloured body, and fine mineral temper. The potteries have a smooth rim that slants inward, and both surfaces of the pottery have a visible slip. The exterior surface and a portion of the interior rim are coloured, and one of the potteries has painted decorations on the rim. These potteries are made using a wheel and seem to be produced in the region.

Type 6

These potsherds are typically dark brown or dark red with a red and buff core. They are made of a fine mineral and mineral-organic combination. Both the exterior and interior surfaces are coated with slip. The dark brown and dark red colouration of the exterior and parts of the interior, such as the pottery's rim and neck, distinguishes this type. Two of the potsherds have horizontal lines on the exterior shoulder of the pottery (No. 23 and No. 42). All the potsherds were made using a pottery wheel. The type 6 shards are commonly found at the site and might have been produced locally.

Type 7

The seventh type of pottery at the site comprises of shards with a core that falls within the red colour spectrum. The core's temperament is a fine mineral. Both the exterior and interior surfaces have been coated with a layer of slip, and the exterior surface and a part of the interior rim are red. The only shard of this type with slip used on both surfaces is the shard No. 39. These potsherds have been made using a wheel and are fairly common in the collection of pottery found at the site.

Certified reference materials (CRMs)

Eleven CRMs were selected for calibrating the quantitative µ-EDXRF data including albitised granite (520-84n), alkaline agpaite granite (3333-85), basalt (2116-81), dolerite (SARM 50), essexitic gabbro (521-84n), granite-gneiss (NCS DC73376), miascite (2121-81), rock (NCS DC73302), a limestone (NCS DC60107), coulsonite (NCS DC19001) and an ultrabasic rock (NCS DC72301). These CRMs cover a fairly broad range of concentration of elements which are above limits of quantification of common EDXRF instrumentation on one hand and, on the other hand, are of interest in sourcing ancient ceramics including K, Ca, Ti, Mn, Fe, Cu, Zn, Rb, Sr, Y and Zr. These standards are fine powders of geological rocks that were pressed under nearly 14 tons of load with no binder in order to prepare pellets suitable for µ-EDXRF analysis.

µ-EDXRF

An XMF-104 benchtop µ-EDXRF device from Unisantis S.A. with a Mo X-ray tube, a Si-PIN detector and a Kumakhov polycapillary lens was used to acquire quantitative compositional data from both pressed pellets from the CRMs and the powdered samples of the potteries. Samples were analysed at 35 kV and 500 µA in air for 300 s using a 5000 X-ray tube from OXFORD Instruments with a 12° anode angle, a 127 µm thick Be window and influence and the excitation angle of 45° while the distance between the sample and the end of the Kumakhov polycapillary lens (which reduced the focal spot of X-ray down to 80 µm) was 3 cm. The detector was an XR-100CR Peltier-cooled Si-PIN detector from AMPTEK (energy resolution at 5.9 keV was 186 eV for 55Fe) with a 7 mm2 active area and a 125 µm thick Be window. The thickness of the detector and its dead layer were 0.5 cm and 150 nm, respectively. The angle and distance between the sample and the detector were 45° and 3 cm, respectively.

Python MultiChannel Analyser (PyMCA), a software package that uses the fundamental parameters (FP) method as a mathematical approach to quantification, was used to acquire quantitative data from the samples and CRMs. The concentrations of the elements in the archaeological samples calculated by PyMCA were then corrected by applying the following linear transformation:

where a and b are the slope and the intercept of the regression line obtained for each element in the calibration curves of the CRMs (Fig. 3). Table 1 shows the corrected concentration of elements in the shards under study and a summary of the statistical evaluation of the data.

Limits of detection and quantification

The minimum limit of detection (CMDL) was calculated based on the net area and the background of µ-EDXRF spectra for a specific element in various CRMs at 95% confidence using the following equation [29]:

where Cstd, P and B are the certified concentration, the net area and background of the element of interest, respectively. The quantification limits (LOQ) were calculated as suggested by Tiwari et al. [30]. The CMDL of elements that could be measured using the employed analytical setting is shown in Table A in Supplementary Material 2.

Optical microscopy (PLM)

The petrographic analysis of the ceramic materials was carried out on sample thin sections, observing them under the polarised-light optical microscope (PLM) Leitz LABORLUX 12 POL S equipped with Leica MC170 HD digital camera and a Primotech PLM from Carl Zeiss Ltd. Samples were prepared as 30 µm-thick thin sections and described according to the method proposed by Quinn [31]. The evaluation of the inclusions, voids and micormass percentages was based on a visual estimation under optical microscopy using special comparative charts [32]. PLM was mainly adopted in our study to check the possible grouping suggested by µ-EDXRF.

Inductively coupled plasma–mass spectrometry

About 0.5 g from the same powder used for making pellets from archaeological samples together with the powdered CRMs were digested in four acids including hydrocholeretic, nitric, hydrofluoric and perchloric acids and analysed by a Perkin Elmer Sciex ELAN 9000 ICP-MS. Geostats reference materials were used to calibrate the ICP-MS quantitative data. The quantification of 37 elements was achieved through the calibration-standard method and the CMDL for all the elements of interest in this study varied between from 0.5 to 100 ppm. The same procedure as performed for correcting the µ-EDXRF data was performed to correct the ICP-MS quantitative data from the CRMs.

Results and discussion

Precision and accuracy of the measurements

To determine the precision and accuracy of the quantitative data, the K energy lines of all elements of interest in the CRMs, which included K, Ca, Ti, Mn, Fe, Cu, Zn, Rb, Sr and Zr, were only considered. Co, Ni, Nb and Th often showed low concentrations below the LOQ of the µ-EDXRF device used in this study. Also, the energy lines of Co, Ni, Nb and Th overlapped either with the K energy lines of Fe (for Co) or the Compton scatter peak of the Mo tube (for Y, Nb and Th). Also, the Kβ1 energy line from Co is overlapped with Kα1 from Ni. Therefore, no reliable data could be acquired from these elements. Also, the characteristic X-ray energy counts emitted from Na, Mg, Al, Si and P were too low to allow quantification as the measurements were performed in air.

The precision and accuracy of the measurements were calculated by analysing the CRMs pellets three times from three different spots. While the standard deviation (σ) was considered as a measure for precision, the relative error (RE%) was calculated as a criterion for accuracy. The expanded uncertainty of the certified and measured values for the CRMs was also calculated, as explained by Linsinger [33], to evaluate the µ-EDXRF data and to verify if there was a significant difference between the measurement result and the certified value of the CRMs (Table 1). In addition, the Mantel test was employed to check the correlation between sets of the certified values of elements in the CRMs and in the ICP-MS and µ-EDXRF data.

As shown in Table 1, σ of the elements of interest decreases by increasing the concentration of the elements (the error bars in Fig. 3 also demonstrate the same fact). It was expected because the absolute variance is often smaller for measurements performed near the detection limits than for measurements with larger values. In terms of accuracy, accurate quantitative data was obtained by µ-EDXRF for most of the elements of interest. In fact, the RE% for the quantified values was better than 25% (Table 1; Fig. 4). Conrey et al. [34] suggest that the FP method may introduce large biases (up to 36%) in the compositional data of archaeological pottery. It is interesting to mention that, as Fig. 4 demonstrates, the accuracy of µ-EDXRF quantitative data is entirely comparable with that of ICP-MS data and, in some cases (e.g., in measuring K2O), is better than the ICP-MS data.

Regression analysis of K2O, CaO, TiO2, MnO, Fe2O3, Cr, Cu, Zn, Rb, Sr, Y and Zr together with the standard error of the regression is shown between the dash lines and the error bars for XRF measurements on the CRMs. The red solid line represents a line with slope = 1 and intercept = 0 (the vertical and horizontal error bars represent the standard deviation of the µ-EDXRF measurements and the CRMs as reported in their certificates, respectively, and the dash lines are the standard error of prediction at 95% confidence)

The higher than 0.94 R2 accounted for the pairs of measured values through µ-EDXRF and certified values of the CRMs showed a high correlation between them (Fig. 3). The regression analysis, together with its error of prediction at 95% confidence for the measured elements, showed that the variance in the measured values of the elements from the regression line is not equal for all the measurements. Also, the expanded uncertainty accounted for the elements above their LOQ (Table 1) showed that there is no significant difference between the measured µ-EDXRF values and the certified value of the CRMs (when ∆m ≤ U∆, there is no significant difference between the measured and certified values).

The Mantel test on the pairs of correlation matrices of the quantitative data obtained by µ-EDXRF and the CRMs (Fig. 5, left) showed that there is a high correlation between the µ-EDXRF quantitative data and the certified values from the CRMs. The R2 value calculated for the Mantel test performed on the correlation matrix of the ICP-MS quantitative of the same elements and the correlation matrix of the CRMs even showed to be very close to that of calculated for the µ-EDXRF data (Fig. 5, right).

Compositional variety within the shards from Varzaneh

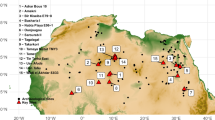

Principal component analysis (PCA) was performed on the log-transformed and standardised µ-EDXRF quantitative data for the elements K, Ca, Ti, Cr, Fe, Rb, Sr and Y, which demonstrated the highest variance within the elements (Fig. 6). The PCA biplot produced by incorporating loading and score plots showed a number of shards included relatively high Ca and Sr while the compositional data of another set of shards was associated with K, Rb, Ti and Fe (Fig. 6; Table B Supplementary Material 2). The higher Ca content of a set of the shards does not necessary indicate a distinct ‘group’ of ceramics but may be due to the post-burial effect of the burial soil in which the potteries were buried in (look at Fig. 7 in which shows calcareous rocks and sediments have covered the area where these ceramics are retrieved from). The well-known high negative correlation of the pairs of elements Sr and Rb points to the clays originating from different parent rocks [35]. In addition, a high association was observed between Cr and Y (Fig. 6). Altogether, the PCA biplot presented in Fig. 6 shows no distinctive group of ceramic in terms of chemical composition and demonstrates that the seven stylistic typologies of the ceramics mentioned earlier in ‘Archaeological typology of the samples’ are in fact from the same source of clay.

Geological map of Isfahan and Varzaneh Plain (reproduced after Zahedi et al. [40])

It is known that trace elements in clays, on average, are the same as those of the parent rocks from which the soils were formed [36]. Therefore, trace elements are often used to have a better idea of the place where ceramic bodies are produced [37]. For example, high amounts of Zr, Y and Rb are usually associated with acidic rocks [38]. The ceramic bodies from Isfahan, however, are associated with mafic rocks having high Ca and Sr content [39]. The clay sources in the Varzaneh Plain most certainly originate from sediments from the Zayandehrud river basin and northern mafic rocks rich in Ca. As the geological map of this region shows (Fig. 7), the Varzaneh Plain is surrounded by Cretaceous limestones and Eocene basic rocks which deliver mafic and calcium carbonate minerals to the younger Quaternary clay flat and piedmont fan in the Varzaneh Plain via Zayandehrud river and the meteoric water drainage. In fact, the leached Ca from the burial environment may be introduced to the bodies and enhance the Ca level in the bodies (Fig. 7). In general, as µ-EDXRF data shows, apart from a shard (i.e., No. 28) with low Ca content (i.e., Ca. 5.3 wt%), a fairly consistent composition is evinced in the entire set of analysed shards (Table B Supplementary Material 2).

Petrographic grouping of shards from Varzaneh

As a complementary method, petrographic thin sections of the representative shards from archaeological groups were studied by PLM. To do so, the mineral-petrographic study was carried out on 17 samples, which were previously analysed by µ-EDXRF, selected as the most representative of the archaeological groups macroscopically analysed. Five distinct petrographic groups were defined mainly on the basis of the inclusion composition. Supplementary Material 3 presents the complete petrographic description of each sample.

Petrographic group I: quartz- and sandstone-rich potsherds

Samples in this group consist of ceramics mainly with an optically inactive micromass, showing a c:f:v (coarse:fine:void) ratio of 15:45:40. The porosity of the shards in this group is high, approximately 40%, and consists of vughs and planar voids. Inclusions are scarce (15%), exhibiting a double-spaced or open-spaced related distribution, average size ranging from 150 to 500 μm and unimodal grain-size distribution. In terms of shape, they vary from sub-rounded to sub-angular and are composed of predominant mono- and polycrystalline quartz (30 – 50%), and a variable percentage of sandstone fragments. Less abundant inclusions comprise of plagioclase, alkaline feldspar, fragments of metamorphic rocks, limestone fragments (10%), and ARF (argillaceous rock fragments) (Fig. 8). Additionally, in a few samples, the presence of decomposed calcite was noted, suggesting that temperatures close to, 850 °C were reached [41].

Microphotographs of representative sample of five main mineral-petrographic groups. Group I: quartz- and sandstone-rich potsherds—sample No. 6; Group II: limestone-rich potsherds—sample No. 29; Group III: quartz-rich potsherds – sample No. 14; Group IV-Vol I: acid lava dominated – sample No. 1; Group V: Vol-II intermediate lava dominated—sample No.38 (images in cross polarised light)

Petrographic group II: limestone-rich potsherds

Samples in this group consist of ceramics with micromass both optically inactive and active and have a c:f:v ratio of 20:45:35. The porosity is high, approximately 35%, and consists of vughs and planar voids. Inclusions are moderate, making up 20% of the samples and show a single-spaced related distribution. They occur mainly as sub-rounded grains with an average size ranging from 150 to 500 μm and a unimodal grain-size distribution. Inclusions are primarily composed of varying amounts of mono- and polycrystalline quartz (10–45%), with a consistent presence of limestone fragments (35%). Less abundant inclusions include plagioclase, alkaline feldspar, fragments of metamorphic rocks, sandstone fragments, flint, and ARF (Fig. 8).

Petrographic group III: quartz-rich potsherds

Shards in this group (No. 14 and No. 31) consist of ceramics with optically inactive to active micromass, with a c:f:v ratio of 10:55:35. The porosity is high, approximately 35%, and mainly consists of vughs. Inclusions are rare, making up 10% of the samples and show an open-spaced related distribution, an average size of 300 μm and a unimodal grain-size distribution. The inclusions are sub-rounded to rounded in shape and predominantly composed of mono- and polycrystalline quartz, and subordinated crystals of plagioclase, alkaline feldspar, and scarce fragments of limestone fragments (Fig. 8).

Petrographic group IV: Vol-I acid lava-rich potsherd

This group is represented by a single sample (No. 1) that under the microscope shows an anisotropic, inactive, heterogeneous matrix with a c:f:v ratio of 20:35:45. The porosity is very high, consisting mainly of vughs, while inclusions are moderate, accounting for 20% of the sample, and show a bimodal, grain-size distribution with two main grain sizes: one averaging 300 μm and the other around 2 mm. The inclusions are rich in mono- and polycrystalline quartz and subordinated plagioclase, alkaline feldspar, limestone fragments, and grog. Notably, about 20% of the inclusions are represented by fragments of effusive rock with an acidic composition (e.g., trachyte) (Fig. 8).

Petrographic group V: Vol-II intermediate lava-rich potsherd

Similar to the previous group, this group is represented by a single sample (No. 38). It features an anisotropic, active, heterogeneous micromass with a c:f:v ratio of 30:40:30. The porosity is medium–high, consisting mainly of vughs, and inclusions are abundant, making up 30% of the sample. Inclusions show a bimodal grain-size distribution, with two main grain sizes: one averaging 300 μm and the other around 2 mm. The inclusions are predominantly composed of fragments of effusive rock with an intermediate composition (e.g., latite). Additionally, there are a few mono- and polycrystalline quartz crystals, plagioclase, and alkaline feldspar (Fig. 8).

Although the petrographic study enabled the classification of the various ceramic fragments into various mineral-petrographic groups, they do not exhibit sufficiently marked differences in terms of the composition of inclusions and the matrix to indicate a non-local origin. In practice, the observed variability is attributable to the intrinsic nature of the deposits from which the raw materials were likely sourced, specifically the Quaternary alluvial deposits within the Zayandehrud River basin (Fig. 7). This ‘hypothesis’ is corroborated by µ-EDXRF data, which suggested that most of the examined fragments are comparable in terms of composition. Exceptions are the two samples belonging to groups IV-Vol I and V-Vol II, both of which contain predominant effusive fragments, although of different compositions (acidic in the first, intermediate in the second). Specifically, sample No. 38, which belongs to group V, suggests that the source of the raw material for the inclusions is closer to the magmatic rock outcrops located to the northeast of the archaeological site Varzaneh. Here, intermediate and basic effusive bodies of the Middle Eocene age are found (Fig. 7). This deviation of sample No. 38 from the other fragments is also confirmed by the µ-EDXRF study (Figure A in Supplementary Material 2). The provenance of the inclusions in sample No. 1 (Group IV-Vol I) is more difficult to determine, but its matrix remains entirely comparable to that of the other samples.

A brief technical and archaeological discussion

The quality of XRF data in sourcing archaeological pottery has been a matter of several research. While the p-EDXRF compositional data has received much controversy [4, 5], bench-top EDXRF has proved to produce comparable data from major elements with ICP-based methods and INAA both on CRMs [42] and archaeological ceramics [43, 44]. The quality of µ-EDXRF data for sourcing ancient ceramics has attracted less attention. Speakman et al. [45] suggest that sourcing archaeological ceramics with µ-EDXRF devices has limited applicability to ceramic provenance studies. Similarly, benchtop μ-XRF has not been advocated for routine quantitative geochemical analysis of geological materials [17]. Other studies on the use of µ-EDXRF in the provenance study of archaeological pottery [46, 47] have been mainly focused on methodology. Flewett et al. [11] propose that µ-XRF could be a suitable method for souring ancient ceramic when there is the possibility of excluding the mineral inclusions and focusing more on the clay matrix and mapping the section of ceramics by X-ray beam provided by synchrotron facilities. As our study shows, the µ-EDXRF quantitative data is accurate and precise enough to perform a proper provenance study when powdered samples, which improve the homogeneity, are used as pressed pellets. As another alternative, fused glass beads, which ensure the homogeneity of samples, can be studied by µ-EDXRF and may consequently end up more precise data.

Our study demonstrates that most of the shards from Varzaneh are to be manufactured locally. Archaeologically speaking, in the third millennium BCE, western Zagros in Iran was home to two distinct cultures: Godin III and Kura-Araxes. In fact, there are certain similarities between the pottery discovered at Tappeh Gabri and that of these two cultures. In addition, some possible burnished "grey ware" examples from the Varzaneh Plain's EBA archaeological site pottery collection (Type 2) may be stylistically linked to the Kura-Araxes cultures in Western Iran in sites such as Godin during the same period. However, INAA analysis of this type shows no significant chemical similarities between Varzaneh grey-wares and Kura-Araxes in this region (Forthcoming). Tappeh Gabri's recognisable Godin III6 and III5 pottery pieces (Type 1) also provide evidence of the archaeological connection to the western Iran. Moreover, the site exhibits a stylistic and cultural connection to the Khuzestan Plain in southwestern Iran. There are few similarities between the archaeological material found at Tappeh Gabri and the EBA sites in the southern Iran. In fact, some archaeological investigations and stylistic similarities suggest a possible connection of the Varzaneh Plain to the archaeological sites like Tappeh Yahya or Konar Sandal in Kerman province (southern Iran) and also a relationship between southwestern, western, and partially southeastern Iran's material cultures [28]. Ceramics from these cultures, which peaked in the 3rd millennium BCE, are appeared in many archaeological sites in Iran.

Conclusions

This research shows that the µ-EDXRF data may be used to create a clearer picture of ceramic production and use in ancient cultures. Although µ-EDXRF has not been advocated for an accurate determination of elemental concentration in archaeological pottery, it must be emphasised that an accurate quantification per se is not and cannot be considered as the sole factor in sourcing archaeological ceramics. Contamination from the burial environment, non-uniform distribution of elements and leaching/enrichment of elements due to deterioration paths may change the distribution of elements in archaeological pottery and, consequently, lead to erroneous information. Based on the µ-EDXRF data, this study suggests that the ceramic shards found in the Varzaneh Plain during the Bronze Age are most probably local products. The compositional and petrographic data, together with the archaeological and stylistic study performed in this study, prompts collecting further compositional and petrographic data from the shards excavated from the south-western and southern Iranian archaeological sites and comparing the data with those acquired from Varzaneh in order to have a clearer picture of any connection between these areas. On the other hand, it is essential to expand excavations and to analyse potshards from other archaeological sites in the Varzaneh Plain in order to have a more comprehensive idea about the ceramic production and use in the 3rd millennium BCE in the lower part of the Zayandehrud River.

Data availability

No datasets were generated or analysed during the current study.

Code availability

Not applicable.

References

Minc LD, Sterba J. Instrumental neutron activation analysis (INAA) in the study of archaeological ceramics. In: Hunt A, editor. The Oxford Handbook of Archaeological Ceramic Analysis. 2017. p. 424–446.

Hall M. X-ray fluorescence-energy dispersive (ED-XRF) and wavelength dispersive (WD-XRF) spectrometry. In: Hunt A, editor. The Oxford handbook of archaeological ceramic analysis. Oxford: Oxford University Press; 2017. p. 343–362.

Frahm E, Doonan RCPRP. The technological versus methodological revolution of portable XRF in archaeology. J Archaeol Sci. 2013;40:1425–34.

Hunt AW, Speakman RJ. Portable XRF analysis of archaeological sediments and ceramics. J Archaeol Sci. 2015;53:626–38.

Frahm E. Ceramic studies using portable XRF: from experimental tempered ceramics to imports and imitations at Tell Mozan. Syria J Archaeol Sci. 2018;90:12–38.

LeMoine JB, Halperin CT. Comparing INAA and pXRF analytical methods for ceramics: a case study with Classic Maya wares. J Archaeol Sci: Rep. 2021;36: 102819.

Frahm E, Carolus CM, Cameron A. Introducing the BRICC (Bricks and Rocks for Instruments’ Ceramic Calibration) sets: open-source calibration materials for quantitative X-ray fluorescence analysis. J Archaeol Sci Rep. 2022;43:103443.

Mentzer SM. Micro XRF. In: Nicosia C, Stoops G, editors. Archaeological soil and sediment micromorphology. 2017. p. 431–440.

Hafez IF, Sorrentino G, Faka M, Cuenca-García C, Makarona C. Geochemical survey of soil samples from the archaeological site Dromolaxia-Vyzakia (Cyprus), by means of micro-XRF and statistical approaches. J Archaeol Sci Rep. 2017;11:447–62.

Papadopoulou D, Sakalis A, Merousisc N, Tsirliganis NC. Study of decorated archaeological ceramics by micro X-ray fluorescence spectroscopy. Nucl Instrum Methods Phys Res A. 2007;580:743–6.

Flewett S, Saintenoy T, Sepúlveda M, Mosso EF, Robles C. Micro X-ray fluorescence study of late pre-Hispanic ceramics from the western slopes of the south-central Andes region in the Arica y Parinacota Region, Chile: a new methodological approach. Appl Spectrosc. 2016;70:1759–69.

Harth A. X-ray fuorescence (XRF) on painted heritage objects: a review using topic modeling. Herit Sci. 2024;12:17.

Attaelmanan AG. Identification of mineral inclusions in archaeological ceramics using microbeam X-ray fluorescence spectrometry. X-ray Spectrom. 2014;43:325–31.

Hložek M, Komoróczy B, Prokeš R. Enamel paint techniques in archaeology and their identification using XRF and micro-XRF. Radiat Phys Chem. 2017;137:243–7.

Wouters B, Makarona C, Nys K, Claeys P. Characterization of archaeological metal remains in micromorphological thin sections using μXRF elemental mapping. Geoarchaeol Intl J. 2017;32:311–8.

Grousset S, Kergourlay F, Neff D, Gallias JL, Reguer S, Dillmann P, et al. In situ monitoring of corrosion processes by coupled micro-XRF/micro-XRD mapping to understand the degradation mechanisms of reinforcing bars in hydraulic binders from historic monuments. J Anal At Spectrom. 2015;30:721–9.

Flude S, Haschke M, Storey M. Application of benchtop micro-XRF to geological materials. Mineral Mag. 2017;81:923–48.

Kantarelou V, Karydas AG. A simple calibration procedure of polycapillary based portable micro-XRF spectrometers for reliable quantitative analysis of cultural heritage materials. X-ray Spectrom. 2016;45:85–91.

Holakooei P, Oudbashi O, Mortazavi M, Ferretti M. On, under and beneath the patina: evaluation of micro energy dispersive X-ray fluorescence quantitative data on the classification of archaeological copper alloys. Spectrochim Acta B. 2021;178:106128.

Shojaee-Esfahani A, Rafiei-Alavi B. Short report on the survey at the eastern part of the Zayandeh-Rud Basin, Kafarved (Kafrood)—Varzaneh Plain. In: Shirazi R, Hurshid S, editors. Proceedings of 17th Annual Symposium on the Iranian Archaeology; 2020; Tehran: Richt. (in Persian).

Rafiei-Alavi B, Shojaei Esfahani A, Jebreili Y. The Center of the Iranian Plateau during the Early Bronze Age, New Archaeological Excavations in the Eastern Zone of the Zāyandehrud River Basin, Varzaneh. In: 2023. Harrassowitz Verlag.

Shojaee-Esfahani A, Jebraeili Y, Entekhabi P, Kakavand M, Mohammadkhani K. The archaeological capacity of the eastern (lower) Zāyandeh-Rud Basin: an outline. Iran J Archaeolog Stud. 2022;12(2):131–7. (in Persian).

Salehi-Kakhki A. Archaeological survey at Chenarud and Bonrud of the Zayandehrud basin. 2007. (in Persian).

Esameili-Jolodar M. Archaeological landscape of the eastern bank of Gavkhuni swamp. In: Fahimi H, Alizadeh K, editors. Namvarnameh: essays in honour of Masoud Azarnoush. Tehran: Iran-Negar; 2013. p. 189–206. (in Persian).

Saeidi-Anaraki F. Regional and transregional connections of Isfahan during the Bronze Age (3000–1600 BC) based on excavations at Tappeh Kopandeh. 2009. (in Persian).

Rafiei-Alavi B, Shojaee Esfahani. A short report on the excavations in two archaeological sites in the eastern side of Zayandehrud basin, Dasht-e Kafrud in Varzaneh. In: Shirazi R, Hurshid S, editors; 2019. Tehran: RICHT. p. 517–26. (in Persian).

Rafiei-Alavi B, Shojaee Esfahani A, Jebreili Y, Allahyari H. A short report on the excavation at site 051 in the eastern side of Zayandehrud basin, Dasht-e Kafrud in Varzaneh, Summer 1398. In: Shirazi R, editor. 2020; Tehran: RICHT. p. 353–62. (in Persian).

Rafiei-Alavi B, Shojaei Esfahani A, Jebreili Y, Kehl M. From Gavkhuni to Jazmuriyan: an investigation to the connections between lowland plains of Zayandehrud river and southeastern Iran in the Bronze Age. 2021; Zabol: University of Zabol. (in Persian).

Jenkins R, Gould RW, Gedcke D. Quantitative X-ray spectrometry. New York: Marcel Dekker Inc.; 1995.

Tiwari M, Singh A, Sawhney K. Sample preparation for evaluation of detection limits in X-ray fluorescence spectrometry. Anal Sci. 2005;21:143–7.

Quinn P. Interpreting silent artefacts: petrographic approaches to archaeological ceramics. Archaeopress; 2009.

Baccelle L, Bosellini A. Diagrammi per la stima visiva: della composizione percentuale nelle rocce sedimentarie. Annali Dell’Università di Ferrara, Nuove Serie, Sezione IX, Scienze Geologiche e Paleontologiche. 1965;1:59–62.

Linsinger T. Comparison of a measurement result with the certified value. 2010.

Conrey RM, Goodman-Elgar M, Bettencourt N, Seyfarth A, Van Hoose A, Wolff JA. Calibration of a portable X-ray fluorescence spectrometer in the analysis of archaeological samples using influence coefficients. Geochem Explor Environ Anal. 2014;14:291–301.

Plimer IR, Elliott SM. The use of Rb/Sr ratios as a guide to mineralization. J Geochem Explor. 1979;12:21–34.

Aubert H, Pinta M. Trace elements in soils. In: Developments in soil science. vol .7. Amsterdam: Elsevier; 1977.

Adriaens A. Non-destructive analysis and testing of museum objects: an overview of 5 years of research. Spectrochim Acta. 2005;60:1503–16.

Blackman MJ, Mery S, Wright RP. Production and exchange of ceramics on the Oman Peninsula from the perspective of Hili. J Field Archaeol. 1989;16:61–77.

Holakooei P, Petrucci FC, Tassinari R, Vaccaro C. Application of WDXRF in the provenance studies of Persian haft rang tiles: a statistical approach. X-Ray Spectrom. 2013;42:105–15.

Zahedi M, Samadian M, Tawosian S, Amidi M. Geological quadrangle maps of Iran no. J7: Isfahan “1:250,000”. Tehran; 1978.

Maritan L, Ganzarolli G, Antonelli F, Rigo M. What kind of calcite? Disclosing the origin of sparry calcite temper in ancient ceramics. J Archaeol Sci. 2021;129:105358.

Hein A, Tsolakidou A, Iliopoulos I, Mommsen H. Standardisation of elemental analytical techniques applied to provenance studies of archaeological ceramics: an inter laboratory calibration study. Analyst. 2002;127:542–53.

Tsolakidou A, Kilikoglou V. Comparative analysis of ancient ceramics by neutron activation analysis, inductively coupled plasma-optical-emission spectrometry, inductively coupled plasma-mass spectrometry, and X-ray fluorescence. Anal Bioanal Chem. 2002;374:566–72.

Padilla R, Van Espen P, Godo Torres PP. The suitability of XRF analysis for compositional classification of archaeological ceramic fabric: a comparison with a previous NAA study. Anal Chim Acta. 2006;558:283–9.

Speakman RJ, Little NC, Creel D, Miller MR, Iñañez JG. Sourcing ceramics with portable XRF spectrometers? A comparison with INAA using Mimbres pottery from the American Southwest. J Archaeol Sci. 2011;38:3483–96.

Papadopoulou D, Zachariadis GA, Anthemidis AN, Tsirliganis NC, Stratis JA. Comparison of a portable micro-X-ray fluorescence spectrometry with inductively coupled plasma atomic emission spectrometry for the ancient ceramics analysis. Spectrochim Acta B. 2004;59:1877–84.

Sakalis AJ, Kazakis NA, Merousis N, Tsirliganis NC. Study of Neolithic pottery from Polyplatanos (Imathia) using micro-X-ray fluorescence spectroscopy, stereoscopic microscopy and multivariate statistical analysis. J Cult Herit. 2013;14:485–98.

Acknowledgements

Mohammad Gheisari and Parvaneh Shafiei are thanked for preparing a number of samples

Funding

The data presented in this article are collected within a research project financed by the Research Department of the Art University of Isfahan, Iran (Grant no: 98/6220/60).

Author information

Authors and Affiliations

Contributions

Conceptualization: PH, BRA, ASE; Methodology: PH, LM, RP; Archaeological Excavation: BRA, ASE, YJ; Writing—original draft preparation: PH, YJ, RP; Writing—review and editing: PH, BRA, YJ; Sample preparation: SB; Scientific analysis: PH, LM, RP; Archaeological Discussion: BRA, YJ, ASE.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Holakooei, P., Rafiei-Alavi, B., Shojaee-Esfahani, A. et al. A provenance study on the ceramics excavated at the Varzaneh Plain, central Iran. Herit Sci 12, 416 (2024). https://doi.org/10.1186/s40494-024-01532-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1186/s40494-024-01532-7